Introduction: Navigating the Global Market for cylinder water bottle

Navigating the intricate landscape of sourcing cylinder water bottles can present significant challenges for international B2B buyers. With diverse applications ranging from beverages to personal care products, understanding the specifications, materials, and designs that best meet market demands is crucial. This comprehensive guide delves into the myriad types of cylinder water bottles available, explores their various applications, and offers insights into supplier vetting, pricing strategies, and sustainability considerations.

For businesses operating in regions like Africa, South America, the Middle East, and Europe, making informed purchasing decisions is essential to remain competitive. This guide equips buyers with actionable insights that facilitate effective sourcing, enabling them to select the right products that align with their brand objectives and customer needs. Whether you are looking for lightweight PET bottles for on-the-go hydration or durable HDPE options for household products, our resource will help streamline your decision-making process.

By addressing key factors such as compliance with international standards, customization options, and cost efficiency, this guide empowers B2B buyers to navigate the global market for cylinder water bottles confidently. As you embark on your sourcing journey, let this guide serve as your authoritative resource to enhance your product offerings and meet the evolving demands of your customers.

Artículo Navegación

- Top 8 Cylinder Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cylinder water bottle

- Understanding cylinder water bottle Types and Variations

- Key Industrial Applications of cylinder water bottle

- 3 Common User Pain Points for ‘cylinder water bottle’ & Their Solutions

- Strategic Material Selection Guide for cylinder water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for cylinder water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cylinder water bottle’

- Comprehensive Cost and Pricing Analysis for cylinder water bottle Sourcing

- Alternatives Analysis: Comparing cylinder water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for cylinder water bottle

- Navigating Market Dynamics and Sourcing Trends in the cylinder water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cylinder water bottle

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for cylinder water bottle

Understanding cylinder water bottle Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| PET Plastic Cylinder Bottles | Lightweight, shatter-resistant, FDA-compliant, recyclable | Cosmetics, household cleaners, food packaging | Pros: Cost-effective, versatile, eco-friendly. Contras: Protección UV limitada. |

| HDPE Cylinder Bottles | High-density polyethylene, durable, resistant to impact | Personal care products, industrial applications | Pros: Excellent chemical resistance, reusable. Contras: Less transparent than PET. |

| Glass Cylinder Bottles | Heavy-duty, premium appearance, non-reactive | High-end beverages, specialty oils, gourmet products | Pros: Recyclable, preserves flavor. Contras: Heavy, fragile, higher shipping costs. |

| Aluminum Cylinder Bottles | Lightweight, insulated options available, modern aesthetic | Beverages, energy drinks, promotional items | Pros: Durable, maintains temperature. Contras: Higher cost, less versatile than plastics. |

| Tamper-Evident Cylinder Bottles | Features seals to indicate tampering, enhances product safety | Pharmaceuticals, food products, personal care | Pros: Ensures safety, builds consumer trust. Contras: Can increase packaging costs. |

What Are the Characteristics of PET Plastic Cylinder Bottles?

PET (Polyethylene Terephthalate) plastic cylinder bottles are a popular choice due to their lightweight and shatter-resistant properties. They are FDA-compliant, making them suitable for food and beverage applications. B2B buyers appreciate their versatility, as they can be used for a wide range of products from cosmetics to household cleaners. However, while they are cost-effective and eco-friendly (being fully recyclable), they offer limited protection against UV light, which may be a consideration for certain products.

How Do HDPE Cylinder Bottles Stand Out?

High-Density Polyethylene (HDPE) cylinder bottles are known for their durability and impact resistance. They are ideal for a variety of applications, especially in the personal care and industrial sectors. B2B buyers often choose HDPE for its excellent chemical resistance and the ability to be reused multiple times. Although HDPE is less transparent than PET, its robustness makes it a preferred choice for products requiring long-term storage.

Why Choose Glass Cylinder Bottles?

Glass cylinder bottles provide a premium packaging option that is non-reactive and preserves the integrity of the contents. They are particularly favored in high-end markets such as gourmet food and beverages. For B2B buyers, glass offers the advantage of being fully recyclable and maintaining the flavor of liquids without leaching. However, the weight and fragility of glass can lead to higher shipping costs and potential breakage, which are crucial factors to consider in logistics.

What Advantages Do Aluminum Cylinder Bottles Offer?

Aluminum cylinder bottles are increasingly popular for their lightweight and modern appearance. They can also offer insulation options, making them suitable for beverages and energy drinks. B2B buyers appreciate aluminum for its durability and ability to maintain temperature, which is essential for certain products. However, the higher cost and limited versatility compared to plastic options may be drawbacks for some businesses.

How Do Tamper-Evident Cylinder Bottles Enhance Product Safety?

Tamper-evident cylinder bottles are designed with seals that provide visual evidence of tampering, making them essential for pharmaceuticals and food products. These bottles enhance product safety and build consumer trust, which is critical in competitive markets. While they may increase packaging costs, the added assurance of safety can be a strong selling point for B2B buyers looking to meet regulatory standards and consumer expectations.

Key Industrial Applications of cylinder water bottle

| Industria/Sector | Specific Application of Cylinder Water Bottle | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Alimentación y bebidas | Packaging for flavored water or juices | Lightweight and cost-effective, enhancing product shelf appeal | Compliance with food safety regulations and recyclability |

| Personal Care Products | Containers for shampoos, conditioners, and lotions | Versatile design allows for branding and easy dispensing | Material quality and customization options for branding |

| Productos farmacéuticos | Storage for liquid medications and health supplements | Ensures product integrity with tamper-evidence and safety features | Certification for FDA compliance and child-resistant options |

| Household Cleaning Products | Packaging for liquid cleaners and detergents | Durable and resistant to chemical degradation | Availability of various closure types and bulk purchasing options |

| Cosmetics | Bottles for serums, oils, and moisturizers | Enhances user experience with easy-to-use dispensing mechanisms | Sourcing options for sustainable materials and design flexibility |

How are Cylinder Water Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, cylinder water bottles are primarily used for packaging flavored waters and juices. Their lightweight design contributes to reduced shipping costs while appealing visually on retail shelves. International B2B buyers should prioritize compliance with local food safety regulations and ensure the materials are recyclable to meet growing consumer demand for sustainable packaging solutions.

What Role do Cylinder Water Bottles Play in Personal Care Products?

Cylinder water bottles serve as versatile containers for personal care products like shampoos, conditioners, and lotions. Their unique shape allows for effective branding, while the wide mouth facilitates easy filling and dispensing. Buyers from various regions, including Africa and South America, should consider the quality of the materials used, as well as customization options to enhance brand recognition and customer engagement.

Why are Cylinder Water Bottles Important for Pharmaceuticals?

In the pharmaceutical industry, cylinder water bottles are essential for storing liquid medications and health supplements. They often feature tamper-evident seals to ensure product safety and integrity. International buyers must ensure that their sourcing aligns with FDA compliance standards and consider options for child-resistant packaging to enhance safety for households with young children.

How are Cylinder Water Bottles Utilized in Household Cleaning Products?

Cylinder water bottles are widely used for packaging liquid household cleaners and detergents. Their durability and resistance to chemical degradation make them ideal for this purpose. B2B buyers should focus on sourcing bottles that offer various closure types to ensure ease of use and consider bulk purchasing options to optimize supply chain efficiency.

In What Ways are Cylinder Water Bottles Beneficial for Cosmetics?

In the cosmetics industry, cylinder water bottles are increasingly popular for packaging serums, oils, and moisturizers. Their design enhances the user experience by providing easy dispensing mechanisms, which can lead to higher customer satisfaction. Buyers should prioritize sourcing options that include sustainable materials and design flexibility to cater to diverse product lines and consumer preferences.

3 Common User Pain Points for ‘cylinder water bottle’ & Their Solutions

Scenario 1: Sourcing Durable Cylinder Water Bottles for Harsh Environments

El problema: Many B2B buyers in industries such as construction or outdoor recreation often face the challenge of sourcing water bottles that can withstand extreme conditions. These environments may include exposure to high temperatures, chemicals, or physical impacts, leading to concerns about durability and safety. When water bottles fail under these conditions, it results in wasted resources and potential hazards for users.

La solución: To overcome this challenge, buyers should prioritize sourcing cylinder water bottles made from high-quality materials such as BPA-free PET or HDPE. These plastics are known for their resilience and ability to resist degradation under extreme conditions. When placing orders, buyers should request detailed specifications, including temperature resistance ratings and chemical compatibility information. Additionally, opting for bottles that feature reinforced designs or specialized closures can enhance durability. Conducting trials with sample products before committing to larger orders can also help verify performance in real-world scenarios, ensuring that the chosen bottles meet operational requirements.

Scenario 2: Managing Supply Chain Disruptions for Consistent Product Availability

El problema: International buyers often deal with supply chain disruptions that can lead to inconsistent availability of cylinder water bottles. Factors such as geopolitical issues, shipping delays, or raw material shortages can cause significant frustration, impacting production schedules and customer satisfaction. This unpredictability may result in lost sales opportunities and strained relationships with end-users.

La solución: To mitigate supply chain risks, B2B buyers should establish relationships with multiple suppliers across different regions. This diversification can help ensure a steady supply of cylinder water bottles even if one source encounters issues. Additionally, implementing a just-in-time inventory strategy can help maintain optimal stock levels without overcommitting resources. Buyers should also stay informed about market trends and potential disruptions by subscribing to industry newsletters and reports. By anticipating challenges and adapting procurement strategies accordingly, businesses can enhance their resilience and maintain product availability.

Scenario 3: Navigating Regulatory Compliance for Food and Beverage Applications

El problema: Buyers in the food and beverage sector face stringent regulations regarding packaging materials, particularly when it comes to safety and hygiene. Ensuring that cylinder water bottles comply with FDA and other international standards can be a daunting task, especially for businesses expanding into new markets. Non-compliance can lead to costly fines, product recalls, and damage to brand reputation.

La solución: To ensure regulatory compliance, buyers should work closely with suppliers who provide documentation of certifications such as FDA approval and ISO standards. It is advisable to engage in thorough due diligence by requesting samples that have been tested for safety and usability. Additionally, staying updated on local regulations in target markets is crucial, as requirements can vary significantly. Participating in industry forums and trade shows can provide valuable insights and networking opportunities with experts who can assist in navigating these complexities. By prioritizing compliance from the outset, businesses can confidently market their products while minimizing legal risks.

Strategic Material Selection Guide for cylinder water bottle

What Are the Key Materials for Cylinder Water Bottles?

When selecting materials for cylinder water bottles, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), glass, and aluminum. Each material presents unique characteristics that cater to different applications and market demands.

How Does PET Perform in Cylinder Water Bottles?

PET is widely used for its lightweight and shatter-resistant properties. It can withstand temperatures up to 70°C (158°F) and is resistant to impact, making it suitable for various applications, including beverages and personal care products. PET bottles are also recyclable, which aligns with growing environmental concerns.

Pros: PET is cost-effective and offers good clarity, allowing consumers to see the contents. It is also compliant with FDA regulations for food contact.

Contras: While PET is durable, it may not be suitable for high-temperature applications beyond its rating. Additionally, prolonged exposure to UV light can degrade the material.

Consideraciones internacionales: Buyers should ensure compliance with local regulations regarding food safety and recycling, such as those set by the European Union or ASTM standards in the U.S.

What Advantages Does HDPE Offer for Cylinder Water Bottles?

HDPE is known for its strength and resistance to impact and chemicals. It can withstand temperatures up to 120°C (248°F) and is suitable for a wide range of products, including household cleaners and industrial chemicals.

Pros: HDPE is highly durable and offers excellent barrier properties against moisture and chemicals. It is also cost-effective and easy to manufacture.

Contras: The material is less transparent than PET, which may not appeal to brands that want to showcase their products visually. HDPE is also less flexible, which can limit design options.

Consideraciones internacionales: HDPE is compliant with various international standards, making it a reliable choice for global markets. Buyers should check for certifications such as ISO and local regulations in their regions.

Why Choose Glass for Cylinder Water Bottles?

Glass is a premium option known for its aesthetic appeal and excellent barrier properties. It is non-reactive and can withstand high temperatures, making it suitable for beverages and food products.

Pros: Glass is recyclable and provides a premium feel that can enhance brand perception. It does not leach chemicals into contents, ensuring product integrity.

Contras: The primary drawback of glass is its weight and fragility, which can lead to higher shipping costs and breakage during transport.

Consideraciones internacionales: Buyers must consider the regulations surrounding glass packaging, especially in regions with strict safety standards. Additionally, they should account for the potential need for protective packaging during shipping.

How Does Aluminum Compare in Cylinder Water Bottles?

Aluminum is lightweight and offers a modern aesthetic, often used for beverage containers. It is resistant to corrosion and can withstand a wide range of temperatures.

Pros: Aluminum is highly recyclable and provides excellent protection against light and oxygen, which can extend product shelf life. It is also cost-effective for large-scale production.

Contras: Aluminum may require a lining to prevent reactions with acidic products, which can add to manufacturing complexity. Additionally, it is less rigid than glass or plastic, which can affect its structural integrity.

Consideraciones internacionales: Buyers should ensure compliance with food safety regulations and recycling standards specific to aluminum in their regions, such as those outlined by the European Union or local health authorities.

Summary Table of Material Selection for Cylinder Water Bottles

| Material | Typical Use Case for Cylinder Water Bottle | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| PET | Bebidas, productos de cuidado personal | Lightweight and shatter-resistant | Limited high-temperature use | Bajo |

| HDPE | Household cleaners, industrial chemicals | Durable and chemical-resistant | Less transparent | Bajo |

| Vidrio | Premium beverages, food products | No reactivo y reciclable | Pesado y frágil | Alta |

| Aluminio | Soft drinks, energy drinks | Excelentes propiedades de barrera | Requires lining for acidic contents | Medio |

This guide serves as a foundational resource for international B2B buyers seeking to make informed decisions regarding material selection for cylinder water bottles, considering both performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cylinder water bottle

What Are the Key Stages in the Manufacturing Process of Cylinder Water Bottles?

The manufacturing process for cylinder water bottles typically consists of several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

Material Preparation: What Materials Are Used?

The primary materials for cylinder water bottles are often plastics like PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene). During the material preparation stage, these plastics are sourced and processed to ensure they meet specific quality standards. The materials undergo rigorous testing for factors such as purity, consistency, and compliance with safety regulations.

In regions like Africa and South America, where recycling rates may vary, suppliers often emphasize the use of recycled materials in their manufacturing processes. Buyers should inquire about the percentage of recycled content in the bottles they plan to source, as this can impact both environmental sustainability and product quality.

How Are Cylinder Water Bottles Formed?

The forming stage is where the actual bottle shapes are created. This is typically achieved through processes such as blow molding or injection molding.

-

Moldeo por soplado: In this method, preheated plastic is placed in a mold. Air is then blown into the material, forcing it to expand and take the shape of the mold. This technique is prevalent for PET bottles, as it allows for lightweight, shatter-resistant designs.

-

Moldeo por inyección: This method involves injecting molten plastic into a mold. While this technique is often used for caps and closures, it can also produce bottle bodies in more complex designs.

The choice of forming technique can affect not only the aesthetics of the bottle but also its functionality, such as its ability to withstand high temperatures or pressure. Buyers should consider these factors based on the intended application of the bottles.

What Quality Control Measures Are In Place During Manufacturing?

Quality control (QC) is an integral part of the manufacturing process for cylinder water bottles. Various international and industry-specific standards guide these practices, ensuring the final products are safe, durable, and meet customer specifications.

¿Qué normas internacionales deben conocer los compradores B2B?

One of the most recognized standards for quality management is ISO 9001. This certification indicates that a company has established a quality management system, which is essential for consistent product quality. Other relevant certifications may include:

- Marcado CE: Indica el cumplimiento de las normas europeas de salud, seguridad y protección del medio ambiente.

- API Certification: Relevant for products intended for the oil and gas industry, focusing on safety and performance.

B2B buyers should ensure that their suppliers comply with these standards, as this can significantly reduce the risk of receiving subpar products.

What Are the Key QC Checkpoints in the Manufacturing Process?

The QC process typically includes several checkpoints:

-

Control de calidad entrante (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. This is crucial for preventing defects in the final product.

-

Control de calidad durante el proceso (IPQC): During manufacturing, samples are taken at various stages to ensure that the process is running smoothly and that the products meet quality standards.

-

Control de calidad final (CCF): After the bottles are produced, they undergo a final inspection to ensure they meet all specifications before being packaged for shipment.

These checkpoints are vital in identifying defects early in the process, thereby minimizing waste and ensuring a higher-quality product.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are some actionable strategies:

-

Auditorías de proveedores: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. During an audit, buyers should assess the materials used, the manufacturing techniques, and the overall cleanliness and organization of the facility.

-

Informes de calidad: Requesting quality control reports from suppliers can provide detailed information on their compliance with international standards, including any testing results for specific batches of products.

-

Inspecciones de terceros: Engaging third-party inspection agencies can offer an unbiased review of a supplier’s quality control practices. These agencies can perform checks at various stages of the production process and provide certification that can be crucial for international trade.

What Common Testing Methods Are Used to Ensure Product Quality?

Different testing methods are employed to ensure that cylinder water bottles meet industry standards. Common methods include:

- Mechanical Testing: This assesses the strength and durability of the bottles, checking for issues like cracking or deformation under stress.

- Pruebas químicas: Ensures that the materials used in the bottles are safe and do not leach harmful substances into the contents.

- Environmental Testing: Evaluates how bottles perform under various conditions, such as extreme temperatures or exposure to UV light.

By understanding these testing methods, B2B buyers can better gauge the reliability of the products they are sourcing.

How Do Quality Control Nuances Affect International B2B Buyers?

International buyers, especially those from regions like Africa, South America, and the Middle East, should be aware of specific nuances related to quality control. Regulations can vary significantly between countries, and some suppliers may not have the same level of compliance with international standards.

Buyers should conduct thorough research on local regulations and ensure that their suppliers can meet these requirements. Additionally, understanding the import/export regulations regarding quality certifications can prevent costly delays or penalties.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

For B2B buyers looking to source cylinder water bottles, understanding the manufacturing processes and quality assurance measures is crucial. By focusing on material preparation, forming techniques, and rigorous quality control checkpoints, buyers can ensure they are partnering with reliable suppliers. Additionally, verifying compliance with international standards and conducting thorough audits can lead to successful and sustainable sourcing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cylinder water bottle’

This practical sourcing guide aims to assist B2B buyers in navigating the procurement process for cylinder water bottles, ensuring they make informed decisions that align with their business needs. By following this checklist, you can streamline your sourcing efforts and secure quality products that meet your specifications.

Primer paso: Defina sus especificaciones técnicas

Establishing clear technical specifications for your cylinder water bottles is essential to ensure they meet your product requirements. Consider factors such as size, material (e.g., PET, HDPE), and intended use (e.g., beverages, cosmetics). This clarity will guide your supplier selection and help avoid miscommunications later in the process.

- Material Considerations: Look for bottles made from FDA-compliant materials, particularly if they will hold consumables.

- Size Options: Determine the volume required based on your product line and target market.

Segundo paso: Buscar posibles proveedores

Conduct thorough research to identify potential suppliers who specialize in cylinder water bottles. Check online directories, industry forums, and trade shows to gather a list of manufacturers and distributors. Understanding the supplier landscape will help you identify reliable partners.

- Supplier Reputation: Look for reviews and testimonials from other B2B buyers, particularly those in your region.

- Product Range: Ensure the supplier offers a variety of bottle sizes and materials to suit your diverse needs.

Tercer paso: Evaluar las certificaciones de los proveedores

Before making a commitment, verify that your chosen suppliers have the necessary certifications. This step is crucial to ensure compliance with safety, quality, and environmental standards.

- Quality Assurance: Check for certifications like ISO 9001, which indicate a commitment to quality management.

- Sustainability Certifications: Look for suppliers who prioritize environmentally friendly practices, as this can enhance your brand’s reputation.

Paso 4: Solicitud de muestras para pruebas

Once you have shortlisted potential suppliers, request samples of the cylinder water bottles. Testing samples allows you to assess the quality, durability, and suitability of the bottles for your specific applications.

- Pruebas de durabilidad: Evaluate how the bottles perform under various conditions, including temperature changes and transportation stress.

- Compatibility Testing: If your product has specific pH or chemical properties, ensure the bottle material is compatible to avoid degradation.

Paso 5: Review Pricing and Terms

Analyze the pricing structures and payment terms offered by your selected suppliers. Understanding the cost implications will help you budget effectively and ensure profitability.

- Bulk Pricing: Inquire about discounts for bulk orders, as this can significantly reduce your overall costs.

- Payment Flexibility: Look for suppliers who offer flexible payment terms that align with your cash flow needs.

Paso 6: Negotiate Contracts

Once you’ve selected a supplier, engage in contract negotiations to establish clear terms and conditions. This step is vital to protect your interests and ensure a smooth supply chain.

- Delivery Timelines: Clearly outline expected delivery schedules to avoid disruptions in your supply chain.

- Liability Clauses: Include terms that specify liability in case of defective products or late deliveries.

Paso 7: Establish a Quality Control Process

Implement a quality control process for incoming shipments of cylinder water bottles. Regular inspections can help you maintain product quality and address any issues before they affect your customers.

- Inspection Criteria: Define what parameters will be checked during inspections, such as bottle integrity and labeling accuracy.

- Feedback Loop: Create a system for providing feedback to suppliers based on quality assessments to foster continuous improvement.

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for cylinder water bottles, ensuring they select high-quality products that meet their business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for cylinder water bottle Sourcing

What Are the Key Cost Components in Sourcing Cylinder Water Bottles?

When sourcing cylinder water bottles, understanding the cost structure is essential for effective budgeting and pricing strategy. Key components include:

-

Materiales: The choice of material significantly impacts cost. Common materials like PET and HDPE vary in price, with PET generally offering a good balance of durability and cost-effectiveness. Factors such as material quality, recyclability, and compliance with FDA standards also play a role in determining prices.

-

Trabajo: Manufacturing labor costs can differ based on geographic location and the complexity of production. Regions with lower labor costs may offer competitive pricing, but it’s crucial to assess the quality of workmanship to ensure product integrity.

-

Gastos generales de fabricación: This includes utilities, facility costs, and indirect labor. Efficient manufacturing processes can minimize overhead, which is particularly important for bulk orders where fixed costs are spread over a larger number of units.

-

Herramientas: Initial investment in molds and production equipment can be significant. However, this cost can be amortized over larger production runs, making it more manageable for high-volume orders.

-

Control de calidad: Implementing rigorous QC processes adds to costs but is essential for maintaining product standards, especially for international markets where compliance with local regulations is mandatory.

-

Logística: Shipping costs can vary significantly depending on the destination and mode of transport. Factors such as distance, weight, and packaging can affect logistics expenses.

-

Margen: Suppliers typically apply a markup to cover their costs and ensure profitability. Understanding industry standards for margins can help buyers negotiate better pricing.

How Do Price Influencers Impact Cylinder Water Bottle Costs?

Several factors influence the pricing of cylinder water bottles, particularly for international buyers:

-

Volumen/MOQ: Minimum order quantities (MOQs) can significantly affect unit pricing. Ordering in bulk usually results in lower per-unit costs. However, buyers should balance the benefits of lower prices with the need for inventory management.

-

Especificaciones/Personalización: Custom designs, sizes, and features (like tamper-evident caps or specialized coatings) can increase costs. Buyers should assess whether the added value of customization justifies the price increase.

-

Calidad del material y certificaciones: Higher-quality materials and certifications (such as FDA compliance or eco-friendly certifications) can result in higher prices but often lead to better product performance and customer satisfaction.

-

Factores del proveedor: The supplier’s reputation, reliability, and geographic location can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding international shipping terms can prevent unexpected costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping responsibilities and costs, affecting total expenses.

What Are Effective Buyer Tips for Negotiating Cylinder Water Bottle Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negociar las condiciones: Don’t hesitate to negotiate pricing based on volume and payment terms. Suppliers may be willing to offer discounts for larger orders or early payment.

-

Centrarse en la rentabilidad: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, storage, and potential disposal costs. Sometimes, a higher upfront cost can lead to lower overall expenses.

-

Entender los matices de los precios: International buyers should be aware of currency fluctuations and import tariffs that can affect final costs. Building relationships with suppliers can provide insights into pricing trends and potential savings.

-

Realizar estudios de mercado: Understanding market prices for cylinder water bottles in your region can empower you during negotiations. Compare quotes from multiple suppliers to ensure competitive pricing.

Final Thoughts

While indicative prices for cylinder water bottles can vary widely based on the factors discussed, being informed about cost components and price influencers allows international buyers to make strategic sourcing decisions. Always consider the broader economic context and potential hidden costs to ensure a successful procurement strategy.

Alternatives Analysis: Comparing cylinder water bottle With Other Solutions

Understanding Alternatives to Cylinder Water Bottles

In the competitive landscape of packaging solutions, B2B buyers often seek alternatives to standard products like cylinder water bottles. Understanding these alternatives can help businesses optimize costs, enhance product appeal, and meet diverse market demands. This analysis compares cylinder water bottles with two viable alternatives: glass bottles and flexible pouches, highlighting their respective strengths and weaknesses.

Cuadro comparativo

| Aspecto comparativo | Cylinder Water Bottle | Botella de vidrio | Flexible Pouch |

|---|---|---|---|

| Rendimiento | Durable, lightweight, and versatile | Heavy and fragile, but premium feel | Lightweight and space-efficient |

| Coste | Moderate cost-effective option | Generally higher due to material and manufacturing | Lower cost, especially for bulk |

| Facilidad de aplicación | Easy to source and customize | More complex, requires careful handling | Simple to fill and seal |

| Mantenimiento | Low maintenance, recyclable | Requires careful cleaning and handling | Minimal maintenance, single-use often |

| El mejor caso de uso | Bebidas, productos de cuidado personal | Premium products, beverages | Snacks, sauces, and liquids |

Desglose detallado de alternativas

1. Glass Bottles

Glass bottles offer a premium packaging option, often associated with high-quality products. Their aesthetic appeal can enhance brand perception, making them a preferred choice for luxury beverages and cosmetics. However, glass is heavier and more fragile than plastic, which can lead to increased shipping costs and potential breakage during transit. Additionally, the production and recycling processes for glass are more resource-intensive. Thus, while glass bottles can elevate a brand’s image, they may not be suitable for all applications, especially in markets sensitive to cost and logistics.

2. Flexible Pouches

Flexible pouches represent an innovative alternative that is gaining traction in various industries, including food and beverage. Their lightweight design and space-efficient nature allow for significant savings in shipping and storage. Pouches can be designed for single-use or resealable options, catering to consumer preferences for convenience. However, their perceived value may be lower compared to rigid containers, which could affect marketability for premium products. Additionally, while flexible pouches are often less expensive to produce, they may not provide the same level of protection against contamination as rigid options.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right packaging solution requires careful consideration of your product’s characteristics, target market, and logistical constraints. Cylinder water bottles offer a balanced approach with versatility and cost-effectiveness, making them suitable for a wide range of applications. However, if brand image and product prestige are top priorities, glass bottles may be the better option, despite their higher costs and fragility. Conversely, if reducing shipping costs and maximizing space efficiency are critical, flexible pouches could be the ideal choice. Ultimately, B2B buyers should assess their unique requirements and market positioning to determine which solution aligns best with their business goals.

Essential Technical Properties and Trade Terminology for cylinder water bottle

What are the Essential Technical Properties of Cylinder Water Bottles?

When evaluating cylinder water bottles for B2B procurement, several critical technical properties must be considered to ensure product suitability and compliance with industry standards.

-

Composición del material

Cylinder water bottles are commonly made from materials such as PET (Polyethylene Terephthalate) or HDPE (High-Density Polyethylene). PET is lightweight, shatter-resistant, and provides excellent clarity, making it ideal for beverages. HDPE is known for its durability and resistance to impact and chemical exposure. Understanding the material helps determine the bottle’s application suitability, environmental impact, and regulatory compliance. -

Capacity and Dimensions

The capacity of a cylinder water bottle typically ranges from 2 oz to 34 oz, affecting the product’s marketability and usability. Dimensions such as height, diameter, and neck size (e.g., 20-410) are critical for compatibility with caps and dispensers. Accurate dimension specifications ensure efficient storage, transportation, and consumer convenience, directly impacting order fulfillment and customer satisfaction. -

Neck Finish and Closure Compatibility

The neck finish, often denoted by numbers like 400 or 410, indicates the type of closure that can be securely fitted. This property is vital for ensuring leak-proof performance and product integrity. Brands must select closures that align with their product requirements, such as tamper-evident or child-resistant options, which enhance safety and consumer trust. -

Thermal Stability

Many cylinder water bottles are designed to withstand various temperature conditions, making them suitable for hot or cold liquids. This property is crucial for products intended for diverse environments or those requiring high-temperature sterilization (e.g., autoclaving). Understanding thermal stability helps manufacturers ensure product safety and longevity. -

Recyclability and Environmental Impact

As sustainability becomes increasingly important, the recyclability of materials used in cylinder water bottles is a key consideration. Bottles that are 100% recyclable minimize environmental footprints and align with global sustainability initiatives. Buyers should prioritize suppliers that offer eco-friendly products, as this can enhance brand reputation and appeal to environmentally-conscious consumers.

What are Common Trade Terms Related to Cylinder Water Bottles?

Understanding industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common trade terms relevant to cylinder water bottles:

-

OEM (fabricante de equipos originales)

This term refers to companies that manufacture products for other brands, often under the client’s specifications. In the context of cylinder water bottles, OEM suppliers can produce customized bottles that meet specific design and functional requirements, offering brands the opportunity to differentiate their products in the market. -

MOQ (Cantidad mínima de pedido)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For cylinder water bottles, MOQs can vary widely based on the supplier and customization level. Understanding MOQ is critical for businesses to manage inventory and budget effectively, ensuring they can meet production demands without overcommitting resources. -

RFQ (solicitud de presupuesto)

An RFQ is a formal document sent by a buyer to suppliers requesting pricing and terms for specific products. In the cylinder water bottle sector, issuing an RFQ can help businesses gather competitive pricing and terms from various manufacturers, enabling informed decision-making and negotiation. -

Incoterms (Términos comerciales internacionales)

These are a set of rules that define the responsibilities of buyers and sellers for the delivery of goods. They outline who is responsible for shipping, insurance, and tariffs during transportation. Familiarity with Incoterms helps B2B buyers navigate logistics and reduce risks associated with international trade, particularly important for sourcing products from diverse regions. -

Certificación BPA-Free

This term indicates that a product does not contain Bisphenol A, a chemical often used in plastics that has raised health concerns. For cylinder water bottles, BPA-free certification is crucial for consumer safety and regulatory compliance, especially in food and beverage applications.

By understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions, ensuring they select the right cylinder water bottles for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cylinder water bottle Sector

What Are the Key Trends Driving the Cylinder Water Bottle Market?

The cylinder water bottle market is witnessing significant growth driven by several global factors. Increasing health consciousness among consumers has led to a surge in demand for convenient and portable hydration solutions, particularly in urban areas across Africa, South America, the Middle East, and Europe. Additionally, the rise of e-commerce platforms has reshaped the B2B landscape, allowing international buyers to access a broader range of suppliers and products. The emergence of innovative materials, such as PET and HDPE, has enabled manufacturers to produce lightweight, shatter-resistant bottles that cater to various applications, from beverages to personal care products.

Current sourcing trends indicate a shift toward customization, with brands seeking unique packaging solutions that enhance product visibility and appeal. This trend is particularly prominent in regions like Nigeria and Vietnam, where local manufacturers are exploring creative designs to differentiate their offerings. Furthermore, the increasing integration of technology in supply chain processes—such as digital inventory management and automated sourcing platforms—has streamlined operations, allowing B2B buyers to make informed decisions quickly.

How Does Sustainability Influence Sourcing in the Cylinder Water Bottle Sector?

Sustainability is becoming a critical factor for B2B buyers in the cylinder water bottle sector. The environmental impact of plastic waste has prompted businesses to prioritize ethical sourcing practices and sustainable materials. Buyers are increasingly seeking suppliers that offer products made from recyclable or biodegradable materials, such as BPA-free PET and HDPE. Certifications from recognized organizations, like the National Sanitation Foundation (NSF) and USDA, can serve as indicators of a supplier’s commitment to sustainability.

Moreover, companies are adopting sustainable practices across their supply chains to minimize their carbon footprint. This includes investing in energy-efficient production processes and exploring alternative materials that reduce reliance on single-use plastics. In regions like Europe, where environmental regulations are stringent, ethical sourcing and sustainability are not just preferences but requirements that can influence purchasing decisions. For international B2B buyers, partnering with suppliers that align with these values not only enhances brand reputation but also meets the expectations of environmentally conscious consumers.

What Has Been the Evolution of the Cylinder Water Bottle Market?

The evolution of the cylinder water bottle market can be traced back to the increasing demand for convenience and functionality in consumer packaging. Initially, glass bottles dominated the market due to their durability and aesthetic appeal. However, the shift towards plastic bottles in the late 20th century marked a significant turning point, as manufacturers sought to offer lighter, more portable options.

With advancements in polymer technology, the introduction of materials like PET and HDPE revolutionized the industry, allowing for greater customization and design flexibility. The rise of eco-conscious consumerism in the 21st century has further shaped the market, driving innovation toward sustainable practices and materials. Today, the cylinder water bottle sector continues to adapt, responding to evolving consumer preferences and regulatory standards, while providing B2B buyers with a diverse range of options that meet both functional and environmental needs.

Frequently Asked Questions (FAQs) for B2B Buyers of cylinder water bottle

-

How do I solve quality concerns when sourcing cylinder water bottles?

To address quality concerns, it’s crucial to thoroughly vet your suppliers. Request samples of the cylinder water bottles to evaluate their material, durability, and design before placing a bulk order. Ensure the manufacturer adheres to international quality standards, such as ISO certifications or FDA compliance for food-grade materials. Conducting a factory audit can also provide insights into production practices. Additionally, you can seek references from other businesses that have sourced from the supplier to gauge their reliability and quality. -

What is the best material for cylinder water bottles?

The best material for cylinder water bottles largely depends on your intended use. PET (Polyethylene Terephthalate) is popular for its lightweight, shatter-resistant properties, making it ideal for beverages. For products requiring higher durability or a more premium feel, HDPE (High-Density Polyethylene) is a robust choice. If sustainability is a priority, look for bottles made from recycled materials or those that are 100% recyclable. Always consider how the material interacts with the contents to ensure safety and longevity. -

What customization options are available for cylinder water bottles?

Customization options for cylinder water bottles include printing labels, choosing colors, and selecting different cap styles. Many suppliers offer the ability to print your branding directly onto the bottle, enhancing brand visibility. You can also request specific neck sizes for compatibility with different caps or dispensing mechanisms. Discuss your requirements with potential suppliers to explore available options, including minimum order quantities for customized products. -

What are the typical minimum order quantities (MOQ) for cylinder water bottles?

Minimum order quantities for cylinder water bottles vary by supplier, but they typically range from 1,000 to 10,000 units. Some manufacturers might accommodate lower MOQs for customized orders, while others may have set limits based on their production capabilities. It’s advisable to discuss your needs directly with suppliers to understand their MOQ policies and negotiate based on your business requirements. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary significantly based on the supplier and your negotiation. Common terms include a 30% deposit upfront with the balance due before shipping, or a letter of credit for larger orders. For new relationships, you might encounter more favorable terms after establishing trust. Always clarify payment methods (e.g., bank transfers, PayPal) and ensure that the terms are documented in your purchase agreement to avoid misunderstandings. -

How can I ensure timely delivery of cylinder water bottles?

To ensure timely delivery, establish clear timelines with your supplier, including production and shipping schedules. Discuss logistics options, such as air freight for quicker delivery or sea freight for cost-effective solutions. It’s also wise to consider potential delays due to customs clearance, especially when importing from different regions. Maintaining open communication with your supplier throughout the process can help you stay informed and address any issues promptly. -

What quality assurance measures should I implement when sourcing?

Implementing quality assurance measures involves setting clear specifications for the cylinder water bottles and conducting regular inspections during production. You can employ third-party inspection services to assess quality before shipment. Create a checklist that includes material compliance, design accuracy, and functional testing (e.g., leak-proof capability). This proactive approach minimizes the risk of receiving subpar products and ensures that they meet your standards. -

What are the key considerations for logistics when importing cylinder water bottles?

When importing cylinder water bottles, consider factors such as shipping costs, customs regulations, and packaging requirements. Understand the import duties and taxes applicable in your country to budget accordingly. Choose a reliable freight forwarder who can navigate international shipping complexities and ensure compliance with local regulations. Additionally, proper packaging is essential to protect the bottles during transit, so discuss options with your supplier to minimize damage risks.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 8 Cylinder Water Bottle Manufacturers & Suppliers List

1. Berlin Packaging - Botellas cilíndricas de plástico PET transparente de 2 oz.

Dominio: berlinpackaging.com

Inscrita: 1997 (28 años)

Introducción: 2 oz Clear PET Plastic Cylinder Bottles – Item # 3410B02-B

Cap Size: 20-410 (sold separately)

Material: Lightweight, shatter-resistant PET plastic

Price: $0.32 each

Free Shipping: Available for orders of $150+

Inventory Status: Currently unavailable

Características:

– Versatile and economical for various applications (shampoos, conditioners, household cleaners)

– Crystal clear with square, flat bases

– …

2. Bottlestore – Cylinder Plastic Bottles

Dominio: bottlestore.com

Inscrito: 1998 (27 años)

Introducción: Cylinder plastic bottles are commonly used for products like shampoo, conditioner, and body wash. They are versatile and can be decorated in various ways, making them popular for brands seeking a unique look. Available in smaller sizes for grab-and-go beverages and larger sizes for hair products, bubble baths, salts, or soap refills. Specific examples include 20ml translucent black PET Chubby Gori…

3. SnapOn – Cylinder Water Bottle

Dominio: ebay.es

Matriculado: 1995 (30 años)

Introducción: {“title”: “SnapOn Cylinder Water Bottle Lime Green New”, “condition”: “New”, “price”: “$25.00 or Best Offer”, “shipping”: “Free shipping”, “estimated_delivery”: “Fri, Aug 29 – Wed, Sep 3”, “local_collection”: “Free local collection in person over 60 mi from 85260”, “quantity_available”: “1”, “item_number”: “267015777512”, “brand”: “Unbranded”, “type”: “Water Bottle”, “description”: “SnapOn cylinde…

4. Wholesale Supplies Plus – Cylinder Plastic Bottles

Dominio: wholesalesuppliesplus.com

Matriculado: 1999 (26 años)

Introducción: This company, Wholesale Supplies Plus – Cylinder Plastic Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

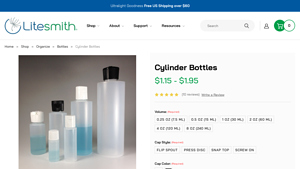

5. Litesmith – Cylinder Bottles

Dominio: litesmith.com

Registrado: 2014 (11 años)

Introducción: {‘product_name’: ‘Cylinder Bottles’, ‘price_range’: ‘$1.15 – $1.95’, ‘sizes_available’: [‘0.25 oz (7.5 ml)’, ‘0.5 oz (15 ml)’, ‘1 oz (30 ml)’, ‘2 oz (60 ml)’, ‘4 oz (120 ml)’, ‘8 oz (240 ml)’], ‘cap_styles’: [‘Flip Spout’, ‘Press Disc’, ‘Snap Top’, ‘Screw On’], ‘material’: {‘bottle’: ‘Low-Density Polyethylene (LDPE) for 0.25 to 4 oz, High-Density Polyethylene (HDPE) for 8 oz’, ‘cap’: ‘Polyethylene…

6. Sudekusa – Custom Labeled Water Bottles

Dominio: sudekusa.com

Inscrito: 2004 (21 años)

Introducción: Custom labeled cylinder style water bottles, size 16.9oz. Price range from $1.152 to $2.200 depending on quantity. Minimum order of 120 pieces. Setup charge: $150.00. Production time: 2-3 weeks. Available in purified water (purified by reverse osmosis, carbon filtration, and ozonation) and award-winning natural spring water. 100% BPA free and 100% recyclable. Eco-friendly rPET bottles made from re…

7. Gold Image Printing – 30 oz. Atlantic Water Bottle

Dominio: goldimageprinting.com

Inscrito: 2003 (22 años)

Introducción: 30 oz. Atlantic Cylindrical Plastic Water Bottle

8. Muji – Polyethylene Cylinder Bottle

Dominio: muji.us

Registered: 2002 (23 years)

Introducción: Polyethylene Cylinder Bottle with Snap Cap

Strategic Sourcing Conclusion and Outlook for cylinder water bottle

Strategic sourcing of cylinder water bottles offers significant advantages for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. By leveraging the versatility of these bottles, which are ideal for various applications from beverages to personal care products, businesses can enhance their product offerings while maintaining cost efficiency. The lightweight and durable nature of cylinder bottles enables more efficient logistics and storage, ultimately contributing to lower operational costs.

Moreover, adopting sustainable practices in sourcing—such as choosing BPA-free and recyclable materials—aligns with growing consumer demand for environmentally friendly products. This not only improves brand reputation but also opens doors to new market segments that prioritize sustainability.

As the global market continues to evolve, staying ahead of trends in packaging design and functionality will be crucial. We encourage international buyers to explore innovative options and strategic partnerships that can elevate their product lines. By investing in high-quality cylinder water bottles, businesses can meet consumer expectations while positioning themselves for future growth. Now is the time to take action—review your sourcing strategies and connect with reputable suppliers to unlock new opportunities.