Introduction: Navigating the Global Market for metal water bottle cycling

In today’s competitive landscape, sourcing high-quality metal water bottles for cycling presents a unique challenge for international B2B buyers. As demand for sustainable and durable hydration solutions rises, businesses must navigate a complex market filled with varying product types, specifications, and supplier options. This guide offers a comprehensive overview of the metal water bottle cycling market, covering key aspects such as product types, applications, supplier vetting processes, and cost considerations.

Understanding the nuances of sourcing metal water bottles is crucial for companies in regions like Africa, South America, the Middle East, and Europe, including emerging markets such as Nigeria and Saudi Arabia. By providing actionable insights and in-depth analysis, this guide empowers buyers to make informed purchasing decisions that align with their business needs and sustainability goals.

With a focus on innovative features—like high-flow nozzles, lightweight designs, and eco-friendly materials—this guide highlights the essential attributes that set top-tier metal water bottles apart. Whether you are looking to enhance your product offerings or meet the increasing consumer demand for environmentally friendly solutions, this resource is designed to equip you with the knowledge necessary to thrive in the global market.

Article Navigation

- Top 7 Metal Water Bottle Cycling Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for metal water bottle cycling

- Understanding metal water bottle cycling Types and Variations

- Key Industrial Applications of metal water bottle cycling

- 3 Common User Pain Points for ‘metal water bottle cycling’ & Their Solutions

- Strategic Material Selection Guide for metal water bottle cycling

- In-depth Look: Manufacturing Processes and Quality Assurance for metal water bottle cycling

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal water bottle cycling’

- Comprehensive Cost and Pricing Analysis for metal water bottle cycling Sourcing

- Alternatives Analysis: Comparing metal water bottle cycling With Other Solutions

- Essential Technical Properties and Trade Terminology for metal water bottle cycling

- Navigating Market Dynamics and Sourcing Trends in the metal water bottle cycling Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of metal water bottle cycling

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for metal water bottle cycling

Understanding metal water bottle cycling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lightweight Single-Wall | Minimal weight, compact design, high flow-rate | Cycling events, outdoor sports retail | Pros: Lightweight, easy to carry; Cons: Not insulated, may dent easily. |

| Insulated Bottles | Double-wall construction for temperature retention | High-end cycling gear retailers | Pros: Keeps drinks cold/hot; Cons: Heavier, higher cost. |

| Specialized Nozzle | Patented high-flow sport nozzle for easy hydration | Competitive cycling brands | Pros: Fast flow, convenient; Cons: May require specific maintenance. |

| Eco-Friendly Options | Made from recyclable materials, BPA-free | Sustainable product retailers | Pros: Appeals to environmentally conscious consumers; Cons: Can be pricier. |

| Customizable Designs | Options for branding and personalization | Corporate gifts, promotional products | Pros: Enhances brand visibility; Cons: Minimum order quantities may apply. |

What Are the Key Characteristics of Lightweight Single-Wall Metal Water Bottles?

Lightweight single-wall metal water bottles are designed for cyclists seeking a balance between volume and weight. These bottles typically feature a minimalist design that maximizes capacity while minimizing heft, making them ideal for long rides or competitive events. B2B buyers should consider the bottle’s compatibility with standard bike cages and its ease of cleaning, as these factors can significantly affect user experience. However, the lack of insulation means these bottles may not keep beverages at a desired temperature for extended periods.

How Do Insulated Metal Water Bottles Stand Out in the Market?

Insulated metal water bottles utilize double-wall construction to maintain the temperature of their contents, making them suitable for varied climates and long-distance cycling. They are particularly appealing to retailers focusing on high-end cycling gear, as they offer substantial value to consumers who prioritize hydration temperature. Buyers should evaluate the weight and cost, as insulated options tend to be heavier and more expensive than their single-wall counterparts. This type can be a strong selling point in regions with extreme weather conditions.

Why Are Specialized Nozzle Designs Important for Cycling Bottles?

Bottles with specialized nozzles, such as patented high-flow designs, cater specifically to the needs of cyclists who require quick and efficient hydration. These nozzles allow for a seamless drinking experience without the need to squeeze, which can be crucial during intense physical activity. B2B buyers should assess the durability and ease of maintenance of these nozzles, as they can impact the longevity of the product. While these features enhance user satisfaction, they may also necessitate additional care to prevent clogging or wear.

What Makes Eco-Friendly Metal Water Bottles a Smart Choice for Retailers?

Eco-friendly metal water bottles are crafted from recyclable materials and are often BPA-free, appealing to a growing market of environmentally conscious consumers. These products can enhance a retailer’s sustainability profile, attracting buyers who prioritize eco-friendly options. However, B2B buyers must consider the potential higher price point and the demand for such products in their specific markets. Offering these bottles can differentiate a brand in regions where sustainability is increasingly becoming a priority.

How Can Customizable Metal Water Bottles Benefit B2B Buyers?

Customizable metal water bottles provide an excellent opportunity for branding and promotional activities. Businesses can use these bottles as corporate gifts or promotional products, allowing for increased brand visibility. B2B buyers should keep in mind the minimum order quantities and the potential for higher upfront costs when considering customization options. However, the ability to offer personalized products can create a lasting impression and foster customer loyalty, making them a valuable addition to any product lineup.

Key Industrial Applications of metal water bottle cycling

| Industry/Sector | Specific Application of Metal Water Bottle Cycling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Hydration solutions for cycling tours and events | Enhances customer experience, promotes sustainability | Quality assurance, customization options, bulk pricing |

| Corporate Wellness Programs | Employee hydration initiatives | Improves employee health, reduces plastic waste | Eco-friendly materials, branding opportunities, volume discounts |

| Sports Teams | Team-branded water bottles for athletes | Boosts team morale, enhances brand visibility | Durability, design flexibility, supplier reliability |

| Retail and E-commerce | Eco-friendly product offerings | Attracts environmentally conscious consumers | Competitive pricing, product variety, shipping logistics |

| Hospitality and Tourism | Guest amenities in cycling-friendly hotels | Enhances guest experience, promotes eco-tourism | Customization for branding, bulk order capabilities, quality |

How Are Metal Water Bottles Used in Outdoor Recreation?

In the outdoor recreation sector, metal water bottles are essential for hydration during cycling tours and events. Companies offering cycling experiences leverage these bottles to enhance customer satisfaction while promoting environmental sustainability. By providing reusable bottles, businesses can solve the problem of plastic waste generated during events, aligning with eco-friendly practices. For international buyers, particularly in Africa and South America, sourcing bottles that meet local regulatory standards while offering customization options for branding can be crucial.

What Role Do Metal Water Bottles Play in Corporate Wellness Programs?

Metal water bottles are increasingly incorporated into corporate wellness programs as part of employee hydration initiatives. By providing high-quality, reusable bottles, companies can encourage healthier habits among employees, thereby improving overall productivity and well-being. Furthermore, these bottles serve as a sustainable alternative to single-use plastics, aligning with corporate social responsibility goals. Buyers in the Middle East and Europe should consider sourcing options that allow for branding and personalization, maximizing their impact in promoting wellness.

How Do Sports Teams Benefit from Metal Water Bottles?

Sports teams often utilize metal water bottles as team-branded hydration solutions for athletes. These bottles not only provide essential hydration during training and competitions but also serve as a marketing tool to enhance brand visibility. The durability of metal bottles ensures they withstand rigorous use, making them a practical choice for teams. Buyers from Europe and Africa should focus on suppliers that offer customizable designs and reliable delivery timelines to meet their needs efficiently.

Why Are Metal Water Bottles Important for Retail and E-commerce?

In the retail and e-commerce sectors, metal water bottles represent a growing trend toward eco-friendly product offerings. Retailers can attract environmentally conscious consumers by providing sustainable hydration solutions, which are increasingly in demand. Sourcing these bottles requires attention to competitive pricing and a diverse product range to meet various customer preferences. Buyers in South America and Europe should prioritize suppliers who can ensure quick shipping and stock availability to maintain a steady inventory.

How Can the Hospitality Industry Enhance Guest Experiences with Metal Water Bottles?

In the hospitality and tourism industry, metal water bottles can be used as guest amenities in cycling-friendly hotels and resorts. Offering these bottles enhances the guest experience, particularly for cycling enthusiasts, while promoting eco-tourism initiatives. Customization options allow hotels to brand the bottles, creating a lasting impression on guests. International buyers, especially from regions with a rising eco-tourism trend, should look for suppliers that provide quality products and support in marketing initiatives.

3 Common User Pain Points for ‘metal water bottle cycling’ & Their Solutions

Scenario 1: Sourcing Durable Metal Water Bottles for Harsh Environments

The Problem: B2B buyers from regions with extreme weather conditions, such as the Middle East or South America, often struggle to find metal water bottles that can withstand high temperatures and rough handling. Many bottles may dent easily, affect user experience, and require frequent replacements, leading to increased costs and customer dissatisfaction. Buyers need a solution that ensures durability without compromising on functionality or safety.

The Solution: When sourcing metal water bottles for cycling, prioritize suppliers that specialize in high-quality stainless steel materials, as these provide better resistance to dents and corrosion. Look for bottles designed with features such as double-walled construction for insulation, which can help maintain the temperature of the liquid inside, even in extreme heat. Additionally, consider bottles that have undergone rigorous testing for impact resistance. Engaging with manufacturers that offer custom branding options may also provide added value, allowing for differentiation in a competitive market. Establish long-term relationships with suppliers who can guarantee consistent quality and prompt delivery, ensuring your inventory remains well-stocked without interruption.

Scenario 2: Addressing Taste and Odor Issues with Metal Water Bottles

The Problem: Another significant pain point for B2B buyers is the lingering taste or odor associated with some metal water bottles. Buyers who cater to cycling enthusiasts are particularly aware that a poor taste can ruin the hydration experience, leading to dissatisfaction among customers. This issue often arises from inadequate cleaning or low-quality materials used in the bottle’s construction.

The Solution: To mitigate taste and odor issues, it is critical to select metal water bottles made from food-grade stainless steel that is known for its non-reactive properties. Ensure that the bottles are easy to clean and have wide openings for thorough access. Buyers should also consider sourcing bottles with silicone or BPA-free components, as these materials are less likely to impart unwanted flavors. Providing detailed care instructions for customers on how to maintain their bottles can also enhance user experience and satisfaction. Additionally, consider offering a variety of cleaning accessories, such as bottle brushes or specialized cleaning tablets, to encourage proper maintenance and prolong the lifespan of the products.

Scenario 3: Ensuring Compatibility with Bicycle Cages

The Problem: Compatibility with bike cages is a recurring issue for B2B buyers, especially when dealing with various bike brands and models. Bottles that do not fit securely can lead to accidents or inconvenience during rides, affecting the overall cycling experience. Buyers must ensure that the products they offer will meet diverse customer needs and preferences.

The Solution: When selecting metal water bottles, prioritize those designed to fit universally in standard bike cages. Look for products that have been tested for compatibility with a wide range of bicycle models and that feature a shape conducive to easy retrieval. It is beneficial to source bottles with innovative designs that prevent rattling during rides, such as those with a silicone grip that enhances stability. Offering a range of sizes and styles can also cater to different customer preferences, ensuring that cyclists can find a bottle that meets their specific needs. Providing detailed product specifications and fit guides on your B2B platform can help customers make informed decisions, reducing the likelihood of returns and enhancing overall satisfaction.

Strategic Material Selection Guide for metal water bottle cycling

When selecting materials for metal water bottles used in cycling, several factors come into play, including performance characteristics, cost, and compliance with international standards. This guide analyzes four common materials—stainless steel, aluminum, titanium, and copper—highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Stainless Steel for Metal Water Bottles?

Stainless steel is a popular choice for cycling water bottles due to its excellent corrosion resistance, durability, and ability to maintain the temperature of liquids. It typically has a temperature rating of up to 500°F (260°C) and is resistant to rust and staining, making it suitable for various environmental conditions.

Pros and Cons:

Stainless steel bottles are highly durable and can withstand impacts, but they can be heavier than other materials. Manufacturing stainless steel products can be complex and costly, especially when using high-grade alloys. However, their long lifespan and recyclability make them a sustainable option.

Impact on Application:

Stainless steel is compatible with a wide range of beverages, including acidic sports drinks, without leaching harmful chemicals. For B2B buyers, ensuring compliance with food safety standards like LFGB (German Food and Feed Code) or FDA regulations is crucial.

How Does Aluminum Compare as a Material for Cycling Water Bottles?

Aluminum is lightweight and offers good thermal conductivity, which can help keep drinks cool. It can be anodized to enhance corrosion resistance and provide a variety of color options for branding.

Pros and Cons:

While aluminum bottles are generally less expensive than stainless steel, they can dent easily upon impact and may require a lining to prevent metallic taste or corrosion from acidic beverages. The manufacturing process is less complex than stainless steel, allowing for lower production costs.

Impact on Application:

Aluminum bottles are suitable for a variety of cycling applications, but international buyers should be aware of potential compliance issues related to coatings and linings. Standards such as ASTM and EN (European Norm) may apply, particularly regarding food safety.

What Are the Advantages of Using Titanium for Metal Water Bottles?

Titanium is a premium material known for its exceptional strength-to-weight ratio and corrosion resistance. It is lightweight and can withstand extreme temperatures, making it ideal for high-performance cycling.

Pros and Cons:

The primary advantage of titanium is its durability and resistance to corrosion, but it comes at a high cost. The manufacturing process is complex, which can further increase the price point.

Impact on Application:

Titanium is compatible with various beverages and does not impart any metallic taste. For international buyers, ensuring compliance with standards like JIS (Japanese Industrial Standards) is essential, especially in markets like Japan and South Korea.

Why Consider Copper for Metal Water Bottles in Cycling?

Copper is less common but offers excellent thermal properties, maintaining the temperature of liquids effectively. It has natural antimicrobial properties, which can be beneficial for hygiene.

Pros and Cons:

Copper bottles can be aesthetically appealing and provide a unique selling point. However, they are heavier and can tarnish over time. The cost of copper is generally high, and the manufacturing process can be labor-intensive.

Impact on Application:

Copper is compatible with many beverages, but it may react with acidic liquids, requiring careful consideration of use cases. B2B buyers should ensure compliance with health standards and regulations, particularly in regions with strict food safety laws.

Summary Table of Material Selection for Metal Water Bottles

| Material | Typical Use Case for metal water bottle cycling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General cycling, sports drinks | Durable and corrosion-resistant | Heavier than alternatives | High |

| Aluminum | Casual cycling, light sports | Lightweight and cost-effective | Can dent easily; may require lining | Medium |

| Titanium | High-performance cycling | Exceptional strength and lightness | Very high cost | High |

| Copper | Specialty cycling, aesthetic appeal | Excellent thermal properties | Heavy; can tarnish | High |

This guide provides a comprehensive overview of material options for metal water bottles in cycling, enabling B2B buyers to make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for metal water bottle cycling

What Are the Key Stages in the Manufacturing Process of Metal Water Bottles for Cycling?

The manufacturing process of metal water bottles, particularly those designed for cycling, involves several critical stages. Each stage ensures the final product meets quality standards and is functional for the end-user.

Material Preparation: What Materials Are Used and How Are They Prepared?

The primary material for metal water bottles is stainless steel due to its durability, resistance to corrosion, and non-reactive properties. The manufacturing process begins with sourcing high-grade stainless steel, typically 304 or 316 grades, which are known for their strength and resistance to staining.

Once sourced, the steel undergoes a thorough cleaning process to remove any contaminants or oils that could affect the bottle’s integrity. This involves a combination of mechanical and chemical cleaning methods. After cleaning, the steel is cut into sheets and then shaped into cylindrical forms, ready for the next stage.

How Are Metal Water Bottles Formed for Optimal Performance?

The forming stage is crucial for shaping the metal into the desired bottle form. Techniques such as deep drawing and hydroforming are commonly used. In deep drawing, the steel sheet is pressed into a die to create the bottle shape. Hydroforming involves using high-pressure hydraulic fluid to form the bottle, allowing for more intricate designs and reducing material wastage.

After forming, the bottles are subjected to a series of tests to ensure structural integrity and functionality. These tests can include pressure testing to confirm that the bottles can withstand typical cycling conditions without leaking.

What Steps Are Involved in the Assembly of Metal Water Bottles?

Following the forming process, the assembly stage involves adding components such as lids, nozzles, and seals. High-quality silicone or rubber is often used for seals to ensure a leak-proof design. The assembly process typically employs automated machinery to ensure precision and consistency, though some components may be assembled manually for better quality control.

During this stage, manufacturers must pay attention to compatibility, especially for multi-functional bottles with interchangeable parts. Quality assurance begins here, with inspections at various checkpoints to identify any defects early in the process.

How Do Finishing Techniques Enhance the Quality of Metal Water Bottles?

The finishing stage includes surface treatments such as polishing, coating, and anodizing. These processes enhance the aesthetic appeal and functionality of the bottles. For instance, a powder coating can provide additional grip and a variety of colors, while anodizing can increase corrosion resistance.

Manufacturers may also apply anti-slip coatings to ensure the bottles are easy to hold, even in wet conditions. Each of these finishing techniques contributes to the overall performance and longevity of the product, making it essential for manufacturers to choose the right method based on the intended use.

What Quality Assurance Standards Should B2B Buyers Expect from Metal Water Bottle Suppliers?

Quality assurance (QA) is paramount in the manufacturing of metal water bottles, especially when catering to international markets. B2B buyers should be aware of relevant international standards that govern manufacturing processes.

Which International Standards Are Relevant for Metal Water Bottles?

ISO 9001 is a fundamental standard that outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the target market and intended use of the product.

In regions like Africa, South America, the Middle East, and Europe, buyers should verify that suppliers adhere to these standards to ensure product safety and reliability.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Ensuring that the stainless steel and other components meet specified standards is crucial.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring and testing at various stages, including forming and assembly. This ensures any defects are identified and rectified promptly.

-

Final Quality Control (FQC): Before the products are shipped, FQC is conducted to verify that the finished bottles meet all specifications and quality standards. This may include leak tests, pressure tests, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential. Here are some effective strategies:

What Methods Can Buyers Use to Assess Supplier Quality?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality management systems, and overall compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC procedures, including defect rates and corrective actions taken in response to past issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process and product quality before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is vital for B2B buyers, especially when dealing with suppliers from diverse regions. Factors such as local regulations, cultural differences in quality expectations, and logistical challenges can all impact the quality assurance process.

For example, buyers in Nigeria and Saudi Arabia may face different regulatory environments compared to their European counterparts. It is crucial to establish clear communication channels with suppliers to ensure that quality expectations are aligned and met consistently.

Conclusion

The manufacturing processes and quality assurance practices for metal water bottles tailored for cycling are multifaceted and require diligence at every stage. B2B buyers must prioritize suppliers who adhere to international standards and demonstrate robust quality control measures to ensure they receive durable, safe, and high-performing products. By understanding the manufacturing process and the associated quality assurance practices, buyers can make informed decisions that align with their business needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal water bottle cycling’

Introduction

This guide aims to equip B2B buyers with a practical checklist for sourcing metal water bottles specifically designed for cycling. As demand for sustainable and high-quality hydration solutions grows, understanding the key factors in sourcing can lead to better purchasing decisions and supplier partnerships.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing metal water bottles that meet the unique needs of cyclists. Consider factors such as size, weight, material composition, and design features.

- Capacity: Look for bottles with varying capacities (e.g., 17 oz, 25 oz) to cater to different cycling preferences.

- Material: Focus on stainless steel options that are BPA-free and recyclable to ensure safety and sustainability.

Step 2: Research Market Trends

Staying informed about current market trends can help you identify popular features and innovations in cycling water bottles.

- Functionality: Investigate features like high-flow nozzles and grip designs, which enhance usability during rides.

- Sustainability: Buyers increasingly prefer eco-friendly products, so consider suppliers that prioritize sustainable practices in their manufacturing processes.

Step 3: Evaluate Potential Suppliers

Before making any commitments, it’s crucial to conduct a thorough evaluation of potential suppliers.

- Company Profile: Request detailed company information, including their history, production capabilities, and market presence.

- References: Seek testimonials or case studies from previous clients in the cycling industry to gauge reliability and quality.

Step 4: Verify Compliance with Standards

Ensure that the products you are considering meet international safety and quality standards.

- Certifications: Look for certifications such as LFGB for food-grade materials and ISO for quality management systems.

- Testing: Ask suppliers about their product testing processes, including durability tests and safety assessments.

Step 5: Assess Pricing and Payment Terms

Understanding pricing structures and payment terms is vital for budgeting and cash flow management.

- Comparative Analysis: Obtain quotes from multiple suppliers to compare prices and identify competitive options.

- Payment Flexibility: Review payment terms to ensure they align with your financial strategy, considering options like deposits or payment upon delivery.

Step 6: Confirm Shipping and Logistics Capabilities

Efficient shipping and logistics are critical for timely delivery of products, particularly in international trade.

- Shipping Options: Inquire about shipping methods and costs, especially for bulk orders.

- Lead Times: Understand typical lead times for production and delivery to plan your inventory effectively.

Step 7: Establish a Long-term Partnership

Building a long-term relationship with your supplier can lead to better pricing, reliability, and product development collaboration.

- Communication: Maintain open lines of communication to address any concerns and facilitate feedback.

- Future Collaboration: Discuss potential for co-development of new products or features tailored to your market needs.

By following these steps, B2B buyers can ensure a comprehensive approach to sourcing metal water bottles for cycling, leading to informed decisions and successful partnerships.

Comprehensive Cost and Pricing Analysis for metal water bottle cycling Sourcing

What Are the Key Cost Components in Metal Water Bottle Cycling Manufacturing?

When sourcing metal water bottles for cycling, understanding the cost structure is crucial. The primary components include:

-

Materials: The choice of materials significantly impacts costs. Stainless steel is popular for its durability and clean taste, but it can be more expensive than plastic. Premium materials, such as titanium, can elevate costs even further.

-

Labor: Labor costs vary by region and are influenced by local wage standards. In countries with lower labor costs, like some regions in Africa and South America, manufacturers may offer more competitive pricing.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses. Higher overhead can arise from advanced manufacturing technologies or more extensive quality control processes.

-

Tooling: Initial tooling costs for molds and production equipment can be significant, particularly for custom designs. This upfront investment is often amortized over larger production runs.

-

Quality Control (QC): Ensuring the bottles meet safety and quality standards (e.g., BPA-free, FDA compliance) incurs costs. Companies focused on premium quality may invest more in QC measures.

-

Logistics: Shipping costs fluctuate based on the distance from the manufacturer to the buyer, mode of transport, and any tariffs or customs duties applicable in the destination country.

-

Margin: Suppliers typically apply a markup to cover costs and ensure profitability. This margin can vary widely based on competition and market demand.

How Do Price Influencers Affect Metal Water Bottle Costs?

Several factors influence the pricing of metal water bottles in the B2B market:

-

Volume/MOQ: Suppliers often set minimum order quantities (MOQs). Higher order volumes can lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs or additional features (like insulated options) can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Materials: The choice of materials not only affects the base cost but also the perceived value. For instance, bottles made from 100% recyclable stainless steel may command higher prices due to their eco-friendly attributes.

-

Quality and Certifications: Bottles that meet international safety and quality certifications may incur higher production costs but can enhance marketability and consumer trust.

-

Supplier Factors: Long-standing relationships with reliable suppliers can lead to better pricing negotiations. It’s essential to evaluate potential suppliers’ track records and capabilities.

-

Incoterms: Understanding shipping terms is vital. Different Incoterms (like FOB, CIF) can impact total landed costs, influencing the final price of the products.

What Buyer Tips Can Help Negotiate Better Prices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, the following strategies can lead to better pricing:

-

Negotiate Volume Discounts: Leverage larger order sizes to negotiate better pricing. Establishing ongoing relationships can also facilitate more favorable terms.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also logistics, storage, and potential warranty costs. A higher upfront cost may result in lower long-term expenses if the product is of superior quality.

-

Understand Pricing Nuances for International Trade: Be aware of currency fluctuations, local tariffs, and potential delays in shipping that can affect overall costs. It’s advisable to include these factors in negotiations.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can help in making informed decisions and avoiding costly mistakes.

-

Explore Alternative Suppliers: Diversifying your supplier base can enhance competition and lead to better pricing. It also mitigates risks associated with relying on a single source.

Disclaimer on Indicative Prices

Pricing for metal water bottles varies significantly based on the aforementioned factors and can fluctuate due to market conditions. The prices referenced in various sources typically range from $12 to over $100, depending on specifications and quality. Always consult with suppliers for the most accurate and current pricing tailored to specific needs.

Alternatives Analysis: Comparing metal water bottle cycling With Other Solutions

Introduction to Alternative Solutions in Cycling Hydration

When it comes to cycling hydration, metal water bottles have gained popularity for their durability and eco-friendliness. However, there are viable alternatives that offer different benefits and drawbacks. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific market needs, especially across diverse regions such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Metal Water Bottle Cycling | Plastic Water Bottles | Hydration Packs |

|---|---|---|---|

| Performance | Excellent flow rate; keeps water fresh without plastic taste | Moderate flow; may retain flavors | High capacity; easy access while riding |

| Cost | $39 – $100+ | $5 – $25 | $30 – $150 |

| Ease of Implementation | Fits standard bike cages; lightweight | Readily available; lightweight | Requires adjustment and fit testing |

| Maintenance | Easy to clean; durable | Disposable; limited reuse | Requires regular cleaning; more components |

| Best Use Case | Eco-conscious cyclists; long rides | Budget-conscious users; short rides | Long-distance cyclists; multi-day events |

Detailed Breakdown of Alternatives

Plastic Water Bottles

Plastic water bottles are a common alternative due to their affordability and lightweight nature. They are widely available and can be purchased in bulk, making them an attractive option for budget-conscious consumers. However, they often retain flavors and odors, which can detract from the drinking experience. Additionally, they contribute to environmental waste, as many are not recycled properly. For businesses targeting cost-sensitive markets, plastic bottles may be viable, but the long-term sustainability implications should be considered.

Hydration Packs

Hydration packs are another alternative that provides convenience for cyclists, especially those on long rides or multi-day adventures. They offer a larger capacity than standard bottles and allow for hands-free drinking, which can enhance the riding experience. However, hydration packs can be more expensive and require regular maintenance to ensure cleanliness. Additionally, they may be cumbersome for casual cyclists. For B2B buyers in markets where endurance cycling is popular, hydration packs can be an excellent choice, but they may not appeal to all segments.

Conclusion: Choosing the Right Hydration Solution

Selecting the appropriate hydration solution for cycling depends on various factors, including performance requirements, budget constraints, and user preferences. Metal water bottles stand out for their sustainability and superior performance, particularly for eco-conscious markets. However, alternatives like plastic bottles and hydration packs can also serve specific needs effectively. B2B buyers should assess their target audience’s preferences and the environmental impact of their product choices to make the best decision for their business strategy.

Essential Technical Properties and Trade Terminology for metal water bottle cycling

What Are the Essential Technical Properties of Metal Water Bottles for Cycling?

When evaluating metal water bottles for cycling, several technical properties stand out as critical for B2B buyers. Understanding these specifications is essential to ensure product quality and market competitiveness.

1. Material Grade

The most common materials used in metal water bottles are stainless steel and aluminum. Stainless steel, particularly food-grade 304 or 316, is favored for its corrosion resistance and durability. Aluminum is lightweight but may require coatings to prevent reactions with acidic beverages. B2B buyers should prioritize high-grade materials to ensure longevity and safety, as these factors directly affect customer satisfaction and brand reputation.

2. Capacity

Bottle capacity is typically measured in ounces or milliliters, with common sizes ranging from 500 ml to 740 ml. The choice of capacity impacts hydration efficiency and consumer preference. Larger capacities may appeal to long-distance cyclists, while smaller options are suitable for shorter rides. Understanding market trends related to capacity can help manufacturers tailor their product offerings to meet specific regional demands.

3. Weight

The weight of a metal water bottle is crucial for cyclists who prioritize performance and efficiency. Lightweight designs (often less than 200 grams for a 25 oz bottle) enhance portability, making it easier for cyclists to carry during rides. For B2B buyers, offering lightweight options can differentiate products in competitive markets, particularly among performance-focused consumers.

4. Flow Rate

The flow rate is a critical performance metric, especially for cycling. A high-flow design allows users to hydrate quickly without needing to squeeze the bottle. Innovations in nozzle design can greatly enhance the drinking experience. B2B buyers should consider flow rate specifications when selecting products, as they can significantly influence consumer satisfaction and repeat purchases.

5. Insulation Properties

While some metal water bottles are single-wall, others offer insulation to maintain temperature. Insulated bottles keep liquids cold or hot for extended periods, which can be a selling point in markets with extreme climates. B2B buyers should assess the insulation technology used, as it can affect product positioning and pricing strategies.

6. Recyclability

With increasing consumer awareness around sustainability, the recyclability of materials used in manufacturing is becoming a crucial selling point. Bottles made from 100% recyclable stainless steel resonate well with environmentally conscious consumers. B2B buyers should prioritize suppliers who emphasize sustainable practices, as this can enhance brand loyalty and marketability.

What Are Common Trade Terms Used in the Metal Water Bottle Cycling Industry?

Familiarity with industry jargon is essential for navigating B2B transactions effectively. Here are several key terms relevant to metal water bottle cycling:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products or components that are later rebranded and sold by another company. In the metal water bottle industry, an OEM may manufacture bottles for various brands. Understanding OEM relationships can help buyers negotiate better pricing and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For metal water bottles, MOQs can vary significantly based on materials and customization options. B2B buyers need to be aware of MOQs to manage inventory and cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ for metal water bottles can facilitate competitive bidding and help identify the best suppliers based on price and service.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is vital for B2B buyers to clarify shipping responsibilities, costs, and risk management when importing metal water bottles from various regions.

5. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension of a product. In metal water bottles, tight tolerances are crucial for ensuring that components fit correctly, especially for lids and nozzles. B2B buyers should assess tolerance specifications to ensure product compatibility and quality.

6. Lead Time

Lead time is the period from when an order is placed until it is delivered. In the metal water bottle industry, lead times can vary based on manufacturing capabilities and supply chain efficiency. Understanding lead times helps B2B buyers manage inventory and meet customer demand effectively.

These technical properties and trade terminologies provide a foundational understanding for B2B buyers in the metal water bottle cycling market, enabling informed purchasing decisions that align with consumer preferences and market trends.

Navigating Market Dynamics and Sourcing Trends in the metal water bottle cycling Sector

What Are the Key Market Drivers and Trends for Metal Water Bottles in Cycling?

The global market for metal water bottles, particularly in the cycling sector, is experiencing significant growth driven by several key factors. Increasing health consciousness among consumers is propelling the demand for sustainable and reusable hydration solutions. As cycling gains popularity as a recreational and competitive sport, the need for high-quality, durable water bottles is becoming paramount. Furthermore, the rise of eco-friendly practices is influencing purchasing decisions, with B2B buyers seeking products that align with their sustainability goals.

Emerging technologies in bottle design are also shaping the market. Innovations such as high-flow nozzles, lightweight materials, and ergonomic designs are enhancing the user experience. For instance, brands like Bivo are leveraging engineering expertise to create bottles that offer superior flow rates without the need to squeeze, appealing to performance-focused cyclists. Additionally, the integration of customization options, including colors and sizes, is catering to diverse consumer preferences, making it easier for B2B buyers to find products that suit their target markets.

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate varying market dynamics that include regional preferences and price sensitivity. Understanding local trends, such as the growing interest in outdoor activities and sustainability, can provide a competitive edge in sourcing decisions. Consequently, B2B buyers should prioritize partnerships with manufacturers who can offer both innovative products and competitive pricing to meet the evolving demands of their customers.

How Does Sustainability Influence Sourcing Decisions in the Metal Water Bottle Sector?

Sustainability is at the forefront of sourcing decisions in the metal water bottle cycling sector. B2B buyers are increasingly aware of the environmental impact of their products, leading to a heightened focus on ethical sourcing practices. Manufacturers are responding by adopting sustainable materials, such as 100% recyclable stainless steel, which not only reduces waste but also appeals to environmentally conscious consumers. This shift is crucial in regions where environmental regulations are becoming more stringent, such as in Europe and parts of South America.

Moreover, ethical supply chains are gaining importance as consumers demand transparency regarding the sourcing of materials and the production processes involved. B2B buyers should seek suppliers who can provide certifications indicating compliance with environmental standards, such as ISO 14001 or other green certifications. These credentials not only enhance brand reputation but also mitigate risks associated with non-compliance in various markets.

In addition, the adoption of practices that offset carbon footprints is becoming a selling point for many brands. For instance, companies like Bivo emphasize their commitment to carbon neutrality, which resonates well with consumers looking to make environmentally responsible choices. B2B buyers can leverage these sustainability narratives to differentiate their offerings in competitive markets, aligning with the growing trend of conscious consumerism.

What Is the Historical Context of Metal Water Bottles in Cycling?

The evolution of metal water bottles in the cycling sector can be traced back to the growing awareness of health and environmental issues. Traditionally, plastic bottles dominated the market due to their lightweight and cost-effective nature. However, the increasing environmental concerns regarding plastic waste led to a resurgence in the popularity of metal alternatives, particularly stainless steel.

Over the past decade, technological advancements have significantly improved the design and functionality of metal water bottles. The introduction of features such as BPA-free materials, easy-to-clean designs, and enhanced durability has transformed consumer expectations. Brands that prioritize innovation and sustainability are now leading the market, catering to a new generation of environmentally conscious cyclists who demand quality and performance from their hydration solutions. This shift in consumer behavior presents valuable opportunities for B2B buyers to align with forward-thinking manufacturers and capitalize on the growing demand for sustainable cycling products.

Frequently Asked Questions (FAQs) for B2B Buyers of metal water bottle cycling

-

How do I choose the right metal water bottle supplier for cycling products?

Selecting a reliable supplier requires thorough research. Start by checking the supplier’s reputation through reviews and testimonials from other B2B buyers. Verify their certifications, such as ISO or FDA compliance, to ensure product quality and safety. Additionally, request product samples to evaluate design, durability, and functionality. It’s also wise to assess their production capacity and lead times to ensure they can meet your demand, especially during peak seasons. -

What is the best material for metal water bottles used in cycling?

Stainless steel is widely regarded as the best material for cycling water bottles. It is durable, resistant to rust, and does not retain flavors or odors, ensuring a clean drinking experience. Look for bottles made from food-grade stainless steel, which guarantees safety and compliance with health regulations. Some suppliers also offer insulated options that keep beverages cold, adding to their appeal for long rides. -

What customization options are available for metal water bottles?

Many suppliers offer customization options such as branding with your logo, various colors, and sizes. You may also request specialized features, like different nozzle types or insulation, depending on your target market’s preferences. Be sure to discuss minimum order quantities (MOQs) for customized products, as these may vary significantly between suppliers. -

What are the typical minimum order quantities (MOQs) for metal water bottles?

MOQs for metal water bottles can vary widely among suppliers, typically ranging from 100 to 1,000 units. Smaller quantities may be available, but they often come at a higher price per unit. When negotiating with suppliers, consider your budget, target market, and inventory management strategy to determine the right quantity for your needs. -

What payment terms should I expect when sourcing metal water bottles?

Payment terms can vary by supplier, but common practices include a deposit upfront (usually 30-50%) with the balance due before shipping. Some suppliers may offer credit terms for established buyers. Always clarify payment methods accepted (e.g., wire transfer, credit card) and ensure they provide a secure transaction process to protect your investment. -

How can I ensure quality assurance (QA) for my orders of metal water bottles?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Conduct pre-shipment inspections to verify that products meet your standards. Many B2B buyers opt for third-party inspection services to assess quality before shipment. Establishing clear quality expectations in your contract can also help mitigate potential issues. -

What logistics considerations should I keep in mind when importing metal water bottles?

Logistics considerations include shipping methods, customs regulations, and potential tariffs or duties. Determine the most cost-effective shipping option (air or sea) based on your timeline and budget. Familiarize yourself with the import regulations of your country, including labeling and safety standards, to avoid delays. Partnering with a reliable freight forwarder can simplify the logistics process. -

How do I handle returns or defects in metal water bottles?

Establish a clear return policy with your supplier that outlines procedures for handling defective products. Ensure that you understand their warranty terms and conditions. It’s advisable to document any defects with photographs and communicate promptly with the supplier to resolve issues. A solid return policy will help maintain a positive relationship and ensure accountability on both sides.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Metal Water Bottle Cycling Manufacturers & Suppliers List

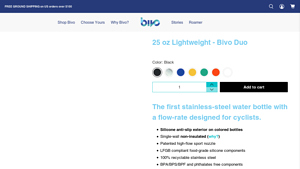

1. Bivo – Stainless Steel Cycling Bottle

Domain: drinkbivo.com

Registered: 2019 (6 years)

Introduction: Bivo Cycling Bottle – Stainless Steel – 25 oz

– Price: $44

– Colors: Black, Raw, True Blue, Sun, Turquoise, Tomato, Roadie White

– Capacity: 25 oz (740 ml)

– Dry Weight: 175 g

– Height: 9.63″ (245 mm)

– Max Diameter: 3″ (77 mm)

– Features:

– First stainless-steel water bottle with a flow-rate designed for cyclists

– Silicone anti-slip exterior on colored bottles

– Single-wall non-insulated

…

2. Bivo – Best Water Flow, Keego – Flexible Metal

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bivo (740ml): Best water flow, more water per sip than plastic bottles, may taste like silicone if un-insulated. Most expensive and hard to find in Europe. Keego (750ml): Marketed as ‘flexible metal’, essentially a plastic bottle with a titanium liner, squeezable, but water flow is not as good.

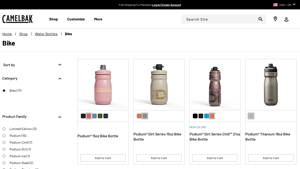

3. CamelBak – Bike Water Bottles

Domain: camelbak.com

Registered: 1996 (29 years)

Introduction: Bike Water Bottles from CamelBak include various models such as Podium® 15oz, Podium® Dirt Series 15oz, Podium® Dirt Series Chill™ 21oz, Podium® Titanium 18oz, Podium® Steel 22oz, Podium® Chill™ 21oz, Podium® Steel 18oz, and Podium® 24oz. Prices range from $12.00 to $100.00. Key features include high-flow caps, customizable options, and different sizes for hydration needs.

4. Bivo – Trio 21oz Water Bottle

Domain: singletracks.com

Registered: 1999 (26 years)

Introduction: Product: Bivo Trio 21oz Water Bottle

Material: Stainless Steel

Insulation: Double-wall vacuum insulated

Weight: 276g

Features:

– Silicone coating for slip-resistance and sound damping

– Patent-pending sport nozzle for high flow rate

– Designed to prevent mold and chemical leaching

Compatibility: Fits snugly in water bottle cage on gravel bikes; taller for full-suspension MTBs

Alternative: Bivo On…

5. Elite – Inox Water Bottles

Domain: elite-it.com

Registered: 1998 (27 years)

Introduction: This company, Elite – Inox Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Cyclist – Bivo and Botl Bottles

Domain: cyclist.co.uk

Registered: 1997 (28 years)

Introduction: Bivo Bottle: RRP from $34, available in 500ml, 621ml, and 740ml sizes, includes vacuum insulation options, anti-slip silicone coating, patented fast flow nozzle, optional dust cap. Botl Bottle: RRP from £24, offers insulated and non-insulated stainless steel bottles, capacities from 500ml, features a cap with built-in straw, replacement caps available. Camelbak Podium Titanium Bottle: RRP £100, 53…

7. Bicycling – Best Insulated Water Bottles

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Stainless Insulated: CamelBak Podium Steel (non-chilled, 3 hours)

Best Plastic Insulated: Specialized Purist Insulated (pre-chilled, 90 mins)

Best Riding Stainless Insulated: Bivo Insulated Trio

Best Riding Plastic Insulated: Elite IceFly 500mL and RockBros Insulated

Tested 5 metal-insulated, 7 plastic-insulated, and 3 non-insulated bottles. Insulated bottle types include plastic and metal, w…

Strategic Sourcing Conclusion and Outlook for metal water bottle cycling

As the demand for sustainable and high-performance cycling gear continues to rise, strategic sourcing of metal water bottles presents a significant opportunity for international B2B buyers. Key takeaways from the current market landscape highlight the advantages of lightweight, durable materials that offer a clean taste and are free from harmful chemicals. Brands like Bivo and CamelBak exemplify innovation with features such as high-flow nozzles and universal fit designs, appealing to the growing segment of eco-conscious consumers.

Investing in metal water bottles not only aligns with sustainability goals but also enhances brand reputation in regions like Africa, South America, the Middle East, and Europe, where consumers increasingly prioritize health and environmental impact. By fostering partnerships with manufacturers that emphasize recyclability and low environmental footprints, businesses can cater to a discerning market while driving profitability.

Looking ahead, the cycling industry is poised for growth. B2B buyers are encouraged to explore partnerships with forward-thinking suppliers to stay ahead of market trends and consumer preferences. Embrace the opportunity to lead in sustainability and innovation within the cycling sector, ensuring that your offerings resonate with the values of today’s cyclists.