Introduction: Navigating the Global Market for stainless steel spray bottle

In today’s competitive landscape, sourcing high-quality stainless steel spray bottles can be a daunting task for B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. With a multitude of suppliers and product variations available, making informed decisions is essential to ensure quality, durability, and cost-effectiveness. This guide aims to simplify the process by providing a comprehensive overview of the global market for stainless steel spray bottles, covering various types, applications, and key factors to consider when vetting suppliers.

From understanding the unique benefits of stainless steel over other materials to exploring the myriad of uses—from industrial cleaning to personal care products—this guide equips international buyers with the insights necessary to navigate their purchasing decisions. Furthermore, we delve into critical aspects such as pricing strategies, shipping considerations, and regulatory compliance, which are crucial for businesses operating across borders.

By arming B2B buyers with actionable information and expert recommendations, this guide empowers them to make strategic choices that not only meet their immediate needs but also contribute to long-term sustainability and operational efficiency. Whether you’re a buyer in Brazil seeking eco-friendly solutions or a procurement officer in Germany looking to streamline your supply chain, this resource is designed to enhance your purchasing strategy and drive success in the global marketplace for stainless steel spray bottles.

Article Navigation

- Top 7 Stainless Steel Spray Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for stainless steel spray bottle

- Understanding stainless steel spray bottle Types and Variations

- Key Industrial Applications of stainless steel spray bottle

- 3 Common User Pain Points for ‘stainless steel spray bottle’ & Their Solutions

- Strategic Material Selection Guide for stainless steel spray bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel spray bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel spray bottle’

- Comprehensive Cost and Pricing Analysis for stainless steel spray bottle Sourcing

- Alternatives Analysis: Comparing stainless steel spray bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for stainless steel spray bottle

- Navigating Market Dynamics and Sourcing Trends in the stainless steel spray bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel spray bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for stainless steel spray bottle

Understanding stainless steel spray bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Spray Bottle | Basic design, often with adjustable nozzle | Cleaning services, hospitality, retail | Pros: Cost-effective, versatile; Cons: May lack durability |

| Chemical-Resistant Spray Bottle | Constructed from durable materials, resistant to chemicals | Industrial cleaning, laboratories | Pros: Long-lasting, safe for harsh chemicals; Cons: Higher cost |

| Multi-Purpose Spray Bottle | Adjustable nozzle for mist or stream, ergonomic design | Food service, landscaping, personal care | Pros: Versatile use, user-friendly; Cons: May require more maintenance |

| Refillable Keeper Bottle | Eco-friendly design, allows bulk refilling | Eco-conscious businesses, retail | Pros: Cost-saving, reduces waste; Cons: Initial investment may be higher |

| Specialty Spray Bottle | Tailored for specific liquids (e.g., oils, cleaners) | Automotive, beauty, health products | Pros: Optimized for specific uses; Cons: Limited versatility |

What Are the Characteristics of Standard Spray Bottles?

Standard spray bottles are the most common type found in various industries. They typically feature a straightforward design with a trigger spray mechanism and an adjustable nozzle. These bottles are widely used in cleaning services, hospitality, and retail sectors due to their cost-effectiveness and versatility. When purchasing, buyers should consider the material quality, as lower-grade plastics may not withstand frequent use.

How Do Chemical-Resistant Spray Bottles Differ?

Chemical-resistant spray bottles are specifically designed to handle harsh cleaning agents and chemicals. Made from durable stainless steel or specialized plastics, these bottles prevent corrosion and damage from aggressive substances. They are ideal for industrial cleaning and laboratory applications. B2B buyers should focus on the chemical compatibility of the materials used, ensuring they meet the safety standards required for their specific applications.

Why Choose Multi-Purpose Spray Bottles?

Multi-purpose spray bottles feature adjustable nozzles that can switch from a fine mist to a focused stream, making them suitable for a variety of applications, from food service to landscaping. Their ergonomic design enhances user comfort, which is essential for frequent use. When considering these bottles, B2B buyers should assess the ease of cleaning and maintenance, as well as the potential for multiple uses within their operations.

What Are the Benefits of Refillable Keeper Bottles?

Refillable keeper bottles are designed for eco-conscious businesses, allowing users to refill them from larger containers, thereby reducing waste. These bottles often feature stylish designs that make them suitable for retail display. B2B buyers should evaluate the initial investment versus long-term savings, as well as the sustainability goals of their organization, when considering this option.

How Do Specialty Spray Bottles Serve Specific Industries?

Specialty spray bottles are tailored for specific liquids, such as oils or beauty products, providing optimal functionality for those applications. They are commonly used in automotive, beauty, and health sectors where precision and compatibility are crucial. Buyers should consider the compatibility of the bottle with the specific substances they will be using, as well as the bottle’s design to ensure it meets their operational needs.

Key Industrial Applications of stainless steel spray bottle

| Industry/Sector | Specific Application of Stainless Steel Spray Bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Sanitation and cleaning in food processing facilities | Ensures compliance with health regulations and maintains hygiene | Must be resistant to chemicals and easy to clean; consider capacity and nozzle type |

| Agriculture | Application of pesticides and fertilizers | Increases efficiency in crop management and reduces chemical waste | Durable construction to withstand harsh chemicals; ergonomic design for ease of use |

| Hospitality | Eco-friendly cleaning solutions for hotels and restaurants | Promotes sustainability and enhances brand image | Customizable designs and sizes; compatibility with various cleaning solutions |

| Automotive | Application of cleaning agents and lubricants | Improves maintenance efficiency and prolongs equipment life | Resistant to oils and solvents; adjustable spray settings for precision |

| Industrial Manufacturing | Use in maintenance and lubrication of machinery | Reduces downtime and maintenance costs | Heavy-duty construction; ability to handle a range of chemicals and fluids |

How are Stainless Steel Spray Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, stainless steel spray bottles are essential for sanitation and cleaning processes. They are used to apply cleaning solutions in processing facilities, ensuring compliance with stringent health regulations. Their durability and resistance to corrosion make them ideal for frequent use in environments exposed to various chemicals. International buyers should prioritize bottles that are easy to clean and have adjustable nozzles to accommodate different cleaning solutions, ensuring effectiveness in maintaining hygiene standards.

What Role Do Stainless Steel Spray Bottles Play in Agriculture?

In agriculture, stainless steel spray bottles are utilized for the application of pesticides and fertilizers. These bottles enhance efficiency in crop management by allowing precise application, which helps in reducing chemical waste and environmental impact. Buyers in this sector should look for bottles that can withstand harsh chemicals and have ergonomic designs for ease of use during long hours in the field. Additionally, features like adjustable nozzles can help tailor the spray to specific needs, improving application accuracy.

How Are Stainless Steel Spray Bottles Beneficial for the Hospitality Sector?

The hospitality industry employs stainless steel spray bottles for eco-friendly cleaning solutions in hotels and restaurants. Using these bottles not only promotes sustainability but also enhances the brand image of establishments committed to environmental responsibility. Sourcing considerations for this sector should include customizable designs and sizes to fit various cleaning needs, as well as compatibility with a range of non-toxic cleaning solutions. This versatility allows businesses to maintain cleanliness while adhering to eco-friendly practices.

In What Ways Are Stainless Steel Spray Bottles Used in Automotive Maintenance?

In the automotive industry, stainless steel spray bottles are crucial for applying cleaning agents and lubricants during vehicle maintenance. Their robust construction allows them to handle oils and solvents, improving maintenance efficiency and extending the lifespan of equipment. Buyers should focus on bottles that feature adjustable spray settings for precision application, as well as those that are resistant to various automotive chemicals. This ensures that maintenance tasks are performed effectively while minimizing waste.

Why Are Stainless Steel Spray Bottles Important in Industrial Manufacturing?

Stainless steel spray bottles are widely used in industrial manufacturing for the maintenance and lubrication of machinery. Their ability to withstand a variety of chemicals and fluids helps reduce downtime and maintenance costs, which is critical in a competitive manufacturing environment. When sourcing these bottles, businesses should consider heavy-duty options that can handle the rigors of industrial use. Additionally, features such as adjustable nozzles can aid in precise application, further enhancing operational efficiency.

3 Common User Pain Points for ‘stainless steel spray bottle’ & Their Solutions

Scenario 1: Difficulties in Sourcing Durable Stainless Steel Spray Bottles

The Problem: B2B buyers often struggle to find high-quality stainless steel spray bottles that can withstand rigorous use in industrial or commercial settings. Many available options are either too flimsy or prone to leaks, resulting in wasted products and increased costs. Additionally, buyers face challenges in verifying the durability and chemical resistance of these bottles, especially when sourcing from international suppliers who may not provide adequate product specifications. This uncertainty can lead to costly procurement mistakes and operational inefficiencies.

The Solution: To address this issue, B2B buyers should prioritize suppliers that offer detailed product specifications, including material grades and chemical resistance ratings. Request samples before making bulk orders to assess the quality firsthand. Furthermore, consider establishing relationships with reputable manufacturers known for their durability standards, such as those with ISO certifications or positive customer reviews. It’s also beneficial to look for suppliers who provide transparent sourcing information, ensuring that the materials used meet the necessary standards for industrial applications. Engaging in direct communication with suppliers about your specific needs can also help tailor the products to your requirements, ensuring both durability and functionality.

Scenario 2: Inconsistent Performance of Spray Mechanism

The Problem: Another common pain point is the inconsistent performance of the spray mechanism in stainless steel bottles. Buyers often report that the spray nozzles either clog frequently or do not deliver a consistent mist or stream, which can compromise the effectiveness of cleaning or dispensing tasks. This inconsistency can lead to frustration among employees and reduce productivity, as they may need to frequently troubleshoot or replace spray bottles.

The Solution: To mitigate this issue, buyers should opt for stainless steel spray bottles equipped with adjustable nozzles that allow for a customizable spray pattern. Look for products that feature ergonomic designs and easy-to-clean mechanisms to prevent clogging. Additionally, consider sourcing from suppliers that offer detailed instructions on proper maintenance and cleaning of the spray nozzles. Regular maintenance routines can be implemented in the workplace to ensure that the spray mechanisms remain functional. Buyers should also evaluate user feedback and product reviews to identify models known for their reliable performance over time.

Scenario 3: Environmental and Safety Compliance Concerns

The Problem: With increasing regulations around environmental safety and chemical handling, B2B buyers face the challenge of ensuring that their stainless steel spray bottles comply with local and international standards. Non-compliance can lead to fines and damage to the company’s reputation. Furthermore, buyers may find it challenging to ascertain whether the materials used in the spray bottles are free from harmful chemicals or safe for use with specific substances, especially in sectors such as food service or healthcare.

The Solution: To navigate these compliance challenges, buyers should conduct thorough research on the safety certifications relevant to their industry, such as FDA approval for food-grade products or REACH compliance for chemical handling. Partnering with suppliers who can provide certifications and documentation for their products is crucial. Additionally, consider investing in spray bottles made from eco-friendly materials that are designed to minimize environmental impact. It’s also advisable to stay updated on local regulations and engage with industry associations that can provide guidance on compliance standards. By ensuring that all products are sourced from compliant manufacturers, businesses can mitigate risks associated with safety and environmental regulations.

Strategic Material Selection Guide for stainless steel spray bottle

What Are the Key Materials Used in Stainless Steel Spray Bottles?

When selecting materials for stainless steel spray bottles, it is essential to consider various options that can significantly affect the product’s performance and suitability for different applications. Below, we analyze four common materials used in the construction of stainless steel spray bottles, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. 304 Stainless Steel

Key Properties:

304 stainless steel is known for its excellent corrosion resistance and good formability. It can withstand temperatures up to 870°C (1600°F) in intermittent service and 925°C (1700°F) in continuous service. This makes it suitable for a wide range of applications, including those involving acidic or alkaline solutions.

Pros & Cons:

The primary advantage of 304 stainless steel is its durability and resistance to rust, which extends the lifespan of the spray bottle. However, it can be more expensive than other materials, and its manufacturing process can be complex, requiring precise welding and finishing techniques.

Impact on Application:

304 stainless steel is compatible with a variety of cleaning agents and chemicals, making it ideal for both household and industrial applications. However, it may not be suitable for highly corrosive substances like concentrated acids.

Considerations for International Buyers:

Buyers from regions such as Europe and the Middle East should ensure that the material complies with relevant standards like ASTM A240 or DIN 1.4301. Additionally, understanding local regulations regarding material safety and environmental impact is crucial.

2. 316 Stainless Steel

Key Properties:

316 stainless steel offers superior corrosion resistance compared to 304, particularly against chlorides and marine environments. It can handle temperatures up to 870°C (1600°F) in intermittent service and 925°C (1700°F) in continuous service.

Pros & Cons:

The key advantage of 316 stainless steel is its enhanced durability, making it ideal for use in harsh environments. However, it is typically more expensive than 304 stainless steel, which can impact overall production costs.

Impact on Application:

This material is particularly suited for applications involving saltwater or corrosive chemicals, making it a preferred choice for industries such as food processing and marine applications.

Considerations for International Buyers:

B2B buyers should verify compliance with international standards such as ASTM A240 and JIS G4303. The higher cost may be justified in regions with stringent corrosion resistance requirements, such as coastal areas in South America.

3. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It can withstand temperatures up to approximately 200°C (392°F), making it less suitable for high-temperature applications compared to stainless steel.

Pros & Cons:

The main advantage of aluminum is its lower cost and lighter weight, making it easier to handle and transport. However, its lower temperature tolerance and potential for denting can be significant drawbacks for durability.

Impact on Application:

Aluminum spray bottles are often used for less aggressive chemicals and applications where weight is a concern, such as in personal care products.

Considerations for International Buyers:

Buyers should check for compliance with standards like ASTM B221 and ensure that the anodization process meets local regulations, especially in regions like Africa, where environmental standards may vary.

4. Plastic Coated Stainless Steel

Key Properties:

Plastic-coated stainless steel combines the durability of stainless steel with the lightweight and aesthetic appeal of plastic. The coating provides additional corrosion resistance and can handle moderate temperatures.

Pros & Cons:

The key advantage is the enhanced grip and aesthetic appeal, which can be beneficial for consumer-facing products. However, the coating can wear off over time, potentially exposing the stainless steel underneath.

Impact on Application:

This material is suitable for applications where aesthetics are important, such as in retail settings. However, it may not be suitable for high-temperature or highly corrosive environments.

Considerations for International Buyers:

B2B buyers should ensure that the coating materials comply with safety standards in their respective markets, particularly in Europe, where regulations on chemical safety are stringent.

Summary Table of Material Selection

| Material | Typical Use Case for stainless steel spray bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | Household cleaning products | Excellent corrosion resistance | Higher manufacturing complexity | Medium |

| 316 Stainless Steel | Marine and food processing applications | Superior durability in harsh environments | Higher cost compared to 304 | High |

| Aluminum | Personal care products | Lightweight and cost-effective | Lower temperature tolerance | Low |

| Plastic Coated Stainless Steel | Retail and consumer products | Enhanced grip and aesthetic appeal | Coating may wear off over time | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in stainless steel spray bottles, enabling informed decisions that align with their specific application needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel spray bottle

What Are the Key Stages in the Manufacturing Process of Stainless Steel Spray Bottles?

The manufacturing process of stainless steel spray bottles involves several crucial stages, each designed to ensure the final product meets both functional and aesthetic standards.

Material Preparation

The journey begins with the selection of high-quality stainless steel, typically 304 or 316 grades, known for their corrosion resistance and durability. Suppliers often conduct rigorous quality checks on the raw materials to verify their compliance with international standards. After the materials are sourced, they are cut into sheets or coils of specific dimensions, ready for the next stage.

Forming Techniques Used in Stainless Steel Spray Bottle Production

Forming is a critical step where the stainless steel is shaped into the desired form. This typically involves processes such as deep drawing, stamping, and hydroforming.

- Deep Drawing: In this process, a flat sheet of stainless steel is drawn into a die to form the body of the bottle. The use of hydraulic presses ensures that the material is uniformly shaped without any defects.

- Stamping: This technique is used for creating the bottle’s base or other components. It involves cutting and shaping the metal using dies and punches.

- Hydroforming: A newer technique that employs high-pressure fluid to mold the stainless steel into complex shapes, providing a seamless finish.

These forming techniques not only enhance the structural integrity of the spray bottles but also contribute to their aesthetic appeal.

What Happens During Assembly and Finishing?

Once the components are formed, they undergo assembly. This stage involves joining parts such as the nozzle, trigger, and body. Automated welding or riveting methods are often employed to ensure strong connections.

After assembly, the finishing process begins. This can include polishing, powder coating, or applying a brushed finish to enhance appearance and resistance to corrosion. Quality control checks are integrated into this phase to catch any imperfections before the products move to packaging.

How Is Quality Assurance Implemented in Stainless Steel Spray Bottle Production?

Quality assurance (QA) is an essential component of manufacturing stainless steel spray bottles. It ensures that products not only meet customer expectations but also comply with international standards.

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding the relevant international standards is crucial. Most manufacturers adhere to ISO 9001, a standard that specifies requirements for a quality management system (QMS). This certification demonstrates a company’s commitment to continuous improvement and customer satisfaction.

Additionally, specific certifications may be relevant depending on the market. For example:

– CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

– API Certification: Relevant for products used in the oil and gas industry, ensuring the product meets specific safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted at various stages of production, this ensures that the manufacturing processes are under control and that products meet quality specifications.

- Final Quality Control (FQC): A thorough inspection of the finished product, checking for defects in functionality, appearance, and safety.

Common testing methods include pressure testing, leak testing, and corrosion resistance testing. These tests validate the durability and reliability of the spray bottles.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure product reliability. Here are several strategies:

- Conducting Audits: Regular audits of the manufacturing facility can provide insights into the operational processes and adherence to quality standards.

- Requesting Quality Reports: Suppliers should be able to provide documentation regarding their QC processes and results from recent inspections or tests.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality.

What Are the Quality Control Nuances for International Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Different regions may have varying expectations regarding product quality, certifications, and testing methods.

- Cultural Expectations: Buyers must consider the cultural contexts of their markets, as customer expectations may differ significantly. For instance, European buyers might prioritize eco-friendly materials and processes more than buyers in other regions.

- Documentation and Compliance: Ensure that suppliers are not only compliant with local regulations but also with international standards. This is particularly important for products intended for markets with strict safety and environmental regulations.

Conclusion

The manufacturing processes and quality assurance measures for stainless steel spray bottles are intricate and essential for ensuring product quality and reliability. B2B buyers must be well-informed about these processes and standards to make educated purchasing decisions. By understanding the key stages of manufacturing and the importance of quality control, businesses can forge successful partnerships with reliable suppliers, ensuring their needs are met with the highest standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel spray bottle’

This guide aims to assist B2B buyers in effectively sourcing stainless steel spray bottles by providing a structured checklist. These bottles are not only durable and reusable but also versatile for various applications, making them a valuable asset for businesses across multiple sectors.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the stainless steel spray bottles you intend to procure. Consider factors such as size, capacity (e.g., 16 oz), nozzle type (adjustable, locking, misting), and compatibility with various liquids (e.g., cleaners, oils). Establishing these specifications helps streamline the sourcing process and ensures that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in stainless steel spray bottles. Utilize online platforms, trade directories, and industry networks to compile a list of reputable manufacturers and distributors. Pay attention to their product range, market presence, and customer reviews, as these factors can indicate reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate compliance with international quality standards. Look for certifications such as ISO 9001 for quality management systems or specific industry certifications that apply to your market. This step is crucial to ensure that the products meet safety and quality benchmarks, reducing the risk of issues down the line.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, request samples from shortlisted suppliers. This allows you to evaluate the quality, durability, and functionality of the stainless steel spray bottles firsthand. Assess aspects such as the spray mechanism, ergonomic design, and overall finish to ensure they align with your expectations and requirements.

Step 5: Compare Pricing and Terms of Sale

Once you have gathered samples and assessed quality, compare pricing among different suppliers. Consider not only the unit price but also shipping costs, payment terms, and potential bulk discounts. Evaluating these factors will help you find a competitive deal while ensuring that you are not compromising on quality.

Step 6: Negotiate Terms and Finalize the Order

Engage in negotiations with your chosen supplier to finalize the terms of the order. Discuss lead times, minimum order quantities, and return policies. Clear communication during this phase ensures that both parties have aligned expectations, which can prevent misunderstandings and facilitate a smoother transaction.

Step 7: Establish a Reliable Supply Chain

After placing your order, work on establishing a robust supply chain with your supplier. Regularly communicate regarding order status, and keep track of inventory levels to avoid disruptions in your operations. Building a reliable relationship with your supplier can lead to better service, faster turnaround times, and enhanced collaboration in future projects.

By following this checklist, B2B buyers can navigate the sourcing process for stainless steel spray bottles effectively, ensuring they secure quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for stainless steel spray bottle Sourcing

What Are the Key Cost Components in Sourcing Stainless Steel Spray Bottles?

When sourcing stainless steel spray bottles, understanding the cost structure is crucial for effective budgeting and supplier negotiations. The primary cost components include:

-

Materials: The choice of stainless steel grade significantly impacts costs. Higher grades, such as 316 stainless steel, offer superior corrosion resistance but come at a premium. Additionally, factors like the thickness of the material and any coatings or finishes applied can also affect material costs.

-

Labor: Labor costs vary widely based on the manufacturing location. For instance, countries with lower labor costs, such as some in Africa and South America, may provide significant savings compared to European manufacturers. However, it’s essential to consider the skill level required for tasks like assembly and quality assurance.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturers often have lower overhead costs, which can be beneficial for buyers seeking competitive pricing.

-

Tooling: Custom tooling for specific designs or features can be a significant upfront expense. Buyers should factor in these costs, especially for customized orders, as they may impact the overall unit price.

-

Quality Control (QC): Investing in robust QC processes can increase initial costs but ultimately leads to higher product reliability and reduced returns. Certifications for quality standards (like ISO) can also elevate costs but are often necessary for international trade.

-

Logistics: Shipping costs can be substantial, particularly for international orders. Factors such as shipping method, distance, and Incoterms (International Commercial Terms) directly influence logistics expenses. Choosing the right logistics partner can help mitigate these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Stainless Steel Spray Bottles?

Several factors can influence the pricing of stainless steel spray bottles:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Bulk orders often result in lower per-unit costs due to economies of scale, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom designs or unique specifications can lead to increased costs. Buyers should communicate their requirements clearly to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and relevant certifications (such as FDA compliance for food-grade applications) can elevate costs. Buyers must weigh the benefits of these enhancements against their budget constraints.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can all influence pricing. Established suppliers with a proven track record may charge higher prices but can offer reliability and quality assurance.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

To optimize sourcing costs, buyers can employ several negotiation strategies:

-

Research and Compare Suppliers: Conduct thorough market research to understand competitive pricing and the range of available options. Use this information as leverage in negotiations.

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs, thus securing better pricing.

-

Discuss Payment Terms: Flexible payment terms can sometimes lead to discounts. Offering upfront payments can incentivize suppliers to lower prices.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also long-term costs associated with durability, maintenance, and logistics. This holistic view can lead to better decision-making.

How Do International Pricing Nuances Affect B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact overall costs. Buyers should consider hedging strategies or negotiate pricing in a stable currency.

-

Import Tariffs and Taxes: Understanding local regulations regarding import duties is crucial. These can significantly increase the final cost of goods.

-

Cultural Factors: Building relationships with suppliers can lead to better deals. Understanding local business practices and communication styles can enhance negotiations.

-

Incoterms: Familiarity with Incoterms is vital for understanding responsibilities related to shipping, insurance, and risk transfer. Clear agreements on these terms can prevent unexpected costs.

Conclusion: What Should Buyers Remember About Pricing?

While the indicative prices for stainless steel spray bottles vary widely based on the factors discussed, careful consideration of the cost components and price influencers can lead to more informed purchasing decisions. By leveraging negotiation strategies and understanding international pricing nuances, B2B buyers can secure better deals and optimize their sourcing strategies.

Alternatives Analysis: Comparing stainless steel spray bottle With Other Solutions

Exploring Alternative Solutions to Stainless Steel Spray Bottles

In the competitive landscape of B2B purchasing, understanding alternative solutions is crucial for making informed decisions. Stainless steel spray bottles are popular for their durability and aesthetic appeal, but they are not the only option available. This section explores two viable alternatives: plastic spray bottles and chemical-resistant spray systems, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Stainless Steel Spray Bottle | Plastic Spray Bottle | Chemical-Resistant Spray System |

|---|---|---|---|

| Performance | High durability; resistant to corrosion and impact | Moderate durability; prone to wear and tear | High durability; designed for harsh chemicals |

| Cost | Moderate to high; typically priced between $10-$20 | Low; often available for $1-$5 | High; typically priced around $60-$100 |

| Ease of Implementation | Simple to use; lightweight and portable | Very easy to use; lightweight and versatile | Requires training for optimal use; may need professional installation |

| Maintenance | Low; easy to clean and refill | Moderate; may require more frequent replacements | Low; designed for longevity with minimal upkeep |

| Best Use Case | Ideal for eco-conscious consumers and general use | Suitable for short-term, low-cost applications | Best for industrial environments and chemical handling |

In-Depth Look at Alternative Solutions

What Are the Pros and Cons of Plastic Spray Bottles?

Plastic spray bottles are widely used in various industries due to their low cost and lightweight nature. They are suitable for simple applications, such as cleaning and gardening, where chemical resistance is not a priority. However, their durability is a significant drawback; they can become brittle over time and are more susceptible to damage from harsh chemicals. Moreover, their shorter lifespan may lead to higher long-term costs if replacements are frequently needed. For businesses focused on cost-effectiveness and simplicity, plastic spray bottles present a viable option.

How Do Chemical-Resistant Spray Systems Compare?

Chemical-resistant spray systems are specifically designed for handling harsh substances, making them ideal for industrial applications, such as laboratories and manufacturing facilities. They are built to withstand corrosive chemicals, ensuring safety and reliability. However, these systems come at a higher initial cost and may require specialized training for staff to operate effectively. While they are durable and low-maintenance, the complexity of their implementation can be a barrier for some businesses. Companies that frequently deal with hazardous materials will find these systems invaluable for maintaining safety and compliance.

Making the Right Choice for Your Business Needs

When evaluating alternatives to stainless steel spray bottles, B2B buyers should consider their specific needs and operational contexts. If the focus is on eco-friendliness and long-term use, stainless steel is hard to beat. For budget-conscious applications, plastic bottles may suffice despite their limitations. Conversely, for industries that require robust solutions for handling chemicals, investing in chemical-resistant spray systems is essential. Ultimately, understanding the unique benefits and drawbacks of each option will empower businesses to make informed purchasing decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for stainless steel spray bottle

What Are the Key Technical Properties of Stainless Steel Spray Bottles?

When selecting stainless steel spray bottles for your business, understanding their technical properties is essential for ensuring they meet your operational needs. Here are several critical specifications:

-

Material Grade: The most common grades for stainless steel spray bottles are 304 and 316. Grade 304 is suitable for general use, while 316 offers enhanced resistance to corrosion and is ideal for applications involving chemicals or saline environments. Choosing the right grade affects the longevity and performance of the spray bottle in various environments.

-

Capacity: Stainless steel spray bottles come in various sizes, typically ranging from 8 oz to 32 oz. The capacity you choose should align with your intended use—larger bottles may be more efficient for commercial settings, while smaller sizes might be better for personal or light-duty applications.

-

Nozzle Type: Spray bottles often feature adjustable nozzles that can provide a range of spray patterns, from fine mist to a focused stream. This versatility is crucial for businesses that require precise application, such as in cleaning or gardening.

-

Durability and Resistance: Look for bottles that are designed to withstand high temperatures and chemical exposure. This property is particularly important in industrial settings where harsh cleaning agents are used. A durable construction ensures fewer replacements and lower long-term costs.

-

Ergonomics: An ergonomic design, including a comfortable grip and lightweight construction, can enhance user experience, especially in environments where the bottles are used frequently. This feature can lead to increased productivity and reduced fatigue for employees.

-

Recyclability: As sustainability becomes increasingly important, consider the recyclability of the materials used in the spray bottles. Stainless steel is highly recyclable, making it a more environmentally friendly option compared to plastic alternatives.

What Trade Terms Should B2B Buyers Know When Purchasing Stainless Steel Spray Bottles?

Familiarizing yourself with industry terminology can streamline the purchasing process and enhance negotiations. Here are several key trade terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help you source high-quality spray bottles tailored to your specifications.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps in budgeting and inventory management, as it affects how much stock you need to order at once.

-

RFQ (Request for Quotation): An RFQ is a standard business process where buyers invite suppliers to bid on the supply of specific products. It’s essential for obtaining competitive pricing and terms from multiple suppliers, ensuring you make an informed decision.

-

Incoterms (International Commercial Terms): These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding Incoterms can help you navigate shipping logistics, including who bears the risk during transit and who is responsible for shipping costs.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. Knowing the lead time is vital for inventory planning and ensuring that you can meet customer demands without delays.

-

Certification: Certifications such as ISO or CE mark indicate that the product meets specific industry standards. For stainless steel spray bottles, these certifications can assure quality and safety, which is particularly important in industries like food service or pharmaceuticals.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the stainless steel spray bottle Sector

What Are the Key Market Dynamics and Sourcing Trends for Stainless Steel Spray Bottles?

The stainless steel spray bottle market is currently experiencing significant growth driven by various global trends. Increasing consumer awareness regarding sustainability is pushing manufacturers to innovate and offer reusable products that reduce waste. As businesses in Africa, South America, the Middle East, and Europe (notably Brazil and Germany) seek eco-friendly alternatives, the demand for stainless steel spray bottles is expected to rise. The versatility of these products—suitable for a range of applications from cleaning solutions to personal care—further enhances their appeal in the B2B sector.

Emerging B2B technologies, such as automated inventory management and digital sourcing platforms, are streamlining the procurement process for international buyers. These advancements allow businesses to efficiently source stainless steel spray bottles from multiple suppliers, enhancing competitive pricing and product availability. Additionally, the integration of Internet of Things (IoT) capabilities in product design—such as smart dispensing systems—could redefine user experiences and operational efficiency in industries ranging from hospitality to manufacturing.

Furthermore, a growing trend towards customization and branding in the B2B market is encouraging suppliers to offer personalized spray bottles. Buyers are increasingly looking for unique designs and functionalities that align with their brand identity, thereby driving innovation in product offerings.

How Does Sustainability Influence Sourcing Decisions for Stainless Steel Spray Bottles?

Sustainability is not just a buzzword; it is a critical factor influencing sourcing decisions in the stainless steel spray bottle sector. The environmental impact of single-use plastics is prompting businesses to consider eco-friendly alternatives, making stainless steel a favored choice due to its durability and recyclability. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to sustainable practices, such as using recycled materials and minimizing carbon footprints.

Ethical sourcing is also gaining traction, with buyers demanding transparency in supply chains. Companies that can provide certifications, such as ISO 14001 for environmental management, or those that adhere to fair labor practices, are more likely to attract international buyers. This shift is particularly relevant in markets like Europe, where regulatory frameworks are stringent regarding sustainability and ethical sourcing.

Moreover, incorporating ‘green’ certifications into product offerings not only enhances marketability but also aligns with the values of environmentally conscious consumers. Suppliers who embrace this trend are likely to build stronger relationships with B2B buyers, fostering loyalty and repeat business.

What is the Evolution of the Stainless Steel Spray Bottle Market?

The stainless steel spray bottle has evolved significantly over the past few decades, transitioning from a niche product to a mainstream solution embraced by various industries. Initially popularized in the culinary sector for oil and vinegar dispensing, these bottles have expanded their applications to cleaning, personal care, and even industrial use.

The shift towards sustainability and the reduction of plastic waste has accelerated this evolution. As consumers and businesses alike become more environmentally aware, stainless steel spray bottles are increasingly seen as a viable alternative. Innovations in design and functionality, such as adjustable nozzles and ergonomic grips, have further enhanced their usability across different sectors.

In summary, the stainless steel spray bottle market is positioned for continued growth, driven by sustainability, technological advancements, and evolving consumer preferences. International B2B buyers should consider these dynamics when sourcing products to ensure alignment with market trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel spray bottle

-

How do I choose the right stainless steel spray bottle for my business needs?

When selecting a stainless steel spray bottle, consider factors such as capacity, nozzle type, and intended use. Assess whether you need a fine mist for delicate applications or a more focused stream for heavier substances. Additionally, evaluate the durability and chemical resistance of the material, especially if you plan to use harsh cleaning agents. Reviewing supplier specifications and customer feedback can also provide insights into the product’s reliability and performance. -

What are the advantages of using stainless steel spray bottles over plastic ones?

Stainless steel spray bottles offer several benefits, including enhanced durability, resistance to corrosion, and eco-friendliness. They are less prone to breakage compared to glass and do not leach harmful chemicals like some plastics can. Additionally, stainless steel is often more aesthetically pleasing, making it suitable for retail environments. The long lifespan of these bottles makes them a cost-effective choice in the long run, especially for businesses focused on sustainability. -

What is the minimum order quantity (MOQ) for stainless steel spray bottles?

Minimum order quantities can vary significantly depending on the supplier and the specific product. Generally, MOQs for stainless steel spray bottles range from 100 to 1,000 units. It’s essential to discuss your requirements with potential suppliers and negotiate terms that suit your business needs. Some suppliers may offer flexibility on MOQs for repeat customers or larger contracts, so it’s worth exploring those options. -

How can I ensure the quality of stainless steel spray bottles from international suppliers?

To ensure product quality, start by requesting samples from suppliers before placing a bulk order. Verify that the bottles meet industry standards and regulations relevant to your market. Conducting factory audits or certifications checks can provide additional assurance. Utilizing third-party quality assurance services can help identify potential issues before shipment, ensuring that you receive products that meet your specifications. -

What customization options are available for stainless steel spray bottles?

Many suppliers offer customization options such as logo printing, color variations, and different nozzle types. Customization can enhance brand visibility and tailor the product to specific applications. Discuss your branding needs with suppliers to understand the available options and associated costs. Some may also offer bulk discounts for customized orders, making it a cost-effective strategy for businesses looking to strengthen their brand identity. -

What payment terms should I expect when sourcing stainless steel spray bottles internationally?

Payment terms can vary widely among suppliers, but common practices include partial payments upfront (30-50%) with the balance due upon shipment or delivery. It’s essential to negotiate terms that align with your cash flow needs. Consider using secure payment methods like letters of credit or escrow services to minimize risk. Always clarify currency exchange rates and transaction fees, especially for international transactions. -

What shipping options are available for stainless steel spray bottles, and how do I choose the best one?

Shipping options typically include air freight, sea freight, and express courier services. The choice depends on your budget, urgency, and volume of the order. Air freight is faster but more expensive, while sea freight is more economical for larger shipments but takes longer. Review shipping costs, transit times, and customs clearance procedures with your supplier to make an informed decision that meets your delivery timeline and budget. -

How can I assess the reliability of a supplier for stainless steel spray bottles?

Assessing a supplier’s reliability involves checking their reputation, certifications, and customer reviews. Look for suppliers with a track record of timely deliveries and consistent product quality. Request references from other clients and verify their experience with the supplier. Additionally, consider suppliers who are members of industry associations or have relevant certifications, as these can indicate adherence to quality standards and ethical business practices.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Stainless Steel Spray Bottle Manufacturers & Suppliers List

1. Target – High-Quality Stainless Steel Spray Bottles

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – High-Quality Stainless Steel Spray Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Flip Spray Bot – Durable Metal Sprayer Solution

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Reusable spray bottles with a metal sprayer head are sought after for durability. The user mentions previous experiences with cheap tops that didn’t last. They consider commercial kitchen spray bottles due to their known durability from working in kitchens. One recommended option is a Flip Spray Bottle from Dynalon, which is designed for industrial/scientific use and is compatible with chemicals. …

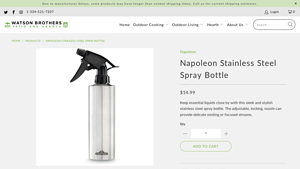

3. Napoleon – Stainless Steel Spray Bottle

Domain: bbqbarn.com

Registered: 1999 (26 years)

Introduction: {“name”: “Stainless Steel Spray Bottle”, “sku”: “62047”, “vendor”: “Napoleon”, “regular_price”: “16.99”, “sale_price”: “16.99”, “description”: “The adjustable, locking nozzle can provide delicate misting or focused streams for basting, seasoning your cooking grids, and keeping your foods moist and succulent. The sleek stainless design is durable and dishwasher safe, so cleanup is a breeze.”, “ship…

4. Stainless Steel Spray Bottles – Set of 2

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, Stainless Steel Spray Bottles – Set of 2, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Napoleon – Stainless Steel Spray Bottle

Domain: watsonbrotherspatioandhearth.com

Registered: 2017 (8 years)

Introduction: Napoleon Stainless Steel Spray Bottle – Price: $14.99 – Features: Sleek and stylish design, adjustable locking nozzle for delicate misting or focused streams.

6. DENIOS – Chemical-Resistant Sprayer 0.26 Gal

Domain: denios-us.com

Registered: 2009 (16 years)

Introduction: Chemical-resistant sprayer 0.26 gal – stainless steel with adjustable nozzle

Item number: M720432

In Stock and Ready to Ship

Features:

– Specially designed large base prevents accidental tipping

– Highly resistant to many cleaning agents

– Ergonomic handling with plastic trigger spray

– Spray head with adjustable nozzle

– Integral plastic pumps

– Constructed of durable, chemical resistant stainles…

7. Napoleon – Stainless Steel Spray Bottle

Domain: napoleon.com

Registered: 1995 (30 years)

Introduction: {“name”: “Stainless Steel Spray Bottle”, “model”: “62047”, “MSRP”: “19.99 CAD”, “features”: [“Stainless Steel Construction resists rust and corrosion”, “Dishwasher safe”, “Adjustable sprayer nozzle for focused streams, gentle misting, and lock position”, “Keeps oil and water within easy reach while cooking”, “Sleek design is stylish”]}

Strategic Sourcing Conclusion and Outlook for stainless steel spray bottle

In the evolving landscape of B2B procurement, strategic sourcing of stainless steel spray bottles offers significant advantages for international buyers. These bottles, known for their durability and reusability, present an opportunity to reduce waste and operational costs while enhancing product presentation. Key considerations include the selection of suppliers that prioritize quality and sustainability, ensuring compliance with international safety standards, and fostering long-term partnerships that can adapt to market demands.

The value of strategic sourcing extends beyond immediate cost savings; it encompasses the ability to streamline supply chains and improve product offerings. As global markets grow increasingly interconnected, businesses in regions such as Africa, South America, the Middle East, and Europe must remain agile and proactive in their sourcing strategies. By investing in high-quality stainless steel spray bottles, companies not only meet consumer demand for eco-friendly products but also position themselves as leaders in their respective industries.

Looking ahead, international buyers are encouraged to leverage data-driven insights and supplier evaluations to optimize their sourcing decisions. Embrace innovation and sustainability in your procurement processes, and capitalize on the opportunities presented by the stainless steel spray bottle market to enhance your brand’s reputation and profitability.