Introduction: Navigating the Global Market for 1 gallon of water bottle

In today’s global market, sourcing a reliable supply of 1-gallon water bottles presents a significant challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With varying consumer preferences and regulatory standards, navigating the complexities of product selection, supplier vetting, and pricing structures is crucial for ensuring successful procurement. This comprehensive guide delves into the various types of 1-gallon water bottles available, including options that cater to both hydration and convenience, as well as applications across multiple industries such as food service, fitness, and event management.

Throughout this guide, international buyers will gain insights into effective supplier evaluation techniques, cost analysis, and logistical considerations tailored to their specific markets. By addressing key factors such as quality assurance, sustainability, and market trends, this resource empowers decision-makers to make informed purchasing choices that align with their operational goals. Whether you are a distributor seeking to expand your product line or a retailer aiming to meet consumer demand, understanding the nuances of the 1-gallon water bottle market is essential for fostering long-term success and customer satisfaction.

Article Navigation

- Top 6 1 Gallon Of Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 1 gallon of water bottle

- Understanding 1 gallon of water bottle Types and Variations

- Key Industrial Applications of 1 gallon of water bottle

- 3 Common User Pain Points for ‘1 gallon of water bottle’ & Their Solutions

- Strategic Material Selection Guide for 1 gallon of water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 1 gallon of water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 gallon of water bottle’

- Comprehensive Cost and Pricing Analysis for 1 gallon of water bottle Sourcing

- Alternatives Analysis: Comparing 1 gallon of water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 1 gallon of water bottle

- Navigating Market Dynamics and Sourcing Trends in the 1 gallon of water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 1 gallon of water bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for 1 gallon of water bottle

Understanding 1 gallon of water bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Bottles | Lightweight, cost-effective, often single-use | Events, catering, outdoor activities | Pros: Low cost, easy to transport. Cons: Environmental concerns, limited reusability. |

| Glass Bottles | Durable, non-reactive, premium appearance | Corporate gifting, high-end events | Pros: Eco-friendly, preserves taste. Cons: Heavier, risk of breakage. |

| Stainless Steel Bottles | Insulated, durable, often with multiple lid options | Fitness, outdoor activities, corporate use | Pros: Long-lasting, keeps beverages cold. Cons: Higher cost, heavier than plastic. |

| Motivational Water Bottles | Time markers for hydration tracking, often BPA-free | Health and wellness programs, gyms | Pros: Encourages hydration, visually appealing. Cons: May not be suitable for all environments. |

| Reusable Jugs | Large capacity, often designed for home or office use | Office hydration stations, home use | Pros: Cost-effective for bulk use. Cons: Bulky, may require regular cleaning. |

What Are the Characteristics of Plastic Bottles for B2B Use?

Plastic water bottles are widely recognized for their lightweight nature and cost-effectiveness, making them ideal for events, catering, and outdoor activities. Typically made from PET or HDPE, these bottles are often single-use, which raises environmental concerns. B2B buyers should consider the trade-off between affordability and sustainability, especially as more companies are moving towards eco-friendly practices. When purchasing, it’s crucial to evaluate the supplier’s recycling policies and the availability of refillable options.

How Do Glass Bottles Stand Out in the Market?

Glass bottles are known for their durability and non-reactive properties, which make them suitable for high-end events and corporate gifting. They maintain the integrity of the liquid inside, preserving taste and quality. While they offer a premium appearance, glass bottles are heavier and more prone to breakage, which can be a consideration for logistics and transportation. B2B buyers should assess the balance between aesthetic appeal and practicality, especially for events where presentation matters.

What Advantages Do Stainless Steel Bottles Offer for Businesses?

Stainless steel bottles are highly regarded for their insulation capabilities, keeping liquids cold or hot for extended periods. They often come with multiple lid options, enhancing usability for various activities like fitness and outdoor adventures. While they represent a higher investment upfront, their durability and reusability can lead to long-term savings. B2B buyers should focus on the quality of materials and insulation performance when selecting stainless steel options, as these factors significantly impact user satisfaction.

Why Are Motivational Water Bottles Gaining Popularity?

Motivational water bottles, featuring time markers for tracking hydration, are increasingly popular among health and wellness programs, particularly in gyms and corporate wellness initiatives. These bottles encourage users to meet their hydration goals, making them visually appealing and functional. While they promote healthy habits, businesses should consider whether these bottles align with their brand image and target audience. Additionally, assessing the quality of materials used is essential to ensure safety and durability.

What Should Businesses Know About Reusable Jugs?

Reusable jugs are designed for larger capacities, making them ideal for office hydration stations or home use. They offer a cost-effective solution for bulk water needs, reducing the frequency of purchases. However, their size can be cumbersome, and they may require regular cleaning to maintain hygiene. B2B buyers should evaluate the ease of use, cleaning requirements, and compatibility with existing hydration systems when considering reusable jugs for their operations.

Key Industrial Applications of 1 gallon of water bottle

| Industry/Sector | Specific Application of 1 gallon of water bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Beverage Distribution for Events and Catering | Provides a convenient hydration solution for large gatherings, ensuring guests stay hydrated. | Ensure bottles are FDA-approved and sourced from reliable suppliers to meet safety standards. |

| Healthcare | Patient Hydration in Hospitals and Clinics | Facilitates easy access to hydration for patients, contributing to better health outcomes. | Consider sourcing BPA-free materials and easy-to-clean designs for hygiene. |

| Construction and Field Services | On-Site Hydration for Workers | Ensures worker safety and productivity by preventing dehydration in demanding environments. | Look for robust and durable bottles that can withstand rough conditions. |

| Sports and Recreation | Hydration for Athletic Events and Training Sessions | Supports athletes in maintaining hydration levels, enhancing performance and recovery. | Evaluate bottles for portability and ease of use, especially for outdoor activities. |

| Education and Institutions | Water Supply for Schools and Universities | Encourages hydration among students, promoting health and well-being. | Focus on bulk purchasing options to ensure consistent supply and cost-effectiveness. |

How is the 1 Gallon Water Bottle Used in the Food and Beverage Industry?

In the food and beverage sector, 1-gallon water bottles serve as a practical solution for hydration at events and catering services. They are ideal for large gatherings, providing easy access to water for guests while minimizing waste associated with single-use bottles. International buyers should prioritize sourcing bottles that are FDA-approved and made from safe materials to comply with health regulations in their respective countries.

What Role Does the 1 Gallon Water Bottle Play in Healthcare Settings?

In healthcare environments, 1-gallon water bottles are essential for patient hydration, especially in hospitals and clinics. They facilitate easy access to water, which is crucial for patient recovery and overall well-being. Buyers in this sector must focus on sourcing BPA-free bottles that are easy to clean and sterilize, ensuring hygiene standards are met to prevent any risk of contamination.

Why are 1 Gallon Water Bottles Important in Construction and Field Services?

For construction sites and field services, providing workers with 1-gallon water bottles is vital for maintaining hydration, particularly in high-temperature conditions. These bottles help prevent dehydration, which can lead to heat-related illnesses, thereby enhancing worker safety and productivity. Buyers should seek durable and rugged designs that can withstand harsh environments and are easy to transport.

How Do 1 Gallon Water Bottles Benefit Sports and Recreation?

In the sports and recreation sector, 1-gallon water bottles are indispensable for athletes during training and events. They ensure that athletes remain hydrated, which is key to optimizing performance and speeding up recovery. When sourcing these bottles, it is important to consider their portability and ease of use, especially for outdoor activities where accessibility may be limited.

What is the Significance of 1 Gallon Water Bottles in Educational Institutions?

Educational institutions, including schools and universities, can greatly benefit from using 1-gallon water bottles to encourage hydration among students. By providing easy access to water, these institutions promote health and well-being, helping students focus better on their studies. Buyers should consider bulk purchasing options to ensure a consistent supply, making it a cost-effective solution for long-term hydration needs.

3 Common User Pain Points for ‘1 gallon of water bottle’ & Their Solutions

Scenario 1: Difficulty in Maintaining Water Quality During Transportation

The Problem: B2B buyers, especially in regions with extreme climates, face significant challenges in ensuring the quality of water in 1-gallon bottles during transportation. The risk of contamination or temperature fluctuation can lead to reduced product quality, negatively affecting customer satisfaction and trust. For companies distributing bottled water, maintaining the integrity of the product is paramount, as compromised water quality can lead to health concerns and legal liabilities.

The Solution: To mitigate these issues, buyers should prioritize sourcing insulated and UV-protected bottles designed for transportation. Companies like Coolflask or Simple Modern offer stainless steel options that are not only durable but also help maintain water temperature, thereby preventing bacterial growth. Additionally, buyers should consider implementing temperature control measures during shipping and storage, such as using refrigerated trucks or insulated containers. Regular quality checks and adherence to FDA standards will ensure that the water remains safe for consumption, bolstering brand reputation and customer trust.

Scenario 2: Managing Inventory and Cost Effectively

The Problem: B2B buyers often struggle with managing inventory levels of 1-gallon water bottles, leading to overstock or stockouts. This issue can be exacerbated by fluctuating demand, seasonal variations, and unpredictable market conditions. Excess inventory can result in increased storage costs and potential waste if products expire, while stockouts can lead to lost sales opportunities and dissatisfied customers.

The Solution: To address inventory management challenges, buyers should adopt a just-in-time (JIT) inventory system that aligns purchases closely with demand forecasts. Utilizing inventory management software can enhance visibility into stock levels and automate reordering processes. Additionally, establishing partnerships with reliable suppliers who can provide flexible ordering options will allow companies to adapt quickly to market changes. By regularly analyzing sales data and customer trends, businesses can optimize their inventory levels, ensuring that they have the right amount of product on hand without incurring unnecessary costs.

Scenario 3: Environmental Concerns and Sustainability Issues

The Problem: As global awareness of environmental issues increases, B2B buyers face pressure to adopt sustainable practices in their operations, including the use of 1-gallon water bottles. Many buyers are concerned about the environmental impact of single-use plastics and seek alternatives that align with their sustainability goals. Failure to address these concerns can lead to reputational damage and loss of business, particularly among eco-conscious consumers.

The Solution: To meet sustainability demands, B2B buyers should consider sourcing reusable 1-gallon bottles made from eco-friendly materials such as stainless steel or BPA-free plastics. These products not only reduce the reliance on single-use bottles but also appeal to environmentally conscious customers. Implementing a bottle return program can further enhance sustainability efforts by encouraging customers to return their bottles for reuse or recycling. Additionally, communicating the environmental benefits of using sustainable water bottles in marketing materials can position the brand as a leader in eco-friendly practices, attracting more customers and enhancing brand loyalty.

Strategic Material Selection Guide for 1 gallon of water bottle

What Are the Most Common Materials Used for 1 Gallon Water Bottles?

When selecting materials for 1-gallon water bottles, several options stand out, each with unique properties and implications for performance, cost, and suitability for international markets. Below, we analyze four common materials: plastic (PET), glass, stainless steel, and aluminum.

How Does Plastic (PET) Perform in 1 Gallon Water Bottles?

Polyethylene Terephthalate (PET) is a popular choice for water bottles due to its lightweight and shatter-resistant properties. It can withstand moderate pressure and is resistant to moisture and corrosion, making it suitable for holding water. However, PET bottles are not designed for high-temperature applications, as they may deform or leach chemicals if exposed to heat.

Pros: PET is cost-effective and widely available, making it an economical choice for mass production. It is also recyclable, which aligns with growing environmental concerns.

Cons: While durable, PET can become brittle over time, especially when exposed to UV light. Additionally, it has a lower temperature resistance compared to other materials, limiting its use in hot climates.

Impact on Application: PET is compatible with water and other non-acidic beverages, but buyers should be aware of its limitations regarding temperature stability.

Considerations for International Buyers: Compliance with international standards such as FDA and EU regulations is crucial. Buyers from regions like Africa and South America should also consider local recycling capabilities and consumer preferences for sustainable products.

What Are the Advantages of Using Glass for Water Bottles?

Glass is another option for 1-gallon water bottles, known for its excellent chemical resistance and ability to maintain the purity of water. Glass bottles can withstand high temperatures, making them suitable for hot beverages as well.

Pros: Glass is non-reactive and does not leach chemicals, ensuring the quality of the water remains intact. Its durability against chemical corrosion makes it ideal for long-term use.

Cons: The primary drawback is its weight and fragility. Glass bottles are heavier than their plastic counterparts and can break easily if dropped, which may not be practical for all consumers.

Impact on Application: Glass is suitable for both water and acidic beverages, but its weight and fragility may limit its use in certain markets, particularly in regions with less developed infrastructure.

Considerations for International Buyers: Compliance with safety standards is essential, especially in countries with strict regulations regarding food and beverage packaging. Buyers should also assess local market preferences for glass versus plastic.

Why Choose Stainless Steel for 1 Gallon Water Bottles?

Stainless steel is increasingly popular for water bottles due to its durability and excellent insulation properties. It can maintain the temperature of liquids, keeping water cool in hot climates.

Pros: Stainless steel is resistant to corrosion and can withstand high pressures, making it suitable for various applications. It is also reusable and recyclable, appealing to environmentally conscious consumers.

Cons: The manufacturing process for stainless steel is more complex and costly than for plastic, which can raise the price point of the final product. Additionally, stainless steel bottles are heavier than plastic alternatives.

Impact on Application: Stainless steel is compatible with a wide range of liquids, including hot beverages, and is ideal for outdoor activities where durability is essential.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for materials and manufacturing processes. The higher cost may be a consideration for markets sensitive to price.

What Are the Benefits of Aluminum in Water Bottles?

Aluminum is lightweight and offers good corrosion resistance, making it a viable option for 1-gallon water bottles. It can be coated to enhance its performance and prevent leaching.

Pros: Aluminum bottles are lightweight and can be manufactured in various shapes and sizes. They are also recyclable, appealing to environmentally conscious consumers.

Cons: Aluminum can dent easily and may not be as durable as stainless steel. Additionally, if not properly coated, it may react with acidic beverages.

Impact on Application: Aluminum is suitable for water and non-acidic beverages, but buyers should consider the potential for leaching if the coating is compromised.

Considerations for International Buyers: Compliance with food safety standards is essential, particularly in regions with stringent regulations. Buyers should also be aware of local recycling capabilities for aluminum products.

Summary Table of Material Selection for 1 Gallon Water Bottles

| Material | Typical Use Case for 1 Gallon Water Bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic (PET) | Everyday hydration | Lightweight and cost-effective | Limited temperature resistance | Low |

| Glass | High-quality water storage | Non-reactive and maintains purity | Heavy and fragile | Medium |

| Stainless Steel | Durable outdoor use | Excellent insulation and corrosion resistance | Higher cost and weight | High |

| Aluminum | Lightweight hydration | Lightweight and recyclable | Can dent easily and may require coating | Medium |

This analysis provides B2B buyers with actionable insights into material selection for 1-gallon water bottles, helping them make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 1 gallon of water bottle

What Are the Main Stages in the Manufacturing Process of a 1 Gallon Water Bottle?

The manufacturing of a 1-gallon water bottle involves several key stages that ensure the final product is both functional and safe for consumer use. Understanding these stages is crucial for B2B buyers looking to source high-quality water bottles.

Material Preparation: What Types of Materials Are Used?

The primary materials used in the production of 1-gallon water bottles are high-density polyethylene (HDPE) and polyethylene terephthalate (PET). HDPE is favored for its durability and resistance to impact, making it ideal for reusable bottles. In contrast, PET is often used for single-use bottles due to its lightweight and recyclable properties.

Before production begins, raw materials undergo rigorous quality checks to ensure they meet industry standards. Suppliers typically request material safety data sheets (MSDS) to verify compliance with local and international regulations.

How Are Water Bottles Formed During Production?

The forming stage involves several techniques, including blow molding and injection molding. In blow molding, pre-formed plastic is heated and then inflated within a mold to take the shape of the bottle. This method is efficient and allows for mass production. Injection molding, on the other hand, involves injecting molten plastic into a mold, which is suitable for creating specific bottle components such as caps.

Both methods require precise temperature control and timing to ensure the integrity of the bottles. B2B buyers should look for suppliers that use advanced machinery capable of maintaining these conditions, as this can significantly affect the final product quality.

What Happens During the Assembly and Finishing Stages?

After forming, the bottles undergo assembly, where components like caps and labels are attached. The finishing stage involves additional processes such as trimming excess plastic and applying surface treatments to enhance aesthetics and functionality. For instance, some bottles may receive a UV coating to protect against sun damage or a non-slip surface treatment.

Attention to detail during these stages can impact the bottle’s usability and durability. Buyers should inquire about the assembly techniques used and any additional quality checks that occur during this process.

What Quality Assurance Practices Are Essential in the Water Bottle Industry?

Quality assurance (QA) is a critical aspect of the manufacturing process for 1-gallon water bottles, ensuring that products meet the necessary standards for safety and performance. Various international and industry-specific standards govern these practices.

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is a widely recognized international standard that outlines requirements for quality management systems. Adherence to this standard demonstrates a supplier’s commitment to continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the intended use of the water bottles.

For B2B buyers, verifying these certifications is crucial to ensuring product reliability, particularly when sourcing from international suppliers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): This initial stage checks raw materials for compliance with specifications. It is vital to prevent defective materials from entering the production line.

-

In-Process Quality Control (IPQC): Conducted during production, IPQC involves monitoring processes to identify and rectify issues in real-time. This can include checking temperature and pressure settings during molding.

-

Final Quality Control (FQC): At this stage, finished bottles undergo rigorous testing to ensure they meet safety and quality standards. Tests may include checking for leaks, strength, and clarity.

B2B buyers should ask suppliers about their QC protocols and the frequency of these checks to ensure consistent product quality.

What Common Testing Methods Are Used for 1 Gallon Water Bottles?

Testing methods for 1-gallon water bottles are essential to verify compliance with safety and quality standards. Common methods include:

-

Leak Testing: Ensures that the bottles do not leak under normal use conditions.

-

Drop Testing: Assesses the durability of the bottle by simulating drops from various heights.

-

Chemical Resistance Testing: Determines how the bottle material reacts to various substances, ensuring it is safe for storing water.

-

Thermal Testing: Evaluates how well the bottles can withstand temperature variations, particularly for insulated options.

By understanding these testing methods, B2B buyers can better assess the reliability of their suppliers.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure they receive high-quality products. There are several ways to do this:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment and QC practices firsthand. This can include reviewing records of past quality issues and resolutions.

-

Quality Control Reports: Suppliers should provide regular QC reports detailing inspection results, testing outcomes, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s QC processes. These agencies typically conduct thorough assessments and can offer certification that products meet specified standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various regulatory landscapes, which can complicate the QC and certification process. For instance, European buyers may require CE certification for certain products, while buyers in Africa or South America might need to adhere to local standards that differ from international norms.

Understanding these nuances is vital for ensuring compliance and avoiding costly delays. Buyers should work closely with suppliers to ensure all necessary certifications are in place and consider consulting with local regulatory bodies if needed.

Conclusion: Why Is a Comprehensive Understanding of Manufacturing and QC Important?

A thorough understanding of the manufacturing processes and quality assurance practices for 1-gallon water bottles is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside robust QC measures and compliance with international standards, buyers can make informed decisions that ensure they source high-quality products suitable for their markets. This knowledge not only enhances purchasing confidence but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 gallon of water bottle’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure 1-gallon water bottles. With a focus on quality, supplier reliability, and market needs, this step-by-step approach will help ensure that your sourcing process is efficient and effective.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your 1-gallon water bottles is crucial. Consider factors such as material (e.g., plastic, stainless steel), insulation properties, and design features (like handles or spouts). This clarity will guide your supplier search and ensure you procure bottles that meet your operational needs.

Step 2: Research Market Trends and Pricing

Before engaging with suppliers, research current market trends and pricing for 1-gallon water bottles. Understanding what similar products are available and their price points will help you negotiate effectively and identify competitive offers. Look for trends in sustainability, such as reusable or eco-friendly options, as these can influence buyer preferences.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your standards. Request company profiles, production capabilities, and references from previous clients within your industry. It’s essential to assess their reputation for quality and reliability, as well as their ability to meet your quantity and timeline requirements.

- Check Certifications: Ensure the supplier adheres to relevant safety and quality standards, such as FDA approval for food-grade materials.

- Look for Experience: Prefer suppliers who have experience in international shipping, particularly to your target regions like Africa, South America, the Middle East, or Europe.

Step 4: Request Samples for Quality Assurance

Before finalizing your order, request samples of the 1-gallon water bottles. Testing samples will allow you to evaluate the quality, usability, and aesthetic appeal. Pay attention to how well the bottles retain temperature, if insulated, and assess the overall construction quality.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clearly outline your expectations to avoid misunderstandings later. Discuss minimum order quantities and explore possibilities for bulk discounts, which can significantly reduce costs.

Step 6: Verify Logistics and Shipping Capabilities

Confirm the supplier’s logistics capabilities to ensure timely delivery of your orders. Discuss shipping options, estimated delivery times, and costs associated with international shipping. Having a reliable logistics plan is essential for maintaining inventory levels and meeting customer demand.

Step 7: Establish Ongoing Communication and Support

After placing your order, maintain open lines of communication with your supplier. This will facilitate quick resolutions to any issues that may arise and ensure a smooth ongoing relationship. Regular check-ins can also help you stay informed about new products or changes in market conditions that may impact your sourcing strategy.

By following these steps, you can effectively navigate the sourcing process for 1-gallon water bottles, ensuring that you make informed decisions that align with your business goals.

Comprehensive Cost and Pricing Analysis for 1 gallon of water bottle Sourcing

What Are the Key Cost Components for Sourcing 1 Gallon Water Bottles?

When sourcing 1-gallon water bottles, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly impacts pricing. Common materials include BPA-free plastics or stainless steel for reusable bottles. High-quality materials may incur higher costs but can enhance durability and customer satisfaction.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. In regions with higher labor costs, such as parts of Europe, expect these expenses to reflect in the final price.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, equipment maintenance, and administrative costs. Efficient operations can help minimize these costs, benefiting the final pricing.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, especially for custom designs. These costs should be amortized over the production volume to understand their impact on unit pricing.

-

Quality Control (QC): Implementing robust quality assurance processes ensures compliance with health and safety regulations, particularly important for water bottles. However, these processes can add to the overall costs.

-

Logistics: Transportation costs, including shipping and handling, play a significant role in the total cost. Factors like distance, shipping methods, and customs duties should be considered, especially for international buyers.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary widely based on market competition and perceived value.

How Do Price Influencers Affect the Cost of 1 Gallon Water Bottles?

Several factors influence the final pricing of 1-gallon water bottles, impacting how B2B buyers should approach sourcing:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Suppliers are more willing to negotiate prices for larger orders, which can significantly reduce unit costs.

-

Specifications/Customization: Custom designs or specific features (like insulation or built-in straws) can increase costs. Buyers should balance their needs against their budget when considering customization.

-

Materials Quality/Certifications: Bottles that meet specific health and safety certifications, such as FDA approval, may come at a premium. Ensuring compliance with international standards is essential for market acceptance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge higher prices due to their perceived reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They determine who bears the costs and risks during shipping, influencing the total cost of ownership.

What Are Effective Buyer Tips for Negotiating Prices on 1 Gallon Water Bottles?

B2B buyers should adopt strategic approaches to negotiate better pricing:

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including logistics, potential storage, and disposal. A lower upfront cost might lead to higher long-term expenses.

-

Conduct Market Research: Stay informed about market trends and competitor pricing. This knowledge can empower buyers during negotiations and help them identify fair pricing.

-

Build Relationships with Suppliers: Establishing a good rapport with suppliers can lead to better deals. Long-term partnerships often yield more favorable terms and pricing.

-

Negotiate Terms: Don’t just focus on price; negotiate payment terms, delivery schedules, and warranties. Favorable terms can improve cash flow and reduce overall costs.

-

Be Aware of Pricing Nuances for International Sourcing: Different regions may have varying pricing strategies and market dynamics. For instance, sourcing from countries with lower labor costs may yield more competitive prices, but consider shipping costs and potential tariffs.

Disclaimer on Pricing Insights

The prices mentioned in this analysis are indicative and subject to change based on market dynamics, supplier negotiations, and material costs. Buyers should conduct thorough due diligence and obtain quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing 1 gallon of water bottle With Other Solutions

Exploring Alternatives to the 1 Gallon Water Bottle

In the quest for efficient hydration solutions, businesses have several alternatives to the traditional 1-gallon water bottle. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and specific use cases. Below is a comparative analysis of the 1-gallon water bottle against two viable alternatives: a water filtration system and a multi-use hydration pack.

| Comparison Aspect | 1 Gallon Of Water Bottle | Water Filtration System | Multi-Use Hydration Pack |

|---|---|---|---|

| Performance | Provides easy access to a large volume of water, suitable for groups or events. | Delivers continuous access to clean water from various sources; quality depends on the filtration technology. | Allows for on-the-go hydration, often insulated; volume varies but generally less than a gallon. |

| Cost | Approximately $8.00 per case (6 bottles). | Initial investment can range from $35 to $200, depending on technology. | Ranges from $20 to $80, depending on brand and features. |

| Ease of Implementation | Ready to use; no setup required. | Requires installation and potential maintenance; initial setup can be complex. | Simple to fill and use, but requires cleaning and occasional maintenance. |

| Maintenance | Minimal; recyclable or disposable after use. | Requires regular filter changes; maintenance can be time-consuming. | Regular cleaning needed; can be cumbersome if not maintained properly. |

| Best Use Case | Ideal for events, offices, or locations needing bulk hydration. | Best for areas with unreliable water sources or for long-term use in remote areas. | Suitable for outdoor activities, sports, and daily commuting. |

In-Depth Analysis of Alternatives

Water Filtration System

A water filtration system is an effective alternative for businesses that require consistent access to clean water. These systems can purify water from taps or natural sources, ensuring safe drinking water for employees or clients. The primary advantage is the long-term cost savings and sustainability, reducing reliance on single-use plastic. However, the upfront investment can be significant, and maintenance is necessary to ensure optimal performance. This solution is best suited for organizations located in areas with poor water quality or those looking to minimize their environmental impact.

Multi-Use Hydration Pack

Multi-use hydration packs are designed for convenience, particularly in active environments such as outdoor sports or events. These packs often feature insulation to keep water cool and are easy to carry, making them ideal for on-the-go hydration. While they are generally less expensive than a filtration system, they hold a smaller volume of water compared to a 1-gallon bottle, which may require frequent refills. Maintenance is essential, as these packs need regular cleaning to prevent bacteria buildup. They are perfect for companies that prioritize an active lifestyle among their employees or engage in outdoor events.

Making the Right Choice for Your Business Needs

When selecting the right hydration solution, B2B buyers should consider their specific needs, such as the intended use, budget constraints, and maintenance capabilities. The 1-gallon water bottle offers simplicity and bulk hydration, making it ideal for static environments like offices or events. In contrast, water filtration systems provide a sustainable long-term solution for locations with inadequate water quality, while hydration packs cater to dynamic environments where mobility and convenience are key. Evaluating these factors will ensure that businesses choose the most effective and appropriate hydration solution for their context.

Essential Technical Properties and Trade Terminology for 1 gallon of water bottle

What Are the Key Technical Properties of a 1 Gallon Water Bottle?

When considering a 1-gallon water bottle for B2B purchasing, understanding the technical specifications is crucial for ensuring product quality and compliance with industry standards. Here are some key properties to consider:

1. Material Composition

Most 1-gallon water bottles are made from materials such as high-density polyethylene (HDPE), polypropylene (PP), or stainless steel. HDPE is lightweight, durable, and resistant to impact, making it ideal for transportation. Stainless steel, on the other hand, offers superior insulation and is resistant to corrosion, which is essential for maintaining water quality. Understanding the material helps in assessing durability, safety, and environmental impact.

2. Capacity and Volume

A 1-gallon water bottle holds approximately 128 fluid ounces or 3.785 liters. This specification is essential for B2B buyers who must ensure that the product meets hydration needs for specific applications, such as outdoor events, corporate wellness programs, or institutional use. Knowing the volume also aids in inventory management and supply chain logistics.

3. BPA-Free Certification

BPA (Bisphenol A) is a chemical often found in plastics that can leach into beverages. A BPA-free certification indicates that the bottle is safe for storing drinking water, which is critical for health-conscious markets. This certification can enhance brand reputation and compliance with international health standards, especially in regions like Europe where regulations are strict.

4. Weight and Portability

The empty weight of a 1-gallon water bottle can vary significantly based on material and design. For instance, a stainless steel bottle might weigh more than a plastic one, which affects shipping costs and ease of handling. Understanding weight specifications helps in calculating shipping logistics and ensures that the product is user-friendly for end consumers.

5. Insulation Properties

For bottles designed to keep liquids hot or cold, insulation technology is vital. Bottles with double-wall vacuum insulation can maintain temperature for extended periods, making them attractive for outdoor and recreational use. This feature is especially appealing in markets with extreme temperatures, providing a competitive edge.

What Are Common Trade Terms Relevant to 1 Gallon Water Bottles?

In the B2B water bottle industry, familiarity with specific trade terminology is essential for effective communication and negotiation. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of 1-gallon water bottles, an OEM might supply the bottle design or material specifications, allowing brands to focus on marketing and distribution.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it influences purchasing decisions and inventory management. Understanding MOQ helps businesses plan their budgets and supply chain logistics effectively.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. This process is essential for comparing costs and ensuring competitive pricing when sourcing 1-gallon water bottles. Including detailed specifications in an RFQ can lead to more accurate and favorable quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Understanding Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit.

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. This is particularly important for businesses with tight schedules or specific events requiring 1-gallon water bottles. Knowing lead times helps in planning and ensures that products are available when needed.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance their supply chain efficiency when sourcing 1-gallon water bottles.

Navigating Market Dynamics and Sourcing Trends in the 1 gallon of water bottle Sector

What Are the Current Market Dynamics and Key Trends Influencing the 1 Gallon Water Bottle Sector?

The global market for 1-gallon water bottles is experiencing significant growth, driven by increasing health consciousness and the demand for hydration solutions. Emerging trends such as the rise of fitness culture, eco-friendly product demand, and the convenience of larger water containers are reshaping buyer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note the growing popularity of both reusable and single-use water bottles, as they cater to diverse consumer needs.

Technological advancements are also transforming the sourcing landscape, with smart water bottles that track hydration levels gaining traction. Companies are increasingly leveraging e-commerce platforms and digital supply chains to streamline procurement processes. Moreover, the adoption of innovative materials—like BPA-free plastics and insulated stainless steel—enhances product appeal, particularly in regions with extreme climates. For buyers in Germany or Nigeria, understanding local consumer preferences is crucial; for instance, while German consumers may prioritize sustainability, Nigerian buyers might focus on affordability and durability.

How Are Sustainability and Ethical Sourcing Influencing B2B Decisions in the 1 Gallon Water Bottle Market?

Sustainability is becoming a core consideration for B2B buyers in the 1-gallon water bottle sector. With growing awareness of environmental issues, companies are increasingly seeking suppliers who prioritize ethical sourcing and environmentally friendly production practices. The impact of plastic waste is prompting a shift towards biodegradable materials and reusable designs, which appeal to environmentally conscious consumers.

Buyers should look for suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management or certifications related to recycled content. These credentials not only enhance brand reputation but also align with global sustainability goals. Furthermore, the integration of recycled materials in production processes reduces the carbon footprint, making products more attractive to eco-conscious markets in Europe and beyond. Ethical supply chains that ensure fair labor practices are also becoming a significant differentiator, particularly for buyers in regions like South America and Africa, where social responsibility is increasingly valued.

What Is the Brief Evolution and History of the 1 Gallon Water Bottle Market?

The 1-gallon water bottle market has evolved significantly over the decades. Initially dominated by glass containers, the industry transitioned to plastic solutions in the late 20th century, driven by the need for lightweight, durable options. The introduction of BPA-free plastics in the early 2000s marked a pivotal moment, addressing health concerns associated with traditional plastic materials.

As consumer preferences shifted towards sustainability in the 2010s, manufacturers began to innovate, incorporating insulated stainless steel and reusable designs into their product lines. This evolution reflects broader societal trends towards health and environmental consciousness, paving the way for modern B2B buyers to prioritize not just functionality, but also sustainability in their procurement decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of 1 gallon of water bottle

-

How do I choose the right supplier for 1 gallon water bottles?

Selecting the right supplier involves evaluating their credentials, product quality, and customer service. Look for suppliers with certifications such as FDA approval or ISO standards, indicating compliance with safety and quality regulations. Additionally, assess their production capacity, lead times, and ability to meet your specific requirements. Request samples to evaluate product quality firsthand, and consider their responsiveness to inquiries as a measure of their customer service. -

What is the best material for 1 gallon water bottles?

The best materials for 1 gallon water bottles are typically BPA-free plastic, glass, and stainless steel. BPA-free plastic is lightweight and durable, making it ideal for shipping and storage. Glass offers a premium look and is excellent for maintaining taste but is heavier and more fragile. Stainless steel provides durability and insulation, keeping liquids cold or hot for extended periods. Consider your target market’s preferences and local regulations when choosing the material. -

What are the common minimum order quantities (MOQs) for 1 gallon water bottles?

Minimum order quantities (MOQs) can vary significantly based on the supplier and the type of bottle. Generally, MOQs for 1 gallon water bottles range from 500 to 5,000 units for wholesale orders. However, some manufacturers may offer lower MOQs for custom designs or smaller runs. It’s essential to discuss your needs with potential suppliers to negotiate an MOQ that aligns with your business requirements. -

How can I customize my 1 gallon water bottles?

Customization options for 1 gallon water bottles often include branding, color selection, and labeling. Most suppliers offer services such as screen printing or labeling to add your logo and design to the bottles. You may also have the option to choose colors and materials to align with your brand image. Discuss your customization needs upfront with suppliers to understand the available options and any associated costs. -

What payment terms should I expect when sourcing 1 gallon water bottles?

Payment terms can vary widely among suppliers but typically include options such as advance payment, partial payment before production, or payment upon delivery. Many international suppliers may request a deposit of 30-50% upfront, with the balance due before shipping. Always clarify payment methods accepted (e.g., bank transfer, credit card) and negotiate terms that protect your interests while ensuring a smooth transaction process. -

What quality assurance measures should I consider when purchasing 1 gallon water bottles?

Quality assurance measures are crucial in ensuring that the products meet your specifications and safety standards. Request documentation of the supplier’s quality control processes, including testing for contaminants and compliance with local regulations. Consider asking for third-party certifications or test results. It’s also beneficial to conduct a factory audit or inspection before placing large orders to verify production practices and quality standards. -

How do I handle logistics and shipping for 1 gallon water bottles?

Managing logistics and shipping involves coordinating with your supplier to determine the best shipping method based on your delivery timeline and budget. Options include air freight for faster delivery or sea freight for cost-effectiveness on larger orders. Ensure you understand the customs regulations in your country and any tariffs or duties that may apply. Collaborating with a freight forwarder can streamline the process and help manage documentation and compliance. -

What are the typical lead times for ordering 1 gallon water bottles?

Lead times can vary based on factors such as supplier location, order size, and production capacity. Generally, you can expect lead times ranging from 4 to 12 weeks, including production and shipping. Custom orders may require additional time for design and approval. It’s essential to communicate your desired timelines with suppliers early in the negotiation process to ensure they can meet your delivery needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 1 Gallon Of Water Bottle Manufacturers & Suppliers List

1. Diamond Rock – 1 Gallon Bottle – 6 Per Case

Domain: diamondrock.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “1 Gallon Bottle – 6 Per Case”, “price”: “$8.00 (delivery per case), $7.00 (cash & carry)”, “quantity”: “6 per case”, “type”: “Bottled Water”, “description”: “100% Natural spring Water, Government tested FDA approved.”, “security_deposit”: “$0.00”, “contact_info”: {“address”: “Diamond Rock Spring Water, 60 Railroad Avenue, Ridgefield Park, NJ 07660”, “phone”: “201.440.1112”}, “ava…

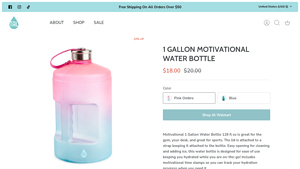

2. TAL™ Hydration – 1 Gallon Motivational Water Bottle

Domain: talhydration.com

Registered: 2016 (9 years)

Introduction: {“product_name”:”1 Gallon Motivational Water Bottle”,”brand”:”TAL™ Hydration”,”price”:”$18.00″,”original_price”:”$20.00″,”capacity”:”128 fl oz (1 Gallon)”,”colors_available”:[“Pink Ombre”,”Blue”],”features”:[“Motivational time stamps for tracking hydration progress”,”Lid attached to a strap for convenience”,”Easy opening for cleaning and adding ice”],”recommended_use”:”Great for the gym, desk, and…

3. Poland Spring® – 1 Gallon Jug Spring Water

Domain: polandspring.com

Registered: 1996 (29 years)

Introduction: Product Name: 1 Gallon Jug Spring Water

Brand: Poland Spring®

Product Size: 1 gallon (128 fl oz)

Available Sizes: 8 fl oz, 12 fl oz, 16.9 fl oz, 20 fl oz, 23.7 fl oz, 1 L, 1.5 L, 3 L, 2.5 G, 3 G, 5 G, 25 fl oz (Aluminum Bottle)

Pack Size: Single

Nutritional Information:

– Calories: 0mg

– Total Fat: 0mg

– Sodium: 0mg

– Protein: 0mg

Ingredients: Spring Water, Naturally occurring electrolyte…

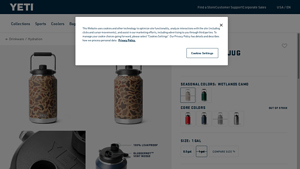

4. YETI – Rambler One Gallon Jug

Domain: yeti.com

Registered: 1995 (30 years)

Introduction: YETI Rambler Reusable One Gallon Jug

– Price: $135.00

– Size: 1 gallon

– Features: 100% leakproof, Glugger-Not™ Vent Wedge for smoother pours, Hands-free MagCap for easy pouring, Double-wall vacuum insulation to keep beverages hot or cold.

5. Durable Insulated Water Bottle – Superior Performance

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: One gallon water bottle, similar to Yeti but with better insulation, durable for drops, designed to last a lifetime, concerns about lid sticking, good insulation performance in high temperatures, some users prefer using it to refill smaller bottles rather than drinking directly from it.

6. Just Bottle – Reusable Water Solutions

Domain: justbottle.co

Registered: 2020 (5 years)

Introduction: 1 gallon is approximately 7.57 standard 16.9 oz (500 ml) water bottles. 1 gallon = 128 fluid ounces. 1 gallon = approximately 3.785 liters. Recommended daily water intake: women – 70% of a gallon, men – 1 gallon. Just Bottle offers reusable options like stainless steel bottles to reduce environmental impact.

Strategic Sourcing Conclusion and Outlook for 1 gallon of water bottle

In the evolving landscape of the bottled water industry, strategic sourcing of 1-gallon water bottles represents a significant opportunity for international B2B buyers. Understanding the diverse product offerings, from standard plastic jugs to premium insulated options, allows businesses to cater to varying consumer preferences while optimizing costs. Notably, sourcing from reliable suppliers who prioritize quality, compliance, and sustainability can enhance brand reputation and customer loyalty.

The value of strategic sourcing extends beyond mere procurement; it encompasses building partnerships that facilitate innovation and responsiveness to market trends. Buyers should focus on suppliers that offer competitive pricing, product diversity, and efficient delivery options, particularly for regions like Africa, South America, the Middle East, and Europe, where logistics and market dynamics can vary widely.

Looking ahead, as consumer demand for hydration solutions continues to rise, there is an increasing necessity for B2B buyers to adapt and align their sourcing strategies accordingly. By leveraging insights into market trends and consumer behavior, businesses can position themselves for success. Engage with trusted suppliers today to secure the best offerings and stay ahead in this competitive market.