Introduction: Navigating the Global Market for 1 gallon plastic bottles

Navigating the intricate landscape of sourcing 1 gallon plastic bottles can pose significant challenges for international B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe. Factors such as varying regulations, quality standards, and logistical complexities can complicate the purchasing process. This guide aims to demystify the global market for 1 gallon plastic bottles by providing comprehensive insights into the different types, applications, and essential considerations for procurement.

From understanding the specifications of high-density polyethylene (HDPE) jugs to identifying the most suitable closures for your products, this resource covers every facet of the purchasing journey. Additionally, we delve into strategies for vetting suppliers effectively, ensuring that you partner with manufacturers who meet stringent quality and sustainability standards. Cost considerations are also addressed, providing a framework for evaluating bulk pricing and discounts that can enhance your profit margins.

Armed with the knowledge presented in this guide, B2B buyers will be empowered to make informed purchasing decisions that align with their operational needs and market demands. Whether you’re based in Nigeria, Germany, or elsewhere, this guide is tailored to help you navigate the complexities of sourcing 1 gallon plastic bottles, ultimately driving efficiency and success in your supply chain.

Artikel Navigation

- Top 2 1 Gallon Plastic Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 1 gallon plastic bottles

- Understanding 1 gallon plastic bottles Types and Variations

- Key Industrial Applications of 1 gallon plastic bottles

- 3 Common User Pain Points for ‘1 gallon plastic bottles’ & Their Solutions

- Strategic Material Selection Guide for 1 gallon plastic bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for 1 gallon plastic bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 gallon plastic bottles’

- Comprehensive Cost and Pricing Analysis for 1 gallon plastic bottles Sourcing

- Alternatives Analysis: Comparing 1 gallon plastic bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for 1 gallon plastic bottles

- Navigating Market Dynamics and Sourcing Trends in the 1 gallon plastic bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 1 gallon plastic bottles

- Wichtiger Haftungsausschluss & Nutzungsbedingungen

- Strategic Sourcing Conclusion and Outlook for 1 gallon plastic bottles

Understanding 1 gallon plastic bottles Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Natural HDPE Square Jug | Square shape, high-density polyethylene (HDPE) | Industrial liquids, cleaning products | Vorteile: Durable, space-efficient. Nachteile: Begrenzte Farboptionen. |

| Taper Top Round Jug | Tapered design, wide neck for easy pouring | Food products, oils, beverages | Vorteile: Easy to fill, versatile. Nachteile: May require specific closures. |

| F-Style Jug with Handle | Rectangular shape, built-in handle | Chemicals, paints, agricultural products | Vorteile: Ergonomic handling, efficient storage. Nachteile: Heavier than other styles. |

| Tamper-Evident Jug | Special cap design to indicate tampering | Pharmaceuticals, food and beverage packaging | Vorteile: Enhanced safety, compliance-friendly. Nachteile: Higher cost due to specialized design. |

| Colored HDPE Jug | Available in various colors for branding | Consumer products, personal care items | Vorteile: Branding opportunities, product differentiation. Nachteile: Limited visibility of contents. |

What Are the Characteristics of Natural HDPE Square Jugs?

Natural HDPE square jugs are a popular choice for bulk liquid storage due to their square shape, which maximizes storage efficiency. Made from high-density polyethylene, these jugs are robust and suitable for a variety of industrial applications, including the storage of cleaning products and chemicals. When considering purchase, buyers should evaluate the jug’s compatibility with their specific liquids and assess the need for custom closures that might be required.

How Do Taper Top Round Jugs Stand Out?

Taper top round jugs are characterized by their tapered design and wide neck, making them ideal for easy filling and pouring. They are commonly used in the food and beverage industry for products like oils and sauces. B2B buyers should consider the jug’s neck size when selecting closures and ensure that the design aligns with their branding and labeling requirements.

Why Choose F-Style Jugs with Handles?

F-style jugs feature a rectangular shape with a built-in handle, providing ergonomic advantages for transport and pouring. They are widely used for chemicals, paints, and agricultural products. Buyers should weigh the benefits of ease of handling against potential weight considerations, as these jugs can be heavier than alternatives. Additionally, compatibility with dispensing equipment should be assessed.

What Are the Benefits of Tamper-Evident Jugs?

Tamper-evident jugs are designed with specialized caps that show visible signs of tampering, making them crucial for pharmaceuticals and food products. These jugs enhance safety and compliance with regulatory standards. When purchasing, buyers should factor in the additional costs associated with tamper-evident designs, as well as the need for specific manufacturing processes.

How Can Colored HDPE Jugs Enhance Branding?

Colored HDPE jugs offer businesses the opportunity to differentiate their products through branding. Available in various colors, these jugs are suitable for consumer goods and personal care items. However, buyers should consider that while colored jugs provide branding benefits, they can obscure the visibility of the contents, which may be a critical factor for certain products.

Key Industrial Applications of 1 gallon plastic bottles

| Industrie/Sektor | Specific Application of 1 Gallon Plastic Bottles | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Lebensmittel und Getränke | Bulk storage of cooking oils, sauces, and dressings | Cost-effective, safe storage; reduces spoilage and waste | Ensure food-grade materials; verify closure compatibility and sealing. |

| Industrial Chemicals | Storage for cleaning agents and industrial liquids | Durable and resistant to chemical corrosion | Confirm chemical compatibility; assess for tamper-evident features. |

| Landwirtschaft | Transport of fertilizers and pesticides | Facilitates bulk handling and reduces packaging waste | Look for UV resistance; check for secure closures to prevent leaks. |

| Personal Care Products | Packaging for shampoos, conditioners, and lotions | Enhances brand visibility; allows for easy dispensing | Consider customization options for labeling and branding. |

| Pharmazeutika | Containment of liquid medications | Ensures safe transport and compliance with health regulations | Verify compliance with industry standards; assess for child-resistant caps. |

How Are 1 Gallon Plastic Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, 1 gallon plastic bottles are essential for the bulk storage of cooking oils, sauces, and dressings. These bottles are made from food-grade materials, ensuring safety and compliance with health regulations. They help businesses reduce spoilage and waste while providing a cost-effective solution for storage. International buyers should prioritize sourcing from suppliers who can guarantee material quality and compatibility with various closures to prevent contamination.

What Role Do 1 Gallon Plastic Bottles Play in Industrial Chemicals?

1 gallon plastic bottles are widely used in the industrial chemicals sector for the storage and transport of cleaning agents and other liquids. Their durability and resistance to chemical corrosion make them an ideal choice for this application. Businesses benefit from reduced packaging waste and enhanced safety during handling. Buyers should ensure that the bottles are compatible with the chemicals they intend to store and consider options for tamper-evident features to enhance security.

How Are 1 Gallon Plastic Bottles Utilized in Agriculture?

In agriculture, these bottles are commonly used for transporting fertilizers and pesticides. Their design allows for bulk handling, which is crucial for efficiency in farming operations. Additionally, using 1 gallon plastic bottles reduces the overall packaging waste associated with smaller containers. Buyers should seek bottles that offer UV resistance to protect contents from degradation and ensure that closures are secure to prevent leaks during transport.

What Benefits Do 1 Gallon Plastic Bottles Offer for Personal Care Products?

For personal care products, 1 gallon plastic bottles serve as effective packaging for shampoos, conditioners, and lotions. They enhance brand visibility and allow for easy dispensing, which is vital for consumer satisfaction. The ability to customize these bottles with labels and colors helps businesses create a strong brand identity. Buyers should consider sourcing options that allow for customization while ensuring that the materials used are safe and compliant with health regulations.

How Are 1 Gallon Plastic Bottles Important in Pharmaceuticals?

In the pharmaceutical industry, 1 gallon plastic bottles are crucial for the safe containment of liquid medications. They ensure compliance with strict health regulations and provide a reliable means of transport. The bottles must meet industry standards for safety and quality, and buyers should verify that the bottles include child-resistant caps to enhance safety. Sourcing from reputable suppliers who can provide documentation of compliance is essential for international buyers, especially in regulated markets.

3 Common User Pain Points for ‘1 gallon plastic bottles’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

Das Problem: B2B buyers often encounter significant issues with quality consistency when sourcing 1-gallon plastic bottles from different suppliers. Variations in material strength, wall thickness, and closure compatibility can lead to product leakage and spoilage. For manufacturers in industries like food and beverage or chemicals, this inconsistency not only impacts product integrity but also results in costly recalls and reputational damage. A buyer may find that while one batch of bottles performs well, subsequent orders might not meet the same standards, leading to frustration and operational disruptions.

Die Lösung: To mitigate quality inconsistencies, buyers should establish long-term partnerships with reputable suppliers who specialize in 1-gallon plastic bottles. Prioritize suppliers that provide detailed product specifications, including material certifications and quality assurance processes. Implementing a robust sampling process before placing large orders can help assess consistency. Consider using third-party testing services to evaluate the physical properties of the bottles. Additionally, maintaining open communication with suppliers about quality expectations and establishing clear return policies can further ensure product reliability.

Scenario 2: Regulatory Compliance Challenges

Das Problem: For businesses dealing with liquid products, regulatory compliance regarding packaging can be a daunting challenge. Different regions—particularly in Africa, South America, and the Middle East—have varying standards for food safety, chemical storage, and environmental impact. A buyer may struggle to ensure that the 1-gallon plastic bottles they source meet the specific regulations required for their product types, risking fines or product bans. The complexity increases when buyers attempt to enter new markets, where compliance requirements may not be well understood.

Die Lösung: To navigate regulatory compliance, buyers should conduct thorough research on the specific regulations applicable to their products in each target market. Engage with legal experts or consultants who specialize in packaging compliance to gain insights into the requirements. When selecting 1-gallon plastic bottles, opt for suppliers who can provide documentation that demonstrates compliance with local and international standards, such as FDA approval for food-grade materials or ISO certifications. Additionally, consider investing in training for internal teams to understand compliance protocols better, which can streamline the sourcing process and reduce the risk of regulatory violations.

Scenario 3: High Shipping Costs and Logistics Issues

Das Problem: Shipping costs for 1-gallon plastic bottles can significantly affect overall operational budgets, especially for businesses that require large volumes. Buyers may find that shipping from suppliers located far away leads to inflated freight costs, which can be exacerbated by container shortages or port delays. This situation is particularly challenging for companies in regions like Africa and South America, where logistics infrastructure may not be as developed. Delays in receiving bottles can lead to production slowdowns and missed sales opportunities.

Die Lösung: To address high shipping costs and logistical challenges, buyers should consider local suppliers or manufacturers who can provide 1-gallon plastic bottles. Sourcing locally reduces shipping distances, lowers costs, and often leads to quicker turnaround times. Collaborating with suppliers that offer bulk discounts can also alleviate some financial pressure. Additionally, employing a just-in-time inventory strategy may help minimize the need for large shipments, reducing storage costs while ensuring that supplies are available when needed. Finally, consider establishing partnerships with logistics providers who specialize in efficient supply chain solutions to enhance shipping and delivery processes.

Strategic Material Selection Guide for 1 gallon plastic bottles

When selecting materials for 1-gallon plastic bottles, it is essential to understand the properties, advantages, and limitations of the most common plastics used in their manufacturing. This knowledge will help international B2B buyers make informed decisions that align with their specific applications and regional compliance standards.

What Are the Key Properties of HDPE for 1 Gallon Plastic Bottles?

High-Density Polyethylene (HDPE) is one of the most widely used materials for 1-gallon plastic bottles. It boasts excellent chemical resistance, making it suitable for a variety of liquids, including cleaning agents and food products. HDPE can withstand temperatures up to 120°C (248°F) and is resistant to impact and stress cracking, which enhances its durability.

Profis: HDPE is lightweight, cost-effective, and recyclable, making it an environmentally friendly choice. Its robust nature allows for safe storage and transportation of various products.

Nachteile: While HDPE is resistant to many chemicals, it may not be suitable for solvents or aromatic hydrocarbons. Additionally, its lower temperature tolerance compared to other plastics may limit its use in certain applications.

How Does PET Compare for Plastic Bottles?

Polyethylene Terephthalate (PET) is another common material for 1-gallon bottles, particularly in the beverage industry. PET offers excellent clarity and barrier properties, making it ideal for products that require visibility and protection from oxygen and moisture. It can handle temperatures up to 60°C (140°F) and is known for its strength and lightweight characteristics.

Profis: PET is highly recyclable and has a strong consumer appeal due to its clarity. It is also less permeable to gases, which helps in preserving the quality of beverages.

Nachteile: PET is generally more expensive than HDPE, and its lower temperature resistance can be a limiting factor for certain products. Additionally, it may not be suitable for products requiring long-term storage due to potential leaching issues.

What Are the Benefits of PVC for 1 Gallon Plastic Bottles?

Polyvinyl Chloride (PVC) is less common for 1-gallon bottles but is still used in certain applications. PVC is known for its excellent chemical resistance, particularly to acids and alkalis, making it suitable for industrial applications. It can withstand temperatures up to 70°C (158°F).

Profis: PVC’s durability and chemical resistance make it ideal for hazardous materials. Its rigidity also allows for a variety of designs and shapes.

Nachteile: The production of PVC can be more environmentally taxing, and it is not as easily recyclable as HDPE or PET. Furthermore, its flexibility can be a disadvantage in applications requiring a rigid structure.

How Does LDPE Fit into the Material Selection?

Low-Density Polyethylene (LDPE) is often used for flexible packaging and is less common for rigid bottles. However, it is worth mentioning due to its unique properties. LDPE can withstand temperatures up to 80°C (176°F) and offers excellent flexibility and impact resistance.

Profis: LDPE is highly resistant to moisture and is less brittle than other plastics, making it suitable for products that require some flexibility.

Nachteile: Its lower density means it is generally less durable than HDPE or PET, and it is not as suitable for products requiring a strong barrier against gases or chemicals.

Summary Table of Material Selection for 1 Gallon Plastic Bottles

| Material | Typical Use Case for 1 gallon plastic bottles | Hauptvorteil | Wesentlicher Nachteil/Beschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| HDPE | Cleaning agents, food products | Excellent chemical resistance | Begrenzte Temperaturtoleranz | Niedrig |

| PET | Beverages, clear liquids | Strong barrier properties | Higher cost, potential leaching | Med |

| PVC | Industrial chemicals, hazardous materials | Excellent chemical resistance | Environmental concerns, less recyclable | Med |

| LDPE | Flexible packaging, low-risk products | High flexibility and moisture resistance | Less durable, not suitable for strong barriers | Niedrig |

This guide provides a comprehensive overview of the materials used for 1-gallon plastic bottles, allowing international B2B buyers to select the most suitable option based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 1 gallon plastic bottles

What Are the Key Stages in the Manufacturing Process of 1 Gallon Plastic Bottles?

The manufacturing of 1 gallon plastic bottles involves several critical stages that ensure the end product meets both quality and functional standards. Understanding these stages is vital for B2B buyers, particularly those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

Vorbereitung des Materials

The process begins with the selection of raw materials, primarily High-Density Polyethylene (HDPE), known for its durability and chemical resistance. Suppliers typically source HDPE pellets, which are then dried and prepared for processing. The preparation stage is crucial, as moisture content can significantly affect the quality of the final product. Using advanced drying techniques, manufacturers ensure that the material is free from contaminants that could compromise the integrity of the bottles.

Forming Techniques: How Are 1 Gallon Plastic Bottles Shaped?

The forming of plastic bottles primarily employs two techniques: blow molding and injection molding. Blow molding is the most common method for producing hollow plastic containers like jugs.

-

Blasformen: In this process, a preform is heated and placed into a mold. Air is then blown into the preform, causing it to expand and take the shape of the mold. This technique allows for efficient production and the creation of complex shapes, which is essential for the functional design of 1 gallon jugs.

-

Spritzgießen: Though less common for bottles, this method is used for creating caps and closures. Plastic is injected into a mold under high pressure, allowing for precise shapes and finishes. This method is crucial for ensuring that closures fit securely, preventing leaks.

Assembly and Finishing: What Comes After Forming?

Once the bottles are formed, they undergo an assembly process where closures and labels are applied. This stage may include additional features such as tamper-evident seals or child-resistant caps, depending on the product’s intended use.

Finishing touches involve processes like printing labels and applying surface treatments to enhance aesthetics and functionality. Quality checks are integrated at this stage to ensure that the assembly aligns with specified standards.

What Quality Assurance Measures Are Standard in the Production of Plastic Bottles?

Quality assurance is integral to the manufacturing of 1 gallon plastic bottles, ensuring that they meet international standards and are suitable for various applications.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards, including:

- ISO 9001: This standard outlines the criteria for a quality management system (QMS) and is crucial for ensuring consistent quality in manufacturing.

- CE-Kennzeichnung: Particularly for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API-Normen: For bottles intended for specific industries, such as oil and gas, adherence to American Petroleum Institute (API) standards is essential.

These certifications not only ensure product safety and reliability but also enhance marketability in various regions.

Was sind die wichtigsten Punkte der Qualitätskontrolle?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify defects and ensure compliance with standards. The main checkpoints include:

-

Eingehende Qualitätskontrolle (IQC): Raw materials are tested upon arrival to verify their quality and compliance with specifications.

-

Prozessbegleitende Qualitätskontrolle (IPQC): During the manufacturing process, regular checks are conducted to monitor production parameters and detect any deviations from standards.

-

Endgültige Qualitätskontrolle (FQC): Once production is complete, the finished products undergo thorough inspection and testing to ensure they meet all required specifications before shipping.

Wie können B2B-Einkäufer die Qualitätskontrolle von Lieferanten überprüfen?

For international B2B buyers, verifying the quality control processes of suppliers is crucial to ensure product reliability. Here are several methods to achieve this:

-

Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and overall compliance with international standards. This direct engagement can provide valuable insights into the supplier’s operational capabilities.

-

Reports and Certifications: Requesting quality assurance reports and certifications can help buyers assess the supplier’s adherence to industry standards. These documents should detail the quality control measures implemented throughout the manufacturing process.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, ensuring that products meet specified requirements before shipment.

What Testing Methods Are Commonly Used for Quality Assurance?

Quality assurance testing for plastic bottles typically includes several standardized methods:

-

Mechanical Testing: This involves testing the tensile strength, impact resistance, and flexibility of the bottles to ensure they can withstand transportation and handling without failure.

-

Dichtheitsprüfung: Ensuring that bottles are leak-proof is critical, especially for liquids. Various methods, including pressure testing and dye penetration tests, are employed to verify seal integrity.

-

Chemical Resistance Testing: For bottles designed to hold specific chemicals or food products, testing for chemical resistance is essential to ensure that the material does not degrade or leach harmful substances.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges in ensuring quality control. These challenges can include:

-

Variability in Standards: Different regions may have varying standards for product safety and quality. Buyers should be aware of local regulations and ensure that suppliers comply with both international and regional standards.

-

Transparenz der Lieferkette: Ensuring transparency in the supply chain can help buyers verify the quality of materials and processes. Establishing strong communication with suppliers can facilitate better oversight.

-

Cultural and Operational Differences: Understanding cultural differences in business practices can enhance collaboration and improve quality assurance efforts. It is essential to foster relationships with suppliers that prioritize quality and compliance.

By navigating these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing 1 gallon plastic bottles, ensuring that they receive reliable, high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1 gallon plastic bottles’

Einführung

Sourcing 1-gallon plastic bottles requires careful consideration to ensure that you meet your business needs effectively. This guide provides a step-by-step checklist tailored for international B2B buyers, focusing on critical aspects of procurement, from defining specifications to evaluating suppliers. By following these steps, you can make informed decisions that align with your product requirements and market demands.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before initiating the sourcing process, clearly outline the technical specifications for the 1-gallon plastic bottles you require. Consider factors such as material type (e.g., HDPE), color (natural or white), and design (square, round, or tapered). These specifications will help you communicate your needs effectively to potential suppliers and ensure that the bottles are suitable for your intended applications, such as food storage or industrial use.

Step 2: Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers that specialize in 1-gallon plastic bottles. Look for manufacturers and distributors with a proven track record and positive reviews from other businesses. Pay attention to suppliers that offer bulk pricing options, as this can lead to significant cost savings when ordering large quantities.

Schritt 3: Bewertung von Lieferantenzertifizierungen

It is essential to verify that your chosen suppliers meet industry standards and certifications relevant to your region and product type. Check for certifications such as ISO, FDA compliance (for food-grade applications), and environmental certifications (like recycling capabilities). These credentials ensure that the bottles are manufactured responsibly and safely, which can mitigate risks related to quality and compliance.

Schritt 4: Muster anfordern

Before placing a bulk order, request samples of the 1-gallon plastic bottles from your shortlisted suppliers. This allows you to assess the quality, durability, and design of the bottles firsthand. Testing samples can also help you determine if the bottles meet your specific requirements, such as closure compatibility and overall appearance.

Step 5: Compare Pricing and Terms

Once you have gathered samples, compare the pricing and terms of each supplier. Look beyond the unit price; consider factors such as minimum order quantities, shipping costs, and payment terms. A supplier offering a slightly higher price but better service or faster delivery may ultimately provide greater value for your business.

Step 6: Assess Production Capabilities

Inquire about the supplier’s production capabilities to ensure they can meet your demand consistently. Ask about lead times for manufacturing and shipping, as well as their ability to scale production if your needs increase. Understanding these factors is critical to maintaining your supply chain and meeting customer expectations.

Step 7: Establish Communication and Support

Finally, ensure that you establish clear communication channels with your chosen supplier. A responsive supplier can provide essential support throughout the procurement process, from order placement to delivery. Make sure to discuss how they handle issues such as returns, quality concerns, and customer service, as this will be vital for a long-term business relationship.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for 1-gallon plastic bottles, ensuring that they select the right products and suppliers to meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for 1 gallon plastic bottles Sourcing

What are the Key Cost Components for 1 Gallon Plastic Bottles?

When sourcing 1-gallon plastic bottles, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materialien: High-density polyethylene (HDPE) is the most common material used for these bottles. Prices for HDPE fluctuate based on market conditions, so sourcing from reliable suppliers can help mitigate costs. Additionally, any customization or special requirements (such as food-grade certifications) can increase material costs.

-

Arbeit: Labor costs vary depending on the region. In areas with higher wage standards, such as parts of Europe, labor costs may contribute significantly to the overall price. Conversely, countries with lower labor costs can offer more competitive pricing.

-

Fertigungsgemeinkosten: This includes utilities, facility maintenance, and administrative costs associated with production. Efficient manufacturing processes can help reduce overhead, impacting the final pricing of the bottles.

-

Werkzeugbau: If custom molds or tooling are required for specific designs, this can lead to significant upfront costs. Buyers should consider whether the investment in custom tooling will lead to long-term savings on larger orders.

-

Qualitätskontrolle (QC): Ensuring that products meet quality standards incurs additional costs. Investing in robust QC processes can prevent costly returns and enhance product reliability.

-

Logistik: Transportation and shipping costs can vary significantly based on distance, shipping mode, and Incoterms. Understanding the total logistics costs is essential, especially for international shipments.

-

Marge: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s market positioning and relationship with the buyer.

How Do Price Influencers Affect Sourcing Decisions for International Buyers?

Several factors can influence the pricing of 1-gallon plastic bottles, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often come with substantial discounts. Buyers should negotiate for lower prices based on their purchasing power, which can significantly lower per-unit costs.

-

Spezifikationen und Anpassungen: Custom designs, colors, or sizes can increase costs. Buyers should evaluate whether these customizations provide enough value to justify the higher price.

-

Materialien und Qualitätszertifikate: The choice of materials and the required certifications (e.g., FDA compliance for food-grade products) can impact pricing. Buyers must balance the need for quality with budget constraints.

-

Lieferanten-Faktoren: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding Incoterms is vital for international shipping. They dictate the responsibilities of buyers and sellers, impacting shipping costs and risk management.

What Tips Can Help Buyers Negotiate Better Prices?

-

Negotiate Strategically: Engage in discussions about pricing and terms early in the sourcing process. Establishing a good relationship with suppliers can lead to better pricing and more favorable terms.

-

Fokus auf Kosteneffizienz: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also logistics, handling, and potential disposal costs. This approach can provide a more comprehensive understanding of the true cost of sourcing.

-

Understand Pricing Nuances for International Transactions: Buyers in regions like Africa, South America, and the Middle East should be aware of local market conditions, tariffs, and import duties that can affect pricing. Researching these factors can aid in negotiations and budget planning.

Schlussfolgerung

Understanding the comprehensive cost structure and pricing influencers for 1-gallon plastic bottles is essential for international B2B buyers. By strategically negotiating and evaluating all cost components, buyers can achieve better pricing and ensure their sourcing decisions align with their business goals. As always, it is advisable to seek quotes and conduct market comparisons to ensure competitiveness and value.

Alternatives Analysis: Comparing 1 gallon plastic bottles With Other Solutions

Exploring Alternative Solutions to 1 Gallon Plastic Bottles

In the realm of packaging and storage for bulk liquids, 1 gallon plastic bottles are a popular choice due to their versatility and cost-effectiveness. However, various alternatives exist that may better suit specific applications depending on factors such as material properties, environmental considerations, and intended use. This analysis will compare 1 gallon plastic bottles with two viable alternatives: glass bottles and metal containers, helping B2B buyers make informed decisions based on their unique needs.

| Vergleich Aspekt | 1 Gallon Plastic Bottles | Glasflaschen | Metal Containers |

|---|---|---|---|

| Leistung | Lightweight, durable, and resistant to breakage | Heavy, fragile, but excellent for preserving taste and quality | Strong and durable, suitable for high-pressure contents |

| Kosten | Low initial cost; bulk discounts available | Higher initial cost; limited bulk pricing | Moderate cost; varies by metal type |

| Leichte Implementierung | Easy to transport and fill; versatile for various liquids | Heavier and requires careful handling; may need special closures | Requires specific filling equipment; may need sealing |

| Wartung | Geringer Wartungsaufwand; recycelbar | Requires careful cleaning; recycling can be limited | Generally low maintenance; may rust if not coated |

| Bester Anwendungsfall | Ideal for non-hazardous liquids, food products, and cleaning supplies | Best for premium products like oils, vinegars, and beverages | Suitable for hazardous materials and industrial applications |

Understanding the Pros and Cons of Each Alternative

Glasflaschen

Glass bottles are often favored for their superior ability to preserve the integrity of the contents, especially for food and beverages. They do not leach chemicals into liquids, making them a safe choice for consumables. However, they are heavier and more fragile than plastic, which can complicate transportation and handling. The initial cost is generally higher, and while they can be recycled, the process may not be as straightforward as with plastics in certain regions.

Metal Containers

Metal containers, particularly those made from aluminum or stainless steel, offer excellent durability and strength, making them suitable for high-pressure applications. They are resistant to breakage and can provide a hermetic seal, enhancing the shelf life of the contents. However, they are typically heavier and may require specific equipment for filling and sealing. The cost can vary significantly based on the type of metal used, and while they are generally recyclable, they may pose challenges in terms of rusting if not properly treated.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate packaging solution involves weighing various factors, including the nature of the product, transportation logistics, and cost considerations. For non-hazardous liquids and general use, 1 gallon plastic bottles stand out due to their affordability and practicality. However, if product integrity is paramount, especially for consumables, glass bottles may be the better choice despite their higher cost and fragility. Conversely, for industrial applications or hazardous materials, metal containers provide the robustness required, albeit with a different cost and handling dynamic. B2B buyers should assess their specific requirements, including product type, storage conditions, and budget constraints, to determine the best packaging solution for their needs.

Essential Technical Properties and Trade Terminology for 1 gallon plastic bottles

What Are the Key Technical Properties of 1 Gallon Plastic Bottles?

Understanding the critical specifications of 1-gallon plastic bottles is essential for making informed purchasing decisions. Here are several key technical properties to consider:

-

Material Klasse

The most common material for 1-gallon plastic bottles is High-Density Polyethylene (HDPE). This material is known for its strength, chemical resistance, and recyclability, making it suitable for storing a variety of liquids, from food products to industrial chemicals. Choosing the right material grade ensures the bottle will withstand the intended application without degrading or leaking. -

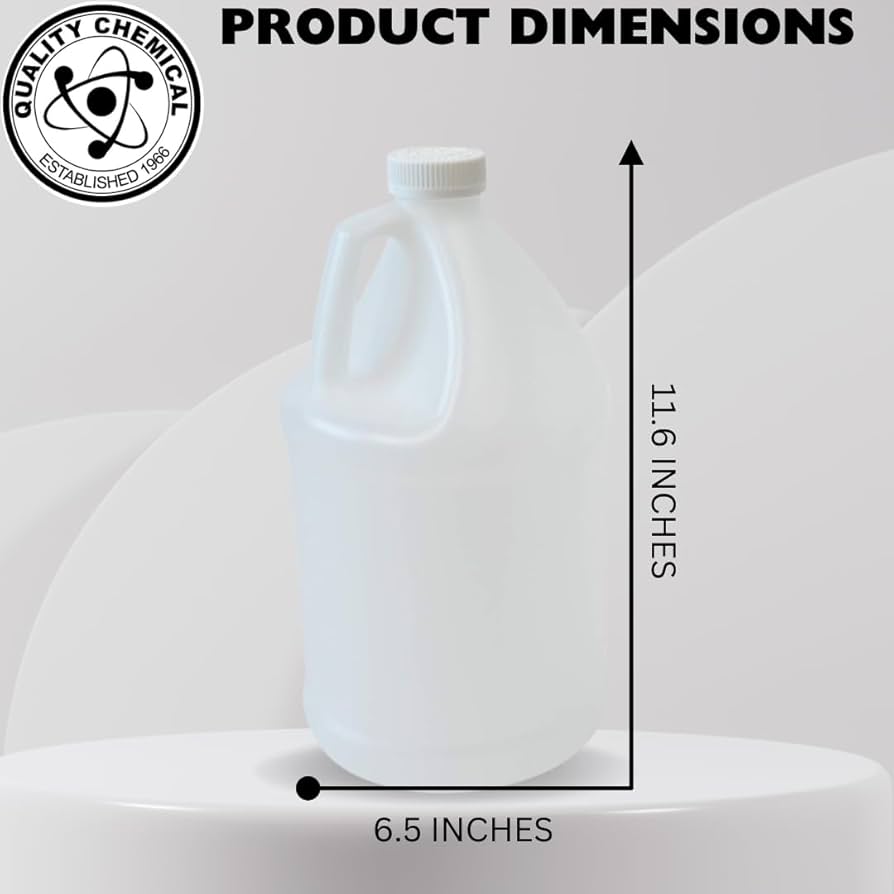

Weight/Tolerance

Bottles are often categorized by weight, typically measured in grams. For example, a 140-gram HDPE jug is a standard offering. Tolerance refers to the allowable variation in dimensions or weight, which is crucial for ensuring compatibility with caps and closures. Maintaining proper weight and tolerance is vital for bulk shipping and storage efficiency. -

Neck Size and Finish

The neck size (e.g., 38-400) and finish determine the type of closure that can be used. A standardized neck size allows for compatibility with various cap types, such as tamper-evident or child-resistant caps. This specification is particularly important for businesses that require specific closures to meet safety regulations or branding needs. -

Closure Options

Options for closures vary widely and include continuous thread, tamper-evident, and child-resistant caps. The selection of closures is critical for ensuring product integrity and safety during transport and storage. Businesses should align their closure choices with their product type and target market to enhance usability and compliance. -

Color and Transparency

While many jugs are available in natural (translucent) and white colors, some companies may require colored bottles for branding or to protect light-sensitive products. The color of the bottle can influence customer perception and marketability, making it a vital consideration in the design phase. -

Recyclability

As sustainability becomes a priority for many businesses, understanding the recyclability of materials is essential. HDPE is widely accepted in recycling programs, which can enhance a company’s eco-friendly profile. Choosing recyclable materials can also appeal to environmentally conscious consumers and comply with international regulations.

What Are Common Trade Terms Used in the 1 Gallon Plastic Bottle Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation capabilities. Here are several common trade terms relevant to 1-gallon plastic bottles:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts and equipment that may be marketed by another manufacturer. In the context of plastic bottles, an OEM may offer customized bottles tailored to specific client requirements, enhancing branding and functionality. -

MOQ (Mindestbestellmenge)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses to avoid overcommitting financially while ensuring they can meet their inventory needs effectively. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. This process helps buyers gather competitive pricing and make informed purchasing decisions. -

Incoterms (Internationale Handelsklauseln)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for managing shipping costs and delivery responsibilities. -

Vorlaufzeit

Lead time refers to the time taken from placing an order to receiving the product. This timeframe is essential for inventory planning and can significantly impact supply chain efficiency. Businesses must communicate lead time expectations clearly to avoid disruptions. -

Personalisierung

This term refers to the ability to tailor a product to meet specific needs or preferences. In the context of plastic bottles, customization can include variations in size, color, and closure types. Offering customized solutions can help businesses differentiate themselves in competitive markets.

By understanding these technical properties and industry terms, B2B buyers can make more informed choices when sourcing 1-gallon plastic bottles, ultimately leading to better alignment with their operational and branding strategies.

Navigating Market Dynamics and Sourcing Trends in the 1 gallon plastic bottles Sector

What Are the Current Market Dynamics Affecting the 1 Gallon Plastic Bottles Sector?

The global market for 1 gallon plastic bottles is witnessing significant shifts driven by various factors, including increasing demand for bulk packaging solutions across multiple industries such as food and beverage, cleaning products, and pharmaceuticals. The rise in e-commerce has accelerated the need for efficient packaging that can withstand transportation challenges while ensuring product integrity. In regions like Africa and South America, where logistics and supply chain infrastructure are evolving, the demand for durable and cost-effective packaging solutions is on the rise.

Emerging technologies are also influencing sourcing trends. Digital platforms are facilitating better supplier-buyer interactions, allowing international B2B buyers to access a wider variety of products and negotiate better terms. Moreover, the integration of data analytics and AI in supply chain management is enabling companies to forecast demand more accurately, optimize inventory levels, and streamline procurement processes. As a result, buyers are increasingly looking for suppliers who can provide flexible and scalable solutions tailored to their specific market needs.

How Is Sustainability Shaping Sourcing Decisions for 1 Gallon Plastic Bottles?

Sustainability has become a critical factor in the sourcing of 1 gallon plastic bottles, particularly as consumers and regulatory bodies increasingly demand environmentally responsible practices. The environmental impact of plastic waste has prompted many businesses to reevaluate their packaging choices, leading to a surge in the adoption of high-density polyethylene (HDPE) bottles, which are recyclable and more sustainable compared to alternative materials.

Furthermore, ethical sourcing is gaining traction as companies recognize the importance of transparency in their supply chains. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or obtaining ‘green’ certifications. These certifications not only enhance a company’s reputation but also meet the growing consumer demand for eco-friendly products. In this context, B2B buyers must consider the environmental credentials of their suppliers to ensure compliance with regulations and align with consumer values.

What Historical Developments Have Influenced the 1 Gallon Plastic Bottle Market?

The evolution of 1 gallon plastic bottles can be traced back to the mid-20th century when the introduction of synthetic materials revolutionized packaging. Initially, glass and metal were the dominant materials, but the advent of plastics provided a lightweight, cost-effective alternative that quickly gained popularity. Over the decades, advancements in manufacturing processes and materials science have led to the development of stronger, more versatile plastic bottles that cater to diverse market needs.

In recent years, the focus has shifted towards sustainability, prompting manufacturers to innovate in areas such as biodegradable plastics and improved recycling techniques. This historical context is essential for international B2B buyers, as understanding the evolution of packaging materials can inform sourcing decisions and align with future trends in consumer preferences and regulatory frameworks.

Schlussfolgerung

Navigating the market dynamics and sourcing trends for 1 gallon plastic bottles requires a nuanced understanding of global drivers, sustainability imperatives, and historical context. By staying informed about these factors, international B2B buyers can make strategic decisions that not only meet their immediate packaging needs but also align with broader environmental and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of 1 gallon plastic bottles

-

How do I select the right 1-gallon plastic bottle for my product?

When selecting a 1-gallon plastic bottle, consider the material, shape, and closure type that best suits your product’s needs. High-Density Polyethylene (HDPE) is commonly used for its durability and resistance to chemicals, making it ideal for various liquids. Evaluate the shape based on storage and handling requirements—round, square, or rectangular designs can influence transport efficiency. Additionally, choose closures that ensure product safety, such as tamper-evident or child-resistant options, depending on your target market and regulatory requirements. -

What are the benefits of sourcing 1-gallon plastic bottles in bulk?

Sourcing 1-gallon plastic bottles in bulk offers significant cost savings through wholesale discounts. This approach reduces per-unit costs, which is essential for businesses aiming to maximize profit margins. Additionally, purchasing in bulk ensures consistent supply, minimizing the risk of stockouts. It also streamlines logistics and inventory management, making it easier to plan for production schedules. For international buyers, bulk orders can enhance negotiating power with suppliers, leading to better terms and conditions. -

What is the minimum order quantity (MOQ) for 1-gallon plastic bottles?

The minimum order quantity (MOQ) for 1-gallon plastic bottles varies by supplier and can range from a few dozen to several hundred units. Suppliers often set MOQs to ensure production efficiency and cost-effectiveness. When negotiating, consider your storage capabilities and demand forecasts. If your needs are lower than the MOQ, some suppliers may offer flexibility or allow for a mixed order with other products to meet the requirement. Always confirm the MOQ before placing an order to avoid unexpected costs. -

How can I ensure the quality of 1-gallon plastic bottles before purchase?

To ensure quality, request samples from suppliers to evaluate the material, construction, and overall design. Conduct a thorough inspection for defects and assess the bottle’s suitability for your specific application. It’s also advisable to inquire about the supplier’s quality assurance processes, such as compliance with international standards (e.g., ISO certifications). Additionally, consider third-party testing for critical applications, particularly if you plan to use the bottles for food or chemical products. -

What are the payment terms typically offered by suppliers for international orders?

Payment terms for international orders can vary widely, but common practices include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may accept letters of credit or escrow services to secure transactions. It’s crucial to clarify these terms before finalizing orders to avoid misunderstandings. Be aware that payment methods may also influence pricing, with some methods incurring additional fees. Always review payment terms in the context of your cash flow and financial strategy. -

How do I vet suppliers for 1-gallon plastic bottles?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with industry standards. Start by checking online reviews and testimonials from previous clients. Request references and contact them to gain insights into their experiences. Additionally, assess the supplier’s certifications, such as ISO or FDA compliance, especially for food-grade products. If possible, conduct site visits to inspect their facilities and quality control processes. Building a relationship with a reliable supplier is essential for long-term success. -

What are the logistics considerations for importing 1-gallon plastic bottles?

Logistics considerations include shipping methods, costs, and customs regulations. Determine whether air or sea freight is more cost-effective based on your delivery timeline and budget. Understand the customs duties and taxes applicable to your imports, as these can significantly affect overall costs. Collaborating with a freight forwarder can simplify the process, ensuring compliance with international shipping regulations and efficient handling of documentation. Proper planning helps mitigate delays and ensures timely delivery of your products. -

Can I customize 1-gallon plastic bottles for branding purposes?

Yes, many suppliers offer customization options for 1-gallon plastic bottles, allowing you to enhance your branding. Customization can include printing your logo, choosing specific colors, or selecting unique bottle shapes that align with your brand identity. Discuss your design requirements with potential suppliers, and request proofs or samples to ensure the final product meets your expectations. Custom bottles can differentiate your products in a competitive market, making them more appealing to consumers.

Wichtiger Haftungsausschluss & Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich Informations- und Bildungszwecken. Sie stellen keine professionelle Kaufberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für etwaige Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensangaben und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due-Diligence-Prüfung durchführen bevor Sie eine Kaufentscheidung treffen. Dazu gehört, dass Sie sich direkt mit den Anbietern in Verbindung setzen, Zertifizierungen überprüfen, Muster anfordern und sich professionell beraten lassen. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt allein der Leser.

Top 2 1 Gallon Plastic Bottles Manufacturers & Suppliers List

1. Bottlestore – 1 Gallon Natural HDPE Square Plastic Jug

Bereich: bottlestore.com

Registriert: 1998 (27 Jahre)

Einleitung: Plastic jugs are ideal for bulk liquid storage and come in a variety of shapes and sizes. Bottlestore.com offers popular plastic jugs available online, with bulk quantity discounts for large orders. Key products include: 1) 1 Gallon (128oz) Natural HDPE Square Plastic Jug – 38-400 Neck, priced at $2.54 per piece, 48 pieces per carton, total carton price $121.92, with a bulk price as low as $103.25…

2. Olive Oil Source – 1 Gallon Plastic Bottle Case

Bereich: wholesale.oliveoilsource.com

Registriert: 1998 (27 Jahre)

Einleitung: 1 Gallon Plastic Bottle – Case of 4, Price: $9.00, Quantity: Case of 4 x 1G (3.79L), Material: Food grade plastic, Purpose: Safe storage and shipping of bulk oil or vinegar, Shipping: Ships via UPS.

Strategic Sourcing Conclusion and Outlook for 1 gallon plastic bottles

In conclusion, the strategic sourcing of 1-gallon plastic bottles is pivotal for businesses looking to optimize their packaging solutions. Key takeaways highlight the importance of selecting the right materials, such as high-density polyethylene (HDPE), which offers durability and recyclability, aligning with global sustainability trends. Additionally, leveraging bulk purchasing options can significantly reduce costs, making it an attractive proposition for B2B buyers.

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable packaging solutions will only grow. Engaging with suppliers who understand local market dynamics and can provide tailored solutions will be essential.

Looking ahead, businesses should prioritize partnerships with manufacturers that offer customization options, ensuring that their packaging not only meets functional needs but also resonates with branding strategies. By taking proactive steps in sourcing, companies can enhance their operational efficiency and market competitiveness. For B2B buyers, the time to act is now—evaluate your packaging needs, explore bulk purchasing opportunities, and connect with suppliers who can support your growth ambitions.