Introduction: Navigating the Global Market for shaker mixer bottle

The global market for shaker mixer bottles presents a myriad of challenges for international B2B buyers, particularly when it comes to sourcing high-quality products that meet diverse regional needs. As businesses seek efficient and reliable solutions for mixing beverages, protein shakes, and supplements, understanding the nuances of shaker mixer bottles becomes essential. This guide delves into the various types of shaker bottles available, their applications across different industries, and how to vet suppliers effectively.

From traditional manual shakers to advanced electric models, the market offers a wide range of options that cater to different consumer preferences and usage scenarios. Buyers will find insights on key factors influencing costs, including materials, design innovations, and brand reputation. Additionally, this guide will equip businesses from Africa, South America, the Middle East, and Europe—such as those in Vietnam and Nigeria—with the knowledge needed to make informed purchasing decisions that align with their operational needs and budgets.

By synthesizing expert insights and data, this comprehensive resource empowers B2B buyers to navigate the complexities of the shaker mixer bottle market confidently. Whether you are looking to enhance your product offerings or improve customer satisfaction, this guide serves as a strategic tool to streamline your sourcing process and optimize your procurement strategies.

Article Navigation

- Top 4 Shaker Mixer Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for shaker mixer bottle

- Understanding shaker mixer bottle Types and Variations

- Key Industrial Applications of shaker mixer bottle

- 3 Common User Pain Points for ‘shaker mixer bottle’ & Their Solutions

- Strategic Material Selection Guide for shaker mixer bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for shaker mixer bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘shaker mixer bottle’

- Comprehensive Cost and Pricing Analysis for shaker mixer bottle Sourcing

- Alternatives Analysis: Comparing shaker mixer bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for shaker mixer bottle

- Navigating Market Dynamics and Sourcing Trends in the shaker mixer bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shaker mixer bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for shaker mixer bottle

Understanding shaker mixer bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

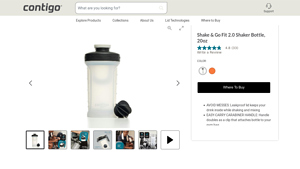

| Classic Shaker Bottles | Simple design, often with a mixing ball, lightweight | Gyms, fitness studios, nutrition shops | Pros: Affordable, easy to use. Cons: May not mix as effectively as others. |

| Insulated Stainless Steel | Double-walled for temperature retention, durable materials | Sports events, outdoor activities | Pros: Keeps drinks cold/hot longer. Cons: Higher cost, heavier. |

| Electric Shaker Bottles | Motorized mixing mechanism, USB rechargeable | Health clubs, professional athletes | Pros: Effortless mixing, no clumps. Cons: Requires charging, more expensive. |

| Capsule Shape Shakers | Unique design for efficient mixing without a ball | Retail, gyms, wellness centers | Pros: No loose parts, easy to clean. Cons: Limited size options. |

| Tritan Sport Shakers | Made from BPA-free Tritan, odor-resistant, various colors | Retail, health-focused brands | Pros: Lightweight, customizable. Cons: Less durable than stainless steel. |

What Are the Characteristics of Classic Shaker Bottles?

Classic shaker bottles are the most basic form of mixing bottles, typically featuring a simple design with a mixing ball or mesh screen. They are lightweight and often made from plastic, making them cost-effective for bulk purchases. These bottles are suitable for gyms, fitness studios, and nutrition shops where affordability is key. While they are user-friendly, they may not mix powders as thoroughly as more advanced models, which can be a consideration for B2B buyers focused on quality.

How Do Insulated Stainless Steel Shakers Stand Out?

Insulated stainless steel shaker bottles are designed with double-walled construction that helps maintain the temperature of liquids for extended periods. This feature is particularly beneficial for sports events and outdoor activities, where temperature control is essential. They are durable and provide a premium feel, appealing to brands aiming for a high-end image. However, their higher price point and increased weight compared to plastic options may deter some budget-conscious buyers.

What Benefits Do Electric Shaker Bottles Offer?

Electric shaker bottles utilize a motorized mixing mechanism, allowing for seamless blending of powders and liquids in seconds. Ideal for health clubs and professional athletes, these bottles eliminate clumps and provide a smooth texture, enhancing the user experience. While they offer convenience and efficiency, B2B buyers should consider the need for recharging and the higher cost associated with these premium products.

Why Choose Capsule Shape Shakers?

Capsule shape shakers are innovative in design, promoting efficient mixing without the need for a ball or screen. Their unique structure is particularly appealing for retail and wellness centers, where aesthetics and functionality are crucial. While they offer ease of cleaning and no loose parts, buyers may find limited size options, which could impact their versatility in different applications.

What Are the Advantages of Tritan Sport Shakers?

Tritan sport shakers are made from BPA-free materials, ensuring safety and odor resistance. Available in various colors, they are popular among health-focused brands looking to offer customizable options. These bottles are lightweight and suitable for retail settings; however, they may not be as durable as stainless steel alternatives, which is an important consideration for buyers prioritizing long-lasting products.

Key Industrial Applications of shaker mixer bottle

| Industry/Sector | Specific Application of shaker mixer bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness & Sports Nutrition | Mixing protein shakes and supplements for athletes | Enhances product effectiveness and customer satisfaction | Durability, ease of cleaning, and leak-proof design |

| Food & Beverage | Preparing beverage mixes and smoothies in cafes and restaurants | Streamlines operations and improves customer experience | Material safety, capacity, and design versatility |

| Pharmaceuticals & Healthcare | Mixing powdered medications or supplements | Ensures accurate dosing and ease of use for patients | Compliance with health regulations and material safety |

| Education & Training | Use in nutrition workshops and fitness classes | Engages participants and enhances learning experiences | Custom branding options and ease of use for diverse audiences |

| Outdoor & Adventure Retail | Mixing hydration solutions for outdoor activities | Meets customer needs for convenience and portability | Lightweight materials, insulation, and design for mobility |

How is the shaker mixer bottle used in the Fitness & Sports Nutrition industry?

In the fitness and sports nutrition sector, shaker mixer bottles are essential for athletes and fitness enthusiasts to mix protein powders and supplements effectively. These bottles solve the common problem of clumping and uneven mixing, ensuring a smooth shake that enhances nutrient absorption. Buyers in this sector should prioritize bottles that are durable, easy to clean, and have a leak-proof design to withstand rigorous use during workouts, particularly in regions like Africa and South America where outdoor fitness activities are popular.

What role do shaker mixer bottles play in the Food & Beverage industry?

In the food and beverage industry, shaker mixer bottles are utilized in cafes and restaurants for preparing beverage mixes, smoothies, and protein shakes. They streamline the mixing process, allowing for quick service and consistent quality, which is crucial in high-demand settings. Buyers should consider sourcing bottles made from safe materials that comply with food safety standards, as well as those with sufficient capacity and versatile designs to cater to various menu items, especially in the Middle East where beverage customization is prevalent.

How do shaker mixer bottles benefit the Pharmaceuticals & Healthcare sector?

In the pharmaceuticals and healthcare sector, shaker mixer bottles are increasingly used to mix powdered medications and nutritional supplements. These bottles ensure that patients can easily and accurately mix their doses without the risk of spillage or contamination. Key considerations for buyers include compliance with health regulations, the use of non-toxic materials, and designs that facilitate ease of use for patients, particularly in regions like Europe where healthcare standards are stringent.

Why are shaker mixer bottles important for Education & Training?

Shaker mixer bottles find valuable applications in education and training environments, particularly during nutrition workshops and fitness classes. They engage participants by providing hands-on experience in mixing healthy shakes and smoothies, enhancing the learning experience. Buyers should look for options that allow for custom branding to promote their programs, as well as features that accommodate a diverse audience, including easy-to-use designs suitable for all ages, which is particularly beneficial in regions like Vietnam where health education is gaining traction.

How do shaker mixer bottles cater to Outdoor & Adventure Retail?

In the outdoor and adventure retail sector, shaker mixer bottles are essential for mixing hydration solutions, protein shakes, and energy drinks on-the-go. They offer convenience and portability, meeting the demands of outdoor enthusiasts who require reliable hydration solutions during their activities. Buyers should focus on lightweight materials, insulation properties, and designs that enhance mobility, which are crucial for users in Africa and South America where outdoor sports are popular and often require robust, portable solutions.

3 Common User Pain Points for ‘shaker mixer bottle’ & Their Solutions

Scenario 1: Ensuring Product Quality and Consistency in Bulk Orders

The Problem: B2B buyers often struggle with ensuring the quality and consistency of shaker mixer bottles when ordering in bulk. Variability in materials, manufacturing processes, and design can lead to discrepancies in product quality, resulting in customer dissatisfaction and increased returns. For buyers in regions like Africa or South America, where logistics and supply chain reliability can be challenging, receiving subpar products can severely impact business operations and reputation.

The Solution: To mitigate this issue, B2B buyers should establish clear specifications for shaker mixer bottles before placing bulk orders. This includes defining the material (e.g., BPA-free plastic, stainless steel), design features (e.g., leak-proof lids, easy-to-clean interiors), and performance characteristics (e.g., mixing efficiency, odor resistance). Conducting thorough due diligence on suppliers is crucial; this could involve requesting samples for testing, reviewing certifications (such as FDA compliance), and checking for consistent quality control measures in the manufacturing process. Additionally, maintaining open communication with suppliers about expectations can lead to better alignment and fewer quality-related issues.

Scenario 2: Overcoming Functional Limitations During Use

The Problem: Many shaker mixer bottles on the market fail to meet the functional needs of users, particularly in high-demand environments like gyms or athletic facilities. Common complaints include difficulty in mixing powders thoroughly, leakage during transport, and challenges with cleaning. These issues can frustrate end-users and reflect poorly on the brand associated with these products.

The Solution: Buyers should prioritize sourcing shaker bottles that feature innovative designs aimed at enhancing functionality. For example, bottles with a unique capsule shape or integrated mixing technology (like electric mixers) can greatly improve mixing efficiency without the need for a traditional shaker ball. Additionally, selecting products that are designed for easy cleaning, such as those with smooth interiors and few crevices, can save users time and effort. It’s also essential to evaluate leak-proof features and materials that resist odors and stains. By focusing on these attributes, buyers can ensure that the shaker bottles they offer meet user expectations and enhance their overall experience.

Scenario 3: Addressing Environmental Concerns in Product Selection

The Problem: As sustainability becomes a crucial consideration for businesses globally, B2B buyers face pressure to select shaker mixer bottles that align with eco-friendly practices. Many conventional bottles are made from single-use plastics that contribute to environmental degradation, which can alienate environmentally conscious customers and tarnish brand reputation.

The Solution: To address environmental concerns, buyers should look for shaker mixer bottles made from sustainable materials, such as recycled plastics or stainless steel, which are both durable and recyclable. Partnering with manufacturers who prioritize eco-friendly production processes and certifications (like ISO 14001 for environmental management) can further enhance a brand’s sustainability credentials. Additionally, buyers can educate their customers on the benefits of using reusable shaker bottles, emphasizing the reduction of plastic waste and the long-term cost savings associated with investing in high-quality, durable products. By taking these steps, B2B buyers not only meet consumer demand for sustainable options but also position their brands as responsible leaders in the marketplace.

Strategic Material Selection Guide for shaker mixer bottle

What Are the Key Materials Used in Shaker Mixer Bottles?

When selecting shaker mixer bottles for international markets, understanding the materials used is crucial. The choice of material impacts not only the functionality and durability of the product but also its compliance with regional standards and buyer preferences. Here, we analyze four common materials used in shaker mixer bottles: plastic (Tritan), stainless steel, glass, and electric components.

How Does Tritan Plastic Perform in Shaker Mixer Bottles?

Tritan is a copolyester plastic known for its clarity, toughness, and resistance to odors and stains. It can withstand temperatures up to 100°C (212°F) and is generally resistant to corrosion, making it suitable for various beverages, including protein shakes and other supplements.

Pros: Tritan is lightweight and durable, making it an excellent choice for portable shaker bottles. Its cost-effectiveness and ease of manufacturing also contribute to its popularity.

Cons: While Tritan is robust, it may not be as impact-resistant as stainless steel or glass. Additionally, it can be less environmentally friendly, as it is a petroleum-based product.

Impact on Application: Tritan is compatible with a wide range of liquids, but it may not be suitable for highly acidic substances, which could degrade the material over time.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that Tritan products meet local health and safety standards. Compliance with international standards such as ASTM or JIS is also essential.

What Advantages Does Stainless Steel Offer for Shaker Mixer Bottles?

Stainless steel is a popular choice for shaker bottles due to its exceptional durability and resistance to corrosion and staining. It can handle high temperatures and is generally more robust than plastic alternatives.

Pros: Stainless steel shaker bottles are long-lasting and can maintain the temperature of beverages for extended periods. They are also environmentally friendly, as they are recyclable.

Cons: The manufacturing process for stainless steel can be more complex, leading to higher production costs. Additionally, stainless steel bottles can be heavier than their plastic counterparts, which may be a consideration for portability.

Impact on Application: Stainless steel is suitable for a wide variety of liquids, including hot beverages, and is less likely to leach chemicals compared to plastic.

Considerations for International Buyers: Buyers should verify that stainless steel products comply with food safety regulations in their respective countries. Certifications like ISO and compliance with EU standards can enhance marketability in Europe and the Middle East.

Why Choose Glass for Shaker Mixer Bottles?

Glass is another material used in shaker bottles, known for its non-reactive properties and aesthetic appeal. It can withstand high temperatures but is more fragile than plastic or stainless steel.

Pros: Glass does not retain odors or flavors, making it ideal for mixing different types of beverages. It is also recyclable and environmentally friendly.

Cons: The fragility of glass makes it less suitable for on-the-go use, as it can break easily. Additionally, glass shaker bottles can be heavier and more expensive to produce.

Impact on Application: Glass is compatible with a wide range of liquids but may not be ideal for high-impact environments.

Considerations for International Buyers: Buyers should ensure that glass products meet safety standards to prevent breakage during shipping and handling. Compliance with local regulations regarding glass manufacturing and recycling can also be beneficial.

What Role Do Electric Components Play in Shaker Mixer Bottles?

Electric shaker bottles, often made from a combination of plastic and stainless steel, use battery-powered mixing technology to blend ingredients seamlessly. These bottles typically feature a USB-C rechargeable battery.

Pros: Electric shakers provide consistent mixing results, eliminating clumps and ensuring a smooth beverage. They are convenient for users who prefer a hands-free mixing experience.

Cons: The complexity of electric components can lead to higher costs and potential reliability issues. Additionally, they require charging, which may not be ideal for all users.

Impact on Application: Electric shakers are suitable for a variety of beverages, including protein shakes and smoothies, but may not be suitable for very hot liquids due to electrical components.

Considerations for International Buyers: Buyers should check the electrical safety standards applicable in their regions, as well as the compatibility of charging systems. Compliance with international certifications can enhance product trustworthiness.

Summary Table of Material Selection for Shaker Mixer Bottles

| Material | Typical Use Case for shaker mixer bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tritan Plastic | General-purpose shaker bottles | Lightweight and durable | Less environmentally friendly | Medium |

| Stainless Steel | Premium shaker bottles | Long-lasting and temperature-retaining | Heavier and higher production cost | High |

| Glass | Eco-friendly and aesthetic shaker bottles | Non-reactive and recyclable | Fragile and heavier | Medium |

| Electric Components | Advanced mixing solutions | Consistent mixing and convenience | Higher cost and requires charging | High |

This analysis provides a comprehensive overview of the materials used in shaker mixer bottles, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for shaker mixer bottle

What Are the Main Stages of Manufacturing a Shaker Mixer Bottle?

The manufacturing process for shaker mixer bottles typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring that the final product meets quality expectations and performs effectively.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage involves selecting appropriate materials, which can include food-grade plastics like Tritan, stainless steel, and silicone. These materials are chosen for their durability, resistance to odors, and safety for food contact. The preparation process includes sourcing raw materials from certified suppliers and conducting initial quality assessments to ensure compliance with international standards.

Once the materials are sourced, they undergo processing, which may involve cutting, molding, or extruding. For instance, plastic components are typically injection molded to create the body of the shaker, while stainless steel parts might be formed through deep drawing techniques.

How Are Shaker Mixer Bottles Formed and Assembled?

The forming stage is crucial for creating the desired shape and functionality of the shaker bottle. In this phase, the prepared materials are shaped into their final forms. For plastic bottles, injection molding is commonly used, where molten plastic is injected into a mold and cooled to solidify. For stainless steel bottles, processes like spinning or stamping may be utilized to achieve the required contours.

After forming, the assembly stage begins. This involves integrating various components, such as lids, mixing mechanisms (like balls or blenders), and seals. Automated assembly lines are often employed to enhance efficiency and precision. Workers may perform final adjustments to ensure that all parts fit seamlessly and function as intended.

What Finishing Techniques Are Commonly Used for Shaker Mixer Bottles?

The finishing stage enhances the aesthetic appeal and functionality of the shaker mixer bottles. Techniques may include surface treatments, painting, or applying protective coatings. For instance, stainless steel bottles may receive a brushed or polished finish to improve durability and appearance. Additionally, labeling and branding are often applied at this stage, which is crucial for B2B buyers seeking to differentiate their products in competitive markets.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is integral to the manufacturing process of shaker mixer bottles. International standards such as ISO 9001 establish frameworks for quality management systems, ensuring that manufacturers maintain consistent product quality. Other relevant certifications include CE marking for compliance with European safety standards and FDA approval for food contact materials.

How Are Quality Control Checkpoints Implemented Throughout the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints in the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards. This is crucial to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During production, random samples are tested to monitor process stability and product quality. This may involve checking dimensions, material properties, and functional tests.

-

Final Quality Control (FQC): Once the shaker bottles are fully assembled, a final inspection is conducted to assess overall quality, appearance, and functionality. This often includes leak tests and durability assessments.

What Testing Methods Are Commonly Used in Quality Assurance for Shaker Mixer Bottles?

Common testing methods include:

-

Mechanical Testing: Assessing the strength and flexibility of materials to ensure they can withstand regular use.

-

Leak Testing: Ensuring that bottles are leak-proof, which is critical for consumer satisfaction and brand reputation.

-

Chemical Testing: Verifying that materials are free from harmful substances and comply with food safety regulations.

These tests help manufacturers identify potential issues before products reach the market, ultimately reducing returns and enhancing customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can ensure the reliability of their suppliers by conducting thorough due diligence:

-

Audits: Regular audits of suppliers can help verify compliance with quality standards and manufacturing processes. This may include on-site inspections to review production practices and QC measures.

-

Quality Reports: Requesting detailed QC reports can provide insights into a supplier’s performance and adherence to standards. These reports should detail testing methods, results, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can add an extra layer of assurance. These services can conduct random sample testing and audits, providing unbiased evaluations of product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding materials and product safety. Buyers should familiarize themselves with local laws and international standards applicable to their markets.

-

Cultural Differences: Understanding cultural attitudes towards quality and safety can influence supplier relationships. Building trust and open communication is essential for successful partnerships.

-

Logistics and Supply Chain Considerations: Factors such as shipping times and customs regulations can impact product delivery and quality. B2B buyers should consider these elements when evaluating suppliers.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring they source high-quality shaker mixer bottles that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shaker mixer bottle’

When sourcing shaker mixer bottles for your business, a systematic approach can significantly enhance your procurement process. This guide outlines essential steps that will help you identify the right products and suppliers tailored to your market needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the shaker mixer bottles you intend to procure. Consider factors such as material (e.g., plastic, stainless steel), size, capacity, and design features like leak-proof lids or built-in mixing mechanisms. This step ensures that you have a clear benchmark for evaluating potential products and suppliers.

Step 2: Research Market Trends

Stay informed about current market trends and consumer preferences in your target regions, such as Africa, South America, the Middle East, and Europe. Understanding popular features—like insulated bottles or electric shakers—can help you align your product offerings with market demand. Utilize industry reports, competitor analysis, and customer feedback to guide your research.

Step 3: Evaluate Potential Suppliers

Before making any commitments, thoroughly vet potential suppliers. Request comprehensive company profiles, including their manufacturing capabilities, certifications, and quality assurance processes. Look for references from other businesses in similar industries or regions to gauge supplier reliability and product quality.

- Check for certifications: Ensure suppliers comply with international standards, such as ISO or FDA certifications, especially if you are sourcing for markets with strict regulatory requirements.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of their shaker mixer bottles. This hands-on evaluation allows you to assess product quality, usability, and design. Pay attention to details such as the mixing performance and durability, as these factors can significantly impact customer satisfaction.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms of sale. Consider the total cost of ownership, including shipping, taxes, and any potential tariffs. Establish clear payment terms and discuss minimum order quantities to ensure that they align with your business’s cash flow and inventory management strategies.

Step 6: Review Logistics and Supply Chain Options

Evaluate the logistics involved in shipping the shaker mixer bottles from the supplier to your location. Consider factors such as lead times, shipping methods, and potential customs clearance issues. A reliable supply chain is crucial for maintaining inventory levels and fulfilling customer orders on time.

Step 7: Plan for Quality Control and Feedback Loops

Implement quality control measures to ensure that the shaker mixer bottles meet your specifications upon arrival. Establish a feedback loop with your customers to gather insights on product performance and areas for improvement. This step is vital for long-term product development and maintaining competitive advantage in the market.

By following this structured sourcing checklist, B2B buyers can streamline their procurement processes, ensuring they select high-quality shaker mixer bottles that meet their business needs and customer expectations.

Comprehensive Cost and Pricing Analysis for shaker mixer bottle Sourcing

What Are the Key Cost Components for Sourcing Shaker Mixer Bottles?

Understanding the cost structure of shaker mixer bottles is crucial for B2B buyers aiming to optimize their sourcing strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts cost. High-quality plastics like Tritan and stainless steel are commonly used due to their durability and resistance to odors. Eco-friendly materials may also be sought after, which can increase costs but appeal to environmentally conscious consumers.

-

Labor: Labor costs vary by region, influenced by local wage rates and labor laws. Countries with lower labor costs may provide significant savings, but buyers should consider the trade-off in quality and manufacturing practices.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturers can keep these costs low, which can reflect in the pricing offered to buyers.

-

Tooling: Custom designs or specifications may require special tooling, increasing initial costs. This is particularly relevant for unique shapes or features that differentiate products in a competitive market.

-

Quality Control (QC): Investing in rigorous QC processes ensures product reliability and compliance with international standards. This may increase costs but can lead to reduced returns and enhanced customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely based on location and chosen Incoterms. Understanding the full logistics chain is essential for calculating the total cost of ownership.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can fluctuate based on market demand, competition, and economic conditions.

How Do Price Influencers Affect Shaker Mixer Bottle Costs?

Several factors influence the final pricing of shaker mixer bottles, which buyers must consider for effective sourcing.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in reduced unit costs due to economies of scale. Buyers should assess their demand forecast to negotiate favorable terms.

-

Specifications/Customization: Custom designs, colors, or features can lead to higher costs. Buyers should balance the need for unique products against budget constraints.

-

Materials: As mentioned, premium materials increase production costs. Buyers should evaluate whether the benefits justify the price increase.

-

Quality and Certifications: Products that meet international certifications (like FDA or ISO) may command higher prices. Buyers should consider whether these certifications are necessary for their market.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is critical for accurate cost estimation.

What Are Effective Buyer Tips for Negotiating Shaker Mixer Bottle Prices?

Navigating the cost landscape requires strategic negotiation and an understanding of total cost implications.

-

Negotiate Smartly: Leverage volume commitments to negotiate better pricing. Building long-term relationships with suppliers can also yield discounts and favorable terms.

-

Focus on Cost Efficiency: Assess total cost of ownership rather than just upfront prices. Consider logistics, durability, and potential warranty costs.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe may face unique challenges, such as currency fluctuations and varying import duties. It’s essential to factor these into the overall pricing strategy.

-

Stay Informed About Market Trends: Keeping abreast of industry trends can provide insights into pricing fluctuations. Economic conditions, material shortages, and emerging technologies can all influence costs.

-

Consider Supplier Location: Sourcing from nearby suppliers can reduce logistics costs and lead times, impacting overall pricing positively.

Disclaimer

The prices and cost structures mentioned in this analysis are indicative and can vary based on market conditions, supplier capabilities, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing and quality.

Alternatives Analysis: Comparing shaker mixer bottle With Other Solutions

Introduction to Alternative Solutions for Mixing Beverages

When it comes to mixing beverages and supplements, the shaker mixer bottle is a popular choice among fitness enthusiasts and health-conscious consumers. However, there are several alternative solutions available in the market, each offering unique advantages and disadvantages. This analysis will compare the shaker mixer bottle against two viable alternatives: electric shaker bottles and traditional blenders. Understanding these options can help international B2B buyers make informed purchasing decisions that align with their specific needs and market demands.

Comparison Table

| Comparison Aspect | Shaker Mixer Bottle | Electric Shaker Bottle | Traditional Blender |

|---|---|---|---|

| Performance | Good mixing with manual shaking; may leave clumps | Excellent mixing; no clumps due to electric blending | Superior mixing; ideal for thick mixtures and smoothies |

| Cost | Generally affordable ($10-$30) | Mid-range ($20-$70) | Higher initial investment ($30-$200) |

| Ease of Implementation | Simple to use; no setup required | Requires charging and occasional maintenance | Requires more effort to set up and clean |

| Maintenance | Low maintenance; easy to clean | Moderate maintenance; battery replacement may be needed | High maintenance; requires thorough cleaning and assembly |

| Best Use Case | Ideal for gym-goers needing convenience | Best for those wanting premium mixing experience | Suitable for preparing large batches and smoothies |

Detailed Breakdown of Alternatives

Electric Shaker Bottles

Electric shaker bottles, such as those offered by PROMiXX, have gained popularity for their ability to mix powders and liquids effortlessly. These devices use battery-powered motors to ensure a smooth blend, eliminating clumps typically associated with manual shaking. The major advantage of electric shakers is their performance; they can efficiently mix dense powders and liquids within seconds. However, they come at a higher price point and require periodic charging, which may not be ideal for all users. Additionally, they may be heavier and less portable than traditional shaker bottles.

Traditional Blenders

For those looking to mix larger quantities or thicker mixtures, traditional blenders present a strong alternative. They provide superior blending capabilities, making them perfect for smoothies or shakes that require fruits or other ingredients. However, the drawbacks include a more complex cleaning process and a larger footprint, which can be a disadvantage for users with limited kitchen space. Furthermore, traditional blenders are generally more expensive and may require more time to prepare and clean compared to shaker bottles. They are best suited for settings where larger volumes are needed, such as cafes or gyms with smoothie bars.

Conclusion: Choosing the Right Solution for Your Needs

For international B2B buyers, selecting the right mixing solution depends on various factors, including performance requirements, budget constraints, and intended use cases. Shaker mixer bottles offer an affordable and convenient option for on-the-go users, while electric shaker bottles cater to those seeking high performance without the need for a traditional blender. On the other hand, traditional blenders are ideal for high-volume mixing but come with higher costs and maintenance requirements. By assessing these alternatives against their specific business needs, buyers can make informed decisions that enhance their product offerings and meet customer expectations effectively.

Essential Technical Properties and Trade Terminology for shaker mixer bottle

What Are the Key Technical Properties of Shaker Mixer Bottles?

When selecting shaker mixer bottles for your business, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Composition

Shaker mixer bottles are typically made from materials such as Tritan™, stainless steel, or BPA-free plastics. Tritan™ is a durable, impact-resistant copolyester that offers clarity and chemical resistance, making it ideal for food applications. Stainless steel provides superior insulation, keeping beverages cold or hot for extended periods. The choice of material directly affects product durability, safety, and user experience, which are essential factors for B2B buyers. -

Capacity

The capacity of shaker bottles can range from 400ml to 2.2 liters. Understanding the capacity needed for your target market helps in catering to different consumer preferences, whether for gym-goers who need smaller portions or athletes requiring larger servings. Offering a range of sizes can enhance your product portfolio and attract a broader customer base. -

Leak-Proof Design

A leak-proof feature is critical for shaker mixer bottles, especially for consumers who carry them during workouts or travel. Many manufacturers employ advanced locking mechanisms and silicone seals to ensure that bottles do not spill. For B2B buyers, offering a reliable leak-proof design can enhance customer satisfaction and reduce product returns. -

Ease of Cleaning

Bottles designed with smooth interiors and fewer crevices are easier to clean, making them more appealing to consumers. Some models feature removable components or wide openings for easy access. This property can significantly impact the product’s usability, especially for health-conscious individuals who frequently use shaker bottles for protein shakes or smoothies. -

Insulation Properties

Insulated shaker bottles maintain the temperature of liquids for longer periods. Double-wall construction is a common feature in high-quality bottles, providing thermal insulation. This property is vital for customers who prefer their beverages to remain cold or hot throughout the day, making it a strong selling point in marketing. -

Durability and Resistance

The durability of the shaker bottle is determined by its resistance to stains, odors, and physical impacts. High-grade materials can enhance the lifespan of the product, which is a significant consideration for B2B buyers looking to minimize replacement costs and maximize customer satisfaction.

What Are Common Trade Terms Used in the Shaker Mixer Bottle Industry?

Understanding industry jargon can facilitate smoother transactions and communication with suppliers and partners. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are then marketed by another company under its brand name. In the shaker bottle industry, businesses may partner with OEMs to create customized products without investing in manufacturing facilities. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Understanding MOQ helps buyers plan their purchases according to market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. This is a standard practice in B2B transactions to ensure that buyers receive competitive pricing and terms before making a purchasing decision. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers mitigate risks and clarify obligations in international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This term is crucial for inventory planning, especially for businesses that operate in fast-paced markets. Understanding lead times can help buyers manage stock levels effectively. -

Customs Duty

Customs duty is a tariff imposed on goods when they are transported across international borders. B2B buyers should be aware of customs duties applicable to shaker mixer bottles, as these can significantly affect overall costs and pricing strategies.

By being well-versed in these technical properties and trade terminologies, B2B buyers can navigate the shaker mixer bottle market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the shaker mixer bottle Sector

What Are the Current Market Dynamics and Key Trends in the Shaker Mixer Bottle Sector?

The global shaker mixer bottle market is experiencing significant growth, driven by increasing health awareness and the rising popularity of fitness activities. Consumers are increasingly seeking convenient solutions for mixing protein shakes and supplements, leading to a surge in demand for innovative shaker designs. Key trends include the emergence of high-performance electric shaker bottles, which provide seamless mixing and enhanced user experience, appealing particularly to tech-savvy consumers in developed markets. Additionally, eco-friendly materials are gaining traction, as buyers become more environmentally conscious and prefer sustainable products.

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the diversification in product offerings, including insulated options, which maintain beverage temperatures for longer durations. This trend caters to the needs of various consumer segments, from athletes to casual gym-goers. Moreover, the customization of shaker bottles with branding opportunities is becoming a critical factor for companies looking to differentiate themselves in a competitive market. Understanding these dynamics can help B2B buyers identify reliable suppliers and make informed purchasing decisions that align with market demands.

How Is Sustainability and Ethical Sourcing Shaping the Shaker Mixer Bottle Market?

Sustainability is increasingly influencing the shaker mixer bottle sector, as consumers and businesses alike prioritize environmentally friendly practices. The production of shaker bottles often involves materials like BPA-free plastics and stainless steel, which are favored for their durability and recyclability. B2B buyers should look for suppliers who utilize sustainable manufacturing processes and materials, ensuring that their products have minimal environmental impact.

Ethical sourcing has also become paramount. Buyers should evaluate suppliers based on their commitment to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s dedication to sustainability and ethical practices. By prioritizing these factors, B2B buyers can not only enhance their brand reputation but also cater to a growing market segment that values sustainability.

What Has Been the Evolution of the Shaker Mixer Bottle Market?

The shaker mixer bottle has evolved significantly from its inception, initially serving a niche market primarily focused on fitness enthusiasts. Early designs were simple, often consisting of basic plastic bottles with a mixing ball. However, as the health and wellness trend gained momentum, the market began to diversify. Innovative features such as leak-proof designs, insulated materials, and electric mixing capabilities emerged, catering to a broader audience.

Today, the shaker mixer bottle market represents a fusion of functionality and design, appealing to both performance-oriented users and style-conscious consumers. This evolution not only reflects changing consumer preferences but also highlights the importance of adapting to market dynamics, making it essential for B2B buyers to stay informed about the latest trends and innovations in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of shaker mixer bottle

-

How do I choose the right shaker mixer bottle for my business needs?

Choosing the right shaker mixer bottle involves assessing your target market’s preferences, such as size, material, and design. Consider whether your customers prefer plastic, stainless steel, or insulated options. Evaluate the features that are important to them, such as leak-proof designs, ease of cleaning, and mixing efficiency. Additionally, analyze your competitors to determine popular models and price points in your region. Request samples from suppliers to ensure the quality meets your standards before making bulk purchases. -

What is the best material for shaker mixer bottles?

The best material for shaker mixer bottles largely depends on your target audience. Tritan plastic is lightweight, durable, and often BPA-free, making it suitable for fitness enthusiasts. Stainless steel offers superior insulation and durability, appealing to those seeking premium products. For eco-conscious consumers, consider biodegradable materials. Understanding the preferences of your customer base can help you select the most appropriate materials, ensuring product satisfaction and repeat purchases. -

What are the typical minimum order quantities (MOQs) for shaker mixer bottles?

Minimum order quantities (MOQs) for shaker mixer bottles can vary significantly based on the manufacturer and customization options. Standard MOQs typically range from 500 to 1,000 units for generic designs, while customized bottles may require higher quantities, often between 1,500 to 5,000 units. It’s essential to discuss MOQs upfront with potential suppliers to align your order volume with their production capabilities, ensuring you can meet market demand without overcommitting financially. -

How can I ensure the quality of shaker mixer bottles before purchase?

To ensure quality, request samples from potential suppliers to evaluate the materials, durability, and overall design. Conduct thorough inspections for leaks, ease of cleaning, and mixing efficiency. Consider implementing quality assurance (QA) measures such as third-party testing for safety and performance standards. Additionally, review supplier certifications, customer feedback, and previous order histories to gauge their reliability and commitment to quality. -

What customization options are available for shaker mixer bottles?

Customization options for shaker mixer bottles include printing logos, selecting colors, and varying sizes and shapes. Some suppliers may also offer personalized designs or specific features like built-in compartments for supplements. Discuss your branding goals and target audience preferences with suppliers to explore all available options. Keep in mind that custom designs may impact MOQs and lead times, so plan your product development timeline accordingly. -

What payment terms should I expect when sourcing shaker mixer bottles?

Payment terms can vary by supplier but typically include options such as a deposit (usually 30% to 50%) upon order confirmation and the balance before shipment. Some suppliers may offer payment through letters of credit or escrow services for larger orders. It’s crucial to negotiate favorable terms that protect your interests while ensuring the supplier’s confidence in fulfilling the order. Always verify the supplier’s payment policies and any additional fees that may apply. -

How can I manage logistics and shipping for shaker mixer bottles?

Managing logistics involves coordinating with suppliers to understand their shipping capabilities and timelines. Choose between air freight for quicker delivery or sea freight for cost-effective bulk shipping, considering the distance and urgency. Collaborate with a logistics provider experienced in international shipping to navigate customs regulations and duties. Ensure that all shipping documentation is in order to avoid delays and additional costs, keeping your supply chain efficient and responsive. -

What are the key trends in shaker mixer bottles that I should consider?

Stay informed about current trends such as eco-friendly materials, multifunctional designs, and smart technology integration in shaker mixer bottles. Consumers are increasingly seeking sustainable options, so consider incorporating biodegradable or recyclable materials. Additionally, innovative features like built-in blenders or app connectivity for tracking hydration can attract tech-savvy customers. Monitoring industry trends through market research and trade shows can help you stay competitive and meet evolving consumer demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Shaker Mixer Bottle Manufacturers & Suppliers List

1. ShakeSphere – Tumbler Original (700ml)

Domain: shakesphere.com

Registered: 2003 (22 years)

Introduction: Best Protein Shaker Bottles & Shaker Cups from ShakeSphere USA. Key products include: 1. Tumbler Original (700ml) – Rose Gold/White Logo – $19.99 2. Hydration Jug (2.2L) – Matte Black/Black Logo – $20.00 3. Steel Shaker ShakeSphere Tumbler Cooler – Matte Black – $50.00 4. Protein Shaker Bottle (24.6 Fl Oz) – Double Wall Steel Mirrored Silver – $70.00. Features include capsule shape mixing with no …

2. PROMiXX – Electric Shaker Bottles

Domain: promixx.com

Registered: 2012 (13 years)

Introduction: Electric Shaker Bottles by PROMiXX are designed for effortless performance and precision mixing. Key features include:

– Smooth shakes guaranteed

– Leak-proof design

– USB-C rechargeable

– Two powerful models available: PROMiXX PRO and PRO Stainless Steel

– Built with premium materials that resist stains and odors

– Genuine leakproof confidence with a secure lid

– Whisper-quiet mixing technology (…

3. Helimix – Innovative Protein Shaker Bottles

Domain: helimix.com

Registered: 2016 (9 years)

Introduction: Helimix offers innovative protein shaker bottles, including the Helimix Original, Helimix Monochrome, and Signature Series. The Monochrome Series features a variety of colors such as Black, Graphite, Cement Gray, White, Quicksand, Espresso, Evergreen, OD Green, Neon Green, Mint, Island Paradise, Slate Blue, Midnight Blue, Purple, Lilac, Bubblegum Pink, Yarrow Red, 140 Burgundy, Citrus Orange, and …

4. Contigo – Fit Shake & Go 2.0 Shaker Bottle

Domain: gocontigo.com

Registered: 2005 (20 years)

Introduction: Product Name: Contigo Fit Shake & Go 2.0 Shaker Bottle, 20 fl oz

Customer Rating: 4.8 out of 5 (33 reviews)

Price: $7.49

Key Features:

– Leakproof lid to prevent spills while shaking and mixing

– Easy-carry carabiner handle that doubles as a clip for gym bags

– Improved agitator ball for better mixing and rounded bottom to avoid clumps

– Cover flips open 180° for easy use while multitasking

– Fits…

Strategic Sourcing Conclusion and Outlook for shaker mixer bottle

In the ever-evolving market for shaker mixer bottles, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality, innovation, and sustainability, companies can leverage the diverse offerings from leading manufacturers to meet the unique demands of their clientele. The variety in materials—from stainless steel to BPA-free plastics—coupled with innovative designs, such as leak-proof features and electric mixing technology, enhances product appeal and functionality.

Investing in high-quality shaker bottles not only elevates brand reputation but also fosters customer loyalty. As global health and fitness trends continue to rise, the demand for efficient and stylish shaker solutions is set to grow, especially in emerging markets across Africa, South America, the Middle East, and Europe.

B2B buyers should consider developing long-term partnerships with reliable suppliers that can ensure consistent quality and timely delivery. As we look to the future, embracing these strategic sourcing principles will empower businesses to capitalize on market opportunities and drive sustainable growth. Engage with suppliers today to secure your competitive edge in this dynamic industry.