Introduction: Navigating the Global Market for big stainless steel water bottle

The global demand for big stainless steel water bottles is surging, driven by a growing awareness of sustainability and health. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate this competitive landscape, sourcing high-quality products that meet both market trends and consumer needs can be a daunting challenge. This guide serves as a comprehensive resource, covering various types of big stainless steel water bottles, their applications across different industries, and essential criteria for supplier vetting.

In this guide, you’ll discover insights into the diverse functionalities of these bottles, from insulated options that maintain temperature to eco-friendly designs that appeal to environmentally conscious consumers. We delve into the cost factors influencing procurement decisions, enabling you to make informed choices that align with your budget and operational requirements. By understanding the nuances of this market, you will be better positioned to engage with suppliers and negotiate effectively.

Empowering you to make strategic purchasing decisions, this guide equips B2B buyers with the knowledge needed to identify reliable manufacturers, evaluate product specifications, and ultimately enhance your product offerings. As you explore the opportunities within the big stainless steel water bottle market, you’ll be poised to meet the evolving demands of your clientele while contributing to a more sustainable future.

Artikel Navigation

- Top 8 Big Stainless Steel Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for big stainless steel water bottle

- Understanding big stainless steel water bottle Types and Variations

- Key Industrial Applications of big stainless steel water bottle

- 3 Common User Pain Points for ‘big stainless steel water bottle’ & Their Solutions

- Strategic Material Selection Guide for big stainless steel water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for big stainless steel water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘big stainless steel water bottle’

- Comprehensive Cost and Pricing Analysis for big stainless steel water bottle Sourcing

- Alternatives Analysis: Comparing big stainless steel water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for big stainless steel water bottle

- Navigating Market Dynamics and Sourcing Trends in the big stainless steel water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of big stainless steel water bottle

- Wichtiger Haftungsausschluss & Nutzungsbedingungen

- Strategic Sourcing Conclusion and Outlook for big stainless steel water bottle

Understanding big stainless steel water bottle Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Isolierte Wasserflaschen | Double-walled vacuum insulation, keeps beverages hot/cold | Veranstaltungen im Freien, Firmengeschenke | Pros: Excellent temperature retention; Cons: Heavier |

| Non-Insulated Water Bottles | Lightweight, durable stainless steel, no insulation | Everyday use, schools, sports teams | Pros: Lightweight; Cons: Not suitable for temperature control |

| Zusammenklappbare Wasserflaschen | Flexible design, space-saving, easy to transport | Travel, camping, trade shows | Pros: Space-efficient; Cons: Less durable |

| Customizable Water Bottles | Options for branding and personalization | Promotional items, giveaways | Pros: Enhances brand visibility; Cons: Higher cost for customization |

| Specialty Water Bottles | Unique features (e.g., built-in filtration, spouts) | Health-focused businesses, fitness centers | Pros: Added functionality; Cons: May be more expensive |

What Are the Key Characteristics of Insulated Water Bottles?

Insulated water bottles are designed with double-walled vacuum insulation, making them ideal for keeping beverages hot or cold for extended periods. This feature is particularly valuable for companies involved in outdoor events, corporate gifts, or employee wellness programs. When purchasing insulated bottles, B2B buyers should consider durability, ease of cleaning, and warranty options, as these factors can significantly affect long-term satisfaction and brand reputation.

How Do Non-Insulated Water Bottles Differ in Use?

Non-insulated stainless steel water bottles are lightweight and durable, making them suitable for everyday use in schools, sports teams, and corporate environments. Their simplicity and lower price point make them attractive for bulk purchases. Buyers should assess factors such as capacity, ease of use, and potential for branding when selecting non-insulated options, as these elements can impact user experience and satisfaction.

Why Consider Collapsible Water Bottles for Your Business?

Collapsible water bottles are designed for easy transport and storage, making them an excellent choice for travel, camping, or trade shows. Their flexible design allows them to be stowed away when not in use, appealing to businesses that prioritize convenience and space-saving solutions. B2B buyers should evaluate the material quality and potential wear over time, as these factors can influence the product’s longevity and customer satisfaction.

What Advantages Do Customizable Water Bottles Offer?

Customizable water bottles enable businesses to enhance brand visibility through personalized designs and logos. This feature is particularly beneficial for promotional items and giveaways, as it creates a lasting impression on customers. When considering customizable options, B2B buyers should weigh the costs of personalization against the marketing benefits, ensuring that the investment aligns with their branding strategies and target audience.

What Are the Unique Features of Specialty Water Bottles?

Specialty water bottles often come with unique features such as built-in filtration systems or integrated spouts for easy pouring. These bottles cater to health-focused businesses and fitness centers that aim to provide added value to their customers. When purchasing specialty bottles, B2B buyers should consider the functionality, ease of use, and cost-effectiveness to ensure that the products meet their specific needs and those of their clientele.

Key Industrial Applications of big stainless steel water bottle

| Industrie/Sektor | Specific Application of big stainless steel water bottle | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Gastfreundschaft | Guest amenities in hotels and resorts | Enhances guest experience and supports sustainability initiatives | Durability, capacity, and eco-friendly materials |

| Erholung im Freien | Equipment for adventure and sports companies | Promotes hydration and brand visibility during outdoor activities | Lightweight design, leakproof features, and branding options |

| Corporate Gifts & Promotions | Branded giveaways for corporate events | Strengthens brand loyalty and visibility among clients | Customization options, bulk pricing, and shipping logistics |

| Bildung | School hydration programs | Encourages healthy habits among students and reduces plastic waste | Safety certifications, child-friendly designs, and ease of cleaning |

| Lebensmittel und Getränke | Beverage service in cafes and restaurants | Offers a premium experience and aligns with eco-conscious consumer trends | Insulation properties, aesthetic appeal, and ease of handling |

How is the Big Stainless Steel Water Bottle Used in Hospitality?

In the hospitality sector, big stainless steel water bottles serve as a luxurious and sustainable amenity for guests in hotels and resorts. By providing these bottles, establishments not only enhance the guest experience but also align with eco-friendly initiatives aimed at reducing single-use plastics. Buyers in this sector must prioritize durability and the ability to customize these bottles with their branding, ensuring they withstand frequent use while also being visually appealing.

What Role Does the Big Stainless Steel Water Bottle Play in Outdoor Recreation?

For companies involved in outdoor recreation, big stainless steel water bottles are essential equipment for promoting hydration during activities such as hiking, camping, and sports. These bottles ensure that users have access to cold or hot beverages, regardless of the weather conditions. B2B buyers should consider lightweight designs and leakproof features, as these attributes enhance usability and brand visibility during outdoor events. Custom branding options can further promote the company’s identity in a competitive market.

How Can Corporations Leverage Big Stainless Steel Water Bottles for Promotions?

In the realm of corporate gifts and promotions, big stainless steel water bottles make effective branded giveaways during events or as employee gifts. They not only foster brand loyalty but also communicate a commitment to sustainability. Businesses should look for customization options that allow for logo engraving or color matching to their brand identity. Additionally, bulk pricing and efficient shipping logistics are crucial for managing costs and ensuring timely delivery.

Why are Big Stainless Steel Water Bottles Important in Education?

Educational institutions are increasingly adopting big stainless steel water bottles as part of their hydration programs to encourage healthy habits among students. These bottles help reduce reliance on plastic while promoting a culture of wellness. Buyers in this sector should focus on safety certifications, child-friendly designs, and ease of cleaning, ensuring that the bottles meet school regulations and are practical for daily use.

How Do Big Stainless Steel Water Bottles Benefit the Food and Beverage Industry?

In the food and beverage industry, big stainless steel water bottles are becoming a staple for cafes and restaurants aiming to offer a premium experience. These bottles can be used for serving beverages, enhancing customer satisfaction while aligning with eco-conscious trends. Key considerations for buyers include insulation properties to maintain beverage temperatures, aesthetic appeal to complement the dining experience, and ease of handling for staff and customers alike.

3 Common User Pain Points for ‘big stainless steel water bottle’ & Their Solutions

Scenario 1: Managing Product Durability and Quality Control

Das Problem: For B2B buyers, ensuring that the products they source, such as big stainless steel water bottles, meet quality standards is crucial. Many buyers face challenges with product durability, particularly in regions with varying climates and conditions. Water bottles that cannot withstand heat or extreme cold may lead to customer dissatisfaction, returns, and damage to the brand’s reputation. Buyers may also struggle with inconsistent quality from different suppliers, making it difficult to establish trust and reliability in their product line.

Die Lösung: To mitigate these concerns, buyers should prioritize sourcing from established manufacturers known for quality assurance processes. Look for suppliers that utilize recycled stainless steel and offer warranties, like a ten-year guarantee, as seen with some brands. Request samples before placing bulk orders to evaluate the product’s insulation capabilities and overall build quality. Additionally, implement a rigorous inspection process upon receipt of goods, checking for leaks, insulation efficiency, and material integrity. Establishing a long-term relationship with a trusted supplier can also ensure consistent product quality and reliability.

Scenario 2: Addressing Environmental Sustainability Concerns

Das Problem: With increasing consumer awareness about environmental issues, B2B buyers are often pressured to offer sustainable products. Buyers may find it challenging to identify which big stainless steel water bottles are truly eco-friendly versus those that simply market themselves as such. This confusion can lead to potential backlash from environmentally conscious customers, affecting sales and brand loyalty.

Die Lösung: To effectively source environmentally sustainable products, buyers should look for certifications or partnerships that demonstrate a commitment to sustainability. For instance, choosing products made from recycled materials or those that contribute to environmental initiatives—such as removing plastic waste from oceans—can resonate with eco-conscious consumers. Furthermore, buyers should communicate the sustainability benefits clearly in their marketing materials, emphasizing how these products help reduce plastic pollution. Engaging with suppliers who actively promote their sustainability practices can also enhance the credibility of your brand.

Scenario 3: Ensuring Functionality for Various Use Cases

Das Problem: B2B buyers often cater to diverse markets, from outdoor enthusiasts to corporate wellness programs. A significant pain point is sourcing big stainless steel water bottles that are versatile enough to meet various consumer needs. Bottles that fail to perform in specific scenarios—such as during outdoor activities or in office settings—risk losing market appeal and customer trust.

Die Lösung: Buyers should consider sourcing bottles that offer multiple features, such as vacuum insulation for temperature retention, leak-proof designs, and easy-to-clean components. When evaluating products, it’s beneficial to assess their usability across different contexts. For instance, options with wide mouths facilitate easy filling and cleaning, while models that fit in standard cup holders cater to commuters. Collaborate with suppliers who offer customization options, allowing businesses to brand the bottles for corporate gifts or promotional events. By prioritizing functionality and versatility, buyers can ensure their product offerings meet a broader range of consumer demands, enhancing marketability and customer satisfaction.

Strategic Material Selection Guide for big stainless steel water bottle

What Are the Key Materials for Big Stainless Steel Water Bottles?

When selecting materials for big stainless steel water bottles, several factors come into play, including performance, cost, and compliance with international standards. This guide analyzes four common materials used in the production of these bottles, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Stainless Steel Grade 304 Perform in Water Bottles?

Stainless Steel Grade 304 is one of the most commonly used materials for big stainless steel water bottles. Known for its excellent corrosion resistance and good formability, this grade can withstand a wide range of temperatures and is ideal for both hot and cold beverages. The material is also non-reactive, ensuring that it does not impart any flavors to the water.

Profis: The durability of Grade 304 is a significant advantage, as it can endure rough handling without denting or breaking. Its relatively low cost makes it accessible for mass production.

Nachteile: While it has good corrosion resistance, it is not as resistant to chlorides as other grades, which can be a concern in coastal regions. Additionally, it may require more complex manufacturing processes to achieve desired finishes.

Auswirkungen auf die Anwendung: Grade 304 is suitable for various beverages, including acidic drinks, making it a versatile choice for international markets.

Überlegungen für internationale Einkäufer: Buyers should ensure compliance with ASTM standards for food safety. In regions like Europe and the Middle East, certifications such as DIN and JIS may also be required.

What Advantages Does Stainless Steel Grade 316 Offer?

Stainless Steel Grade 316 is often regarded as a premium option for water bottles due to its superior corrosion resistance, particularly against saltwater and chlorides. This makes it ideal for outdoor and marine applications.

Profis: The enhanced corrosion resistance extends the product’s lifespan, making it suitable for long-term use. Its strength and durability also contribute to a higher perceived value.

Nachteile: The primary drawback is the higher cost compared to Grade 304, which may impact pricing strategies for B2B buyers. Additionally, the manufacturing process can be more complex.

Auswirkungen auf die Anwendung: Grade 316 is particularly well-suited for environments with high salinity or chemicals, ensuring the integrity of the bottle over time.

Überlegungen für internationale Einkäufer: Compliance with international standards is crucial, especially in regions with stringent regulations. Buyers should verify certifications that align with local market requirements.

How Does Recycled Stainless Steel Benefit Sustainability?

Recycled stainless steel is increasingly being used in the production of big stainless steel water bottles, aligning with global sustainability initiatives. This material retains many properties of virgin stainless steel while reducing environmental impact.

Profis: The use of recycled materials can significantly lower production costs and energy consumption. It also appeals to eco-conscious consumers, enhancing brand reputation.

Nachteile: The variability in quality can be a concern, as recycled materials may not always meet the same standards as new materials. This can affect product consistency.

Auswirkungen auf die Anwendung: Recycled stainless steel is suitable for a wide range of beverages, but quality control is essential to ensure safety and performance.

Überlegungen für internationale Einkäufer: Buyers should look for certifications that verify the recycled content and compliance with food safety standards, particularly in markets that prioritize sustainability.

What Role Does Coating Play in Stainless Steel Water Bottles?

Coatings, such as powder coating or enamel, are often applied to stainless steel water bottles to enhance aesthetics and provide additional protection against scratches and corrosion.

Profis: Coatings can improve the visual appeal of the product and offer an extra layer of protection, which can extend the lifespan of the bottle. They also allow for customization, appealing to diverse consumer preferences.

Nachteile: The application of coatings can increase manufacturing complexity and costs. Additionally, some coatings may not be as durable as the stainless steel itself, leading to potential wear over time.

Auswirkungen auf die Anwendung: Coated bottles can be suitable for various beverages, but care must be taken to ensure that the coating is food-safe and durable.

Überlegungen für internationale Einkäufer: Buyers should ensure that coatings comply with relevant food safety standards and are suitable for the intended market, especially in regions with strict regulations.

Summary Table of Material Selection for Big Stainless Steel Water Bottles

| Material | Typical Use Case for big stainless steel water bottle | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stainless Steel Grade 304 | General-purpose hydration bottles | Ausgezeichnete Korrosionsbeständigkeit | Limited resistance to chlorides | Mittel |

| Stainless Steel Grade 316 | Marine and outdoor hydration bottles | Superior corrosion resistance | Higher cost | Hoch |

| Recycled Stainless Steel | Eco-friendly hydration solutions | Lower environmental impact | Variable quality | Mittel |

| Coated Stainless Steel | Customizable and visually appealing bottles | Enhanced aesthetics and protection | Increased manufacturing complexity | Mittel |

This strategic material selection guide aims to equip international B2B buyers with the insights necessary to make informed decisions when sourcing big stainless steel water bottles. Understanding the properties and implications of each material will help in aligning product offerings with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for big stainless steel water bottle

What Are the Key Stages in the Manufacturing Process of Big Stainless Steel Water Bottles?

The manufacturing process of big stainless steel water bottles involves several critical stages, each designed to ensure high-quality production. The primary stages include material preparation, forming, assembly, and finishing.

Vorbereitung des Materials

The process begins with the selection of high-grade stainless steel, typically 304 or 316, known for their corrosion resistance and durability. The stainless steel is sourced from reputable suppliers, often certified to meet international standards. After procurement, the material undergoes a thorough inspection to ensure it meets the required specifications. This initial quality check is crucial as it lays the foundation for the entire manufacturing process.

Bildung von

Once the materials are approved, they are cut into sheets or rolls, which are then fed into forming machines. Techniques such as deep drawing and hydroforming are commonly used to shape the stainless steel into the desired bottle form. These methods not only ensure precision but also enhance the structural integrity of the bottle. Advanced technologies, including computer numerical control (CNC) machines, may be employed to achieve intricate designs and uniformity across batches.

Montage

After forming, the components, such as the bottle body, cap, and seals, are assembled. This stage may involve welding or mechanical fastening techniques to create a leak-proof seal. The assembly process is critical as it directly impacts the product’s performance and usability. Quality control measures are implemented at this stage to ensure that all parts fit seamlessly, which is essential for functionality.

Fertigstellung

The final stage involves surface treatment, which can include polishing, powder coating, or anodizing. These processes not only enhance the aesthetic appeal of the bottles but also contribute to their durability and resistance to scratches and corrosion. Quality assurance checks are performed to ensure that the finish meets the brand’s specifications and international standards.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a continuous process integrated at every stage of manufacturing to ensure that the final product meets both company and regulatory standards.

What International Standards Are Relevant to Stainless Steel Water Bottle Manufacturing?

For manufacturers targeting international markets, adhering to standards such as ISO 9001 is essential. This standard outlines the criteria for a quality management system, ensuring consistent product quality and continuous improvement. Additionally, certifications like CE mark for products sold in the European Economic Area signify compliance with health, safety, and environmental protection standards.

Was sind die wichtigsten Punkte der Qualitätskontrolle im Herstellungsprozess?

Quality control involves several checkpoints, including:

-

Eingehende Qualitätskontrolle (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Materials not meeting specifications are rejected and re-sourced.

-

Prozessbegleitende Qualitätskontrolle (IPQC): During manufacturing, various checks are performed to ensure that the processes are followed correctly. This includes monitoring temperature and pressure settings in forming processes and ensuring proper assembly techniques are utilized.

-

Endgültige Qualitätskontrolle (FQC): Once production is complete, each water bottle undergoes a final inspection. This includes checking for leaks, verifying dimensions, and ensuring the finish is flawless.

Welche Prüfverfahren werden üblicherweise zur Sicherstellung der Produktqualität eingesetzt?

Manufacturers employ various testing methods to validate the quality and durability of big stainless steel water bottles:

- Dichtheitsprüfung: This method ensures that all seals and joints are secure, preventing any leakage during use.

- Druckprüfung: Bottles are subjected to pressure to ensure they can withstand the rigors of everyday use without deforming or breaking.

- Prüfung der Wärmedämmung: For insulated bottles, manufacturers test the effectiveness of the insulation to ensure it maintains temperature as advertised.

- Corrosion Resistance Testing: This test assesses how well the stainless steel withstands exposure to various environmental conditions, including humidity and saltwater.

Wie können B2B-Einkäufer die Qualitätskontrollpraktiken von Lieferanten überprüfen?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensuring product reliability.

What Steps Can Buyers Take to Ensure Supplier Compliance?

1. Lieferanten-Audits: Conducting regular audits of the manufacturing facility allows buyers to assess quality control practices firsthand. This includes reviewing the manufacturing processes, quality control checkpoints, and testing methods.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports that outline the supplier’s compliance with international standards and the results of various tests conducted on the products.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. These inspections can be particularly valuable for buyers looking to enter new markets or establish long-term partnerships.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Einkäufer?

Navigating quality control nuances can be challenging for international B2B buyers. Different regions may have varying standards and regulations that affect product quality and safety.

Understanding Local Standards: Buyers should familiarize themselves with the specific regulations governing stainless steel products in their target markets. For instance, European buyers may prioritize CE certification, while buyers in the Middle East may focus on Gulf Standards Organization (GSO) certifications.

Establishing Clear Communication: Open lines of communication with suppliers regarding quality expectations and standards can mitigate misunderstandings. Buyers should clearly outline their requirements in contracts and specifications to ensure alignment.

By understanding the manufacturing processes and quality assurance practices in place for big stainless steel water bottles, B2B buyers can make informed decisions that align with their quality expectations and sustainability goals. This knowledge not only enhances product reliability but also strengthens supplier relationships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘big stainless steel water bottle’

Einführung

When sourcing big stainless steel water bottles, B2B buyers must navigate a complex landscape of options, materials, and supplier capabilities. This guide serves as a comprehensive checklist to streamline your procurement process, ensuring that you select high-quality products that meet your operational needs and sustainability goals.

-

✅ Define Your Technical Specifications

Clearly outline the specifications for the big stainless steel water bottles you need. Consider factors such as capacity (e.g., 1 liter or larger), insulation type (vacuum-insulated for temperature retention), and design features (like anti-leak seals and ease of cleaning). Precise specifications will help you communicate effectively with suppliers and ensure that the products meet your requirements. -

✅ Research Sustainable Materials

Sustainability is increasingly important in product sourcing. Look for bottles made from recycled stainless steel or those that contribute to environmental initiatives, such as reducing ocean-bound plastic. This not only enhances your brand’s eco-friendly image but also aligns with global trends towards sustainable consumer products. -

✅ Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications, such as ISO 9001 for quality management and compliance with food safety standards. Certifications indicate a commitment to quality and can provide peace of mind regarding the safety and durability of the products. Request documentation and verify their authenticity through independent sources. -

✅ Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers. Review their company profiles, product ranges, and customer testimonials. It’s beneficial to ask for case studies or references from buyers in similar markets or industries, ensuring that the supplier has a proven track record of delivering quality products. -

✅ Request Samples Before Committing

Always request product samples before finalizing your order. This allows you to assess the quality, design, and functionality of the water bottles firsthand. During this stage, pay attention to the weight, finish, and any features that might be essential for your target market. -

✅ Analyze Pricing and Payment Terms

Compare pricing among different suppliers while considering the total cost of ownership. Look for transparency in pricing, including shipping costs and any additional fees. Additionally, negotiate favorable payment terms that align with your cash flow and procurement strategy, such as net payment options or bulk order discounts. -

✅ Plan for After-Sales Support and Warranty

Investigate the warranty and after-sales support offered by suppliers. A robust warranty (e.g., 10 years) can signify quality and durability, giving you confidence in your purchase. Ensure that suppliers provide responsive customer service for any issues that may arise post-purchase, including repairs or replacements.

By following these steps, B2B buyers can effectively source high-quality big stainless steel water bottles that meet their business needs while also promoting sustainability and customer satisfaction.

Comprehensive Cost and Pricing Analysis for big stainless steel water bottle Sourcing

Understanding the cost structure and pricing dynamics of sourcing big stainless steel water bottles is crucial for international B2B buyers. This analysis delves into the various cost components, influential pricing factors, and practical tips for buyers, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Big Stainless Steel Water Bottle Manufacturing?

-

Materialien: The primary material for stainless steel water bottles is high-grade stainless steel, which can vary in price depending on market conditions. Recycled stainless steel may offer cost savings and appeal to eco-conscious brands. Additional materials, such as silicone seals for leak-proofing, also contribute to the total material costs.

-

Arbeit: Labor costs can differ significantly by region. In countries with lower labor costs, such as parts of Africa and South America, manufacturing expenses may be reduced. However, skilled labor for quality assurance and craftsmanship in regions like Europe may demand higher wages.

-

Fertigungsgemeinkosten: This includes factory utilities, equipment maintenance, and administrative costs. Efficient factories may manage overhead better, allowing for competitive pricing.

-

Werkzeugbau: Custom molds and tooling for unique designs or specifications can lead to higher initial costs. Buyers should consider these costs when assessing the total expenditure for customized products.

-

Qualitätskontrolle (QC): Implementing stringent quality control processes ensures product reliability and compliance with international standards. This may involve additional labor and testing expenses, impacting the overall cost.

-

Logistik: Shipping costs can vary greatly based on distance, transportation mode, and the chosen Incoterms. Buyers should factor in duties, taxes, and potential tariffs, especially when sourcing from overseas suppliers.

-

Marge: Suppliers typically add a markup to cover costs and achieve profit. Understanding industry standards for margins can aid buyers in evaluating pricing fairness.

How Do Price Influencers Affect the Cost of Big Stainless Steel Water Bottles?

-

Volumen und Mindestbestellmenge (MOQ): Bulk orders often lead to significant discounts. Suppliers may impose MOQs, which can affect pricing strategies for smaller businesses or start-ups.

-

Spezifikationen und Anpassungen: Custom designs, colors, or additional features (like vacuum insulation) can increase costs. Buyers should clearly outline their specifications to receive accurate quotes.

-

Materialien und Qualitätszertifikate: The choice of materials impacts both cost and perceived quality. Certifications (e.g., ISO, FDA) can also influence pricing, as they often require additional processes and documentation.

-

Lieferanten-Faktoren: Supplier reputation, production capabilities, and geographical location can all impact pricing. Established suppliers with a proven track record may command higher prices due to their reliability and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) dictate who bears the risk and costs during shipping. Understanding these terms is essential for accurate cost forecasting.

Was sind wirksame Tipps für Käufer, um Preise zu verhandeln?

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs, allowing for better pricing per unit.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, customs, potential warranty claims, and the durability of the product. A higher initial price may yield better long-term value.

-

Bedingungen verhandeln: Engage suppliers in discussions about payment terms, lead times, and after-sales service. Flexibility on both sides can lead to favorable agreements.

-

Understand Pricing Nuances for International Sourcing: Different regions may have varying pricing expectations. For example, buyers from Nigeria may face different logistical challenges than those in Germany. Tailoring your negotiation approach based on regional factors can yield better results.

-

Stay Informed: Regularly monitor market trends in materials and labor costs. Staying ahead of price fluctuations can aid in strategic purchasing decisions.

Haftungsausschluss

The prices mentioned in this analysis are indicative and can vary widely based on market conditions, supplier negotiations, and specific product requirements. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing big stainless steel water bottle With Other Solutions

Exploring Alternatives to Big Stainless Steel Water Bottles

As businesses increasingly prioritize sustainability and functionality in their product offerings, the demand for effective hydration solutions has risen. While the big stainless steel water bottle is a popular choice, various alternatives exist that can meet similar hydration needs. This section provides a comparative analysis of the big stainless steel water bottle against other viable solutions, allowing B2B buyers to make informed decisions based on their unique requirements.

| Vergleich Aspekt | Big Stainless Steel Water Bottle | Reusable Plastic Water Bottle | Glass Water Bottle |

|---|---|---|---|

| Leistung | Excellent insulation, durable | Moderate insulation, lightweight | Fragile, no insulation |

| Kosten | $40 – $60 | $10 – $30 | $15 – $50 |

| Leichte Implementierung | Ready to use, no setup required | Ready to use, no setup required | Ready to use, no setup required |

| Wartung | Easy to clean, dishwasher safe | Easy to clean, but may retain odors | Requires careful handling, hand wash recommended |

| Bester Anwendungsfall | Outdoor activities, long-term use | Everyday use, light travel | Office settings, home use |

What are the Pros and Cons of Reusable Plastic Water Bottles?

Reusable plastic water bottles are a cost-effective alternative that offers a lightweight solution for hydration. They are often available in various sizes and designs, making them attractive for consumers looking for convenience. However, they may not provide the same insulation benefits as stainless steel bottles, which can affect the temperature of beverages. Additionally, some plastics may retain odors or flavors over time, potentially impacting user satisfaction. For businesses targeting budget-conscious customers or those seeking lightweight options, reusable plastic bottles can be a viable solution.

How Does a Glass Water Bottle Compare?

Glass water bottles present a more elegant hydration solution, often favored for their aesthetic appeal and the absence of chemical leaching associated with plastics. They are easy to clean and do not retain odors, making them a popular choice in office and home environments. However, their fragility is a significant drawback, as they can break easily during transportation or outdoor activities. Additionally, glass bottles typically lack insulation, which may limit their effectiveness for temperature-sensitive beverages. For companies aiming to offer premium hydration solutions, glass bottles can enhance brand perception but may require a more cautious marketing approach.

Schlussfolgerung: Wie Sie die richtige Hydratationslösung für Ihr Unternehmen auswählen

When selecting the right hydration solution for your organization, consider the specific needs of your target audience. If durability and temperature retention are paramount, a big stainless steel water bottle is likely the best choice. However, for businesses aiming to attract budget-conscious consumers or those who value aesthetics, reusable plastic or glass bottles may be more suitable. Ultimately, understanding the performance, cost, and maintenance aspects of each option will empower B2B buyers to align their product offerings with customer expectations and market trends.

Essential Technical Properties and Trade Terminology for big stainless steel water bottle

What Are the Key Technical Properties of Big Stainless Steel Water Bottles?

When sourcing big stainless steel water bottles for B2B purposes, understanding their technical properties is crucial for making informed purchasing decisions. Below are some essential specifications that international buyers should consider:

1. Material Klasse

Stainless steel water bottles are typically made from 304 or 316 stainless steel. Grade 304 is common due to its corrosion resistance and good weldability, while Grade 316 offers superior resistance to salt and acidic environments, making it ideal for marine applications. Choosing the right grade impacts durability and longevity, which are vital for businesses requiring reliable hydration solutions.

2. Insulation Type

Most high-quality big stainless steel water bottles feature double-wall vacuum insulation. This technology keeps beverages hot or cold for extended periods, enhancing user experience. For B2B buyers, products with effective insulation can lead to increased customer satisfaction and brand loyalty, especially in sectors like outdoor recreation or hospitality.

3. Capacity and Size Specifications

Big stainless steel water bottles usually range from 1 liter to 2 liters in capacity. Understanding the size specifications is essential for determining how the product fits into your supply chain or retail space. Additionally, considering the bottle’s dimensions helps in assessing shipping costs and storage requirements.

4. Leakproof Design

A reliable leakproof seal is critical for ensuring that the bottles are safe for transport and use in various environments. Features like silicone gaskets or screw-on caps are common in high-quality products. For B2B buyers, investing in leakproof bottles reduces the risk of product returns and enhances customer satisfaction.

5. Eco-Friendly Features

Many manufacturers now produce stainless steel bottles using recycled materials, reinforcing their commitment to sustainability. This aspect is increasingly important for businesses aiming to align with eco-conscious consumers. Understanding the eco-friendly properties can also enhance your brand’s marketability in regions where sustainability is a priority.

6. Warranty and After-Sales Support

A robust warranty, such as a 10-year repair or replace guarantee, indicates the manufacturer’s confidence in their product’s quality. For B2B buyers, a strong warranty can reduce long-term costs and foster a trustworthy relationship with suppliers.

What Are Common Trade Terms Associated with Big Stainless Steel Water Bottles?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms related to stainless steel water bottles:

1. OEM (Original Equipment Manufacturer)

An OEM produces products that are sold under another company’s brand. For B2B buyers, partnering with OEMs can provide opportunities for customization and branding, enabling businesses to differentiate their offerings in competitive markets.

2. MOQ (Mindestbestellmenge)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budget planning and inventory management. Buyers should assess their needs to ensure that the MOQ aligns with their operational capacity.

3. RFQ (Request for Quotation)

An RFQ is a formal document soliciting price quotes from suppliers. It’s an essential tool for B2B buyers to compare costs and terms across multiple vendors, ensuring they make the best purchasing decision.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for understanding shipping costs, liability, and risk management, especially for businesses operating in diverse regions.

5. Vorlaufzeit

Lead time refers to the period from placing an order to receiving the goods. Understanding lead time helps buyers plan their inventory and sales strategies effectively, ensuring that they meet customer demand without overstocking.

6. Zertifizierungsstandards

These are industry-specific standards that the product must meet to ensure safety and quality. Certifications like FDA, BPA-free, or ISO can influence buyer decisions, as they provide assurance about the product’s quality and compliance with regulations.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when selecting big stainless steel water bottles, ultimately enhancing their procurement strategies and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the big stainless steel water bottle Sector

What Are the Current Market Dynamics and Key Trends Affecting the Big Stainless Steel Water Bottle Sector?

The global market for big stainless steel water bottles is experiencing robust growth, driven by a rising awareness of environmental sustainability and the demand for durable, reusable products. Key drivers include an increasing consumer preference for eco-friendly alternatives to single-use plastics, heightened health consciousness, and a shift toward outdoor activities and wellness lifestyles. For B2B buyers, this translates into opportunities to cater to a growing segment of environmentally conscious consumers who prioritize sustainability in their purchasing decisions.

Emerging trends in technology and sourcing are reshaping the sector. Digital transformation is enhancing supply chain transparency, allowing international buyers to trace the origins of materials used in manufacturing. Innovations in production processes, such as the use of recycled stainless steel, are becoming standard, appealing to brands that wish to bolster their sustainability credentials. Additionally, customization options, including personalized engravings, are increasingly popular, providing businesses with a unique selling proposition to attract diverse customer demographics.

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding local market preferences and aligning product offerings accordingly is crucial. Factors such as regional climate, cultural preferences, and economic conditions can significantly influence purchasing behavior. Engaging with local distributors and leveraging digital marketing strategies can facilitate market entry and enhance brand visibility.

How Is Sustainability and Ethical Sourcing Transforming the Big Stainless Steel Water Bottle Market?

Sustainability has become a cornerstone of the big stainless steel water bottle sector, significantly influencing purchasing decisions among B2B buyers. The environmental impact of plastic pollution has led to a heightened demand for products that minimize carbon footprints. Stainless steel water bottles are not only reusable but are also often made from recycled materials, which reduces the need for virgin resources and lowers overall environmental impact.

Ethical sourcing practices are gaining importance as well, with consumers and businesses alike increasingly scrutinizing supply chains for social responsibility. Certifications such as Fair Trade and ISO 14001 are becoming essential indicators of a company’s commitment to ethical practices. For B2B buyers, sourcing products from manufacturers that adhere to these standards not only enhances brand reputation but also aligns with the values of socially conscious consumers.

Moreover, utilizing green materials and processes can provide a competitive edge in the market. Companies that prioritize eco-friendly production methods, such as energy-efficient manufacturing or the use of biodegradable packaging, are well-positioned to attract environmentally aware clients. As sustainability becomes a key differentiator in the marketplace, B2B buyers must prioritize suppliers that demonstrate a clear commitment to these values.

What Is the Evolution and Historical Context of the Big Stainless Steel Water Bottle Industry?

The history of stainless steel water bottles can be traced back to the early 20th century, primarily used in industrial applications due to their durability and resistance to corrosion. However, their rise in popularity as consumer products began in the late 1990s, coinciding with a growing awareness of the environmental impacts of plastic waste. This shift was fueled by campaigns advocating against single-use plastics, leading to a surge in demand for reusable alternatives.

Over the years, the design and functionality of stainless steel water bottles have evolved significantly. Innovations such as double-wall vacuum insulation have enhanced their utility, allowing consumers to maintain beverage temperatures for extended periods. The introduction of various sizes, colors, and customization options has further broadened their appeal, making them not just practical items but also lifestyle accessories.

Today, the big stainless steel water bottle sector stands at a crossroads, balancing functionality with sustainability. The focus on ethical sourcing and eco-friendly practices continues to shape the industry, presenting significant opportunities for B2B buyers to engage with manufacturers who align with these evolving consumer values.

Frequently Asked Questions (FAQs) for B2B Buyers of big stainless steel water bottle

-

How do I choose the right supplier for big stainless steel water bottles?

Choosing the right supplier involves evaluating several key factors. Begin by researching potential suppliers’ reputations through reviews and testimonials. Verify their manufacturing capabilities, production capacity, and compliance with international quality standards (ISO, FDA). It’s also important to assess their responsiveness and communication efficiency. Request samples to evaluate product quality and check for customization options. Finally, consider their logistical capabilities, including shipping times and costs, to ensure they align with your business needs. -

What are the common minimum order quantities (MOQs) for big stainless steel water bottles?

Minimum order quantities can vary widely depending on the supplier and the product specifications. Typically, MOQs for big stainless steel water bottles range from 500 to 1,000 units. However, some suppliers may offer lower MOQs for customized designs. When sourcing, inquire about bulk pricing and potential discounts for larger orders. Understanding MOQs will help you manage inventory effectively and ensure that your initial investment aligns with your sales projections. -

What customization options are available for big stainless steel water bottles?

Many suppliers offer a variety of customization options for big stainless steel water bottles, including color, size, and branding. Common customization features include engraving or printing logos, which enhance brand visibility. Some manufacturers also provide options for unique designs or additional features, such as built-in straws or specialized lids. Discuss your requirements with potential suppliers to understand the extent of customization they can offer and any associated costs. -

Mit welchen Zahlungsbedingungen muss ich bei internationaler Beschaffung rechnen?

Payment terms can differ significantly between suppliers. Commonly, suppliers may request a deposit (20-50%) before production, with the balance due prior to shipment. Other payment options include letters of credit or payment through platforms like PayPal or Alibaba Trade Assurance for added security. It’s crucial to negotiate terms that protect your interests while ensuring a smooth transaction process. Always confirm payment methods accepted by the supplier before finalizing agreements. -

How can I ensure product quality for my big stainless steel water bottles?

To ensure product quality, start by requesting samples from potential suppliers. Conduct inspections during production, if possible, to verify adherence to quality standards. Check for certifications like ISO 9001, which indicates a commitment to quality management. Additionally, consider third-party quality assurance services to conduct final inspections before shipment. Establish clear quality expectations in your contract, including acceptable tolerance levels and testing protocols. -

What are the logistics considerations when importing big stainless steel water bottles?

Logistics is a critical aspect of importing products. Assess shipping options, including air freight for speed or sea freight for cost-effectiveness. Understand the customs regulations in your country, including tariffs and import duties that may apply. Collaborate with a freight forwarder to navigate these complexities and ensure timely delivery. Additionally, plan for warehousing and distribution within your region to manage inventory efficiently. -

What are the eco-friendly features to look for in big stainless steel water bottles?

When sourcing big stainless steel water bottles, consider eco-friendly features such as materials sourced from recycled stainless steel and BPA-free components. Look for suppliers that emphasize sustainable manufacturing practices, including reduced carbon footprints and waste management. Some brands may also offer a recycling program or contribute to environmental initiatives, such as ocean cleanup efforts. Highlighting these features can enhance your brand’s sustainability profile and attract environmentally conscious customers. -

How can I effectively market big stainless steel water bottles in international markets?

To market big stainless steel water bottles internationally, start by understanding local consumer preferences and cultural nuances. Leverage digital marketing channels, including social media, SEO, and influencer partnerships to reach your target audience. Highlight unique selling points such as durability, eco-friendliness, and customization options. Participate in trade shows and industry events to showcase your products directly to potential buyers. Tailor your marketing strategies to align with regional trends and compliance regulations for effective outreach.

Wichtiger Haftungsausschluss & Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Top 8 Big Stainless Steel Water Bottle Manufacturers & Suppliers List

1. Ocean Bottle – 1 Liter Insulated Stainless Steel Water Bottle

Bereich: oceanbottle.co

Registered: 2019 (6 years)

Einleitung: 1 Liter Stainless Steel Water Bottle, Insulated, Double Walled Vacuum Insulation, Made from Recycled Materials, Fully Recyclable, 10-Year Repair and Replace Warranty, Contributes to Removal of 1,000 Plastic Bottles from Oceans, Available in Various Colors, Custom Engraving Options.

2. Thermos – 18 oz Stainless Steel Water Bottle

Bereich: thermos.de

Registriert: 1997 (28 Jahre)

Einleitung: This company, Thermos – 18 oz Stainless Steel Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Hydro Flask – Insulated Water Bottles

Bereich: hydroflask.com

Registriert: 2009 (16 Jahre)

Einleitung: Insulated & Stainless Steel Water Bottles from Hydro Flask. Key products include: 16 oz Coffee with Flex Sip™ Lid ($32.95, now $24.71), 21 oz Standard Mouth with Flex Straw Cap ($34.95), Remix 32 oz Wide Mouth with Flex Straw Cap – Polar Plunge ($31.47, originally $44.95), Remix 24 oz Wide Mouth with Flex Straw Cap – Polar Plunge ($27.97, originally $39.95), Remix 32 oz Wide Mouth with Flex Straw …

4. Hydroflask – 64+ oz Metal Water Bottle

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: 64+ oz metal water bottle, durable, options include Hydroflask, Klean Kanteen, Yeti, and Snow Peak, insulated and non-insulated options available, preference for stainless steel, concerns about dishwasher safety.

5. Owala – Free Sip Vacuum Water Bottle

Bereich: seriouseats.com

Registriert: 2006 (19 Jahre)

Einleitung: {“Top Picks”: {“Best Water Bottle”: {“Name”: “Owala Free Sip Vacuum Water Bottle”, “Price”: “$30”}, “Best Budget Water Bottle”: {“Name”: “Contigo Courtland Chill 2.0”, “Price”: “$23”}, “Best No-Frills Water Bottle”: {“Name”: “Hydro Flask 24 oz Wide Mouth Water Bottle”, “Price”: “$29”}, “Best Insulated Tumbler Water Bottle”: {“Name”: “Simple Modern 40 oz Trek Tumbler with Handle and Straw Lid”, “Pr…

6. Stanley – Insulated Water Bottles

Bereich: stanley1913.com

Registered: 2019 (6 years)

Einleitung: Stainless Steel, Insulated Water Bottles; Features: double-wall vacuum insulation, eliminates condensation, available sizes: 14 OZ, 16 OZ, 20 OZ, 24 OZ, 30 OZ, 40 OZ; technology: QuadVac™ for extra insulation; not recommended for freezing.

7. Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap

Bereich: nytimes.com

Registriert: 1994 (31 Jahre)

Einleitung: Dieses Unternehmen, Hydro Flask - 24 oz Wide Mouth with Flex Chug Cap, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails ist es empfehlenswert, ihre Website direkt zu besuchen.

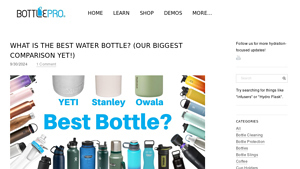

8. BottlePro – Top Water Bottle Comparisons

Bereich: bottlepro.net

Registriert: 2014 (11 Jahre)

Einleitung: 31 water bottles compared including brands like Camelbak, EcoVessel, Hydro Flask, Iron Flask, Klean Kanteen, Nalgene, Owala, Ozark Trail, RevoMax, S’well, Takeya, ThermoFlask, YETI, and Stanley. Recommendations for best bottles based on use: Everyday use – Owala FreeSip and FJbottle; Best value – Ozark Trail 32oz, Iron Flask, ThermoFlask, Nalgene 32oz; Best for hiking – Nalgene 32oz, Hydro Flask T…

Strategic Sourcing Conclusion and Outlook for big stainless steel water bottle

In conclusion, the strategic sourcing of big stainless steel water bottles presents a promising avenue for B2B buyers seeking sustainable, high-quality hydration solutions. Key factors to consider include the growing demand for eco-friendly products, the importance of durability, and the potential for customization. Sourcing from manufacturers that prioritize recycled materials and offer robust warranties can enhance your product offerings while aligning with global sustainability goals.

As international buyers from regions like Africa, South America, the Middle East, and Europe increasingly seek responsible sourcing options, investing in big stainless steel water bottles not only meets market demands but also supports environmental initiatives. The ability to provide products that combat plastic waste resonates well with consumers, enhancing brand loyalty and market competitiveness.

Looking ahead, it is essential for businesses to engage with suppliers who share a commitment to sustainability and innovation. By strategically sourcing these products, you can position your company as a leader in responsible consumption, ultimately driving growth and success in the evolving global marketplace. Embrace this opportunity to make a meaningful impact while meeting your customers’ hydration needs.