Introduction: Navigating the Global Market for bottle lid types

In today’s competitive landscape, international B2B buyers face the critical challenge of sourcing the right bottle lid types to meet diverse product requirements and consumer expectations. With a myriad of options available—from standard screw caps and child-proof lids to sophisticated spray and pump caps—selecting the appropriate closure can significantly impact product integrity, safety, and user experience. This comprehensive guide delves into the various types of bottle lids, their applications across multiple industries, and the best practices for supplier vetting and cost analysis.

Understanding the nuances of different bottle lid types is essential for businesses looking to optimize their packaging solutions. This guide is designed to empower buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—by providing actionable insights and expert recommendations. By exploring the specific characteristics and benefits of each lid type, this resource enables informed purchasing decisions that align with product goals and regulatory standards.

Additionally, we will address the logistical considerations of sourcing these products internationally, including compatibility with capping machinery and the importance of quality assurance. As you navigate the global market for bottle lid types, this guide will serve as an invaluable tool in enhancing your product offerings and ensuring customer satisfaction.

Artikel Navigation

- Top 7 Bottle Lid Types Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle lid types

- Understanding bottle lid types Types and Variations

- Key Industrial Applications of bottle lid types

- 3 Common User Pain Points for ‘bottle lid types’ & Their Solutions

- Strategic Material Selection Guide for bottle lid types

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle lid types

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle lid types’

- Comprehensive Cost and Pricing Analysis for bottle lid types Sourcing

- Alternatives Analysis: Comparing bottle lid types With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle lid types

- Navigating Market Dynamics and Sourcing Trends in the bottle lid types Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle lid types

- Wichtiger Haftungsausschluss & Nutzungsbedingungen

- Strategic Sourcing Conclusion and Outlook for bottle lid types

Understanding bottle lid types Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Screw Cap | Simple, twist-on design; often includes tamper-proof seal | Beverages, sauces, chemicals | Vorteile: Versatile, cost-effective. Nachteile: May not prevent child access. |

| Child Proof Caps | Safety mechanism requiring specific action to open | Pharmaceuticals, cleaning agents | Vorteile: Enhances safety for children. Nachteile: Can be difficult for adults. |

| Flip Top Cap | Hinged lid for easy access; often used for thicker liquids | Personal care products, condiments | Vorteile: Convenient for users; minimizes spills. Nachteile: Limited to certain liquid viscosities. |

| Trigger Heads | Squeeze mechanism for sprays or jets; often includes locking feature | Cleaning products, garden supplies | Vorteile: Effective for precise application. Nachteile: Can jam in capping machines. |

| Pump Caps | Dispenser mechanism for creams and liquids; twist to lock | Hand sanitizers, lotions | Vorteile: Reduces contamination; easy to use. Nachteile: May complicate packaging process. |

What Are the Characteristics and Suitability of Standard Screw Caps?

Standard screw caps are ubiquitous in packaging, featuring a straightforward twist-on design that allows for easy sealing and access. These caps are typically made from either plastic or aluminum and are suitable for a wide range of products, including beverages, sauces, and industrial chemicals. For B2B buyers, the versatility and cost-effectiveness of standard screw caps make them an attractive option; however, it’s important to consider that they may not provide adequate child safety features, which could be a concern for certain products.

How Do Child Proof Caps Enhance Safety in Packaging?

Child proof caps are designed with safety mechanisms that require a specific action to open, such as pushing down while twisting. This feature is crucial for products that may be harmful to children, including pharmaceuticals and cleaning agents. B2B buyers must weigh the safety benefits against potential usability issues for adults, as these caps can be more challenging to open. Overall, investing in child proof caps can enhance brand trust and compliance with safety regulations.

Why Choose Flip Top Caps for Personal Care Products?

Flip top caps are characterized by their hinged lid, which allows users to easily access the product without removing the entire cap. This design is particularly beneficial for thicker liquids, making them ideal for personal care items like shampoos and sauces. For B2B buyers, the convenience offered by flip top caps can enhance customer satisfaction and reduce spills during use. However, it’s essential to ensure compatibility with the product’s viscosity to prevent leakage.

What Advantages Do Trigger Heads Offer for Cleaning Products?

Trigger heads are specialized caps that allow users to dispense a product by squeezing a trigger, often resulting in a spray or jet application. This type of cap is commonly found on cleaning supplies and garden products, providing precise application. B2B buyers should consider the effectiveness of trigger heads in their intended use while being aware of potential challenges during the capping process, such as jamming in machinery. The locking mechanism also adds a layer of safety for storage.

How Do Pump Caps Facilitate Hygiene in Packaging?

Pump caps feature a dispenser mechanism that releases liquid or cream when depressed, making them popular for products like hand sanitizers and lotions. They offer the advantage of minimizing direct contact, thus enhancing hygiene, which is increasingly important in today’s market. For B2B buyers, selecting pump caps can improve user experience, but they may complicate the packaging process, requiring specialized capping machinery. Careful consideration of compatibility with the product is essential to ensure functionality.

Key Industrial Applications of bottle lid types

| Industrie/Sektor | Specific Application of bottle lid types | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Lebensmittel und Getränke | Standard screw caps for bottled beverages | Ensures product freshness and extends shelf life | Compatibility with bottling machines and regulatory compliance |

| Pharmazeutika | Child-proof caps for medicinal products | Enhances safety for consumers, especially children | Compliance with safety standards and ease of opening for adults |

| Personal Care | Flip top caps for shampoos and lotions | Facilitates ease of use and reduces product spillage | Material durability and compatibility with various product viscosities |

| Household Chemicals | Trigger heads for cleaning products | Provides controlled dispensing and minimizes waste | Resistance to chemical corrosion and compatibility with capping machines |

| Cosmetics | Spray caps for perfumes and sprays | Enhances user experience through fine mist application | Aesthetic appeal and compatibility with luxury packaging standards |

How Are Bottle Lid Types Used in the Food and Beverage Industry?

In the food and beverage sector, standard screw caps are widely used for bottled drinks, from soft drinks to oils. These caps are designed to maintain product freshness and prevent leakage during transport. For international B2B buyers, particularly from Africa and South America, sourcing caps that are compatible with local bottling machines and meet food safety regulations is crucial. Additionally, businesses should consider the environmental impact of their closures, opting for recyclable materials when possible to appeal to sustainability-conscious consumers.

What Role Do Child-Proof Caps Play in Pharmaceuticals?

Child-proof caps are essential in the pharmaceutical industry, particularly for medications that could be harmful if ingested by children. These caps incorporate safety mechanisms that require specific actions to open, thus preventing accidental consumption. For B2B buyers in the Middle East and Europe, it’s vital to ensure these caps comply with local safety regulations and are easy for adults to operate. Suppliers should also focus on the caps’ ability to maintain an airtight seal, ensuring product integrity and efficacy throughout its shelf life.

Why Are Flip Top Caps Important in Personal Care Products?

Flip top caps are prevalent in personal care items like shampoos and lotions, allowing for convenient dispensing. Their design minimizes spillage and ensures that users can easily access the product, even with wet hands. For international buyers, especially from regions like Nigeria and Saudi Arabia, it’s important to source caps that are durable and compatible with various product viscosities. Additionally, the aesthetic aspect of these caps can enhance brand perception, making them an important consideration in product development.

How Do Trigger Heads Benefit Household Chemical Products?

Trigger heads are commonly used in household cleaning products, providing controlled dispensing for efficient use. This design not only helps reduce waste but also enhances user experience by allowing for targeted application. For B2B buyers in diverse markets, including South America and Africa, sourcing trigger heads that are resistant to chemical corrosion is critical. Furthermore, ensuring compatibility with existing capping machinery can streamline production processes and reduce operational costs.

What Advantages Do Spray Caps Offer in the Cosmetics Industry?

Spray caps are a staple in the cosmetics sector, particularly for products like perfumes and facial mists. They allow for a fine mist application, enhancing the user experience while minimizing product waste. For international B2B buyers, especially those in Europe and the Middle East, aesthetic appeal is vital, as luxury products often require high-quality, visually appealing closures. Additionally, ensuring that the spray mechanism is reliable and compatible with various formulations will be crucial for maintaining product integrity and consumer satisfaction.

3 Common User Pain Points for ‘bottle lid types’ & Their Solutions

Scenario 1: Ensuring Product Safety with Child-Proof Caps

Das Problem: For manufacturers in sectors like pharmaceuticals or cleaning supplies, the safety of their products is paramount. A significant challenge arises when selecting bottle lids that prevent children from opening potentially hazardous substances. A failure in this area can lead to severe consequences, including health risks and legal ramifications. B2B buyers must ensure that the selected caps not only provide safety but also comply with regional regulations, which can vary greatly across markets in Africa, South America, the Middle East, and Europe.

Die Lösung: To address this issue, B2B buyers should prioritize sourcing child-proof caps that meet international safety standards. When evaluating suppliers, it’s essential to request detailed specifications and certifications for the caps, ensuring they comply with safety regulations in your target markets. Additionally, consider conducting compatibility tests with your product to ensure that the caps can withstand the intended use while maintaining their safety features. Engage with manufacturers who offer a range of designs, such as push-down-and-twist caps, which are effective in deterring children. Regularly review your packaging processes to adapt to new safety standards and consumer expectations, ensuring that your products remain compliant and safe.

Scenario 2: Overcoming Compatibility Issues with Capping Machines

Das Problem: A common pain point for B2B buyers is the compatibility of bottle lids with existing capping machinery. Many companies invest in sophisticated capping machines, only to discover that the lids they’ve sourced jam or do not fit properly, leading to production delays and increased costs. This issue can be particularly problematic in regions with less access to advanced machinery or where specific lid types are scarce, making the selection process even more critical.

Die Lösung: To mitigate compatibility issues, B2B buyers should conduct thorough research on the capping machines they use and the lids they intend to purchase. This includes understanding the technical specifications of both the machinery and the lids, such as material properties and closure mechanisms. When sourcing caps, work closely with suppliers who can provide samples for testing before making bulk purchases. It’s advisable to establish a relationship with a supplier who understands your machinery and can recommend the most compatible bottle lids. Furthermore, consider investing in versatile capping machines that can accommodate a range of lid types, reducing the risk of operational disruptions.

Scenario 3: Balancing Aesthetic Appeal with Functionality

Das Problem: In competitive markets, especially in the beauty and beverage industries, the visual appeal of packaging plays a crucial role in attracting consumers. B2B buyers often face the challenge of selecting bottle lids that not only function effectively but also enhance the overall aesthetic of the product. Striking the right balance between functionality—such as ease of use and sealing capabilities—and visual design can be challenging, particularly when dealing with diverse markets where consumer preferences vary widely.

Die Lösung: To navigate this challenge, B2B buyers should collaborate with suppliers who offer a wide variety of customizable lid options. Explore lids that can be tailored in terms of color, finish, and design elements while still meeting functional requirements. Engage in market research to understand the preferences of your target audience in different regions. For instance, vibrant colors and unique shapes may appeal to consumers in South America, while minimalist designs might be favored in Europe. Conduct consumer testing to gather feedback on both functionality and aesthetics before finalizing your choices. By integrating feedback into the design process, you can select bottle lids that not only perform well but also resonate with your target market, ultimately enhancing your product’s appeal.

Strategic Material Selection Guide for bottle lid types

What are the Key Properties of Different Materials Used for Bottle Lids?

When selecting materials for bottle lids, it is crucial to consider their properties, performance, and compatibility with various products. This analysis focuses on four common materials: plastic, aluminum, cork, and glass. Each material offers unique advantages and limitations that can significantly impact product performance and market acceptance.

How Does Plastic Stand Up as a Material for Bottle Lids?

Plastic is one of the most prevalent materials used for bottle lids due to its versatility and cost-effectiveness. Common types include polyethylene (PE) and polypropylene (PP), which provide good temperature resistance and are lightweight. Plastic lids can withstand moderate pressure, making them suitable for carbonated beverages and personal care products.

Profis: Plastic lids are generally low-cost, lightweight, and resistant to corrosion. They can be produced in various colors and designs, enhancing branding opportunities.

Nachteile: However, plastic may not be suitable for high-temperature applications, and certain types may leach chemicals into products, raising safety concerns. Additionally, environmental regulations are becoming stricter, which may affect the marketability of plastic products.

Auswirkungen auf die Anwendung: Plastic lids are ideal for non-corrosive liquids and food products. However, international buyers should ensure compliance with safety standards such as FDA regulations in the U.S. or EU food safety directives.

What Advantages Does Aluminum Provide for Bottle Lids?

Aluminum is often used for bottle caps, especially in the beverage industry. It offers excellent strength-to-weight ratios and can withstand higher pressures than plastic. Aluminum lids are also recyclable, making them an environmentally friendly option.

Profis: Aluminum caps provide a tamper-proof seal and are resistant to corrosion and UV light, making them suitable for sensitive products like beverages and pharmaceuticals.

Nachteile: The primary limitation is cost; aluminum is generally more expensive than plastic. Additionally, the manufacturing process can be more complex, requiring specialized equipment.

Auswirkungen auf die Anwendung: Aluminum lids are ideal for carbonated drinks and spirits, where maintaining product integrity is crucial. Buyers in regions like Europe may favor aluminum due to stringent recycling regulations.

Why Choose Cork for Bottle Lids?

Cork is a traditional material often associated with wine bottles. It offers excellent sealing properties and is biodegradable, appealing to environmentally conscious consumers. Cork can withstand a wide range of temperatures and provides a unique aesthetic.

Profis: Cork is natural, renewable, and provides an airtight seal, making it ideal for wine and spirits. Its unique texture can also enhance the product’s perceived value.

Nachteile: Cork can be more expensive than synthetic materials and is less durable over time, especially when exposed to moisture. Additionally, cork may not be suitable for all types of liquids, particularly those that are corrosive.

Auswirkungen auf die Anwendung: Cork is best suited for wine and high-end spirits. Buyers should consider local preferences and standards, as cork is often associated with premium products in markets like Europe.

What are the Benefits of Using Glass for Bottle Lids?

Glass is less common for bottle lids but is used in specific applications, particularly for high-end products. Glass lids provide an airtight seal and are chemically inert, meaning they won’t react with the contents.

Profis: Glass lids offer excellent product protection and are completely recyclable. They also provide a premium feel that can enhance brand perception.

Nachteile: The primary drawbacks are weight and fragility, making glass less suitable for mass-market products. The cost of production can also be higher compared to plastic or aluminum.

Auswirkungen auf die Anwendung: Glass lids are ideal for luxury products, such as perfumes and gourmet foods. Buyers should be aware of shipping and handling considerations due to the fragility of glass.

Summary Table of Material Selection for Bottle Lids

| Material | Typical Use Case for bottle lid types | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kunststoff | Soft drinks, personal care products | Leicht und kostengünstig | May leach chemicals | Niedrig |

| Aluminium | Carbonated beverages, spirits | Tamper-proof and recyclable | Higher cost and complex mfg | Med |

| Cork | Wine, premium spirits | Natural and biodegradable | More expensive and less durable | Hoch |

| Glas | Luxury perfumes, gourmet foods | Premium feel and chemically inert | Schwer und zerbrechlich | Hoch |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions that align with their product requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for bottle lid types

What Are the Key Stages in the Manufacturing Process of Bottle Lids?

The manufacturing of bottle lids involves a series of well-defined stages to ensure that the final product meets quality and functionality standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is the selection and preparation of materials. Most bottle lids are made from plastics such as polypropylene (PP), polyethylene (PE), or polystyrene (PS), as well as metals like aluminum for specific applications. The choice of material depends on the product’s intended use, such as whether it requires a tamper-proof seal or is designed for food-grade applications.

During this stage, raw materials are sourced from certified suppliers to ensure compliance with international safety and quality standards. These materials undergo testing for consistency in physical properties, such as tensile strength and thermal stability, before being approved for production.

How Are Bottle Lids Formed?

The next step is the forming process, where the prepared materials are shaped into the desired lid form. This is typically achieved through techniques such as injection molding, compression molding, or blow molding.

-

Spritzgießen: This is the most common method for producing plastic lids. In this process, molten plastic is injected into a mold, where it cools and solidifies into the final shape. This method allows for high precision and scalability.

-

Compression Molding: This technique involves placing preheated material into a mold cavity, which is then closed under pressure. It’s ideal for producing thicker lids, such as those used for jars.

-

Blasformen: Used primarily for hollow lids, blow molding involves inflating a plastic tube within a mold to form the desired shape.

Each of these techniques has implications for the lid’s performance and cost, making it crucial for B2B buyers to understand the manufacturing process when selecting suppliers.

What Happens During the Assembly and Finishing Stages?

After forming, the lids undergo assembly, where any additional components, such as seals or liners, are added. This step is particularly important for lids that require tamper-evident features or child-proof mechanisms.

Finishing involves surface treatments, which may include printing, labeling, or applying coatings. This is crucial for branding and ensuring product safety. For instance, some lids may require UV resistance or anti-static coatings, depending on the product they are intended for.

What Quality Control Measures Are Essential for Bottle Lid Manufacturing?

Quality assurance in bottle lid manufacturing is critical for ensuring that the final products meet both safety and functionality requirements. International standards such as ISO 9001 play a pivotal role in establishing quality management systems across manufacturing processes.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be aware of various international and industry-specific standards that govern the manufacturing of bottle lids:

-

ISO 9001: This standard outlines the criteria for a quality management system and is essential for suppliers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE-Kennzeichnung: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: For pharmaceutical applications, adherence to American Petroleum Institute (API) standards is crucial for ensuring that closures are safe for medicinal products.

Understanding these standards helps B2B buyers assess the credibility and reliability of their suppliers.

Was sind die wichtigsten Punkte der Qualitätskontrolle?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Eingehende Qualitätskontrolle (IQC): This step involves inspecting raw materials before they enter the production line. Suppliers must provide certificates of compliance to ensure materials meet specified standards.

-

Prozessbegleitende Qualitätskontrolle (IPQC): Continuous monitoring during the manufacturing stages is vital. This includes checking for defects, ensuring proper alignment of molds, and monitoring temperature and pressure settings.

-

Endgültige Qualitätskontrolle (FQC): Once the lids are produced, they undergo rigorous testing to ensure they meet all specifications. Common tests include leak testing, tensile strength testing, and compatibility testing with the intended product.

Wie können B2B-Einkäufer die Qualitätskontrollpraktiken von Lieferanten überprüfen?

B2B buyers can take several steps to verify the quality control practices of their suppliers. Conducting audits is a vital first step. These can be either internal or third-party audits, which assess the supplier’s adherence to quality standards and their production capabilities.

What Documentation Should Buyers Request?

Buyers should request documentation such as:

-

Qualitätssicherungsberichte: These documents detail the QC processes followed by the supplier, including test results and corrective actions taken for any non-conformities.

-

Certificates of Compliance: Suppliers should provide certificates that demonstrate adherence to relevant international standards, such as ISO 9001 or CE marking.

-

Testing Protocols: Understanding the testing methods used can help buyers assess the reliability of the lids. Common methods include burst testing for pressure resistance and drop testing for impact resistance.

What Are the Specific QC and Certification Nuances for International Buyers?

For international buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe, navigating QC and certification can be complex. Each region may have different regulatory requirements that impact the import of goods.

Buyers should familiarize themselves with local regulations regarding food safety, chemical safety, and environmental impact. Additionally, they should consider the potential need for additional certifications, such as those related to sustainability or recyclability, which are increasingly important in global supply chains.

In conclusion, understanding the manufacturing processes and quality assurance measures for bottle lids is essential for B2B buyers. By focusing on supplier quality control practices, relevant international standards, and specific regional regulations, buyers can make informed decisions that ensure product reliability and compliance in their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle lid types’

In the competitive landscape of packaging, selecting the right bottle lid type is critical for ensuring product integrity, user convenience, and regulatory compliance. This practical sourcing guide provides a step-by-step checklist to help B2B buyers navigate the complexities of bottle lid procurement effectively.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before initiating the sourcing process, clearly outline the technical requirements for your bottle lids. Consider factors such as material (plastic, metal, or cork), size, closure mechanism, and compatibility with your product. This step is crucial as it sets the groundwork for identifying suitable suppliers and ensuring that the lids meet safety and quality standards.

Schritt 2: Forschung Markttrends und Regulierungen

Understanding current market trends and regulations in your target regions (such as Africa, South America, the Middle East, and Europe) is vital. Look for information on consumer preferences, environmental regulations regarding packaging materials, and any safety standards that may apply. This knowledge will guide your selection process and help you stay compliant.

Schritt 3: Potenzielle Lieferanten evaluieren

Before committing to any supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and references from businesses in your industry or region. It’s essential to assess their manufacturing capabilities, quality control processes, and experience with your specific type of bottle lids.

- Supplier Certifications: Ensure that potential suppliers have relevant certifications, such as ISO 9001 for quality management or FDA approval for food-grade materials.

- Production Capacity: Verify that the supplier can meet your volume requirements without compromising quality.

Schritt 4: Request Samples for Testing

Obtaining samples from shortlisted suppliers allows you to assess the quality and functionality of the bottle lids firsthand. Test the samples for durability, ease of use, and compatibility with your products. This step is crucial to avoid costly mistakes in bulk orders.

Schritt 5: Compare Pricing and Terms

Once you have evaluated the quality of the samples, compare pricing and payment terms among the suppliers. Look for a balance between cost and quality; the cheapest option may not always be the best in the long run. Additionally, negotiate terms such as minimum order quantities, lead times, and delivery schedules to align with your business needs.

Schritt 6: Check for Customization Options

If your product requires specific branding or functional features, inquire about customization options. Many suppliers offer tailored solutions that can enhance your product’s market appeal. Consider aspects such as color, design, and additional functionalities like child-proof mechanisms or tamper-evident features.

Schritt 7: Finalize the Contract and Place Order

Once you have selected a supplier, ensure that all terms are clearly outlined in a contract. This should include pricing, delivery timelines, quality assurances, and return policies. A well-defined agreement protects both parties and helps to mitigate potential disputes.

By following this checklist, B2B buyers can streamline the sourcing process for bottle lids, ensuring they make informed decisions that align with their product requirements and market expectations.

Comprehensive Cost and Pricing Analysis for bottle lid types Sourcing

What Are the Key Cost Components in Sourcing Bottle Lid Types?

Understanding the cost structure for sourcing various bottle lid types is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materialien: The type of material—plastic, metal, or composite—significantly impacts the cost. High-quality materials that comply with food safety standards or possess specific certifications will typically command higher prices. For example, aluminum caps may be more expensive than plastic due to material sourcing and processing costs.

-

Arbeit: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this could come at the expense of quality. Thus, it’s essential to assess not just the labor cost but also the skill level of the workforce.

-

Fertigungsgemeinkosten: This includes utilities, rent, and other operational costs. Manufacturers that employ advanced technology may have higher overheads but can offer better quality and efficiency, which can lead to long-term savings.

-

Werkzeugbau: Custom molds for specialized cap types can be a significant initial investment. However, the cost per unit generally decreases with higher production volumes, making it essential to consider your expected order quantities when evaluating tooling costs.

-

Qualitätskontrolle: Ensuring the caps meet industry standards requires investment in QC processes. This can include testing for durability, leak-proof capabilities, and compliance with health regulations. A robust QC process can prevent costly recalls and enhance brand reputation.

-

Logistik: Shipping costs can vary based on the weight, dimensions, and destination of the caps. International shipping, especially to regions like Africa or South America, can incur additional tariffs and taxes, affecting the total cost.

-

Supplier Margin: This is the profit margin that suppliers include in their pricing. Understanding the supplier’s business model can provide insight into their pricing structure. Transparent suppliers may offer better negotiation opportunities.

How Do Price Influencers Affect the Cost of Bottle Lid Types?

Several factors influence pricing beyond the basic cost components, especially for international buyers:

-

Volumen/MOQ: Minimum order quantities (MOQ) often dictate pricing structures. Larger orders typically reduce the per-unit cost, making it beneficial for buyers to consolidate orders whenever possible.

-

Spezifikationen und Anpassungen: Custom designs or specific requirements (e.g., child-proof caps, eco-friendly materials) can increase costs. It’s essential to balance the need for customization with budget constraints.

-

Qualität und Zertifizierungen: Certifications for food safety and environmental standards can significantly affect pricing. Suppliers that can demonstrate compliance may charge a premium, but this can be a worthwhile investment for brand integrity.

-

Lieferanten-Faktoren: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may offer higher prices due to perceived reliability but can provide peace of mind regarding product quality and delivery timelines.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for cost management in international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total cost of ownership.

What Are Some Buyer Tips for Cost-Efficiency in Bottle Lid Sourcing?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, here are some tips to enhance cost-efficiency:

-

Bedingungen verhandeln: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules. Long-term relationships can sometimes yield better terms.

-

Consider Total Cost of Ownership: Evaluate the total cost, including shipping, customs, and potential quality issues. Sometimes, a cheaper product may lead to higher costs in the long run due to quality failures.

-

Research Supplier Options: Diversifying your supplier base can help you find competitive pricing and mitigate risks. It’s beneficial to explore local suppliers in emerging markets to reduce logistics costs.

-

Bleiben Sie über Markttrends auf dem Laufenden: Keeping abreast of market fluctuations in materials and manufacturing can help you anticipate price changes and make informed purchasing decisions.

-

Muster anfordern: Before committing to large orders, request samples to assess compatibility with your products. This will help you avoid costly mistakes in the long run.

Schlussfolgerung

While indicative prices for bottle lid types can vary widely based on the factors outlined, understanding these components and influencers will empower B2B buyers to make informed decisions. By focusing on total cost of ownership and leveraging negotiation tactics, international buyers can optimize their sourcing strategies for better profitability.

Alternatives Analysis: Comparing bottle lid types With Other Solutions

Understanding Alternatives to Bottle Lid Types

When it comes to securing and dispensing liquid products, bottle lid types are essential. However, several alternative solutions exist that can also meet the needs of producers and consumers. Understanding these alternatives can help businesses choose the most effective and efficient option for their specific applications. This section compares traditional bottle lid types with two viable alternatives: pump dispensers and aerosol spray systems.

Vergleichstabelle

| Vergleich Aspekt | Bottle Lid Types | Pump Dispensers | Aerosol Spray Systems |

|---|---|---|---|

| Leistung | Reliable seal, multiple variations | Controlled dispensing, minimizes waste | Fine mist application, even coverage |

| Kosten | Generally low to moderate cost | Moderate to high initial investment | Higher initial costs, ongoing refill expenses |

| Leichte Implementierung | Easy to integrate with existing lines | Requires specific machinery and setup | Needs specialized equipment for filling |

| Wartung | Low maintenance; occasional replacement | Moderate; cleaning and servicing needed | High; can require regular maintenance to prevent clogging |

| Bester Anwendungsfall | Beverages, pharmaceuticals, cosmetics | Liquids requiring precise dosage | Products requiring even application, like paints or perfumes |

Exploring Pump Dispensers as an Alternative

Pump dispensers offer a controlled means of dispensing liquids, making them ideal for products that require precise measurement, such as lotions and hand sanitizers. They minimize waste by allowing users to dispense only what is needed, which can lead to better product utilization. However, the initial investment for pump dispensers can be higher due to the need for specialized machinery. Additionally, they require regular cleaning and maintenance to ensure optimal performance, especially when dealing with viscous liquids.

Evaluating Aerosol Spray Systems as an Alternative

Aerosol spray systems provide a unique solution for dispensing products in a fine mist, which is particularly useful for applications like perfumes, cleaning agents, and paints. They ensure an even application and can cover large areas efficiently. However, the cost of setting up aerosol systems is generally higher than that of traditional bottle lids due to the need for pressurization equipment and specialized filling processes. Furthermore, maintenance can be demanding, as aerosol systems require regular checks to prevent clogging and ensure consistent spray quality.

Conclusion: Making the Right Choice for Your Business Needs

When selecting between bottle lid types and alternative solutions like pump dispensers and aerosol spray systems, B2B buyers should carefully consider their specific product requirements, production capabilities, and budget constraints. Bottle lid types remain a versatile and cost-effective choice for many applications, particularly in the beverage and pharmaceutical sectors. However, for products that require precise dispensing or an even application, exploring pump dispensers or aerosol systems might provide significant advantages. Ultimately, understanding the unique benefits and challenges of each option will enable businesses to make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for bottle lid types

What Are the Key Technical Properties of Bottle Lid Types?

When selecting bottle lids, understanding critical technical properties is essential for ensuring product compatibility, functionality, and safety. Here are some key specifications:

-

Material Klasse

The material used for bottle lids can significantly affect durability, chemical resistance, and seal integrity. Common materials include polyethylene (PE), polypropylene (PP), and aluminum. Each material has unique properties: PE is flexible and resistant to moisture, while aluminum offers a robust barrier against oxygen. For B2B buyers, selecting the appropriate material can impact product shelf life and customer satisfaction. -

Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. For bottle lids, this includes the diameter, height, and threading specifications. Tight tolerances ensure that lids fit securely on bottles, preventing leaks and contamination. Inconsistent tolerances can lead to production delays and increased costs due to rework or returns. Buyers should prioritize suppliers who can consistently meet stringent tolerance requirements. -

Seal Integrity

Seal integrity measures how well a lid prevents leakage and preserves product freshness. This property is influenced by design features such as pilfer-proof seals or inner liners. A high seal integrity is crucial for products sensitive to air or moisture, such as pharmaceuticals or food items. B2B buyers must ensure that their chosen lid type provides the necessary level of protection for their specific products. -

Closure Type

Closure type defines how the lid is applied and removed. Options include screw-on, snap-on, or push-pull mechanisms. Each closure type offers distinct advantages, such as ease of use or tamper evidence. Understanding these differences helps B2B buyers choose lids that align with their product’s application and consumer preferences. -

Compatibility with Capping Equipment

Certain lid types may require specialized capping machinery for efficient production. For example, trigger heads and pump caps often necessitate specific handling capabilities due to their unique designs. Buyers should evaluate the compatibility of lid types with their existing capping equipment to avoid operational inefficiencies and ensure seamless production.

What Are Common Trade Terms Related to Bottle Lid Types?

In the world of B2B transactions, understanding specific trade terminology can facilitate smoother negotiations and collaborations. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For bottle lids, this means that a supplier may manufacture lids that are branded and sold by a different company. Understanding OEM relationships can help buyers identify reliable suppliers who can meet their production needs without compromising quality. -

MOQ (Mindestbestellmenge)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their production schedules and market demand to minimize excess stock and associated costs. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. B2B buyers should prepare detailed RFQs that outline their requirements for bottle lids, including specifications, quantities, and delivery timelines. A well-structured RFQ can lead to competitive pricing and better supplier relationships. -

Incoterms (Internationale Handelsklauseln)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping, insurance, and delivery responsibilities. Familiarity with Incoterms can prevent misunderstandings and ensure compliance with global trade regulations. -

Vorlaufzeit

Lead time refers to the time taken from placing an order to receiving the goods. This metric is crucial for B2B buyers who must align their production schedules with inventory availability. Clear communication about lead times can help buyers manage expectations and plan for potential delays in the supply chain.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when selecting bottle lid types, ultimately enhancing their product offerings and supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the bottle lid types Sector

What Are the Key Market Dynamics and Trends Influencing the Bottle Lid Types Sector?

The bottle lid types sector is experiencing significant transformation driven by several global factors. Key among these is the growing demand for convenience in packaging. As consumers increasingly prefer ready-to-use products, manufacturers are turning to innovative closures such as flip-top and sports caps. Additionally, the rise of e-commerce necessitates packaging solutions that ensure product integrity during transit, prompting a shift towards more secure and tamper-proof closures like ROPP caps and child-proof mechanisms.

Emerging technologies are also reshaping the market. Automation in capping processes, particularly with the integration of smart capping machines, enhances efficiency and reduces production costs. International buyers are increasingly interested in sourcing suppliers who utilize advanced capping technologies that align with their production needs. Furthermore, the adoption of e-sourcing platforms is gaining traction, allowing buyers from regions like Africa, South America, the Middle East, and Europe to connect with a wider range of suppliers and compare products easily.

The market dynamics are further influenced by regional preferences. For instance, buyers in Europe may prioritize sustainability in their sourcing decisions, while those in the Middle East might focus on functionality and durability. Understanding these regional nuances is essential for B2B buyers looking to establish long-term partnerships and ensure their packaging meets local market demands.

How Is Sustainability Shaping the Sourcing of Bottle Lid Types?

Sustainability has become a cornerstone of modern sourcing practices in the bottle lid types sector. Environmental concerns surrounding plastic waste and the carbon footprint of manufacturing processes are prompting buyers to seek out eco-friendly alternatives. This shift is reflected in the growing demand for biodegradable materials and recycled plastics in cap production. B2B buyers, particularly from environmentally conscious markets in Europe and North America, are increasingly prioritizing suppliers who demonstrate commitment to sustainability.

Moreover, ethical sourcing is gaining importance. Buyers are now more inclined to partner with manufacturers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for sustainably sourced materials are becoming essential criteria for procurement decisions. Suppliers who can provide these certifications not only enhance their credibility but also appeal to a broader range of international buyers looking for responsible sourcing options.

As the market evolves, the integration of sustainable practices in the design and production of bottle lids will likely dictate future trends. Innovations such as plant-based caps and reusable closures are on the rise, offering solutions that align with the global push towards sustainability.

What Is the Historical Context of Bottle Lid Types and Their Impact on B2B Sourcing?

The evolution of bottle lid types can be traced back to ancient civilizations that utilized corks and rudimentary seals to preserve liquids. Over time, advancements in materials and manufacturing processes have led to the development of various cap types designed for specific applications. The 20th century saw the introduction of screw caps and crown caps, revolutionizing the beverage industry by providing airtight seals that enhanced product shelf life.

In recent decades, the focus has shifted towards consumer convenience and safety, leading to the creation of specialized closures such as child-proof caps and easy-open designs. This historical context is crucial for B2B buyers, as it underscores the importance of selecting the right cap for their products based on intended use, regulatory requirements, and consumer preferences.

As the market continues to evolve, understanding the historical developments in bottle lid types can aid buyers in making informed sourcing decisions, ensuring they choose closures that not only meet current demands but also anticipate future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle lid types

-

How do I choose the right bottle lid type for my product?

Choosing the appropriate bottle lid type depends on several factors, including the product’s nature, usage, and target market. Consider the viscosity of the liquid, whether it requires a tamper-evident seal, and the convenience needed by your consumers. For instance, products like sauces might benefit from flip-top caps for easy dispensing, while pharmaceuticals may require child-proof caps. It’s also crucial to assess compatibility with your bottling line and capping machines to ensure efficient production. -

What are the most common bottle cap types used in different industries?

Various industries utilize specific bottle cap types to meet their unique needs. For the food and beverage sector, standard screw caps and twist tops are prevalent for their ease of use and sealing capabilities. Personal care products often use flip top or disc top caps for convenient dispensing. Meanwhile, the pharmaceutical industry typically opts for child-proof caps to ensure safety. Understanding these trends can help you select the most suitable cap type for your product category. -

What customization options are available for bottle lids?

Customization options for bottle lids include material choice, color, size, shape, and branding elements like logos and labels. Many suppliers offer the ability to create bespoke designs that cater to your specific requirements, enhancing product appeal. It’s advisable to discuss your customization needs early in the sourcing process to ensure the supplier can meet your specifications and timelines, especially if you are targeting specific markets in Africa, South America, or the Middle East. -

What are the minimum order quantities (MOQs) for bottle lids?

Minimum order quantities for bottle lids can vary significantly depending on the supplier and the type of cap. Generally, MOQs can range from as low as 1,000 units for standard caps to 10,000 or more for customized designs. It’s essential to communicate your needs clearly with potential suppliers, as negotiating MOQs may be possible, especially if you are willing to establish a long-term partnership or commit to future orders. -

How do I vet suppliers for bottle lids in international markets?

Vetting suppliers involves researching their reputation, product quality, and compliance with international standards. Start by checking online reviews, requesting samples, and evaluating their certifications (like ISO). Additionally, consider their experience in exporting to your target regions, as this can impact logistics and compliance with local regulations. Engaging in direct communication with potential suppliers can also provide insights into their reliability and customer service. -

What payment terms should I expect when sourcing bottle lids internationally?

Payment terms can vary widely among suppliers but typically include options like advance payment, letters of credit, or net 30/60/90 days. When negotiating terms, consider the financial stability of the supplier and the risks involved in international transactions. It’s prudent to establish clear agreements in writing, including payment schedules, to avoid any misunderstandings later in the process. -

How can I ensure quality assurance (QA) for my bottle lids?

To ensure quality assurance for bottle lids, implement a robust QA process that includes pre-production samples, regular inspections during production, and final quality checks before shipment. Collaborate closely with your supplier to establish clear quality standards and specifications. Consider hiring third-party inspection services if you are unable to oversee production directly, particularly for international orders to ensure compliance with your quality expectations. -

What logistics considerations should I keep in mind when importing bottle lids?

When importing bottle lids, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with your target market to navigate these complexities. Additionally, account for any tariffs or duties that may apply, and ensure that your supplier provides all necessary documentation for customs clearance. Planning for potential delays and having contingency plans can help mitigate disruptions in your supply chain.

Wichtiger Haftungsausschluss & Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Top 7 Bottle Lid Types Manufacturers & Suppliers List

1. Asset Packaging – Screw and Child Proof Caps

Bereich: assetpackaging.com.au

Einleitung: 1. Standard Screw Cap: Commonly used for various products, made from plastic or aluminium, often includes a pilfer proof seal and inner foil or plastic seal.

2. Child Proof Caps: Designed for dangerous products, requires a specific opening mechanism to prevent children from accessing the contents.

3. Flip Top Caps: Used for squeezable containers, includes a small hole for product flow and a flip…

2. CosmoPacks – Essential Bottle Caps for Cosmetics

Bereich: cosmopacks.com

Registered: 2015 (10 years)

Einleitung: Types of bottle caps in the cosmetic industry include: 1. Screw Caps: Commonly used for various products, offering a secure seal and preventing leakage. 2. Dispensing Caps: Allow controlled dispensing of thicker liquids, ideal for lotions and creams. 3. Snap Caps (Flip-Top Caps): Easy to open and close, suitable for frequently used products. 4. Disc Tops: Provide quick access and controlled dispen…

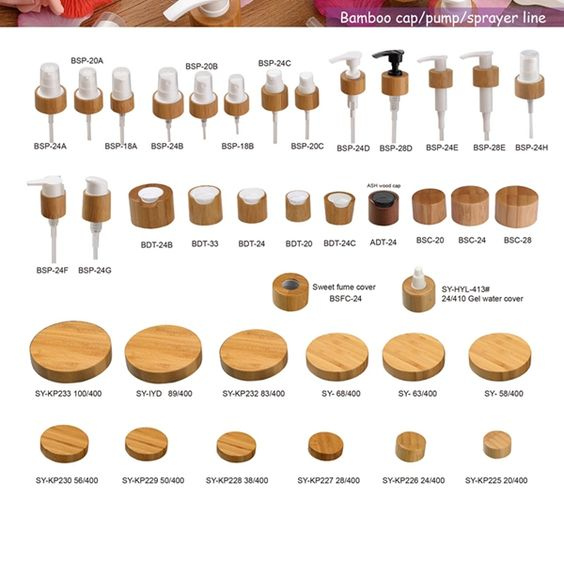

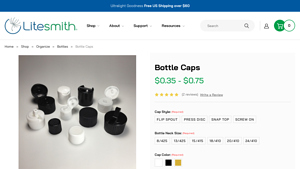

3. Litesmith – Bottle Caps

Bereich: litesmith.com

Registriert: 2014 (11 Jahre)

Einleitung: Bottle Caps available in four styles: Flip Spout, Press Disc, Snap Top, and Screw On. Neck sizes include 8/425, 13/425, 15/415, 18/410, 20/410, and 24/410. Cap colors are White, Black, and Gold. Made from Polyethylene (PE) or Polypropylene (PP) with F-217 liners for sealing. Prices range from $0.35 to $0.75. Flip Spout is ideal for liquids/lotion with orifice diameters from 0.08 to 0.13 inches. Pr…

4. Klean Kanteen – Accessory Caps and Lids

Bereich: kleankanteen.com

Registriert: 2003 (22 Jahre)

Einleitung: Accessory Caps and Lids for Bottles, Mugs and Cups. Interchangeable caps designed for flexibility, suitable for various beverages from coffee to smoothies. All caps are BPA-free, easy to clean, and many are leakproof. Features include easy carry loops and swivel handles. Available types: sport caps, loop caps, café caps, straw caps, sippy caps, and stainless interior caps. Compatible with classic,…

5. Fisher Scientific – Bottle Caps

Bereich: fishersci.com

Registriert: 1995 (30 Jahre)

Einleitung: Bottle caps provide an air-tight seal ensuring leak- and spill-proof containment, temperature resistance, and mobility. The most common style is the threaded screw cap, available in various sizes and colors, specialized for different container types. Popular materials include phenolic plastic, polypropylene, and PTFE. Caps can be lined with additional materials and come in solid or open designs re…

6. Iron Flask – Versatile Water Bottle with Interchangeable Lids

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: The user discusses a water bottle (Iron Flask) that comes with three interchangeable lids: one with a straw, one with a spout for chugging, and one that slides open for hot coffee. The user prefers the straw lid but is considering switching to the spout lid.

7. Hydro Flask – Wide Mouth Straw Lid

Bereich: hydroflask.com

Registriert: 2009 (16 Jahre)

Einleitung: Wide Mouth Straw Lid – Black: $7.46 (was $9.95) 25% off; Stainless Steel Straw Set: $9.95 (was $7.46) 25% off; Tea Infuser: $16.95 (was $12.71) 25% off; 3-Pack Replacement Straw Pack: $4.95 (was $3.71) 25% off; Wide Mouth Flex Chug Cap: $12.95 (was $9.71) 25% off; Wide Mouth Flex Straw Cap: $14.95 (was $11.21) 25% off; Standard Mouth Flex Cap: $9.95 (was $7.46) 25% off; Standard Mouth Flex Straw C…

Strategic Sourcing Conclusion and Outlook for bottle lid types

In summary, the diverse landscape of bottle lid types presents significant opportunities for international B2B buyers. Understanding the functional attributes and market applications of each cap type—from standard screw caps to innovative dispensing solutions—enables businesses to make informed decisions that enhance product integrity and consumer safety.

Strategic sourcing is paramount as it not only ensures compatibility with capping machinery but also aligns with regulatory standards prevalent in various regions, such as Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers who offer customizable options and robust quality assurance processes, ensuring that their products meet both local and international market demands.

As we look to the future, the demand for sustainable and innovative packaging solutions will only grow. Engaging with forward-thinking suppliers who prioritize eco-friendly materials and advanced technology will be essential for staying competitive in a rapidly evolving market. We encourage international B2B buyers to explore these opportunities, align sourcing strategies with business goals, and leverage the insights gained from this guide to drive their packaging initiatives forward.