Introduction: Navigating the Global Market for flat water bottle

Navigating the global market for flat water bottles presents a unique challenge for international B2B buyers, particularly those sourcing innovative hydration solutions in regions like Africa, South America, the Middle East, and Europe. The increasing demand for eco-friendly, space-efficient, and stylish water bottles has made flat water bottles a sought-after alternative to traditional designs. However, the diversity in types, materials, and supplier reliability can complicate the purchasing process.

This comprehensive guide aims to demystify the flat water bottle market by exploring various types, including reusable plastic, stainless steel, and collapsible options. We will delve into applications that cater to corporate branding, hospitality, and travel, ensuring that buyers understand the versatility of these products. Additionally, this guide will provide actionable insights on supplier vetting processes, cost considerations, and market trends to empower informed purchasing decisions.

By equipping B2B buyers with the necessary knowledge to navigate this evolving landscape, this guide facilitates a smoother sourcing experience. Whether you are looking to enhance your product offerings or seeking sustainable solutions for your business, understanding the flat water bottle market will help you make strategic decisions that align with both consumer preferences and environmental goals.

Article Navigation

- Top 8 Flat Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for flat water bottle

- Understanding flat water bottle Types and Variations

- Key Industrial Applications of flat water bottle

- 3 Common User Pain Points for ‘flat water bottle’ & Their Solutions

- Strategic Material Selection Guide for flat water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for flat water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘flat water bottle’

- Comprehensive Cost and Pricing Analysis for flat water bottle Sourcing

- Alternatives Analysis: Comparing flat water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for flat water bottle

- Navigating Market Dynamics and Sourcing Trends in the flat water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of flat water bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for flat water bottle

Understanding flat water bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slim Memobottle | Tall, slender design; BPA-free Tritan plastic; stainless steel lid | Corporate gifts, promotional events | Pros: Space-saving, stylish; Cons: Not suitable for carbonated drinks. |

| Stainless Steel Memobottle | Durable, insulated; maintains temperature; stylish finish | Outdoor events, corporate giveaways | Pros: Long-lasting, good for hot/cold drinks; Cons: Heavier than plastic options. |

| Foldable Water Bottles | Lightweight, collapsible design; made from flexible materials | Travel, outdoor activities | Pros: Highly portable, saves space; Cons: May not be as durable as rigid bottles. |

| Original Memobottle | Glass-like clarity; flat design fits easily in bags | Office use, branding opportunities | Pros: Elegant appearance, eco-friendly; Cons: More fragile than plastic alternatives. |

| Silicone Sleeve Bottles | Customizable, protective silicone covers for flat bottles | Retail, branding, personal gifts | Pros: Offers grip and insulation; Cons: Additional cost for accessories. |

What Are the Key Characteristics of Slim Memobottles?

Slim Memobottles are designed with a tall, slender profile that allows them to fit into narrow spaces, making them ideal for corporate gifts or promotional events. Constructed from BPA-free Tritan plastic, they are both lightweight and shatterproof. Their stylish appearance, complemented by a stainless steel lid, enhances brand visibility, making them an excellent choice for businesses looking to promote sustainability while maintaining a modern aesthetic. However, buyers should note that these bottles are not suitable for carbonated beverages.

How Do Stainless Steel Memobottles Stand Out?

Stainless Steel Memobottles offer durability and insulation, making them suitable for outdoor events and corporate giveaways. They maintain the temperature of beverages, keeping drinks hot or cold for extended periods. The sleek design appeals to a wide audience, promoting a premium brand image. While they are heavier than their plastic counterparts, their longevity and robust nature can justify the investment for businesses focused on quality and functionality.

Why Consider Foldable Water Bottles for Travel?

Foldable water bottles are made from flexible materials that allow them to collapse when empty, making them exceptionally portable for travel or outdoor activities. Their lightweight design is perfect for businesses catering to active lifestyles, such as travel agencies or outdoor gear retailers. While they excel in convenience, potential buyers should consider that their durability may not match that of rigid bottles, which could impact long-term use.

What Makes Original Memobottles a Unique Choice?

Original Memobottles feature a glass-like clarity and a flat design that fits effortlessly in bags, making them suitable for office use and branding opportunities. Their eco-friendly materials appeal to environmentally conscious businesses. While they offer an elegant appearance that enhances brand image, the fragility of these bottles compared to plastic options should be a consideration for buyers aiming for durability.

How Can Silicone Sleeve Bottles Enhance Brand Visibility?

Silicone Sleeve Bottles provide a customizable protective layer for flat bottles, allowing businesses to enhance their branding efforts. These sleeves offer grip and insulation, making them a practical choice for retail and personal gifts. While they add aesthetic value and functionality, businesses should factor in the additional cost of these accessories when budgeting for promotional products.

Key Industrial Applications of flat water bottle

| Industry/Sector | Specific Application of flat water bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | In-room amenities for hotels and resorts | Enhances guest experience by providing convenient hydration options | Custom branding options and material safety certifications |

| Corporate & Office | Employee wellness programs | Promotes sustainability and encourages hydration among employees | Bulk purchasing discounts and eco-friendly materials |

| Travel & Tourism | Travel kits for tour operators | Provides a unique selling point and enhances customer satisfaction | Durability and lightweight design for easy transport |

| Education | Student hydration stations | Supports health initiatives and reduces single-use plastic waste | Compliance with safety standards and child-friendly materials |

| Outdoor & Adventure | Gear for adventure sports companies | Appeals to environmentally-conscious consumers and enhances brand loyalty | Versatility in temperature handling and material durability |

How Are Flat Water Bottles Used in the Hospitality Sector?

In the hospitality industry, flat water bottles are increasingly used as in-room amenities in hotels and resorts. Their sleek design allows them to fit seamlessly into various spaces, enhancing the aesthetic appeal of hotel rooms. Providing guests with these reusable bottles not only elevates their experience but also aligns with sustainability initiatives by reducing single-use plastic waste. International buyers in this sector should consider custom branding options to reinforce their hotel’s identity and ensure that materials meet safety certifications.

Why Are Flat Water Bottles Important for Corporate Wellness Programs?

Corporate offices are adopting flat water bottles as part of employee wellness programs. These bottles encourage hydration and promote a healthier workplace culture. Their compact design makes them easy to store in desks or bags, fostering a sustainable approach to hydration. When sourcing, businesses should look for bulk purchasing options to achieve cost efficiency and ensure that the bottles are made from eco-friendly materials that resonate with corporate social responsibility goals.

How Do Flat Water Bottles Enhance Travel Experiences?

In the travel and tourism industry, flat water bottles are included in travel kits offered by tour operators. Their space-saving design is ideal for travelers who need to pack light. By providing these bottles, companies can differentiate themselves in a competitive market and improve customer satisfaction through practical, eco-friendly solutions. Buyers should prioritize durability and lightweight materials when sourcing to ensure that these bottles withstand the rigors of travel.

What Role Do Flat Water Bottles Play in Educational Settings?

Educational institutions are increasingly implementing flat water bottles in hydration stations across campuses. This initiative supports health and wellness goals while significantly reducing the reliance on single-use plastic bottles. For international buyers in the education sector, compliance with safety standards is crucial, as well as ensuring the materials used are child-friendly and durable enough for frequent use.

How Are Flat Water Bottles Beneficial for Outdoor Adventure Gear?

Outdoor and adventure sports companies are incorporating flat water bottles into their gear offerings. These bottles appeal to environmentally-conscious consumers looking for sustainable hydration solutions while participating in outdoor activities. When sourcing, companies should focus on versatility in temperature handling and the durability of materials to withstand harsh outdoor conditions, ensuring a reliable product that enhances brand loyalty among adventure enthusiasts.

3 Common User Pain Points for ‘flat water bottle’ & Their Solutions

Scenario 1: Limited Storage Space for Transportation

The Problem: B2B buyers, especially in logistics and retail, often face challenges in transporting products due to limited storage space. Traditional round water bottles can take up unnecessary room, leading to inefficient packing and increased shipping costs. This is particularly pressing for businesses that need to maximize every inch of cargo space, especially in regions with higher shipping fees or when transporting goods over long distances.

The Solution: Flat water bottles, such as those designed with a slim profile, are the ideal solution for this pain point. Buyers should look for options that are specifically marketed as space-saving or designed to fit in tight spaces. When sourcing these products, consider bulk purchasing to reduce costs and ensure you have enough supply without taking up valuable storage space. Additionally, assess the dimensions of the flat water bottles to guarantee they fit efficiently into your packaging. Utilizing flat bottles can enhance your logistics strategy, enabling you to transport more units within the same space, thereby optimizing costs and resources.

Scenario 2: Risk of Damage During Transportation

The Problem: Another significant concern for B2B buyers is the risk of damage to water bottles during transportation. Traditional bottles are often made of glass or thin plastic, making them susceptible to breaking or leaking. This not only leads to product loss but also affects customer satisfaction and increases return rates, especially in markets where reliability is key, such as in the Middle East or Africa.

The Solution: To mitigate this issue, B2B buyers should consider sourcing flat water bottles made from durable materials like Tritan plastic, which is shatterproof and lightweight. When selecting suppliers, prioritize those who provide comprehensive packaging solutions that ensure the bottles are protected during transit. It may also be advantageous to inquire about additional protective features, such as silicone sleeves or reinforced lids, that can further enhance durability. By opting for robust flat water bottles, businesses can significantly reduce the likelihood of product damage, ensuring that customers receive their orders in perfect condition.

Scenario 3: Consumer Preferences for Eco-Friendly Options

The Problem: As sustainability becomes a pivotal factor in purchasing decisions, B2B buyers are increasingly challenged to meet the demand for eco-friendly products. Many consumers are seeking reusable water bottles that minimize environmental impact. Failing to offer sustainable options can result in losing market share to competitors who prioritize eco-consciousness, particularly in regions like Europe and South America, where environmental awareness is high.

The Solution: To address this challenge, B2B buyers should focus on sourcing flat water bottles that are marketed as reusable and made from environmentally friendly materials. Look for suppliers that emphasize their commitment to sustainability, such as those that provide information on how their products reduce single-use plastic waste. Additionally, consider forming partnerships with brands that support social causes, like those contributing to clean water initiatives, which can enhance your brand image and appeal to eco-conscious consumers. Educating your customers about the benefits of using flat water bottles—such as their convenience and reduced carbon footprint—can also drive sales and improve brand loyalty. By aligning your product offerings with consumer values, you can maintain a competitive edge in the marketplace.

Strategic Material Selection Guide for flat water bottle

What are the Key Properties of Common Materials Used in Flat Water Bottles?

When selecting materials for flat water bottles, several options stand out due to their unique properties and suitability for various applications. This analysis focuses on four common materials: Tritan plastic, stainless steel, glass, and silicone. Each material presents distinct advantages and challenges, influencing the decision-making process for international B2B buyers.

Tritan Plastic: A Versatile and Lightweight Option

Tritan plastic is a popular choice for flat water bottles due to its glass-like clarity and shatterproof nature. It is BPA and BPS-free, ensuring safety for consumers. Tritan can withstand temperatures ranging from -40°C to 100°C, making it suitable for both hot and cold beverages.

Pros: Tritan is lightweight, durable, and resistant to odors and stains. Its manufacturing process is relatively straightforward, allowing for cost-effective production.

Cons: While Tritan is robust, it may not be as long-lasting as stainless steel or glass. Over time, it can scratch and lose clarity.

Impact on Application: Tritan is compatible with various liquids, but care should be taken with carbonated beverages, as the unique shape of flat bottles may not accommodate them well.

Considerations for International Buyers: Buyers from regions such as Africa and the Middle East should ensure compliance with local safety standards, such as ASTM and ISO certifications, to guarantee product safety and quality.

Stainless Steel: The Durable and Eco-Friendly Choice

Stainless steel is another excellent option for flat water bottles, known for its strength and resistance to corrosion. It can handle high temperatures and is generally dishwasher safe, making it easy to clean.

Pros: Stainless steel is highly durable, resistant to rust, and does not retain flavors or odors. It is also recyclable, appealing to environmentally conscious consumers.

Cons: The manufacturing process for stainless steel can be more complex and costly compared to plastics. Additionally, stainless steel bottles may be heavier than their plastic counterparts.

Impact on Application: Stainless steel is ideal for both hot and cold beverages, including carbonated drinks, making it versatile for various consumer needs.

Considerations for International Buyers: Compliance with standards such as JIS (Japanese Industrial Standards) and DIN (Deutsches Institut für Normung) is crucial for ensuring product quality and safety in diverse markets.

Glass: The Premium and Aesthetic Option

Glass offers a premium feel and aesthetic appeal for flat water bottles. It is non-reactive, ensuring that beverages maintain their original flavor without any leaching of chemicals.

Pros: Glass is recyclable and provides excellent clarity, allowing users to see the contents easily. It is also easy to clean and does not retain flavors.

Cons: Glass is heavier and more fragile than plastic or stainless steel, making it less suitable for active lifestyles or travel.

Impact on Application: Glass is best suited for still liquids and is not recommended for carbonated beverages due to the risk of breakage.

Considerations for International Buyers: Buyers should be aware of shipping and handling regulations for glass products, especially in regions with high transportation risks.

Silicone: The Flexible and Lightweight Alternative

Silicone is increasingly being used in flat water bottle designs, particularly for collapsible options. It is flexible, lightweight, and can withstand a wide range of temperatures.

Pros: Silicone is durable, easy to clean, and can be molded into various shapes, making it versatile for innovative designs.

Cons: While silicone is resistant to high temperatures, it may not be as rigid as other materials, potentially affecting durability in harsh conditions.

Impact on Application: Silicone bottles are suitable for both hot and cold liquids, but they may not provide the same level of insulation as stainless steel.

Considerations for International Buyers: Compliance with FDA standards for food-grade silicone is essential, particularly in markets focused on health and safety.

Summary Table of Material Properties

| Material | Typical Use Case for Flat Water Bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tritan Plastic | Everyday use, casual settings | Lightweight and shatterproof | Scratches over time | Medium |

| Stainless Steel | Outdoor activities, travel | Durable and eco-friendly | Heavier and costlier | High |

| Glass | Premium markets, home use | Aesthetic and non-reactive | Fragile and heavy | High |

| Silicone | Travel, collapsible designs | Flexible and lightweight | Less rigid | Medium |

This strategic material selection guide provides essential insights for B2B buyers, enabling informed decisions based on the unique properties and implications of each material in the context of flat water bottles.

In-depth Look: Manufacturing Processes and Quality Assurance for flat water bottle

What Are the Key Stages in the Manufacturing Process of Flat Water Bottles?

The manufacturing of flat water bottles involves several critical stages that ensure the final product meets both functional and aesthetic standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves selecting the appropriate materials, predominantly BPA-free plastics like Tritan or stainless steel. These materials are chosen for their safety, durability, and lightweight properties. The preparation process may include drying and granulating the raw materials to achieve optimal processing conditions. For instance, Tritan is often pre-processed to enhance its clarity and strength, ensuring the final product is not only visually appealing but also long-lasting.

How Are Flat Water Bottles Formed?

Forming is the next stage, where the prepared materials are shaped into the desired bottle design. Common techniques include injection molding for plastic bottles and stamping for metal options. Injection molding allows for precision in creating the flat profile that distinguishes these bottles from traditional round ones. This technique also enables manufacturers to produce complex designs, such as ergonomic grips or unique lid configurations.

What Does the Assembly Process Involve?

After forming, the assembly stage integrates various components, such as lids, seals, and any additional features like silicone sleeves or cleaning tablets. Automated assembly lines are often employed to enhance efficiency and reduce labor costs. This stage is crucial for ensuring that each bottle is fully functional, with leak-proof lids and secure seals that prevent spills during transportation.

What Finishing Techniques Are Commonly Used?

Finishing processes can include surface treatments, printing, and quality checks. Bottles may undergo processes such as polishing to enhance clarity or applying coatings to improve grip. Additionally, branding elements, like logos or product information, are often printed during this stage using techniques like screen printing or pad printing, which provide durability against wear and tear.

How Is Quality Assurance Managed Throughout the Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for flat water bottles. To ensure that products meet international and industry-specific standards, a robust QA framework is implemented.

Which International Standards Are Relevant for Flat Water Bottle Production?

Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems, and specific certifications like CE (Conformité Européenne) for products sold in Europe. These standards ensure that manufacturing processes are consistent and that products are safe for consumer use. For B2B buyers, understanding these standards is critical as they reflect the manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is usually segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production line. Ensuring that the materials meet specified standards is crucial to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and identify potential issues early. This can involve visual inspections, measurements, and functional tests to ensure that each bottle meets design specifications.

-

Final Quality Control (FQC): Once the bottles are assembled, a final inspection is performed to assess overall quality, functionality, and aesthetic appeal. This may include pressure testing for leak-proof assurances and durability tests to evaluate the bottle’s resistance to damage.

What Common Testing Methods Are Employed for Flat Water Bottles?

To ensure compliance with safety and quality standards, various testing methods are utilized. These may include:

-

Chemical Resistance Testing: Ensures that the material does not degrade when exposed to various substances, including different liquids.

-

Drop Testing: Assesses the durability of bottles by dropping them from specific heights to simulate real-world usage.

-

Thermal Testing: Evaluates how the bottle withstands extreme temperatures, ensuring it remains functional whether used for hot or cold beverages.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks associated with product defects. Here are several strategies:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers should conduct comprehensive audits of potential suppliers. This includes reviewing their manufacturing facilities, observing QC processes, and checking for compliance with international standards. Audits can be performed by the buyers themselves or outsourced to third-party auditing firms, providing an objective assessment of the supplier’s capabilities.

How to Request Quality Reports and Certifications?

Buyers should request detailed quality reports and certifications from suppliers. This includes documentation of past QC tests, ISO certifications, and any relevant compliance certificates (e.g., CE, FDA). Reviewing these documents can provide insights into the supplier’s commitment to quality and adherence to international standards.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection agencies can provide an additional layer of assurance. These agencies can conduct random inspections during production and before shipment, ensuring that products meet the required standards. This is particularly valuable for buyers from regions like Africa, South America, and the Middle East, where access to reliable quality assurance may vary.

What QC and Certification Nuances Should International Buyers Consider?

International buyers must navigate various nuances regarding quality control and certification. For instance, specific markets may have unique regulations or certifications that must be met. Understanding these requirements is crucial for compliance and market access. Additionally, language barriers and different regulatory environments can complicate the verification of certifications and QC processes, necessitating clear communication and possibly the assistance of local experts.

By comprehensively understanding the manufacturing processes and quality assurance measures in place for flat water bottles, B2B buyers can make informed decisions that ensure product quality, safety, and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flat water bottle’

Introduction

This guide serves as a practical checklist for B2B buyers looking to source flat water bottles. These innovative containers offer a space-saving design, making them an attractive option for various markets. By following this step-by-step checklist, you can ensure that your procurement process is efficient, meets quality standards, and aligns with your business needs.

Step 1: Define Your Technical Specifications

Begin by determining the specific features you require in a flat water bottle. Consider factors such as material (e.g., Tritan, stainless steel, or BPA-free plastic), capacity (e.g., 450ml, 750ml), and design (e.g., slim, collapsible). Defining these specifications upfront will help streamline the sourcing process and ensure you find a product that meets your functional requirements.

Step 2: Research Market Trends and Consumer Preferences

Understanding current market trends and consumer preferences is crucial for making informed purchasing decisions. Analyze the demand for flat water bottles in your target regions, such as Africa, South America, the Middle East, and Europe. Look for insights on popular designs, colors, and branding that resonate with consumers, as this can influence your product selection and marketing strategy.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their product quality, production capabilities, and lead times. This evaluation will help ensure that you partner with reliable suppliers who can meet your specifications and delivery requirements.

Step 4: Request Samples for Quality Assessment

Always request samples before finalizing your order. This step allows you to assess the quality, functionality, and design of the flat water bottles firsthand. Pay attention to aspects such as durability, ease of cleaning, and how well the bottle fits into various carrying scenarios. Evaluating samples can prevent costly mistakes and ensure the product meets your expectations.

Step 5: Verify Compliance with Safety and Environmental Standards

Ensure that the products comply with relevant safety and environmental regulations. Check for certifications like FDA approval for food safety and BPA-free claims. Additionally, inquire about the supplier’s sustainability practices, such as the use of recyclable materials or initiatives to reduce plastic waste. This not only protects your brand but also appeals to eco-conscious consumers.

Step 6: Negotiate Pricing and Terms

Engage in negotiations to secure the best pricing and favorable terms. Discuss bulk purchase discounts, payment options, and delivery schedules. Understanding the total cost of ownership, including shipping and handling, will help you make a more informed financial decision. Establishing clear terms upfront can prevent misunderstandings later in the process.

Step 7: Plan for Marketing and Distribution

Finally, develop a strategy for marketing and distributing your flat water bottles. Consider how you will position the product in the market, including branding, packaging, and promotional activities. Assess distribution channels that align with your target audience, whether through online platforms, retail partnerships, or direct sales. A well-thought-out marketing plan will enhance your product’s visibility and drive sales.

By following these steps, you can efficiently source flat water bottles that meet your business needs while ensuring quality and compliance with industry standards.

Comprehensive Cost and Pricing Analysis for flat water bottle Sourcing

What Are the Key Cost Components in Sourcing Flat Water Bottles?

When evaluating the cost structure for sourcing flat water bottles, several critical components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the cost. Flat water bottles are commonly made from BPA-free plastics, Tritan, stainless steel, or glass. Each material has different price points and durability characteristics. For example, Tritan offers a glass-like appearance at a lower weight but may be more expensive than standard plastics.

-

Labor and Manufacturing Overhead: Labor costs vary by region and impact the overall pricing. In countries with lower wage rates, such as some in Africa and South America, labor costs may contribute to a lower overall price. Manufacturing overhead, which includes utilities, equipment maintenance, and factory rent, should also be factored into the pricing.

-

Tooling: Custom designs or unique bottle shapes may require specific molds or tooling, which can add to the initial costs. This is especially important for B2B buyers seeking customization to differentiate their products in the market.

-

Quality Control (QC): Ensuring that products meet international standards often incurs additional costs. Certifications for quality assurance can influence the pricing, making it essential for buyers to understand the QC processes employed by suppliers.

-

Logistics: Shipping costs, which depend on the distance, weight, and mode of transport, can add significantly to the total cost. Buyers should consider Incoterms that define the responsibilities of buyers and sellers in international shipping to better understand these costs.

-

Margin: Suppliers typically mark up prices to ensure profitability. The margin can vary based on market competition and the perceived value of the product.

How Do Price Influencers Affect Flat Water Bottle Sourcing?

Several factors can influence the price of flat water bottles, making it crucial for international B2B buyers to understand them.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide tiered pricing based on the order volume. Higher volumes can lead to significant discounts, so negotiating for larger quantities can be beneficial.

-

Specifications and Customization: Customization requests, such as unique colors, logos, or sizes, may increase the price. Buyers should be clear about their specifications to avoid unexpected costs.

-

Material Quality and Certifications: The quality of materials used and the presence of certifications can influence the price. Bottles made from premium materials or those with certifications (like FDA approval) will typically command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is vital for international buyers as they dictate who is responsible for shipping costs and liabilities. This knowledge can help in negotiating better terms.

What Are Essential Buyer Tips for Cost-Efficient Sourcing?

-

Negotiation Strategies: Effective negotiation can lead to better pricing. Buyers should research market prices and be prepared to discuss potential volume discounts and long-term partnerships.

-

Consider Total Cost of Ownership (TCO): Beyond the initial price, buyers should evaluate the TCO, which includes shipping, handling, and potential costs associated with quality issues. This holistic view can lead to more informed purchasing decisions.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to tariffs, taxes, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when sourcing flat water bottles.

-

Request Samples: Before committing to large orders, requesting samples can help assess quality and confirm that the product meets expectations. This can prevent costly mistakes down the line.

-

Stay Informed on Market Trends: Keeping an eye on market trends and competitor offerings can provide insights into pricing strategies and help buyers make better sourcing decisions.

Disclaimer on Indicative Prices

Prices for flat water bottles can fluctuate based on market conditions, raw material costs, and supplier pricing strategies. It is advisable for buyers to request quotes and conduct thorough market research to ensure they are getting the best value for their investment.

Alternatives Analysis: Comparing flat water bottle With Other Solutions

Introduction: Understanding Alternatives to Flat Water Bottles

In the ever-evolving landscape of hydration solutions, the flat water bottle has gained popularity for its innovative design that maximizes space efficiency. However, businesses must consider various alternatives that may better suit their specific needs and operational contexts. This analysis compares the flat water bottle with two viable alternatives: traditional round water bottles and collapsible water bottles. Each option has its unique advantages and disadvantages, making it essential for B2B buyers to assess which solution aligns best with their objectives.

Comparison Table

| Comparison Aspect | Flat Water Bottle | Traditional Round Bottle | Collapsible Water Bottle |

|---|---|---|---|

| Performance | Lightweight, fits in tight spaces | Standard capacity, versatile | Space-saving when empty, lightweight |

| Cost | Mid-range ($20 – $50) | Low to mid-range ($5 – $30) | Low to mid-range ($10 – $25) |

| Ease of Implementation | Simple to use; no setup required | No special requirements | Requires careful handling to prevent leaks |

| Maintenance | Easy to clean; dishwasher safe | Generally easy to clean | Requires thorough drying to prevent mold |

| Best Use Case | Travel, office, and events | Everyday use, fitness, and outdoor activities | Travel, hiking, and emergency kits |

Detailed Breakdown of Alternatives

Traditional Round Bottles

Traditional round water bottles are the most common hydration solution. They come in various materials, including plastic, stainless steel, and glass. The primary advantage of these bottles is their availability and cost-effectiveness. They are generally less expensive than flat water bottles, making them ideal for bulk purchases, especially for organizations looking to provide hydration to employees or customers.

However, traditional round bottles can be bulkier and may not fit easily into tight spaces, such as bags or car cup holders. This limitation can be a disadvantage for businesses focused on convenience and efficient space utilization. Furthermore, while they are straightforward to clean, some designs may be prone to leakage if not properly secured.

Collapsible Water Bottles

Collapsible water bottles are an innovative alternative that provides flexibility in storage. These bottles can be folded down when empty, significantly reducing their size and making them easy to transport. Their lightweight nature makes them ideal for outdoor activities, travel, or emergency preparedness kits.

The main downside of collapsible bottles is their potential for leakage if not handled properly. They also require regular maintenance to ensure they are thoroughly dried after use, as moisture can lead to mold growth. For businesses that prioritize space-saving and portability, collapsible water bottles offer a compelling solution, albeit with some added responsibilities regarding care.

Conclusion: Choosing the Right Hydration Solution for Your Needs

When selecting the appropriate hydration solution, B2B buyers must weigh the unique advantages and disadvantages of each option. The flat water bottle excels in environments where space is at a premium, making it ideal for travel and office use. In contrast, traditional round bottles offer affordability and versatility for everyday use, while collapsible bottles provide unparalleled portability for outdoor and emergency scenarios.

Ultimately, the decision should be guided by specific use cases, budget constraints, and maintenance capabilities. By carefully evaluating these factors, businesses can choose the hydration solution that best meets their operational requirements and enhances their overall efficiency.

Essential Technical Properties and Trade Terminology for flat water bottle

What Are the Key Technical Properties of a Flat Water Bottle?

When considering flat water bottles for B2B purchases, understanding their technical properties is essential for ensuring product quality and suitability for various markets. Here are some critical specifications to consider:

-

Material Composition

– Flat water bottles are commonly made from materials like Tritan plastic, stainless steel, or BPA-free plastics. Tritan is known for its durability and glass-like clarity, while stainless steel offers enhanced insulation and longevity. The choice of material impacts the bottle’s weight, safety, and environmental footprint, which are crucial factors for buyers focused on sustainability. -

Dimensions and Volume

– Typical dimensions for flat water bottles range from 265 x 80 x 30 mm to larger sizes, with capacities often around 450ml to 1 liter. The slim profile allows these bottles to fit into tight spaces, making them ideal for travel and daily use. Understanding the dimensions helps buyers assess whether the product meets their packaging and transport needs. -

Temperature Resistance

– Many flat water bottles are designed to handle a range of temperatures, from hot to cold, without compromising their structural integrity. This property is particularly relevant for buyers in regions with varying climates, ensuring that the product remains functional in different environments. -

Weight

– The weight of a flat water bottle typically ranges from 120 grams to 250 grams, depending on the material and size. A lightweight design is advantageous for consumers who prioritize portability, especially in markets with high travel demands. -

Cleaning and Maintenance

– Ease of cleaning is a significant factor, as many flat water bottles can be cleaned with simple soap and water or specialized cleaning tablets. This feature is essential for B2B buyers looking to promote hygiene and usability among end consumers. -

Durability and Warranty

– Durability is often backed by warranties, with many manufacturers offering a two-year guarantee against defects. This assurance is vital for B2B buyers, as it reduces the risk of returns and enhances customer satisfaction.

Which Trade Terminology Should B2B Buyers Know for Flat Water Bottles?

Familiarity with industry-specific terminology can streamline communication and negotiations in the B2B market for flat water bottles. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or products that are sold under another company’s brand name. Understanding OEM relationships can help buyers negotiate better terms and establish quality standards. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory levels and financial commitments effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for a specific product. It allows buyers to compare offers and negotiate better deals, especially when sourcing flat water bottles from multiple suppliers. -

Incoterms (International Commercial Terms)

– These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risk transfer, and delivery obligations. -

Sustainability Certifications

– This term refers to third-party certifications that confirm a product’s environmental claims, such as being BPA-free or made from recycled materials. Buyers increasingly prioritize sustainability, making knowledge of relevant certifications important. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times helps B2B buyers plan their inventory and sales strategies effectively.

In conclusion, grasping these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing flat water bottles, ultimately enhancing their supply chain efficiency and product offerings.

Navigating Market Dynamics and Sourcing Trends in the flat water bottle Sector

What Are the Key Market Dynamics and Trends Affecting Flat Water Bottles Globally?

The flat water bottle market is experiencing notable growth, driven by a surge in consumer demand for space-saving and environmentally friendly hydration solutions. As urbanization continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, buyers are increasingly looking for products that fit seamlessly into their busy lifestyles. The global market is projected to expand as businesses recognize the opportunity to cater to consumers who prioritize convenience without compromising on sustainability.

Emerging trends in B2B sourcing include the integration of innovative materials such as Tritan and stainless steel, which offer durability and safety while reducing environmental impact. Suppliers are also leveraging advanced manufacturing technologies to optimize production efficiency and reduce costs. As international buyers seek reliable partners, those who can demonstrate agility in adapting to market fluctuations will have a competitive edge. Additionally, the rise of e-commerce platforms provides a unique avenue for B2B buyers to access a diverse range of products from global suppliers, enhancing sourcing options and flexibility.

How Is Sustainability and Ethical Sourcing Shaping the Flat Water Bottle Market?

The focus on sustainability is reshaping purchasing decisions among B2B buyers in the flat water bottle sector. With increasing awareness of environmental issues, businesses are prioritizing ethical sourcing and sustainable practices in their supply chains. The impact of single-use plastics has prompted a shift towards reusable options, with flat water bottles positioned as a practical alternative. Companies that adopt eco-friendly materials, such as BPA-free plastics and recycled materials, not only meet consumer demand but also enhance their brand reputation.

Certifications such as Fair Trade, ISO 14001 (Environmental Management), and other ‘green’ labels are becoming essential for manufacturers aiming to establish credibility in the marketplace. These certifications assure buyers that their sourcing decisions contribute positively to environmental conservation and social responsibility. As international regulations tighten around plastic use, buyers who prioritize sustainable products will find themselves better positioned to navigate compliance challenges and appeal to environmentally conscious consumers.

What Is the Evolution of the Flat Water Bottle Sector?

The flat water bottle concept emerged as a response to the growing need for portable, space-efficient hydration solutions. Initially popularized by brands like memobottle, the design capitalized on the idea of a sleek, minimalist aesthetic that complements modern lifestyles. Over the years, innovation has propelled the evolution of flat water bottles, introducing variations in materials, sizes, and functionalities. The shift from traditional round bottles to flat designs not only maximizes storage space but also aligns with the increasing consumer demand for sustainable products.

As the market continues to evolve, B2B buyers are encouraged to keep an eye on emerging brands and technologies that challenge the status quo. This evolution signifies a broader trend towards personalization and customization in the B2B landscape, allowing businesses to cater to diverse consumer preferences while maintaining a strong commitment to sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of flat water bottle

-

How do I evaluate the quality of flat water bottles before purchasing?

To assess the quality of flat water bottles, request samples from potential suppliers to inspect the material and craftsmanship firsthand. Look for bottles made from BPA-free plastics or stainless steel for durability and safety. Check for certifications that indicate compliance with international safety standards. Additionally, examine customer reviews and ratings to gauge product performance and reliability. Establishing clear quality criteria before sourcing will help ensure you select a product that meets your standards. -

What is the best material for flat water bottles for international shipping?

For international shipping, stainless steel and Tritan plastic are ideal materials for flat water bottles. Stainless steel is robust and resistant to damage, making it suitable for long-distance transport. Tritan plastic offers a lightweight, shatterproof alternative, ensuring safety during transit. Both materials are BPA-free, providing added health benefits. When choosing a material, consider your target market’s preferences and regulatory requirements in their respective regions. -

What customization options are available for flat water bottles?

Customization options for flat water bottles often include branding, color choices, and accessory options. Many suppliers offer printing services for logos or designs on the bottles, allowing you to create a unique product that resonates with your brand. Additionally, consider options like silicone sleeves or different lid types to enhance functionality and aesthetics. Discuss your specific requirements with suppliers to explore available customization possibilities that align with your brand identity. -

What are the typical minimum order quantities (MOQs) for flat water bottles?

Minimum order quantities (MOQs) for flat water bottles can vary significantly between suppliers, often ranging from 500 to 5,000 units depending on the material and customization options. Some manufacturers may offer lower MOQs for standard models without customization. It’s essential to communicate your needs clearly with suppliers and negotiate MOQs that align with your purchasing strategy. Be mindful that larger orders may qualify for discounts, potentially increasing your profit margins. -

What payment terms should I expect when sourcing flat water bottles?

Payment terms for sourcing flat water bottles typically include options like a deposit upfront (often 30% to 50%) and the balance due before shipment. Some suppliers may offer net payment terms, allowing payment within 30 to 90 days after delivery. It’s crucial to negotiate terms that suit your cash flow and risk tolerance. Always ensure that payment methods are secure and consider using escrow services for larger transactions to protect both parties. -

How can I ensure compliance with international trade regulations when importing flat water bottles?

To ensure compliance with international trade regulations, familiarize yourself with the import regulations of your target country, including safety standards and labeling requirements. Collaborate with suppliers who can provide necessary certifications and documentation, such as compliance with FDA or EU regulations. Consulting with a customs broker or trade attorney can also be beneficial in navigating complex regulations, ensuring that all products meet legal requirements before shipment. -

What quality assurance processes should I implement when sourcing flat water bottles?

Implementing a robust quality assurance (QA) process is essential when sourcing flat water bottles. Start by establishing clear quality criteria and specifications for the products. Request pre-production samples and conduct inspections during production and before shipment. Consider third-party quality control services that can perform audits and checks to verify compliance with your standards. Documenting these processes will help mitigate risks and ensure that the final products meet your expectations. -

What are the best logistics practices for shipping flat water bottles internationally?

When shipping flat water bottles internationally, consider using a reliable freight forwarder familiar with your destination markets. Optimize packaging to minimize space and reduce shipping costs; flat bottles are advantageous here. Ensure all customs documentation is complete and accurate to avoid delays. Additionally, track shipments and maintain communication with your logistics partners to address any issues promptly. Planning logistics efficiently will enhance your supply chain and help maintain delivery schedules.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Flat Water Bottle Manufacturers & Suppliers List

1. Memobottle – Slim Memobottle

Domain: memobottle.us

Registered: 2017 (8 years)

Introduction: {“name”: “Slim memobottle”, “volume”: “450ml / 15oz”, “dimensions”: {“mm”: {“height”: 265, “width”: 80, “depth”: 30}, “inches”: {“height”: 10.4, “width”: 3.2, “depth”: 1.2}}, “weight”: “4.2 ounces / 120 grams”, “material”: “Original Tritan™ Plastic”, “features”: [“BPA and BPS Free”, “Shatterproof”, “Glass-like clarity”, “Hot Water and Freezer Safe”, “Stainless Steel Lid”], “warranty”: “2-Year Warr…

2. Walmart – Portable Flat Water Bottle

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Portable Flat Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Biome – Reusable Flat Water Bottle

Domain: biomestores.com

Registered: 2022 (3 years)

Introduction: This company, Biome – Reusable Flat Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Milligram – Flat Drink Bottles

Domain: milligram.com

Registered: 1999 (26 years)

Introduction: Flat Drink Bottles are lightweight, reusable drink bottles designed for convenience during travel or daily commutes. They help reduce waste while keeping you hydrated.

5. Vapur – Incognito Flexible Alcohol Flask

Domain: thewaterbottlestore.com

Registered: 2005 (20 years)

Introduction: Flat and Foldable Water Bottles available at TheWaterBottleStore.com. Key brands include Vapur and B�bi. Products include: Vapur Incognito Flexible Alcohol Flask (0.3 Liter, 10oz, $6.99), Vapur Solid (0.7 Liter, collapsible, freezable, $11.88), Vapur Eclipse (0.7 Liter, collapsible, matte finish, $11.99), Vapur Wide Mouth Anti-Bottle (0.7L, SuperCap, $11.99), Vapur Solid (1 Liter, collapsible, fre…

6. CNOC – Vessica

Domain: backpackinglight.com

Registered: 2000 (25 years)

Introduction: CNOC Vessica: Semi-collapsible, same size and has 28mm threads, less burping when filtering, floppier when drinking, comfortable against the chest, grippier for removal/insertion, may impart a taste initially but fades over time. Nalgene HDPE: Durable, safe from leaching chemicals, bulky. Smartwater bottles: Rigid, long-lasting, used for multiple seasons, may develop a patina of dirt, concerns abo…

7. Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap

Domain: nytimes.com

Registered: 1994 (31 years)

Introduction: This company, Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

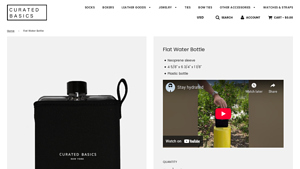

8. Curated Basics – Free Delivery Essentials

Domain: curatedbasics.com

Registered: 2013 (12 years)

Introduction: This company, Curated Basics – Free Delivery Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for flat water bottle

The global demand for flat water bottles is on the rise, driven by their unique design and practicality for on-the-go hydration. B2B buyers should prioritize sourcing products that not only meet functionality but also align with sustainability goals. The flat water bottle’s space-saving design is particularly appealing in regions where storage is limited, making them a smart choice for both retail and corporate gifting opportunities.

Strategic sourcing in this niche can enhance brand reputation, as consumers increasingly seek eco-friendly alternatives to single-use plastic bottles. By partnering with reputable manufacturers who prioritize quality materials—such as BPA-free Tritan and stainless steel—buyers can ensure they offer products that resonate with environmentally conscious consumers.

Looking ahead, the flat water bottle market is poised for growth, particularly in emerging markets across Africa, South America, and the Middle East. International B2B buyers should seize this opportunity to expand their product offerings and meet the evolving needs of their customers. Now is the time to engage with suppliers that can provide innovative designs and sustainable solutions, setting your business apart in a competitive landscape.