Introduction: Navigating the Global Market for 1 gallon drinking bottle

In today’s fast-paced global market, sourcing a reliable and high-quality 1 gallon drinking bottle can pose significant challenges for international B2B buyers. As demand for sustainable and durable hydration solutions continues to rise across diverse regions—including Africa, South America, the Middle East, and Europe—businesses must navigate a landscape filled with varying product standards, supplier reliability, and logistical considerations. This guide serves as a comprehensive resource, equipping buyers with essential insights into the types of 1 gallon drinking bottles available, their applications across industries, and practical strategies for supplier vetting.

Within these pages, you will discover detailed analyses of materials, designs, and features that cater to specific market needs, from insulated options ideal for hot climates to eco-friendly alternatives that align with sustainability goals. Additionally, we address critical factors such as cost analysis, import regulations, and potential partnerships, empowering you to make informed purchasing decisions that enhance your product offerings and satisfy your customer base. By leveraging this guide, B2B buyers can confidently navigate the complexities of sourcing 1 gallon drinking bottles, ensuring they meet both quality expectations and market demands.

Article Navigation

- Top 7 1 Gallon Drinking Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 1 gallon drinking bottle

- Understanding 1 gallon drinking bottle Types and Variations

- Key Industrial Applications of 1 gallon drinking bottle

- 3 Common User Pain Points for ‘1 gallon drinking bottle’ & Their Solutions

- Strategic Material Selection Guide for 1 gallon drinking bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 1 gallon drinking bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 gallon drinking bottle’

- Comprehensive Cost and Pricing Analysis for 1 gallon drinking bottle Sourcing

- Alternatives Analysis: Comparing 1 gallon drinking bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 1 gallon drinking bottle

- Navigating Market Dynamics and Sourcing Trends in the 1 gallon drinking bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 1 gallon drinking bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for 1 gallon drinking bottle

Understanding 1 gallon drinking bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Insulated Stainless Steel | Keeps beverages cold or hot for extended periods, durable, often BPA-free | Outdoor events, corporate gifting, fitness facilities | Pros: Excellent temperature retention; Cons: Higher cost compared to plastic options. |

| BPA-Free Plastic | Lightweight, affordable, and often available in various colors | Schools, gyms, and healthcare settings | Pros: Cost-effective and lightweight; Cons: Less durable and may not retain temperature well. |

| Glass with Protective Sleeve | Aesthetic appeal, eco-friendly, often with silicone or neoprene sleeves | Wellness brands, eco-conscious companies | Pros: Non-toxic and stylish; Cons: Heavier and more fragile than other materials. |

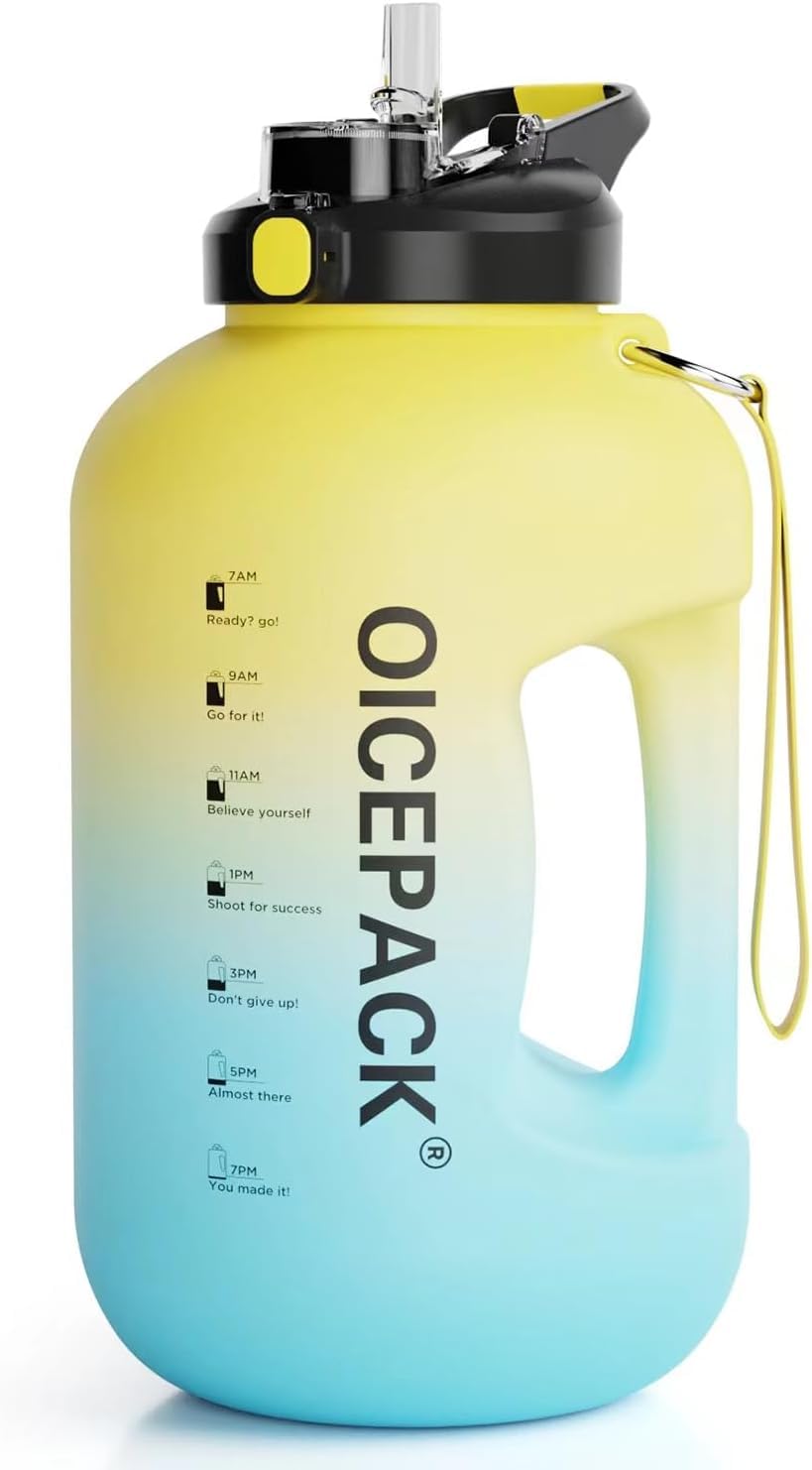

| Motivational Water Bottles | Features time markers for hydration tracking, often made from plastic or stainless steel | Health and wellness programs, employee wellness initiatives | Pros: Encourages healthy habits; Cons: May not be suitable for rugged outdoor use. |

| Tactical Water Bottles | Rugged design, often includes features like built-in handles and attachments | Military, outdoor adventure companies, emergency preparedness | Pros: Highly durable and functional; Cons: Typically heavier and bulkier. |

What Are the Characteristics of Insulated Stainless Steel Gallon Bottles?

Insulated stainless steel gallon bottles are designed to maintain beverage temperatures for long periods, making them ideal for outdoor events and corporate gifts. Their robust construction typically includes features like multiple lid options and BPA-free materials, appealing to businesses focused on quality and safety. When purchasing, consider the insulation performance, weight, and additional accessories, as these factors can significantly affect user experience.

Why Choose BPA-Free Plastic Gallon Bottles for Your Business?

BPA-free plastic gallon bottles are lightweight and affordable, making them a popular choice for schools, gyms, and healthcare settings. Their versatility in color and design allows businesses to customize for branding purposes. However, while they are cost-effective, it’s essential to consider their lower durability and temperature retention capabilities when making bulk purchases.

What Makes Glass Bottles with Protective Sleeves a Smart Choice?

Glass bottles with protective sleeves offer an eco-friendly solution with aesthetic appeal, making them suitable for wellness brands and companies focused on sustainability. The protective sleeve helps prevent breakage, enhancing usability in various settings. Buyers should evaluate the weight and fragility of glass options, especially if they intend to distribute them in environments prone to accidents.

How Do Motivational Water Bottles Benefit Businesses?

Motivational water bottles feature time markers that encourage users to stay hydrated throughout the day, making them ideal for health and wellness programs. They are often made from either plastic or stainless steel, catering to different budget ranges. When considering these products for employee wellness initiatives, assess the design and capacity to ensure they meet the users’ needs.

What Are the Advantages of Tactical Water Bottles for Outdoor Use?

Tactical water bottles are designed for rugged environments, featuring durable materials and practical designs that often include built-in handles and attachment points. These bottles are particularly suited for military, outdoor adventure companies, and emergency preparedness applications. Buyers should focus on the weight and bulkiness of these bottles, as they can impact portability and convenience in field settings.

Key Industrial Applications of 1 gallon drinking bottle

| Industry/Sector | Specific Application of 1 gallon drinking bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Bulk beverage storage and distribution | Cost-effective hydration solution for large events | Food-grade materials, durability, ease of transport |

| Agriculture | Hydration for livestock and farm workers | Ensures consistent water supply for productivity | UV resistance, portability, and ease of cleaning |

| Construction and Outdoor | On-site hydration for workers | Promotes health and safety by preventing dehydration | Insulation properties, durability, and ease of handling |

| Fitness and Wellness | Personal hydration for gyms and fitness centers | Encourages water intake, enhancing performance | BPA-free materials, ergonomic design, and branding options |

| Hospitality and Events | Beverage service for catering and events | Improves guest experience with convenient hydration | Customization options, aesthetic appeal, and ease of use |

How is the 1 Gallon Drinking Bottle Used in the Food and Beverage Industry?

In the food and beverage sector, 1-gallon drinking bottles serve as a practical solution for bulk beverage storage and distribution, particularly for events and catering services. These bottles can hold large quantities of water or other drinks, making it easier to serve guests efficiently. Businesses benefit from reduced costs associated with purchasing smaller containers, while also ensuring that they meet health and safety standards. When sourcing, it is crucial to ensure that the bottles are made from food-grade materials to maintain beverage quality and safety.

What Role Does the 1 Gallon Drinking Bottle Play in Agriculture?

In agriculture, 1-gallon drinking bottles are essential for providing hydration to both livestock and farm workers. These bottles can be placed in various locations around farms, ensuring that animals and workers have access to fresh water throughout the day. This not only promotes health and productivity but also helps prevent dehydration-related issues. Buyers should consider sourcing bottles that are UV resistant and easy to clean, as they will be exposed to outdoor conditions and require regular maintenance.

Why are 1 Gallon Drinking Bottles Important for Construction and Outdoor Work?

For construction sites and outdoor work environments, 1-gallon drinking bottles are vital for ensuring workers stay hydrated, particularly in hot weather. These bottles are designed to be durable and portable, making them easy to transport across job sites. By promoting hydration, companies can enhance worker safety and productivity. When sourcing these bottles, it’s important to look for options with insulation properties to keep water cool and designs that facilitate easy handling.

How Do Fitness Centers Utilize 1 Gallon Drinking Bottles?

In fitness and wellness facilities, 1-gallon drinking bottles are increasingly popular among gym-goers and fitness enthusiasts. These bottles encourage individuals to increase their water intake, which is essential for optimal performance during workouts. They often feature ergonomic designs and motivational markers to track hydration levels. For B2B buyers, selecting BPA-free materials is critical to ensure safety, alongside options for customization to enhance brand visibility in gyms and fitness centers.

What Benefits Do 1 Gallon Drinking Bottles Provide in Hospitality and Events?

In the hospitality sector, especially during events and catering services, 1-gallon drinking bottles offer a convenient way to serve beverages. They enhance the guest experience by providing easy access to hydration without the need for constant refills from smaller containers. Additionally, these bottles can be customized for branding purposes, making them a marketing tool in addition to a functional item. Buyers should focus on sourcing aesthetically pleasing designs that are also easy to use and refill, ensuring they meet the demands of high-traffic events.

3 Common User Pain Points for ‘1 gallon drinking bottle’ & Their Solutions

Scenario 1: Ensuring Durability for Harsh Environments

The Problem: B2B buyers in industries such as construction or outdoor recreation often require water bottles that can withstand rough handling and extreme conditions. Traditional plastic or glass gallon bottles may crack, shatter, or leak under stress, leading to wasted water and increased costs. In regions with extreme temperatures, such as the deserts of the Middle East or the cold climates of northern Europe, maintaining the integrity of the water bottle is critical for hydration and operational efficiency.

The Solution: When sourcing 1-gallon drinking bottles for tough environments, prioritize materials known for durability, such as food-grade stainless steel. Look for bottles that are specifically designed for rugged use, featuring double-walled insulation to prevent condensation and keep water cold or hot for extended periods. Additionally, consider bottles with reinforced handles and impact-resistant designs. Suppliers should provide detailed specifications about the materials used and offer warranties to ensure buyers feel confident in their investment. Conducting thorough product testing in real-world conditions can also help in selecting the right bottle, ensuring it meets the demands of your specific environment.

Scenario 2: Addressing Hygiene and Cleanliness Concerns

The Problem: In sectors such as healthcare or food services, maintaining hygiene standards is paramount. Traditional water bottles can harbor bacteria, especially if they are not cleaned frequently or are made from materials that can absorb odors or stains. B2B buyers need to ensure that the bottles they purchase do not compromise their operational health standards, which can lead to serious repercussions if not addressed.

The Solution: Opt for 1-gallon drinking bottles made from BPA-free materials that are easy to clean and resistant to bacterial growth. Stainless steel and certain types of high-grade plastics are ideal as they do not retain flavors or odors and can often be washed in commercial dishwashers. Buyers should also consider bottles with wide mouths for easy filling and cleaning. Implementing a regular cleaning schedule and training staff on proper hygiene practices can further mitigate risks. Additionally, seeking suppliers who offer customization options, such as branded bottles with time markers or motivational messages, can enhance both hygiene and brand presence.

Scenario 3: Managing Logistics and Bulk Supply Issues

The Problem: For businesses that require large quantities of 1-gallon drinking bottles—such as event organizers or corporate offices—managing logistics can be a significant challenge. Coordinating bulk orders, ensuring timely deliveries, and maintaining consistent quality across batches can lead to frustrations and potential operational disruptions.

The Solution: Establish relationships with reliable suppliers that specialize in bulk sales of 1-gallon drinking bottles. When negotiating contracts, include clauses for quality assurance and delivery schedules to ensure that the bottles meet your specifications and arrive on time. Utilizing a centralized procurement system can streamline the ordering process, making it easier to track inventory levels and reorder supplies before running low. Additionally, consider suppliers that offer flexible shipping options, such as direct-to-site deliveries, which can reduce logistical burdens. Regular communication with your suppliers will help address any issues proactively, ensuring that your hydration needs are consistently met without interruption.

Strategic Material Selection Guide for 1 gallon drinking bottle

What Are the Key Materials for 1 Gallon Drinking Bottles?

In the competitive landscape of 1-gallon drinking bottles, selecting the right material is crucial for performance, safety, and marketability. This section analyzes four common materials used in the production of these bottles: BPA-free plastic, stainless steel, glass, and aluminum. Each material has distinct properties, advantages, and limitations that can significantly impact product performance and customer satisfaction.

How Does BPA-Free Plastic Perform in 1 Gallon Drinking Bottles?

BPA-free plastic is a popular choice for 1-gallon drinking bottles due to its lightweight nature and resistance to shattering. Key properties include a temperature rating that can withstand moderate heat and cold, making it suitable for various beverages. However, while BPA-free plastics offer a safer alternative to traditional plastics, they may not be as durable as other materials.

Pros of BPA-free plastic include low manufacturing costs and the ability to produce bottles in various colors and designs. However, the cons involve potential issues with long-term durability and environmental concerns regarding plastic waste. For international buyers, compliance with regulations such as FDA standards is essential, especially in regions like Europe where environmental sustainability is prioritized.

What Advantages Does Stainless Steel Offer for 1 Gallon Drinking Bottles?

Stainless steel is renowned for its durability and resistance to corrosion, making it an excellent choice for 1-gallon drinking bottles. It can withstand high temperatures and is generally resistant to dents and scratches. The material is also non-reactive, ensuring that beverages maintain their original taste without leaching harmful chemicals.

The key advantages of stainless steel include its long lifespan and superior insulation properties, which keep beverages hot or cold for extended periods. However, the disadvantages include higher manufacturing costs and weight, which can deter some consumers. B2B buyers should consider compliance with international standards, such as ASTM or JIS, to ensure product quality and safety, especially in markets like the Middle East and Africa, where durability is a key consideration.

How Does Glass Compare as a Material for 1 Gallon Drinking Bottles?

Glass is an increasingly popular choice for drinking bottles due to its aesthetic appeal and safety. It is completely non-toxic and does not interact with beverages, ensuring a clean taste. Glass bottles can also handle a wide range of temperatures, though they are more susceptible to breakage.

The pros of glass include its recyclability and the premium feel it provides, which can enhance brand image. The cons, however, are significant, including weight and fragility, which can lead to higher shipping costs and potential breakage during transit. For international buyers, ensuring compliance with safety standards is critical, particularly in regions with stringent regulations regarding food and beverage containers.

What Role Does Aluminum Play in 1 Gallon Drinking Bottles?

Aluminum is a lightweight and durable material often used for 1-gallon drinking bottles. It is resistant to corrosion and can be easily shaped, allowing for creative designs. Aluminum bottles are typically lined to prevent any metallic taste from affecting the beverage.

The key advantages of aluminum include its lightweight nature and the ability to create eye-catching designs, which can be appealing in competitive markets. However, the disadvantages include potential issues with insulation and the need for a lining, which can complicate the manufacturing process. Buyers in regions like South America and Europe should be aware of compliance with environmental regulations, as aluminum recycling is a significant factor in sustainability initiatives.

Summary Table of Material Selection for 1 Gallon Drinking Bottles

| Material | Typical Use Case for 1 gallon drinking bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| BPA-Free Plastic | Lightweight, budget-friendly options | Low manufacturing cost | Less durable, environmental concerns | Low |

| Stainless Steel | Premium, insulated bottles | Long lifespan, excellent insulation | Higher cost, heavier weight | High |

| Glass | Eco-friendly, premium aesthetic | Non-toxic, recyclable | Fragile, heavier | Medium |

| Aluminum | Lightweight, creative designs | Lightweight, corrosion-resistant | Potential insulation issues | Medium |

This material selection guide provides actionable insights for B2B buyers, enabling informed decisions that align with market demands and compliance requirements across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 1 gallon drinking bottle

What Are the Main Stages in the Manufacturing Process of a 1 Gallon Drinking Bottle?

The manufacturing of a 1-gallon drinking bottle typically involves several key stages, each critical to ensuring product quality and performance.

Material Preparation

The first step is the selection and preparation of materials, which can include plastics (such as PET, HDPE, or BPA-free options) or stainless steel. For plastic bottles, raw materials are sourced from reputable suppliers, ensuring compliance with international safety standards. The materials are then processed through various methods, such as extrusion or injection molding, to create preforms or blanks that will later be shaped into the final product. For stainless steel bottles, high-grade food-safe stainless steel is cut and prepared for forming.

Forming Techniques

Once materials are prepared, the forming process begins. For plastic bottles, the most common methods are blow molding or injection molding. Blow molding involves heating the plastic until it is malleable, then inflating it within a mold to form the desired shape. In contrast, injection molding forces molten plastic into a mold, allowing for precision in bottle design. For stainless steel bottles, processes such as deep drawing or spinning may be employed, where sheets of metal are shaped into a bottle form.

Assembly and Finishing

After forming, the next stage is assembly. This may include attaching lids, straws, or handles, depending on the bottle design. Quality assurance checks are often integrated into this stage to ensure that all components fit properly and function as intended. Finally, finishing processes such as polishing, coating, or printing are applied to enhance aesthetics and functionality. These steps not only improve the product’s appearance but also its resistance to wear and tear.

How Is Quality Assurance Implemented in 1 Gallon Drinking Bottle Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, particularly for products intended for international markets. A robust QA system helps to ensure that the bottles meet safety and quality standards while also satisfying customer expectations.

What Are the Relevant International Standards for Quality Assurance?

Manufacturers of 1-gallon drinking bottles must adhere to various international standards, such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain applications may also be relevant.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage inspects raw materials and components upon arrival. Suppliers must provide documentation proving compliance with specifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes are followed correctly and that any deviations are addressed immediately. This includes monitoring temperature, pressure, and material consistency during forming.

-

Final Quality Control (FQC): After assembly, a final inspection verifies that each bottle meets quality standards before packaging. This includes checks for leaks, surface defects, and functionality.

What Common Testing Methods Are Used for 1 Gallon Drinking Bottles?

Various testing methods are employed to ensure the integrity and safety of drinking bottles. Common tests include:

-

Leak Testing: Bottles are filled with water and subjected to pressure tests to ensure they do not leak.

-

Thermal Insulation Testing: For insulated bottles, manufacturers may test their ability to maintain temperature over time.

-

Material Safety Testing: This includes checks for BPA and other harmful chemicals, particularly for plastic bottles, to comply with health regulations.

-

Durability Testing: Bottles undergo drop tests and stress tests to determine their resistance to impact and wear.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those in international markets, should implement robust strategies to verify the quality control practices of their suppliers.

What Are the Best Practices for Supplier Audits?

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Audits should assess compliance with international standards and evaluate the effectiveness of their QA systems.

-

Request Quality Reports: Suppliers should be able to provide detailed reports on their quality control measures, including test results and compliance certifications. These documents should be reviewed carefully.

-

Utilize Third-Party Inspection Services: Employing third-party inspection services can help ensure unbiased evaluations of the supplier’s quality practices. These services can conduct inspections at various stages of production, providing an extra layer of assurance.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various regulations and certification requirements specific to their regions. For instance, products sold in the European Union may need to comply with the General Product Safety Directive and require CE marking. In contrast, buyers in the Middle East may need to consider local regulations and standards set by agencies such as the Saudi Standards, Metrology and Quality Organization (SASO).

Understanding these nuances is essential for ensuring compliance and avoiding costly delays or penalties. Buyers should engage with legal or compliance experts familiar with the target market to ensure that all necessary certifications and quality standards are met.

Conclusion

Understanding the manufacturing processes and quality assurance measures for 1-gallon drinking bottles is essential for B2B buyers. By comprehensively assessing supplier capabilities, adhering to international standards, and implementing robust verification strategies, buyers can ensure they procure high-quality products that meet their specific needs. This proactive approach not only fosters trust with suppliers but also enhances the overall integrity of their supply chain.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 gallon drinking bottle’

In the global market for 1-gallon drinking bottles, making informed decisions can significantly impact your procurement success. This guide offers a structured approach to sourcing these essential products, ensuring you select high-quality options that meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring the product meets your requirements. Consider factors such as material (e.g., BPA-free plastic, stainless steel), insulation properties, and design features like handles or straws. This clarity helps in comparing options and communicating effectively with suppliers.

Step 2: Research Market Trends and Demand

Understanding current market trends and consumer preferences can guide your purchasing decisions. Analyze data regarding popular materials, sustainability practices, and design innovations. Keeping abreast of market insights ensures you align your procurement strategy with consumer expectations, especially in diverse regions like Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers that demonstrate reliability and have a track record of timely deliveries and quality assurance.

- Check Certifications: Ensure suppliers comply with international standards and regulations, such as ISO certifications.

- Assess Product Range: A supplier with a diverse product range can offer flexibility in sourcing additional items as your needs evolve.

Step 4: Request Samples for Quality Assurance

Before finalizing your order, request samples to evaluate the quality of the bottles. Testing the bottles for durability, insulation, and overall functionality can prevent potential issues once they are in use. Pay attention to the weight, feel, and ease of use, as these factors can affect customer satisfaction.

Step 5: Negotiate Pricing and Terms

Engage in discussions regarding pricing, payment terms, and delivery schedules. A thorough negotiation can lead to better pricing structures, especially for bulk orders. Always clarify shipping costs and timelines to avoid surprises that could affect your supply chain.

Step 6: Understand Import Regulations

For international transactions, familiarize yourself with import regulations specific to your region. Understanding duties, taxes, and compliance standards is essential to avoid delays and additional costs during shipping. Consulting with logistics experts can provide valuable insights into the best practices for smooth customs clearance.

Step 7: Establish a Long-term Relationship

Building a strong relationship with your suppliers can lead to better service, pricing, and product innovations in the long run. Regular communication and feedback can help you stay informed about new product offerings and market trends. Establishing trust can also facilitate smoother negotiations and faster problem resolution in the future.

By following this checklist, B2B buyers can streamline their procurement process for 1-gallon drinking bottles, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for 1 gallon drinking bottle Sourcing

What Are the Key Cost Components for Sourcing 1 Gallon Drinking Bottles?

When sourcing 1-gallon drinking bottles, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of material significantly impacts cost. Common options include BPA-free plastic, stainless steel, and glass. Stainless steel, while more durable and insulated, tends to be pricier than plastic alternatives.

-

Labor: Labor costs vary by region and manufacturing processes. Automated production methods can reduce labor costs, while skilled labor may be required for quality assurance in premium products.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing facilities can help minimize these costs.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, especially for customized designs. Understanding the tooling requirements early in the sourcing process can help buyers anticipate these expenses.

-

Quality Control (QC): Ensuring product safety and quality is crucial, particularly for international buyers concerned about compliance with local regulations. QC processes can add to the overall cost but are essential for maintaining brand integrity.

-

Logistics: Shipping costs depend on the distance from the supplier, shipping method, and the size and weight of the bottles. International logistics may involve additional tariffs and customs fees, impacting the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the industry standard margins can aid buyers in negotiations.

How Do Price Influencers Affect the Cost of 1 Gallon Drinking Bottles?

Several factors influence the pricing of 1-gallon drinking bottles:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit prices. Suppliers may offer tiered pricing based on order volume, encouraging larger orders.

-

Specifications and Customization: Custom designs, colors, and features (like insulation or built-in straws) can significantly increase costs. Standardized products generally come at a lower price point.

-

Materials and Quality Certifications: High-quality materials and certifications (like FDA approval for food safety) can raise the price. Buyers should weigh the benefits of these features against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge a premium, while newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) dictate who bears the shipping costs and risks. Understanding these terms is crucial for calculating the total landed cost.

What Are Effective Buyer Tips for Sourcing 1 Gallon Drinking Bottles?

To maximize cost-efficiency when sourcing 1-gallon drinking bottles, buyers should consider the following tips:

-

Negotiate Terms: Leverage volume purchases to negotiate better pricing and payment terms. Building a relationship with suppliers can also lead to favorable conditions.

-

Assess Total Cost of Ownership: Look beyond the initial purchase price. Consider factors like durability, maintenance, and logistics costs to determine the true cost over the product’s lifecycle.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying costs due to labor, material availability, and shipping expenses. Buyers from Africa, South America, the Middle East, and Europe should account for these regional differences in their sourcing strategy.

-

Stay Informed on Market Trends: Regularly review market trends and competitor pricing to ensure you’re getting a fair deal. This knowledge can empower you during negotiations and help identify potential cost-saving opportunities.

Disclaimer on Indicative Prices

Prices for 1-gallon drinking bottles can fluctuate based on market conditions, material costs, and supplier factors. Therefore, it’s advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing 1 gallon drinking bottle With Other Solutions

Understanding Alternatives to 1 Gallon Drinking Bottles

In the quest for hydration solutions, 1 gallon drinking bottles are a popular choice among businesses. However, several alternatives exist that may better meet the specific needs of different organizations. Each option offers unique benefits and drawbacks that can significantly impact operational efficiency, cost, and user satisfaction. Here, we will compare the 1 gallon drinking bottle against two viable alternatives: bulk water dispensers and reusable water pouches.

Comparison Table

| Comparison Aspect | 1 Gallon Drinking Bottle | Bulk Water Dispenser | Reusable Water Pouch |

|---|---|---|---|

| Performance | Good insulation; portable | High volume, less portable | Lightweight, collapsible |

| Cost | Moderate ($20 – $60) | Variable ($50 – $200+ depending on size) | Low ($10 – $30) |

| Ease of Implementation | Simple; ready to use | Requires space and setup | Easy to use, minimal setup |

| Maintenance | Low; occasional cleaning | Moderate; requires regular cleaning and refilling | Low; easy to clean and store |

| Best Use Case | Individual use, events | Offices, large gatherings | Outdoor activities, travel |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Bulk Water Dispensers?

Bulk water dispensers serve as a significant alternative for organizations that require large volumes of water. They can hold several gallons at once and are ideal for environments where multiple users need access simultaneously, such as offices or event venues. While they offer convenience in terms of volume, they come with higher initial costs and require dedicated space for installation. Maintenance involves regular cleaning and refilling, which can be a logistical challenge in busy settings. However, for organizations focused on high-capacity hydration needs, bulk dispensers can be an efficient solution.

How Do Reusable Water Pouches Compare to 1 Gallon Drinking Bottles?

Reusable water pouches are designed for portability and convenience, making them an excellent option for outdoor activities or travel. These lightweight alternatives can be easily folded and stored when not in use. The initial investment is typically lower than that of a gallon bottle, making it budget-friendly. However, while they are easy to clean, they may not provide the same level of insulation or durability as traditional bottles, particularly for long-term use. Businesses that prioritize mobility and minimal storage space will find these pouches particularly advantageous.

Choosing the Right Solution for Your Business Needs

When selecting the best hydration solution, B2B buyers should consider the specific requirements of their organization. If hydration needs are centered around high-capacity consumption, a bulk water dispenser may be the most effective choice despite its higher cost and maintenance needs. On the other hand, for businesses that prioritize individual use or require portable options for outdoor events, 1 gallon drinking bottles or reusable water pouches might be more suitable. Understanding the unique benefits and limitations of each alternative will empower businesses to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for 1 gallon drinking bottle

What Are the Key Technical Properties of a 1 Gallon Drinking Bottle?

When assessing 1 gallon drinking bottles for business procurement, understanding their technical specifications is crucial. Here are several critical properties that influence performance, usability, and safety:

-

Material Grade

The most common materials for 1 gallon bottles include BPA-free plastic, stainless steel, and glass. Each material has distinct advantages; for instance, stainless steel offers superior durability and insulation, while BPA-free plastic is lightweight and cost-effective. Selecting the right material is vital for ensuring product safety and longevity, particularly in markets sensitive to health regulations. -

Insulation Properties

Insulation performance is measured by the ability to maintain the temperature of the contents. Bottles designed with vacuum insulation can keep liquids cold for over 24 hours or hot for up to 12 hours. This is particularly valuable in regions with extreme temperatures, ensuring customer satisfaction and repeat purchases. -

Weight Tolerance

Weight tolerance refers to the maximum weight a bottle can hold without deforming or breaking. A 1 gallon bottle filled with water weighs approximately 8.34 pounds, so understanding the material’s weight tolerance is critical for user safety and comfort, especially in outdoor or industrial settings. -

Capacity Accuracy

While most bottles are labeled as 1 gallon (128 ounces), actual capacity can vary due to manufacturing tolerances. For B2B buyers, ensuring that products meet stated specifications is essential for compliance with industry standards and customer expectations. -

Closure Type

The type of closure (e.g., screw cap, flip-top, or straw lid) affects usability and leak prevention. A robust closure mechanism is vital for transporting liquids without spills, especially in international shipping scenarios. Understanding the closure design can influence the choice based on target market preferences. -

Recyclability and Environmental Impact

With a growing emphasis on sustainability, the recyclability of the materials used in 1 gallon bottles is increasingly important. Buyers should consider products made from recycled materials or those that are easily recyclable, aligning with corporate social responsibility goals and appealing to eco-conscious consumers.

What Are Common Trade Terms Related to 1 Gallon Drinking Bottles?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Below are several common terms relevant to the procurement of 1 gallon drinking bottles:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of drinking bottles, understanding OEM relationships can help buyers source high-quality products that meet their specifications without compromising brand integrity. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory costs and cash flow. Understanding MOQs helps businesses manage their purchasing strategy and avoid excess stock. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific quantities of products. Utilizing RFQs effectively can streamline the procurement process and ensure competitive pricing, which is essential for maintaining profit margins. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for understanding shipping costs, risk, and insurance responsibilities, particularly for businesses operating across different continents. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is critical for inventory management and planning, especially in regions with fluctuating demand or supply chain challenges. -

Quality Assurance (QA)

QA refers to the processes and procedures put in place to ensure that products meet specified quality standards. For B2B buyers, understanding QA protocols can provide assurance of product reliability, which is crucial for customer satisfaction and brand reputation.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing 1 gallon drinking bottles, ensuring alignment with market demands and business objectives.

Navigating Market Dynamics and Sourcing Trends in the 1 gallon drinking bottle Sector

What Are the Key Market Trends in the 1 Gallon Drinking Bottle Sector?

The global market for 1-gallon drinking bottles is experiencing significant growth, driven by increasing health consciousness and the rising demand for hydration solutions across various demographics. Key trends include the growing popularity of reusable water bottles, which are seen as sustainable alternatives to single-use plastics. Innovations in materials, such as BPA-free plastics and insulated stainless steel, are enhancing the appeal of these products, especially among environmentally conscious consumers. Moreover, the integration of technology, such as water tracking apps and smart lids, is emerging as a way to engage users and promote healthier hydration habits.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking reliable suppliers who can offer high-quality products at competitive prices. The shift towards e-commerce platforms for sourcing and procurement is also noteworthy, as it allows buyers to access a broader range of products and suppliers. Additionally, the demand for customization—such as branded bottles for corporate gifts or specific color schemes for promotional events—continues to rise, creating opportunities for manufacturers and suppliers to differentiate themselves in a crowded market.

How Is Sustainability Influencing the Sourcing of 1 Gallon Drinking Bottles?

Sustainability is a critical consideration for B2B buyers in the 1-gallon drinking bottle sector. The environmental impact of plastic waste has led to heightened scrutiny of supply chains and material sourcing. Buyers are increasingly favoring products made from recycled or eco-friendly materials, as well as those that have been certified for their low environmental impact. Certifications such as Green Seal, Cradle to Cradle, and B Corporation status are becoming essential for suppliers aiming to establish credibility and trust in the market.

Moreover, ethical sourcing practices are gaining traction, with buyers looking to partner with manufacturers who prioritize fair labor practices and transparency in their supply chains. This shift not only helps mitigate risks associated with unethical sourcing but also aligns with the values of socially conscious consumers, thereby enhancing brand reputation. As such, suppliers who can demonstrate a commitment to sustainability and ethical practices are likely to gain a competitive edge in the market.

What Is the Historical Context of the 1 Gallon Drinking Bottle Market?

The 1-gallon drinking bottle has evolved significantly over the past few decades. Initially popularized as bulk water storage solutions for outdoor activities and sporting events, these bottles have transitioned into everyday hydration tools for a wide range of consumers. The introduction of innovative materials and designs, such as insulated stainless steel and ergonomic handles, has expanded their use and appeal.

In recent years, the rise of health and wellness trends has further propelled the demand for these products, with consumers seeking convenient ways to meet daily hydration goals. As the market continues to mature, the focus on sustainability and ethical practices is expected to shape its future trajectory, influencing both product development and sourcing strategies for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of 1 gallon drinking bottle

-

How do I ensure the quality of 1-gallon drinking bottles from international suppliers?

To ensure quality, start by vetting suppliers through verified platforms or trade shows. Request product samples to assess materials, durability, and design. Look for certifications such as FDA or ISO standards that guarantee safety and quality. Additionally, consider conducting factory audits or hiring third-party inspection services to verify production practices and quality control measures. Establishing a clear quality assurance agreement with your supplier can also help mitigate risks. -

What is the best material for 1-gallon drinking bottles?

The best materials for 1-gallon drinking bottles depend on their intended use. Stainless steel is ideal for durability and insulation, keeping beverages cold or hot for extended periods. BPA-free plastic is lightweight and cost-effective, suitable for various applications, while glass offers a premium feel and is free from chemical leaching. Consider your target market’s preferences and whether the bottles need to be reusable, insulated, or portable when making your choice. -

What are the typical minimum order quantities (MOQs) for 1-gallon drinking bottles?

Minimum order quantities vary by supplier and material but typically range from 500 to 5,000 units for custom orders. Some manufacturers may offer lower MOQs for standard products. It’s crucial to discuss your specific needs with potential suppliers and negotiate MOQs based on your budget and market demand. Smaller initial orders may be feasible if you are willing to pay a premium, which can help you test the market before scaling up. -

How can I customize 1-gallon drinking bottles for my brand?

Customization options include printing your logo, selecting specific colors, and choosing materials that align with your brand values. Many suppliers offer services like custom molds for unique designs or shapes. When discussing customization, provide clear specifications and artwork files to ensure accuracy. Be aware that custom orders may impact lead times and MOQs, so plan accordingly to meet your branding and marketing timelines. -

What payment terms are common for international orders of 1-gallon drinking bottles?

Common payment terms include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer net payment terms after delivery. It’s advisable to use secure payment methods such as letters of credit or escrow services to protect your transaction. Always clarify payment terms before finalizing orders to avoid misunderstandings that could delay production or delivery. -

How do I manage logistics for importing 1-gallon drinking bottles?

Effective logistics management involves selecting reliable freight forwarders and understanding shipping regulations in your destination country. Work closely with your supplier to coordinate shipping schedules, and ensure all necessary documentation, such as bills of lading and customs declarations, is in order. Consider the best shipping method (air vs. sea) based on your urgency and budget. Also, be prepared for potential tariffs and duties that may apply to your imports. -

What are the best practices for storage and handling of 1-gallon drinking bottles?

Proper storage and handling are essential to maintaining product quality. Store bottles in a cool, dry place away from direct sunlight to prevent warping or degrading materials. Use pallets to keep bottles off the ground and ensure good airflow. Train staff on safe handling procedures to minimize damage during transportation and storage. Regularly inspect inventory for signs of damage or defects to maintain quality standards. -

How can I effectively market 1-gallon drinking bottles in international markets?

To market 1-gallon drinking bottles internationally, conduct market research to understand consumer preferences in different regions. Utilize digital marketing strategies, including social media advertising and influencer partnerships, to reach your target audience. Highlight unique features, such as sustainability or insulation, to differentiate your product. Attending international trade shows can also help you showcase your products and build relationships with potential buyers and distributors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 1 Gallon Drinking Bottle Manufacturers & Suppliers List

1. Hawsaiy – 128oz Insulated Water Bottle

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Hawsaiy – 128oz Insulated Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Hydro Gallon® – Key Products

Domain: hydrogallon.com

Registered: 2020 (5 years)

Introduction: Hydro Gallon® offers a range of gallon water bottles designed for all-day hydration. Key products include: 1 Gallon Hydro Gallon, Hydro Gallon 1 Pro, Hydro Gallon Tactical, and Hydro Gallon Nomad (new half gallon option). Features include 24-hour cold retention and durability. The bottles come with sleeves and replacement parts are available. Customers can also purchase gift cards.

3. H2O Capsule – One Gallon Inspo Water Bottle

Domain: h2ocapsule.com

Registered: 2019 (6 years)

Introduction: One Gallon Inspo Water Bottle with Time Marker and Straw; Available in multiple colors: Rocky Shore, Rainy Ashville, Lotus Bloom, Fresh Avocado; Regular price: $23.99 (Lotus Bloom on sale for $19.99, Fresh Avocado for $21.99); Designed for hydration tracking with time markers.

4. The Water Bottle Store – 1 Gallon BPA Free Water Bottles

Domain: thewaterbottlestore.com

Registered: 2005 (20 years)

Introduction: 1 Gallon BPA Free Water Bottles, Jugs, and Containers available at TheWaterBottleStore.com. Key products include: 4 Liter Vacuum Insulated Thermos Flask with Portable Cup – Price: $78.88; 1 Gallon Combo BPA Free Water Bottle Geo – Price: $34.48; GEO Sports 1 Gallon BPA Free Water Bottle with Stainless Steel Cap and Handle in Purple – Price: $18.88; 1 Gallon BPA Free Reusable Plastic Drinking Water…

5. Diamond Rock – 1 Gallon Natural Spring Water

Domain: diamondrock.com

Registered: 1997 (28 years)

Introduction: {“product_name”:”1 Gallon Bottle”,”quantity_per_case”:6,”price_delivery”:”$8.00″,”price_cash_and_carry”:”$7.00″,”water_type”:”100% Natural Spring Water”,”certifications”:”Government tested, FDA approved”,”location”:”Diamond Rock Spring Water, 60 Railroad Avenue, Ridgefield Park, NJ 07660″,”phone”:”201.440.1112″}

6. Briowt – 1 Gallon BPA Free Water Bottles

Domain: briowt.com

Registered: 2020 (5 years)

Introduction: 1 Gallon Bottles: 1. BPA Free 1 Gallon Water Bottle, Plastic Bottle, Sports Bottle, PC Bottle, with Screw Cap and Handle. 2. 1 Gallon Frosted Glass Bottle, Water Bottle, with Screw Cap. 3. BPA Free 1 Gallon Water Bottle, Plastic Bottle, Sports Bottle, with Screw Cap. 4. 1 Gallon, BPA Free Beverage Dispenser, Plastic Bottle. 5. Glass Bottle, Carboy Bottle, with Screw Cap. 6. BPA Free 1 Gallon Juice…

7. Durable One Gallon Water Bottle – Superior Insulation for Work Use

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: One gallon water bottle, similar to Yeti but with better insulation, durable for drops, intended for work use, needs to last a lifetime.

Strategic Sourcing Conclusion and Outlook for 1 gallon drinking bottle

What Are the Key B2B Insights for Sourcing 1 Gallon Drinking Bottles?

In conclusion, the strategic sourcing of 1 gallon drinking bottles offers significant advantages for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Buyers should prioritize factors such as material quality, insulation capabilities, and design versatility to meet diverse consumer needs. The importance of BPA-free materials and sustainable production processes cannot be overstated, as these elements increasingly influence purchasing decisions.

Furthermore, understanding regional preferences and price sensitivities is crucial for establishing competitive advantages. Engaging with reliable suppliers who can provide innovative designs and effective branding strategies will enhance market penetration and customer loyalty.

How Can B2B Buyers Prepare for Future Trends in the Drinking Bottle Market?

As the demand for hydration solutions continues to rise, especially in warmer climates, there is an opportunity for B2B buyers to capitalize on trends such as insulated bottles and motivational designs. Looking ahead, it is essential to stay informed about market developments and consumer preferences.

We encourage you to explore partnerships with manufacturers that align with your quality standards and sustainability goals. By proactively adapting your sourcing strategies, you can position your business for success in the dynamic landscape of the 1 gallon drinking bottle market.