Introduction: Navigating the Global Market for water bottle smells

Navigating the complexities of the global market for water bottle smells is a significant challenge for B2B buyers looking to source high-quality products that meet the demands of consumers across diverse regions. The presence of unpleasant odors in water bottles can impact brand reputation and customer satisfaction, making it crucial for businesses to understand the underlying causes and effective solutions. This comprehensive guide delves into the various types of odors that can emanate from water bottles, the materials that contribute to these smells, and the best practices for maintenance and cleaning.

In the following sections, we will explore the applications of different water bottle types, the importance of proper supplier vetting to ensure quality and safety, and the cost implications associated with sourcing odor-free options. We will also provide insights into consumer preferences across key markets in Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany.

By equipping international B2B buyers with actionable insights and strategies, this guide aims to empower informed purchasing decisions that prioritize quality, sustainability, and customer satisfaction. Understanding the nuances of water bottle smells not only helps in maintaining product integrity but also enhances market competitiveness, ultimately driving success in an increasingly discerning global marketplace.

Article Navigation

- Top 8 Water Bottle Smells Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water bottle smells

- Understanding water bottle smells Types and Variations

- Key Industrial Applications of water bottle smells

- 3 Common User Pain Points for ‘water bottle smells’ & Their Solutions

- Strategic Material Selection Guide for water bottle smells

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle smells

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle smells’

- Comprehensive Cost and Pricing Analysis for water bottle smells Sourcing

- Alternatives Analysis: Comparing water bottle smells With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle smells

- Navigating Market Dynamics and Sourcing Trends in the water bottle smells Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle smells

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for water bottle smells

Understanding water bottle smells Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Funky Odor | Strong, musty smell often due to bacteria and mold buildup | Food and beverage packaging, outdoor gear | Pros: Easy to clean; Cons: Frequent cleaning needed; can affect product taste. |

| Plastic Smell | Chemical-like odor from plastic degradation | Consumer goods, promotional items | Pros: Lightweight; Cons: Potential health concerns; odor can linger. |

| Wet Dog Smell | Unpleasant odor resembling wet dog due to bacteria | Fitness and sports equipment | Pros: Durable materials can resist smells; Cons: Requires regular maintenance to prevent smell. |

| Metallic Smell | Metallic or metallic-like odor from certain metals | Industrial applications, water treatment | Pros: Long-lasting; Cons: Potential for taste transfer; requires quality materials. |

| Chemical Smell | Strong odor from cleaning agents or residual chemicals | Medical and laboratory supplies | Pros: Effective for sterilization; Cons: May require thorough rinsing to remove odors. |

What are the Characteristics of Funky Odor in Water Bottles?

Funky odors in water bottles typically arise from the accumulation of bacteria and mold, especially when bottles are used for liquids other than water. This smell is most common in environments where bottles are sealed and stored in warmth, leading to microbial growth. For B2B buyers, selecting bottles designed for easy cleaning and maintenance can mitigate this issue. Ensuring that your products can withstand regular cleaning cycles is essential for maintaining hygiene standards, particularly in food and beverage applications.

How Does Plastic Smell Impact Water Bottles?

Plastic smells are often attributed to the degradation of the material, which can release volatile organic compounds (VOCs). This is particularly relevant for promotional items or consumer goods made from lower-quality plastics. Buyers should consider investing in higher-grade plastics or alternatives like stainless steel to avoid lingering odors that could compromise product appeal. The lightweight nature of plastic may be appealing, but the potential health concerns and odor retention could deter customers.

What Causes the Wet Dog Smell in Water Bottles?

The wet dog smell is primarily caused by bacteria buildup from moisture retention in the bottle. This is a common problem for fitness and sports equipment where bottles are frequently used and not adequately cleaned. B2B buyers in this sector should prioritize products that are easy to clean and designed to dry quickly. Additionally, promoting bottles with antimicrobial properties can enhance product appeal and customer satisfaction, as they reduce the likelihood of unpleasant odors.

What is the Source of Metallic Smell in Water Bottles?

Metallic odors in water bottles can stem from the type of metal used or from reactions with acidic beverages. This smell is particularly pertinent in industrial applications where water quality is critical. Buyers should focus on sourcing high-quality stainless steel options that are less prone to odor retention and chemical reactions. Ensuring that the materials used are food-grade can help maintain the integrity of the contents and avoid unpleasant taste transfers.

How Do Chemical Smells Affect Water Bottles?

Chemical smells often result from cleaning agents or residual chemicals left in bottles. This is especially significant in medical and laboratory settings where sterilization is crucial. B2B buyers must ensure that their products are designed for thorough rinsing and are compatible with various cleaning agents. While effective sterilization is a priority, the potential for lingering chemical odors can affect product usability, making it essential to balance cleaning effectiveness with user experience.

Key Industrial Applications of water bottle smells

| Industry/Sector | Specific Application of Water Bottle Smells | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Quality Control in Bottled Water Production | Ensures consumer safety and satisfaction | Sourcing high-grade materials that resist odor retention; compliance with health regulations. |

| Hospitality | Cleaning and Maintenance Protocols for Reusable Bottles | Enhances guest experience and brand reputation | Availability of effective cleaning solutions; training for staff on best practices. |

| Sports and Fitness | Marketing of Odor-Free Water Bottles | Attracts health-conscious consumers | Selection of materials that prevent odor absorption; eco-friendly options. |

| Retail | Consumer Education on Proper Bottle Maintenance | Reduces product returns and increases customer loyalty | Development of educational materials; partnerships with cleaning product suppliers. |

| Manufacturing | Production of Odor-Resistant Bottles | Reduces warranty claims and increases product lifespan | Investment in advanced manufacturing techniques; quality control systems to monitor odor retention. |

How is Water Bottle Smells Relevant in the Food and Beverage Sector?

In the food and beverage industry, the smell of water bottles can significantly impact product quality and consumer safety. Bottled water producers must ensure that their containers do not retain odors from previous contents, which could compromise the taste and safety of the water. International buyers, particularly from Africa and South America, need to source materials that are not only durable but also resistant to odor absorption. Compliance with local health regulations is essential, requiring suppliers to provide documentation on material safety and non-odor retention.

What Role Does Water Bottle Smells Play in the Hospitality Industry?

In the hospitality sector, the cleanliness and maintenance of reusable water bottles are crucial for guest satisfaction. A water bottle that emits unpleasant odors can tarnish a hotel’s reputation. To combat this, hospitality businesses can implement rigorous cleaning protocols and use high-quality cleaning agents. Buyers from Europe and the Middle East should consider suppliers that offer training on proper cleaning techniques to ensure staff can maintain hygiene standards effectively, enhancing the overall guest experience.

How Can Sports and Fitness Brands Leverage Odor-Free Water Bottles?

In the sports and fitness industry, the marketing of odor-free water bottles can be a significant selling point for health-conscious consumers. Bottles that do not retain smells are more appealing and ensure that users enjoy a fresh taste with every sip. Brands must focus on sourcing materials like stainless steel that inherently resist odor absorption. Buyers should prioritize suppliers who can provide eco-friendly options, as sustainability is increasingly important to consumers in markets like Germany and Vietnam.

Why is Consumer Education on Water Bottle Maintenance Important for Retail?

Retailers can enhance customer loyalty by educating consumers on the importance of maintaining their water bottles to prevent unpleasant odors. Providing information about proper cleaning methods and the benefits of odor-resistant materials can reduce product returns and improve customer satisfaction. International buyers should seek partnerships with suppliers of cleaning products and educational materials, ensuring they have the resources necessary to support their customers in maintaining their products effectively.

How Do Manufacturing Processes Impact Odor Resistance in Bottles?

Manufacturers producing water bottles must focus on creating products that resist odor retention to reduce warranty claims and enhance product longevity. This requires investment in advanced manufacturing techniques and rigorous quality control measures to ensure that materials do not degrade over time. Buyers from emerging markets should look for suppliers who can demonstrate their commitment to quality through certifications and testing, ensuring that the products meet international standards for odor resistance.

3 Common User Pain Points for ‘water bottle smells’ & Their Solutions

Scenario 1: Persistent Odors from Reusable Water Bottles

The Problem: Many businesses supply employees with reusable water bottles to promote hydration and sustainability. However, users often encounter persistent odors, especially when the bottles are used for liquids other than water, such as juices or coffee. This not only leads to unpleasant drinking experiences but also affects the overall perception of the brand, particularly if employees are embarrassed to use their bottles in public settings. Additionally, if the bottles are not cleaned regularly, bacteria can accumulate, leading to further odor issues, which can become a health concern.

The Solution: To combat persistent odors, it is essential to establish a robust cleaning protocol. First, choose high-quality water bottles made from materials that resist odor retention, such as stainless steel. This material is less prone to harboring bacteria compared to plastic. Next, implement a regular cleaning schedule—ideally, bottles should be cleaned daily with soap and a bottle brush to reach all surfaces. For deeper cleans, encourage employees to soak their bottles in a solution of vinegar and water overnight, followed by a thorough rinse. Consider providing employees with cleaning supplies or even organizing periodic group cleaning sessions to foster a culture of hygiene and care for their reusable bottles.

Scenario 2: Smells Caused by Improper Storage of Water Bottles

The Problem: In many workplaces, employees may inadvertently store water bottles in damp or poorly ventilated areas, such as gym bags or desks. This improper storage can lead to a buildup of moisture and subsequently, unpleasant smells. For businesses that prioritize employee wellness and hydration, this can be a significant hurdle, as it discourages regular water consumption and could negatively impact employee health and productivity.

The Solution: Educate employees on the importance of proper storage techniques. Encourage them to store their water bottles in dry, well-ventilated areas when not in use. To facilitate this, consider providing designated storage spaces for bottles, such as shelves or hooks near break areas. Additionally, recommend that employees leave the lids off their bottles while storing them to allow for air circulation. To further enhance the experience, businesses can also explore the use of odor-neutralizing sachets or gel packs that can be placed in storage areas to absorb excess moisture and odors.

Scenario 3: Material-Related Smells from Flavored Waters

The Problem: With the growing trend of flavored waters, many businesses have adopted flavored water solutions to make hydration more appealing. However, using certain types of water bottles, particularly those made from lower-grade plastics, can lead to chemical leaching and unpleasant odors that taint the water’s taste. This situation can deter employees from drinking enough water, counteracting the initiative’s health benefits and potentially impacting employee satisfaction.

The Solution: To effectively address the issue of material-related smells, it is crucial to invest in high-grade stainless steel or BPA-free plastic water bottles specifically designed for flavored beverages. These materials are less likely to absorb odors or impart flavors to the water. Additionally, businesses should provide clear guidelines on how to clean flavored water bottles after each use, emphasizing the importance of thorough rinsing and drying. Offering flavored water options in conjunction with educational workshops on hydration can also help employees understand how to maintain their bottles effectively and encourage them to drink more water without the worry of unpleasant smells.

Strategic Material Selection Guide for water bottle smells

What Are the Key Properties of Common Water Bottle Materials?

When selecting materials for water bottles, particularly concerning odor retention, it’s essential to consider the properties of each material. The most common materials used in water bottles include stainless steel, plastic (polyethylene and polypropylene), glass, and aluminum. Each material has unique characteristics that influence its performance, durability, and suitability for various applications.

How Does Stainless Steel Perform in Terms of Odor Retention?

Stainless steel is renowned for its durability and resistance to corrosion, making it a popular choice for water bottles. It typically has a high-temperature rating, allowing it to withstand boiling water without warping or leaching chemicals. Stainless steel does not retain odors, ensuring that the water remains fresh even after prolonged storage. However, the manufacturing process can be complex, involving multiple stages of polishing and finishing to achieve a smooth surface that resists bacteria growth.

Pros: High durability, excellent temperature resistance, does not retain odors, and is easy to clean.

Cons: Higher manufacturing costs compared to plastic, potential for denting, and heavier than other materials.

Impact on Application: Ideal for both hot and cold beverages, suitable for outdoor and sports applications.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA, EU regulations) is crucial, especially in regions like Europe and the Middle East.

What Are the Limitations of Plastic Water Bottles?

Plastic bottles, particularly those made from polyethylene (PET) and polypropylene, are lightweight and cost-effective. However, they are prone to retaining odors, especially when used for beverages other than water. Over time, exposure to heat can degrade the plastic, leading to leaching of chemicals and unpleasant smells. While these bottles are generally dishwasher safe, their long-term durability is often less than that of metal or glass.

Pros: Low cost, lightweight, and available in various designs and colors.

Cons: Prone to odor retention, potential chemical leaching, and less durable over time.

Impact on Application: Suitable for single-use or short-term applications but may not be ideal for long-term storage of flavored beverages.

Considerations for International Buyers: Must comply with local regulations regarding food safety and recycling, which can vary significantly by region.

How Does Glass Compare in Terms of Odor Resistance?

Glass water bottles are non-porous and do not retain odors, making them an excellent choice for maintaining the taste of water. They are highly resistant to chemical leaching and can withstand high temperatures. However, glass is fragile and can break easily, which may not be suitable for all environments, particularly in regions with high physical activity or rough handling.

Pros: Excellent odor resistance, non-reactive, and maintains beverage purity.

Cons: Fragile, heavier than plastic, and can be more expensive to produce.

Impact on Application: Best suited for home use or environments where breakage is less likely.

Considerations for International Buyers: Glass bottles must meet stringent safety standards to prevent breakage during transport and use.

What Are the Benefits and Drawbacks of Aluminum Water Bottles?

Aluminum water bottles are lightweight and often come with an inner lining to prevent reaction with acidic beverages. They are generally resistant to corrosion but can retain odors if the lining is damaged or if the bottle is not cleaned properly. While aluminum is durable, it can dent upon impact, which may compromise the bottle’s integrity.

Pros: Lightweight, recyclable, and good thermal insulation when insulated.

Cons: Potential for odor retention, susceptibility to dents, and higher manufacturing costs than plastic.

Impact on Application: Suitable for sports and outdoor activities but requires careful handling.

Considerations for International Buyers: Must comply with local regulations regarding aluminum use and recycling.

Summary Table of Material Selection for Water Bottles

| Material | Typical Use Case for Water Bottle Smells | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Long-term use for hot/cold beverages | High durability and odor resistance | Higher cost and potential for denting | High |

| Plastic | Single-use or short-term applications | Low cost and lightweight | Prone to odor retention and chemical leaching | Low |

| Glass | Home use or low-activity environments | Excellent odor resistance and purity | Fragile and heavier | Medium |

| Aluminum | Sports and outdoor activities | Lightweight and recyclable | Potential for odor retention and dents | Medium |

This analysis provides a comprehensive understanding of the material properties and considerations relevant to B2B buyers in various international markets, aiding in informed decision-making when selecting water bottle materials.

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle smells

What Are the Key Stages in the Manufacturing Process of Water Bottles to Prevent Odors?

The manufacturing process for water bottles involves several critical stages designed to minimize the risk of odor retention, ensuring that the final product meets high-quality standards. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: Selecting the Right Ingredients

The first step in manufacturing water bottles involves selecting appropriate materials that are less prone to odors. Common materials include stainless steel and BPA-free plastics. Stainless steel, particularly 18/8 grade, is favored for its durability and resistance to corrosion, which helps prevent the buildup of bacteria and odors.

Before production, materials undergo rigorous inspections to ensure they meet industry standards. For instance, plastics must be verified for FDA compliance, ensuring they are safe for food and drink applications.

Forming: Shaping the Bottle

Once the materials are prepared, the next stage is forming the bottles. This process can vary depending on the material used. For stainless steel bottles, techniques such as deep drawing and hydroforming are employed. These methods create a seamless design, reducing the chances of bacteria accumulation in joints or seams.

For plastic bottles, blow molding is commonly used. This technique allows for the creation of lightweight bottles but requires careful monitoring to ensure that the material’s integrity is maintained, preventing any porous areas that could harbor odors.

How Is Assembly Done to Ensure Quality and Odor Resistance?

The assembly stage involves the integration of various components, including caps, straws, and insulation layers. For insulated bottles, manufacturers employ double-wall vacuum sealing technology, which not only enhances thermal performance but also minimizes the risk of odor transfer between layers.

Attention to detail during this stage is vital. Each component must be fitted correctly, and seals must be airtight to prevent leaks and maintain hygiene. Automated assembly lines often utilize advanced robotics to enhance precision and reduce human error.

What Finishing Techniques Are Used to Reduce Odors in Water Bottles?

Finishing processes play a significant role in odor prevention. Common techniques include surface treatments and coatings that create a non-porous barrier, making it difficult for bacteria and odors to penetrate the material. For stainless steel bottles, passivation is often employed to enhance corrosion resistance, while plastic bottles may undergo UV treatments to inhibit microbial growth.

In addition, manufacturers may apply antimicrobial coatings to the interior of bottles. These coatings actively inhibit the growth of bacteria and mold, significantly reducing the risk of unpleasant odors.

What International Quality Standards Should B2B Buyers Consider?

When sourcing water bottles, B2B buyers should be aware of international quality standards that govern manufacturing processes. ISO 9001 is a widely recognized standard that outlines quality management systems, ensuring consistent product quality and customer satisfaction. Suppliers should be able to provide certification to demonstrate compliance with ISO standards.

In addition to ISO certifications, industry-specific standards such as CE marking for products sold in Europe and compliance with FDA regulations for food-safe materials are critical. Understanding these certifications can help buyers assess the reliability and safety of their suppliers.

What Are the Key Quality Control Checkpoints in Water Bottle Manufacturing?

Quality control (QC) is integral to the manufacturing process. Several checkpoints are established to ensure that each bottle meets quality standards:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. Suppliers must provide documentation that demonstrates compliance with relevant standards.

-

In-Process Quality Control (IPQC): During production, random samples are tested to monitor the manufacturing process. This can include checks for dimensional accuracy, surface finish, and the integrity of seals.

-

Final Quality Control (FQC): After production, finished bottles undergo a final inspection. This involves testing for leaks, odor retention, and overall appearance.

Implementing these checkpoints helps ensure that any potential issues are identified and rectified before the product reaches the market.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

-

Request Documentation: Suppliers should provide quality management system documentation, including ISO certifications and reports from quality audits.

-

Conduct Audits: Periodic audits can help assess the supplier’s adherence to quality standards. Buyers should consider on-site audits to verify compliance with manufacturing processes and QC practices.

-

Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. These services can perform checks at various stages of production, ensuring that the products meet specified standards.

-

Review Test Reports: Buyers should request testing reports that demonstrate compliance with relevant standards. This includes results from odor retention tests, microbial contamination tests, and other relevant assessments.

What Unique QC Considerations Should International B2B Buyers Keep in Mind?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that may affect their sourcing decisions.

-

Cultural and Regulatory Differences: Different regions may have varying standards for water bottle materials and safety. Understanding these regulations can help buyers avoid compliance issues.

-

Supply Chain Transparency: Buyers should seek suppliers that offer transparency in their supply chains, including traceability of materials and components. This is especially crucial in regions where regulations may be less stringent.

-

Logistical Considerations: Shipping and storage conditions can impact the quality of water bottles. Buyers should inquire about how suppliers handle products during transport and storage to mitigate the risk of odor retention.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when sourcing water bottles, ultimately ensuring they invest in high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle smells’

Introduction

This guide provides a practical checklist for B2B buyers looking to address and prevent unpleasant odors in water bottles. Understanding the causes of water bottle smells and implementing effective sourcing strategies is essential for maintaining product quality and ensuring customer satisfaction.

Step 1: Identify the Source of Odors

Before sourcing solutions, it’s vital to determine the root cause of the smells. Common sources include bacterial growth from improper cleaning, residual liquids, or material degradation. This understanding will help you select appropriate cleaning agents and materials that mitigate odor retention.

- Consider factors like:

- Previous contents stored in the bottle (e.g., juices, teas).

- Duration of storage and environmental conditions (heat, moisture).

Step 2: Select the Right Materials

Choosing the correct materials for water bottles is crucial in preventing odors. Stainless steel and BPA-free plastics are preferable as they resist microbial growth and do not absorb odors as easily as some materials.

- Key considerations:

- Opt for 18/8 stainless steel for durability and odor resistance.

- Ensure any plastic options are certified food-safe and free from harmful chemicals.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers adhere to international safety and quality standards. Certifications such as ISO 9001 (quality management) and FDA approval for food contact materials can indicate a supplier’s commitment to safety and quality.

- What to check:

- Request documentation of certifications.

- Inquire about their quality control processes and testing procedures.

Step 4: Assess Cleaning Solutions Offered

Investigate the cleaning solutions or methods recommended by suppliers. Effective cleaning methods can significantly reduce odors and prolong the life of water bottles.

- Look for:

- Recommendations for natural cleaning agents like vinegar or baking soda.

- Instructions for maintaining cleanliness post-purchase, such as air-drying techniques.

Step 5: Request Product Samples

Before finalizing any purchase, request samples of the water bottles from potential suppliers. This allows you to test for odor retention and overall quality firsthand.

- Testing should include:

- Simulating regular use and cleaning to evaluate any odor development.

- Assessing the ease of cleaning and durability over time.

Step 6: Review Customer Feedback and Case Studies

Investigate customer feedback regarding odor issues with the supplier’s products. Positive testimonials and case studies can provide insights into the effectiveness of the water bottles and the supplier’s reliability.

- Focus on:

- Reviews that specifically mention odor resistance and ease of cleaning.

- Case studies from similar industries or regions for relevance.

Step 7: Establish a Maintenance Protocol

After procurement, establish a maintenance protocol to ensure longevity and odor prevention. Regular cleaning and proper storage practices can significantly mitigate odor issues.

- Components of the protocol:

- Define cleaning frequency based on usage patterns.

- Recommend specific cleaning methods and drying techniques to prevent moisture retention.

By following this step-by-step checklist, B2B buyers can effectively source high-quality water bottles that minimize odor issues and maintain a positive customer experience.

Comprehensive Cost and Pricing Analysis for water bottle smells Sourcing

What Are the Key Cost Components in Sourcing Water Bottles?

When sourcing water bottles, particularly those that are resistant to odors, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The choice of material significantly affects costs. Stainless steel bottles tend to be more expensive than plastic options due to their durability and resistance to odors. High-grade materials, such as 18/8 stainless steel, are preferred for their non-reactive properties, which help in preventing smells.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with lower labor costs, such as certain parts of South America or Asia, may offer competitive pricing. However, labor quality and expertise in handling specific materials can influence the overall cost.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate overhead costs, impacting the final pricing.

-

Tooling: The cost of molds and machinery necessary for producing custom designs or unique bottle shapes can add to initial costs. Investing in high-quality tooling can lead to better production efficiency and lower long-term costs.

-

Quality Control (QC): Ensuring that water bottles meet health and safety standards requires a robust QC process. This includes testing for materials that do not leach harmful chemicals and verifying odor resistance, which can increase production costs.

-

Logistics: Shipping costs can vary widely based on the origin of the materials and the destination. Factors like distance, transportation mode, and the volume of goods shipped affect overall logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s position in the market and their operational efficiency.

How Do Price Influencers Affect Water Bottle Sourcing?

Several factors can influence the pricing of water bottles:

-

Volume/MOQ: Bulk purchasing often leads to lower unit prices. Buyers should negotiate minimum order quantities (MOQs) to maximize cost efficiency.

-

Specifications and Customization: Customized designs or specific features (like double-walled insulation) typically incur additional costs. Understanding the balance between desired features and budget is essential.

-

Materials: As mentioned, the choice of materials directly impacts pricing. Buyers should assess the long-term benefits of higher-quality materials against initial costs.

-

Quality and Certifications: Certifications for food safety, BPA-free materials, and eco-friendliness may come at a premium. However, these certifications can also enhance marketability.

-

Supplier Factors: Supplier reputation, reliability, and service levels can all affect pricing. Established suppliers may charge more due to their proven track record and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for managing shipping responsibilities and costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence total landed costs.

What Tips Can Help Buyers Optimize Their Sourcing Strategy?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Leverage your purchasing power by negotiating prices, especially for bulk orders. Establish a good relationship with suppliers to foster better terms.

-

Focus on Cost Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider maintenance, durability, and potential replacements when assessing value.

-

Understand Pricing Nuances: Different regions have varying pricing structures based on local economic conditions, labor costs, and material availability. Researching these factors can provide insight into fair pricing.

-

Plan for Logistics: Factor in shipping times and costs when making purchasing decisions. Working with suppliers who have efficient logistics can save time and money.

-

Stay Informed: Keep abreast of market trends and material innovations. This knowledge can help in making informed decisions and negotiating better deals.

Disclaimer on Indicative Prices

While this analysis provides a framework for understanding costs and pricing in the water bottle sourcing landscape, actual prices may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and request quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing water bottle smells With Other Solutions

Exploring Alternatives to Addressing Water Bottle Odors

In the world of B2B, addressing the issue of unpleasant odors in water bottles is essential for maintaining product quality and customer satisfaction. Various solutions exist, ranging from traditional cleaning methods to innovative technologies that prevent odor build-up altogether. This analysis compares the effectiveness and practicality of various approaches, enabling buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Water Bottle Smells | Odor-Resistant Materials | Advanced Cleaning Technology |

|---|---|---|---|

| Performance | Moderate effectiveness; relies on regular cleaning | High; prevents odors from developing | High; eliminates existing odors effectively |

| Cost | Low; basic cleaning supplies | Moderate to high; premium materials required | High initial investment; ongoing maintenance costs |

| Ease of Implementation | Simple; requires regular cleaning routines | Moderate; requires sourcing specific materials | Complex; may require specialized training |

| Maintenance | High; frequent cleaning necessary | Low; minimal upkeep needed | Moderate; regular servicing required |

| Best Use Case | Everyday users needing a quick solution | Long-term users seeking odor-free options | Commercial settings with high usage rates |

Detailed Breakdown of Alternatives

Odor-Resistant Materials

Utilizing water bottles made from odor-resistant materials, such as high-grade stainless steel, is a proactive solution to the smell issue. These bottles are engineered to prevent bacteria and odor build-up, significantly reducing the likelihood of unpleasant smells. The primary advantage of this alternative is its long-lasting nature; once purchased, these bottles require minimal maintenance. However, the initial cost can be higher compared to regular plastic bottles, which may deter some buyers. Additionally, while the performance is excellent, sourcing these materials may require additional effort.

Advanced Cleaning Technology

Advanced cleaning technologies, such as ultrasonic cleaners or ozone sanitization systems, offer a high-performance solution for eliminating odors. These technologies effectively remove bacteria and odors without the need for harsh chemicals. While they provide superior cleaning results, the complexity of these systems may necessitate specialized training for staff. Furthermore, the initial investment can be significant, making it more suitable for larger organizations or commercial environments where the volume of usage justifies the cost. Regular servicing is also required to maintain optimal performance.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate solution for addressing water bottle odors, B2B buyers should consider their specific circumstances, including usage patterns, budget constraints, and maintenance capabilities. For businesses looking for a straightforward, cost-effective solution, regular cleaning practices may suffice. However, those seeking long-term odor prevention and durability might find odor-resistant materials to be a valuable investment. In contrast, companies that prioritize hygiene in high-use environments may benefit from advanced cleaning technologies despite their higher costs and complexity. Ultimately, the choice hinges on balancing initial investment against long-term benefits and operational efficiency.

Essential Technical Properties and Trade Terminology for water bottle smells

What Are the Key Technical Properties Affecting Water Bottle Smells?

When evaluating water bottles for odor retention and contamination, certain technical properties become crucial in ensuring product quality and customer satisfaction. Here are some key specifications:

-

Material Grade

Water bottles are often constructed from various materials, such as stainless steel, plastic, or glass. The grade of these materials significantly influences odor retention. For instance, 18/8 stainless steel is known for its durability and resistance to corrosion and odors. In contrast, lower-grade plastics may degrade over time, allowing bacteria to build up, which can lead to unpleasant smells. Understanding material grade helps B2B buyers select products that maintain quality over time. -

Microbial Resistance

Some materials are treated or designed to resist microbial growth. For example, certain plastics are infused with antimicrobial agents to inhibit bacteria and mold, which are common culprits of odors. B2B buyers should assess whether the water bottles they are sourcing have such features, as they can significantly reduce customer complaints and increase product longevity. -

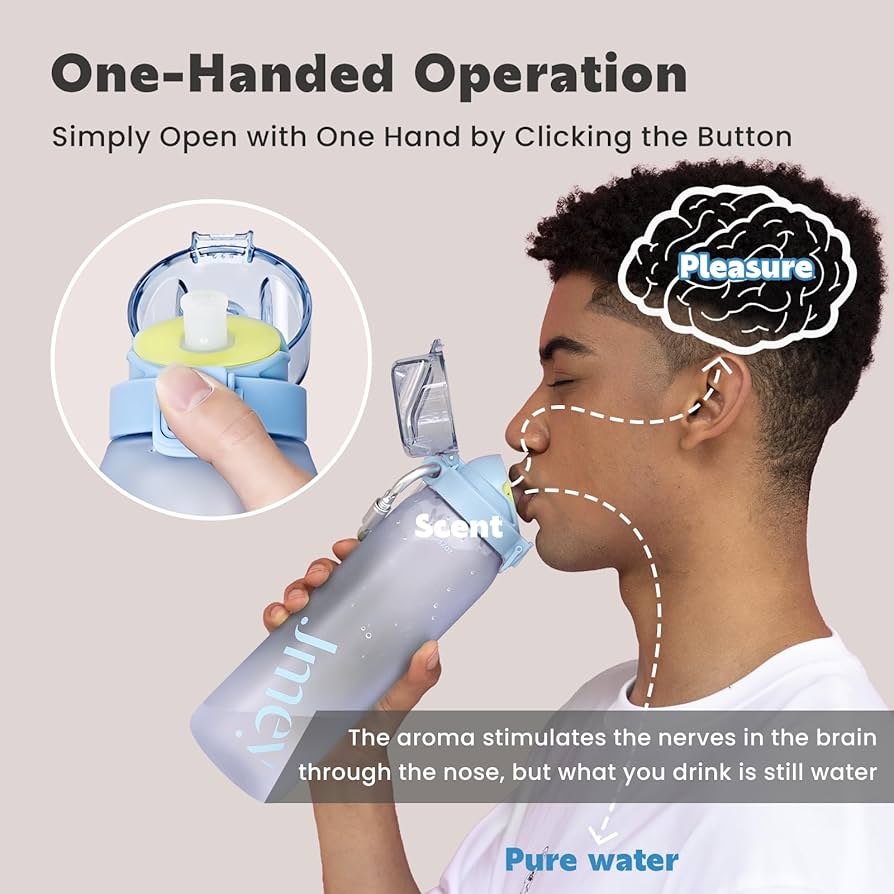

Thermal Insulation Properties

The ability of a water bottle to maintain temperature affects its odor profile. Bottles with advanced insulation technologies can keep liquids hot or cold without altering their taste or smell. For instance, Hydro Cell bottles utilize ThermoCell technology, which prevents temperature fluctuations that could lead to odor development. This property is essential for buyers who want to ensure their products remain appealing in varying climates. -

Porosity and Surface Finish

The porosity of the bottle material can affect how well it retains odors. Non-porous materials like high-grade stainless steel do not absorb smells, while porous plastics can trap odors over time. The surface finish, whether smooth or textured, also plays a role in how easily the bottle can be cleaned. Buyers should inquire about these properties to ensure easy maintenance and longevity of their products. -

Volume and Capacity Tolerance

Understanding the volume tolerance of water bottles is critical, especially in markets where consumers demand various sizes. Bottles must be manufactured to exact specifications to avoid leaks and ensure proper sealing. This aspect is crucial for buyers who require consistency in product offerings and customer satisfaction.

What Common Trade Terms Should B2B Buyers Know Regarding Water Bottles?

Familiarity with industry jargon can streamline procurement processes and facilitate clear communication between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. B2B buyers often engage with OEMs for customized water bottle designs, allowing for unique branding opportunities while ensuring quality manufacturing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory costs and ensure they can meet market demand without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific quantities of products. B2B buyers use RFQs to compare prices and terms from different suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and costs during cross-border transactions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time helps B2B buyers plan their inventory and sales strategies effectively, ensuring they meet consumer demands without delays.

By understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions that enhance product quality and customer satisfaction while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the water bottle smells Sector

What Are the Key Market Trends Influencing Water Bottle Smells?

The global water bottle market is experiencing a surge driven by increased consumer awareness of hygiene and health. Buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking bottles that not only prevent unpleasant odors but also enhance user experience. Key trends include the adoption of advanced materials that resist odor retention, such as high-grade stainless steel, which is becoming a preferred choice among manufacturers. Additionally, the integration of technology in the production process—such as antimicrobial coatings—helps in minimizing bacteria build-up, which is a primary cause of foul smells.

Moreover, the rise in e-commerce has transformed the sourcing landscape. B2B buyers now have access to a broader range of suppliers from different geographical locations, allowing for competitive pricing and innovative product offerings. This shift is particularly significant for international buyers who can now compare quality and price more effectively, ensuring they get the best value for their investments.

Another emerging trend is the increasing demand for customizable water bottles. Businesses are seeking products that can be tailored to their branding needs, which includes offering specific designs that address odor issues more effectively. This trend presents opportunities for suppliers to differentiate their offerings in a crowded marketplace.

How Is Sustainability Impacting the Sourcing of Water Bottles?

Sustainability is increasingly influencing sourcing decisions in the water bottle sector. International B2B buyers are prioritizing suppliers who demonstrate a commitment to environmentally responsible practices. The environmental impact of plastic waste has led to a shift toward sustainable materials, with stainless steel and BPA-free plastics gaining traction.

Ethical supply chains are also a major concern. Buyers are looking for certifications such as Fair Trade and ISO 14001, which ensure that products are sourced responsibly and with minimal environmental impact. These certifications not only enhance a brand’s reputation but also appeal to a growing segment of eco-conscious consumers.

Sourcing from manufacturers that utilize recycled materials or sustainable production methods can significantly reduce the environmental footprint associated with water bottles. Additionally, companies that can provide transparency in their supply chain processes are more likely to build trust and foster long-term relationships with B2B buyers. As the market evolves, those who adopt sustainability as a core business strategy will not only meet regulatory requirements but also enhance their competitive edge.

What Is the Historical Context Behind Water Bottle Smells?

The issue of water bottle odors has evolved significantly over the years. Initially, most water bottles were made from single-use plastics, which quickly became associated with unpleasant smells due to their porous nature and susceptibility to bacterial growth. As consumer awareness regarding health and hygiene increased, manufacturers began to innovate, moving towards more durable materials like stainless steel and glass.

These materials not only provided a better barrier against odors but also offered improved longevity and performance. Over time, the introduction of advanced cleaning technologies and antimicrobial coatings has further addressed the issue of foul smells, making it easier for consumers to maintain their bottles. The evolution reflects a broader trend in consumer behavior towards sustainability and health, emphasizing the need for products that not only serve a functional purpose but also align with modern ethical standards.

In summary, understanding these market dynamics, sustainability imperatives, and the historical context will empower international B2B buyers to make informed sourcing decisions in the water bottle sector.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle smells

-

How do I eliminate unpleasant odors from water bottles?

To effectively remove bad smells from water bottles, start by cleaning them thoroughly with a bottle brush and warm, soapy water. For persistent odors, soak the bottle overnight in a solution of white vinegar or a mixture of baking soda and warm water. Ensure that the bottle dries completely before sealing it, as moisture can promote bacteria growth. Regular maintenance, including washing the bottle after each use, will help prevent odors from developing in the first place. -

What materials are best for odor-resistant water bottles?

Stainless steel water bottles are generally the best choice for preventing odors. Unlike plastic, stainless steel does not absorb smells or flavors, ensuring that water remains fresh. Additionally, high-quality stainless steel bottles often come with vacuum-sealed insulation, which helps maintain the temperature of the liquid without imparting any odors. When sourcing, consider suppliers that offer food-grade stainless steel products for optimal performance. -

How can I verify the quality of water bottles from international suppliers?

When sourcing from international suppliers, request samples of the water bottles to assess their quality firsthand. Additionally, check for certifications such as ISO or FDA compliance, which indicate adherence to safety and quality standards. Conducting thorough due diligence on suppliers, including reading reviews and testimonials, can also provide insights into their reliability and product quality. -

What are the typical minimum order quantities (MOQs) for water bottles?

Minimum order quantities for water bottles can vary significantly based on the supplier and the type of product. Many manufacturers set MOQs ranging from 500 to 5,000 units for custom designs, while standard products may have lower MOQs. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that fit your business model, especially if you’re just starting out. -

What payment terms are standard for international water bottle purchases?

Standard payment terms for international purchases often include a deposit upfront (typically 30% to 50%) with the balance due prior to shipment. However, terms can vary based on the supplier’s policies and your relationship with them. Always clarify payment methods accepted (e.g., wire transfer, PayPal) and consider using a letter of credit for larger transactions to mitigate risk. -

How do I ensure proper logistics and shipping for my water bottle orders?

To manage logistics effectively, partner with suppliers who have established relationships with reliable shipping companies. Discuss shipping options, including air freight for faster delivery or sea freight for cost-effectiveness, based on your timelines and budget. Ensure that the supplier provides tracking information and confirm that all customs documentation is in order to prevent delays upon arrival. -

What quality assurance (QA) practices should I look for in suppliers?

When sourcing water bottles, inquire about the supplier’s quality assurance practices, such as regular inspections and testing procedures. Look for suppliers that implement third-party inspections and have a clear return policy for defective items. Establishing a quality control checklist tailored to your requirements can also help ensure that the products meet your standards before shipment. -

How can I customize water bottles for my brand?

Many suppliers offer customization options for water bottles, including color, logo printing, and design modifications. When discussing customization, be specific about your requirements, including the materials and design elements you envision. Additionally, request digital mock-ups or samples to visualize the final product before placing a bulk order, ensuring it aligns with your branding strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Water Bottle Smells Manufacturers & Suppliers List

1. LifeHacks – Essential Water Bottle Care

Domain: lifehacks.stackexchange.com

Registered: 2009 (16 years)

Introduction: 1. Water Bottle: A reusable container for drinking water, often made of plastic or stainless steel. 2. Gasket: An o-ring seal inside the lid that keeps the bottle airtight and is often neglected in cleaning. 3. Cleaning Solutions: Suggestions include vinegar, baking soda, and bleach (diluted) for cleaning and odor removal. 4. Material: Stainless steel (18-8) is recommended for its antimicrobial pr…

2. Hydro Cell – Premium Stainless Steel Water Bottles

Domain: hydrocellusa.com

Registered: 2017 (8 years)

Introduction: Hydro Cell stainless steel water bottles are made from the highest grade 18/8 stainless steel, ensuring durability and preventing decomposition or erosion. They feature proprietary ThermoCell technology for excellent insulation, which helps maintain the freshness of water for over a week. Hydro Cell bottles do not retain odors or flavors, making them easy to clean and ideal for preventing unpleasa…

3. REI – Rigid Water Bottles

Domain: rei.com

Registered: 1996 (29 years)

Introduction: Most rigid water bottles are made out of either polyethylene plastic, polypropylene, or copolyester. Polyethylene bottles can develop unpleasant tastes/odors when used to store acidic juices. General care includes rinsing after each use and letting it air dry completely. For cleaning, a mixture of a teaspoon of bleach and a teaspoon of baking soda in water can be used, letting it sit overnight bef…

4. Huttopia – Clean Water Bottles for Outdoor Adventures

Domain: campdebase.huttopia.com

Registered: 2000 (25 years)

Introduction: The text discusses the importance of maintaining a clean, odor-free water bottle for outdoor activities. It identifies common sources of unwanted tastes and smells, such as food residue, mold, and the material of the bottle. Effective cleaning methods include rinsing after each use and using cleaning products designed for water bottles. Natural solutions like vinegar, baking soda, and lemon are re…

5. Gatorade – Swim Water Bottle

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: swim water bottle, plastic, Gatorade brand

6. LARQ – Self-Cleaning Water Bottle

Domain: basq.livelarq.com

Registered: 2018 (7 years)

Introduction: LARQ Bottle is made of food-grade 18/8 stainless steel, features UV-C LED technology for self-cleaning, activates self-cleaning every 2 hours, has an on-demand cleaning button, and offers an Adventure Mode for a 3-minute cleaning cycle.

7. Silicone Mania – Silicone Water Bottle

Domain: siliconemania.com

Registered: 2024 (1 years)

Introduction: Silicone Water Bottle: Flexible, portable, and easy to use; typically odorless but can develop unpleasant smells due to long-term use, lack of cleaning, storing flavored liquids, moisture, food remains, or long-term storage of liquids. Recommended cleaning methods include using baking soda and water or a vinegar and warm water wash.

8. Instagram – Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact for scraping Instagram services, inquire about the number of pages to scrape per month.

Strategic Sourcing Conclusion and Outlook for water bottle smells

In the dynamic landscape of B2B sourcing for water bottles, understanding the factors contributing to unpleasant odors is crucial for maintaining product quality and customer satisfaction. Key takeaways emphasize the importance of selecting high-quality materials, such as stainless steel, which resist odor retention and bacterial growth. Regular cleaning protocols and proper storage practices are essential to prevent contamination and ensure the longevity of your products.

Strategic sourcing not only enhances product durability but also fosters brand loyalty among consumers who prioritize hygiene and quality. By investing in innovative solutions and sustainable practices, businesses can differentiate themselves in competitive markets across Africa, South America, the Middle East, and Europe.

As the demand for functional and aesthetically pleasing water bottles continues to rise, international B2B buyers are encouraged to seek out suppliers who prioritize quality, sustainability, and effective odor management. Embrace this opportunity to elevate your product offerings and meet the evolving needs of your customers. Together, we can create a healthier and more enjoyable hydration experience for consumers worldwide.