Introduction: Navigating the Global Market for can you put a water bottle in the microwave

In today’s fast-paced global market, the question of whether you can put a water bottle in the microwave is more than just a matter of convenience; it encapsulates broader challenges in product safety and consumer health. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—you face the critical task of sourcing products that meet safety standards while also catering to local consumer preferences. This comprehensive guide delves into the nuances of microwave safety concerning water bottles, examining various plastic types, their applications, and the potential risks involved.

By outlining the essential criteria for selecting microwave-safe bottles, including material specifications and supplier vetting processes, this guide equips you with the knowledge necessary to make informed purchasing decisions. Additionally, we will explore cost considerations and market trends, ensuring that you not only understand the safety implications but also the economic factors that influence product viability. With actionable insights and authoritative recommendations, this resource empowers B2B buyers to navigate the complexities of sourcing water bottles suitable for microwave use, ultimately enhancing your product offerings and ensuring consumer satisfaction.

Artículo Navegación

- Top 9 Can You Put A Water Bottle In The Microwave Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for can you put a water bottle in the microwave

- Understanding can you put a water bottle in the microwave Types and Variations

- Key Industrial Applications of can you put a water bottle in the microwave

- 3 Common User Pain Points for ‘can you put a water bottle in the microwave’ & Their Solutions

- Strategic Material Selection Guide for can you put a water bottle in the microwave

- In-depth Look: Manufacturing Processes and Quality Assurance for can you put a water bottle in the microwave

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you put a water bottle in the microwave’

- Comprehensive Cost and Pricing Analysis for can you put a water bottle in the microwave Sourcing

- Alternatives Analysis: Comparing can you put a water bottle in the microwave With Other Solutions

- Essential Technical Properties and Trade Terminology for can you put a water bottle in the microwave

- Navigating Market Dynamics and Sourcing Trends in the can you put a water bottle in the microwave Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of can you put a water bottle in the microwave

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for can you put a water bottle in the microwave

Understanding can you put a water bottle in the microwave Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Microwave-Safe Plastic Bottles | Made from materials like PET, PP, or HDPE; labeled as microwave-safe | Food service, catering, beverage packaging | Pros: Safe for heating; lightweight. Contras: Limited heat resistance; potential leaching if not properly used. |

| Single-Use Plastic Bottles | Typically made of PET; designed for one-time use; often not microwave-safe | Events, quick-service restaurants | Pros: Convenient; readily available. Contras: Not suitable for heating; potential chemical release when microwaved. |

| Reusable Water Bottles | Often made from stainless steel or high-grade plastics; designed for multiple uses | Regalos de empresa, productos promocionales | Pros: Durable; eco-friendly. Contras: More expensive; may not be microwave-safe depending on material. |

| Botellas de vidrio para agua | Made from tempered glass; often labeled as microwave-safe; reusable | Health-conscious markets, premium brands | Pros: No chemical leaching; retains taste. Contras: Heavier; breakable, requiring careful handling. |

| Thermal Insulated Bottles | Double-walled; designed to maintain temperature; usually not microwave-safe | Outdoor activities, travel, corporate gifts | Pros: Excellent temperature retention; durable. Contras: Cannot be microwaved; higher cost. |

What Are Microwave-Safe Plastic Bottles and Their Suitability for B2B Buyers?

Microwave-safe plastic bottles are manufactured from materials such as polyethylene terephthalate (PET), polypropylene (PP), or high-density polyethylene (HDPE). These materials are specifically designed to withstand microwave heating without releasing harmful chemicals. For B2B buyers in the food service and catering industries, these bottles offer a practical solution for heating beverages quickly. However, it is crucial to ensure that these products are labeled as microwave-safe to mitigate risks associated with leaching or melting during heating.

How Do Single-Use Plastic Bottles Fit into the B2B Market?

Single-use plastic bottles, typically made from PET, are ubiquitous in the beverage industry, particularly for events and quick-service restaurants. While convenient for immediate consumption, these bottles are not designed for microwave use, raising concerns about chemical release when exposed to heat. B2B buyers should consider the environmental impact of single-use plastics and explore alternatives that align with sustainability goals, particularly in regions where environmental regulations are tightening.

What Advantages Do Reusable Water Bottles Offer for B2B Purchases?

Reusable water bottles are often made from high-grade plastics or stainless steel and are designed for multiple uses. They are ideal for corporate gifts or promotional products aimed at health-conscious consumers. While many reusable bottles are not microwave-safe, they do provide durability and eco-friendliness, appealing to businesses focused on sustainability. B2B buyers should assess the materials used in these products to ensure they meet safety standards for their intended use.

Why Consider Glass Water Bottles in Your B2B Strategy?

Glass water bottles are a premium option for businesses targeting health-conscious markets. Made from tempered glass, these bottles are often labeled as microwave-safe, allowing for safe heating of contents. They do not leach chemicals, preserving the taste and quality of beverages. However, the weight and fragility of glass can be a drawback for some applications. B2B buyers should weigh the benefits of taste retention against the potential for breakage during transport and use.

What Are the Characteristics of Thermal Insulated Bottles for B2B Buyers?

Thermal insulated bottles are designed to maintain the temperature of liquids for extended periods. While they offer excellent durability and temperature retention, these bottles are typically not microwave-safe due to their construction. B2B buyers in outdoor and travel markets should consider these products for their practicality and appeal to consumers seeking convenience. However, the inability to microwave these bottles should be a factor in purchasing decisions, particularly in settings where quick heating is required.

Key Industrial Applications of can you put a water bottle in the microwave

| Industria/Sector | Specific Application of can you put a water bottle in the microwave | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Alimentación y bebidas | Heating water for food preparation and beverages | Ensures quick and efficient heating, improving service speed | Seek microwave-safe bottles that meet local food safety regulations. |

| Healthcare | Preparing baby formula or medications | Provides a safe method for warming liquids, ensuring patient safety | Ensure bottles are BPA-free and comply with healthcare standards. |

| Hostelería | Catering services for events and restaurants | Allows for quick beverage service, enhancing customer experience | Source durable, reusable bottles that are easy to clean and maintain. |

| Educación | School cafeterias and childcare facilities | Facilitates safe heating of drinks for children, promoting health | Look for bottles with clear labeling for microwave safety compliance. |

| Retail and Distribution | Packaging for ready-to-drink beverages | Increases product versatility and consumer convenience | Choose materials that are both cost-effective and compliant with safety standards. |

How is ‘can you put a water bottle in the microwave’ used in the Food and Beverage Industry?

In the food and beverage sector, microwaving water bottles is commonly utilized for quickly heating water for cooking or beverage preparation. This application ensures that food service establishments can meet customer demands promptly, thereby enhancing service efficiency. For B2B buyers, it is crucial to source water bottles that are specifically labeled as microwave-safe, ensuring compliance with local food safety regulations to prevent contamination or chemical leaching.

What role does microwaving water bottles play in Healthcare?

In healthcare settings, particularly in pediatric care, the ability to safely warm liquids is vital for preparing baby formula or medications. Using microwave-safe water bottles allows healthcare professionals to provide a quick and reliable method of heating, which is essential for patient safety. Buyers in this sector should prioritize sourcing bottles made from materials free of harmful chemicals like BPA, and ensure they adhere to strict healthcare standards.

How does the Hospitality Industry benefit from microwaving water bottles?

Catering services and restaurants often rely on microwaving water bottles to expedite beverage service during events. This practice allows for the quick preparation of hot drinks, enhancing the overall customer experience. For businesses in this sector, sourcing durable and reusable bottles that can withstand frequent heating and cleaning is essential, as well as ensuring that they meet safety guidelines to prevent any risk of melting or chemical release.

Why is microwaving water bottles important in Educational Settings?

In schools and childcare facilities, the ability to safely heat drinks for children is crucial. Using microwave-safe water bottles ensures that caregivers can prepare beverages quickly without compromising safety. B2B buyers in education should focus on sourcing bottles that have clear, visible labels indicating microwave safety compliance, as well as those that are easy to clean and maintain for frequent use.

How does the Retail and Distribution Sector utilize microwavable water bottles?

In the retail and distribution sector, ready-to-drink beverages often come in microwave-safe packaging, allowing consumers to heat products conveniently. This versatility can enhance product appeal and customer satisfaction. For businesses sourcing these products, it is essential to choose materials that are not only cost-effective but also compliant with safety regulations to avoid any potential health risks associated with heating plastics.

3 Common User Pain Points for ‘can you put a water bottle in the microwave’ & Their Solutions

Scenario 1: Misleading Labeling of Water Bottles

El problema: In the B2B landscape, especially in markets where product regulations may vary, buyers often face the challenge of sourcing water bottles that are safe for microwave use. Many suppliers may not provide clear labeling regarding the microwave safety of their products. This can lead to purchasing bottles that warp, leach chemicals, or even explode in the microwave, posing safety risks and potential liability for businesses.

La solución: To mitigate this issue, B2B buyers should establish strong relationships with suppliers who adhere to stringent safety standards and provide transparent product information. When evaluating water bottles, look specifically for those marked with the “microwave-safe” symbol, which typically features a square with wavy lines inside. Conducting regular audits of suppliers’ safety certifications and product specifications can ensure that the products meet necessary safety criteria. Additionally, consider implementing a standardized checklist for product evaluation that includes microwave safety as a critical factor, thereby reducing the risk of purchasing unsafe items.

Scenario 2: Operational Efficiency and Employee Safety

El problema: In a busy workplace, employees may frequently need to heat water quickly, yet they might be unsure whether their water bottles are microwave-safe. This indecision can lead to delays in operations, increased frustration, and potential injuries from mishaps such as hot water spills or burns from improperly microwaved bottles. The lack of a clear policy or training on the safe use of water bottles in microwaves can further exacerbate these issues.

La solución: Companies should develop and disseminate clear guidelines on the appropriate use of water bottles in microwaves as part of their employee training programs. This could include a quick reference guide that outlines which types of bottles are safe for microwave use, emphasizing the importance of removing caps and checking for damage before microwaving. Regular training sessions can reinforce safe practices and empower employees to make informed decisions about their equipment. Additionally, consider investing in microwave-safe containers specifically designed for heating liquids, which can streamline operations and enhance employee safety.

Scenario 3: Environmental Concerns and Chemical Leaching

El problema: As global awareness of environmental issues rises, B2B buyers are increasingly concerned about the implications of using plastic water bottles in microwaves. Heating certain plastics can release harmful chemicals like BPA, which not only poses health risks but also contradicts sustainable business practices. This concern is particularly pronounced in regions where regulatory scrutiny on plastic use is intensifying.

La solución: To address environmental concerns, businesses should prioritize sourcing eco-friendly, microwave-safe water bottles made from materials such as polypropylene or high-density polyethylene. These materials are less likely to leach harmful chemicals when heated. Furthermore, companies can engage in responsible procurement practices by asking suppliers for certifications related to sustainability and chemical safety. Implementing a recycling program for used water bottles can also minimize environmental impact while promoting a culture of sustainability within the organization. Lastly, consider educating customers and employees on the benefits of using reusable, microwave-safe containers as part of a broader corporate social responsibility initiative.

Strategic Material Selection Guide for can you put a water bottle in the microwave

What Are the Key Materials for Water Bottles and Their Microwave Compatibility?

When considering the compatibility of water bottles with microwave use, several materials are commonly employed. Each material has distinct properties, advantages, and disadvantages that can significantly influence their performance in a microwave setting. Understanding these factors is crucial for B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

What Are the Properties of Polyethylene Terephthalate (PET) in Microwave Applications?

Polyethylene Terephthalate (PET) is widely used for single-use water bottles due to its lightweight and clear characteristics. PET has a temperature tolerance of up to 70°C (158°F), making it suitable for brief microwave exposure. However, it is crucial to note that PET is not designed for prolonged heating, as it may warp or leach chemicals if subjected to high temperatures for extended periods.

Pros: PET is cost-effective, lightweight, and recyclable, making it an attractive option for manufacturers. It is also transparent, allowing consumers to see the contents.

Contras: The primary limitation of PET is its low heat resistance, which can lead to deformation and potential chemical leaching when heated. This poses a risk for consumer safety and product integrity.

Impacto en la aplicación: PET is suitable for short-term heating applications but should not be used for boiling or prolonged microwave exposure.

Consideraciones para compradores internacionales: Buyers should ensure compliance with local regulations regarding food safety and plastic usage. Standards such as ASTM D6400 for compostability may also be relevant in regions with strict environmental policies.

How Does Polypropylene (PP) Perform in Microwave Settings?

Polypropylene (PP) is another common material for water bottles, particularly for reusable options. It boasts a higher temperature tolerance, typically around 120°C (248°F), making it more suitable for microwave applications compared to PET. PP is also resistant to chemical leaching, which enhances its safety profile.

Pros: PP is durable, has a high melting point, and is resistant to many chemicals, making it ideal for repeated use. It is also lightweight and cost-effective.

Contras: While PP is generally microwave-safe, it can still warp or degrade over time with repeated heating, especially if the bottle is of lower quality.

Impacto en la aplicación: PP is suitable for both short and moderate heating applications, making it a versatile choice for consumers looking to heat beverages.

Consideraciones para compradores internacionales: Buyers should check for certifications indicating microwave safety and compliance with local standards. In regions such as Europe, adherence to EU regulations on food contact materials is critical.

What Are the Characteristics of High-Density Polyethylene (HDPE) in Microwaving?

High-Density Polyethylene (HDPE) is commonly used for containers such as milk jugs and some reusable water bottles. It has a temperature tolerance of about 120°C (248°F) and is generally considered microwave-safe. However, similar to PP, HDPE may not withstand prolonged exposure to high temperatures.

Pros: HDPE is known for its strength, durability, and resistance to impact and chemicals. It is also recyclable and widely available.

Contras: HDPE can warp under high heat, which may compromise the integrity of the bottle. Additionally, it is less transparent than PET, making it difficult for consumers to see the contents.

Impacto en la aplicación: HDPE is suitable for moderate heating applications, but caution should be exercised to avoid overheating.

Consideraciones para compradores internacionales: Buyers should verify that HDPE products meet local safety standards, such as those set by ASTM or ISO, particularly in regions with stringent regulations on plastic use.

How Does Polycarbonate (PC) Compare in Microwave Use?

Polycarbonate (PC) is often used in high-end reusable water bottles due to its strength and clarity. However, it is essential to note that PC can release harmful chemicals like bisphenol A (BPA) when heated, making it a less favorable option for microwaving.

Pros: PC is highly durable, resistant to impact, and can withstand high temperatures.

Contras: The potential for chemical leaching when heated poses significant health risks, making it unsuitable for microwave use.

Impacto en la aplicación: Due to safety concerns, PC should not be used in microwave applications.

Consideraciones para compradores internacionales: Buyers should be aware of regulations banning BPA in certain regions, such as the European Union, and seek alternatives that are BPA-free.

Summary Table of Material Properties for Water Bottles in Microwave Use

| Material | Typical Use Case for can you put a water bottle in the microwave | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Tereftalato de polietileno (PET) | Single-use water bottles, short microwave heating | Cost-effective, recyclable | Low heat resistance, potential leaching | Bajo |

| Polipropileno (PP) | Reusable water bottles, moderate heating | High melting point, durable | Can warp with repeated heating | Medio |

| Polietileno de alta densidad (HDPE) | Milk jugs, some reusable bottles, moderate heating | Strong, durable, recyclable | Can warp under high heat | Medio |

| Polycarbonate (PC) | High-end reusable bottles, not recommended for microwaving | Highly durable, impact-resistant | Chemical leaching risk | Alta |

This analysis provides B2B buyers with a comprehensive understanding of the materials used in water bottles and their compatibility with microwave use, ensuring informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for can you put a water bottle in the microwave

What Are the Main Stages of Manufacturing Processes for Microwave-Safe Water Bottles?

Manufacturing microwave-safe water bottles involves several critical stages that ensure the final product is safe, durable, and compliant with industry standards. Understanding these stages can help B2B buyers make informed decisions when sourcing products.

Material Preparation: What Materials Are Used for Microwave-Safe Water Bottles?

The first step in the manufacturing process is material preparation. Typically, materials such as Polyethylene Terephthalate (PET), Polypropylene (PP), or High-Density Polyethylene (HDPE) are used for microwave-safe bottles. Each of these materials possesses unique properties that make them suitable for microwave use, such as heat resistance and low leaching potential.

During this stage, raw materials are sourced from certified suppliers to ensure quality. Manufacturers may conduct initial quality checks on these materials to confirm they meet specific standards, such as FDA approval for food contact safety.

Forming: How Are Water Bottles Shaped?

Once the materials are prepared, the next stage is forming. This process usually involves techniques like injection molding or blow molding.

-

Moldeo por inyección: This method involves injecting molten plastic into a mold to create the desired shape. It is widely used for producing complex designs and ensures uniform thickness, crucial for maintaining structural integrity during microwaving.

-

Moldeo por soplado: Commonly used for bottles, this process involves inflating a heated plastic tube into a mold. It allows for the creation of hollow containers and is efficient for mass production.

Both methods require precise control over temperature and pressure to ensure the final products are free from defects that could compromise safety.

Assembly: How Are Components Integrated?

In the assembly phase, various components, such as caps and seals, are integrated with the bottle body. These components must also be made from microwave-safe materials to ensure compatibility. Quality checks are performed at this stage to confirm that all parts fit correctly and function as intended.

Finishing: What Treatments Are Applied?

The final stage involves finishing processes, such as surface treatment and labeling. Surface treatments may include UV coatings to enhance durability and resistance to scratches. Labels often contain essential information, such as recycling symbols and safety warnings, which are crucial for consumer awareness.

What Quality Assurance Practices Are Followed in Water Bottle Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of microwave-safe water bottles. It ensures that products meet both safety and performance standards, which is particularly important for B2B buyers who need reliable products.

¿Qué normas internacionales son pertinentes para la garantía de calidad?

Manufacturers often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that the manufacturing process is consistently monitored and improved.

Additionally, industry-specific certifications like CE marking in Europe or FDA approval in the U.S. are vital for products intended for food contact. These certifications indicate that the products meet necessary safety and health requirements.

What QC Checkpoints Are Critical in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify any defects or issues early. Common checkpoints include:

-

Control de calidad entrante (IQC): This involves inspecting raw materials upon receipt to ensure they meet predefined specifications.

-

Control de calidad durante el proceso (IPQC): During manufacturing, periodic checks are performed to monitor process parameters and product quality. This stage helps catch defects before they become a larger issue.

-

Control de calidad final (CCF): After production, a final inspection is conducted to verify that the products meet all specifications and standards before packaging.

What Testing Methods Are Commonly Used for Microwave-Safe Water Bottles?

Various testing methods are employed to ensure the safety and performance of microwave-safe water bottles. These may include:

-

Leaching Tests: These tests assess whether harmful chemicals, such as BPA or phthalates, leach from the plastic when exposed to heat.

-

Thermal Stability Tests: This involves exposing the bottles to high temperatures to verify their structural integrity and performance.

-

Mechanical Testing: These tests evaluate the bottle’s resistance to impact and deformation, ensuring they can withstand typical handling and usage conditions.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers must be diligent in verifying supplier quality control measures to ensure they are sourcing safe and reliable products. Here are several strategies:

-

Realizar auditorías de proveedores: Regular audits can provide insight into a supplier’s manufacturing practices and adherence to quality standards. Buyers should look for evidence of ISO certification and compliance with relevant regulations.

-

Solicitar informes de calidad: Suppliers should be able to provide documentation demonstrating their quality control processes, including results from testing and inspections.

-

Contratar inspectores externos: Utilizing third-party inspection services can add an extra layer of assurance. These organizations can conduct independent assessments of the manufacturing process and product quality.

¿Cuáles son los matices del control de calidad y la certificación para los compradores B2B internacionales?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is crucial. Different regions may have varying regulations and standards that need to be adhered to.

-

Regional Compliance: Buyers should familiarize themselves with local regulations regarding food safety and packaging. For example, the EU has stringent guidelines for materials that come into contact with food.

-

Consideraciones culturales: Different markets may have unique consumer expectations and preferences. Therefore, understanding these cultural nuances can guide buyers in selecting products that align with local demands.

-

Barreras lingüísticas: Documentation and certifications may be in different languages, which could pose challenges in understanding compliance requirements. Buyers should ensure they have access to translations or interpreters when necessary.

By paying close attention to these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing microwave-safe water bottles, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you put a water bottle in the microwave’

Introducción

This guide is designed for B2B buyers looking to procure water bottles that are suitable for microwave use. Understanding the technical specifications and safety standards associated with microwavable water bottles is crucial to ensure compliance with health regulations and customer satisfaction. This checklist outlines the essential steps to make informed purchasing decisions that align with your business needs.

Primer paso: Defina sus especificaciones técnicas

Before initiating the sourcing process, clarify the technical requirements for the water bottles you intend to purchase. Key specifications include material type, size, and microwave safety ratings.

– Material Considerations: Look for bottles made from polyethylene terephthalate (PET) or polypropylene (PP), as these are generally deemed safe for microwave use.

– Capacidad: Determine the volume needed for your target market, ensuring it aligns with customer preferences.

Segundo paso: Research Regulatory Compliance

Verify that the water bottles meet relevant health and safety regulations applicable in your target markets, such as those enforced by the FDA or equivalent organizations in your region.

– Requisitos de etiquetado: Ensure that products are labeled as microwave-safe if they can be used in microwaves.

– Seguridad de los materiales: Investigate whether the materials used are free from harmful chemicals like BPA or phthalates, which can leach into beverages when heated.

Tercer paso: Evaluar posibles proveedores

Conduct a thorough assessment of potential suppliers to ensure they can meet your specific needs. This includes reviewing their product quality, certifications, and customer feedback.

– Company Profiles: Request detailed company profiles and product catalogs to understand their offerings better.

– Referencias: Seek references from other businesses within your industry to gauge supplier reliability and product performance.

Paso 4: Solicitud de muestras

Before finalizing any orders, request samples of the water bottles you are considering. This step allows you to assess the quality and functionality of the products firsthand.

– Microwave Testing: Conduct tests in a controlled environment to ensure the bottles perform safely in a microwave.

– Durability Assessment: Evaluate how well the bottles withstand heating and whether they maintain their structural integrity.

Paso 5: Negociar condiciones y precios

Once you have identified suitable suppliers and products, engage in discussions to negotiate pricing and terms of service.

– Bulk Pricing: Inquire about bulk purchase discounts that can significantly reduce costs.

– Condiciones de pago: Ensure that payment terms align with your cash flow needs, and discuss any warranties or return policies.

Paso 6: Establish a Quality Assurance Process

Implement a quality assurance process to monitor product quality and safety after procurement.

– Regular Inspections: Schedule regular inspections of incoming shipments to ensure compliance with your specifications.

– Customer Feedback Loop: Create a system to gather and analyze customer feedback regarding the usability and safety of the products.

Conclusión

By following this practical sourcing checklist, B2B buyers can make informed decisions when procuring microwave-safe water bottles. Adhering to these steps not only ensures product safety and compliance but also enhances customer satisfaction and brand reputation in the marketplace.

Comprehensive Cost and Pricing Analysis for can you put a water bottle in the microwave Sourcing

What Are the Key Cost Components for Sourcing Water Bottles Suitable for Microwaving?

When evaluating the costs associated with sourcing water bottles that are deemed safe for microwave use, it is essential to break down the cost structure into several key components: materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materiales: The choice of plastic significantly impacts cost. Microwave-safe plastics such as polypropylene (PP), high-density polyethylene (HDPE), and polyethylene terephthalate (PET) come at different price points. For instance, PP is often more expensive due to its heat resistance and safety features, while PET is generally more affordable but may have limitations in heat exposure.

-

Trabajo: Labor costs can vary widely based on the region of production. In countries like Nigeria or Brazil, labor might be less expensive compared to European nations. This can affect the overall production cost, especially if the manufacturing process is labor-intensive.

-

Gastos generales de fabricación: This encompasses costs associated with running the factory, including utilities, equipment maintenance, and administrative expenses. Facilities that are equipped with modern technology may have lower overhead costs due to efficiencies in production.

-

Herramientas: Initial tooling costs can be significant, especially if the design of the water bottle requires unique molds for production. Custom designs or specialized features that enhance microwave safety can increase these costs.

-

Control de calidad: Ensuring that the products meet safety standards is crucial, particularly for international markets. Companies must allocate budget for rigorous testing to confirm that materials do not leach harmful chemicals when microwaved, which can add to the overall cost.

-

Logística: Transportation costs, including shipping and handling, play a crucial role in the final price. Incoterms, which define the responsibilities of buyers and sellers in international shipping, can further influence logistics costs. For example, “Delivered Duty Paid” (DDP) terms may include customs duties, which can significantly affect pricing for buyers from different regions.

-

Margen: Finally, suppliers will include their profit margin in the pricing. This can vary based on market conditions, competition, and the perceived value of the product.

How Do Price Influencers Affect Sourcing Decisions for Water Bottles?

Several factors can influence the pricing of microwave-safe water bottles, including volume or minimum order quantities (MOQs), specifications and customization, materials used, quality certifications, supplier factors, and Incoterms.

-

Volumen/MOQ: Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their sales forecasts to optimize pricing.

-

Especificaciones/Personalización: Custom designs or features that enhance usability and safety may increase costs. Buyers must weigh the benefits of customization against the potential increase in price.

-

Materiales: The choice of material not only impacts safety but also the price. Buyers should seek materials that offer the best balance of safety, cost, and functionality.

-

Calidad/Certificaciones: Products certified by recognized safety standards can command higher prices. International buyers should consider the value of certifications that can facilitate market entry and consumer trust.

-

Factores del proveedor: Supplier reputation, reliability, and geographic location can also influence pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding the implications of different Incoterms is essential for international buyers. Terms that shift more responsibility to the buyer can affect the total landed cost of the products.

What Are the Best Negotiation Tips for International B2B Buyers?

To optimize costs and ensure a favorable purchasing experience, international B2B buyers should consider the following tips:

-

Comprender el coste total de propiedad (TCO): This includes not just the purchase price but also logistics, potential tariffs, and the long-term reliability of the product. A lower initial price may not always be the best value.

-

Leverage Volume Discounts: When negotiating with suppliers, emphasize potential order volumes to secure better pricing. Suppliers are often willing to offer discounts for large orders.

-

Explore Multiple Suppliers: Diversifying suppliers can provide leverage in negotiations. It allows buyers to compare prices and terms, ensuring they secure the best deal.

-

Be Informed on Local Regulations: Understanding local regulations regarding plastic safety can provide an edge in negotiations, particularly when discussing certifications and compliance.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better terms, prioritization in production schedules, and insights into future pricing trends.

Conclusión

Navigating the complexities of sourcing microwave-safe water bottles requires a keen understanding of the cost components and pricing influencers. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must approach sourcing strategically, leveraging negotiation tactics and thorough market knowledge to ensure cost-efficiency and safety in their purchases.

Alternatives Analysis: Comparing can you put a water bottle in the microwave With Other Solutions

Introduction: Exploring Alternatives to Microwaving Water Bottles

In today’s fast-paced world, finding efficient ways to heat water is crucial for both personal and commercial use. While microwaving a water bottle may seem convenient, various risks and limitations make it less than ideal. This section examines alternative methods to heat water, offering insights into their respective advantages and disadvantages for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe.

Cuadro comparativo

| Aspecto comparativo | Can You Put A Water Bottle In The Microwave | Electric Kettle | Stovetop Kettle |

|---|---|---|---|

| Rendimiento | Quick but risks overheating and melting | Fast and efficient | Moderate speed |

| Coste | Low (if using existing microwave) | Moderate initial cost | Low to moderate cost |

| Facilidad de aplicación | Simple but risky | User-friendly | Requires more effort |

| Mantenimiento | Minimal maintenance required | Limpieza regular necesaria | Requires manual upkeep |

| El mejor caso de uso | Quick, single-use heating | High volume and speed | Traditional cooking |

Desglose detallado de alternativas

Electric Kettle

Electric kettles are specifically designed for boiling water quickly and efficiently. With most models heating water in just a few minutes, they offer high performance and are ideal for settings that require rapid service, such as cafes or restaurants. The initial investment can be moderate, but the long-term benefits include energy efficiency and ease of use. Regular cleaning is necessary to prevent mineral buildup, but this maintenance is minimal compared to the risks associated with microwaving plastic bottles. Electric kettles are best suited for environments needing consistent hot water, making them a reliable choice for B2B buyers.

Stovetop Kettle

Stovetop kettles are a traditional method of heating water and can be found in various materials, including stainless steel and ceramic. While they may take longer to heat water compared to electric kettles, they offer a classic aesthetic appeal and can be used anywhere with a heat source. The cost is generally low to moderate, depending on the material and design. However, using a stovetop kettle requires more effort, as it involves monitoring the heat source and transferring the kettle from the stove to pour. This method is suitable for businesses that value a traditional approach or operate in locations where electricity might be an issue.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate method for heating water depends on various factors, including efficiency, cost, and specific use cases. For businesses requiring quick and efficient service, electric kettles present a superior alternative to microwaving water bottles. In contrast, stovetop kettles may appeal to those preferring a more traditional approach or operating in areas with limited electrical access. B2B buyers should carefully evaluate their operational needs, budget constraints, and the potential risks associated with each method to make an informed decision.

Essential Technical Properties and Trade Terminology for can you put a water bottle in the microwave

What Are the Key Technical Properties of Water Bottles Suitable for Microwave Use?

When considering the safety and functionality of water bottles in microwave applications, several critical technical properties must be evaluated. These specifications not only ensure product safety but also help in meeting consumer demands and regulatory standards.

1. Calidad del material

The type of plastic used in water bottles is paramount. Common materials include Polyethylene Terephthalate (PET), Polypropylene (PP), and High-Density Polyethylene (HDPE). PET, often used for single-use bottles, is acceptable for short microwave exposure but less heat-resistant than PP. Understanding material grades helps buyers select products that align with safety standards and consumer preferences, particularly in regions with stringent health regulations.

2. Resistencia al calor

Heat resistance is a measure of how well a material can withstand elevated temperatures without deforming or releasing harmful substances. Bottles labeled as microwave-safe typically have high heat resistance, which is crucial to prevent melting or warping. For B2B buyers, sourcing products with confirmed heat resistance ensures compliance with safety regulations and reduces liability risks.

3. Chemical Leaching Potential

Different plastics exhibit varying levels of chemical leaching when heated. Materials such as BPA-containing plastics can release toxic substances when exposed to high temperatures. It is critical for businesses to verify that their products are free from harmful chemicals, as this is increasingly demanded by consumers and regulators, particularly in markets like Europe and North America.

4. Capacity and Tolerance

Capacity refers to the volume of liquid a bottle can hold, while tolerance indicates the permissible variation in this capacity. Ensuring that bottles can hold specified volumes without risk of overflow or spillage during microwaving is essential for consumer satisfaction. For manufacturers, maintaining tight tolerances can enhance product quality and reduce returns.

5. Reciclabilidad

The recyclability of materials used in water bottles is increasingly important to environmentally conscious consumers. Bottles made from recyclable materials not only meet sustainability goals but also align with global efforts to reduce plastic waste. This property can be a significant selling point in B2B negotiations, especially with companies focused on corporate social responsibility.

What Are the Common Trade Terms Related to Microwave-Safe Water Bottles?

Understanding trade terminology is crucial for effective communication in B2B transactions, particularly when dealing with international suppliers and buyers. Here are some key terms relevant to this sector:

1. OEM (fabricante de equipos originales)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of water bottles, businesses might partner with OEMs to create custom designs or materials that meet specific microwave safety standards.

2. MOQ (Cantidad mínima de pedido)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers to understand, as it impacts inventory management and pricing strategies. Knowing the MOQ can help businesses plan their purchasing and stock levels effectively.

3. RFQ (solicitud de presupuesto)

An RFQ is a formal request to suppliers to provide pricing for specific products. In the case of microwave-safe water bottles, issuing an RFQ allows buyers to compare offers and ensure they receive competitive pricing based on desired specifications.

4. Incoterms (Términos comerciales internacionales)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. They clarify the responsibilities of buyers and sellers in shipping goods, including who is responsible for costs and risks during transportation. Understanding Incoterms is essential for B2B transactions involving international shipping of water bottles.

5. Plazos de entrega

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. This term is critical for businesses as it affects inventory levels and production schedules, particularly for seasonal products like water bottles that may see fluctuating demand.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing microwave-safe water bottles, ensuring safety, compliance, and marketability in their respective regions.

Navigating Market Dynamics and Sourcing Trends in the can you put a water bottle in the microwave Sector

What Are the Key Trends Influencing the Water Bottle Microwave Safety Market?

The market for water bottles that can be safely microwaved is influenced by several global drivers, including increased consumer awareness regarding health and safety, the push for sustainable materials, and evolving packaging regulations. As urbanization accelerates in regions such as Africa and South America, consumers seek convenience in their daily routines, prompting a rise in demand for quick-heating solutions like microwave-safe water bottles. This trend is particularly pronounced in countries like Nigeria and Brazil, where busy lifestyles drive the need for time-efficient products.

Emerging B2B technology trends include the development of advanced materials that can withstand microwave heating without releasing harmful chemicals. Manufacturers are increasingly investing in research to identify and produce plastics that are both microwave-safe and environmentally friendly. Additionally, there is a notable shift towards reusable bottles, spurred by consumer preferences for sustainable options. This trend is also reflected in Europe and the Middle East, where regulations are tightening around single-use plastics, prompting a demand for durable, microwave-safe alternatives.

International B2B buyers should pay close attention to certifications that indicate safety and sustainability, such as FDA approval for materials that can be used in microwave applications. By understanding these dynamics, businesses can better navigate sourcing decisions and align with consumer expectations for health-conscious and eco-friendly products.

How Are Sustainability and Ethical Sourcing Impacting the Water Bottle Market?

Sustainability has become a cornerstone of modern B2B sourcing strategies, particularly in the context of microwave-safe water bottles. The environmental impact of plastic waste is a pressing concern, driving businesses to seek materials that minimize ecological footprints. Ethical sourcing practices not only enhance brand reputation but also resonate with increasingly conscientious consumers who prefer products that reflect their values.

In the water bottle sector, the importance of ethical supply chains cannot be overstated. Companies are now expected to demonstrate transparency in their sourcing practices, ensuring that materials are procured responsibly and sustainably. This includes the use of recyclable and biodegradable materials, as well as adherence to fair labor practices throughout the supply chain. Certifications such as the Global Recycle Standard (GRS) and ISO 14001 can serve as benchmarks for sustainability, helping businesses to validate their claims.

Moreover, as the market evolves, there is a growing emphasis on the recyclability of microwave-safe plastics. Buyers should prioritize suppliers that offer products made from materials such as polyethylene terephthalate (PET) or polypropylene (PP), which are known for their recyclability and lower environmental impact. By aligning with suppliers committed to sustainability, businesses can enhance their market position while contributing positively to global environmental efforts.

What Is the Historical Context of Microwave-Safe Water Bottles?

The evolution of microwave-safe water bottles has been shaped by advancements in materials science and consumer safety awareness. Initially, most plastic containers were not designed to withstand the rigors of microwave heating, leading to safety concerns regarding chemical leaching. The introduction of microwave-safe plastics in the late 20th century marked a significant turning point, allowing consumers to heat water and other liquids more conveniently.

Over the years, as health and safety regulations evolved, manufacturers began to adopt stricter standards to ensure that their products could safely endure microwave heating without compromising user health. This historical progression has laid the groundwork for the current market, where consumer demand for convenience and safety intersects with the need for sustainable practices. As a result, today’s B2B buyers are presented with a broader array of options that meet both safety and environmental criteria, reflecting an industry that has matured in response to consumer needs and regulatory frameworks.

Frequently Asked Questions (FAQs) for B2B Buyers of can you put a water bottle in the microwave

-

1. How do I determine if a water bottle is microwave-safe?

To ascertain if a water bottle is microwave-safe, check for specific labeling. Look for the recycling symbol and ensure it is made from materials like polyethylene terephthalate (PET), polypropylene (PP), or high-density polyethylene (HDPE), which are generally safer for microwave use. Additionally, the bottle may have a microwave-safe symbol, typically depicted as a square with wavy lines inside. Always consult the manufacturer’s guidelines for precise information regarding the safety of their products in a microwave. -

2. What precautions should I take when microwaving a plastic water bottle?

Before microwaving a plastic water bottle, remove the cap to prevent pressure buildup and potential explosions. Ensure the bottle is free from any cracks or deformities that could lead to leaks. Heat the bottle in short intervals to prevent overheating, and monitor the water to avoid reaching a rolling boil, which can cause the bottle to warp or release harmful substances. Following these precautions can help ensure safe usage. -

3. Are there specific types of water bottles that are better suited for microwave use?

Yes, certain types of water bottles are designed to withstand microwave temperatures. Look for bottles made from polypropylene (PP) or high-density polyethylene (HDPE), as they are known for their heat resistance and lack of harmful chemical leaching. Single-use bottles labeled with the recycling symbol #1 (PET) can be used for brief microwave periods, but it’s best to opt for reusable options made from microwave-safe materials for regular use. -

4. How can I effectively vet suppliers for microwave-safe water bottles?

To vet suppliers for microwave-safe water bottles, review their product certifications and compliance with international safety standards. Request samples to test their microwave safety personally, and inquire about the materials used in production. Additionally, check supplier reviews and ratings, and consider their experience in exporting to your target markets in Africa, South America, or the Middle East, ensuring they understand regional regulations and customer needs. -

5. What minimum order quantities (MOQs) are typical for microwave-safe water bottles?

Minimum order quantities for microwave-safe water bottles can vary significantly based on the supplier and the customization options you require. Typically, MOQs range from 500 to 5,000 units. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Some suppliers may offer flexibility for new buyers, especially if you can demonstrate potential for repeat business or larger future orders. -

6. What payment terms should I expect when sourcing water bottles internationally?

Payment terms when sourcing internationally can vary by supplier and region. Common terms include a 30% deposit upfront with the remaining balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for added security. Always clarify payment methods accepted, including wire transfers or credit terms, and ensure you have a clear understanding of the currency exchange rates and potential transaction fees involved. -

7. How do I ensure quality assurance (QA) for imported water bottles?

To ensure quality assurance for imported water bottles, establish clear specifications and standards with your supplier before production begins. Implement regular inspections during the manufacturing process, and consider third-party quality control services to conduct thorough checks before shipping. Additionally, request certificates of compliance to verify that the bottles meet safety and regulatory requirements in your target markets. -

8. What logistics considerations should I keep in mind when importing water bottles?

When importing water bottles, consider factors such as shipping methods, customs regulations, and potential tariffs. Opt for reliable logistics partners experienced in handling your specific product type and understand the import regulations in your destination country. Plan for lead times, especially if customization is involved, and ensure you have adequate insurance coverage during transit to protect against damage or loss.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 9 Can You Put A Water Bottle In The Microwave Manufacturers & Suppliers List

1. Reddit – Plastic Safety Concerns

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: This company, Reddit – Plastic Safety Concerns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

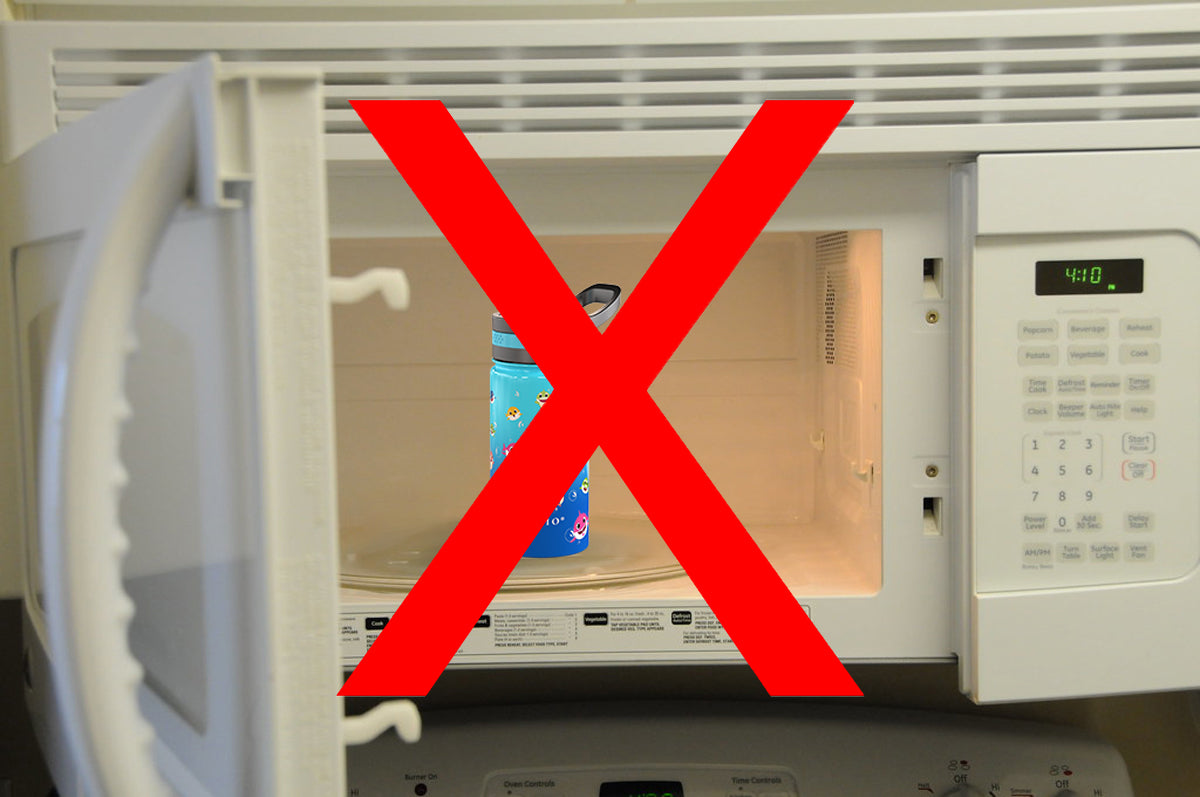

2. Buzio – Microwave-Safe Water Bottles

Dominio: buziolife.com

Inscrito: 2017 (8 años)

Introducción: Buzio water bottles are made of polyethylene terephthalate (PET), indicated by recycling symbol #1, which is microwave-safe. Users are advised to remove the cap before microwaving to prevent pressure build-up, avoid overfilling, and ensure the bottle is placed in the center of the microwave for even heating. It is recommended not to heat the water for more than two minutes to avoid scalding.

3. Bearaby – Hot Water Bottles

Dominio: bearaby.com

Registrado: 2018 (7 años)

Introducción: Hot water bottles are versatile for warmth and pain relief. Microwaving depends on the specific design; always check manufacturer guidelines. Overheating can cause burns, leaks, or safety hazards. Inspect materials, design, and labels to determine if microwavable.

4. Samply – Hot Water Bottles UZhen 1.7L & 1.2L

Dominio: samply.com

Inscrito: 2006 (19 años)

Introducción: Hot Water Bottle UZhen CAPACITY:1.7L, UZhen CAPACITY:1.2L

5. WaterBottle – Safety Guide

Dominio: waterbottle.tech

Registrado: 2018 (7 años)

Introducción: Hydro Flasks and Yeti Cups are not microwave safe due to their stainless steel construction, which can cause sparks and potential fire hazards when microwaved. The plastic components, such as caps and handles, may also not withstand high temperatures. It is recommended to transfer contents to a microwave-safe container for heating. Proper usage includes washing before first use, preheating or prec…

6. Facebook – Key Product

Dominio: facebook.com

Inscrita: 1997 (28 años)

Introducción: This company, Facebook – Key Product, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Parenting – Bottle Safety

Dominio: parenting.stackexchange.com

Inscrito: 2009 (16 años)

Introducción: This company, Parenting – Bottle Safety, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Hotties – Safe Microwave Hot Water Bottles

Dominio: thenakedscientists.com

Registered: 2001 (24 years)

Introducción: Hotties microwave hot water bottles are designed for safety and have been sold in the UK and Europe for over ten years without significant injuries or product liability claims. They are engineered to fail-safe in case of overheating, preventing dangerous ballooning or explosive failure. Hotties are particularly beneficial for the elderly, infirm, and disabled, and are designed to hold heat for aro…

9. Answers.com – Ice Expansion in Bottles

Dominio: answers.com

Matriculado: 1996 (29 años)

Introducción: When freezing water in a bottle, if the bottle is half-filled, it will remain intact due to the airspace accommodating the expansion of ice. However, if the bottle is completely filled, it is likely to crack or break because there is no airspace to absorb the expansion.

Strategic Sourcing Conclusion and Outlook for can you put a water bottle in the microwave

In conclusion, understanding the implications of microwaving water bottles is critical for B2B buyers in the consumer goods sector. While certain plastics are deemed microwave-safe, the potential risks associated with harmful chemicals leaching into food and beverages cannot be overlooked. It is essential for businesses to prioritize sourcing materials that meet safety standards and regulatory requirements. By investing in high-quality, microwave-safe products—like those made from polypropylene or high-density polyethylene—companies can enhance their product offerings while ensuring consumer safety.

As the global market continues to evolve, buyers from regions such as Africa, South America, the Middle East, and Europe should consider the growing demand for sustainable and safe packaging solutions. Engaging with suppliers who are committed to transparency and compliance will not only bolster brand reputation but also foster consumer trust.

Looking ahead, the strategic sourcing of microwave-safe products presents a unique opportunity for international buyers to lead in innovation and safety within their markets. Embrace the future of consumer safety and quality by aligning your sourcing strategies with best practices in product integrity.