Introduction: Navigating the Global Market for 2.5 gallon water bottle

In the ever-evolving global market, sourcing a reliable 2.5 gallon water bottle can present significant challenges for international B2B buyers. Whether you’re catering to office hydration needs or planning outdoor events in regions like Africa, South America, the Middle East, or Europe, understanding the variety of available options is crucial. This guide offers a comprehensive overview of the 2.5 gallon water bottle market, highlighting various types—including spring water, flavored options, and eco-friendly materials—as well as their diverse applications in both residential and commercial settings.

Navigating supplier vetting processes, cost considerations, and distribution logistics can be daunting. However, this guide is designed to empower you with actionable insights, helping you make informed purchasing decisions tailored to your specific market needs. By addressing key factors such as quality assurance, compliance with local regulations, and sustainability practices, we aim to equip you with the knowledge to identify trustworthy suppliers and negotiate favorable terms.

With a focus on the unique requirements of buyers from emerging markets, this guide will serve as an essential resource, ensuring that you can confidently select the best 2.5 gallon water bottles for your business needs, ultimately enhancing customer satisfaction and operational efficiency.

Article Navigation

- Top 7 2.5 Gallon Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 2.5 gallon water bottle

- Understanding 2.5 gallon water bottle Types and Variations

- Key Industrial Applications of 2.5 gallon water bottle

- 3 Common User Pain Points for ‘2.5 gallon water bottle’ & Their Solutions

- Strategic Material Selection Guide for 2.5 gallon water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 2.5 gallon water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.5 gallon water bottle’

- Comprehensive Cost and Pricing Analysis for 2.5 gallon water bottle Sourcing

- Alternatives Analysis: Comparing 2.5 gallon water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 2.5 gallon water bottle

- Navigating Market Dynamics and Sourcing Trends in the 2.5 gallon water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 2.5 gallon water bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for 2.5 gallon water bottle

Understanding 2.5 gallon water bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Water Jugs | Lightweight, cost-effective, recyclable | Offices, homes, events | Pros: Affordable, easy to transport. Cons: Less durable, potential leaching concerns. |

| Glass Water Bottles | Premium quality, maintains water purity, reusable | High-end offices, restaurants, hotels | Pros: Eco-friendly, premium branding. Cons: Heavier, higher initial cost. |

| Flavored Water Bottles | Infused with natural flavors, appealing to consumers | Cafés, vending services, retail environments | Pros: Attractive to health-conscious consumers. Cons: May have added sugars or preservatives. |

| Spring Water Bottles | Sourced from natural springs, rich in minerals | Gyms, wellness centers, outdoor events | Pros: Health benefits, natural taste. Cons: Higher cost, limited availability in some regions. |

| Reusable Water Dispensers | Designed for long-term use, compatible with coolers | Corporate offices, schools, public spaces | Pros: Cost-effective over time, eco-friendly. Cons: Requires maintenance and cleaning. |

What Are the Key Characteristics of Plastic Water Jugs?

Plastic water jugs are the most common type of 2.5-gallon water bottles used in various settings, including offices and homes. They are lightweight and generally more affordable than glass alternatives. These jugs are typically made from recyclable materials, making them an eco-friendlier option if properly disposed of. When purchasing plastic jugs, B2B buyers should consider factors such as BPA-free certification and the supplier’s recycling program to ensure safety and sustainability.

Why Choose Glass Water Bottles for High-End Applications?

Glass water bottles are ideal for businesses aiming for a premium image, such as upscale restaurants and hotels. They maintain water purity and taste better than plastic, appealing to health-conscious consumers. Moreover, glass is recyclable and reusable, making it an environmentally responsible choice. However, buyers should consider the higher costs and weight of glass bottles, which may affect shipping and handling expenses.

How Do Flavored Water Bottles Appeal to Consumers?

Flavored water bottles infuse water with natural flavors, making them a popular choice in cafés and retail environments. They can attract health-conscious consumers looking for alternatives to sugary beverages. When purchasing, B2B buyers should evaluate the ingredients and nutritional information to ensure they align with consumer preferences. However, it’s essential to consider the potential for added sugars or preservatives that may deter some customers.

What Advantages Do Spring Water Bottles Offer?

Spring water bottles are sourced from natural springs, offering a rich mineral content that can enhance taste and health benefits. They are particularly popular in gyms, wellness centers, and outdoor events where hydration is critical. B2B buyers should assess the sourcing and quality of the spring water, as well as pricing and delivery options. The main downside is that spring water can be more expensive and may have limited availability depending on the region.

Why Consider Reusable Water Dispensers?

Reusable water dispensers are designed for long-term use and are compatible with various cooler systems. They are cost-effective for businesses that require consistent hydration solutions, such as corporate offices and schools. B2B buyers should consider the maintenance and cleaning requirements associated with these dispensers to ensure longevity and hygiene. While initial costs can be higher, the long-term savings and reduced environmental impact make them an attractive choice for many organizations.

Key Industrial Applications of 2.5 gallon water bottle

| Industry/Sector | Specific Application of 2.5 Gallon Water Bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Used in restaurants and cafes for serving water. | Enhances customer experience by providing readily available hydration. | Ensure quality certifications and sourcing from reputable suppliers. |

| Corporate Offices | Installed in break rooms for employee hydration. | Promotes employee health and productivity through easy access to water. | Consider delivery logistics and bottle recycling options. |

| Healthcare Facilities | Utilized in clinics and hospitals for patient hydration. | Supports patient care and staff hydration needs effectively. | Compliance with health regulations and availability of BPA-free options. |

| Educational Institutions | Provided in schools for student hydration. | Encourages healthy habits among students and reduces waste from single-use bottles. | Assess bulk purchasing options and compatibility with dispensers. |

| Events and Outdoor Activities | Supplied at festivals, camps, and sports events. | Ensures hydration for attendees, enhancing overall experience and safety. | Evaluate transport logistics and availability in various regions. |

How is the 2.5 Gallon Water Bottle Utilized in the Food and Beverage Industry?

In restaurants and cafes, the 2.5-gallon water bottle serves as a convenient solution for providing customers with fresh water. This size is ideal for table service, allowing staff to refill glasses quickly without the need for frequent trips to a larger storage area. By ensuring a steady supply of hydration, businesses can enhance customer satisfaction and encourage longer stays. For international buyers, it is crucial to source bottles that meet local health regulations and quality standards.

What Role Does the 2.5 Gallon Water Bottle Play in Corporate Offices?

In corporate environments, 2.5-gallon water bottles are commonly placed in break rooms and meeting areas, offering employees easy access to hydration throughout the day. This practice not only promotes better health and wellness among staff but also boosts productivity by reducing downtime spent away from workstations. For B2B buyers, it’s essential to consider reliable delivery services and the sustainability of the bottles, including options for recycling.

Why is the 2.5 Gallon Water Bottle Important in Healthcare Facilities?

Healthcare facilities utilize 2.5-gallon water bottles to meet the hydration needs of patients and staff alike. The availability of clean, fresh water supports patient care, especially in settings where hydration is critical for recovery. Additionally, these bottles can be easily stored and transported within various departments. Buyers in the healthcare sector should prioritize sourcing BPA-free options and ensure compliance with relevant health regulations.

How Does the 2.5 Gallon Water Bottle Support Educational Institutions?

Schools and universities often use 2.5-gallon water bottles to promote healthy hydration habits among students. By providing easy access to water, educational institutions can reduce reliance on single-use plastic bottles, fostering a more sustainable environment. This initiative not only benefits student health but also aligns with educational goals around environmental responsibility. B2B buyers should look for bulk purchasing options to meet the needs of large populations efficiently.

In What Ways is the 2.5 Gallon Water Bottle Valuable for Events and Outdoor Activities?

At festivals, sports events, and camping trips, 2.5-gallon water bottles ensure that participants remain hydrated, which is vital for safety and enjoyment. These bottles can be stationed at various points to facilitate quick refills, reducing the risk of dehydration during high-activity periods. For international buyers, considering the logistics of transportation and local sourcing can help streamline operations and ensure the availability of water for diverse events.

3 Common User Pain Points for ‘2.5 gallon water bottle’ & Their Solutions

Scenario 1: Difficulty in Ensuring Consistent Supply of 2.5 Gallon Water Bottles

The Problem: For B2B buyers, particularly in regions like Africa and South America, the challenge of maintaining a consistent supply of 2.5-gallon water bottles can be daunting. Fluctuations in local suppliers’ inventories, logistics issues, and transportation disruptions can lead to shortages. This inconsistency not only affects hydration needs for employees or customers but can also disrupt business operations, especially in sectors like hospitality or corporate offices where water is a necessity.

The Solution: To mitigate supply chain disruptions, B2B buyers should establish relationships with multiple suppliers to diversify their sources of 2.5-gallon water bottles. Conduct thorough market research to identify reliable suppliers both locally and internationally. Implementing a just-in-time inventory system can help maintain stock levels without overcommitting resources. Additionally, consider negotiating long-term contracts with suppliers, which can include penalties for non-compliance on delivery timelines. This proactive approach ensures a steady supply, thus safeguarding business continuity.

Scenario 2: Challenges with the Environmental Impact of Water Bottles

The Problem: Increasingly, businesses are being held accountable for their environmental footprints. For B2B buyers, the use of 2.5-gallon water bottles—often made from single-use plastics—can raise concerns about sustainability. This can affect brand reputation, particularly among environmentally-conscious consumers and partners, and may lead to regulatory scrutiny in various regions.

The Solution: To address these concerns, companies should consider sourcing 2.5-gallon water bottles made from recyclable or biodegradable materials. Engage with suppliers who prioritize sustainable practices, such as using recycled plastics or offering refillable options. Implementing a bottle return program can also encourage responsible disposal and recycling. Additionally, transparently communicating your sustainability efforts to clients and stakeholders can enhance brand image and align with corporate social responsibility goals. By leading the charge in sustainable practices, businesses can not only reduce their environmental impact but also attract eco-conscious customers.

Scenario 3: Space Constraints in Office or Facility Environments

The Problem: Many businesses, especially in urban areas, struggle with limited space for storing large water bottles. The 2.5-gallon jug, while smaller than the 5-gallon options, can still take up valuable real estate in offices or production areas. This can lead to clutter, disorganization, and even safety hazards if the bottles are not stored properly.

The Solution: B2B buyers should evaluate their spatial requirements before selecting their water bottle sizes. Consider investing in water cooler systems that are designed specifically for 2.5-gallon bottles, allowing for vertical storage and minimizing floor space usage. Moreover, implementing a regular delivery schedule can ensure bottles are used before new deliveries arrive, reducing the need for excess storage. Utilizing wall-mounted dispensers can also maximize space efficiency while providing easy access to hydration. This strategic approach not only keeps the workspace organized but also promotes a culture of health and wellness among employees.

Strategic Material Selection Guide for 2.5 gallon water bottle

What Are the Key Materials Used for 2.5 Gallon Water Bottles?

When selecting materials for 2.5-gallon water bottles, various factors such as durability, cost, and compliance with international standards must be considered. Below are analyses of four common materials used in the manufacturing of these bottles.

How Does Plastic Perform as a Material for 2.5 Gallon Water Bottles?

Key Properties: Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is lightweight and has a good temperature resistance, typically up to 120°C (248°F). It is also resistant to corrosion and does not leach harmful chemicals under normal conditions.

Pros & Cons: Plastic bottles are generally more affordable to produce, making them a cost-effective option for mass production. They are durable and resistant to breakage, but they may not withstand extreme temperatures as well as glass or metal. Additionally, some plastics may have limitations concerning recycling and environmental impact.

Impact on Application: Plastic is suitable for storing water and other non-corrosive liquids. However, certain types of plastic can interact with specific chemicals, which is a consideration for international buyers dealing with various water types.

Considerations for International Buyers: Compliance with food safety standards such as FDA regulations in the U.S. or EFSA in Europe is essential. Buyers from regions like Africa and South America should also consider local regulations regarding plastic use and recycling practices.

What Are the Benefits of Glass for 2.5 Gallon Water Bottles?

Key Properties: Glass is highly resistant to corrosion and can withstand high temperatures without deforming. It is also non-reactive, ensuring that the water’s taste remains unaffected.

Pros & Cons: Glass bottles are reusable and recyclable, making them an environmentally friendly option. They provide superior taste preservation compared to plastic. However, they are heavier and more fragile, which can lead to higher shipping costs and breakage during transport.

Impact on Application: Glass is ideal for premium bottled water products, especially in markets where consumers prioritize taste and quality. However, the weight and fragility may limit its use in certain regions, particularly where transportation infrastructure is less developed.

Considerations for International Buyers: Buyers must consider the additional costs associated with glass, including deposits for returnable bottles. Compliance with packaging regulations in various countries, such as those in the EU, is also crucial.

Why Choose Stainless Steel for 2.5 Gallon Water Bottles?

Key Properties: Stainless steel is known for its durability and resistance to corrosion and temperature extremes. It can handle high pressures and is non-reactive, making it suitable for various liquids.

Pros & Cons: Stainless steel bottles are extremely durable and can last for years, making them an excellent long-term investment. However, they are more expensive to manufacture than plastic or glass. Additionally, they may require more complex manufacturing processes.

Impact on Application: Stainless steel is suitable for both cold and hot liquids, making it versatile. However, it may not be as widely accepted in all markets due to higher costs.

Considerations for International Buyers: Buyers should ensure that the stainless steel used complies with international food safety standards. Additionally, they should consider the market demand for premium products, particularly in regions like Europe and the Middle East.

What Role Does Aluminum Play in 2.5 Gallon Water Bottles?

Key Properties: Aluminum is lightweight and has good corrosion resistance. It can be treated to enhance its durability and is often coated to prevent interaction with the contents.

Pros & Cons: Aluminum bottles are lightweight and easy to transport, making them a good option for outdoor and travel applications. However, they may not be as durable as stainless steel or glass and can dent easily. The coating used can also affect recyclability.

Impact on Application: Aluminum is suitable for beverages and can be used for both still and sparkling water. However, the interaction with certain liquids can be a concern, depending on the coating used.

Considerations for International Buyers: Compliance with recycling and food safety regulations is essential. Buyers should also consider consumer preferences for aluminum versus other materials in their specific markets.

Summary Table of Material Selection for 2.5 Gallon Water Bottles

| Material | Typical Use Case for 2.5 Gallon Water Bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General hydration in homes and offices | Cost-effective and lightweight | Environmental concerns and recycling | Low |

| Glass | Premium bottled water products | Superior taste preservation | Heavy and fragile | High |

| Stainless Steel | Long-term hydration solutions | Extremely durable and versatile | Higher manufacturing costs | Med |

| Aluminum | Outdoor and travel applications | Lightweight and easy to transport | Can dent and may require coatings | Med |

This guide provides a comprehensive overview of the materials used in 2.5-gallon water bottles, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for 2.5 gallon water bottle

What Are the Key Stages in the Manufacturing Process of 2.5 Gallon Water Bottles?

The manufacturing of 2.5-gallon water bottles involves several critical stages, each designed to ensure efficiency, safety, and product quality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of raw materials, typically food-grade plastic (like PET) or glass. For plastic bottles, granules of resin are sourced from reputable suppliers to ensure safety and compliance with international standards. These materials undergo thorough inspections to check for contaminants and impurities, ensuring only high-quality inputs enter the production line.

-

Forming: In this stage, the prepared material is heated and molded into the desired bottle shape. For plastic bottles, processes like blow molding or injection molding are common. Blow molding involves inflating a heated plastic preform into the shape of the mold, while injection molding creates the bottle in a single step. For glass bottles, the molten glass is formed into molds using a process called glass blowing. Both methods require precision to maintain uniformity in size and shape.

-

Assembly: After forming, the bottles are moved to the assembly stage, where they may receive additional components such as caps and labels. This stage often includes automated machinery to streamline the capping and labeling process, ensuring that each bottle is sealed correctly to prevent contamination.

-

Finishing: The final stage includes quality checks and packaging. Bottles undergo rinsing and sanitization processes to eliminate any residues from manufacturing. They are then inspected visually and through automated systems for any defects, ensuring that only flawless products reach the market.

How Is Quality Assurance Implemented in the Manufacturing of 2.5 Gallon Water Bottles?

Quality assurance is critical in the manufacturing of 2.5-gallon water bottles, especially given the health implications associated with bottled water. Several international standards and industry-specific guidelines govern the quality assurance processes.

-

International Standards: Compliance with ISO 9001 is essential for manufacturers targeting international markets. This standard outlines requirements for a quality management system, ensuring that manufacturers can consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE marking (for European markets) and API (American Petroleum Institute) standards are crucial for specific applications, particularly in regions where safety regulations are stringent.

-

Quality Control Checkpoints: The quality assurance process includes several checkpoints throughout the production line:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring of the production process is conducted. This includes checking temperature settings, pressure levels, and material consistency.

– Final Quality Control (FQC): After production, finished products undergo a comprehensive quality check, including weight, dimensions, and visual inspections. Advanced testing methods may include pressure tests for plastic bottles to ensure they can withstand handling and transport.

What Testing Methods Are Commonly Used in Quality Assurance for 2.5 Gallon Water Bottles?

To ensure the safety and quality of 2.5-gallon water bottles, various testing methods are employed throughout the manufacturing process:

- Chemical Testing: Bottles are tested for leachables and extractables, ensuring that no harmful substances migrate from the bottle into the water.

- Microbial Testing: This testing is crucial for bottled water. Samples are analyzed for microbial contamination, ensuring that the water remains safe for consumption.

- Physical Testing: This includes checks for bottle integrity under stress, such as drop tests and pressure tests, to simulate transportation conditions.

- Shelf-life Testing: Manufacturers conduct accelerated aging tests to determine how long the bottled water remains safe and palatable under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is vital. Here are actionable steps to ensure supplier compliance with quality standards:

-

Supplier Audits: Conducting regular audits of suppliers is an effective way to assess their adherence to quality standards. Buyers should develop a checklist based on international standards and industry-specific regulations.

-

Quality Assurance Reports: Request detailed quality assurance reports from suppliers. These should outline their quality control processes, testing methods, and results from recent inspections.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. This is particularly important for large orders where financial stakes are high.

-

Certifications Verification: Ensure that suppliers have valid certifications (e.g., ISO 9001, CE) by checking with the certifying bodies. This step confirms that the supplier meets international quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions must be aware of certain nuances in quality control that can affect their procurement decisions.

- Regional Regulations: Different regions may have specific regulations regarding bottled water. For example, EU regulations may be more stringent than those in other regions, affecting sourcing and compliance strategies.

- Cultural Expectations: Buyers must understand local consumer preferences, which may influence the choice of materials (e.g., glass versus plastic) and labeling requirements.

- Supply Chain Considerations: International logistics can introduce risks that affect product quality. Buyers should consider how their supplier manages the supply chain and what measures are in place to mitigate risks during transportation.

By understanding the manufacturing processes, quality assurance protocols, and verification methods, B2B buyers can make informed decisions when sourcing 2.5-gallon water bottles, ensuring that they meet both international standards and local market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.5 gallon water bottle’

To assist international B2B buyers in sourcing 2.5-gallon water bottles effectively, this guide outlines a practical checklist that ensures a streamlined procurement process. This resource focuses on critical steps that enhance supplier selection, product quality, and compliance with regional standards.

Step 1: Identify Your Specific Needs

Understanding your requirements is the foundation of a successful procurement process. Consider factors such as the intended use of the water bottles—whether for office hydration, retail sales, or catering services. Additionally, think about the material (plastic or glass), branding needs, and whether you require flavored options or purely spring water.

- Sub-bullet: Determine the volume needed per month and any potential seasonal fluctuations in demand.

- Sub-bullet: Evaluate whether you’ll need customized packaging or labeling to align with your brand.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who can meet your specifications. Look for manufacturers with a proven track record in producing high-quality bottled water. Utilize platforms like industry directories, trade shows, or professional networks to compile a list of potential vendors.

- Sub-bullet: Check for suppliers that have experience in the specific markets you are targeting, such as Africa, South America, or Europe.

- Sub-bullet: Pay attention to customer reviews and testimonials to gauge supplier reliability.

Step 3: Verify Supplier Certifications

Before engaging further, ensure that potential suppliers hold necessary certifications that comply with local and international standards. This may include FDA approval, ISO certifications, or other health and safety regulations relevant to bottled water production.

- Sub-bullet: Inquire about their quality control processes to ensure consistent product safety.

- Sub-bullet: Request documentation that verifies sourcing practices, especially if natural spring water is claimed.

Step 4: Request Samples for Evaluation

Once you have shortlisted suppliers, request samples of their 2.5-gallon water bottles. This step is crucial to assess the taste, quality, and packaging of the product.

- Sub-bullet: Conduct sensory evaluations to determine the water’s clarity and flavor profile.

- Sub-bullet: Examine the packaging for durability and ease of use, especially if the bottles are intended for commercial dispensers.

Step 5: Negotiate Pricing and Terms

Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Understanding the total cost, including shipping and potential tariffs, is essential for effective budgeting.

- Sub-bullet: Explore bulk purchase discounts or long-term contract options for better pricing.

- Sub-bullet: Clarify return policies and warranty terms in case of product defects.

Step 6: Establish Logistics and Delivery Plans

Logistics is a key component of the procurement process. Collaborate with your supplier to establish a reliable delivery schedule that aligns with your operational needs.

- Sub-bullet: Consider potential challenges in transportation specific to your region, such as customs delays or infrastructure issues.

- Sub-bullet: Ensure your supplier can accommodate your delivery requirements, whether through direct shipping or local distribution partners.

Step 7: Monitor and Review Supplier Performance

After procurement, continually assess the performance of your supplier. This includes monitoring product quality, delivery timelines, and customer service responsiveness.

- Sub-bullet: Schedule regular reviews to address any issues promptly and maintain a good working relationship.

- Sub-bullet: Gather feedback from end-users to ensure the product meets expectations and identify areas for improvement.

By following this structured checklist, B2B buyers can efficiently source 2.5-gallon water bottles that meet their specific needs while ensuring quality and compliance with relevant standards.

Comprehensive Cost and Pricing Analysis for 2.5 gallon water bottle Sourcing

What are the Key Cost Components in Sourcing 2.5 Gallon Water Bottles?

When sourcing 2.5-gallon water bottles, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice between plastic and glass significantly impacts costs. Plastic bottles are generally less expensive, while glass bottles, despite being higher in price, offer enhanced quality and a premium image. Additionally, sourcing high-quality spring water adds to the material costs but can justify a higher retail price.

-

Labor and Manufacturing Overhead: Labor costs vary by region. In countries with lower labor costs, such as certain parts of Africa and South America, manufacturing expenses may be reduced. However, international standards for labor practices must be adhered to, which can affect pricing. Manufacturing overhead includes utilities, facility maintenance, and other indirect costs, which can vary widely based on geographic location.

-

Tooling and Quality Control: The initial setup for tooling can be a significant investment, especially for custom designs. Quality control processes ensure that the products meet safety and quality standards, which is crucial for maintaining brand reputation and compliance with regulations.

-

Logistics: Transportation costs are influenced by distance, shipping methods, and regional infrastructure. Incoterms also play a vital role in determining who bears the risk and costs during shipping, which can affect the overall pricing structure.

-

Margin: Suppliers typically mark up prices to cover their costs and generate profit. Understanding the expected margins can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of 2.5 Gallon Water Bottles?

Several factors can influence the pricing of 2.5-gallon water bottles. Volume and minimum order quantities (MOQ) are among the most significant. Larger orders often yield better pricing, allowing buyers to take advantage of economies of scale.

Customization can also affect pricing; unique designs or features will typically incur additional costs. Material quality is another crucial factor—bottles made from BPA-free plastic or certified glass can command higher prices due to health and safety considerations.

Supplier factors, including their reputation and reliability, can also impact pricing. A well-established supplier may charge more, but the assurance of quality and timely delivery can justify the higher cost. Lastly, Incoterms define the responsibilities of buyers and sellers in international transactions, which can affect the final price.

What Are Effective Buyer Tips for Negotiating 2.5 Gallon Water Bottle Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies are essential. Here are several tips to consider:

-

Leverage Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the total cost of ownership, including shipping, storage, and potential waste. This broader view can lead to more informed purchasing decisions.

-

Negotiate on Volume: If possible, consolidate orders to meet or exceed MOQs. This strategy can lead to significant savings per unit, making it more cost-effective in the long run.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide a clearer picture of market pricing and help identify competitive offers.

-

Understand Local Regulations: Familiarize yourself with local regulations regarding bottled water. Compliance can affect sourcing decisions and pricing, especially for international shipments.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing, priority service, and more favorable terms over time.

What Should B2B Buyers Keep in Mind Regarding Indicative Prices?

It is essential to note that prices for 2.5-gallon water bottles can vary widely based on the factors discussed above. The indicative prices provided by suppliers may not reflect the final cost after negotiations, shipping, and potential tariffs. Buyers should be prepared for fluctuations and be proactive in discussing all aspects of pricing with their suppliers to ensure transparency and alignment on expectations.

Alternatives Analysis: Comparing 2.5 gallon water bottle With Other Solutions

Exploring Alternatives to the 2.5 Gallon Water Bottle

As businesses increasingly prioritize hydration solutions, the 2.5-gallon water bottle stands out for its convenience and portability. However, various alternatives may offer distinct advantages depending on specific operational needs, budgets, and environmental considerations. This section delves into a comparative analysis of the 2.5-gallon water bottle against other viable hydration options, including filtration systems and larger bulk containers.

| Comparison Aspect | 2.5 Gallon Water Bottle | Water Filtration System | 5 Gallon Water Bottle |

|---|---|---|---|

| Performance | Reliable hydration source with natural spring water | Provides continuous access to filtered water, but quality depends on source | Larger capacity, suitable for high-volume needs |

| Cost | Moderate; varies by brand and delivery fees | Initial investment for the system, but lower ongoing costs | Typically higher due to larger size and delivery |

| Ease of Implementation | Simple; requires minimal setup | Requires installation; maintenance needed | Simple to use but requires storage space |

| Maintenance | Low; replace bottles as needed | Moderate; filters require regular replacement | Low; infrequent bottle replacement |

| Best Use Case | Ideal for homes and small offices | Best for long-term use in larger offices or facilities | Suitable for high-demand environments, like large offices or events |

What Are the Pros and Cons of Water Filtration Systems?

Water filtration systems provide an ongoing source of clean drinking water, making them an attractive alternative to bottled water. They reduce the need for physical storage and offer potentially unlimited hydration. However, the initial setup cost can be significant, and the effectiveness of the system is dependent on the quality of the water supply. Regular maintenance, including filter replacements, is necessary to ensure optimal performance, which can lead to additional costs over time. For businesses looking for a sustainable and long-term solution, this can be an excellent option.

Why Consider a 5 Gallon Water Bottle?

The 5-gallon water bottle serves as an alternative for those needing higher hydration volumes. This option is popular in offices and larger settings where many employees require access to drinking water. While the cost per gallon may be lower than that of 2.5-gallon bottles, the larger size can be cumbersome and requires more storage space. Additionally, businesses must consider the logistics of handling and replacing these larger bottles, which may involve additional labor or delivery challenges. For high-traffic environments, this solution can be effective, but it may not be as convenient for smaller teams.

Conclusion: How to Choose the Right Hydration Solution for Your Business Needs

Selecting the right hydration solution hinges on various factors including your organization’s size, budget, and environmental considerations. The 2.5-gallon water bottle is an excellent choice for small to medium-sized businesses seeking convenience and flexibility. Conversely, water filtration systems are ideal for those looking for a long-term, sustainable solution that minimizes waste. Finally, the 5-gallon bottle may suit larger operations with high consumption needs but comes with its own logistical challenges. By assessing these alternatives carefully, B2B buyers can make informed decisions that align with their hydration goals and operational requirements.

Essential Technical Properties and Trade Terminology for 2.5 gallon water bottle

What are the Key Technical Properties of a 2.5 Gallon Water Bottle?

When sourcing 2.5-gallon water bottles for B2B purposes, understanding the technical specifications is crucial. Here are some critical properties to consider:

-

Material Composition:

– Most 2.5-gallon water bottles are made from high-density polyethylene (HDPE) or glass. HDPE is lightweight, durable, and recyclable, making it a popular choice for bulk water distribution. Glass bottles, while heavier and more fragile, offer a premium feel and better preservation of water quality. Selecting the right material can impact transport costs and consumer perception. -

Capacity and Dimensions:

– The nominal capacity is 2.5 gallons (approximately 9.5 liters), but actual dimensions may vary slightly among manufacturers. Understanding the specific dimensions is essential for compatibility with dispensers and storage solutions. This information helps in logistical planning and shelf-space optimization. -

Weight:

– An empty 2.5-gallon plastic jug typically weighs around 1.5 lbs (0.68 kg), while glass versions can weigh up to 30.5 lbs (13.8 kg) when full. The weight directly affects shipping costs and handling requirements. B2B buyers should factor in the weight for both storage and distribution. -

Closure Type:

– Bottles often feature a screw cap or a spill-proof cap designed for water dispensers. The type of closure ensures easy pouring and minimizes spills, which is vital for maintaining hygiene and reducing waste during handling and transportation. -

Recyclability:

– Many bottles are designed to be recyclable, which is increasingly important for sustainability. B2B buyers should look for products that offer recyclable options, as this aligns with global trends towards environmental responsibility and can enhance brand reputation. -

Nutritional Information:

– While water itself doesn’t contain calories, understanding the source and any added minerals can be vital for branding. Products may advertise naturally occurring electrolytes or mineral content, appealing to health-conscious consumers.

What Common Trade Terms Should B2B Buyers Know for 2.5 Gallon Water Bottles?

Understanding industry jargon can streamline communication and negotiations. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer):

– Refers to companies that produce parts or products that are used in another company’s end product. In the context of water bottles, OEMs may provide the bottles to brands for private labeling. -

MOQ (Minimum Order Quantity):

– This term indicates the smallest quantity of product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory planning, especially when entering new markets. -

RFQ (Request for Quotation):

– A formal process where buyers request price quotes from suppliers. An RFQ outlines specifications such as materials, quantities, and delivery timelines. This is essential for comparing prices and evaluating supplier capabilities. -

Incoterms (International Commercial Terms):

– These are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers in shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for cost management and risk assessment. -

Lead Time:

– The amount of time from placing an order to receiving the goods. Understanding lead times helps in inventory management and ensures that businesses can meet customer demand without delays. -

Bottling Services:

– Refers to companies that specialize in filling and packaging water into bottles. Some buyers may choose to partner with bottling services to streamline production and distribution, especially in regions with high demand.

By familiarizing yourself with these technical properties and trade terminology, you can make informed decisions that optimize your supply chain and enhance your market positioning in the competitive bottled water industry.

Navigating Market Dynamics and Sourcing Trends in the 2.5 gallon water bottle Sector

What Are the Key Market Drivers and Trends in the 2.5 Gallon Water Bottle Sector?

The 2.5 gallon water bottle market is experiencing significant growth, driven by increased consumer demand for convenient hydration solutions. This trend is particularly notable in emerging markets across Africa, South America, the Middle East, and Europe, where urbanization and a growing middle class are expanding the consumer base for bottled water. International B2B buyers are increasingly sourcing these products for residential, commercial, and industrial applications, recognizing the versatility of the 2.5-gallon format for both home and office use.

Technological advancements in water purification and bottling processes are also shaping the market. Innovations such as enhanced filtration systems and automated bottling lines improve product quality and reduce production costs, making it easier for suppliers to meet rising demand. Additionally, the rise of e-commerce platforms has streamlined distribution channels, enabling B2B buyers to access a broader range of suppliers and products.

Sustainability is another crucial factor influencing market dynamics. Many consumers now prefer brands that prioritize eco-friendly practices, prompting suppliers to adopt greener packaging solutions and reduce plastic waste. This shift is particularly relevant in regions like Europe, where stringent regulations on single-use plastics are in place.

How Is Sustainability Impacting Sourcing Decisions for 2.5 Gallon Water Bottles?

Sustainability has become a pivotal concern for international B2B buyers in the 2.5 gallon water bottle sector. The environmental impact of plastic waste is prompting companies to seek out suppliers who adhere to ethical sourcing practices and offer sustainable packaging options. Buyers are increasingly prioritizing products made from recyclable or biodegradable materials, as well as those with minimal environmental footprints.

The importance of ethical supply chains cannot be overstated. B2B buyers are now scrutinizing their suppliers’ sourcing practices to ensure they align with sustainability goals. Certifications such as the Global Recycled Standard (GRS) or Forest Stewardship Council (FSC) are becoming vital in supplier selection, as they provide assurance that materials are sourced responsibly.

Moreover, the demand for “green” certifications is reshaping product offerings. Suppliers who can demonstrate their commitment to sustainability through certifications or eco-labels are gaining a competitive edge. By sourcing from environmentally responsible manufacturers, B2B buyers not only enhance their corporate social responsibility (CSR) image but also cater to a growing customer base that values sustainability.

What Is the Historical Context of the 2.5 Gallon Water Bottle Market?

The evolution of the 2.5 gallon water bottle can be traced back to the late 20th century when bottled water began to gain popularity as a convenient alternative to sugary beverages. Initially dominated by larger 5-gallon bottles, the market recognized the need for smaller, more manageable sizes, leading to the introduction of the 2.5 gallon format. This smaller jug appealed to households and offices seeking hydration solutions without the bulk of larger bottles.

Over the years, the market has adapted to changing consumer preferences and regulatory pressures. The focus has shifted towards quality, sustainability, and convenience, with innovations in bottling technology and packaging material. Today, the 2.5 gallon water bottle stands as a versatile product that meets diverse hydration needs while aligning with modern values of health and environmental responsibility. As the sector continues to evolve, B2B buyers are well-positioned to capitalize on emerging trends that prioritize both convenience and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of 2.5 gallon water bottle

-

How do I ensure the quality of 2.5 gallon water bottles from suppliers?

To ensure quality, start by vetting suppliers through certifications such as ISO 9001 or HACCP. Request samples to evaluate the product’s material, clarity, and taste. Additionally, inquire about their sourcing practices, such as the water source and purification methods. Conduct site visits if possible or utilize third-party inspection services to assess manufacturing processes. Regular quality audits and checks can also help maintain consistent standards in your supply chain. -

What is the best packaging for 2.5 gallon water bottles for international shipping?

The best packaging for international shipping of 2.5 gallon water bottles includes sturdy, eco-friendly materials that provide insulation and protection against breakage. Consider using reinforced cardboard boxes with dividers to prevent movement during transit. Utilize cushioning materials like bubble wrap or biodegradable packing peanuts. Ensure that packaging is compliant with international shipping regulations, including labeling for hazardous materials if applicable. -

What are the typical minimum order quantities (MOQ) for 2.5 gallon water bottles?

Minimum order quantities can vary significantly by supplier and region, typically ranging from 100 to 1,000 units for 2.5 gallon water bottles. Some suppliers may offer lower MOQs for first-time buyers or bulk discounts for larger orders. It’s essential to communicate your needs directly with potential suppliers to negotiate favorable terms, especially if you’re entering a new market or testing demand. -

What payment terms should I expect when sourcing 2.5 gallon water bottles internationally?

Payment terms can vary, but common practices include a 30% deposit upfront with the remaining balance due upon shipment or delivery. Some suppliers may offer letter of credit or escrow services for larger transactions to protect both parties. Always clarify payment methods, currency, and any additional fees upfront. Building a good relationship with suppliers may also provide more flexible terms over time. -

How can I customize 2.5 gallon water bottles for my brand?

Customization options typically include printing your brand logo, choosing specific colors for the bottles, or even altering the bottle shape. Many suppliers offer private labeling services, allowing you to create a unique product that stands out in the market. Discuss your requirements with potential suppliers to understand their capabilities and any associated costs for customization. -

What are the logistics considerations for importing 2.5 gallon water bottles?

Logistics considerations include understanding shipping methods (air vs. sea), lead times, and customs regulations in your destination country. Factor in storage and handling costs, especially if you require warehousing upon arrival. Collaborate with a freight forwarder who has experience with bottled water imports to streamline the process. Ensure compliance with local health and safety regulations regarding bottled water distribution. -

What quality assurance measures should I implement when sourcing 2.5 gallon water bottles?

Implementing quality assurance measures involves setting clear specifications for the bottles, including material standards, fill levels, and labeling. Regularly monitor supplier performance through audits and product testing. Establish a feedback loop with your suppliers to address any quality issues promptly. Consider third-party testing for contaminants or impurities to ensure that the water meets local health regulations. -

What are the environmental considerations for sourcing 2.5 gallon water bottles?

When sourcing 2.5 gallon water bottles, consider the environmental impact of the materials used. Opt for suppliers that use recyclable or biodegradable materials and practice sustainable sourcing. Investigate the carbon footprint of their production and transportation processes. Supporting suppliers with eco-friendly practices can enhance your brand’s reputation and appeal to environmentally conscious consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 2.5 Gallon Water Bottle Manufacturers & Suppliers List

1. Ozarka® – 2.5 Gallon Spring Water

Domain: ozarkawater.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Ozarka® Brand 100% Natural Spring Water”, “size”: “2.5 Gallon”, “description”: “A great option for hydration at home or the office, smaller than the 5-gallon bottle, ideal for reusable water bottles.”, “nutritional_information”: {“calories”: “0mg”, “total_fat”: “0mg”, “sodium”: “0mg”, “protein”: “0mg”}, “ingredients”: “Natural spring water”, “bottle_material”: “Recyclable bottles…

2. Arrowhead® – 2.5 Gallon Jug Spring Water

Domain: arrowheadwater.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “2.5 Gallon Jug Spring Water”, “brand”: “Arrowhead®”, “type”: “100% Mountain Spring Water”, “jug_size”: “2.5 Gallon”, “description”: “Great for the home or your next camping trip, this jug is just the right size to keep everyone hydrated and refreshed. Think of it as your very own mountain spring.”, “nutrition_facts”: {“calories”: “0mg”, “total_fat”: “0mg”, “sodium”: “0mg”, “prote…

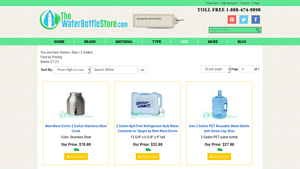

3. New Wave Enviro – 2 Gallon Stainless Steel Crock

Domain: thewaterbottlestore.com

Registered: 2005 (20 years)

Introduction: 2 Gallon Water Jugs available in various types including stainless steel, BPA free plastic, and PET. Key products include: 1. New Wave Enviro 2 Gallon Stainless Steel Crock – Price: $78.88 2. 2 Gallon BPA Free Refrigerator Bulk Water Container with Spigot by New Wave Enviro – Dimensions: 13-5/8″ x 6-5/8″ x 9″ tall, Price: $32.88 3. Geo 2 Gallon PET Reusable Water Bottle with Screw Cap, Blue – Pric…

4. Mountain Valley – Spring Water 2.5 Gallon Glass Bottle

Domain: nkb.bxq.mybluehost.me

Registered: 2016 (9 years)

Introduction: {“product_name”: “Mountain Valley Spring Water 2.5 Gallon Glass Bottle”, “price_range”: “$17.90 – $57.90”, “bottled_at”: “source in the Ouachita Mountains, Arkansas”, “established”: “Since 1871”, “description”: “Mineral rich spring water from the heart of the Ouachita Mountains, sodium-free with a naturally detoxifying pH and rich blend of calcium, magnesium, and potassium.”, “weight”: “approximat…

5. Reddit – 2.5 Gallon Water Jug

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2.5 gallon grocery store type water jug

6. Poland Spring® – 2.5 Gallon Jug Spring Water

Domain: polandspring.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “2.5 Gallon Jug Spring Water”, “Brand”: “Poland Spring®”, “Product Size”: “2.5 gallons”, “Other Sizes Available”: [“12 fl oz”, “8 fl oz”, “16.9 fl oz”, “20 fl oz”, “23.7 fl oz”, “1 L”, “1.5 L”, “3 L”, “1 G”, “2.5 G”, “3 G”, “5 G”, “25 fl oz”], “Pack Size”: “single”, “Nutritional Information”: {“Calories”: “0mg”, “Total Fat”: “0mg”, “Sodium”: “0mg”, “Protein”: “0mg”}, “Ingredients”…

7. Alive Waters – 2.5 Gallon Jug

Domain: alivewaters.com

Registered: 2019 (6 years)

Introduction: {“name”:”Empty 2.5 Gallon Jug (generic silicone cap)”,”regular_price”:”$44.00 USD”,”sale_price”:”$41.00 USD”,”quantity_options”:[1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30],”weight”:”4536 grams”,”dimensions”:{“width”:”10.5 inches”,”height”:”10 inches”},”features”:”Manufactured in Italy with high-quality glass formula, uniform wall thickness for durability, pre…

Strategic Sourcing Conclusion and Outlook for 2.5 gallon water bottle

The 2.5-gallon water bottle segment presents significant opportunities for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. As consumer preferences shift towards convenient, sustainable hydration solutions, strategic sourcing becomes essential for businesses aiming to meet these demands. Sourcing from reputable suppliers of spring and mineral waters not only ensures product quality but also aligns with the growing trend of health-conscious consumption.

Moreover, the versatility of the 2.5-gallon format makes it an ideal choice for diverse applications, from home use to corporate settings. Buyers should prioritize suppliers that offer recyclable packaging and sustainability initiatives, reflecting a commitment to environmental responsibility.

Looking ahead, the demand for 2.5-gallon water bottles is expected to rise as businesses recognize the importance of hydration in workplace wellness and customer satisfaction. We encourage B2B buyers to engage with suppliers who can provide competitive pricing, reliable delivery, and high-quality products to secure a sustainable supply chain. Your next step is to evaluate potential partners and leverage strategic sourcing to elevate your business offerings in this growing market.