Introduction: Navigating the Global Market for typical water bottle size

In the competitive landscape of global commerce, sourcing the right typical water bottle size can present significant challenges for B2B buyers. With varying preferences influenced by regional hydration habits and environmental considerations, selecting the optimal water bottle for diverse markets—including those in Africa, South America, the Middle East, and Europe—requires a nuanced approach. This comprehensive guide delves into the myriad types of water bottles available, from compact 8-ounce options for individual use to larger half-gallon containers suited for outdoor activities and bulk consumption.

Throughout this guide, we will explore essential aspects such as the applications of different bottle sizes, the advantages of various materials (like BPA-free plastics and stainless steel), and effective supplier vetting strategies. Understanding the cost implications and potential return on investment for bulk purchases will also be covered, empowering B2B buyers to make informed decisions that align with their operational needs and sustainability goals.

By equipping international buyers with actionable insights and a clear understanding of market trends, this guide serves as a vital resource. It aims to streamline the purchasing process, enhance product offerings, and ultimately drive business growth in an ever-evolving global marketplace. Whether your focus is on quality, capacity, or environmental impact, this guide is tailored to help you navigate the complexities of sourcing water bottles effectively.

Article Navigation

- Top 7 Typical Water Bottle Size Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for typical water bottle size

- Understanding typical water bottle size Types and Variations

- Key Industrial Applications of typical water bottle size

- 3 Common User Pain Points for ‘typical water bottle size’ & Their Solutions

- Strategic Material Selection Guide for typical water bottle size

- In-depth Look: Manufacturing Processes and Quality Assurance for typical water bottle size

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘typical water bottle size’

- Comprehensive Cost and Pricing Analysis for typical water bottle size Sourcing

- Alternatives Analysis: Comparing typical water bottle size With Other Solutions

- Essential Technical Properties and Trade Terminology for typical water bottle size

- Navigating Market Dynamics and Sourcing Trends in the typical water bottle size Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of typical water bottle size

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for typical water bottle size

Understanding typical water bottle size Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 8 oz – 10 oz | Compact size, ideal for single servings | Events, promotions, giveaways | Pros: Cost-effective, portable. Cons: Limited capacity for hydration needs. |

| 16.9 oz (500 ml) | Standard single-use size, widely recognized | Retail, hospitality, vending | Pros: Familiarity, easily customizable. Cons: Environmental concerns with single-use plastic. |

| 32 oz (1 liter) | Larger capacity, often features insulated options | Sports, outdoor activities, corporate gifts | Pros: Sufficient hydration, versatile. Cons: Bulkier to carry. |

| 64 oz (half-gallon) | High capacity, excellent for long durations | Corporate wellness programs, outdoor events | Pros: Reduces refill frequency, eco-friendly alternatives available. Cons: Heavy when full. |

| 1 Gallon | Maximum capacity, often used for bulk distribution | Catering, large events, water stations | Pros: Ideal for group settings, cost-effective per ounce. Cons: Difficult to transport. |

What Are the Characteristics and Suitability of 8 oz – 10 oz Water Bottles?

The 8 oz and 10 oz water bottles are compact and designed for single-serving uses, making them ideal for events, promotions, and giveaways. They are lightweight and easy to handle, appealing to businesses looking for economical options for branded merchandise. However, their limited capacity may not satisfy hydration needs for all consumers, making them best suited for short-term use or as part of a larger hydration strategy.

How Do 16.9 oz Water Bottles Fit into B2B Applications?

The 16.9 oz (500 ml) water bottle is a standard size recognized globally, making it a popular choice in retail and hospitality. Its familiar size appeals to consumers, and businesses can easily customize these bottles with branding. While they are effective for promotional purposes, the environmental concerns associated with single-use plastic may lead some companies to seek more sustainable options.

Why Choose 32 oz Water Bottles for Corporate Gifts?

The 32 oz water bottle strikes a balance between portability and capacity, making it ideal for sports, outdoor activities, and corporate gifting. Many options feature insulated designs, keeping beverages at optimal temperatures. This size is versatile and encourages hydration throughout the day, though its bulkiness may deter some users from carrying it regularly. B2B buyers should consider the trade-off between size and user convenience.

What Advantages Do 64 oz Water Bottles Offer for Corporate Wellness Programs?

The 64 oz (half-gallon) water bottle caters to consumers seeking significant hydration without frequent refills, making it perfect for corporate wellness programs and outdoor events. This size promotes a healthier lifestyle by encouraging users to drink more water. While many options are now available in eco-friendly materials, the weight of a full bottle can be a drawback for some users, necessitating careful consideration of target audience preferences.

How Are 1 Gallon Water Bottles Used in Catering and Events?

The 1-gallon water bottle is designed for bulk distribution and is commonly used in catering, large events, and water stations. This maximum capacity option is cost-effective per ounce, making it attractive for businesses looking to provide hydration for groups. However, the size can make transportation challenging, so companies should evaluate their logistical capabilities before opting for this type.

Key Industrial Applications of typical water bottle size

| Industry/Sector | Specific Application of Typical Water Bottle Size | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Custom-branded water bottles for events | Enhances brand visibility and customer loyalty | Quality of materials, customization options, and eco-friendliness |

| Sports and Fitness | Hydration solutions for gyms and sports teams | Supports athlete performance and health | Durability, portability, and insulation properties |

| Healthcare | Water bottles for hospitals and clinics | Encourages hydration among patients and staff | BPA-free materials, ease of cleaning, and capacity options |

| Education | Reusable bottles for schools and universities | Promotes sustainability and reduces waste | Bulk purchasing options, customization for branding, and safety standards |

| Corporate Gifts | Promotional water bottles for client gifts | Strengthens client relationships and brand loyalty | Custom design capabilities, material quality, and pricing competitiveness |

How is ‘Typical Water Bottle Size’ Utilized in the Food and Beverage Industry?

In the food and beverage sector, businesses often leverage custom-branded water bottles for events, trade shows, and promotional campaigns. These bottles serve not only as functional hydration solutions but also as marketing tools that enhance brand visibility. For international B2B buyers, it’s essential to consider the quality of materials used, customization options for branding, and the sustainability of products, especially in regions where eco-consciousness is growing.

What Role Do Water Bottles Play in Sports and Fitness Environments?

Water bottles are crucial in the sports and fitness industry, providing hydration solutions for gyms, sports teams, and outdoor activities. A well-designed bottle can support athlete performance and overall health by ensuring easy access to hydration during workouts. Buyers in this sector should prioritize durability, portability, and insulation properties to meet the demands of active users, particularly in diverse climates across Africa and the Middle East.

Why are Water Bottles Important in Healthcare Settings?

In healthcare settings, water bottles are vital for encouraging hydration among patients and staff. Hospitals and clinics often require BPA-free options that are easy to clean and maintain. The capacity of these bottles is also a significant consideration, as larger sizes may be preferred for patient use. International buyers must ensure compliance with health regulations and prioritize sourcing from reputable manufacturers that adhere to safety standards.

How Can Educational Institutions Benefit from Reusable Water Bottles?

Educational institutions are increasingly adopting reusable water bottles to promote sustainability and reduce plastic waste. By providing students with branded bottles, schools and universities can foster a culture of hydration while reinforcing their commitment to environmental responsibility. For B2B buyers in this sector, bulk purchasing options, customization for school branding, and adherence to safety standards are critical factors to consider.

What Advantages Do Promotional Water Bottles Offer for Corporate Gifting?

Promotional water bottles make excellent corporate gifts, helping to strengthen client relationships and enhance brand loyalty. These bottles can be customized to reflect the company’s branding, making them memorable gifts that resonate with clients. When sourcing for this application, businesses should focus on custom design capabilities, material quality, and pricing competitiveness to ensure maximum value and impact.

3 Common User Pain Points for ‘typical water bottle size’ & Their Solutions

Scenario 1: Struggling with Size Compatibility for Events

The Problem: B2B buyers organizing events often face the challenge of selecting the appropriate water bottle size that caters to diverse audiences. For example, a company planning a large outdoor corporate retreat must consider the varying hydration needs of participants engaged in activities such as hiking, sports, or leisurely networking. If they opt for a one-size-fits-all approach, they may end up with bottles that are either too large and cumbersome for casual attendees or too small to meet the demands of active participants. This mismatch can lead to waste, dissatisfaction, and an unprofessional image.

The Solution: To address this issue, B2B buyers should conduct a thorough needs assessment before purchasing water bottles. Start by estimating the demographic and activity levels of attendees. For active participants, consider half-gallon (64 oz) bottles, which provide ample hydration for strenuous activities. For more sedentary or casual settings, offering a mix of 16 oz and 32 oz bottles can cater to varying needs. Suppliers can often provide customization options, such as branding and labels, which enhance the event experience and ensure the bottles align with the corporate image. By planning with the audience in mind, buyers can ensure that hydration options are practical, appealing, and effective.

Scenario 2: Navigating Cost-Effectiveness with Bulk Purchases

The Problem: Many B2B buyers grapple with the balance of cost and quality when sourcing water bottles in bulk. The temptation to choose the lowest-priced option can lead to subpar products that fail to meet safety standards or customer expectations, especially in markets that require BPA-free materials or sustainable practices. This can result in negative feedback from clients or partners and potential legal liabilities, especially in regions where health regulations are stringent.

The Solution: Buyers should prioritize sourcing from reputable manufacturers who offer transparent information about their products’ materials and certifications. When evaluating potential suppliers, request samples to assess the quality and durability of the bottles. It is also wise to compare the total cost of ownership, including shipping and potential returns, rather than just the upfront price. Consider options like aluminum bottles, which are not only recyclable but also have a higher perceived value among consumers. By investing in quality products upfront, companies can enhance their brand reputation and customer satisfaction while ensuring compliance with health standards.

Scenario 3: Addressing Environmental Concerns in Bottle Selection

The Problem: As sustainability becomes increasingly important in global markets, B2B buyers must navigate the challenge of selecting water bottles that align with eco-friendly practices. Many buyers find themselves torn between providing adequate hydration options and minimizing their environmental footprint. Traditional plastic bottles contribute to waste and can damage a company’s reputation among environmentally conscious consumers, particularly in regions where sustainability is a key consumer value.

The Solution: To mitigate these concerns, B2B buyers should consider sourcing stainless steel or aluminum water bottles, which are more sustainable alternatives to plastic. These materials are not only recyclable but also durable, reducing the need for frequent replacements. Suppliers often offer customizable options that allow businesses to incorporate their branding while promoting eco-friendly practices. Additionally, implementing a bottle return program or encouraging refills can further enhance sustainability efforts. By prioritizing environmentally friendly products, buyers can position their companies as responsible and forward-thinking, thereby appealing to a growing segment of eco-conscious consumers.

Strategic Material Selection Guide for typical water bottle size

What Are the Key Properties of Common Materials Used in Water Bottles?

When selecting materials for water bottles, especially for international B2B buyers, understanding the properties of each material is crucial. Here, we analyze four common materials: plastic (PET), stainless steel, aluminum, and glass.

How Does PET Plastic Perform in Water Bottle Applications?

Polyethylene Terephthalate (PET) is a widely used plastic in the beverage industry. It is lightweight, has a good temperature resistance (up to 60°C), and is relatively inexpensive to produce. PET is also resistant to impact and shattering, making it suitable for various applications. However, it has limitations regarding heat resistance and can degrade under prolonged exposure to sunlight, leading to potential leaching of chemicals.

Pros: Cost-effective, lightweight, and recyclable.

Cons: Limited temperature resistance and potential for chemical leaching.

For international buyers, especially those in Africa and South America, compliance with local regulations regarding food safety and recyclability is essential. PET is generally compliant with standards like FDA and EU regulations, making it a viable option.

What Are the Benefits of Using Stainless Steel for Water Bottles?

Stainless steel is known for its durability and resistance to corrosion and temperature extremes. It can withstand high pressures and does not retain flavors or odors, making it ideal for various beverages. Stainless steel bottles are also eco-friendly, as they are fully recyclable and can last for years.

Pros: High durability, excellent temperature retention, and eco-friendly.

Cons: Higher manufacturing costs and weight compared to plastic.

B2B buyers from the Middle East and Europe should consider the material’s compliance with standards like ASTM and DIN, especially for food-grade applications. The preference for stainless steel is rising due to its long-term economic benefits and sustainability.

Why Choose Aluminum for Water Bottles?

Aluminum offers a lightweight alternative to stainless steel while providing good corrosion resistance. It is often coated to prevent reactions with acidic beverages. Aluminum bottles can be produced in various colors and designs, appealing to branding needs.

Pros: Lightweight, customizable, and good thermal conductivity.

Cons: Less durable than stainless steel and can dent easily.

For international buyers, particularly in regions like Saudi Arabia and Vietnam, ensuring that aluminum bottles meet food safety standards is crucial. Aluminum is generally compliant with international safety standards, but buyers should verify specific regulations in their markets.

What Are the Considerations for Glass Water Bottles?

Glass is a premium option known for its chemical inertness and ability to maintain beverage quality. It is completely recyclable and does not leach chemicals, making it a safe choice for consumers. However, glass is heavier and more fragile than other materials, which can complicate shipping and handling.

Pros: Excellent beverage quality, non-toxic, and fully recyclable.

Cons: Heavier and prone to breakage.

B2B buyers in Europe may find glass bottles appealing due to the increasing consumer demand for sustainable products. However, they must consider the logistics of shipping glass internationally, especially in regions where breakage could lead to significant losses.

Summary Table of Material Selection for Water Bottles

| Material | Typical Use Case for typical water bottle size | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET Plastic | Single-use and lightweight bottles | Cost-effective and recyclable | Limited temperature resistance | Low |

| Stainless Steel | Reusable bottles for long-term use | High durability and eco-friendly | Higher manufacturing costs | High |

| Aluminum | Lightweight and customizable bottles | Lightweight and good thermal conductivity | Less durable and can dent easily | Medium |

| Glass | Premium reusable bottles | Excellent beverage quality | Heavier and prone to breakage | Medium |

This material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in water bottles, helping them make informed decisions that align with market demands and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for typical water bottle size

What Are the Main Stages of the Manufacturing Process for Typical Water Bottles?

Manufacturing water bottles involves a systematic process that ensures high quality and durability. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Water Bottle Production?

The manufacturing process begins with the selection of materials. Common materials include BPA-free PET plastic, aluminum, and stainless steel. Each material is chosen based on the intended use of the bottle, such as insulation properties or environmental concerns. Once selected, the materials undergo a thorough cleaning and sterilization process to ensure they are free from contaminants. This step is crucial for maintaining the integrity of the bottled water and ensuring consumer safety.

What Techniques Are Used in the Forming Stage of Water Bottle Production?

The forming stage is where the prepared materials are shaped into bottles. For plastic bottles, the process often involves blow molding, where heated plastic is inflated into a mold to achieve the desired shape. For aluminum bottles, the process typically uses extrusion and deep drawing techniques to create a lightweight yet durable product. In both cases, precision is vital to ensure consistent bottle sizes and shapes, which is essential for compatibility with caps and labels.

What Is the Assembly Process Like in Water Bottle Manufacturing?

Once the bottles are formed, they enter the assembly stage. This involves the installation of caps, labels, and any additional features such as handles or straws. Automation plays a significant role in this stage, enhancing efficiency and reducing labor costs. However, manual assembly may be employed for custom orders or specialized designs. Quality checks are integrated into this stage to ensure that all components fit correctly and function as intended.

How Is the Finishing Stage Conducted in the Production of Water Bottles?

The finishing stage includes the application of surface treatments, such as coatings or polishing, to enhance durability and aesthetics. For stainless steel bottles, a powder coating may be applied to prevent scratches and improve grip. This stage also involves printing labels and branding, which must comply with international regulations regarding product information and safety warnings. Effective finishing not only improves the visual appeal of the bottles but also contributes to their longevity.

What Are the Key Quality Assurance Processes for Water Bottles?

Quality assurance (QA) is a critical component of water bottle manufacturing. It ensures that products meet established standards and customer expectations. Various international and industry-specific standards guide these processes.

Which International Standards Are Relevant for Water Bottle Quality Assurance?

ISO 9001 is a widely recognized standard for quality management systems that applies to various industries, including packaging. Compliance with ISO 9001 ensures that manufacturers follow a systematic approach to quality management, focusing on continuous improvement and customer satisfaction. Other relevant certifications may include CE marking for compliance with European safety standards and FDA approval for materials in contact with food and beverages.

What Are the Key Quality Control Checkpoints in Water Bottle Manufacturing?

Quality control (QC) is implemented at several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify any deviations from quality standards in real-time. This may include checking dimensions, weight, and visual defects.

-

Final Quality Control (FQC): After production, a comprehensive inspection is conducted to verify that the finished products meet quality specifications and regulatory requirements. This includes leak testing, strength testing, and aesthetic evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures of their suppliers:

-

Supplier Audits: Conducting regular audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. This may involve on-site visits to assess production facilities and QC systems.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certificates. Buyers should request these reports to ensure transparency and accountability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of product quality. These inspections can be scheduled at various stages of production, from raw material sourcing to final product delivery.

What Are the Common Testing Methods for Water Bottles?

Testing methods are essential for validating the quality and safety of water bottles. Common techniques include:

-

Leak Testing: Ensures that bottles are sealed properly and do not leak during use or transportation.

-

Drop Testing: Assesses the durability of bottles by simulating accidental drops to evaluate resistance to damage.

-

Chemical Analysis: Tests for leaching of harmful substances from materials, ensuring that the bottles comply with food safety standards.

-

Environmental Testing: Evaluates the bottles’ performance under various temperature and humidity conditions to ensure they can withstand typical usage scenarios.

What Quality Control Nuances Should International B2B Buyers Consider?

International buyers should be aware of specific nuances in quality control, especially when sourcing from different regions:

-

Regulatory Compliance: Different countries may have varying regulations regarding materials used in water bottles. Understanding these regulations is critical to ensure compliance and avoid potential legal issues.

-

Cultural Considerations: Approaches to quality control may vary by region. Buyers should familiarize themselves with the local manufacturing culture and practices to set realistic expectations.

-

Logistical Challenges: Sourcing from distant suppliers can introduce logistical complexities that impact quality. Buyers should establish clear communication channels and protocols to address any issues that arise during shipping and handling.

By understanding the manufacturing processes and quality assurance measures involved in producing typical water bottles, B2B buyers can make informed decisions when selecting suppliers. Prioritizing quality, compliance, and reliable verification methods will ensure successful partnerships and high-quality products that meet market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘typical water bottle size’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure typical water bottle sizes. Whether you are catering to events, promotional activities, or retail needs, understanding the various bottle sizes and specifications is crucial for making informed decisions that align with your business objectives.

Step 1: Identify Your Target Market Needs

Understanding the preferences and hydration habits of your target market is essential. Conduct market research to determine which water bottle sizes are most popular in your region. Consider factors such as age demographics, lifestyle, and specific use cases (e.g., outdoor activities, fitness, or corporate events).

Step 2: Define Your Technical Specifications

Before reaching out to suppliers, establish clear technical specifications for the water bottles you intend to purchase. This includes size (e.g., 16 oz, 32 oz, half-gallon), material (e.g., BPA-free plastic, stainless steel, aluminum), and design features (e.g., insulated, collapsible). Clearly defined specifications will streamline the sourcing process and ensure you receive products that meet your exact requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from other buyers in similar industries or regions. Look for suppliers that demonstrate reliability and quality in their offerings, and consider their production capacity to meet your order volume.

- Check Certifications: Ensure suppliers comply with international safety and quality standards.

- Review Product Samples: Request samples to evaluate the quality and functionality of the water bottles.

Step 4: Assess Cost and Pricing Structures

Price is a significant factor in any procurement decision. Gather quotes from multiple suppliers and analyze their pricing structures. Look beyond just the unit price; consider shipping costs, bulk discounts, and payment terms. Understanding the total cost of ownership will help you make a financially sound decision.

Step 5: Verify Quality Assurance Processes

Ensure that the suppliers have robust quality assurance processes in place. This includes checks during manufacturing and final inspections before shipment. Quality assurance is critical to reducing defects and ensuring that the products meet the standards expected by your customers.

- Request Quality Reports: Ask for documentation that demonstrates their quality control measures.

- Understand Return Policies: Familiarize yourself with their return and exchange policies in case of defects or non-conformities.

Step 6: Consider Customization Options

If you aim to strengthen your brand presence, look for suppliers that offer customization options. This could include custom labels, unique bottle designs, or specific color choices. Customized water bottles can serve as effective marketing tools, enhancing brand visibility and customer engagement.

Step 7: Finalize Logistics and Delivery Terms

Once you’ve selected a supplier, finalize logistics and delivery terms. Discuss lead times, shipping methods, and delivery schedules to ensure that your products arrive on time for your intended use. Establish clear communication channels to facilitate updates and resolve any potential issues that may arise during the delivery process.

By following this checklist, you will be well-equipped to make informed decisions in sourcing typical water bottle sizes, ensuring that your procurement aligns with your business goals and market demands.

Comprehensive Cost and Pricing Analysis for typical water bottle size Sourcing

What Are the Key Cost Components in Sourcing Typical Water Bottles?

When sourcing water bottles, understanding the cost structure is essential for effective budgeting and supplier selection. The primary cost components include:

-

Materials: The choice of materials significantly influences cost. Common materials for water bottles include BPA-free PET plastic, aluminum, and stainless steel. Each material carries different price points based on quality, durability, and sourcing logistics.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs, such as parts of Asia or South America, can offer competitive pricing, but this may come at the expense of quality or reliability.

-

Manufacturing Overhead: This encompasses factory costs, utilities, and administrative expenses. Efficient factories often have lower overhead costs, which can translate to better pricing for buyers.

-

Tooling: Custom molds for unique bottle designs can represent a significant upfront investment. Buyers should consider these costs when evaluating suppliers, especially for custom-sized bottles.

-

Quality Control (QC): Implementing rigorous QC processes adds to overall costs but is essential for ensuring product consistency and safety, particularly for international markets that may have stringent regulations.

-

Logistics: Shipping costs can fluctuate based on the distance from the supplier and the chosen Incoterms. Buyers should factor in freight, insurance, and tariffs when calculating total logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing model can help negotiate better terms.

How Do Price Influencers Impact Water Bottle Sourcing?

Several factors can affect the pricing of water bottles:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly influence pricing. Larger orders often qualify for bulk discounts, which can be a deciding factor for budget-conscious buyers.

-

Specifications/Customization: Custom designs and specifications can drive up costs. Buyers should weigh the benefits of customization against the additional expenses incurred.

-

Materials: Higher-quality materials, such as food-grade stainless steel, may increase upfront costs but can reduce total ownership costs due to durability and reusability.

-

Quality and Certifications: Certifications, such as FDA approval for food safety, can add to costs but are crucial for compliance in many markets. Buyers should assess whether these certifications are necessary for their target market.

-

Supplier Factors: Supplier reliability, production capacity, and reputation can affect pricing. Established suppliers may charge a premium, but they often provide better quality assurance and customer service.

-

Incoterms: Understanding international shipping terms is crucial for cost management. Different Incoterms define who bears the costs and risks at various stages of transportation, impacting the total landed cost of products.

What Buyer Tips Can Enhance Cost-Efficiency in Water Bottle Sourcing?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can lead to significant savings:

-

Negotiation: Engaging in open discussions about pricing, especially regarding bulk orders, can yield favorable terms. Don’t hesitate to negotiate on MOQ and payment terms.

-

Cost-Efficiency: Conduct a Total Cost of Ownership (TCO) analysis that factors in initial costs, longevity, maintenance, and potential resale value. This holistic view can help identify the most cost-effective options.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect pricing. Establishing relationships with local suppliers may mitigate some of these costs.

-

Supplier Diversity: Consider sourcing from multiple suppliers to reduce dependency on a single source. This approach can enhance negotiation leverage and ensure consistent supply.

Disclaimer on Indicative Prices

Pricing for water bottles can vary widely based on factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing typical water bottle size With Other Solutions

Exploring Viable Alternatives to Typical Water Bottle Sizes

In today’s market, businesses are increasingly considering various solutions to meet hydration needs effectively. While typical water bottle sizes serve a fundamental purpose, alternatives can offer unique advantages tailored to specific applications. This analysis compares traditional water bottles with two alternative hydration solutions: water dispensing stations and reusable hydration packs.

| Comparison Aspect | Typical Water Bottle Size | Water Dispensing Station | Reusable Hydration Pack |

|---|---|---|---|

| Performance | Portable and easy to use; ideal for personal hydration. | Provides a continuous supply; supports multiple users simultaneously. | Convenient for hands-free hydration during activities; allows for easy transport. |

| Cost | Generally low-cost; bulk purchasing can reduce expenses. | Higher initial investment for installation; lower long-term cost per use. | Moderate price; cost-effective for active environments. |

| Ease of Implementation | Simple to distribute and use; minimal setup required. | Requires plumbing and maintenance; installation can be complex. | Easy to use once acquired; requires periodic cleaning. |

| Maintenance | Minimal; refill as needed; clean occasionally. | Regular maintenance needed to ensure cleanliness and functionality. | Requires regular cleaning and water refilling. |

| Best Use Case | Individual use, events, and on-the-go hydration. | Offices, schools, and public spaces with high traffic. | Outdoor activities, sports events, and travel. |

Detailed Breakdown of Alternatives

Water Dispensing Stations

Water dispensing stations provide a centralized hydration solution, catering to multiple users at once. These stations can be strategically placed in high-traffic areas such as offices, schools, or public parks. The primary advantage is their ability to deliver a continuous supply of water, significantly reducing the reliance on single-use plastic bottles. However, the initial installation cost can be substantial, and ongoing maintenance is essential to ensure water quality and functionality. For businesses committed to sustainability and high usage rates, these stations can offer a long-term, cost-effective hydration solution.

Reusable Hydration Packs

Reusable hydration packs are designed for active individuals who require hands-free hydration. These packs are particularly beneficial for outdoor activities, allowing users to drink water while engaging in sports or hiking. They are generally lightweight and portable, making them easy to carry. While they can be cost-effective over time, especially in active environments, hydration packs require regular cleaning to maintain hygiene. Additionally, they may not be suitable for large groups, limiting their use in settings where multiple users need access to water simultaneously.

Conclusion: Choosing the Right Hydration Solution for Your Needs

Selecting the appropriate hydration solution for your organization involves evaluating your specific requirements and usage patterns. For businesses focused on individual hydration, typical water bottle sizes remain a practical choice due to their affordability and ease of use. However, for environments with higher traffic or a focus on sustainability, water dispensing stations may offer a superior alternative. Meanwhile, reusable hydration packs cater to active settings where mobility is paramount. Ultimately, understanding the unique benefits and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for typical water bottle size

Understanding the key technical properties and trade terminology associated with typical water bottle sizes is essential for B2B buyers to make informed purchasing decisions. This knowledge enables companies to ensure product quality, compliance, and cost-effectiveness while meeting their hydration needs.

What are the Critical Technical Properties of Water Bottles?

-

Material Grade: The most common materials for water bottles include BPA-free PET plastic, stainless steel, and aluminum. Each material has distinct advantages; for instance, stainless steel is durable and environmentally friendly, while PET plastic is lightweight and cost-effective. B2B buyers must consider the material grade to ensure product safety, regulatory compliance, and longevity.

-

Capacity Tolerance: This specification refers to the volume of liquid a bottle can hold, typically measured in ounces or liters. Common sizes include 8 oz, 16.9 oz, 32 oz, and 64 oz. Understanding capacity tolerance is critical for meeting customer hydration needs and optimizing shipping logistics. Buyers should ensure that the chosen capacity aligns with market demand.

-

Durability Rating: This property evaluates how well a water bottle can withstand physical impacts, temperature changes, and general wear and tear. For example, stainless steel bottles often have higher durability ratings compared to plastic counterparts. A higher durability rating translates to lower replacement costs and enhanced customer satisfaction, making it a vital consideration for B2B buyers.

-

Insulation Performance: For bottles designed to keep liquids hot or cold, insulation performance is key. Insulated bottles may feature vacuum-sealed technology, which helps maintain temperature over extended periods. Buyers should assess insulation performance to cater to specific customer preferences, such as outdoor activities or daily commuting.

-

Labeling Area: The surface area available for branding or labeling is another critical property. Bottles come in various shapes and sizes, affecting how much branding can be displayed. Understanding the labeling area is essential for companies looking to enhance brand visibility and create a unique product identity.

-

Weight: The overall weight of the bottle, including its empty state, is crucial for both shipping and user experience. Lighter bottles may be preferable for consumers on the go, whereas heavier bottles might signify sturdiness. Buyers should consider the balance between weight and durability to meet customer expectations.

What are Common Trade Terms in the Water Bottle Industry?

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products based on another company’s specifications. B2B buyers often engage OEMs for custom water bottle designs, ensuring that the final product meets their specific branding and quality requirements.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively and to negotiate favorable terms with suppliers.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and availability for specific products. It helps buyers compare multiple suppliers and make informed decisions based on cost, lead time, and quality.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, insurance, and risk management during transport.

-

BPA-Free: This term indicates that a product does not contain Bisphenol A, a chemical found in many plastics. As consumer awareness of health and safety grows, B2B buyers should prioritize BPA-free products to meet market demands and regulatory standards.

-

Custom Labels: Many companies offer the option to create custom labels for their water bottles. This feature allows businesses to enhance brand recognition and tailor products to specific markets. Buyers should consider the implications of custom labeling on production timelines and costs.

By understanding these essential technical properties and trade terms, B2B buyers can navigate the water bottle market more effectively, ensuring they select products that align with their operational needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the typical water bottle size Sector

What Are the Key Market Dynamics Influencing the Typical Water Bottle Size Sector?

The global market for water bottles is evolving rapidly, driven by increased health consciousness and a growing demand for sustainable products. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are witnessing a significant shift toward larger capacity bottles, such as half-gallon and 32-ounce sizes, which cater to both hydration needs and convenience. Additionally, the rise of outdoor activities and sports is contributing to the popularity of portable hydration solutions, with consumers seeking durable, insulated options that maintain beverage temperature.

Emerging technologies are reshaping the sourcing landscape. Advanced manufacturing processes, such as blow molding and injection molding, enable the production of high-quality bottles in various sizes while optimizing cost efficiency. Moreover, the integration of e-commerce platforms facilitates easier access to suppliers, allowing international buyers to compare products and prices seamlessly. As a result, businesses can streamline their procurement processes and achieve better profit margins by selecting suppliers that meet their specific size and material requirements.

How Is Sustainability Shaping Sourcing Trends for Water Bottles?

Sustainability has become a crucial consideration in the sourcing of water bottles, with significant implications for environmental impact and ethical supply chains. The shift away from single-use plastics has led to increased demand for eco-friendly materials, such as stainless steel and BPA-free plastics. These materials not only reduce ecological footprints but also enhance product durability, making them more appealing to environmentally-conscious consumers.

International buyers are increasingly prioritizing suppliers with green certifications, such as the Global Recycle Standard (GRS) or the Forest Stewardship Council (FSC), which indicate adherence to sustainable practices. Furthermore, the emphasis on ethical sourcing is driving companies to scrutinize their supply chains, ensuring fair labor practices and minimizing waste. By aligning with suppliers that prioritize sustainability, businesses can enhance their brand reputation and meet consumer demand for responsible products, ultimately leading to increased market share.

How Has the Water Bottle Size Market Evolved Over Time?

The evolution of the water bottle market reflects changing consumer lifestyles and growing environmental awareness. Initially dominated by single-use plastic bottles, the sector has seen a marked shift toward reusable options in response to the global plastic crisis. Over the past two decades, the introduction of various sizes—from compact 8-ounce bottles to larger gallon containers—has catered to diverse consumer needs, including hydration during outdoor activities and daily use in urban settings.

As consumers become more health-conscious, the demand for larger bottles, such as half-gallon and 32-ounce sizes, has surged. This trend is complemented by innovations in design and material, enhancing the functionality and aesthetic appeal of water bottles. The focus on sustainability has further accelerated this evolution, prompting manufacturers to invest in eco-friendly materials and ethical production processes, reshaping the water bottle landscape for B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of typical water bottle size

-

1. How do I choose the right water bottle size for my business needs?

Selecting the appropriate water bottle size hinges on your target market’s preferences and the intended use. For bulk distribution, consider larger sizes like half-gallon (64 oz) or gallon bottles, which are ideal for events or workplaces. If your focus is on retail or convenience, smaller sizes (16 oz to 32 oz) might be more appealing. Conduct market research to understand customer preferences, and consider factors such as portability, hydration goals, and environmental impact when making your decision. -

2. What are the most common water bottle sizes available in the market?

The most common sizes for water bottles include 8 oz, 16 oz, 32 oz, and half-gallon (64 oz). Each size serves different purposes: 8 oz bottles are often used for kids or single servings, while 16 oz and 32 oz are popular for personal hydration. Larger half-gallon bottles are suitable for sports and outdoor activities. Additionally, custom sizes can be produced based on specific requirements, allowing businesses to cater to niche markets. -

3. How can I ensure the quality of water bottles from international suppliers?

To verify the quality of water bottles from international suppliers, conduct thorough vetting by requesting samples, certifications (like BPA-free), and third-party testing reports. Look for suppliers with a strong track record of quality assurance practices, such as ISO certifications. Establish clear communication regarding your quality expectations and consider visiting the supplier’s facility if feasible. Building a relationship with suppliers who prioritize quality can help ensure your products meet industry standards. -

4. What are the minimum order quantities (MOQs) for water bottle purchases?

Minimum order quantities (MOQs) for water bottles can vary significantly based on the supplier, bottle type, and customization options. Typically, MOQs can range from as low as 500 units for standard sizes to several thousand for custom designs. It’s essential to discuss MOQs directly with potential suppliers, as many are willing to negotiate based on your business needs or potential for future orders. This flexibility can help you manage inventory and cash flow effectively. -

5. What payment terms should I expect when sourcing water bottles internationally?

When sourcing water bottles internationally, payment terms can vary widely. Common arrangements include a deposit upfront (usually 30% to 50%) with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or payment through secure platforms like PayPal for added protection. It’s crucial to negotiate terms that align with your cash flow and risk tolerance, and ensure all agreements are documented to avoid disputes. -

6. How do I manage logistics and shipping for water bottle orders?

Managing logistics for water bottle orders involves coordinating with suppliers to understand shipping options, lead times, and costs. Choose between air freight for faster delivery or sea freight for cost-effectiveness, especially for larger orders. Work with freight forwarders who can navigate customs regulations and ensure compliance with local laws. Additionally, plan for potential delays by building buffer time into your delivery schedule to maintain customer satisfaction. -

7. Can I customize water bottles with my branding?

Yes, many suppliers offer customization options for water bottles, including printing your logo, choosing colors, or even altering bottle shapes. Customization can help enhance brand visibility and appeal to your target audience. Discuss your specific branding needs with suppliers, including artwork specifications and lead times for production. Be aware that custom orders may have higher MOQs and longer turnaround times, so plan accordingly. -

8. What quality assurance practices should I look for in water bottle suppliers?

When evaluating water bottle suppliers, seek those with established quality assurance (QA) practices, such as regular inspections, compliance with safety standards, and certifications like ISO 9001. Inquire about their production processes, testing methods, and how they handle defects or customer complaints. A reliable supplier should have a clear QA policy that outlines their commitment to delivering high-quality products consistently, which is essential for maintaining your brand’s reputation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Typical Water Bottle Size Manufacturers & Suppliers List

1. Water Bottle Sizes – Daily Use Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ideal sizes for daily use water bottles are 24oz, 32oz, and 40oz. Recommendations suggest that 24oz fits well in most backpack side pouches and is easier to carry, while 32oz is suitable for short hikes. Some users prefer smaller sizes like 16oz for convenience and lighter weight.

2. My Own Water – Water Bottles

Domain: myownwater.com

Registered: 2000 (25 years)

Introduction: We offer several water bottle sizes ranging from 8 oz up to 1 gallon. Our bottles are available in various styles and materials, including:

1. **Value Bottles** (Ribbed style, made from BPA free PET plastic):

– 8 oz

– 10 oz

– 12 oz

– 16.9 oz

– 23.7 oz

– 33.8 oz

2. **Modern Bottles** (Sleek, no ribs):

– 12 oz

– 16.9 oz

– 23.7 oz

– 33.8 oz

– 50 oz

3. **Aluminum Bo…

3. Owala – FreeSip Water Bottle

Domain: owalalife.com

Registered: 2019 (6 years)

Introduction: Owala offers a variety of water bottles with different sizes and features. The FreeSip Water Bottle is available in Stainless Steel or Tritan Plastic, with sizes of 19 oz. (9.88 inches tall), 24 oz. (10.68 inches tall), 25 oz. (9.87 inches tall), 32 oz. (10.66 inches tall), and 40 oz. (11.64 inches tall). The Flip™ Water Bottle also comes in Stainless Steel and Tritan, with sizes of 19 oz. (9.94 i…

4. CustomWater – 8oz BPA Free Water Bottle

Domain: customwater.com

Registered: 2002 (23 years)

Introduction: CustomWater.com offers a variety of plastic water bottle sizes including:

1. **8oz Water Bottle**

– Dimensions: 5″ tall, 2.25″ wide, 8.25″ around

– Label Size: 1.625″ H x 7.25″ W to 2″ H x 7″ W

– BPA free

– Packed: 24 bottles per case

– Order in increments of 12 cases

– Pallet: 120 cases (2880 bottles) or 130 cases (3120 bottles)

2. **12oz Water Bottle**

– D…

5. Dual Drinks – Single-Use Plastic Water Bottles

Domain: dualdrinks.com

Registered: 2023 (2 years)

Introduction: Standard size for single-use plastic water bottles is 16.9 fluid ounces (500 milliliters). Smaller bottles range from 8 to 12 ounces, while larger options include 1-liter (33.8 ounces) and 1.5-liter (50.7 ounces) bottles. Approximately 7.57 standard 16.9-ounce bottles equal one gallon of water.

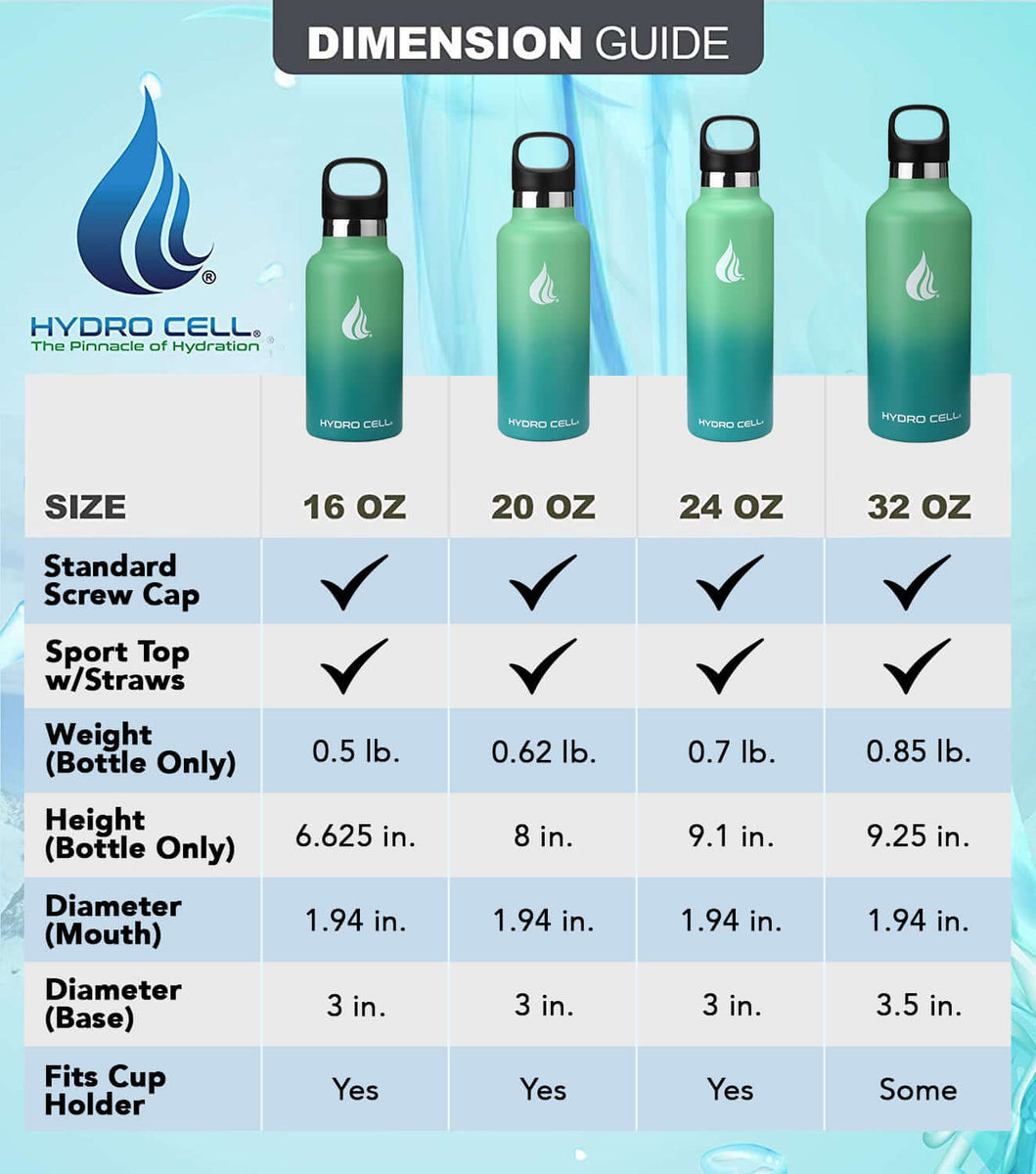

6. Hydrocell – Optimal Water Bottle Sizes

Domain: hydrocellusa.com

Registered: 2017 (8 years)

Introduction: The best size of water bottle is 16 to 24 ounces (473 to 708 milliliters) for daily hydration. For more water needs, a 32-ounce bottle is suitable. For overnight camping, choose 40 to 64 ounces. Kids should use 10 to 14 ounces insulated bottles. Everyday use bottles should be 16 to 20 ounces, with 18-ounce stainless steel being ideal. For travel, a 20 to 24-ounce bottle is recommended. A 24-ounce …

7. Silicone Mania – Silicone Travel Water Bottles

Domain: siliconemania.com

Registered: 2024 (1 years)

Introduction: 750ml Silicone Travel Water Bottle, Silicone Compass Water Bottle, Silicone Foldable Water Bottles, BPA free Silicone Foldable Water Bottle.

Strategic Sourcing Conclusion and Outlook for typical water bottle size

In summary, selecting the appropriate water bottle size is pivotal for businesses aiming to meet diverse consumer needs across global markets. The range of sizes—from compact 8 oz bottles to larger 64 oz options—affords flexibility in targeting different demographics and usage scenarios. For instance, smaller bottles are ideal for convenience and portability, while larger containers cater to outdoor and sports enthusiasts.

Strategic sourcing plays a crucial role in this decision-making process. By partnering with reliable suppliers who provide high-quality, eco-friendly materials, businesses can enhance their product offerings while also aligning with sustainability goals, a growing concern for consumers worldwide. The trend towards stainless steel and aluminum bottles reflects a broader commitment to environmental stewardship, which resonates particularly well in markets across Africa, South America, the Middle East, and Europe.

As international B2B buyers navigate these options, they are encouraged to prioritize quality, durability, and design in their sourcing strategies. Engaging with innovative suppliers can yield competitive advantages in rapidly evolving markets. The future of water bottle consumption is bright; seize the opportunity to lead in this dynamic space and cater to the hydration needs of a diverse global customer base.