Introduction: Navigating the Global Market for top rated shaker bottles

In the competitive landscape of fitness and wellness products, sourcing top-rated shaker bottles can pose a significant challenge for international B2B buyers. With a plethora of options available, it’s crucial to identify bottles that not only meet quality standards but also cater to diverse market needs across regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany. This comprehensive guide addresses those challenges head-on, providing insights into various types of shaker bottles, their applications, and essential supplier vetting processes.

Throughout this guide, we delve into key factors influencing purchasing decisions, such as material durability, mixing efficiency, and user-friendliness. We also explore cost considerations and emerging trends in shaker bottle design and functionality. By equipping B2B buyers with actionable insights and detailed product comparisons, this resource empowers informed purchasing decisions, ensuring that businesses can confidently stock their shelves with high-quality shaker bottles that resonate with their target audiences.

As you navigate the global market for shaker bottles, this guide serves as your trusted partner, offering clarity and direction in a crowded marketplace. Prepare to enhance your procurement strategy and meet the rising demand for innovative, reliable, and stylish shaker bottles that cater to the health-conscious consumer.

Article Navigation

- Top 7 Top Rated Shaker Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for top rated shaker bottles

- Understanding top rated shaker bottles Types and Variations

- Key Industrial Applications of top rated shaker bottles

- 3 Common User Pain Points for ‘top rated shaker bottles’ & Their Solutions

- Strategic Material Selection Guide for top rated shaker bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for top rated shaker bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘top rated shaker bottles’

- Comprehensive Cost and Pricing Analysis for top rated shaker bottles Sourcing

- Alternatives Analysis: Comparing top rated shaker bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for top rated shaker bottles

- Navigating Market Dynamics and Sourcing Trends in the top rated shaker bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of top rated shaker bottles

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for top rated shaker bottles

Understanding top rated shaker bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Plastic Shaker | Lightweight, budget-friendly, simple design | Gyms, health clubs, retail stores | Pros: Affordable, easy to clean. Cons: Less durable, may retain odors. |

| Insulated Stainless Steel | Double-wall insulation, keeps drinks cold | Premium fitness brands, corporate gifts | Pros: Durable, keeps beverages cold/hot. Cons: Heavier, higher price point. |

| Electric Blender Shaker | Battery-operated, automatic mixing mechanism | Rehabilitation centers, sports teams | Pros: Effortless mixing, suitable for diverse users. Cons: Requires charging, more complex to clean. |

| Tritan Sport Shaker | BPA-free, odor-resistant, various color options | Retail, promotional giveaways | Pros: Durable, lightweight, customizable. Cons: Not insulated, may scratch easily. |

| 2-in-1 Shaker Tumbler | Combines shaker and tumbler functionalities | On-the-go fitness, convenience stores | Pros: Versatile, space-saving. Cons: Limited capacity, may not mix as well. |

What Are the Characteristics of Classic Plastic Shakers?

Classic plastic shakers are the most common type, often made from lightweight materials like BPA-free plastic. Their simple design typically features a screw-on lid and a mixing ball or net for effective blending. These shakers are ideal for gyms and health clubs, appealing to budget-conscious consumers. When purchasing, B2B buyers should consider the balance between cost and quality, as lower-priced options may compromise durability and odor resistance.

How Do Insulated Stainless Steel Shakers Stand Out?

Insulated stainless steel shakers are designed to maintain the temperature of beverages, making them suitable for both hot and cold drinks. Their double-wall construction offers superior durability, ideal for high-end fitness brands and corporate gift options. B2B buyers should evaluate the weight and price point, as these shakers tend to be heavier and more expensive than their plastic counterparts, which could affect shipping costs and retail pricing strategies.

What Are the Benefits of Electric Blender Shakers?

Electric blender shakers utilize a battery-operated mechanism to mix beverages seamlessly, making them particularly useful in rehabilitation centers or for athletes with joint issues. These shakers provide an effortless mixing experience, reducing the physical effort required. When considering these products, B2B buyers must take into account the additional cleaning complexities and the need for battery maintenance, which could impact long-term customer satisfaction.

Why Choose Tritan Sport Shakers for Your Business?

Tritan sport shakers are made from a durable, BPA-free plastic that is both lightweight and odor-resistant. They come in various colors and designs, allowing for customization, which is advantageous for promotional giveaways. B2B buyers should focus on the durability and aesthetic appeal when selecting these shakers, as they can enhance brand visibility while remaining cost-effective.

What Makes 2-in-1 Shaker Tumblers a Convenient Choice?

The 2-in-1 shaker tumbler combines the functions of a shaker and a traditional tumbler, catering to consumers seeking versatility and convenience. This makes them ideal for on-the-go fitness enthusiasts and convenience stores. However, the limited capacity and potential mixing inefficiency are drawbacks. B2B buyers should assess the target market’s needs for functionality versus capacity when considering these products for their inventory.

Key Industrial Applications of top rated shaker bottles

| Industry/Sector | Specific Application of top rated shaker bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness and Sports | Mixing protein supplements for athletes | Enhances performance through proper nutrition; promotes brand loyalty | Durability, ease of cleaning, and insulation features |

| Food and Beverage | Preparing flavored beverages or smoothies | Diversifies product offerings; meets consumer demand for convenience | Material safety, design aesthetics, and portability |

| Health and Wellness | Mixing dietary supplements and vitamins | Supports health trends; improves customer satisfaction | Non-toxicity, ease of use, and storage capabilities |

| Pharmaceuticals | Compounding medication solutions | Ensures accurate dosing; enhances patient compliance | Precision in mixing, material integrity, and compliance with regulations |

| Education and Training | Demonstrating mixing techniques in nutrition courses | Engages students; enhances learning experiences | Educational branding, visibility, and instructional materials |

How Are Top Rated Shaker Bottles Used in the Fitness and Sports Industry?

In the fitness and sports sector, top rated shaker bottles are essential for athletes to mix protein supplements, pre-workout powders, and recovery drinks. Their design allows for easy shaking, ensuring that ingredients blend smoothly without clumping. For B2B buyers, durability and ease of cleaning are paramount, as these bottles undergo rigorous daily use. Additionally, insulated options are highly sought after to keep drinks at optimal temperatures during workouts, appealing to athletes’ preferences for functionality and performance.

What Role Do Shaker Bottles Play in the Food and Beverage Sector?

In the food and beverage industry, shaker bottles serve as a convenient tool for preparing flavored beverages, smoothies, and meal replacements. Their versatility allows businesses to cater to health-conscious consumers seeking quick and easy nutrition solutions. When sourcing these products, companies should consider material safety and design aesthetics, as attractive packaging can enhance brand appeal. Portability is another critical factor, especially for products aimed at on-the-go consumers, making shaker bottles a strategic addition to product lines.

How Do Shaker Bottles Support Health and Wellness Trends?

Top rated shaker bottles are widely used in the health and wellness sector for mixing dietary supplements and vitamins. Their ability to create smooth, lump-free mixtures aligns with consumer expectations for quality and effectiveness. B2B buyers must prioritize non-toxicity and ease of use, as these factors significantly influence customer satisfaction. Moreover, storage capabilities, such as compartments for powders, are beneficial for consumers looking for convenience in their daily routines, thus enhancing the product’s marketability.

Why Are Shaker Bottles Important in Pharmaceuticals?

In pharmaceuticals, shaker bottles are utilized for compounding medication solutions, where accurate mixing is crucial for ensuring correct dosages. This application requires precise engineering to maintain material integrity and compliance with health regulations. B2B buyers in this sector should focus on sourcing shaker bottles that meet stringent quality standards, as the safety and effectiveness of medications depend on proper mixing. The ability to provide clear labeling and user instructions can also enhance operational efficiency within pharmacies and healthcare facilities.

How Can Shaker Bottles Enhance Educational Experiences in Nutrition Training?

In educational settings, particularly in nutrition courses, shaker bottles are employed to demonstrate mixing techniques for various dietary supplements. Their use engages students and enriches the learning experience by providing hands-on practice with real-world applications. When sourcing these products, educational institutions should consider branding opportunities, such as custom designs that reflect the institution’s identity. Visibility and instructional materials, including guides on effective mixing methods, can further enhance the educational value of these bottles in training programs.

3 Common User Pain Points for ‘top rated shaker bottles’ & Their Solutions

Scenario 1: Inconsistent Mixing Quality Across Different Shaker Bottle Brands

The Problem: B2B buyers often face frustration when sourcing shaker bottles that consistently deliver high mixing quality. Many brands vary significantly in their ability to dissolve protein powders and other supplements effectively. This inconsistency not only affects the quality of the end product but can also lead to dissatisfied customers and increased returns, particularly when businesses rely on shaker bottles for their branding or retail purposes.

The Solution: To ensure a consistent mixing experience, B2B buyers should prioritize sourcing shaker bottles that have been rigorously tested for performance. Look for brands that utilize advanced mixing technologies, such as patented mixing systems or specialized mixing balls designed to break down powders efficiently. Request samples from suppliers and conduct thorough testing with various protein powders to evaluate the mixing capabilities. Additionally, consider bottles that have a reputation for being easy to clean and maintain, which can enhance their longevity and performance. Establish partnerships with suppliers who offer transparent feedback and insights from other users in the industry to make more informed purchasing decisions.

Scenario 2: Concerns Over Durability and Material Safety

The Problem: Durability and safety of materials are paramount for B2B buyers, especially when dealing with shaker bottles intended for frequent use in gyms or outdoor activities. Many buyers are apprehensive about the potential for bottles to crack, leak, or degrade over time, especially those made from plastic. Additionally, concerns about harmful chemicals like BPA in plastic materials can deter buyers, impacting their purchasing decisions and trust in the product.

The Solution: To address these concerns, B2B buyers should prioritize shaker bottles made from high-quality, food-grade materials. Options such as stainless steel or BPA-free Tritan plastic provide excellent durability while ensuring safety. When selecting a supplier, inquire about their quality assurance processes and request certifications that demonstrate compliance with safety standards. Consider investing in insulated options that not only provide durability but also maintain the temperature of beverages, appealing to health-conscious consumers. Buyers should also look for brands that offer warranties or guarantees, ensuring that they can return or replace defective products without hassle.

Scenario 3: Difficulty in Cleaning and Maintenance

The Problem: Many B2B buyers encounter challenges with cleaning shaker bottles, particularly those with complex designs or numerous components. Residues from protein powders and other supplements can build up over time, leading to unpleasant odors and unsanitary conditions. This issue is particularly critical for businesses that promote hygiene and cleanliness, as it can negatively affect their brand image and customer satisfaction.

The Solution: To mitigate cleaning challenges, B2B buyers should seek shaker bottles designed for easy maintenance. Opt for bottles with wider openings that allow for thorough cleaning and those that are dishwasher safe. Inquire about the design of the lids and seals; simpler designs with fewer nooks and crannies can significantly reduce cleaning time and effort. Additionally, providing guidance to customers on proper cleaning techniques, such as using warm soapy water or specialized cleaning tablets, can enhance user experience. Partnering with suppliers that offer educational resources on product care can also empower buyers to maintain their shaker bottles effectively, thus prolonging their usability and ensuring a positive customer experience.

Strategic Material Selection Guide for top rated shaker bottles

What Are the Key Materials Used in Top Rated Shaker Bottles?

When selecting shaker bottles for international markets, understanding the materials used in their construction is crucial. Different materials offer varying properties that can affect product performance, durability, and user satisfaction. Here, we analyze four common materials used in top-rated shaker bottles: plastic (Tritan), stainless steel, aluminum, and glass.

How Does Tritan Plastic Perform in Shaker Bottles?

Tritan plastic is a popular choice for shaker bottles due to its lightweight and shatter-resistant properties. It can withstand temperatures up to 100°C (212°F) and is resistant to staining and odors, making it suitable for various beverages. Tritan is also BPA-free, which is a significant selling point in health-conscious markets.

Pros: Tritan is durable, cost-effective, and easy to manufacture. It is also available in various colors and designs, appealing to a broad consumer base.

Cons: Despite its durability, Tritan can scratch over time and may not withstand extreme temperatures as well as metal options. Its lifespan is generally shorter compared to stainless steel.

Impact on Application: Tritan is compatible with a wide range of liquids, including protein shakes, smoothies, and water, making it versatile for fitness enthusiasts.

Considerations for International Buyers: Compliance with food safety standards such as FDA or EU regulations is essential. Buyers in regions like Africa and South America may prefer BPA-free options, while European buyers might focus on certifications like DIN.

What Are the Advantages of Stainless Steel Shaker Bottles?

Stainless steel shaker bottles are renowned for their durability and insulation properties. They can maintain the temperature of liquids for extended periods, making them ideal for both hot and cold beverages. Stainless steel also has a high resistance to corrosion and is easy to clean.

Pros: These bottles are extremely durable and often feature double-wall insulation, which enhances their thermal performance. They also have a premium look and feel, appealing to higher-end markets.

Cons: The manufacturing process for stainless steel is more complex and costly compared to plastic. Additionally, they are heavier, which may deter some users.

Impact on Application: Stainless steel is suitable for a variety of liquids, including hot beverages, without the risk of leaching harmful chemicals.

Considerations for International Buyers: Compliance with ASTM standards for food safety is crucial. Buyers in the Middle East may prefer insulated options due to the region’s hot climate, while European buyers often seek sustainability in materials.

How Does Aluminum Compare in Shaker Bottle Construction?

Aluminum shaker bottles are lightweight and often feature a powder-coated finish for added durability. They provide a good balance between weight and strength, making them popular among athletes.

Pros: Aluminum is generally more affordable than stainless steel and offers a good strength-to-weight ratio. The powder coating can provide additional customization options.

Cons: Aluminum can react with acidic liquids, which may lead to leaching if not properly coated. It is also less durable than stainless steel and can dent easily.

Impact on Application: Aluminum is suitable for protein shakes and water but may not be ideal for acidic beverages like citrus juices.

Considerations for International Buyers: Buyers should ensure that the aluminum used is food-grade and complies with relevant health standards. In regions like Nigeria, where cost is a significant factor, aluminum might be preferred for budget-conscious consumers.

What Role Does Glass Play in Shaker Bottle Design?

Glass shaker bottles are praised for their aesthetic appeal and purity of taste. They do not leach chemicals and are easy to clean, making them a popular choice for health-conscious consumers.

Pros: Glass is non-reactive, making it suitable for all types of beverages. It is also recyclable, appealing to environmentally conscious buyers.

Cons: Glass is heavy and prone to breaking, which can be a significant drawback for active users.

Impact on Application: Glass is ideal for water and protein shakes but may not be practical for on-the-go use due to its fragility.

Considerations for International Buyers: Buyers in Europe may prioritize glass due to environmental concerns, while those in Africa may be more cautious about the fragility of glass products.

Summary Table of Material Properties for Shaker Bottles

| Material | Typical Use Case for top rated shaker bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tritan Plastic | Protein shakes, smoothies, water | Lightweight and shatter-resistant | Scratches easily, shorter lifespan | Medium |

| Stainless Steel | Hot and cold beverages | Durable and excellent insulation | Heavier and more expensive | High |

| Aluminum | Protein shakes, water | Affordable and lightweight | Can react with acidic liquids | Low |

| Glass | Water, protein shakes | Non-reactive and recyclable | Heavy and prone to breakage | Medium |

By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for top rated shaker bottles

What Are the Main Stages in the Manufacturing Process of Top Rated Shaker Bottles?

The manufacturing of top-rated shaker bottles involves several critical stages, ensuring the final product meets both functional and aesthetic standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality materials, such as BPA-free plastics, stainless steel, or Tritan™. Suppliers often perform a thorough evaluation of raw materials to ensure they meet industry standards for safety and durability. For plastic bottles, granules are pre-processed and tested for purity and consistency, while metal components undergo a similar quality check.

-

Forming: This stage focuses on shaping the bottles. For plastic shaker bottles, techniques like injection molding are commonly used, allowing for mass production with high precision. In contrast, stainless steel bottles may be formed using deep-drawing or hydroforming techniques, which shape the material without compromising its integrity. Manufacturers may also employ advanced methods, such as blow molding, for creating complex shapes.

-

Assembly: Once the individual components are formed, the assembly process begins. This includes attaching lids, mixing mechanisms (like balls or nets), and any additional features such as compartments for storing powders. Automation plays a significant role in this stage, ensuring consistency in assembly and reducing labor costs.

-

Finishing: The final stage involves surface treatments, which enhance both aesthetics and functionality. This may include applying coatings for color, texture, or insulation properties. Quality checks are performed to ensure that the finishing meets the design specifications and that there are no defects.

How Is Quality Assurance Implemented in the Production of Shaker Bottles?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the shaker bottles produced are safe, durable, and reliable. Several international and industry-specific standards guide these processes.

-

International Standards: Many manufacturers adhere to ISO 9001, which sets the criteria for a quality management system. This standard helps organizations ensure they meet customer and regulatory requirements consistently. Compliance with ISO standards signals to B2B buyers that the manufacturer is committed to quality and continuous improvement.

-

Industry-Specific Certifications: Certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the market. CE certification ensures that products meet EU safety, health, and environmental requirements, while API standards may apply to specific industrial applications.

-

Quality Control Checkpoints: Quality control (QC) typically involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified standards before they enter the production line.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards, allowing for immediate corrective actions.

– Final Quality Control (FQC): After assembly, a thorough inspection is conducted to ensure the finished products meet all quality criteria. This includes functionality tests, visual inspections, and sometimes even stress testing.

What Testing Methods Are Commonly Used for Shaker Bottles?

Testing methods are crucial for validating the quality and safety of shaker bottles. Common testing procedures include:

- Leak Testing: Ensures that bottles do not leak when filled with liquid. This is often done through pressure testing or submersion tests.

- Durability Testing: Evaluates how well the bottles withstand physical stress, including drop tests and cyclic loading tests.

- Thermal Insulation Testing: For insulated bottles, tests measure how well the bottles maintain temperature under different conditions.

- Chemical Testing: This assesses the safety of materials used, ensuring they are free from harmful substances like BPA or phthalates.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential. Here are key strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s facilities, processes, and adherence to quality standards. This firsthand evaluation can provide insights into the supplier’s capabilities.

-

Quality Assurance Reports: Requesting detailed quality assurance documentation can help buyers understand the QC measures in place. These reports should outline testing methods, results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality. These inspections can also verify that the supplier complies with international standards.

-

Certifications and Compliance: Buyers should verify that suppliers possess relevant certifications (e.g., ISO 9001, CE) and understand any nuances in compliance that may vary by region. This can help mitigate risks associated with importing products that may not meet local regulations.

What Nuances Should International Buyers Consider in Quality Control?

International buyers must navigate various complexities when it comes to quality control:

-

Cultural Differences: Understanding the manufacturing culture in different regions can impact communication and expectations. For example, different regions may have varying standards for what constitutes “acceptable quality.”

-

Regulatory Variations: Compliance requirements can differ significantly between regions. Buyers should familiarize themselves with local regulations regarding product safety and quality to ensure compliance.

-

Logistical Challenges: Shipping and logistics can affect product quality, particularly if items are exposed to extreme temperatures or conditions during transport. Buyers should consider working with suppliers who have robust logistics solutions in place.

By understanding these manufacturing and quality assurance processes, international B2B buyers can make informed decisions when sourcing top-rated shaker bottles, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘top rated shaker bottles’

Introduction

Sourcing top-rated shaker bottles requires a strategic approach to ensure quality, functionality, and supplier reliability. This guide provides a step-by-step checklist designed for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. By following these steps, you will be better equipped to make informed purchasing decisions that meet your business needs.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s essential to outline your technical specifications for shaker bottles. Consider factors such as material (plastic, stainless steel, or insulated), capacity (typically ranging from 16 to 32 ounces), and design features (such as leak-proof lids and mixing mechanisms). Establishing these parameters will help narrow down your options and ensure the products meet your quality standards.

Step 2: Research Market Trends

Understanding current market trends is crucial for making informed purchasing decisions. Investigate what features are gaining popularity among consumers, such as eco-friendly materials or innovative designs. Analyze competitors and gather insights on what types of shaker bottles are performing well in your target regions, as this can inform your purchasing strategy and product offerings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with established reputations and positive customer feedback, as this will help ensure reliability and quality.

- Key Considerations:

- Certifications (ISO, FDA, etc.)

- Production capacity and lead times

- Previous experience with international shipping

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the shaker bottles. Testing samples allows you to evaluate the quality, functionality, and durability of the products before making a bulk purchase. Pay attention to how well the shaker mixes ingredients, ease of cleaning, and overall user experience.

Step 5: Analyze Pricing and Payment Terms

When sourcing shaker bottles, analyze pricing structures and payment terms offered by suppliers. Compare costs across different suppliers while considering quality and features to ensure you’re getting the best value. Look for flexible payment options that suit your cash flow requirements, such as net terms or bulk purchase discounts.

Step 6: Verify Compliance with Regional Regulations

Ensure that the shaker bottles comply with the regulations and standards of your target markets. Different regions may have specific safety, health, and environmental regulations that your products must meet. Verify that your supplier can provide necessary documentation and certifications to facilitate smooth import processes.

Step 7: Establish a Communication Plan

Effective communication with your supplier is vital for a successful sourcing experience. Establish a clear communication plan outlining preferred channels, response times, and points of contact. Regular updates on order status, production timelines, and any potential issues will help maintain a strong working relationship and ensure timely delivery.

By following this checklist, B2B buyers can effectively navigate the sourcing process for top-rated shaker bottles, ensuring that they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for top rated shaker bottles Sourcing

What Are the Key Cost Components in Sourcing Top Rated Shaker Bottles?

When sourcing shaker bottles, understanding the cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences the cost. Common materials include plastic (Tritan, polypropylene) and stainless steel. While plastic shakers are typically cheaper, stainless steel options, known for their durability and insulation properties, command higher prices.

-

Labor: Labor costs can vary widely based on geographic location. In regions with lower labor costs, such as parts of Asia, the overall production cost may decrease. Conversely, sourcing from Europe may incur higher labor costs but can offer better quality assurance.

-

Manufacturing Overhead: This includes expenses related to the production facility, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead, ultimately lowering the cost for buyers.

-

Tooling: Initial tooling costs for custom designs can be significant. Buyers should consider whether they need unique molds for their branding or specific product features, as this can impact the overall pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards. However, it adds to the overall cost structure. Buyers should factor in these costs when evaluating suppliers.

-

Logistics: Shipping costs vary based on the origin and destination, volume, and Incoterms. Buyers must account for these expenses in their total cost assessment.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margin in the industry can provide insight into fair pricing.

How Do Price Influencers Impact the Cost of Shaker Bottles?

Several factors influence the pricing of shaker bottles, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk orders. Understanding the MOQ can help negotiate better pricing, especially for larger buyers.

-

Specifications and Customization: Customized shaker bottles with unique features or branding may incur additional costs. Buyers should weigh the benefits of customization against the added expense.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., BPA-free, FDA-approved) can justify higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: Supplier reputation, reliability, and history can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive pricing to build their market presence.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. CIF (Cost, Insurance, and Freight) may include insurance costs, while FOB (Free on Board) places more responsibility on the buyer, impacting overall pricing.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing Shaker Bottles?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate with Suppliers: Leverage volume commitments and long-term partnerships to negotiate better pricing and terms. Building a relationship with suppliers can lead to more favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with the product over its lifecycle, including purchase price, shipping, potential tariffs, and disposal. This comprehensive view helps in making informed decisions.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations, import duties, and taxes can significantly affect costs. Buyers should stay informed about these factors to avoid surprises.

-

Conduct Market Research: Regularly assess market trends and competitor pricing to ensure you are sourcing at competitive rates. This knowledge can be a powerful tool during negotiations.

Disclaimer on Indicative Prices

Prices for shaker bottles can vary widely based on multiple factors, including but not limited to the aforementioned cost components and price influencers. Therefore, the prices provided in various references are indicative and may not represent the final costs incurred by buyers. Always conduct thorough due diligence and obtain quotes from multiple suppliers to ensure a fair and competitive price.

Alternatives Analysis: Comparing top rated shaker bottles With Other Solutions

In the competitive landscape of beverage preparation, particularly for protein shakes and supplements, B2B buyers have various options beyond traditional shaker bottles. Understanding these alternatives can help businesses make informed decisions based on their specific operational needs, budgets, and target markets.

| Comparison Aspect | Top Rated Shaker Bottles | Electric Blender Bottles | Manual Mixing Techniques |

|---|---|---|---|

| Performance | Excellent mixing, minimal clumps | Superior blending, eliminates granules | Variable, depends on user technique |

| Cost | $10 – $30 per unit | $30 – $70 per unit | Minimal (requires no equipment) |

| Ease of Implementation | User-friendly, portable | Requires charging and maintenance | Simple, no special tools needed |

| Maintenance | Low, easy to clean | Moderate, parts may wear out | None, just requires a container |

| Best Use Case | Ideal for on-the-go use | Best for high-volume production | Suitable for small batches, home use |

What Are the Pros and Cons of Electric Blender Bottles?

Electric blender bottles offer a significant advantage in terms of performance, providing a smooth and consistent mix without the need for vigorous shaking. This is particularly beneficial for users with physical limitations or those who prefer convenience. However, they come with a higher cost and require regular charging, which may not be practical for all users. Maintenance can also be an issue, as the motor and other components may wear out over time, necessitating replacement.

How Do Manual Mixing Techniques Compare to Shaker Bottles?

Manual mixing techniques, such as using a simple container and a whisk or spoon, can be incredibly cost-effective. They require no special equipment and are easy to implement, making them accessible to everyone. However, the performance is inconsistent; achieving a smooth mixture depends heavily on the user’s technique and effort. This method may lead to more clumps and an overall less pleasant drinking experience, especially for protein shakes that require thorough mixing.

Conclusion: How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting between top-rated shaker bottles and alternative solutions, B2B buyers should consider their target market and specific use cases. For businesses catering to fitness enthusiasts or on-the-go consumers, high-quality shaker bottles may be the best fit due to their portability and ease of use. Conversely, if the focus is on convenience and high-volume mixing, electric blender bottles could be more suitable despite their higher cost and maintenance needs. Manual mixing techniques may serve niche markets or budget-conscious consumers but might not meet the expectations of users seeking premium performance. Ultimately, understanding the unique requirements of your clientele will guide you in making the best choice.

Essential Technical Properties and Trade Terminology for top rated shaker bottles

What Are the Key Technical Properties of Top Rated Shaker Bottles?

Understanding the essential technical properties of shaker bottles is crucial for B2B buyers looking to source high-quality products. Here are some critical specifications to consider:

-

Material Grade

The most common materials used in shaker bottles include Tritan, stainless steel, and high-density polyethylene (HDPE). Tritan is known for its durability and resistance to odors and stains, making it a popular choice for high-end models. Stainless steel provides excellent insulation and longevity, while HDPE is lightweight and cost-effective. Selecting the right material can impact product durability, customer satisfaction, and overall brand reputation. -

Capacity (Volume)

Shaker bottles typically range from 16 oz to 32 oz. Understanding the capacity is essential for targeting specific consumer segments, such as athletes who may require larger volumes for hydration or casual users who prefer smaller sizes. Offering a range of capacities can enhance market reach and cater to diverse customer needs. -

Leak Resistance

A key feature that influences customer satisfaction is leak resistance. Look for bottles with silicone seals or lockable lids that ensure a secure closure. Testing for leak resistance can reduce product returns and enhance brand trust, especially for users who transport liquids frequently. -

Mixing Mechanism

Different shaker bottles utilize various mixing mechanisms, such as wire whisks, mesh screens, or built-in blending props. Each mechanism affects the mixing efficiency and the final texture of the drink. Understanding the benefits of each type can guide buyers in selecting products that meet their specific mixing needs. -

Insulation Properties

Insulated shaker bottles keep beverages cold or hot for extended periods, making them ideal for fitness enthusiasts. Double-walled stainless steel is a common choice for insulation. Evaluating insulation properties can be critical for positioning products in markets where temperature retention is a selling point. -

Ease of Cleaning

Shaker bottles that are dishwasher safe or have simple designs are more appealing to consumers. Products with fewer crevices or removable components can be easier to clean, which is a significant factor in user satisfaction. Ensuring ease of cleaning can enhance product longevity and customer loyalty.

What Are the Common Trade Terms Associated with Shaker Bottles?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of shaker bottles, B2B buyers may engage with OEMs to create custom designs or brands without investing in manufacturing infrastructure. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell in a single order. Understanding MOQs is essential for inventory management and financial planning, especially for businesses that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. It is a critical step in the procurement process, enabling buyers to compare offers and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help in negotiating contracts and understanding the logistics involved in importing shaker bottles. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving it. Knowing the lead time is crucial for inventory planning and meeting customer demand, especially in fast-moving markets. -

Quality Assurance (QA)

QA is a systematic process to ensure that products meet specified requirements. Implementing quality assurance protocols can help buyers maintain product consistency, reduce defects, and enhance customer satisfaction.

Understanding these properties and terms can empower B2B buyers to make informed decisions when sourcing shaker bottles, ultimately leading to better partnerships and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the top rated shaker bottles Sector

What Are the Key Trends Influencing the Global Shaker Bottle Market?

The global shaker bottle market is experiencing significant growth, driven by a surge in health consciousness and fitness trends. As more consumers prioritize nutrition and hydration, demand for high-quality shaker bottles that can effectively mix protein powders and supplements is on the rise. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly focused on sourcing products that meet local preferences and market demands.

Emerging technologies are also influencing sourcing trends, with innovations such as BPA-free plastics and insulated materials becoming commonplace. These advancements cater to the needs of health-conscious consumers who seek products that enhance their overall wellness experience. Furthermore, the rise of e-commerce platforms has made it easier for B2B buyers to access a wider range of shaker bottles, providing them with the ability to compare products and prices efficiently.

Additionally, the market dynamics are shifting towards custom branding and private labeling as companies strive to differentiate their offerings. Buyers are looking for suppliers who can provide unique designs and features, such as odor-resistant materials and easy-to-clean components. The ability to cater to these specific requirements is crucial for suppliers aiming to penetrate these diverse markets.

How Is Sustainability Shaping the Sourcing of Shaker Bottles?

Sustainability has become a pivotal concern for international B2B buyers, impacting their sourcing decisions significantly. The environmental impact of plastic waste is prompting buyers to seek shaker bottles made from eco-friendly materials. Suppliers that offer products made from recycled or biodegradable plastics are increasingly favored, as they align with the sustainability goals of businesses across various sectors.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about the sourcing practices of their suppliers, preferring those who can demonstrate responsible manufacturing processes. Certifications such as ISO 14001 for environmental management and Fair Trade practices are becoming essential for suppliers to gain credibility in the market.

The adoption of ‘green’ certifications is also a growing trend, with many companies striving to achieve compliance with global environmental standards. This shift not only helps mitigate the environmental impact but also enhances brand reputation, making products more appealing to eco-conscious consumers. For B2B buyers in regions like Germany and Nigeria, aligning with suppliers who prioritize sustainability can lead to improved market positioning and customer loyalty.

How Has the Shaker Bottle Market Evolved Over Time?

The evolution of the shaker bottle market reflects broader changes in consumer behavior and lifestyle. Initially, shaker bottles were primarily viewed as functional containers for mixing supplements. However, as the fitness industry evolved and consumer preferences shifted, shaker bottles have transformed into lifestyle products.

In recent years, the introduction of innovative designs and materials has expanded the functionality of shaker bottles. Features such as built-in compartments for powders, insulated walls for temperature retention, and ergonomic designs for easier handling have become standard. This evolution has allowed shaker bottles to cater to a broader audience, including athletes, fitness enthusiasts, and casual users alike.

As the market continues to grow, it remains vital for B2B buyers to stay informed about these trends and adapt their sourcing strategies accordingly. Understanding the historical context can provide valuable insights into current market dynamics and help buyers make informed decisions when selecting suppliers and products.

Frequently Asked Questions (FAQs) for B2B Buyers of top rated shaker bottles

-

How do I choose the right shaker bottle for my business needs?

Choosing the right shaker bottle involves evaluating several factors, including material, capacity, and intended use. For instance, if your target market includes fitness enthusiasts, consider durable and insulated options. Assess your branding needs; customizable bottles with your logo can enhance brand visibility. Additionally, examine the price points that align with your budget and customer expectations. Conducting a survey or obtaining samples can help determine the preferences of your target audience, ensuring you select a product that meets their needs. -

What is the best material for shaker bottles?

The best material for shaker bottles largely depends on their intended use and market preferences. Plastic shakers, typically made from BPA-free Tritan, are lightweight and affordable but may not be as durable as stainless steel options. Stainless steel shakers offer superior insulation and longevity, making them ideal for premium markets. For eco-conscious consumers, consider biodegradable or recyclable materials. Ultimately, the choice of material should reflect your brand’s values and the expectations of your target market. -

What customization options are available for shaker bottles?

Customization options for shaker bottles can vary by supplier. Common options include printing logos, selecting colors, and adding unique designs or features like compartments for supplements. Some manufacturers offer bespoke molds for entirely unique shapes. When sourcing, inquire about the minimum order quantities (MOQs) for customized products, as these can differ significantly among suppliers. Customization not only enhances brand recognition but also allows you to cater to specific market trends or consumer preferences. -

How can I vet suppliers for shaker bottles?

Vetting suppliers for shaker bottles involves a thorough assessment of their credibility, production capabilities, and quality assurance processes. Start by checking their business licenses and certifications, such as ISO standards. Request samples to evaluate product quality firsthand. Additionally, consider their production capacity and lead times to ensure they can meet your demands. Look for reviews or testimonials from other B2B clients, and consider visiting their manufacturing facilities if possible. Building a relationship with reliable suppliers is crucial for long-term success. -

What are typical minimum order quantities (MOQs) for shaker bottles?

Minimum order quantities (MOQs) for shaker bottles can vary widely based on the manufacturer and the level of customization. Generally, standard plastic shaker bottles may have MOQs ranging from 500 to 1,000 units, while customized or premium options may require larger orders, often starting at 1,500 to 5,000 units. It’s essential to discuss MOQs upfront with potential suppliers to understand their policies and negotiate terms that align with your business needs and market strategy. -

What payment terms should I expect when sourcing shaker bottles internationally?

Payment terms can vary by supplier and region, but it’s common to encounter options like 30% upfront payment and 70% upon shipment. Some suppliers may offer letter of credit (LC) options for larger orders, providing additional security. Always clarify payment methods accepted, such as wire transfers, PayPal, or escrow services. For international transactions, consider potential currency exchange fluctuations and transaction fees. Establishing clear payment terms can help mitigate risks and facilitate smoother transactions. -

How do I ensure quality assurance for shaker bottles?

To ensure quality assurance for shaker bottles, establish clear specifications and standards before production begins. Request a quality control plan from your supplier, detailing inspection processes at various production stages. Consider conducting third-party inspections or audits, particularly for larger orders. Additionally, request samples and perform quality checks upon receipt. Building a strong relationship with your supplier can also encourage adherence to quality standards, as reputable manufacturers prioritize customer satisfaction and product integrity. -

What logistics considerations should I keep in mind when importing shaker bottles?

When importing shaker bottles, logistics considerations include shipping methods, customs regulations, and lead times. Decide between air freight for faster delivery or ocean freight for cost-effectiveness, depending on your budget and urgency. Familiarize yourself with import duties and tariffs that may apply in your country. Collaborate with a reliable freight forwarder to navigate logistics efficiently. Additionally, ensure you have adequate warehousing solutions in place to manage inventory upon arrival, minimizing storage costs and potential disruptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Top Rated Shaker Bottles Manufacturers & Suppliers List

1. BlenderBottle – Insulated Stainless Sport Shaker

Domain: blenderbottle.com

Registered: 1999 (26 years)

Introduction: Best Shaker Cups & Protein Shaker Bottles | BlenderBottle®

– Insulated Stainless Shakers

– Plastic Shakers

– The Classic – #1 Shaker Bottle in the World

– Free US Shipping on Orders $50+

– Product Variants:

– Insulated Stainless Sport: $27.99, 4.5 (739 reviews), Colors: Cobalt, Cranberry, Nightshade, Grapefruit

– Stainless Sleek Sport: $29.99, 4.4 (113 reviews), Colors: Sherbet, Seafoam, Lave…

2. BlenderBottle – Classic V2 Shaker Bottle

Domain: garagegymreviews.com

Registered: 2014 (11 years)

Introduction: Best Shaker Bottle Overall: BlenderBottle Classic V2 Shaker Bottle\nGGR Score: 4.65\nProduct Highlights: New and improved V2 BlenderBall Classic with rounded base and Spoutguard.\nFeatures: Measurements markings, rounded base, adjustable carry loop, classic BlendBall wire whisk, spout guard.\nPros: More affordable than competitors, top rack dishwasher safe, available in multiple sizes from 20-45 o…

3. Helimix – Innovative Protein Shaker

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Helimix protein shaker: durable, easy to clean, no mixing device required, utilizes bottle shape for mixing, no rubber seals for easier cleaning, measures up to 600ml/20oz, made of high-quality thick plastic.

4. Contigo – Shake and Go Fit Shaker Bottle

Domain: verywellfit.com

Registered: 2017 (8 years)

Introduction: Best Overall: Contigo Shake and Go Fit Shaker Bottle – $15, Capacity: 28 ounces, Material: BPA-free plastic, Blending Mechanism: Weighted shaker ball, Insulated: No, Dishwasher Safe: Yes, top rack only. Easiest to Clean: Helimix Vortex Blender Shaker Bottle – $25, Capacity: 28 ounces, Material: BPA-free plastic, Blending Mechanism: Helix walls of cup, Insulated: No, Dishwasher Safe: Yes, top rack …

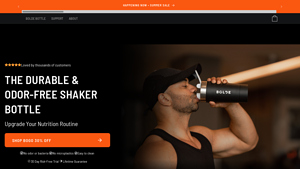

5. Bolde – Bolde Bottle

Domain: self.com

Registered: 1994 (31 years)

Introduction: Best Overall: Bolde Bottle – $55, Material: Stainless steel, food-grade silicone, Sizes: 20-oz. bottle with 6 oz. storage compartment or 26-oz. bottle with no storage compartment, Pros: Lifetime guarantee, Dishwasher-safe (top rack recommended), Fits in most standard cupholders, Cons: Heavier than plastic options, Higher price point, but built to last. Runner-up: Huel Shaker – $15, Pros: Lightweig…

6. BOLDE® – All-Steel Shaker Bottle

Domain: boldebottle.com

Registered: 2018 (7 years)

Introduction: BOLDE® Bottle is an all-steel, odor-free shaker bottle designed for durability and hygiene. Key features include:

– Made with 304 Stainless Steel to prevent odor and bacteria absorption.

– No microplastics, ensuring a healthier drinking experience.

– Easy to clean and dishwasher safe.

– Premium silicone seal to prevent leaks.

– Available in two sizes: 20 oz and 26 oz.

– Backed by a lifetime guaran…

7. Helimix – Shaker Bottle 2.0

Domain: helimix.com

Registered: 2016 (9 years)

Introduction: Product Name: Helimix Shaker Bottle 2.0

Key Features:

– Made in the USA

– Available Sizes: 20-ounce and 28-ounce

– Material: BPA/BPS-free Copolyester plastic

– Unique hexagonal vortex design for effective mixing without balls or screens

– Odor-resistant and top-rack dishwasher safe

– Leak-proof lid with a satisfying snap closure

– Variety of colors available: Black, Graphite, Cement Gray, White, Q…

Strategic Sourcing Conclusion and Outlook for top rated shaker bottles

In summary, strategic sourcing of top-rated shaker bottles presents a significant opportunity for B2B buyers to enhance their product offerings. By focusing on key features such as material durability, mixing effectiveness, and ease of cleaning, businesses can cater to diverse customer preferences across various regions. The increasing demand for high-quality, functional shaker bottles underscores the importance of sourcing from reputable manufacturers that align with international quality standards.

As buyers in Africa, South America, the Middle East, and Europe evaluate their options, it is crucial to prioritize suppliers who demonstrate innovation and responsiveness to market trends. Engaging with manufacturers that offer a variety of designs and functionalities—such as insulated options and those with integrated storage compartments—can enhance customer satisfaction and brand loyalty.

Looking ahead, the shaker bottle market is poised for growth, driven by the rising health and wellness trend. International B2B buyers should act now to secure partnerships with leading suppliers, ensuring they are well-positioned to meet the evolving demands of health-conscious consumers. Your next strategic sourcing decision could significantly impact your competitive edge—embrace this opportunity for growth and market leadership.