Introduction: Navigating the Global Market for gallon jug water bottle

In today’s competitive landscape, sourcing high-quality gallon jug water bottles presents a significant challenge for international B2B buyers. The demand for these versatile containers is on the rise, driven by health-conscious consumers and businesses prioritizing hydration solutions. However, navigating the myriad of options available can be daunting. This comprehensive guide aims to simplify the process by covering various types of gallon jug water bottles, their applications across different industries, and critical factors to consider when selecting suppliers.

From understanding material quality to evaluating cost-effectiveness and supply chain reliability, this guide provides actionable insights tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Vietnam and Saudi Arabia. By addressing key considerations such as customization options, regulatory compliance, and market trends, we empower decision-makers to make informed purchasing choices that align with their business needs.

With a focus on supplier vetting and performance metrics, this guide not only streamlines the procurement process but also enhances the potential for successful partnerships. As you delve deeper into this resource, you will gain the knowledge needed to confidently navigate the global market for gallon jug water bottles, ensuring that your sourcing decisions support your operational goals and customer satisfaction.

Article Navigation

- Top 6 Gallon Jug Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for gallon jug water bottle

- Understanding gallon jug water bottle Types and Variations

- Key Industrial Applications of gallon jug water bottle

- 3 Common User Pain Points for ‘gallon jug water bottle’ & Their Solutions

- Strategic Material Selection Guide for gallon jug water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for gallon jug water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘gallon jug water bottle’

- Comprehensive Cost and Pricing Analysis for gallon jug water bottle Sourcing

- Alternatives Analysis: Comparing gallon jug water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for gallon jug water bottle

- Navigating Market Dynamics and Sourcing Trends in the gallon jug water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gallon jug water bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for gallon jug water bottle

Understanding gallon jug water bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Insulated Stainless Steel | Keeps beverages cold/hot for extended periods, durable design | Outdoor events, construction sites | Pros: Excellent temperature retention, durable. Cons: Heavier, higher cost. |

| BPA-Free Plastic | Lightweight, affordable, and often transparent for easy filling | Schools, gyms, corporate offices | Pros: Cost-effective, lightweight. Cons: Less durable, potential for leaching. |

| Motivational Marked | Time markers for hydration goals, often colorful | Fitness centers, wellness programs | Pros: Encourages hydration, visually appealing. Cons: Limited durability compared to metal options. |

| Tactical/Outdoor | Rugged design, often with features for outdoor use (e.g., handles, attachments) | Camping, military, emergency services | Pros: Highly durable, versatile. Cons: Bulkier, may be more expensive. |

| Half Gallon Variants | Smaller capacity, often with similar features to full gallon jugs | Individual users, smaller teams | Pros: More portable, suitable for lighter use. Cons: Less capacity, frequent refills needed. |

What Are the Characteristics of Insulated Stainless Steel Gallon Jugs?

Insulated stainless steel gallon jugs are designed for maximum temperature retention, keeping liquids cold or hot for extended periods. These jugs are ideal for B2B applications in environments like outdoor events or construction sites, where hydration is crucial. Buyers should consider factors such as weight and cost, as these jugs tend to be heavier and more expensive than their plastic counterparts, but their durability and insulation capabilities make them a worthwhile investment.

How Do BPA-Free Plastic Gallon Jugs Compare?

BPA-free plastic gallon jugs are lightweight and affordable, making them a popular choice for schools, gyms, and corporate offices. Their transparent design allows users to easily monitor fluid levels, which is particularly beneficial in settings where hydration tracking is important. However, potential buyers should be aware that while these jugs are cost-effective, they may not be as durable as stainless steel options and could leach chemicals if exposed to heat.

What Benefits Do Motivational Marked Jugs Offer?

Motivational marked gallon jugs feature time markers to encourage users to meet their hydration goals. Their colorful designs make them visually appealing, particularly for fitness centers and wellness programs. While they can effectively promote hydration, buyers should consider their durability; these jugs are often made from plastic, which may not withstand heavy use as well as metal alternatives.

What Makes Tactical/Outdoor Gallon Jugs Unique?

Tactical or outdoor gallon jugs are built for rugged use, often featuring additional elements like handles and attachment points for convenience. They are well-suited for camping, military, and emergency services applications where durability is paramount. While they provide excellent functionality in demanding environments, their bulkiness and higher price point may be a consideration for some buyers.

Why Consider Half Gallon Variants?

Half gallon variants offer a more portable option for users who may not require a full gallon of water. These jugs often maintain many features of full-sized jugs, making them suitable for individual users or smaller teams. However, buyers should keep in mind that while they are easier to carry, they may require more frequent refills, which could be a drawback in certain settings.

Key Industrial Applications of gallon jug water bottle

| Industry/Sector | Specific Application of Gallon Jug Water Bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Beverage Distribution | Ensures hydration for staff and customers, improving productivity and satisfaction. | Quality of materials (BPA-free), durability for transport, and ease of cleaning. |

| Construction and Labor | On-site Hydration Stations | Provides workers with easy access to hydration, enhancing safety and performance. | Insulation properties, capacity, and ease of refill and transport. |

| Sports and Recreation | Team Training and Events | Facilitates hydration during practice and events, promoting athlete health and performance. | Custom branding options, lightweight design, and ergonomic features for easy carrying. |

| Healthcare | Patient and Staff Hydration | Supports hydration in healthcare facilities, contributing to patient care and staff wellness. | Compliance with health regulations, ease of sanitization, and spill-proof designs. |

| Education | Campus Hydration Solutions | Encourages hydration among students, fostering better focus and health. | Variety in colors for school branding, ease of use, and bulk purchasing options. |

How is the Gallon Jug Water Bottle Utilized in the Food and Beverage Industry?

In the food and beverage sector, gallon jug water bottles serve as essential tools for beverage distribution, particularly in restaurants, cafes, and catering services. These bottles ensure that staff and customers have access to hydration, leading to improved productivity and customer satisfaction. When sourcing, businesses should prioritize BPA-free materials to ensure safety, as well as durability to withstand frequent use and transport. Additionally, ease of cleaning is vital to maintain hygiene standards in food service environments.

What Role Does the Gallon Jug Water Bottle Play in Construction and Labor?

On construction sites, gallon jug water bottles are crucial for establishing hydration stations that provide easy access to water for workers. This not only enhances safety by preventing dehydration but also boosts overall performance and morale on the job. Buyers in this sector should consider bottles with excellent insulation properties to keep water cool in hot climates, a large capacity to reduce refill frequency, and designs that facilitate easy transport and refill.

How is the Gallon Jug Water Bottle Beneficial in Sports and Recreation?

In the sports and recreation industry, gallon jug water bottles are widely used during team training sessions and events. They help ensure that athletes stay hydrated, which is vital for maintaining performance and health. When sourcing these bottles, teams often look for custom branding options to promote team identity, lightweight designs for easy transport, and ergonomic features that make them comfortable to carry during workouts.

Why is the Gallon Jug Water Bottle Important in Healthcare Settings?

In healthcare facilities, gallon jug water bottles support both patient and staff hydration needs. Providing easy access to water contributes positively to patient care and staff wellness, which is particularly important in high-stress environments. Buyers in this sector must ensure that the bottles comply with health regulations, are easy to sanitize, and feature spill-proof designs to prevent accidents in sensitive areas.

How Does the Gallon Jug Water Bottle Support Educational Institutions?

Educational institutions use gallon jug water bottles as part of their hydration solutions on campus. These bottles encourage students to stay hydrated, which can lead to improved focus and overall health. When sourcing, schools often seek a variety of colors for branding purposes, ease of use for students of all ages, and bulk purchasing options to provide hydration solutions across the campus effectively.

3 Common User Pain Points for ‘gallon jug water bottle’ & Their Solutions

Scenario 1: Struggles with Insulation and Temperature Control

The Problem: One common challenge faced by B2B buyers, especially those in regions with extreme temperatures, is finding a gallon jug water bottle that effectively maintains the temperature of beverages over extended periods. Buyers may be concerned that their products will not keep water cold in hot climates or hot in cold environments, leading to unsatisfactory customer experiences and potential loss of business.

The Solution: To overcome this issue, buyers should prioritize sourcing high-quality insulated gallon water bottles made from materials such as food-grade stainless steel. Look for products that specifically advertise their insulation capabilities, such as double-wall vacuum insulation, which can keep drinks cold for up to 48 hours or hot for 24 hours. When specifying the bottles, ensure they have a wide mouth for easy filling and cleaning, and consider options with multiple lid types, such as a spout or straw for convenience. Additionally, conducting trials with different brands can help determine which models perform best in specific climate conditions, allowing for informed purchasing decisions that align with customer needs.

Scenario 2: Concerns About Durability and Safety Standards

The Problem: Another significant pain point for B2B buyers is ensuring the durability and safety of gallon jug water bottles. In industries like food and beverage, construction, or outdoor events, bottles are subjected to rough handling, and any breakage could lead to safety hazards and financial losses. Moreover, ensuring compliance with health standards, such as being BPA-free and lead-free, is crucial to avoid legal ramifications.

The Solution: Buyers should seek gallon water bottles that are designed for rugged use, often constructed with impact-resistant materials. When evaluating suppliers, request certifications or documentation that demonstrate compliance with safety standards, such as FDA approval for food-grade materials. Additionally, investing in bottles with features like a soft molded handle and a secure grip can reduce the risk of accidents. Implementing a quality assurance process, including testing the bottles under typical usage conditions, can further ensure product reliability and safety for end-users.

Scenario 3: Difficulty in Managing Inventory and Logistics

The Problem: For businesses operating in multiple regions, managing inventory and logistics for gallon jug water bottles can become a daunting task. Variations in demand based on local climate, cultural preferences, and seasonal trends can lead to overstocking or stockouts, resulting in increased costs and dissatisfied customers.

The Solution: To address these logistical challenges, B2B buyers should implement a demand forecasting strategy that takes into account historical sales data, regional weather patterns, and market trends. Utilizing inventory management software can streamline tracking and ordering processes, ensuring that businesses maintain optimal stock levels. Additionally, establishing relationships with multiple suppliers can provide flexibility in sourcing and enable quicker replenishment when demand surges. Collaborating with local distributors may also facilitate more efficient delivery and inventory turnover, reducing the risk of excess stock while meeting customer needs effectively.

Strategic Material Selection Guide for gallon jug water bottle

When selecting materials for gallon jug water bottles, it is crucial to consider properties that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of these bottles, highlighting their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyethylene (PE) in Gallon Jug Water Bottles?

Polyethylene (PE) is a widely used thermoplastic polymer known for its versatility and cost-effectiveness. It typically exhibits good chemical resistance and can withstand moderate temperatures, making it suitable for water storage. PE is lightweight, which is advantageous for shipping and handling.

Pros and Cons:

– Pros: Low cost, lightweight, good chemical resistance, and easy to mold.

– Cons: Lower durability compared to other materials, can be prone to UV degradation, and has limited temperature resistance.

Impact on Application:

PE is compatible with water and other non-aggressive liquids but may not be suitable for hot liquids due to its lower temperature threshold.

Considerations for International Buyers:

Compliance with food safety standards is critical. Buyers should ensure that the PE used is FDA-approved and meets local regulations in their respective regions, such as those set by the European Union (EU) or the South African Bureau of Standards (SABS).

How Does Stainless Steel Enhance the Performance of Gallon Jug Water Bottles?

Stainless steel, particularly food-grade stainless steel (e.g., 304 or 316), is known for its exceptional durability and resistance to corrosion, making it an ideal material for gallon water jugs. It can maintain the temperature of liquids for extended periods, which is a significant advantage for consumers in warmer climates.

Pros and Cons:

– Pros: Highly durable, excellent temperature retention, corrosion-resistant, and recyclable.

– Cons: Higher manufacturing costs and weight compared to plastic options.

Impact on Application:

Stainless steel is suitable for both cold and hot liquids, making it a versatile choice for various applications, including outdoor activities and sports.

Considerations for International Buyers:

Buyers should verify compliance with international standards such as ASTM and ISO for food-grade materials. Additionally, the weight of stainless steel bottles may impact shipping costs, particularly for bulk orders.

What Role Does Tritan Play in the Manufacturing of Gallon Jug Water Bottles?

Tritan is a copolyester that has gained popularity due to its clarity, toughness, and resistance to impact and heat. It is BPA-free, making it a safe choice for consumers concerned about chemical leaching.

Pros and Cons:

– Pros: Lightweight, shatter-resistant, BPA-free, and maintains clarity over time.

– Cons: Higher cost than traditional plastics and may not be as durable as stainless steel.

Impact on Application:

Tritan is suitable for cold liquids and is often used in environments where glass would be too hazardous. It is ideal for consumer markets that prioritize safety and aesthetics.

Considerations for International Buyers:

Ensure that Tritan products comply with local regulations regarding food safety and chemical exposure. Certifications like NSF or FDA approval can enhance marketability in regions like Europe and South America.

How Does Glass Compare as a Material for Gallon Jug Water Bottles?

Glass is a traditional material known for its purity and non-reactive properties. It does not leach chemicals and is often preferred for high-end or eco-friendly products.

Pros and Cons:

– Pros: Excellent chemical resistance, does not leach, and maintains taste.

– Cons: Heavier, more fragile, and typically more expensive than plastic options.

Impact on Application:

Glass is suitable for water and other non-carbonated beverages but may not be ideal for outdoor use due to its fragility.

Considerations for International Buyers:

Glass products must comply with safety standards to prevent breakage during transport. Buyers should also consider the implications of weight on shipping costs and packaging requirements.

Summary Table of Material Selection for Gallon Jug Water Bottles

| Material | Typical Use Case for gallon jug water bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | General consumer use for water storage | Cost-effective and lightweight | Lower durability | Low |

| Stainless Steel | Outdoor activities and sports | Durable and excellent insulation | Higher cost | High |

| Tritan | Eco-friendly consumer markets | Shatter-resistant and BPA-free | Higher cost than plastic | Med |

| Glass | Premium and eco-conscious markets | Non-reactive and maintains taste | Fragile and heavy | High |

This strategic material selection guide provides essential insights for B2B buyers in various international markets, ensuring informed decisions that align with product performance, regulatory compliance, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for gallon jug water bottle

What Are the Key Stages in the Manufacturing Process of Gallon Jug Water Bottles?

Manufacturing a gallon jug water bottle involves several critical stages that ensure the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing. Each stage employs specific techniques that are crucial for achieving a durable and safe product.

-

Material Preparation: The first step involves selecting high-quality materials, typically BPA-free plastics or food-grade stainless steel. Suppliers often conduct rigorous checks on raw materials to ensure they comply with international safety standards. For plastic bottles, the resin is usually dried and prepped to remove any moisture, while stainless steel is cut into sheets or coils.

-

Forming: This stage involves shaping the raw materials into the desired bottle form. For plastic bottles, techniques such as blow molding or injection molding are commonly used. Blow molding involves inflating a heated plastic tube to conform to the shape of the mold, while injection molding injects molten plastic into a mold. For stainless steel bottles, processes like deep drawing or spinning are used to achieve the final shape.

-

Assembly: After forming, the various components of the gallon jug, such as lids, handles, and seals, are assembled. This may involve welding, screwing, or snap-fit techniques, depending on the design. Ensuring that all components fit securely is vital to prevent leaks and enhance usability.

-

Finishing: The finishing stage includes surface treatment and quality checks. Plastic bottles may undergo processes like UV coating or color printing, while stainless steel bottles might receive polishing to enhance aesthetic appeal. This stage also includes applying any branding or labeling required by the buyer.

How Is Quality Assurance Implemented in the Production of Gallon Jug Water Bottles?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that each gallon jug water bottle meets the required safety and quality standards. The QA process typically follows international standards such as ISO 9001 and industry-specific certifications like CE and API.

-

Quality Control Checkpoints: Manufacturers implement several quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival. Suppliers verify that materials meet specified standards and reject any that do not.

– In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the forming and assembly stages. This can include checking dimensions, weights, and the integrity of seals.

– Final Quality Control (FQC): Once the bottles are finished, a comprehensive quality check is performed to assess the final product against specifications. This includes testing for leaks, pressure resistance, and material safety. -

Common Testing Methods: Various testing methods are employed to ensure product quality:

– Leak Testing: Bottles are filled with water and checked for leaks to ensure proper sealing.

– Temperature Resistance Testing: For insulated bottles, manufacturers test the thermal performance by measuring how long the bottle maintains temperature.

– Drop Testing: Bottles are subjected to drop tests to evaluate their durability and resistance to impact.

What International Standards Should B2B Buyers Be Aware of When Sourcing Gallon Jug Water Bottles?

International standards play a crucial role in ensuring the safety and quality of gallon jug water bottles. B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should be familiar with relevant standards.

-

ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization, regardless of size or industry. Compliance with ISO 9001 indicates that a manufacturer has established a robust quality management framework.

-

CE Marking: Required for products sold within the European Economic Area, the CE marking signifies that the product meets EU safety, health, and environmental protection standards. It is particularly important for B2B buyers looking to enter the European market.

-

API Certification: For manufacturers involved in the production of water bottles for specific industrial applications, API certification can be a critical requirement, ensuring that products meet specific standards for safety and performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This is especially vital when sourcing from international manufacturers.

-

Supplier Audits: Conducting audits of the supplier’s facilities can provide insights into their manufacturing processes and quality control measures. This may involve reviewing documentation related to ISO certification and observing the production line in action.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers assess compliance with international standards. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can further validate the quality of products before shipment. These services can perform independent testing and provide unbiased assessments of the product’s quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control that may vary by region.

-

Cultural Expectations: Different cultures may have varying expectations regarding product quality. Understanding these nuances can help buyers communicate effectively with suppliers and ensure that the products meet their specific requirements.

-

Regulatory Compliance: Each region may have unique regulatory requirements that must be met. For example, countries in the Middle East may have specific food safety regulations that differ from those in Europe. B2B buyers should familiarize themselves with these regulations to avoid compliance issues.

-

Logistical Challenges: Sourcing products internationally can present logistical challenges, including delays and customs inspections. It is essential for buyers to establish clear communication with suppliers to manage expectations and timelines effectively.

By understanding the manufacturing processes and quality assurance measures involved in producing gallon jug water bottles, B2B buyers can make informed decisions when sourcing these products. This knowledge not only enhances the likelihood of securing high-quality products but also builds stronger relationships with suppliers across various regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gallon jug water bottle’

In the growing market for gallon jug water bottles, B2B buyers must navigate various factors to ensure they procure high-quality products that meet their needs. This checklist will guide you through the essential steps for sourcing gallon jug water bottles effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the technical specifications that your business requires. Consider factors such as material (e.g., BPA-free plastic or stainless steel), size, insulation capabilities, and design features like handles or spouts. Defining these specifications upfront will help narrow down your options and ensure that the products align with your brand’s quality standards.

Step 2: Identify Your Target Market

Understanding your target market is crucial for selecting the right gallon jug water bottles. Research the preferences of your customers in different regions, such as Africa, South America, the Middle East, and Europe. Factors like climate, lifestyle, and cultural preferences can influence the design and features that will appeal most to your audience.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other businesses within your industry or region. Look for suppliers who have a proven track record of delivering quality products and reliable service.

- Supplier Certifications: Verify that suppliers hold relevant certifications (e.g., ISO, FDA) which ensure compliance with safety and quality standards.

- Production Capacity: Assess their ability to meet your order sizes and delivery timelines.

Step 4: Request Samples for Testing

Always request product samples before finalizing your order. Testing samples allows you to evaluate the quality, durability, and functionality of the gallon jug water bottles. Pay attention to aspects like insulation performance, weight, and ease of use.

- Temperature Retention: For insulated bottles, test how well they maintain cold or hot temperatures over time.

- Material Quality: Check for any signs of defects or inferior materials that could affect product longevity.

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and tested samples, it’s time to negotiate pricing and terms. Discuss bulk order discounts, payment terms, and shipping options. Aim for a balance between cost and quality to ensure you are making a financially sound decision without compromising on the product.

Step 6: Review Shipping and Logistics

Consider the logistics of shipping, particularly if you are sourcing from international suppliers. Evaluate shipping costs, delivery timelines, and customs regulations that may impact your order. Understanding these factors will help you avoid unexpected delays and costs.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process for your orders. Define inspection criteria to ensure that the products received meet your specifications. This step is crucial for maintaining product quality and customer satisfaction.

- Regular Audits: Conduct periodic audits of your suppliers’ production processes to ensure ongoing compliance with your quality standards.

By following this checklist, you can streamline the sourcing process for gallon jug water bottles and ensure that you make informed decisions that benefit your business and meet your customers’ expectations.

Comprehensive Cost and Pricing Analysis for gallon jug water bottle Sourcing

What Are the Key Cost Components in Sourcing Gallon Jug Water Bottles?

When sourcing gallon jug water bottles, understanding the cost structure is crucial for effective budgeting and negotiations. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. Common materials include BPA-free plastics, stainless steel, and glass. Stainless steel options generally incur higher costs due to their durability and insulation properties.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs can provide competitive pricing, but this must be balanced against quality and production standards.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and factory maintenance. A well-managed facility can reduce overhead costs, impacting the final price.

-

Tooling: Custom molds for unique designs or features can add to initial costs. Tooling expenses are often amortized over production runs, making larger orders more cost-effective.

-

Quality Control (QC): Investing in robust QC processes ensures that the products meet international standards, which is particularly important for buyers in regulated markets. Higher QC standards may lead to increased costs but can enhance brand reputation.

-

Logistics: Shipping costs can vary significantly based on the origin and destination. Factors such as shipping method, distance, and volume impact logistics costs. Understanding Incoterms is essential for determining responsibilities and costs in the supply chain.

-

Margin: Suppliers will typically add a markup to cover their costs and profit margin. This can vary widely based on market demand, competition, and the supplier’s brand strength.

How Do Price Influencers Affect Gallon Jug Water Bottle Sourcing?

Several factors can influence the pricing of gallon jug water bottles:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally lead to lower per-unit costs. Suppliers often offer tiered pricing, incentivizing bulk purchases.

-

Specifications and Customization: Customized designs, colors, or branding can increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like FDA approval or environmental standards) often come with a premium. Buyers should assess whether these certifications align with their market needs.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can influence pricing. Established suppliers may charge higher prices due to their perceived quality and service.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. For example, choosing FOB (Free on Board) can allow buyers to control shipping costs but requires careful coordination.

What Tips Can Help Buyers Negotiate Better Prices?

Navigating the procurement of gallon jug water bottles requires strategic negotiation and a focus on cost efficiency:

-

Leverage Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term costs, including shipping, storage, and potential returns. A lower upfront price may lead to higher TCO if quality issues arise.

-

Negotiate Volume Discounts: Discuss potential discounts for larger orders or long-term contracts. Many suppliers are willing to negotiate based on guaranteed sales.

-

Be Transparent About Needs: Clearly communicate your specifications and requirements to suppliers. This transparency fosters trust and can lead to more favorable pricing.

-

Stay Informed on Market Trends: Understanding current market conditions and pricing trends can empower buyers during negotiations. Knowledge of seasonal fluctuations or material shortages can provide leverage.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times. This is particularly relevant for markets in Africa, South America, and the Middle East.

What Should International Buyers Be Aware of Regarding Pricing Nuances?

International buyers should be aware of various nuances when sourcing gallon jug water bottles:

-

Currency Fluctuations: Pricing can be affected by changes in currency exchange rates. Establishing contracts in stable currencies may mitigate this risk.

-

Import Duties and Tariffs: Understanding the import regulations and potential tariffs in your country is vital. These can significantly impact the total cost.

-

Cultural Considerations: Building relationships with suppliers may yield better pricing and terms. Cultural nuances can affect negotiation styles and expectations.

-

Regulatory Compliance: Ensure that products meet local regulations, which can affect pricing if additional certifications or modifications are required.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and negotiation strategies can empower international B2B buyers to make informed decisions when sourcing gallon jug water bottles.

Alternatives Analysis: Comparing gallon jug water bottle With Other Solutions

When evaluating hydration solutions for businesses, understanding the various alternatives to the gallon jug water bottle is essential. This analysis provides a comparative overview of the gallon jug against two viable alternatives: multi-use water dispensers and individual portable water bottles. Each option presents unique benefits and challenges, allowing B2B buyers to make informed decisions based on their operational needs.

| Comparison Aspect | Gallon Jug Water Bottle | Multi-Use Water Dispenser | Individual Portable Water Bottle |

|---|---|---|---|

| Performance | Excellent for bulk hydration, maintains temperature well. | Provides a constant supply of water for multiple users. | Limited capacity; best for personal use. |

| Cost | Moderate initial investment; often reusable, reducing long-term costs. | Higher upfront costs for installation; potential ongoing water supply fees. | Low cost per unit; ideal for personal or small group use. |

| Ease of Implementation | Simple to use and refill; requires minimal setup. | Requires installation and potentially plumbing; may need regular maintenance. | Extremely easy to use; no setup required. |

| Maintenance | Low maintenance; regular cleaning needed. | Moderate maintenance; needs regular servicing and filter changes. | Minimal maintenance; generally easy to clean. |

| Best Use Case | Ideal for offices, gyms, and outdoor events needing bulk water. | Best for workplaces with high foot traffic requiring continuous access to water. | Suitable for individuals or small teams, especially in mobile settings. |

What are the Pros and Cons of a Multi-Use Water Dispenser?

Multi-use water dispensers provide a constant supply of hydration, catering to larger groups. They often feature filtration systems that ensure clean drinking water, making them a reliable choice for busy environments such as offices or factories. However, the installation costs can be significant, and ongoing maintenance, including filter replacements, can add to the total cost of ownership. Additionally, they require a dedicated space and may not be suitable for smaller or mobile setups.

How Do Individual Portable Water Bottles Compare?

Individual portable water bottles are an excellent choice for personal hydration, especially for employees on the go. They are lightweight, easy to carry, and often come in various designs and materials. The low cost per unit makes them an attractive option for bulk purchases. However, their capacity is limited compared to gallon jugs or dispensers, which may necessitate frequent refills for heavy users. They are also less effective in scenarios where large groups need simultaneous access to water.

Conclusion: Which Hydration Solution is Right for Your Business Needs?

When selecting the most suitable hydration solution for your organization, consider factors such as the size of your workforce, the expected water consumption, and the nature of your operations. The gallon jug water bottle excels in environments requiring bulk hydration with minimal maintenance, while multi-use water dispensers are ideal for high-traffic areas needing continuous access. Individual portable water bottles serve well for personal use but may fall short in group settings. Assessing your specific needs will guide you in choosing the right solution that balances cost, efficiency, and convenience.

Essential Technical Properties and Trade Terminology for gallon jug water bottle

What Are the Key Technical Properties of a Gallon Jug Water Bottle?

When evaluating gallon jug water bottles for B2B procurement, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

Most gallon jug water bottles are made from materials such as food-grade stainless steel, BPA-free plastic, or glass. Stainless steel offers durability and insulation, while BPA-free plastics are lightweight and often more affordable. The choice of material impacts the product’s longevity, safety, and thermal insulation properties, making it essential for buyers to consider the intended use and market demands. -

Capacity and Dimensions

The standard capacity of a gallon jug is 128 ounces. However, dimensions can vary based on design and material. Understanding the specific dimensions is critical for logistics, storage, and shipping purposes, especially for bulk orders. Buyers should ensure that the jugs fit within their distribution channels and retail spaces. -

Thermal Insulation Performance

Insulation properties are vital for maintaining beverage temperatures. Many high-quality gallon jugs offer double-wall vacuum insulation, which keeps drinks cold for extended periods. This property is particularly important for markets in hotter climates, as it enhances customer satisfaction and product appeal. -

Weight Tolerance

The weight of a filled gallon jug can exceed 10 pounds, depending on the material and design. Understanding the weight tolerance is essential for ensuring that the bottles can be comfortably handled and transported by end-users. It also affects shipping costs and packaging requirements. -

Durability and Impact Resistance

Durability is determined by the material and design of the bottle. Many gallon jugs are designed to be impact-resistant, which is crucial for reducing breakage during shipping and handling. This property is particularly important for B2B buyers looking to minimize losses and maintain supply chain efficiency. -

Cleaning and Maintenance Requirements

Ease of cleaning is an important property for B2B buyers, especially those in the food and beverage industry. Bottles with wide mouths or dishwasher-safe designs simplify maintenance, making them more appealing to consumers who prioritize convenience.

What Are Common Trade Terminology and Jargon Used in the Gallon Jug Water Bottle Industry?

Understanding industry-specific terminology can facilitate smoother transactions and negotiations. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of gallon jugs, an OEM may manufacture the bottles for a brand that markets them under its own name. This term is important for buyers who are looking to partner with manufacturers for custom branding. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it directly impacts inventory management and cost efficiency. Knowing the MOQ helps in budgeting and planning for large-scale purchases. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific products. Understanding how to issue an RFQ can lead to better pricing and terms, making it an essential tool for B2B negotiations. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, which are vital for international trade. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This term is significant for supply chain management, as longer lead times can affect inventory levels and sales. B2B buyers should negotiate lead times to ensure timely product availability. -

Certification Standards

Certification standards, such as ISO or FDA approval, indicate that a product meets specific safety and quality criteria. For gallon jug water bottles, understanding these certifications can assure buyers that the products are safe for consumer use, especially in markets with stringent regulations.

By understanding these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing gallon jug water bottles, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the gallon jug water bottle Sector

What Are the Global Drivers and Key Trends Shaping the Gallon Jug Water Bottle Market?

The gallon jug water bottle market is experiencing robust growth, driven by increasing health consciousness and the rising demand for sustainable drinking solutions. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing products that not only provide utility but also align with evolving consumer preferences for health and wellness. The trend of hydration awareness is fueling the popularity of gallon-sized water bottles, as consumers seek to meet daily hydration goals conveniently.

Emerging technologies in manufacturing and design are transforming the sector. Companies are investing in advanced materials that enhance insulation properties, ensuring that beverages maintain optimal temperatures for longer periods. Furthermore, customization options, including personalized branding and color choices, are becoming essential for B2B buyers looking to differentiate their offerings in competitive markets.

Market dynamics also reflect a shift towards e-commerce and digital platforms for sourcing. International buyers are leveraging online marketplaces to access a broader range of suppliers and products, facilitating easier comparisons in terms of pricing, quality, and sustainability credentials. As a result, businesses that embrace digital transformation in their procurement processes are more likely to secure advantageous deals and streamline their supply chains.

How Important Is Sustainability and Ethical Sourcing in the Gallon Jug Water Bottle Sector?

Sustainability is a critical consideration for international B2B buyers in the gallon jug water bottle sector. The environmental impact of plastic waste has prompted many companies to explore eco-friendly alternatives, such as reusable stainless steel and BPA-free materials. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through their manufacturing processes, packaging, and overall supply chain management.

Ethical sourcing is gaining traction as consumers demand transparency in the origins of their products. Brands that can showcase sustainable practices, such as reduced carbon footprints and responsible labor policies, are more likely to build trust with B2B partners and end consumers alike. Certifications like ISO 14001 for environmental management and the Global Recycled Standard (GRS) for recycled materials are becoming essential benchmarks for buyers evaluating suppliers.

In addition to meeting regulatory requirements, adopting sustainable practices can enhance brand reputation and customer loyalty. By aligning with suppliers that prioritize environmental stewardship, B2B buyers can contribute to a more sustainable future while also capitalizing on the growing market demand for eco-conscious products.

What Is the Historical Context Behind the Development of Gallon Jug Water Bottles?

The evolution of gallon jug water bottles can be traced back to the early 20th century when the need for portable hydration solutions became apparent, particularly in outdoor and athletic contexts. Initially crafted from glass and later transitioning to plastic, the design has continuously improved to enhance usability and durability. The introduction of insulated materials in recent decades marked a significant turning point, catering to a growing consumer desire for both convenience and performance.

Today, the market features a diverse array of products designed to meet various consumer needs, from rugged outdoor options to sleek, stylish designs for everyday use. This evolution reflects broader societal trends toward health, wellness, and sustainability, underscoring the importance of adaptability in product development for suppliers aiming to succeed in the competitive B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of gallon jug water bottle

-

How do I choose the right gallon jug water bottle supplier?

When selecting a supplier for gallon jug water bottles, prioritize those with a solid reputation and experience in the industry. Research their product range, focusing on quality certifications and compliance with international standards such as FDA or EU regulations. Request samples to evaluate material quality and durability. Additionally, assess their responsiveness and customer service by initiating inquiries. Consider suppliers who can provide testimonials or case studies from other businesses, particularly those in your target market regions. -

What customization options are available for gallon jug water bottles?

Many suppliers offer customization options for gallon jug water bottles, including color, branding, and size variations. You can request features such as personalized logos, unique shapes, or additional functionalities like built-in straws or handles. Minimum order quantities (MOQs) for customization often vary, so clarify these details with your supplier. Ensure that any customization aligns with your branding strategy and meets the preferences of your target market. -

What are the minimum order quantities (MOQs) for gallon jug water bottles?

MOQs for gallon jug water bottles can differ significantly between suppliers, typically ranging from 100 to 1,000 units depending on customization and production capabilities. When negotiating, consider the balance between your budget and the supplier’s requirements. If you’re a smaller business, look for suppliers willing to accommodate lower MOQs or explore options for combining orders with other buyers to meet the minimums. -

What payment terms should I expect when sourcing gallon jug water bottles?

Payment terms can vary widely among suppliers, often influenced by factors such as order size and relationship history. Common terms include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer net 30 or 60-day terms for established relationships. Always ensure that payment methods are secure, and consider using escrow services for large transactions to mitigate risks. -

How can I ensure quality assurance (QA) when purchasing gallon jug water bottles?

To maintain quality assurance, request detailed information about the supplier’s QA processes, including material sourcing, production methods, and testing protocols. Ask for certifications that confirm compliance with safety standards and regulations. Conduct factory audits if possible, or utilize third-party inspection services to verify product quality before shipment. Establish clear communication regarding your quality expectations and ensure they are documented in your purchase agreement. -

What logistics considerations should I keep in mind when importing gallon jug water bottles?

When importing gallon jug water bottles, factor in shipping costs, customs duties, and import regulations specific to your country. Work with a logistics partner familiar with international shipping to navigate these complexities. Determine the best shipping method based on cost and urgency, whether by sea or air. Additionally, ensure that your supplier provides the necessary documentation for customs clearance, including invoices and packing lists. -

What are the benefits of using insulated gallon jug water bottles for my business?

Insulated gallon jug water bottles offer significant advantages for businesses, particularly in hot climates. They help maintain beverage temperature for extended periods, ensuring that customers enjoy refreshing cold water. This feature can enhance customer satisfaction and encourage repeat purchases. Additionally, insulated bottles often come with robust designs that can withstand rough handling, making them suitable for various settings, including outdoor events or sports activities. -

How do I handle returns or defects with my gallon jug water bottle orders?

Establish a clear return policy with your supplier before placing an order, detailing the process for handling defective items or unsatisfactory quality. Typically, suppliers will require you to report defects within a specified timeframe and may ask for photographic evidence. Understand the supplier’s warranty policy, which may cover replacements for defective products. Maintain open communication to resolve issues promptly and ensure customer satisfaction, as this reflects positively on your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Gallon Jug Water Bottle Manufacturers & Suppliers List

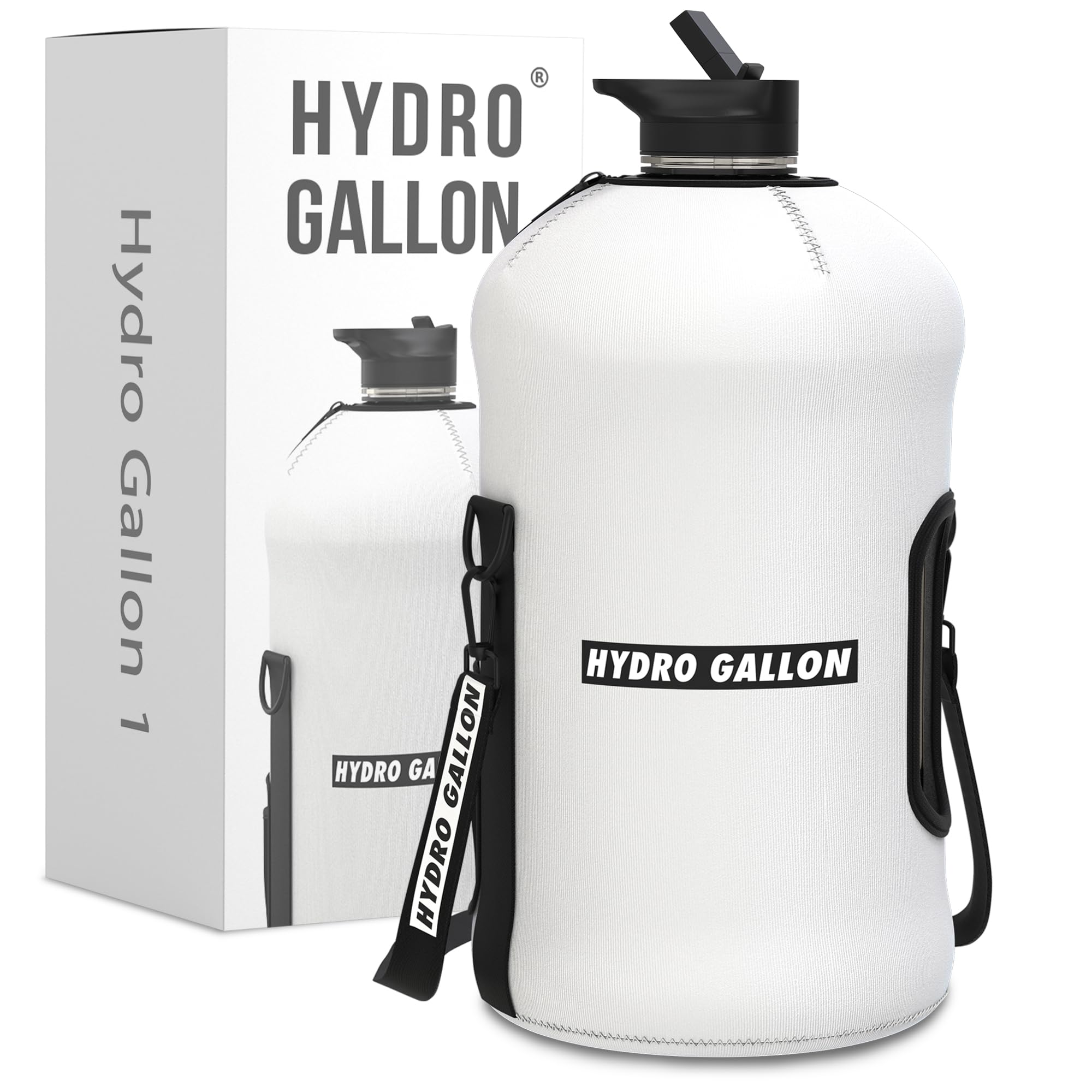

1. Hydro Gallon – Key Products

Domain: hydrogallon.com

Registered: 2020 (5 years)

Introduction: Hydro Gallon offers a range of gallon water bottles designed for all-day hydration. Key products include: 1 Gallon Hydro Gallon, Hydro Gallon 1 Pro, Hydro Gallon Tactical, and a new Half Gallon Nomad. Features include a backpack mode for the Nomad, 24-hour cold retention for the Tactical model, and durability for the original Hydro Gallon 1. The brand also provides sleeves, replacement parts, and …

2. 6 Pack Fitness – Gallon Gear Jug

Domain: 6packfitness.com

Registered: 2004 (21 years)

Introduction: Gallon Gear 1 Gallon Jug | Gym Water Bottle (Black)

3. Under Armour – UA Sideline 1-Gallon Jug Water Bottle

Domain: underarmour.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘UA Sideline 1-Gallon Jug Water Bottle’, ‘price’: ‘$22’, ‘rating’: ‘4.3’, ‘reviews_count’: 98, ‘colors’: [‘Black / Red – 001’, ‘Silica Green / Titan Gray – 348’, ‘Stream – 494’, ‘Blaze Orange – 825’], ‘features’: [‘Leakproof 2-way cap with smooth spout design’, ‘Wide mouth top for easy cleaning and adding ice or supplements’, ‘Air gaps on the bottom to reduce heat generation’, ‘Durable, s…

4. Durable One-Gallon Water Bottles – Top Alternatives to Yeti

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a good one-gallon water bottle to bring to work. Considering alternatives to Yeti due to insulation performance issues. Desired features include durability, ability to last a lifetime, and resistance to drops. Concerns about weight for carrying around.

5. Poland Spring® – 1 Gallon Jug Spring Water

Domain: polandspring.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “1 Gallon Jug Spring Water”, “Brand”: “Poland Spring®”, “Product Size”: “1 gal”, “Available Sizes”: [“12 fl oz”, “8 fl oz”, “16.9 fl oz”, “20 fl oz”, “23.7 fl oz”, “1 L”, “1.5 L”, “3 L”, “1 G”, “2.5 G”, “3 G”, “5 G”, “25 fl oz”], “Pack Size”: “single”, “Nutritional Information”: {“Calories”: “0mg”, “Total Fat”: “0mg”, “Sodium”: “0mg”, “Protein”: “0mg”}, “Ingredients”: “Spring Wate…

6. Target – Gallon Water Bottles

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Gallon Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for gallon jug water bottle

In conclusion, the strategic sourcing of gallon jug water bottles offers significant advantages for international B2B buyers, particularly in markets across Africa, South America, the Middle East, and Europe. By focusing on quality, durability, and insulation performance, businesses can ensure they select products that meet the diverse needs of their clientele. The variety of options available—from budget-friendly to premium insulated models—allows buyers to tailor their selections based on specific market demands and consumer preferences.

The importance of sourcing from reliable suppliers cannot be overstated; it not only enhances product quality but also fosters long-term partnerships that drive business growth. As global demand for hydration solutions continues to rise, staying informed about trends and innovations in the water bottle sector will be crucial for maintaining a competitive edge.

Looking ahead, international B2B buyers should actively seek partnerships that prioritize sustainability, product versatility, and innovative designs. By embracing these strategies, businesses can position themselves to capitalize on emerging market opportunities and ensure they remain at the forefront of the hydration solutions industry. Now is the time to explore new sourcing strategies that align with your business goals and customer needs.