Introduction: Navigating the Global Market for growler bottle size

In the ever-evolving landscape of beverage packaging, understanding growler bottle sizes is essential for international B2B buyers navigating the complexities of sourcing and distribution. As demand for craft beer surges globally, businesses face the challenge of selecting the appropriate growler sizes to meet diverse market needs. This comprehensive guide delves into the various types of growlers, including traditional glass and innovative aluminum crowlers, their applications, and the critical factors to consider when vetting suppliers.

By providing in-depth insights into cost structures, labeling requirements, and regional preferences, this resource equips buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Nigeria—with the knowledge needed to make informed purchasing decisions. With an authoritative focus on practical solutions, this guide empowers businesses to enhance their product offerings and improve customer satisfaction through strategic sourcing of growler bottles. Whether you’re aiming to optimize your supply chain or expand your product line, our expert insights will help you navigate the global market effectively.

Artikel Navigation

- Top 9 Growler Bottle Size Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for growler bottle size

- Understanding growler bottle size Types and Variations

- Key Industrial Applications of growler bottle size

- 3 Common User Pain Points for ‘growler bottle size’ & Their Solutions

- Strategic Material Selection Guide for growler bottle size

- In-depth Look: Manufacturing Processes and Quality Assurance for growler bottle size

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘growler bottle size’

- Comprehensive Cost and Pricing Analysis for growler bottle size Sourcing

- Alternatives Analysis: Comparing growler bottle size With Other Solutions

- Essential Technical Properties and Trade Terminology for growler bottle size

- Navigating Market Dynamics and Sourcing Trends in the growler bottle size Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of growler bottle size

- Wichtiger Haftungsausschluss & Nutzungsbedingungen

- Strategic Sourcing Conclusion and Outlook for growler bottle size

Understanding growler bottle size Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Growler | Typically 64 oz; glass or stainless steel | Breweries, taprooms, retail beer sales | Pros: Reusable, maintains beer quality; Cons: Breakable, heavier to transport. |

| Howler | Smaller 32 oz variant of the growler | Craft breweries, specialty beer shops | Pros: More portable, ideal for smaller servings; Cons: Less capacity, limited use. |

| Crowler | 32 oz aluminum can, single-use | Festivals, outdoor events, beer-to-go sales | Pros: Lightweight, no glass restrictions; Cons: Not reusable, single-use cost. |

| Mini Growler | 16 oz option, often used for sampling | Breweries, tasting rooms | Pros: Great for tastings, lower price point; Cons: Limited volume, not suitable for takeout. |

| Custom Growler | Personalized branding options available | Corporate gifts, promotional items | Pros: Enhances brand visibility; Cons: Higher initial investment, design fees. |

What Are the Characteristics of Standard Growlers?

Standard growlers typically hold 64 ounces of liquid and are made from glass or stainless steel. They are designed to maintain the freshness and carbonation of draft beer, making them ideal for breweries and taprooms. B2B buyers should consider the durability of the material, as glass growlers can break easily, while stainless steel offers greater resilience. Additionally, the larger size is suitable for customers looking to transport multiple servings, but it can be cumbersome for some users.

How Do Howlers Serve B2B Needs?

Howlers, with a capacity of 32 ounces, are essentially half-sized growlers. Their compact size makes them an excellent option for craft breweries and specialty beer shops that wish to offer a smaller, more portable option to consumers. B2B buyers may find howlers particularly advantageous for tastings or events where customers prefer to sample multiple beers without committing to a full growler. However, the reduced capacity means they may not be suitable for all markets, especially where larger quantities are preferred.

Why Choose Crowlers for Events and Festivals?

Crowlers are a modern alternative to traditional growlers, featuring a 32-ounce aluminum can that is filled and sealed on-demand. They are particularly useful in settings like festivals and outdoor events where glass containers are often prohibited. For B2B buyers, the lightweight nature of crowlers makes them easy to transport, and they eliminate concerns about breakage. However, since they are single-use, businesses should weigh the cost-effectiveness of recurring purchases against the initial investment in reusable growlers.

What Benefits Do Mini Growlers Offer?

Mini growlers, usually 16 ounces, are perfect for sampling and are often used in tasting rooms. They allow breweries to offer customers a lower price point for smaller servings, thus encouraging more trial purchases. B2B buyers should consider mini growlers as an effective way to attract customers who may be hesitant to commit to a full-sized growler. However, their limited volume may restrict their use in environments where larger quantities are preferred.

How Can Custom Growlers Enhance Brand Visibility?

Custom growlers provide an opportunity for businesses to incorporate branding and marketing into their packaging. They can be personalized with logos and designs, making them ideal for corporate gifts or promotional items. B2B buyers should consider the higher initial investment and potential design fees, but the long-term benefits of increased brand visibility can be significant. Custom growlers can help businesses stand out in a crowded market, fostering customer loyalty and repeat purchases.

Key Industrial Applications of growler bottle size

| Industrie/Sektor | Specific Application of growler bottle size | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Craft Breweries | Offering refillable growlers for customers | Enhances customer loyalty and promotes sustainable practices | Durability of materials, custom branding options, compliance with local regulations |

| Restaurants & Bars | Utilizing growlers for takeaway options | Increases sales during off-peak hours and attracts new customers | Size variety (32 oz vs. 64 oz), ease of cleaning, and storage solutions |

| Veranstaltungsmanagement | Providing growlers for festivals and outdoor events | Facilitates easy distribution of beverages, enhancing attendee experience | Portability, weight, and regulatory compliance for public consumption |

| E-commerce Platforms | Selling growlers as part of home brewing kits | Expands product offerings and taps into the growing home brewing market | Shipping considerations, packaging durability, and branding opportunities |

| Beverage Distributors | Using growlers to supply local businesses with fresh beer | Supports local breweries and encourages community engagement | Sourcing from local manufacturers, logistics for transportation, and quality assurance |

How Are Growler Bottles Used in Craft Breweries?

Craft breweries leverage growler bottles to provide a unique customer experience by allowing patrons to take home fresh, locally brewed beer. This approach not only enhances customer loyalty but also promotes sustainable practices by encouraging reusable containers. For international buyers, especially from regions like Africa and South America, sourcing durable materials that withstand shipping challenges is crucial. Additionally, breweries should consider custom branding options to enhance their market presence.

In What Ways Do Restaurants and Bars Benefit from Growler Bottles?

Restaurants and bars can utilize growler bottles to offer takeaway options, particularly during off-peak hours. This strategy helps in increasing sales and attracting new customers who may prefer enjoying craft beer at home. For B2B buyers, considerations such as the variety of sizes (32 oz vs. 64 oz), ease of cleaning, and efficient storage solutions are essential. Ensuring compliance with local regulations regarding alcohol transport is also critical to avoid legal issues.

What Role Do Growler Bottles Play in Event Management?

In the event management sector, growler bottles are increasingly popular for festivals and outdoor events. They facilitate the easy distribution of beverages, significantly enhancing the attendee experience. For businesses sourcing growlers for events, factors such as portability, weight, and compliance with public consumption regulations must be prioritized. This ensures that the growlers can be easily transported and used in diverse settings, from parks to concert venues.

How Are Growlers Incorporated into E-commerce Platforms?

E-commerce platforms can expand their product offerings by including growlers as part of home brewing kits. This taps into the growing trend of home brewing, allowing customers to enjoy craft beer at home. For international B2B buyers, shipping considerations and packaging durability are paramount to ensure that the growlers arrive intact. Additionally, offering branding opportunities can enhance the appeal of these products to consumers.

Why Are Growler Bottles Important for Beverage Distributors?

Beverage distributors can use growler bottles to supply local businesses with fresh beer, thereby supporting local breweries and fostering community engagement. When sourcing growlers, distributors should focus on quality assurance, logistics for transportation, and sourcing from local manufacturers to reduce costs and improve delivery times. Understanding the specific needs of the local market can also help distributors tailor their offerings effectively.

3 Common User Pain Points for ‘growler bottle size’ & Their Solutions

Scenario 1: Misalignment of Growler Sizes with Market Demand

Das Problem: B2B buyers often face challenges in aligning their product offerings with the specific preferences of their target market. For instance, a brewery in Nigeria may find that customers prefer larger growlers for social gatherings, while another in Saudi Arabia might see a trend towards smaller, more portable options. This misalignment can lead to excess inventory of unpopular sizes, resulting in increased costs and waste.

Die Lösung: To effectively address this issue, buyers should conduct thorough market research to understand regional preferences and consumption patterns. Implementing a dual-sizing strategy—offering both 32 oz (howlers) and 64 oz (growlers)—can cater to diverse consumer needs. Additionally, leveraging digital tools and analytics can help track sales data and customer feedback to refine inventory choices. Engaging with local distributors and retailers can also provide insights into market trends, ensuring that the right sizes are stocked in line with consumer demand.

Scenario 2: Challenges with Shipping and Storage of Growlers

Das Problem: International B2B buyers often encounter logistical challenges when it comes to shipping and storing growlers. Glass growlers are prone to breakage during transport, and their size can complicate storage in warehouses, especially in regions where space is at a premium, such as urban centers in Europe or South America.

Die Lösung: To mitigate these issues, buyers should consider sourcing durable materials, such as stainless steel or reinforced glass, which offer better resilience during shipping. Additionally, optimizing packaging solutions, such as using protective padding or custom-sized boxes, can minimize the risk of breakage. In terms of storage, implementing vertical shelving systems can maximize space efficiency and allow for better organization of various growler sizes. Establishing a streamlined inventory management system can also help track stock levels and predict reorder needs, reducing unnecessary clutter.

Scenario 3: Compliance and Regulatory Issues with Growler Sizes

Das Problem: B2B buyers may struggle with compliance issues related to the size and labeling of growlers, especially when navigating diverse regulations across regions. For instance, certain countries in the Middle East may have strict guidelines on container sizes and the information that must be displayed on labels, leading to potential legal complications and delays in product launches.

Die Lösung: To ensure compliance, buyers should engage legal experts familiar with the regulations in their specific markets. It is crucial to stay updated on local laws regarding beverage containers, including size restrictions and labeling requirements. When sourcing growlers, buyers should request samples that meet these regulations before placing bulk orders. Collaborating with manufacturers who have experience in international markets can streamline the process, ensuring that all products are compliant from the outset. Establishing a clear labeling strategy that adheres to local guidelines will not only prevent legal issues but also enhance brand credibility and consumer trust.

Strategic Material Selection Guide for growler bottle size

What Are the Key Materials for Growler Bottle Sizes?

When selecting growler bottle sizes for international markets, it is crucial to understand the properties, advantages, and disadvantages of various materials. The choice of material not only affects the performance and durability of the growler but also has implications for cost, manufacturing complexity, and compliance with regional standards. Below, we analyze four common materials used for growler bottles: glass, stainless steel, aluminum, and ceramic.

How Does Glass Perform as a Material for Growler Bottles?

Glass is a traditional choice for growler bottles, known for its excellent barrier properties against gases and moisture. It maintains the beer’s flavor and carbonation effectively, making it ideal for preserving the quality of craft brews. However, glass is fragile and can break easily, which poses a risk during transportation and handling.

Vorteile: Glass growlers are aesthetically pleasing, allowing for branding opportunities through custom designs. They are also inert, meaning they do not react with the beverage inside, ensuring that the taste remains unaffected.

Nachteile: The fragility of glass increases the risk of breakage, leading to potential losses. Additionally, the weight of glass can increase shipping costs, particularly for international buyers.

Auswirkungen auf die Anwendung: Glass is suitable for a wide range of beverages but may not be ideal for environments where breakage is a concern, such as outdoor events.

International Considerations: Compliance with local regulations regarding glass packaging is essential. For example, countries may have specific recycling and disposal standards that affect glass usage.

What Are the Advantages of Stainless Steel for Growler Bottles?

Stainless steel has gained popularity in recent years due to its durability and resistance to corrosion. It can withstand high pressures and temperatures, making it suitable for both hot and cold beverages.

Vorteile: Stainless steel growlers are highly durable, resistant to breakage, and easy to clean. They also provide excellent insulation, keeping beverages cold for extended periods.

Nachteile: The initial cost of stainless steel is generally higher than glass or aluminum. Additionally, the manufacturing process can be more complex, impacting lead times for international orders.

Auswirkungen auf die Anwendung: Stainless steel is compatible with a variety of beverages, including those with high acidity, making it versatile for different markets.

International Considerations: Buyers should ensure that the stainless steel used meets international standards such as ASTM for quality assurance, particularly in regions with strict import regulations.

How Does Aluminum Compare for Growler Bottles?

Aluminum growlers, often referred to as crowlers, are lightweight and offer excellent protection against light and oxygen, which can degrade beer quality. They are typically used for single-use applications but can also be designed for reusability.

Vorteile: Aluminum is lightweight, reducing shipping costs. It is also recyclable, which appeals to environmentally conscious consumers.

Nachteile: While aluminum is durable, it can dent and may not provide the same premium feel as glass or stainless steel. Additionally, it may impart a metallic taste if not properly lined.

Auswirkungen auf die Anwendung: Aluminum is ideal for outdoor events and festivals where glass is prohibited. It is also suitable for breweries looking to offer portable options.

International Considerations: Compliance with local recycling regulations and standards for aluminum packaging is crucial, especially in regions like Europe where sustainability is a priority.

What Role Does Ceramic Play in Growler Bottle Sizes?

Ceramic growlers offer a unique aesthetic and are often used for specialty brews. They are typically heavier and more fragile than glass but provide excellent insulation.

Vorteile: Ceramic can be designed in various colors and styles, providing branding opportunities. It is also non-reactive, preserving the flavor of the beverage.

Nachteile: The weight and fragility of ceramic can be significant drawbacks, especially for shipping. Additionally, the manufacturing process can be more costly.

Auswirkungen auf die Anwendung: Ceramic is best suited for niche markets or premium products where presentation is key.

International Considerations: Buyers should consider local regulations regarding ceramic materials, particularly in regions with stringent import standards.

Summary Table of Material Selection for Growler Bottles

| Material | Typical Use Case for growler bottle size | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Glas | Craft beer transport | Excellent flavor preservation | Fragile, risk of breakage | Mittel |

| Rostfreier Stahl | Versatile beverage storage | Durable, insulated | Higher initial cost | Hoch |

| Aluminium | Outdoor events, single-use applications | Lightweight, recyclable | Can dent, potential metallic taste | Niedrig |

| Ceramic | Specialty brews, premium markets | Unique aesthetic, non-reactive | Schwer, zerbrechlich | Mittel bis Hoch |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for growler bottles, enabling informed decisions that align with market demands and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for growler bottle size

What Are the Main Stages of Manufacturing Growler Bottles?

The manufacturing process of growler bottles involves several critical stages, each of which contributes to the final product’s quality and functionality. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Growler Bottle Production?

The primary materials used in growler bottle production are glass and stainless steel. For glass growlers, raw materials such as silica sand, soda ash, and limestone are mixed in precise ratios. The mixture is then melted in a furnace at high temperatures, typically around 1,700°C, until it becomes molten glass. For stainless steel growlers, high-grade stainless steel sheets are sourced and cut into appropriate sizes for forming.

What Techniques Are Used in Forming Growler Bottles?

Forming techniques vary based on the material. For glass growlers, blow molding is a common method. The molten glass is shaped into a preform, which is then blown into the final growler shape within a mold. This method ensures uniform thickness and design fidelity. For stainless steel, processes like deep drawing or spinning are employed. In deep drawing, a flat sheet is pressed into a mold to create the growler shape, while spinning involves rotating the sheet around a mandrel to form the desired profile.

How Are Growler Bottles Assembled and Finished?

Assembly for growler bottles is relatively straightforward but crucial for ensuring functionality. For glass growlers, the assembly involves attaching a cap or lid, which must be airtight to maintain beer freshness. Stainless steel growlers may include additional components like handles or insulation layers for thermal retention.

The finishing stage includes surface treatment and quality checks. Glass growlers may undergo processes like polishing or coating to enhance appearance and durability. Stainless steel growlers are often polished to a mirror finish and may be coated with a protective layer to prevent scratches and corrosion.

What Quality Assurance Measures Are Essential for Growler Bottles?

Quality assurance (QA) is vital in ensuring that growler bottles meet international standards and customer expectations. For B2B buyers, understanding the QA process is essential for selecting reliable suppliers.

Which International Standards Should Growler Bottle Manufacturers Comply With?

Compliance with international standards such as ISO 9001 is essential for manufacturers. ISO 9001 sets the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement. Additionally, industry-specific certifications, such as CE marking for European markets and API standards for metal containers, ensure that products meet safety and performance criteria.

What Are the Key Quality Control Checkpoints in Growler Bottle Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These typically include:

- Eingehende Qualitätskontrolle (IQC): Die Rohstoffe werden bei ihrem Eintreffen geprüft, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen.

- Prozessbegleitende Qualitätskontrolle (IPQC): Continuous monitoring during manufacturing helps identify defects early, preventing costly rework.

- Endgültige Qualitätskontrolle (FQC): The finished products are thoroughly inspected for defects, weight, dimensions, and functionality before packaging.

Common testing methods include pressure testing for sealing integrity, thermal cycling tests for thermal resistance, and visual inspections for surface defects.

Wie können B2B-Einkäufer die Qualitätskontrollpraktiken von Lieferanten überprüfen?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is critical to verify the quality control practices of suppliers. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and adherence to quality standards. Buyers should request audit reports and certifications to assess compliance.

- Qualitätsberichte anfordern: Suppliers should provide detailed quality reports, including inspection results and testing methodologies. This transparency helps in evaluating their commitment to quality.

- Inspektionen durch Dritte: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s manufacturing practices and product quality. This is particularly important for buyers in regions where regulatory compliance may vary.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Einkäufer?

International B2B buyers must navigate various quality control nuances when sourcing growler bottles. Differences in local regulations, cultural expectations, and market demands can affect quality standards. For instance, buyers from Saudi Arabia may have specific requirements for food safety and material certifications that differ from those in Nigeria or Brazil.

Additionally, language barriers and varying interpretations of quality standards can lead to misunderstandings. It is advisable for buyers to establish clear communication channels with suppliers, ensuring that all quality expectations are documented and agreed upon.

Conclusion: Ensuring Quality in Growler Bottle Sourcing

By understanding the manufacturing processes and quality assurance measures for growler bottles, B2B buyers can make informed decisions that align with their quality expectations and market demands. Thoroughly vetting suppliers, verifying compliance with international standards, and maintaining open lines of communication can significantly enhance the sourcing experience, particularly in diverse and rapidly evolving markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘growler bottle size’

In the competitive beverage market, particularly for craft breweries and taprooms, selecting the right growler bottle size is crucial for ensuring product quality and customer satisfaction. This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure growler bottles effectively.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Begin by determining the specific requirements for the growler bottles you intend to purchase. Consider factors such as size (32 oz vs. 64 oz), material (glass vs. aluminum), and design features (e.g., airtight seals). Identifying these parameters upfront helps streamline the sourcing process and ensures that your bottles meet both regulatory and customer expectations.

Schritt 2: Research Market Trends and Demands

Understanding current market trends is essential for making informed decisions. Analyze consumer preferences in your target regions—like Africa, South America, the Middle East, and Europe—regarding growler sizes and materials. This insight allows you to align your procurement strategy with market demands, enhancing the likelihood of successful sales.

Schritt 3: Potenzielle Lieferanten evaluieren

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, client testimonials, and case studies from similar businesses in your industry. Assessing their reliability and quality standards is crucial to ensure they can meet your specifications and provide consistent product quality.

- Zertifizierungen prüfen: Verify if suppliers hold relevant certifications, such as food safety and quality management standards, which affirm their commitment to quality.

Schritt 4: Muster für die Qualitätsbewertung anfordern

Always ask for samples of the growler bottles before placing a bulk order. This step allows you to evaluate the product’s durability, design, and functionality firsthand. Pay attention to aspects such as the seal integrity and ease of use, which can significantly impact customer experience.

Schritt 5: Preise und Bedingungen verhandeln

Once you have selected a few potential suppliers, initiate negotiations to secure the best pricing and terms. Discuss volume discounts, payment terms, and delivery schedules. A well-negotiated agreement not only enhances your profit margins but also establishes a solid foundation for a long-term partnership.

Schritt 6: Assess Logistics and Shipping Options

Consider the logistics involved in shipping the growler bottles to your location. Evaluate the supplier’s shipping capabilities, including lead times and costs. Reliable shipping arrangements are vital to ensure that you receive your products on time and in good condition, preventing disruptions in your supply chain.

Schritt 7: Plan for Custom Branding Opportunities

If branding is a priority for your business, discuss customization options with your suppliers. Many manufacturers offer labeling and printing services, which can enhance your product’s marketability. Ensure that your branding aligns with your target audience’s preferences to maximize impact.

By following these steps, B2B buyers can effectively navigate the procurement of growler bottles, ensuring they select the right products that meet their business needs and enhance customer satisfaction.

Comprehensive Cost and Pricing Analysis for growler bottle size Sourcing

What Are the Key Cost Components in Sourcing Growler Bottle Sizes?

When sourcing growler bottles, various cost components contribute to the overall expense. Materialien form the primary cost driver, with glass and aluminum being the most common materials used. Glass growlers, typically 64 oz or 32 oz, can range in price based on the type of glass, thickness, and whether they come with custom branding options. On the other hand, aluminum crowlers, which are often cheaper due to lower material costs, can be purchased with minimal additional charges, particularly in bulk.

Labor costs are another significant component, influenced by the manufacturing process. For instance, glass growlers require skilled labor for shaping and finishing, while crowlers involve automated processes that may reduce labor costs. Fertigungsgemeinkosten covers expenses related to utilities, maintenance, and facility costs, which can vary by region and factory efficiency.

Werkzeugkosten also need consideration, especially for customized or branded growlers. Setting up molds or printing equipment can lead to initial investments that impact pricing. Quality control (QC) processes ensure that the final product meets industry standards and consumer expectations, contributing to additional costs.

Zum Schluss, Logistik plays a crucial role. Shipping costs can vary widely based on the destination, packaging requirements, and whether the supplier is using Incoterms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), which can shift the cost burden from the supplier to the buyer.

How Do Price Influencers Impact Growler Bottle Sourcing?

Several price influencers can affect the final cost of growler bottles. Volume and minimum order quantities (MOQ) are pivotal; larger orders typically lead to lower per-unit costs. Suppliers are often willing to negotiate prices based on order size, so buyers should consider bulk purchases when possible.

Spezifikationen und Anpassungen also play a significant role in pricing. Custom branding, special designs, or unique sizes can significantly increase the cost. Buyers should carefully evaluate their branding needs against budget constraints.

Material quality and certifications are critical factors, especially for international buyers. Certifications related to food safety, sustainability, and recyclability can add to costs but may be necessary for compliance in certain markets. Understanding the regulatory landscape in regions such as Africa, South America, the Middle East, and Europe is essential for making informed decisions.

Lieferantenfaktoren such as reputation, reliability, and production capabilities can also influence pricing. Established suppliers may command higher prices due to perceived quality and service levels, while newer suppliers might offer competitive rates to build their client base.

What Tips Can Help Buyers Optimize Costs When Sourcing Growler Bottles?

To maximize cost-efficiency in sourcing growler bottles, buyers should engage in Verhandlung. Establishing relationships with suppliers can lead to better terms, discounts, and exclusive offers. Moreover, understanding the Gesamtbetriebskosten (TCO) is essential. TCO includes not only the purchase price but also shipping, handling, storage, and potential waste or damage costs.

Buyers should also consider Preisnuancen specific to their regions. For example, tariffs, taxes, and local regulations can impact the final cost of imported goods in markets like Saudi Arabia or Nigeria. Buyers should conduct thorough market research to understand these factors.

Finally, it is crucial to maintain flexibility in sourcing strategies. Exploring alternative suppliers or materials can lead to significant cost savings. Always request quotes from multiple suppliers and compare not just prices, but also the value offered, including service, quality, and delivery timelines.

Haftungsausschluss

The prices and cost estimates provided herein are indicative and may vary based on current market conditions, supplier negotiations, and regional factors. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing growler bottle size With Other Solutions

Introduction: Exploring Alternatives to Growler Bottle Size

When considering the best way to package and transport draft beer, growler bottles are a popular choice due to their size and reusability. However, various alternatives offer unique benefits that may better suit specific business needs. This analysis compares growler bottles with two viable alternatives: crowlers (aluminum cans) and traditional beer bottles. Each option presents distinct advantages and disadvantages, making it essential for B2B buyers to evaluate their requirements carefully.

Vergleichstabelle

| Vergleich Aspekt | Growler Bottle Size | Crowler (Aluminum Can) | Traditional Beer Bottle |

|---|---|---|---|

| Leistung | Excellent flavor retention and carbonation | Good flavor retention, but less than glass | Moderate flavor retention; carbonation may degrade over time |

| Kosten | Higher initial investment (reusable) | Lower cost, single-use | Varies widely; often lower per unit but not reusable |

| Leichte Implementierung | Requires cleaning and maintenance | No maintenance needed; fill and go | Widely available and easy to use |

| Wartung | Needs regular cleaning to avoid residue | Single-use; no maintenance required | Minimal; often recyclable |

| Bester Anwendungsfall | Craft breweries and taprooms looking for reusable options | Outdoor events and locations where glass is prohibited | Retail distribution and mass production |

Detaillierte Aufschlüsselung der Alternativen

Crowler (Aluminum Can)

Crowlers are a modern solution for transporting draft beer, typically holding 32 ounces. Their main advantage lies in their single-use design, which eliminates the need for cleaning and maintenance. This makes them ideal for outdoor events or locations where glass containers are restricted. However, while they do a good job of preserving beer flavor and carbonation, they may not maintain the same quality as glass growlers over extended periods. For businesses focused on convenience and compliance with outdoor regulations, crowlers can be a cost-effective choice.

Traditional Beer Bottle

Traditional beer bottles, commonly available in 12-ounce sizes, are a staple in the beverage industry. They offer a well-established method for packaging and distributing beer, making them widely accepted in retail settings. The lower cost per unit can be attractive for mass production; however, traditional bottles have limitations regarding flavor retention compared to growlers or crowlers. Once opened, the beer in a traditional bottle may lose its freshness quickly, making them less suitable for customers seeking draft-quality beer on the go. They are best utilized for large-scale distribution and retail environments.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right beer packaging solution requires a careful assessment of your business’s specific needs and operational context. Growler bottles are best for establishments focused on providing a premium, reusable product that retains the quality of craft beer. Crowlers serve well in situations that demand convenience and compliance with glass restrictions, while traditional beer bottles offer an economical option for mass distribution. By understanding the strengths and weaknesses of each alternative, B2B buyers can make informed decisions that align with their business goals and customer preferences.

Essential Technical Properties and Trade Terminology for growler bottle size

What Are the Key Technical Properties of Growler Bottles?

When evaluating growler bottle sizes for B2B transactions, several critical technical specifications must be considered to ensure product quality and functionality. Here are some essential properties:

-

Material Klasse

Growlers are typically made from glass, stainless steel, or ceramic. The material grade affects durability, insulation, and taste preservation. For instance, food-grade stainless steel is preferred for its resistance to corrosion and ability to maintain temperature, which is crucial for preserving the freshness of craft beer during transportation. -

Kapazität

Growlers generally come in sizes of 32 oz (howler) and 64 oz. This specification is vital for inventory management and customer preferences. Understanding the right capacity helps breweries and distributors cater to different consumer needs, from casual drinkers to larger gatherings. -

Dimensions and Weight

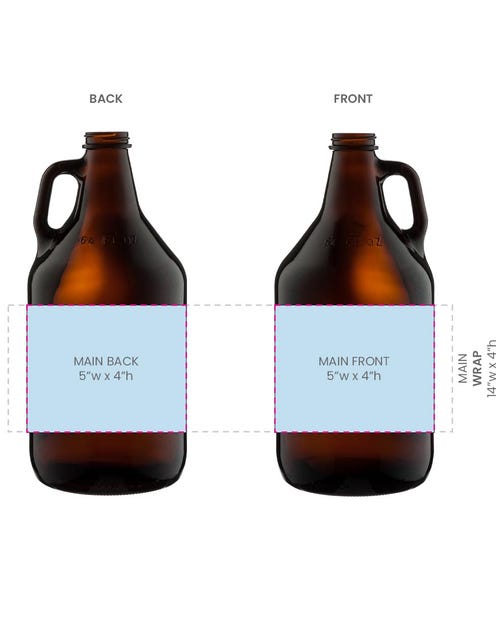

The physical dimensions (height, diameter) and weight of growlers impact shipping costs and storage requirements. For example, a standard 64 oz growler might measure approximately 10.937 inches in height and weigh about 39 oz when empty. This information is essential for logistics planning and optimizing shelf space in retail locations. -

Labeling Area

The labeling area is crucial for branding and regulatory compliance. Growlers often require a larger label area (e.g., 4×6 inches for 64 oz) for branding and information. This aspect is significant for B2B buyers who may need to adhere to local labeling regulations while maximizing brand visibility. -

Dichtungsmechanik

The sealing mechanism, which can be a continuous thread or swing-top, plays a crucial role in maintaining the beer’s freshness and carbonation. A reliable sealing system is important for minimizing spoilage and ensuring customer satisfaction. -

Reusability and Maintenance Requirements

Understanding the maintenance needs of growlers is essential for long-term use. Glass growlers require regular cleaning to prevent bacterial growth, while aluminum crowlers are designed for single use. This distinction affects the lifecycle cost for businesses and the sustainability of their operations.

What Are Common Trade Terms in the Growler Industry?

In the realm of growler bottles, familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the growler industry, an OEM might supply specific components like caps or labels for breweries. -

MOQ (Mindestbestellmenge)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their inventory efficiently and manage costs effectively, especially in regions with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing information from suppliers. This process is crucial for B2B buyers to ensure they receive competitive pricing for growler bottles and related products. -

Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps businesses navigate shipping, insurance, and customs duties associated with importing growler bottles. -

Vorlaufzeit

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for businesses to manage their supply chains and ensure timely availability of growlers for their customers. -

Customs Clearance

This term refers to the process of passing goods through customs so they can enter or leave a country. For international B2B transactions involving growler bottles, understanding customs clearance procedures is essential to avoid delays and additional costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands. This knowledge is crucial for optimizing procurement strategies and enhancing business relationships in the growler bottle market.

Navigating Market Dynamics and Sourcing Trends in the growler bottle size Sector

What Are the Current Market Dynamics and Key Trends in the Growler Bottle Size Sector?

The global market for growler bottles is witnessing significant growth, driven by the rising popularity of craft beer and the increasing consumer preference for fresh, local brews. As craft breweries expand in regions like Africa, South America, the Middle East, and Europe, the demand for effective and sustainable packaging solutions is on the rise. Key trends include the transition from traditional glass growlers to more versatile options like crowlers, which offer convenience and portability. This shift is particularly relevant in markets where outdoor consumption is popular, such as festivals and public events, where glass containers are often restricted.

Emerging B2B tech trends also play a crucial role in this sector. Innovations such as smart labeling solutions and automated filling systems are enhancing operational efficiency for breweries and distributors. Furthermore, the integration of e-commerce platforms enables smaller breweries to reach international buyers, facilitating a broader distribution of growler bottles. International B2B buyers, particularly those from regions like Saudi Arabia and Nigeria, should focus on suppliers who are not only providing high-quality products but are also responsive to market shifts, ensuring they stay competitive in this dynamic landscape.

How Is Sustainability and Ethical Sourcing Influencing the Growler Bottle Size Market?

Sustainability has become a cornerstone of consumer preference, and this trend extends to the growler bottle size sector. The environmental impact of packaging materials is a significant concern for international B2B buyers. As a result, many breweries are seeking to source growlers made from recycled materials or those that are fully recyclable. The use of stainless steel and glass, which can be reused multiple times, aligns with the growing demand for eco-friendly practices.

Moreover, ethical sourcing is gaining traction, with buyers increasingly favoring suppliers who prioritize transparent supply chains and fair labor practices. Certifications such as FSC (Forest Stewardship Council) for wood products or various recycling certifications can enhance a supplier’s appeal. Buyers should look for partners who not only meet product specifications but also contribute positively to environmental and social standards, ensuring that their sourcing decisions reflect their corporate values and resonate with eco-conscious consumers.

What Is the Brief Evolution and History of Growler Bottle Sizes?

The growler bottle has evolved significantly since its inception in the late 19th century, originally serving as a simple glass jug for transporting beer from local breweries. As craft beer culture gained momentum in the late 20th century, the growler transformed into a popular vessel for consumers seeking fresh beer on-the-go. The introduction of the crowler in the early 2000s, an aluminum alternative that offers better preservation and portability, marked a pivotal moment in the market. This evolution reflects the changing preferences of consumers and the increasing emphasis on sustainability and convenience in beverage packaging. International B2B buyers should recognize this historical context as they navigate sourcing strategies and partnerships in the growler bottle size sector.

Frequently Asked Questions (FAQs) for B2B Buyers of growler bottle size

-

How do I choose the right growler bottle size for my business needs?

Choosing the right growler bottle size depends on your target market and the consumption patterns of your customers. The most common sizes are 32 oz (howlers) and 64 oz (growlers). If your clientele prefers larger quantities for gatherings or events, 64 oz might be ideal. Conversely, for individual consumption, 32 oz could suffice. Consider your pricing strategy, storage capabilities, and the type of beverages you intend to sell to determine the best fit for your business. -

What is the best material for growler bottles: glass or aluminum?

The choice between glass and aluminum growlers hinges on your specific requirements. Glass growlers are excellent for preserving flavor and carbonation, making them ideal for craft breweries. However, they can be fragile and are often restricted in certain public spaces. Aluminum crowlers, on the other hand, are lightweight, shatterproof, and better suited for outdoor events. They also offer superior protection against light and oxygen, which can degrade beer quality. Analyze your distribution channels to make the best choice. -

What are the minimum order quantities (MOQ) for growler bottles?

Minimum order quantities for growler bottles can vary significantly based on the supplier and the type of bottle you are ordering. Typically, MOQs for custom-branded glass growlers range from 100 to 500 units. For aluminum crowlers, you may find MOQs starting as low as 50 units due to lower production costs. Always clarify with your supplier about their MOQ policies to plan your inventory effectively. -

How can I customize my growler bottles for branding purposes?

Customizing growler bottles is an effective way to enhance your brand visibility. Most suppliers offer options for screen printing or labels with your logo. Ensure you have high-quality artwork ready for submission, as some suppliers may charge a design fee. Discuss with your supplier about their customization capabilities, including color options and placement, to achieve the desired branding effect on your growlers. -

What payment terms should I expect when sourcing growler bottles internationally?

Payment terms for international sourcing can vary by supplier, but common arrangements include 30% upfront and 70% upon delivery. Some suppliers may offer net 30 or net 60 terms after establishing a relationship. It’s essential to negotiate terms that suit your cash flow while ensuring that you have protections in place, such as letters of credit or escrow services, to mitigate risks associated with international transactions. -

What quality assurance measures should I consider when sourcing growler bottles?

Quality assurance is crucial when sourcing growler bottles to ensure that the products meet safety and quality standards. Inquire about the supplier’s quality control processes, including material sourcing, production standards, and testing protocols. Request samples to inspect for defects or inconsistencies. Additionally, ensure that the bottles comply with international regulations, especially if you are exporting to different regions. -

What logistics considerations should I keep in mind when importing growler bottles?

When importing growler bottles, logistics play a key role in ensuring timely and cost-effective delivery. Consider factors such as shipping methods, customs duties, and handling fees. Work with a reliable freight forwarder experienced in beverage container logistics to navigate international shipping challenges. Also, assess the lead times for production and shipping to avoid disruptions in your supply chain. -

How do I find reputable suppliers for growler bottles in different regions?

Finding reputable suppliers involves thorough research and vetting processes. Utilize online B2B marketplaces, industry trade shows, and professional networks to identify potential suppliers. Check their reviews, certifications, and previous client testimonials. It’s advisable to request samples before placing bulk orders and to establish clear communication to discuss your specific needs. Engaging with local trade organizations can also provide insights into trustworthy suppliers in your region.

Wichtiger Haftungsausschluss & Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Top 9 Growler Bottle Size Manufacturers & Suppliers List

1. Reddit – Growlers

Bereich: reddit.de

Registriert: 2005 (20 Jahre)

Einleitung: Growlers are commonly found in two sizes: 64 U.S. fl oz (the most popular) and 32 U.S. fl oz. They are used for transporting fresh beer, especially from local breweries that may not bottle or can their products. The fascination with growlers may stem from their convenience, the novelty of fresh beer, and the avoidance of accumulating bottles.

2. Wine and Beer Supply – Growler 64oz

Bereich: wineandbeersupply.com

Registered: 2015 (10 years)

Einleitung: {“name”:”Growler 64oz”,”original_price”:”$5.22″,”current_price”:”$5.22″,”capacity”:”64 oz”,”weight”:”39 oz”,”diameter”:”4.974 in”,”height”:”10.937 in”,”label_panel_height”:”4.594 in”,”label_panel_width”:”15.224 in”,”finish_type”:”Continuous Thread”,”color”:”Amber”,”minimum_order”:”8 Cases”,”colors_available”:”Amber 6 growlers/case 84 cases per pallet”,”additional_info”:”Caps sold separately. $40 s…

3. Fresh Water Systems – Amber 64oz Glass Growler

Bereich: freshwatersystems.com

Registriert: 1998 (27 Jahre)

Einleitung: Amber 64oz Glass Beer Growler or Water Bottle With Cap

4. Wayfair – Growler Sizes

Bereich: wayfair.com

Registriert: 2004 (21 Jahre)

Einleitung: The text discusses four growler sizes suitable for home bars, including details about their capacities, typical uses, and advantages. It highlights the importance of choosing the right size for different occasions and preferences.

5. Thirsty Bastards – The Gutsy Growler

Bereich: thirstybastards.com

Registriert: 2016 (9 Jahre)

Einleitung: The Gutsy Growler is a 64-ounce glass jug used for transporting beer from breweries. It holds approximately four pints or 5 1/3 twelve-ounce bottles. There are variations such as the Howler (32 ounces) and Crowler (32 ounces, non-reusable can). Beer in a growler stays fresh for about 36 hours after opening, but can last longer if sealed properly. The uKeg 64 oz Pressurized Stainless Steel Growler …

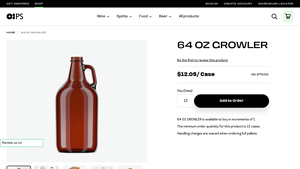

6. O-I – 64 OZ GROWLER

Bereich: store.o-i.com

Registriert: 1998 (27 Jahre)

Einleitung: {‘product_name’: ’64 OZ GROWLER’, ‘price_per_case’: ‘$12.05’, ‘sku’: ‘c000000000010039654’, ‘minimum_order_quantity’: ’12 cases’, ‘handling_charges’: ‘waived when ordering full pallets’, ‘color’: ‘AMBER RED’, ‘finish_type’: ‘CONTINUOUS THREAD’, ‘shape’: ‘ROUND’, ‘height_mm’: 277.825, ‘diameter_mm’: 126.34, ‘finish_size’: 38, ‘sold_by’: ‘Case’, ‘packaging_type’: ‘CARTON’, ‘bottles_per_pallet’: 504,…

7. Das Stahl Bierhaus – Craft Beer Growlers

Bereich: shopdsb.com

Registriert: 2020 (5 Jahre)

Einleitung: Craft Beer Growlers are jugs used to transport draft beer, typically made of glass, ceramic, or stainless steel. Common size is 64 oz., but they can be filled up to 128 oz. at Das Stahl Bierhaus. Recommended size for best quality and value is 64 oz. Growlers are designed to keep beer fresh by preventing UV light and oxygen from spoiling the beer. It is advised to consume the beer within two days o…

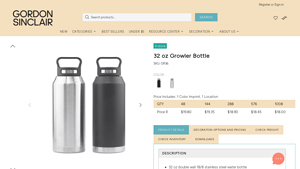

8. Gordon Sinclair – 32 oz Growler Bottle

Bereich: gordonsinclair.com

Registriert: 1998 (27 Jahre)

Einleitung: {“product_name”: “32 oz Growler Bottle”, “sku”: “GR36”, “colors_available”: [“Black”, “Silver”], “price”: {“qty_48”: 19.80, “qty_144”: 19.35, “qty_288”: 18.90, “qty_576”: 18.45, “qty_1008”: 18.00}, “decoration_options”: {“silkscreen”: {“setup_charge”: 60, “first_run_charge”: “-“, “additional_run_charge_per_color”: 0.60}, “pad_print”: {“setup_charge”: 60, “first_run_charge”: “-“, “additional_run_ch…

9. The Cary Company – 64 oz. Amber Glass Beer Growler

Bereich: thecarycompany.com

Registriert: 1999 (26 Jahre)

Einleitung: {“product_name”: “64 oz. Amber Glass Beer Growler”, “capacity”: “1/2 Gallon (64 oz.)”, “color”: “Amber”, “material”: “Glass”, “closure_type”: “38mm 38-405”}

Strategic Sourcing Conclusion and Outlook for growler bottle size

In the dynamic landscape of beverage packaging, the strategic sourcing of growler bottles presents significant opportunities for international buyers. As consumer preferences evolve, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances between growlers and crowlers can enhance product offerings. Growlers, available in both 32 oz and 64 oz sizes, cater to diverse market needs, allowing breweries to provide fresh craft beer in reusable containers. Conversely, crowlers offer a lightweight, single-use alternative that appeals to consumers seeking convenience without compromising on quality.

For B2B buyers, the decision between sourcing growlers or crowlers should be driven by market demand, cost-effectiveness, and logistical considerations, such as shipping regulations in specific regions. Establishing strong supplier relationships will be key to navigating these choices effectively.

Looking ahead, as craft beer culture continues to expand globally, now is the time for businesses to invest in sustainable and innovative packaging solutions. By strategically sourcing the right growler sizes, companies can not only meet consumer expectations but also position themselves as leaders in the competitive beverage market. Engage with suppliers today to explore how tailored packaging solutions can elevate your brand’s presence in emerging markets.