Introduction: Navigating the Global Market for bulk blender bottles

In an increasingly competitive global market, B2B buyers face the challenge of sourcing high-quality bulk blender bottles that meet diverse consumer demands while adhering to local regulations and preferences. The need for reliable, durable, and effective blending solutions is paramount for businesses in sectors such as fitness, health, and nutrition. This guide aims to provide a comprehensive overview of the bulk blender bottle market, detailing various types, applications, and essential factors to consider when making purchasing decisions.

Throughout this guide, international B2B buyers, especially those from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Vietnam—will find actionable insights to enhance their sourcing strategies. We delve into critical aspects such as supplier vetting processes, cost considerations, and customization options to ensure that your investment aligns with your brand identity and market needs. Additionally, we will address quality standards and certifications that are vital for ensuring product safety and consumer satisfaction.

By empowering you with the knowledge to navigate the complexities of the bulk blender bottle market, this guide facilitates informed purchasing decisions that can drive your business success and foster long-term partnerships with manufacturers. Whether you are looking to enhance your product line or meet the rising demand for blending solutions, the insights provided here will serve as a valuable resource on your journey.

Article Navigation

- Introduction: Navigating the Global Market for bulk blender bottles

- Top 10 Bulk Blender Bottles Manufacturers & Suppliers List

- Understanding bulk blender bottles Types and Variations

- Key Industrial Applications of bulk blender bottles

- 3 Common User Pain Points for ‘bulk blender bottles’ & Their Solutions

- Strategic Material Selection Guide for bulk blender bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for bulk blender bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bulk blender bottles’

- Comprehensive Cost and Pricing Analysis for bulk blender bottles Sourcing

- Alternatives Analysis: Comparing bulk blender bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for bulk blender bottles

- Navigating Market Dynamics and Sourcing Trends in the bulk blender bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bulk blender bottles

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for bulk blender bottles

Top 10 Bulk Blender Bottles Manufacturers & Suppliers List

1. BlenderBottle – Insulated Stainless Sport

Domain: blenderbottle.com

Registered: 1999 (26 years)

Introduction: Best Shaker Cups & Protein Shaker Bottles from BlenderBottle® include a variety of options such as Insulated Stainless Shakers, Plastic Shakers, and the Classic Shaker Bottle, which is noted as the #1 Shaker Bottle in the World. Key products include:

– Insulated Stainless Sport: Sale price $27.99, 4.5 stars (739 reviews), available in colors like Cobalt, Cranberry, Nightshade, and Grapefruit.

– S…

2. Discount Mugs – Custom Shaker Bottles and Blender Cups

Domain: discountmugs.com

Registered: 2002 (23 years)

Introduction: Custom shaker bottles and blender cups are designed for fitness enthusiasts, athletes, and individuals needing quick hydration or nutrition. They are ideal for gyms, corporate wellness programs, and promotional giveaways, combining practicality with brand visibility. The bottles are made from high-quality, durable, BPA-free plastic, available in various styles, shapes, and colors (including pink, …

3. Gains in Bulk – Shaker Bottle

Domain: gainsinbulk.com

Registered: 2015 (10 years)

Introduction: Product Name: Shaker Bottle

Regular Price: $19.00

Sale Price: $15.00 (21% discount)

Volume: 600mL

Features:

– Curved bottom design for easy mixing and to avoid supplement buildup

– Easy to clean and prevents bacteria buildup

– Stylish and reusable

– Carry handle for convenience

– Odor resistant

– Rubber seal and double lock to prevent leakage

– Suitable for smoothies, protein, pre-workout, daily s…

4. Net World Sports – 700ml Shaker Bottles

5. Phoenix Fitness – Protein Shaker – Pink

Domain: faire.com

Registered: 1998 (27 years)

Introduction: Wholesale blender bottles available for your store from over 100,000 brands. Key products include:

– Protein Shaker – Pink by Phoenix Fitness, rated 4.6 (84 reviews)

– Portable Blender, Juicer, Travel Blender Bottles with USB by VIGOR, rated 3.7 (154 reviews)

– 350ml Portable Blender Juicer Electric USB Rechargeable Mixer by Volcanic Cult, available in 2 colors

– Pink Compartment Protein Shaker b…

6. KingStar – Custom Protein Shaker Bottles

Domain: waterbottle.tech

Registered: 2018 (7 years)

Introduction: KingStar specializes in high-performance custom protein shaker bottles tailored to brand vision. Key features include: Full OEM/ODM services for customization of logos, colors, and features; Bulk order flexibility; Quality guaranteed with compliance to global standards (RoHS, FDA, LFGB, Prop65); Made from BPA-free Tritan plastic and 18/8 stainless steel; Leak-proof lids; Equipped with stainless st…

7. Everich – Wholesale Protein Shaker Bottles

Domain: everich.com

Registered: 2010 (15 years)

Introduction: Everich is a wholesale shaker bottle manufacturer based in China, specializing in protein shaker bottles since 2000. They offer tailored solutions and comprehensive OEM&ODM services. Key product details include: 1. Materials: BPA Free Stainless Steel and Plastic. 2. Product Types: – BPA Free Stainless Steel Blender Bottle (01702) – Insulated Shaker Bottle for Protein Mixes (750ml) – BPA Free Elect…

8. BlenderBottle – Bulk Shaker Bottles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking to buy around 28 blender/shaker bottles, preferably around 28oz in size. Suggestions for sites that sell them in bulk or at a heavily discounted price.

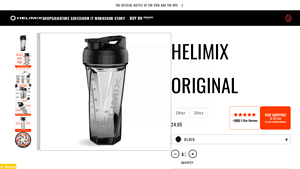

9. Helimix – Innovative Shaker Bottle

Domain: helimix.com

Registered: 2016 (9 years)

Introduction: Innovative Shaker Bottle | BPA-Free, Vortex Design, USA Made – Helimix

Key Features:

– 100% Made in the USA for unmatched quality and durability.

– Available in 20-ounce and 28-ounce shaker cup capacities.

– Made from BPA/BPS-free Copolyester plastic.

– Unique hexagonal vortex design eliminates the need for mixing balls or screens.

– Odor-resistant and top-rack dishwasher safe for easy maintenanc…

Understanding bulk blender bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Shaker Bottles | Lightweight, various sizes, often BPA-free, affordable | Gyms, fitness centers, promotional items | Pros: Cost-effective, customizable. Cons: Less durable than stainless steel. |

| Stainless Steel Shaker Bottles | Insulated, durable, leak-proof, odor-resistant | High-end fitness brands, corporate gifts | Pros: Long-lasting, maintains temperature. Cons: Higher cost, heavier. |

| Tritan Shaker Bottles | Clear, BPA-free, impact-resistant, dishwasher safe | Health-focused brands, retail sales | Pros: Lightweight, good visibility for branding. Cons: Can scratch easily. |

| Custom Blender Bottles | Tailored designs, branding options, various materials and sizes | Promotional giveaways, brand marketing | Pros: Unique branding opportunity. Cons: Minimum order quantities may apply. |

| Multi-Compartment Shaker Bottles | Separate compartments for powders and liquids, convenient design | Nutrition brands, meal prep services | Pros: Versatile for different supplements. Cons: Bulkier design may deter some users. |

What are the characteristics of Plastic Shaker Bottles?

Plastic shaker bottles are lightweight and come in various sizes, often made from BPA-free materials. Their affordability makes them attractive for bulk purchases, especially for gyms and fitness centers looking to provide promotional items. When considering B2B purchases, buyers should evaluate the durability and potential for customization, as these bottles can be branded with logos and colors to enhance marketing efforts.

How do Stainless Steel Shaker Bottles stand out in the market?

Stainless steel shaker bottles offer durability and insulation, keeping beverages at optimal temperatures. They are often designed to be leak-proof and odor-resistant, making them ideal for high-end fitness brands and corporate gifting. Buyers should consider their higher cost and weight, but the long-term investment can yield customer satisfaction and brand loyalty due to the quality associated with stainless steel products.

What advantages do Tritan Shaker Bottles provide for B2B buyers?

Tritan shaker bottles are known for their clarity, allowing users to see the contents easily, which is beneficial for branding. They are impact-resistant and dishwasher safe, appealing to health-focused brands and retailers. B2B buyers should assess the visibility for branding and the lightweight nature but also be aware of the potential for scratching, which could affect the product’s aesthetic appeal over time.

Why should businesses consider Custom Blender Bottles?

Custom blender bottles can be tailored to specific brand needs, including design, size, and materials. This customization provides a unique branding opportunity that can enhance marketing campaigns and promotional giveaways. However, B2B buyers should consider minimum order quantities and production timelines when planning their purchases, ensuring that the investment aligns with their marketing strategies.

What are the benefits of Multi-Compartment Shaker Bottles for nutrition brands?

Multi-compartment shaker bottles allow users to store different powders and liquids separately, catering to the needs of nutrition brands and meal prep services. Their versatile design enhances user convenience, appealing to fitness enthusiasts who require multiple supplements. Buyers should weigh the practicality of this design against the potential bulkiness, which may affect user preference.

Key Industrial Applications of bulk blender bottles

| Industry/Sector | Specific Application of bulk blender bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness and Nutrition | Custom shaker bottles for gyms and fitness centers | Enhances brand visibility and customer loyalty | Quality materials (BPA-free), customization options |

| Food and Beverage | Mixing and serving beverages in cafes and restaurants | Increases efficiency in beverage preparation | Durability, ease of cleaning, and aesthetic appeal |

| Pharmaceuticals | Mixing powdered supplements for health products | Ensures accurate dosing and consistency in products | Compliance with health standards, leak-proof designs |

| Sports and Recreation | Promotional giveaways for sporting events | Boosts brand awareness and customer engagement | Cost-effective bulk purchasing, custom branding options |

| Education and Training | Educational use in nutrition and health courses | Facilitates hands-on learning experiences for students | Versatile designs, educational branding opportunities |

How Are Bulk Blender Bottles Utilized in the Fitness and Nutrition Sector?

In the fitness and nutrition sector, bulk blender bottles are essential for gyms and fitness centers that offer protein shakes and supplements. Custom-branded shaker bottles not only enhance the gym’s visibility but also foster customer loyalty by providing a quality product that promotes health. Buyers in this sector should focus on sourcing BPA-free materials that ensure safety and durability, alongside customizable options to reflect their brand identity.

What Role Do Bulk Blender Bottles Play in the Food and Beverage Industry?

In cafes and restaurants, bulk blender bottles are used for mixing and serving beverages like smoothies and protein shakes. Their robust design allows for quick preparation, which is crucial in a fast-paced environment. For B2B buyers in this industry, sourcing bottles that are easy to clean and visually appealing is essential, as these factors contribute to customer satisfaction and operational efficiency.

How Are Bulk Blender Bottles Applied in Pharmaceuticals?

Pharmaceutical companies utilize bulk blender bottles for mixing powdered supplements, ensuring accurate dosing and product consistency. This application is critical for maintaining quality standards and consumer trust. Buyers in this field must prioritize compliance with health regulations and look for leak-proof designs that prevent contamination, thereby safeguarding product integrity.

Why Are Bulk Blender Bottles Important for Sports and Recreation?

In the sports and recreation industry, bulk blender bottles serve as promotional giveaways during events, helping to boost brand awareness. They are often used by athletes and fitness enthusiasts, making them a valuable marketing tool. B2B buyers should consider cost-effective bulk purchasing options and customizable branding to maximize their promotional impact at events.

How Do Bulk Blender Bottles Enhance Educational Experiences?

In educational settings, particularly in nutrition and health courses, bulk blender bottles facilitate hands-on learning experiences. They allow students to engage actively with nutritional concepts by preparing their own shakes and smoothies. Buyers in the education sector should look for versatile designs that can be customized for branding purposes, enhancing the educational experience while promoting healthy habits.

3 Common User Pain Points for ‘bulk blender bottles’ & Their Solutions

Scenario 1: Concerns Over Product Durability in Harsh Environments

The Problem: B2B buyers often face the challenge of ensuring that bulk blender bottles can withstand the rigors of various environments, especially in industries like fitness, health supplements, and outdoor activities. For example, a distributor in the Middle East may worry that bottles made from inferior materials will crack or leak under intense heat, leading to customer dissatisfaction and increased returns. Additionally, bottles that cannot handle repeated use may tarnish the brand’s reputation, creating a ripple effect on sales.

The Solution: To mitigate these concerns, buyers should prioritize sourcing bulk blender bottles made from high-quality, durable materials such as BPA-free Tritan plastic or stainless steel. It’s crucial to request samples from suppliers to evaluate their resilience in real-world scenarios before placing a bulk order. Look for products that are specifically designed for durability, such as those featuring reinforced seams and leak-proof designs. Additionally, inquire about the manufacturer’s quality assurance processes to ensure that all products meet international safety and durability standards. By ensuring the bottles are built to last, businesses can enhance customer satisfaction and reduce return rates.

Scenario 2: Difficulty in Maintaining Hygiene Standards

The Problem: In sectors like health and wellness, maintaining hygiene is paramount. B2B buyers may struggle with sourcing blender bottles that are easy to clean and resistant to odor and bacterial buildup. For instance, a gym owner providing these bottles to members might find that some products retain odors or become stained, leading to negative experiences for users and ultimately reflecting poorly on their business.

The Solution: Buyers should seek out bulk blender bottles that feature designs specifically aimed at promoting hygiene. Look for bottles with rounded bottoms and wider openings that facilitate thorough cleaning, as these designs prevent residue buildup in hard-to-reach corners. Additionally, consider materials that are inherently resistant to odors, such as Tritan or stainless steel, which do not absorb smells. It’s also beneficial to provide clear usage instructions to end-users, emphasizing the importance of proper cleaning and maintenance. By selecting products that prioritize hygiene, businesses can ensure a safer and more enjoyable experience for their customers.

Scenario 3: Complexity in Custom Branding Options

The Problem: Many B2B buyers want to enhance brand visibility through custom branding on bulk blender bottles. However, they often encounter challenges in sourcing products that offer adequate customization options. For example, a promotional products distributor may find that certain suppliers have limited color choices or printing capabilities, which can stifle creativity and lead to missed marketing opportunities.

The Solution: To address this issue, buyers should collaborate with manufacturers that offer extensive customization services, including a variety of colors, sizes, and printing methods. Before committing to a bulk order, request a portfolio of previous customizations to evaluate the supplier’s capabilities. It’s also advisable to engage in discussions regarding minimum order quantities and lead times for custom designs. Buyers can enhance their branding by opting for unique finishes, such as matte or gradient effects, and incorporating their logos through methods like laser engraving or full-color printing. By leveraging these custom options, businesses can create standout products that effectively promote their brand and resonate with their target audience.

Strategic Material Selection Guide for bulk blender bottles

What Are the Key Materials for Bulk Blender Bottles?

When selecting materials for bulk blender bottles, it is crucial to consider their properties, advantages, disadvantages, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of blender bottles: Tritan plastic, stainless steel, polypropylene, and glass.

How Does Tritan Plastic Perform in Bulk Blender Bottles?

Tritan plastic is a popular choice due to its BPA-free nature and durability. It has excellent temperature resistance, making it suitable for both hot and cold beverages. Tritan is also known for its clarity and aesthetic appeal, which can enhance branding opportunities for B2B buyers.

Pros: Tritan plastic is lightweight, shatter-resistant, and has high impact resistance. It is also dishwasher safe and does not retain odors, which is essential for maintaining beverage quality.

Cons: While Tritan is durable, it may not withstand extreme temperatures as well as stainless steel. Additionally, it can be more expensive than traditional plastics, which may affect cost-sensitive buyers.

Impact on Application: Tritan is compatible with a variety of beverages, including protein shakes and smoothies. However, it is not suitable for high-pressure applications.

Considerations for International Buyers: Compliance with global standards such as FDA and RoHS is essential. Buyers from regions like Africa and South America may also prefer locally sourced materials to reduce costs.

What Are the Benefits of Using Stainless Steel for Blender Bottles?

Stainless steel, particularly 18/8 grade, is renowned for its durability and resistance to corrosion and rust. It can maintain the temperature of beverages for extended periods, making it ideal for both hot and cold drinks.

Pros: Stainless steel is extremely durable and can withstand rough handling. Its resistance to odors and stains is a significant advantage for maintaining product integrity.

Cons: The initial cost of stainless steel bottles is typically higher than plastic options. Additionally, they can be heavier, which may not appeal to all consumers.

Impact on Application: Stainless steel is suitable for a wide range of beverages, including acidic drinks, without the risk of leaching harmful substances.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM and DIN. In regions like the Middle East, where temperature extremes are common, insulated options may be preferred.

How Does Polypropylene Compare for Bulk Blender Bottles?

Polypropylene is a cost-effective material that offers decent strength and flexibility. It is often used in budget-friendly options and can be produced in various colors.

Pros: Polypropylene is lightweight and has a lower manufacturing cost, making it an attractive option for bulk orders. It is also resistant to moisture and chemicals.

Cons: While it is durable, polypropylene is less resistant to heat compared to Tritan and stainless steel, which may limit its use for hot beverages. It can also become brittle over time.

Impact on Application: Polypropylene is suitable for cold beverages and protein shakes but may not be ideal for hot liquids or high-pressure applications.

Considerations for International Buyers: B2B buyers should check for compliance with local regulations and standards, especially in regions with stringent safety requirements.

Is Glass a Viable Material for Blender Bottles?

Glass is less common in bulk blender bottles but is favored for its purity and aesthetic appeal. It does not leach chemicals and is easy to clean.

Pros: Glass bottles are environmentally friendly, reusable, and do not retain odors or flavors. They provide a premium feel, which can enhance brand image.

Cons: The primary disadvantage is their fragility; glass can shatter easily, making it less suitable for active lifestyles. Additionally, glass is heavier than plastic or stainless steel.

Impact on Application: Glass is ideal for smoothies and juices but may not be practical for on-the-go use or high-impact environments.

Considerations for International Buyers: Buyers should consider shipping costs due to weight and fragility. Compliance with safety standards is also critical, particularly in regions with high transit risks.

Summary Table of Material Selection for Bulk Blender Bottles

| Material | Typical Use Case for bulk blender bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tritan Plastic | Protein shakes, smoothies | Lightweight and shatter-resistant | Higher cost than traditional plastic | Medium |

| Stainless Steel | Hot and cold beverages | Excellent durability and insulation | Heavier and higher initial cost | High |

| Polypropylene | Budget-friendly protein shakes | Low manufacturing cost | Less heat resistance | Low |

| Glass | Premium smoothies and juices | No leaching, aesthetic appeal | Fragile and heavy | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used for bulk blender bottles, helping them make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for bulk blender bottles

What Are the Main Stages of Manufacturing Bulk Blender Bottles?

The manufacturing process of bulk blender bottles is a complex operation that typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product meets quality standards and satisfies customer expectations.

How Is Material Prepared for Bulk Blender Bottles?

The first step in the manufacturing process is material preparation. Most blender bottles are made from high-quality, BPA-free plastics like Tritan or stainless steel. The materials are sourced from reputable suppliers who adhere to international standards, ensuring that they are safe for food contact. Prior to production, raw materials undergo rigorous inspections to verify their quality and compliance with safety standards. This step is crucial for manufacturers aiming to meet regulatory requirements in international markets, particularly for B2B buyers in regions like Europe and the Middle East.

What Techniques Are Used in Forming Blender Bottles?

Once materials are prepared, the next step is forming. This typically involves injection molding or blow molding techniques. In injection molding, melted plastic is injected into molds that shape the bottle. For stainless steel bottles, a process called deep drawing is often employed, where flat sheets of metal are formed into the desired shape. This stage is critical for achieving the precise dimensions and design features that differentiate products in a competitive market. Manufacturers may also utilize automated machinery to ensure consistent quality and reduce production time.

How Are Bulk Blender Bottles Assembled and Finished?

Following the forming process, assembly comes into play. This includes attaching components such as lids, seals, and mixing balls. Quality control during assembly is paramount, as any defects at this stage can lead to leaks or poor functionality. Once assembled, the bottles undergo finishing processes, which can include surface treatments, labeling, and packaging. Finishing not only enhances the aesthetic appeal of the bottles but also adds functional properties like insulation or odor resistance.

What Quality Assurance Measures Are Implemented in Blender Bottle Production?

Quality assurance (QA) is integral to the manufacturing of bulk blender bottles. Manufacturers typically adopt international standards such as ISO 9001, which outlines criteria for an effective quality management system. This certification is crucial for B2B buyers, as it signals that the manufacturer has implemented systematic processes to ensure product quality.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to catch defects early. These checkpoints generally include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during various stages of production, IPQC monitors the manufacturing processes to ensure adherence to quality standards.

- Final Quality Control (FQC): This step verifies that the finished products meet all specifications before they are packaged and shipped.

Each of these checkpoints helps minimize defects and ensures that only high-quality products reach the market.

What Testing Methods Are Commonly Used for Blender Bottles?

Common testing methods for bulk blender bottles include:

- Leak Testing: Bottles are filled with water and subjected to pressure tests to ensure they do not leak.

- Durability Testing: This assesses the resistance of materials to wear and tear, ensuring long-lasting performance.

- Chemical Testing: Ensures that the materials used do not leach harmful substances into beverages, complying with safety regulations.

B2B buyers should inquire about the specific testing methods employed by manufacturers to ensure product safety and quality.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to quality standards, B2B buyers should consider the following verification methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operational efficiency.

- Quality Assurance Reports: Requesting detailed reports on quality metrics, including defect rates and compliance with international standards, can provide insights into a supplier’s reliability.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the products and manufacturing processes, adding an extra layer of assurance.

What Are the Nuances of QC/Certifications for International Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of QC certifications is essential. Different regions may have varying standards, such as CE marking in Europe or FDA compliance in the United States. It is crucial for buyers to clarify which certifications are required for their specific markets.

Additionally, manufacturers may need to be familiar with local regulations regarding materials used in food contact products. Buyers should ensure that suppliers are compliant with these regulations to avoid potential legal issues.

Conclusion

Understanding the manufacturing processes and quality assurance measures for bulk blender bottles is vital for B2B buyers aiming to source high-quality products. By grasping the intricacies of material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions. Moreover, verifying supplier quality through audits, reports, and third-party inspections can mitigate risks and ensure compliance with international standards. Ultimately, a thorough understanding of these processes will empower buyers to build strong partnerships with reliable manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bulk blender bottles’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to source bulk blender bottles. By following these actionable steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your business needs. The right blender bottles can enhance your brand’s image while meeting the demands of your customers, making this sourcing process critical.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as material (BPA-free plastic, stainless steel), capacity (e.g., 16 oz, 24 oz), and design features (e.g., leak-proof lids, mixing mechanisms). This clarity will help you communicate your needs effectively to suppliers and avoid misalignments later in the process.

- Material Considerations: Opt for materials that are durable and resistant to odors and stains.

- Design Requirements: Think about ergonomic features that enhance usability for your target market.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in bulk blender bottles. Look for manufacturers that have a solid reputation in the industry, particularly those that can cater to your specific regional needs, such as compliance with local regulations and standards.

- Supplier Directories: Utilize online platforms and trade directories to compile a list of manufacturers.

- Industry Reviews: Check reviews and testimonials to gauge the reliability and quality of potential suppliers.

Step 3: Evaluate Supplier Certifications and Compliance

Before engaging further, verify that potential suppliers hold relevant certifications and comply with international quality standards. Certifications such as FDA, RoHS, and ISO indicate that the products meet safety and quality requirements.

- Request Documentation: Ask for copies of certifications and quality assurance documents.

- Understand Compliance: Ensure that the supplier’s materials and manufacturing processes align with your market’s regulations.

Step 4: Request Samples for Quality Assessment

Once you have narrowed down your options, request samples from suppliers. This step is crucial for assessing the quality, functionality, and design of the blender bottles firsthand.

- Quality Check: Evaluate the samples for durability, ease of use, and overall design.

- Testing Functionality: Test the leak-proof features and mixing capabilities to ensure they meet your expectations.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. Consider factors such as bulk order discounts, payment terms, and delivery timelines. A well-negotiated agreement can significantly impact your overall costs.

- Cost Analysis: Compare quotes from multiple suppliers to identify the best value.

- Understand Terms: Clarify lead times, minimum order quantities, and warranty policies.

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for updates, feedback, and any issues that may arise. This will foster a collaborative relationship with your supplier.

- Regular Updates: Schedule periodic check-ins to discuss progress and address any concerns.

- Feedback Mechanism: Create a system for providing feedback on product quality and service.

Step 7: Finalize the Order and Confirm Delivery Arrangements

After reaching an agreement, finalize your order and confirm delivery arrangements. Ensure that you have a clear understanding of shipping logistics, including tracking and handling procedures.

- Order Confirmation: Document all agreed-upon terms in a formal contract.

- Logistics Planning: Coordinate with the supplier on shipping methods to avoid delays upon delivery.

By following this checklist, you can streamline your sourcing process for bulk blender bottles, ensuring you choose the right products and suppliers for your business needs.

Comprehensive Cost and Pricing Analysis for bulk blender bottles Sourcing

What Are the Key Cost Components in Bulk Blender Bottle Sourcing?

When sourcing bulk blender bottles, understanding the cost structure is crucial for international B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common options include BPA-free Tritan plastic and stainless steel, with prices varying based on quality and specifications. Higher-quality materials often come with a premium but can enhance durability and user satisfaction.

-

Labor: Labor costs can vary depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this should be balanced with considerations of quality and reliability.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, affecting the overall price.

-

Tooling: Custom designs may require specialized tooling, which can be a significant upfront cost. However, this investment can lead to greater product differentiation and brand value.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is essential, particularly for international markets that may have strict compliance requirements. The costs associated with QC should be factored into the overall pricing strategy.

-

Logistics: Shipping and transportation costs are critical, particularly for international buyers. Factors such as shipping distance, freight methods, and customs duties can all influence the final price.

-

Margin: Finally, suppliers will include a profit margin in their pricing. This can vary widely based on market conditions and competitive landscape.

How Do Price Influencers Affect Bulk Blender Bottle Costs?

Several key influencers can affect the pricing of bulk blender bottles:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can impact pricing significantly. Larger orders typically lead to lower per-unit costs, making it essential to negotiate favorable terms that align with your purchasing capacity.

-

Specifications and Customization: Custom features such as unique designs, colors, and branding can increase costs. Understanding the balance between desired features and budget constraints is critical.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like FDA or RoHS compliance) can raise costs but may be necessary for certain markets. Buyers should assess the value of these certifications against their target market’s requirements.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge a premium due to their track record of quality and service.

-

Incoterms: The choice of Incoterms affects logistics costs. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) will help in calculating the total landed cost.

What Tips Should Buyers Consider for Cost-Efficiency in Bulk Blender Bottle Sourcing?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, optimizing sourcing costs requires strategic negotiation and awareness of pricing nuances:

-

Negotiation: Building strong relationships with suppliers can lead to better pricing. Consider long-term partnerships to negotiate favorable terms that benefit both parties.

-

Total Cost of Ownership (TCO): Evaluate the total cost, including shipping, duties, and potential quality issues. A lower initial price may not equate to cost savings if quality leads to higher returns or replacements.

-

Pricing Nuances: International buyers should be mindful of currency fluctuations and geopolitical factors that can impact pricing. Locking in prices through contracts can mitigate these risks.

-

Market Research: Conduct thorough research to understand pricing trends and competitor offerings in your region. This knowledge can empower negotiation and sourcing strategies.

-

Flexibility: Be open to adjusting specifications or considering alternative suppliers to achieve better pricing without compromising on quality.

Disclaimer on Indicative Prices

Prices for bulk blender bottles can vary widely based on the factors mentioned above. It is essential for buyers to obtain quotes from multiple suppliers and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing bulk blender bottles With Other Solutions

In the competitive landscape of beverage solutions, particularly for fitness and nutritional supplements, bulk blender bottles stand out for their convenience and functionality. However, businesses should consider alternative solutions that may better meet their unique needs. Below is a comparison of bulk blender bottles against two viable alternatives: traditional shaker bottles and automated mixing machines.

| Comparison Aspect | Bulk Blender Bottles | Traditional Shaker Bottles | Automated Mixing Machines |

|---|---|---|---|

| Performance | Excellent for mixing powders and liquids; minimizes clumping | Good for basic mixing; may leave clumps | Superior mixing efficiency; no clumping |

| Cost | Moderate cost; typically ranges from $15-$30 each | Lower cost; usually $5-$15 each | Higher initial investment; $500+ for machines |

| Ease of Implementation | Simple to use; no special setup needed | Easy to use; no setup required | Requires initial setup and training |

| Maintenance | Low maintenance; easy to clean | Low maintenance; generally dishwasher safe | Higher maintenance; requires regular cleaning and servicing |

| Best Use Case | Ideal for gyms, health clubs, and meal prep companies | Suitable for casual use and individual consumers | Best for large-scale operations like smoothie bars and health food manufacturers |

What Are the Pros and Cons of Traditional Shaker Bottles Compared to Bulk Blender Bottles?

Traditional shaker bottles are often more affordable and widely available, making them an attractive option for individual users or smaller businesses. They typically feature a simple design that is easy to use and clean. However, their mixing performance may not match that of bulk blender bottles, as they can leave clumps of powder if not shaken vigorously. For B2B buyers focused on cost efficiency and basic functionality, traditional shaker bottles can serve as a practical alternative.

How Do Automated Mixing Machines Compare with Bulk Blender Bottles?

Automated mixing machines represent a high-tech alternative for businesses that require consistent and efficient mixing of beverages or supplements. These machines can handle larger volumes and provide a higher level of mixing precision, eliminating clumping and ensuring a smooth consistency. However, they come with a significant upfront cost and may necessitate additional training for staff. For larger operations, such as smoothie bars or health product manufacturers, the investment in automated mixing machines can yield substantial returns in productivity and quality.

Conclusion: How Should B2B Buyers Select the Right Mixing Solution?

When choosing between bulk blender bottles and alternative solutions, B2B buyers should assess their specific operational needs, budget constraints, and the volume of products they intend to mix. For small to medium-sized businesses or those prioritizing portability and ease of use, bulk blender bottles are an excellent choice. Conversely, businesses with high production demands may find that investing in automated mixing machines is justified for the efficiency and quality they provide. Ultimately, the right solution will align with the company’s operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for bulk blender bottles

What Are the Essential Technical Properties of Bulk Blender Bottles?

Understanding the technical properties of bulk blender bottles is crucial for B2B buyers. These specifications not only ensure product quality but also influence usability, safety, and customer satisfaction. Here are some critical specifications to consider:

1. Material Grade

The material used in bulk blender bottles significantly impacts durability, safety, and performance. Common materials include BPA-free Tritan plastic and stainless steel. Tritan is favored for its lightweight, shatter-resistant properties, while stainless steel offers superior insulation and longevity. Selecting the right material is vital as it can affect product lifespan and user experience, which are essential for maintaining brand reputation in competitive markets.

2. Capacity and Size Variations

Bulk blender bottles come in various sizes, typically ranging from 16 oz to 28 oz or more. The capacity chosen should align with the target market’s needs—fitness enthusiasts may prefer larger sizes for protein shakes, while casual users might opt for smaller options. Understanding the market demand for different capacities helps businesses stock the right products, catering to diverse consumer preferences and maximizing sales potential.

3. Leak-Proof Design

Leak-proof features are essential for maintaining product integrity and user convenience. Bottles often incorporate silicone seals and precision-engineered lids to prevent spills. This is particularly important for B2B buyers who supply products to customers who value reliability, especially in active environments. A strong leak-proof design reduces customer complaints and enhances brand loyalty.

4. Insulation Properties

Insulated bottles are designed to keep beverages cold or hot for extended periods. This feature is achieved through double-wall construction, which is crucial for products aimed at fitness and outdoor markets. Insulation not only improves user experience but also allows for branding opportunities—consumers are more likely to carry and use bottles that maintain their drink’s temperature, increasing brand visibility.

5. Ease of Cleaning

The design of a blender bottle should facilitate easy cleaning, which is essential for hygiene and product longevity. Features like wide mouths and smooth interiors help prevent residue build-up, making them easier to maintain. For B2B buyers, promoting ease of cleaning can be a strong selling point, especially in regions where consumers prioritize health and sanitation.

6. Customization Options

Customization capabilities, such as color options, logo printing, and unique designs, are vital for branding. Many manufacturers offer OEM (Original Equipment Manufacturer) services, allowing businesses to create products tailored to their brand. This flexibility can significantly enhance marketability and customer engagement.

What Are Common Trade Terms Related to Bulk Blender Bottles?

Navigating the B2B landscape requires familiarity with specific trade terminology. Here are some common terms that are essential for international buyers:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are sold by another company under its brand name. In the context of bulk blender bottles, it allows businesses to customize designs and features without investing in manufacturing facilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively while ensuring they meet supplier requirements for cost efficiency.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing, terms, and conditions from suppliers. It is an essential step in procurement, allowing buyers to compare options and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps in avoiding misunderstandings during international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This is particularly important in bulk purchasing, as it impacts inventory management and sales strategies. Understanding lead times allows businesses to plan effectively and meet customer demands promptly.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their product offerings and streamline purchasing processes.

Navigating Market Dynamics and Sourcing Trends in the bulk blender bottles Sector

What Are the Current Market Dynamics and Key Trends Impacting the Bulk Blender Bottles Sector?

The global market for bulk blender bottles is witnessing significant growth driven by the increasing health consciousness among consumers and the rising demand for convenient fitness solutions. As more individuals embrace active lifestyles, the need for efficient mixing solutions for protein shakes and dietary supplements continues to surge. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where fitness culture is rapidly evolving, supported by the proliferation of gyms and wellness centers.

Emerging B2B tech trends are reshaping sourcing strategies. Innovations such as online procurement platforms and digital supply chain management tools are enhancing transparency and efficiency for international buyers. Additionally, the rise of custom and branded products is creating opportunities for businesses to differentiate themselves in a competitive marketplace. Buyers are increasingly seeking manufacturers that offer OEM/ODM services, allowing them to tailor products to meet specific market demands and consumer preferences.

Furthermore, the emphasis on quality and durability is reshaping purchasing decisions. Buyers are prioritizing materials that not only enhance product performance—such as BPA-free plastics and stainless steel—but also offer aesthetic appeal through various designs and colors. As sustainability becomes a focal point, suppliers who integrate eco-friendly practices into their operations are likely to gain a competitive edge.

How Is Sustainability and Ethical Sourcing Reshaping the Bulk Blender Bottles Market?

Sustainability and ethical sourcing are becoming critical factors for B2B buyers in the bulk blender bottles sector. The environmental impact of plastic waste is prompting companies to seek out suppliers that utilize sustainable materials and practices. Many manufacturers are now offering options made from biodegradable or recyclable materials, addressing the growing consumer demand for eco-friendly products.

The importance of ethical supply chains cannot be overstated, as buyers increasingly prefer partners who adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and compliance with RoHS and FDA standards are essential indicators of a supplier’s commitment to sustainability. Buyers should prioritize manufacturers who can demonstrate these certifications, ensuring their products align with global sustainability goals.

Additionally, integrating sustainable practices into the production process—such as reducing energy consumption and waste—can enhance brand reputation and consumer loyalty. As the market for bulk blender bottles evolves, those who adopt sustainable sourcing strategies will not only contribute positively to the environment but also position themselves favorably in the eyes of conscientious buyers.

What Is the Evolution of the Bulk Blender Bottles Market and Its Significance for B2B Buyers?

The bulk blender bottles market has evolved significantly over the past few decades, transitioning from basic mixing containers to sophisticated, high-performance products. Initially, the market was dominated by simple plastic bottles, but as the fitness trend gained traction, the demand for more durable and functional designs emerged. The introduction of stainless steel and BPA-free plastics marked a turning point, as consumers began prioritizing safety and performance.

With the rise of social media and influencer marketing, the visibility of bulk blender bottles has increased dramatically. Today, they are not only functional items but also fashion statements, with various designs appealing to a broader audience. This evolution signifies the importance of branding and customization for B2B buyers, who must consider how product aesthetics can influence consumer purchasing decisions.

As the market continues to expand, B2B buyers must stay informed about these developments to make strategic sourcing decisions that align with consumer trends and sustainability goals. By understanding the historical context and current dynamics, buyers can better navigate the complexities of sourcing high-quality bulk blender bottles in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of bulk blender bottles

-

How do I choose the right supplier for bulk blender bottles?

Selecting the right supplier involves thorough research and assessment. Look for manufacturers with a proven track record in producing high-quality products and positive customer reviews. It’s essential to verify certifications such as ISO, FDA, or RoHS to ensure compliance with international standards. Additionally, request samples to evaluate product quality firsthand. Engaging in direct communication can also help gauge their responsiveness and willingness to accommodate your specific needs, including customization options and bulk order capabilities. -

What customization options are available for bulk blender bottles?

Many manufacturers offer extensive customization options for bulk blender bottles, including material selection (BPA-free plastic or stainless steel), size, color, and branding elements like logos and labels. You can choose various lid types, such as flip tops or screw caps, and even add mixing mechanisms like stainless steel balls for better blending. Discuss your brand’s specific requirements with potential suppliers to ensure they can meet your vision and quality standards. -

What is the minimum order quantity (MOQ) for bulk orders?

The MOQ for bulk blender bottles varies by supplier, typically ranging from 100 to 1,000 units. Factors influencing MOQ include material type, customization complexity, and production capacity. It’s advisable to inquire about the MOQ during your initial discussions with suppliers. If your order volume is lower than the MOQ, some suppliers may offer flexibility or charge a premium for smaller orders, so it’s worth negotiating based on your needs. -

What payment terms should I expect when sourcing internationally?

Payment terms can differ significantly between suppliers and regions. Common practices include a deposit upfront (usually 30-50%) with the balance due before shipment. Other options include letters of credit or payment through secure platforms like PayPal. Clarify all payment terms in your agreement to avoid misunderstandings. Additionally, consider the currency exchange rates and potential transaction fees when dealing with international suppliers. -

How can I ensure the quality of bulk blender bottles?

Ensuring product quality involves several steps. First, ask for samples to assess materials and construction. Discuss quality assurance processes with your supplier, including certifications and testing procedures. Request details about their manufacturing practices, such as adherence to safety standards. Finally, consider conducting third-party inspections before shipment to verify that the products meet your specifications and quality requirements. -

What are the shipping options for bulk orders of blender bottles?

Shipping options for bulk orders typically include air freight, sea freight, and express courier services. Sea freight is generally more economical for large orders but takes longer, while air freight is faster but more expensive. Consider your delivery timeline and budget when selecting a shipping method. Additionally, discuss with your supplier if they offer door-to-door delivery services or if you’ll need to handle customs clearance and logistics on your end. -

Are there specific regulations for importing blender bottles in my region?

Import regulations for blender bottles can vary widely by country. It’s crucial to check local regulations regarding materials used (e.g., BPA-free standards), labeling requirements, and safety certifications. In some regions, specific import duties or tariffs may apply. Consulting with a customs broker or legal expert familiar with trade regulations in your target market can help ensure compliance and avoid potential issues during the import process. -

What factors should I consider when evaluating the cost of bulk orders?

When evaluating costs, consider the unit price, which often decreases with larger orders, but also factor in shipping, customs duties, and any additional fees for customization. Assess the total landed cost to understand the overall investment. Additionally, consider the quality of materials and construction; cheaper options may lead to higher return rates or customer dissatisfaction. A balance between cost and quality is essential for long-term success in your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bulk blender bottles

In conclusion, the strategic sourcing of bulk blender bottles presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By prioritizing quality, customization, and supplier reliability, businesses can enhance their product offerings and meet the evolving demands of health-conscious consumers. Key factors include selecting materials that ensure durability and safety, such as BPA-free Tritan plastic and stainless steel, while also considering features like leak-proof designs and efficient mixing capabilities.

The value of strategic sourcing lies not only in cost savings but also in fostering long-term partnerships with manufacturers who can provide tailored solutions that align with your brand vision. As the market for fitness and wellness products continues to grow, staying ahead of trends and consumer preferences will be crucial.

Looking forward, we encourage B2B buyers to explore diverse sourcing options and engage with reputable suppliers to build a competitive edge. By investing in quality blender bottles, companies can enhance customer satisfaction and drive brand loyalty in an increasingly crowded marketplace. Embrace the future of fitness hydration solutions—partner with the right manufacturers today to propel your business forward.