Introduction: Navigating the Global Market for branded metal water bottles

As the demand for sustainable and stylish promotional products continues to rise, sourcing branded metal water bottles has emerged as a strategic challenge for international B2B buyers. These versatile drinkware options not only serve as effective marketing tools but also align with eco-conscious consumer trends, making them essential for businesses looking to enhance their brand visibility. However, navigating the global market involves understanding various factors such as product types, customization options, supplier reliability, and cost management.

This comprehensive guide delves into the multifaceted world of branded metal water bottles, offering insights into different materials, capacities, and designs suitable for diverse markets. From stainless steel to aluminum options, each type of bottle presents unique benefits tailored to specific branding needs. Furthermore, we provide actionable strategies for vetting suppliers, ensuring product quality, and negotiating favorable pricing—all critical for making informed purchasing decisions.

With a targeted focus on B2B buyers from Africa, South America, the Middle East, and Europe, including regions like Vietnam and Germany, this guide empowers stakeholders to confidently navigate the complexities of sourcing. By equipping you with the necessary knowledge and tools, we aim to streamline your procurement process and enhance your brand’s promotional efforts, ultimately leading to successful business outcomes.

Article Navigation

- Top 7 Branded Metal Water Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for branded metal water bottles

- Understanding branded metal water bottles Types and Variations

- Key Industrial Applications of branded metal water bottles

- 3 Common User Pain Points for ‘branded metal water bottles’ & Their Solutions

- Strategic Material Selection Guide for branded metal water bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for branded metal water bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘branded metal water bottles’

- Comprehensive Cost and Pricing Analysis for branded metal water bottles Sourcing

- Alternatives Analysis: Comparing branded metal water bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for branded metal water bottles

- Navigating Market Dynamics and Sourcing Trends in the branded metal water bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of branded metal water bottles

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for branded metal water bottles

Understanding branded metal water bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Water Bottles | Durable, double-wall insulation, FDA compliant | Corporate gifts, promotional events | Pros: Long-lasting, premium feel. Cons: Higher cost. |

| Aluminum Water Bottles | Lightweight, often includes carabiners, eco-friendly | Sports events, outdoor promotions | Pros: Cost-effective, versatile designs. Cons: Less insulation. |

| Insulated Tumblers | Keeps beverages hot or cold for extended periods | Coffee shops, catering, corporate gifting | Pros: Excellent temperature retention. Cons: Bulkier design. |

| Recycled Metal Bottles | Made from recycled materials, eco-conscious choice | Sustainability initiatives, eco-friendly brands | Pros: Appeals to eco-conscious consumers. Cons: Limited styles. |

| Customizable Color Options | Wide range of colors and finishes available | Branding opportunities, event giveaways | Pros: Enhances brand visibility. Cons: May require higher minimum orders. |

What Are the Characteristics of Stainless Steel Water Bottles?

Stainless steel water bottles are renowned for their durability and premium appearance. They often feature double-wall insulation, which helps maintain the temperature of beverages for longer periods. These bottles are FDA compliant, making them safe for consumer use. B2B buyers often choose stainless steel options for corporate gifts and promotional events, as they convey a sense of quality and sophistication. However, buyers should consider the higher cost associated with these bottles compared to other materials.

How Do Aluminum Water Bottles Stand Out?

Aluminum water bottles are lightweight and often come with features such as carabiners for easy attachment to bags. They are typically more cost-effective, making them ideal for large events like sports competitions and outdoor promotions. While they offer versatility in design, B2B buyers should note that aluminum bottles may not provide the same level of insulation as stainless steel options.

Why Choose Insulated Tumblers for Your B2B Needs?

Insulated tumblers are designed to keep beverages hot or cold for extended periods, making them an excellent choice for coffee shops, catering services, and corporate gifting. Their bulkier design offers a premium feel, but it may not be as portable as other options. When purchasing insulated tumblers, B2B buyers should focus on their temperature retention capabilities and the potential for branding through customization.

What Are the Benefits of Recycled Metal Bottles?

Recycled metal bottles appeal to businesses focused on sustainability and eco-friendliness. Made from recycled materials, these bottles are an excellent choice for companies looking to enhance their green credentials. While they may offer limited styles compared to traditional options, the growing demand for eco-conscious products makes them an attractive choice for B2B buyers. It’s essential to consider the branding potential and consumer interest in sustainable products when selecting these bottles.

How Do Customizable Color Options Enhance Branding?

Customizable color options allow businesses to tailor metal water bottles to their specific branding needs. With a wide range of colors and finishes available, these bottles can effectively enhance brand visibility during events and promotions. However, B2B buyers should be aware that customizable options often come with higher minimum order requirements. The ability to create unique, eye-catching designs can significantly impact promotional efforts and customer engagement.

Key Industrial Applications of branded metal water bottles

| Industry/Sector | Specific Application of branded metal water bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Corporate Wellness | Employee gifts for health and wellness programs | Enhances brand image, promotes health, and increases employee satisfaction | Customization options, bulk purchasing, and eco-friendly materials |

| Hospitality and Events | Promotional giveaways at conferences and trade shows | Increases brand visibility and customer engagement | Durable materials, design flexibility, and quick turnaround times |

| Sports and Fitness | Merchandise for sports teams and fitness clubs | Builds team spirit and loyalty while providing practical use | Size options, branding capabilities, and materials for insulation |

| Education | School events and fundraising initiatives | Promotes sustainability and school spirit among students | Compliance with safety standards, customizable designs, and affordability |

| Outdoor and Adventure | Gear for outdoor events and promotional activities | Appeals to eco-conscious consumers and enhances outdoor experiences | Lightweight design, functionality, and branding opportunities |

How Can Corporate Wellness Programs Benefit from Branded Metal Water Bottles?

In the corporate sector, branded metal water bottles are increasingly utilized in wellness programs aimed at improving employee health. By gifting employees these bottles, companies not only promote hydration but also align their brand with a health-conscious lifestyle. This contributes to employee satisfaction and retention. Buyers should consider customization options that reflect the company’s branding and values, as well as ensure that the bottles meet health and safety standards.

What Role Do Branded Metal Water Bottles Play in Hospitality and Events?

In the hospitality industry, branded metal water bottles are popular promotional items at conferences and trade shows. They serve as practical giveaways that enhance brand visibility while providing attendees with a reusable option to stay hydrated. Sourcing considerations include the durability of materials, the ability to customize designs to fit event themes, and the need for quick production timelines to meet event schedules.

How Are Branded Metal Water Bottles Used in Sports and Fitness?

Sports teams and fitness clubs leverage branded metal water bottles as merchandise to foster team spirit and loyalty among fans and members. These bottles are practical items that athletes can use during training and competitions. Buyers in this sector should focus on options that offer various sizes, insulation capabilities, and high-quality branding opportunities to ensure durability and appeal.

Why Are Branded Metal Water Bottles Important for Educational Institutions?

Educational institutions often use branded metal water bottles for school events and fundraising initiatives. These bottles promote sustainability and school pride among students. When sourcing, schools should ensure compliance with safety standards, affordability for bulk orders, and the availability of customizable designs that resonate with students and parents alike.

How Do Outdoor and Adventure Companies Utilize Branded Metal Water Bottles?

Outdoor and adventure companies find branded metal water bottles essential for promotional activities and events. These bottles appeal to eco-conscious consumers and enhance the outdoor experience by providing a practical hydration solution. Key considerations when sourcing include lightweight designs that are easy to carry, functionality for various outdoor activities, and the potential for branding that stands out in nature-focused settings.

3 Common User Pain Points for ‘branded metal water bottles’ & Their Solutions

Scenario 1: Sourcing High-Quality Metal Water Bottles at Competitive Prices

The Problem: B2B buyers often struggle to find suppliers who offer high-quality branded metal water bottles at competitive prices. This issue can be particularly challenging for businesses operating in regions like Africa and South America, where access to premium materials may be limited, and shipping costs can be prohibitive. Buyers may face difficulties in assessing the quality of materials, leading to concerns about durability and customer satisfaction. Furthermore, fluctuating market prices can complicate budgeting and forecasting, causing stress for procurement teams.

The Solution: To overcome this challenge, buyers should engage in thorough market research to identify reputable suppliers who specialize in branded metal water bottles. Look for suppliers who provide detailed product specifications, including material certifications (e.g., FDA compliance for food safety) and customer reviews. Establish partnerships with manufacturers who offer transparency in their production processes and can provide samples for quality evaluation. Leveraging bulk purchasing agreements can also secure better pricing while ensuring that the quality remains consistent. Additionally, consider suppliers that offer customization options without significant price increases; this can enhance brand visibility without compromising on quality.

Scenario 2: Ensuring Timely Delivery for Promotional Events

The Problem: Another common issue B2B buyers face is the risk of delayed deliveries when ordering branded metal water bottles for promotional events or corporate gifts. Time-sensitive marketing campaigns can be jeopardized by logistical challenges, leading to dissatisfaction among clients and stakeholders. Buyers may find themselves scrambling for last-minute alternatives, which can be costly and may not align with their branding goals.

The Solution: To mitigate this risk, it is crucial for buyers to establish clear timelines with their suppliers from the outset. When placing orders, specify production timelines and confirm whether the supplier can meet these deadlines. Utilizing suppliers who offer rush production options can be beneficial for urgent needs. Additionally, implement a buffer period in planning—ordering at least two weeks in advance of the event can allow for unforeseen delays. Communication is key; maintain regular contact with the supplier to receive updates on the order status and shipping logistics. Consider diversifying your supplier base to have contingency options if one supplier cannot deliver on time.

Scenario 3: Selecting Eco-Friendly Options Without Compromising Quality

The Problem: Many B2B buyers are increasingly pressured to select eco-friendly products that align with corporate sustainability goals. However, they may worry that choosing recycled or environmentally friendly materials will compromise the quality and durability of branded metal water bottles. This concern can create a dilemma for companies that wish to promote their commitment to sustainability while also meeting customer expectations for high-quality products.

The Solution: To address this concern, buyers should seek out suppliers who offer a range of eco-friendly options, such as recycled aluminum or stainless steel bottles. Evaluate the certifications associated with these products to ensure they meet industry standards for sustainability. Conduct trials to compare the performance of eco-friendly bottles against traditional options. Educating the sales and marketing teams on the benefits of sustainable products can also enhance brand storytelling, allowing companies to effectively communicate their values to customers. By investing in eco-friendly solutions that do not sacrifice quality, businesses can align their product offerings with their sustainability goals, ultimately enhancing their brand reputation and customer loyalty.

Strategic Material Selection Guide for branded metal water bottles

What Are the Key Properties of Stainless Steel for Branded Metal Water Bottles?

Stainless steel is a popular choice for branded metal water bottles due to its excellent corrosion resistance and durability. It typically has a temperature rating that allows it to withstand high heat, making it suitable for both hot and cold beverages. The most common grades used in water bottles are 304 and 316, with 316 offering superior resistance to harsh environments, particularly in marine applications.

Pros and Cons: Stainless steel bottles are robust, long-lasting, and can be easily cleaned, which is crucial for hygiene. However, they tend to be more expensive than other materials, which can impact overall production costs. Manufacturing complexity is moderate, as stainless steel requires specialized processes like welding and polishing.

Impact on Application: Stainless steel is compatible with a wide range of beverages, including acidic drinks, which can corrode other materials. For international buyers, compliance with food safety standards (like FDA and EU regulations) is essential, particularly in regions like Europe and North America.

How Does Aluminum Compare in Terms of Performance for Branded Metal Water Bottles?

Aluminum is another widely used material for metal water bottles, known for its lightweight and malleable properties. It is typically anodized to enhance corrosion resistance and improve durability. Aluminum bottles can withstand moderate pressure but are not suitable for extremely hot liquids.

Pros and Cons: The primary advantage of aluminum is its low cost and lightweight nature, making it ideal for promotional products. However, aluminum is less durable than stainless steel and can dent or scratch easily. The manufacturing process is generally simpler and more cost-effective, allowing for mass production.

Impact on Application: Aluminum bottles are suitable for a variety of beverages but are best used with non-acidic liquids to prevent leaching. International buyers should consider the anodization process to ensure compliance with safety standards, particularly in regions with strict regulations like Germany.

What Are the Benefits of Using Recycled Materials for Branded Metal Water Bottles?

Recycled aluminum and stainless steel are increasingly popular among environmentally conscious brands. These materials maintain the same properties as their virgin counterparts but offer a lower environmental impact.

Pros and Cons: The key advantage of using recycled materials is the reduced carbon footprint and appeal to eco-conscious consumers. However, sourcing recycled materials can sometimes lead to variability in quality. The manufacturing complexity remains similar to that of new materials, but it may require additional processes to ensure quality.

Impact on Application: Recycled materials are compatible with the same beverages as their non-recycled versions. For international buyers, certifications related to recycled content can enhance brand reputation, particularly in markets like Europe, where sustainability is a significant purchasing factor.

How Do Coatings and Linings Affect the Performance of Metal Water Bottles?

Many metal water bottles are coated or lined to enhance performance. For example, epoxy or BPA-free liners can be applied to aluminum bottles to prevent leaching and improve taste.

Pros and Cons: Coatings can enhance the usability of metal bottles by providing additional protection against corrosion and improving the aesthetic appeal. However, the application of coatings can increase production costs and complicate the manufacturing process.

Impact on Application: Coated bottles can be used with a wider range of beverages, including acidic drinks. International buyers should ensure that coatings comply with local food safety regulations, as standards can vary significantly between regions.

| Material | Typical Use Case for branded metal water bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end promotional items, outdoor activities | Excellent durability and corrosion resistance | Higher cost than other materials | High |

| Aluminum | Budget-friendly promotional giveaways | Lightweight and cost-effective | Less durable, prone to dents | Low |

| Recycled Aluminum/Stainless Steel | Eco-friendly promotional products | Lower environmental impact | Potential variability in quality | Medium |

| Coated/ Lined Aluminum | Versatile beverage applications | Enhanced usability and aesthetic appeal | Increased production costs | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in branded metal water bottles. Understanding these factors will help in making informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for branded metal water bottles

What Are the Key Stages in the Manufacturing Process of Branded Metal Water Bottles?

The manufacturing process of branded metal water bottles consists of several critical stages: material preparation, forming, assembly, and finishing. Each of these stages is essential for producing high-quality products that meet international standards.

Material Preparation

The first step involves selecting the right materials, typically stainless steel or aluminum. Stainless steel, often 18/8 grade, is favored for its durability and resistance to corrosion, while aluminum is lightweight and cost-effective. Materials are sourced from reputable suppliers, ensuring compliance with safety standards, such as FDA regulations for food-grade materials. Pre-processing involves cutting the metal sheets into appropriate sizes, which may include surface treatments to enhance adhesion for coatings or paints.

Forming Techniques

Once the materials are prepared, they undergo forming techniques such as stamping, extrusion, or injection molding. For stainless steel bottles, deep drawing is a common method, where metal sheets are shaped into cylindrical forms. In the case of aluminum, extrusion techniques are often employed to create various bottle shapes. Advanced machinery, including CNC machines, ensures precision in shaping, which is crucial for maintaining consistent product quality.

Assembly Process

After forming, components such as lids, seals, and handles are assembled. This stage may involve welding or riveting to ensure that all parts are securely attached. For insulated bottles, a double-walled construction is utilized, where an inner layer is formed and then encased in an outer layer, creating a vacuum that enhances insulation. Automated assembly lines are frequently used to increase efficiency and reduce labor costs, ensuring a higher throughput.

Finishing Techniques

The finishing stage involves surface treatments such as polishing, powder coating, or anodizing. These processes not only enhance the aesthetic appeal of the bottles but also improve their resistance to scratches and corrosion. Custom branding elements, such as logos and designs, are applied using techniques like laser engraving or screen printing, which offer durability and visibility.

How is Quality Assurance Implemented in Metal Water Bottle Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process, ensuring that the final products meet both customer expectations and international standards. Various quality control measures are implemented throughout the manufacturing stages.

International Standards and Certifications

Reputable manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe, and API (American Petroleum Institute) standards for specific applications, may also apply. These certifications help in validating the manufacturer’s commitment to quality and safety.

Key Quality Control Checkpoints

Quality control is typically segmented into several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. Non-conforming materials are rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to monitor production parameters. This includes measuring dimensions, checking weld integrity, and assessing assembly accuracy. Any deviations from standards are addressed immediately to mitigate risks.

-

Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive inspection is conducted. This includes functional testing, leak testing, and visual inspections to ensure that the products are free from defects and meet all specifications.

What Testing Methods Are Commonly Used for Metal Water Bottles?

Several testing methods are employed to ensure the durability and safety of metal water bottles:

-

Pressure Testing: This method assesses the bottle’s ability to withstand internal pressure without leaking or deforming. It is particularly important for insulated bottles.

-

Drop Testing: To evaluate the product’s durability, bottles are subjected to drop tests from specified heights. This simulates real-world conditions and helps identify potential weaknesses.

-

Thermal Insulation Testing: For insulated bottles, thermal tests measure how well the bottle retains temperature over time, ensuring that it meets the advertised performance claims.

-

Chemical Testing: This involves testing for harmful substances such as BPA or heavy metals, ensuring compliance with health regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and internal quality protocols.

-

Requesting Quality Reports: Suppliers should be able to provide quality assurance documentation, including inspection reports and test results. This transparency can help build trust and ensure that the products meet required standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These inspections can be scheduled at various stages of production to ensure compliance.

What Are the Specific Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is critical. Factors such as shipping regulations, local compliance standards, and cultural expectations can impact quality assurance.

-

Regulatory Compliance: Buyers must ensure that the products comply with local regulations in their markets. This may involve additional testing or certifications that are specific to certain regions.

-

Cultural Expectations: Understanding the cultural context of your target market can influence how quality is perceived. For example, certain regions may prioritize eco-friendly materials or specific design features.

-

Logistics and Supply Chain Management: Quality can also be affected by logistics. Ensuring that products are handled properly during shipping and storage is essential to maintain product integrity.

In conclusion, a robust understanding of the manufacturing processes and quality assurance measures for branded metal water bottles is essential for B2B buyers. By prioritizing quality, conducting thorough due diligence, and understanding international standards, buyers can ensure they partner with reliable manufacturers that deliver high-quality products tailored to their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘branded metal water bottles’

This guide serves as a practical checklist for B2B buyers seeking to procure branded metal water bottles. By following these steps, you can ensure a smooth sourcing process that meets your quality, budget, and branding needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the metal water bottles you require. Consider factors such as material (stainless steel vs. aluminum), size (capacity), and insulation properties. Detailing these specifications helps suppliers understand your needs and allows you to compare products effectively.

- Material Type: Choose between stainless steel for durability or aluminum for lightweight options.

- Size and Capacity: Determine the preferred volume (e.g., 16 oz, 25 oz) based on your target market and usage scenarios.

Step 2: Identify Your Target Market

Understand who will be using these water bottles. Different markets may have varying preferences regarding style, functionality, and eco-friendliness. Knowing your target audience helps in selecting the right features and designs.

- Demographics: Consider age, lifestyle, and interests of your audience.

- Usage Context: Will these bottles be used for corporate gifts, outdoor activities, or fitness promotions?

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers. This step is crucial to ensure reliability and quality. Request company profiles, case studies, and references from similar buyers to gauge their reputation.

- Supplier Background: Investigate how long they’ve been in business and their experience in manufacturing metal water bottles.

- Quality Assurance: Ask about their quality control processes and certifications (e.g., FDA compliance).

Step 4: Request Samples

Always ask for samples before making a bulk order. Testing samples allows you to assess the quality, design, and functionality of the bottles. This step is vital to avoid costly mistakes after placing an order.

- Quality Check: Inspect the material, finishing, and any branding options.

- Functionality Test: Ensure the bottle meets your practical requirements, such as insulation and leak-proofing.

Step 5: Compare Pricing and Terms

Analyze pricing structures and payment terms from different suppliers. Pricing can vary significantly based on material, customization, and order volume. Understanding the cost breakdown helps in making an informed decision.

- Minimum Order Quantities (MOQs): Be aware of the minimum quantities required for orders.

- Delivery Terms: Check for shipping costs, lead times, and whether rush production is available.

Step 6: Verify Compliance with Regulations

Ensure that the water bottles meet local and international regulations. Compliance is essential, especially when exporting goods to different regions. Non-compliance can lead to fines or shipment delays.

- Safety Standards: Confirm that products meet safety and health regulations pertinent to your market.

- Eco-friendly Certifications: If relevant, check for certifications that highlight sustainable practices.

Step 7: Finalize Your Branding

Plan your branding strategy carefully. Decide on the logo placement, colors, and any additional messaging that will enhance brand visibility. A well-branded product can significantly impact customer perception.

- Design Mockups: Request digital mockups to visualize your branding on the bottles.

- Consider Additional Features: Think about adding custom features such as unique lids or carrying straps that enhance usability and brand appeal.

By following this checklist, B2B buyers can streamline the process of sourcing branded metal water bottles, ensuring that they meet both quality and branding standards while catering to their target markets effectively.

Comprehensive Cost and Pricing Analysis for branded metal water bottles Sourcing

When sourcing branded metal water bottles, a thorough understanding of the cost structure and pricing dynamics is essential for international B2B buyers. This analysis will delve into the various components that contribute to the overall cost, influencing factors in pricing, and actionable tips for maximizing value during procurement.

What Are the Main Cost Components in Sourcing Branded Metal Water Bottles?

Materials: The primary cost driver in metal water bottle production is the raw materials. Stainless steel and aluminum are the most common materials used, each with varying costs based on market fluctuations and quality specifications. Stainless steel generally commands a higher price due to its durability and resistance to corrosion, while aluminum offers a lightweight, cost-effective alternative.

Labor and Manufacturing Overhead: Labor costs can differ significantly by region, influencing the overall pricing. For instance, countries with lower labor costs may provide competitive pricing, though this may come with trade-offs in quality. Manufacturing overhead encompasses expenses related to facilities, utilities, and equipment maintenance, which also impact the final product cost.

Tooling and Quality Control (QC): Tooling costs are incurred during the setup of production lines for custom designs, especially for unique bottle shapes or features. Quality control is crucial, particularly for products that will bear branding. Ensuring compliance with international standards can add to costs but is essential for long-term brand reputation.

Logistics and Margin: Shipping and logistics play a significant role, especially for international buyers. Factors such as freight costs, customs duties, and insurance must be factored into the total cost. Suppliers typically include a profit margin in their pricing, which can vary based on their business model and market positioning.

How Do Price Influencers Affect the Cost of Branded Metal Water Bottles?

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Suppliers frequently set minimum order quantities that can affect pricing. Buyers should assess their needs to find a balance between quantity and cost efficiency.

Specifications and Customization: Customization options, such as unique colors, logos, or additional features (e.g., insulation), can elevate costs. Buyers should evaluate the necessity of these customizations against their marketing goals and budget constraints.

Material Quality and Certifications: Products with certifications (like FDA compliance) and higher-quality materials can command premium prices. Buyers should consider whether these certifications align with their brand values and customer expectations.

Supplier Factors and Incoterms: The choice of supplier can significantly influence pricing. Established suppliers may offer better reliability and quality assurance but at a higher cost. Understanding Incoterms is crucial, as they define the responsibilities of buyers and sellers in the shipping process, impacting logistics costs and risk.

What Tips Can Help Buyers Negotiate Better Prices for Branded Metal Water Bottles?

Negotiation Strategies: Start by researching market prices and competitors’ offerings to strengthen your negotiation position. Communicate your purchasing volume and potential for repeat business to encourage suppliers to offer better pricing.

Understanding Total Cost of Ownership (TCO): TCO goes beyond the initial purchase price and includes shipping, customs, storage, and potential future costs related to quality issues. Buyers should calculate TCO to make informed purchasing decisions.

Navigating Pricing Nuances for International Purchases: For international buyers, currency fluctuations can affect costs. It’s advisable to agree on a currency for transactions to mitigate this risk. Additionally, be aware of import duties and taxes that may apply in your region, as these can significantly alter the total cost.

Conclusion

Navigating the cost and pricing landscape for branded metal water bottles involves understanding various components and influencers. By leveraging negotiation strategies and considering the Total Cost of Ownership, B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make informed purchasing decisions that align with their business objectives. Keep in mind that the prices mentioned are indicative and can vary based on several factors, including market conditions and supplier negotiations.

Alternatives Analysis: Comparing branded metal water bottles With Other Solutions

Understanding Alternatives to Branded Metal Water Bottles

When considering branded metal water bottles for promotional purposes, it’s essential to evaluate alternative solutions that might better suit specific needs or contexts. This analysis compares branded metal water bottles with two viable alternatives: branded plastic water bottles and reusable glass water bottles. Each option has its own strengths and weaknesses, making it crucial for B2B buyers to assess which aligns best with their branding and operational goals.

| Comparison Aspect | Branded Metal Water Bottles | Branded Plastic Water Bottles | Reusable Glass Water Bottles |

|---|---|---|---|

| Performance | Durable, long-lasting, and often insulated for temperature retention. | Lightweight and easily portable, but less durable and may warp over time. | Excellent temperature retention and aesthetic appeal, but can be fragile. |

| Cost | Generally higher initial investment (e.g., starting around $2.65 for aluminum). | Lower initial cost (e.g., starting around $0.50 to $1.50). | Moderate to high cost (e.g., starting around $5.00 to $10.00). |

| Ease of Implementation | Simple to customize with logos and branding; quick turnaround times available. | Highly customizable and often quicker to produce in bulk. | Customization can be more complex due to fragility during printing. |

| Maintenance | Easy to clean and maintain; resistant to odors and stains. | May retain odors; cleaning can be less effective over time. | Requires careful handling and cleaning; prone to breakage. |

| Best Use Case | Ideal for corporate gifts, outdoor events, and long-term branding. | Suitable for large events, giveaways, and low-budget promotions. | Excellent for eco-conscious brands and high-end promotional events. |

In-Depth Look at Alternatives

Branded Plastic Water Bottles

Branded plastic water bottles are a popular choice due to their affordability and lightweight nature. They are ideal for mass distribution at events where budget constraints are a priority. However, they often lack the durability and temperature retention features of metal options. Additionally, plastic can be perceived as less environmentally friendly, which may not align with brands focusing on sustainability.

Reusable Glass Water Bottles

Reusable glass water bottles offer a premium feel and aesthetic appeal that can enhance brand image. They are excellent for brands aiming to convey a commitment to quality and sustainability. However, they come with a higher price point and require careful handling to avoid breakage. Their customization can also be more challenging, which may affect production timelines.

Making the Right Choice for Your Business Needs

Selecting the right promotional drinkware involves assessing the specific needs of your target audience and brand values. Branded metal water bottles are excellent for businesses seeking a durable and long-lasting option that reflects quality. In contrast, if budget constraints or mass distribution are primary concerns, branded plastic water bottles may be more suitable. For brands that prioritize sustainability and a premium image, reusable glass water bottles could be the best fit. Ultimately, understanding the strengths and limitations of each option will empower B2B buyers to make informed decisions that align with their branding strategies and customer expectations.

Essential Technical Properties and Trade Terminology for branded metal water bottles

What Are the Key Technical Properties of Branded Metal Water Bottles?

When selecting branded metal water bottles for promotional or corporate gifts, understanding the technical specifications is crucial. Here are some essential properties to consider:

-

Material Grade

The most common materials for metal water bottles are stainless steel and aluminum. Stainless steel, particularly grades 304 and 316, is highly durable, resistant to rust and corrosion, and maintains the temperature of liquids longer. Aluminum is lightweight and often more affordable, but it may require an inner lining to prevent leaching of flavors or chemicals. Choosing the right material affects not only the bottle’s longevity but also the perception of quality in your brand. -

Capacity

The volume of liquid a bottle can hold, typically measured in ounces or milliliters, is a key consideration. Common capacities range from 12 oz. to 40 oz. Depending on your target market, larger capacities may appeal to outdoor enthusiasts, while smaller sizes may be preferred for fitness or office use. Understanding capacity helps align product offerings with consumer needs and preferences. -

Insulation Type

Insulated bottles can keep beverages hot or cold for extended periods. Double-wall vacuum insulation is a popular choice for premium products, providing superior thermal performance. This feature is particularly appealing in markets with extreme temperatures, making it a valuable selling point for promotional items. -

FDA Compliance

Ensuring that products meet FDA regulations for food and beverage safety is essential for building trust with customers. Compliance indicates that the materials used are safe for contact with consumables, which is especially important in markets sensitive to health standards. This property not only protects consumers but also shields brands from potential legal issues. -

Imprint Area

The size and location of the area designated for branding or logos significantly impact the marketing effectiveness of the bottle. A larger imprint area allows for more visibility and creative branding opportunities. Understanding imprint specifications helps buyers maximize their promotional impact. -

Durability and Tolerance

Durability refers to the ability of the bottle to withstand everyday use, while tolerance indicates the allowable variations in manufacturing dimensions. High tolerance levels in production ensure that each bottle meets quality standards and functions properly, which is critical for maintaining brand reputation and customer satisfaction.

What Are Common Trade Terms in the Metal Water Bottle Industry?

Familiarizing yourself with industry jargon can enhance communication and streamline procurement processes. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are then branded by another company. In the context of metal water bottles, businesses may source bottles from OEMs to customize with their branding, ensuring high-quality manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially those looking to manage costs effectively while ensuring sufficient inventory levels. It can also impact negotiations regarding pricing and production timelines. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to bid on the pricing of their products or services. This is especially useful in the B2B sector for comparing offers and negotiating terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, insurance, and responsibilities for goods at different points in transit. Familiarity with these terms is essential for international buyers to avoid misunderstandings and ensure smooth transactions. -

Lead Time

Lead time is the period between placing an order and receiving the goods. In the context of branded metal water bottles, understanding lead times helps buyers plan their marketing campaigns and inventory needs efficiently. -

Sustainability Certifications

These are standards that indicate a product has been produced with environmentally friendly practices. Certifications such as recycled materials or sustainable sourcing can enhance a brand’s reputation and appeal to eco-conscious consumers.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions that align with their branding strategies and operational needs, ultimately leading to successful partnerships and enhanced market presence.

Navigating Market Dynamics and Sourcing Trends in the branded metal water bottles Sector

What Are the Key Market Dynamics and Trends in the Branded Metal Water Bottles Sector?

The branded metal water bottles market is experiencing significant growth driven by several global factors. Increased consumer awareness regarding health and environmental sustainability is pushing brands to offer high-quality, reusable bottles. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where consumers are seeking durable and eco-friendly alternatives to single-use plastics. The market is also influenced by the rise of personalization, with businesses looking to enhance their brand visibility through customized products. As a result, B2B suppliers are increasingly adopting advanced technologies such as digital printing and laser engraving, which allow for intricate designs and faster turnaround times.

In addition, e-commerce platforms are reshaping the sourcing landscape for international buyers. The convenience of online ordering and the ability to compare prices and products across multiple suppliers have made it easier for businesses to procure branded metal water bottles. Furthermore, the demand for innovative features—such as double-wall insulation, built-in straws, and multifunctional designs—continues to drive product development. Companies are also leveraging data analytics to predict trends and optimize inventory management, ensuring that they meet the evolving preferences of their clientele.

How Is Sustainability Influencing Sourcing Decisions in the Branded Metal Water Bottles Sector?

Sustainability has become a pivotal aspect of sourcing decisions in the branded metal water bottles market. As consumers and businesses alike prioritize environmental responsibility, the demand for eco-friendly materials is on the rise. Suppliers are increasingly offering products made from recycled aluminum and stainless steel, which not only reduce waste but also appeal to the environmentally-conscious consumer. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 are gaining importance, as they signal a commitment to sustainable practices.

Moreover, ethical sourcing is becoming a critical factor for B2B buyers. Companies are scrutinizing their supply chains to ensure that their products are sourced responsibly, minimizing the environmental impact and ensuring fair labor practices. This shift towards transparency is prompting manufacturers to adopt more sustainable practices, such as reducing carbon emissions during production and utilizing renewable energy sources. As a result, buyers can not only enhance their brand image by aligning with sustainable products but also potentially benefit from long-term cost savings associated with eco-friendly materials.

What Is the Historical Context of the Branded Metal Water Bottles Market?

The evolution of the branded metal water bottles market can be traced back to the early 2000s when health and fitness trends began to gain traction. Initially, the focus was primarily on functionality and durability, with stainless steel bottles emerging as a popular alternative to plastic. However, as environmental concerns became more prominent, the market shifted towards sustainable solutions. The introduction of customizable branding options further propelled growth, allowing businesses to leverage promotional products as a marketing tool. Today, the sector is characterized by a diverse range of designs and features, catering to the specific needs of consumers while emphasizing sustainability and ethical sourcing. This historical context underscores the ongoing transformation within the industry, driven by changing consumer preferences and global environmental challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of branded metal water bottles

-

1. How do I choose the right supplier for branded metal water bottles?

Selecting the right supplier involves several key considerations. First, assess their reputation by checking reviews, testimonials, and case studies from previous clients. Ensure they have experience in international trade, particularly in your target regions such as Africa, South America, the Middle East, and Europe. Request samples to evaluate product quality, and inquire about their production capacity, lead times, and compliance with relevant safety standards. Establish clear communication channels to facilitate effective collaboration. -

2. What customization options are available for branded metal water bottles?

Most suppliers offer a range of customization options, including various colors, sizes, and materials. You can typically add your logo or branding through techniques like screen printing or laser engraving. Some suppliers also provide options for additional features, such as double-wall insulation or unique lid designs. Be sure to discuss your specific branding needs and the minimum order quantities required for customization with your supplier. -

3. What are the minimum order quantities (MOQ) for bulk purchases?

Minimum order quantities can vary significantly between suppliers and product types. Generally, MOQs for branded metal water bottles range from 12 to 108 units, depending on the specific model and customization options. It’s crucial to confirm the MOQ with your chosen supplier as it can impact your overall budget and inventory management strategy. Some suppliers may offer flexibility on MOQs for larger orders or long-term partnerships. -

4. What payment terms should I expect when ordering from international suppliers?

Payment terms can differ based on the supplier’s policies and your negotiation. Common terms include a deposit (often 30-50%) upfront, with the balance due before shipping. Some suppliers may accept letter of credit or payment through secure platforms like PayPal. Always clarify payment methods, timelines, and potential additional costs such as shipping fees or customs duties to avoid misunderstandings. -

5. How do I ensure quality assurance for my order of metal water bottles?

Quality assurance should be a priority when sourcing metal water bottles. Request certifications that demonstrate compliance with international safety standards, such as FDA or ISO certifications. Consider implementing a quality control process, which may include pre-production samples, in-line inspections, and final product assessments. Building a strong relationship with your supplier can also enhance accountability and transparency regarding product quality. -

6. What are the logistics considerations for shipping branded metal water bottles internationally?

Logistics play a crucial role in international sourcing. Discuss with your supplier the best shipping methods, which may include air freight for speed or sea freight for cost-effectiveness. Consider the shipping lead times, customs clearance procedures, and potential tariffs or import duties applicable in your country. It’s advisable to work with a freight forwarder who can help manage the logistics and ensure compliance with local regulations. -

7. How can I evaluate the sustainability of the metal water bottles I purchase?

To assess sustainability, inquire about the materials used in the manufacturing process. Look for suppliers that offer eco-friendly options, such as recycled aluminum or stainless steel. Additionally, ask about their production practices, waste management, and any certifications related to environmental responsibility. Supporting suppliers with sustainable practices not only benefits the environment but can also enhance your brand’s reputation among eco-conscious consumers. -

8. What are the current trends in branded metal water bottles?

Current trends include the rise of eco-friendly materials, such as recycled metals and BPA-free options, reflecting growing consumer demand for sustainability. Customization continues to be popular, with businesses seeking unique designs and colors to stand out. Insulated bottles that maintain beverage temperature are also in high demand, particularly in regions with extreme climates. Staying informed about these trends can help you make more strategic purchasing decisions and align your products with market preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Branded Metal Water Bottles Manufacturers & Suppliers List

1. 4imprint – Custom Stainless Steel Water Bottles

Domain: 4imprint.com

Registered: 1998 (27 years)

Introduction: Custom stainless steel water bottles, long-lasting, upscale gift, keeps logo visible, available in various colors, multiple production times (24 hours, 2 days or less, 3 days or less), customizable imprint colors and locations, 418 products found in the category.

2. CamelBak – Customized Hydration Solutions

Domain: camelbak.com

Registered: 1996 (29 years)

Introduction: Customized Hydration: CamelBak offers a range of customizable water bottles including the Custom Thrive™ Flip Straw (32oz and 20oz) made with Tritan™ Renew, and various sizes of the Custom Thrive™ Chug bottles (25oz, 32oz, and 40oz) available in both insulated stainless steel and Tritan™ Renew. Prices range from $25.99 to $54.00. The customization options allow users to create unique designs for t…

3. Vistaprint – Quick Delivery Solutions

Domain: vistaprint.com

Registered: 1999 (26 years)

Introduction: This company, Vistaprint – Quick Delivery Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Rush Order Tees – Custom Metal Water Bottles

Domain: rushordertees.com

Registered: 2003 (22 years)

Introduction: Custom Metal Water Bottles made from stainless steel or aluminum. Available in various sizes including 25 oz., 32 oz., 40 oz., and more. Options include vacuum insulated, eco-friendly designs, and different lid types (e.g., straw lid, flex cap). Minimum order quantities vary by product, with some items having no minimums. Free shipping included with every order. Customization options available thr…

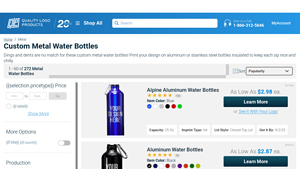

5. Quality Logo Products – Custom Insulated Metal Water Bottles

Domain: qualitylogoproducts.com

Registered: 2003 (22 years)

Introduction: Custom metal water bottles available in aluminum or stainless steel. Insulated to keep drinks cold. Various types include BPA-Free, Vacuum Insulated, Shaker Bottles, and Eco-Friendly options. Prices start as low as $2.44 each. Capacity ranges from 17 Oz to 40 Oz. Multiple lid styles available including Closed-Top, Flip-Top, and Flip-Straw. Most products have high customer ratings (4.5 to 5 stars)….

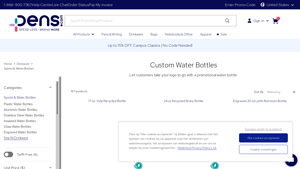

6. Pens – Custom Water Bottles

Domain: pens.com

Registered: 1995 (30 years)

Introduction: Custom water bottles available in various materials including plastic, stainless steel, aluminum, glass, and insulated options. Prices range from $0.67 to $69.99. Capacity options include 6 to 10 oz, 10 to 15 oz, 15 to 20 oz, 20 to 25 oz, 25 to 40 oz, and 40+ oz. Available colors include beige, black, blue, brown, clear, dark blue, gray, green, light blue, light green, orange, pink, purple, red, r…

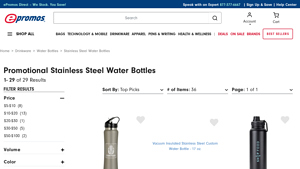

7. ePromos – Branded Stainless Steel & Metal Water Bottles

Domain: epromos.com

Registered: 1998 (27 years)

Introduction: Branded Stainless Steel & Metal Water Bottles available at ePromos. Price range: $5-$100. Volume options: 15-20 oz, 20-25 oz, 25-36 oz, over 36 oz. Color options include Wood, White, Red, Purple, Orange/Peach, Multicolor, Metallics, Maroon/Burgundy, Green, Gray, Blue, and Black. Ready to ship options available in 1 day or sooner. Minimum order quantities range from 20 to 100 or less. Materials inc…

Strategic Sourcing Conclusion and Outlook for branded metal water bottles

How Can Strategic Sourcing Enhance Your Branded Metal Water Bottle Procurement?

In the rapidly evolving market for branded metal water bottles, strategic sourcing emerges as a critical factor for international B2B buyers. The diverse range of options—from stainless steel to aluminum—provides opportunities to align product offerings with brand values and consumer preferences. Key takeaways emphasize the importance of selecting suppliers who not only meet quality and compliance standards but also offer competitive pricing and flexibility in production times.

Investing in quality branded metal water bottles can significantly enhance brand visibility and customer loyalty, especially as sustainability becomes a priority for consumers worldwide. The availability of eco-friendly materials, such as recycled aluminum, allows businesses to demonstrate their commitment to environmental responsibility, which resonates particularly well in markets across Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for innovative and customizable water bottles is likely to grow. By leveraging strategic sourcing practices, businesses can position themselves to capitalize on these trends. Now is the time to engage with reliable suppliers and explore new possibilities in your procurement strategies to ensure your brand remains competitive in this dynamic landscape.