Introduction: Navigating the Global Market for average water bottle oz

When sourcing average water bottle oz for your business, navigating the diverse landscape of options can be a daunting challenge. With a multitude of sizes ranging from compact 8 oz bottles to larger 64 oz variants, it’s crucial for international B2B buyers to understand which products best meet their needs. This guide delves into the various types of water bottles, their applications across different markets, and key considerations for supplier vetting and cost analysis.

Understanding the average water bottle oz is not just about choosing a size; it involves recognizing how these products fit into local hydration habits and consumer preferences in regions like Africa, South America, the Middle East, and Europe, including countries such as Brazil and Nigeria. By providing insights into market trends, popular sizes, and effective sourcing strategies, this guide empowers you to make informed purchasing decisions that align with your business goals.

Whether you are looking to enhance your product offerings or ensure compliance with local regulations, this comprehensive resource equips you with the knowledge to navigate the complexities of the global water bottle market effectively. With clear, actionable insights, you can confidently approach your suppliers, ensuring that you select products that not only meet customer expectations but also drive your business success.

Artículo Navegación

- Top 3 Average Water Bottle Oz Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for average water bottle oz

- Understanding average water bottle oz Types and Variations

- Key Industrial Applications of average water bottle oz

- 3 Common User Pain Points for ‘average water bottle oz’ & Their Solutions

- Strategic Material Selection Guide for average water bottle oz

- In-depth Look: Manufacturing Processes and Quality Assurance for average water bottle oz

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘average water bottle oz’

- Comprehensive Cost and Pricing Analysis for average water bottle oz Sourcing

- Alternatives Analysis: Comparing average water bottle oz With Other Solutions

- Essential Technical Properties and Trade Terminology for average water bottle oz

- Navigating Market Dynamics and Sourcing Trends in the average water bottle oz Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of average water bottle oz

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for average water bottle oz

Understanding average water bottle oz Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| 8 oz Bottle | Compact size, ideal for children and events | Events, promotions, kids’ products | Pros: Lightweight, easy to transport. Contras: Frequent refills needed for adults. |

| 16.9 oz Bottle | Standard size, commonly used in single-use bottles | Retail, vending machines | Pros: Popular choice, widely available. Contras: Limited hydration for active users. |

| 20 oz Bottle | Slightly larger, balances portability and capacity | Gyms, offices, travel | Pros: Convenient size, good for daily use. Contras: May require refilling for heavy users. |

| 32 oz Bottle | Larger capacity, ideal for outdoor activities | Sports, outdoor events | Pros: Reduces refill frequency, great for hydration. Contras: Más voluminoso de llevar. |

| 64 oz Bottle | Extra-large capacity for serious hydration needs | Fitness, camping, long trips | Pros: Ideal for extended use, fewer refills. Contras: Heavy and cumbersome to transport. |

What Are the Key Characteristics of an 8 oz Water Bottle?

The 8 oz water bottle is designed for portability and convenience, making it an excellent choice for children’s events or promotional giveaways. Its compact size ensures easy handling, but it may not meet the hydration needs of adults during extended activities. B2B buyers should consider this bottle for marketing campaigns or child-focused events, as it allows for custom branding while being lightweight and cost-effective.

How Does the 16.9 oz Water Bottle Stand Out in the Market?

As the most common water bottle size, the 16.9 oz option is widely recognized and frequently used in retail and vending applications. It strikes a balance between convenience and hydration, making it suitable for everyday use. B2B buyers can benefit from its popularity by stocking up for events or distribution in high-traffic areas. However, its relatively smaller capacity may not suffice for active individuals who require more hydration.

Why Choose a 20 oz Water Bottle for Daily Use?

The 20 oz water bottle is a versatile option that caters to a broad range of users, from office workers to gym-goers. This size provides a manageable balance between capacity and portability, making it ideal for daily hydration needs. For B2B buyers, this bottle is a strong candidate for corporate branding or employee wellness programs. However, those who engage in high-intensity activities may still find themselves refilling frequently.

What Are the Advantages of a 32 oz Water Bottle for Outdoor Activities?

The 32 oz water bottle is particularly beneficial for outdoor enthusiasts and athletes, as it offers ample hydration without the need for constant refills. Its larger capacity is perfect for hiking, sports events, or camping trips, where access to water may be limited. B2B buyers should consider this size for promotional items aimed at fitness or outdoor markets. However, its bulkier design can be a drawback for those seeking lightweight options.

When Is a 64 oz Water Bottle Necessary for Hydration?

The 64 oz water bottle is designed for serious hydration needs, making it an essential choice for fitness enthusiasts and individuals on long outdoor excursions. Its substantial capacity minimizes the need for refills, ensuring users stay hydrated throughout their activities. B2B buyers should target this option for specialized markets such as gyms or camping retailers. However, the weight and size can be cumbersome, which may deter casual users from choosing this option.

Key Industrial Applications of average water bottle oz

| Industria/Sector | Specific Application of average water bottle oz | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Alimentación y bebidas | Custom-branded bottled water for events | Enhances brand visibility and customer experience | Quality of materials, labeling options, and compliance with local regulations |

| Sports & Fitness | Hydration solutions for gyms and fitness centers | Meets hydration needs of clients, promoting health and wellness | Durability, ease of use, and size variations to accommodate different activities |

| Hospitality & Tourism | In-room bottled water for hotels | Improves guest satisfaction and adds to the luxury experience | Sourcing sustainable options, packaging design, and cost-effectiveness |

| Educación | Water bottles for schools and universities | Supports student health and hydration, reducing waste | Bulk purchasing options, safety standards, and custom branding for school spirit |

| Corporate Gifts & Promotions | Promotional water bottles for corporate events | Strengthens brand loyalty and provides practical giveaways | Customization options, pricing for bulk orders, and timely delivery |

How is average water bottle oz utilized in the Food & Beverage industry?

In the Food & Beverage sector, companies often use average water bottle sizes, especially the 16.9 oz and 20 oz formats, for custom-branded bottled water at events. This application enhances brand visibility while providing hydration to attendees. Businesses must consider the quality of materials used in the bottles, ensuring they comply with local health regulations, especially in regions like Africa and South America, where regulations may vary significantly. Custom labeling options also play a vital role in creating a memorable brand experience.

What are the applications of average water bottle oz in Sports & Fitness?

In gyms and fitness centers, average water bottle sizes such as 20 oz or 32 oz are crucial for providing hydration solutions. These bottles cater to the diverse needs of clients engaging in various physical activities, promoting health and wellness. B2B buyers in this sector should prioritize durability and ease of use in their sourcing decisions, as well as consider the size variations that accommodate different workout intensities. This ensures that members remain hydrated throughout their fitness journeys, enhancing their overall experience.

Why is average water bottle oz important for Hospitality & Tourism?

Hotels and resorts often provide in-room bottled water, typically in 16.9 oz sizes, to enhance guest satisfaction and contribute to a luxurious experience. This application not only meets the hydration needs of guests but also serves as a branding opportunity for the hotel. For international buyers, sourcing sustainable options is crucial, as eco-conscious practices are increasingly valued by travelers. Additionally, packaging design and cost-effectiveness are key considerations to ensure a positive return on investment.

How does average water bottle oz support Education?

In educational institutions, water bottles ranging from 12 oz to 20 oz are provided to students to promote hydration and health. This application supports initiatives aimed at reducing waste, particularly when schools opt for reusable bottles. Buyers in this sector should focus on bulk purchasing options and safety standards, ensuring that the bottles are made from non-toxic materials. Custom branding can also foster school spirit, making these bottles not just functional but also a source of pride for students.

What role do average water bottle oz play in Corporate Gifts & Promotions?

Promotional water bottles, typically sized around 16.9 oz, are popular giveaways at corporate events. They serve as practical items that enhance brand loyalty while providing hydration to recipients. For B2B buyers in this space, customization options are vital, allowing companies to imprint their logos and messages. Pricing for bulk orders and timely delivery are also critical factors that influence sourcing decisions, particularly for international businesses looking to maximize their promotional efforts.

3 Common User Pain Points for ‘average water bottle oz’ & Their Solutions

Scenario 1: Confusion Over Standard Sizes for Bulk Orders

El problema: B2B buyers often face confusion when ordering water bottles in bulk, particularly regarding the average ounces per bottle. With a wide variety of sizes available—from 8 oz to 64 oz—buyers may struggle to determine which size best fits their needs. This confusion can lead to over-ordering or under-ordering, resulting in wasted resources or insufficient supply for events, promotions, or retail needs. Buyers in regions like Africa or South America, where access to reliable product information may be limited, find this especially challenging.

La solución: To navigate this issue, B2B buyers should establish clear specifications for their water bottle needs before placing an order. This involves evaluating the target audience and the intended use of the bottles—whether for events, retail, or distribution. Create a chart that outlines the common sizes, their capacities, and their typical applications (e.g., 8 oz for kids, 16.9 oz for standard use, 32 oz for outdoor events). Additionally, partner with suppliers who provide detailed product catalogs and samples. This proactive approach allows buyers to visualize the sizes and make informed decisions, ultimately streamlining the ordering process and ensuring that they have the right quantities on hand.

Scenario 2: Balancing Portability and Capacity for Different Markets

El problema: B2B buyers operating in diverse markets often grapple with the challenge of balancing portability and capacity in their water bottle offerings. For instance, buyers in urban areas may prefer smaller, lightweight bottles for convenience, while those in rural or outdoor settings may require larger bottles for longer hydration needs. This disparity can lead to mismatches between product offerings and consumer demand, impacting sales and customer satisfaction.

La solución: To effectively cater to various markets, buyers should conduct thorough market research to understand regional preferences regarding water bottle sizes. Engage with local distributors and retailers to gather insights about customer behaviors and preferences. Based on this data, curate a product line that includes a range of sizes—small (8-12 oz) for urban consumers, medium (16-24 oz) for everyday use, and large (32-64 oz) for outdoor enthusiasts. Furthermore, consider offering customizable options that allow customers to choose sizes that best fit their specific needs. This strategy not only enhances customer satisfaction but also positions the buyer as a responsive and versatile supplier in the market.

Scenario 3: Environmental Concerns and Sustainability in Water Bottle Sizing

El problema: As sustainability becomes a key consideration for consumers, B2B buyers are increasingly pressured to choose water bottle sizes that minimize environmental impact. The average water bottle size can significantly affect the amount of plastic waste generated, especially with single-use options. Buyers are often uncertain about how to balance consumer demand for convenience with their responsibility to reduce waste, which can lead to reputational risks and missed market opportunities.

La solución: To address these concerns, buyers should prioritize sourcing reusable water bottles and educate their customers on the environmental benefits of these options. Focus on promoting average sizes that encourage refilling rather than single-use consumption. For instance, a 20 oz reusable bottle can be marketed as an ideal choice for daily hydration, significantly reducing plastic waste compared to smaller, single-use bottles. Additionally, consider partnering with suppliers that offer eco-friendly materials and sustainable manufacturing practices. Providing clear messaging about the environmental impact of different bottle sizes can also resonate with eco-conscious consumers, enhancing brand loyalty and positioning the buyer as a leader in sustainable practices within the industry.

Strategic Material Selection Guide for average water bottle oz

What Are the Most Common Materials for Average Water Bottles?

When selecting materials for average water bottles, it’s essential to consider the properties, advantages, and limitations of each option. This analysis focuses on four common materials: plastic, stainless steel, aluminum, and glass. Each material offers unique characteristics that can impact performance, cost, and suitability for various applications.

How Does Plastic Perform in Water Bottle Manufacturing?

Plastic, particularly polyethylene terephthalate (PET) and high-density polyethylene (HDPE), is widely used for water bottles due to its lightweight nature and cost-effectiveness. PET bottles are commonly found in single-use applications, while HDPE is often used for reusable bottles.

Propiedades clave: Plastic bottles can withstand moderate temperature variations but are not suitable for high-pressure applications. They are resistant to corrosion and generally safe for food and beverage use.

Pros y contras: The primary advantages of plastic include low manufacturing costs and versatility in design. However, they can be less durable than metal options, especially under extreme conditions. Additionally, concerns over leaching chemicals from plastic can deter environmentally conscious consumers.

Impacto en la aplicación: Plastic bottles are compatible with a wide range of beverages but may not be suitable for hot liquids.

Consideraciones para compradores internacionales: Compliance with local regulations regarding food safety and environmental impact is crucial. For instance, in Europe, compliance with EU regulations on food contact materials is mandatory, while in Africa and South America, standards may vary significantly.

What Are the Benefits of Using Stainless Steel for Water Bottles?

Stainless steel is a popular choice for reusable water bottles, known for its durability and resistance to corrosion.

Propiedades clave: Stainless steel can withstand high temperatures and pressures, making it suitable for hot beverages. It is also resistant to rust and staining, ensuring a longer lifespan.

Pros y contras: The main advantage of stainless steel is its durability and ability to maintain beverage temperature, whether hot or cold. However, it comes at a higher cost compared to plastic, and its heavier weight can be a disadvantage for portability.

Impacto en la aplicación: Stainless steel bottles are ideal for outdoor activities and sports, where durability and temperature retention are critical.

Consideraciones para compradores internacionales: Buyers should ensure compliance with international standards such as ASTM for material safety and performance. Additionally, the preference for insulated options is growing in markets like Europe and North America.

Why Choose Aluminum for Average Water Bottles?

Aluminum is another viable option, especially for lightweight and portable water bottles.

Propiedades clave: Aluminum bottles are lightweight and can be coated to prevent corrosion. They can handle moderate temperature changes but are not suitable for extreme heat.

Pros y contras: The key advantage of aluminum is its lightweight nature, making it easy to carry. However, it may dent easily and is less durable than stainless steel. Additionally, the cost can be higher than plastic.

Impacto en la aplicación: Aluminum bottles are suitable for cold beverages and are often used in promotional items due to their customizable surfaces.

Consideraciones para compradores internacionales: Compliance with local regulations regarding food safety is essential. In regions like the Middle East, where temperatures can be extreme, aluminum’s limitations should be considered.

What Role Does Glass Play in Water Bottle Selection?

Glass water bottles are gaining popularity due to their aesthetic appeal and safety.

Propiedades clave: Glass is inert, meaning it does not leach chemicals, and can handle high temperatures. However, it is fragile and can break easily.

Pros y contras: The primary advantage of glass is its safety and the ability to preserve the taste of beverages. However, the fragility and weight can be significant drawbacks, particularly for active users.

Impacto en la aplicación: Glass bottles are ideal for home use or in settings where aesthetics matter, but they are less suitable for travel or outdoor activities.

Consideraciones para compradores internacionales: Glass bottles must comply with stringent safety standards, particularly in regions with high transit volumes. Buyers should also consider the environmental impact of glass production and recycling.

Summary Table of Material Selection for Average Water Bottles

| Material | Typical Use Case for average water bottle oz | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plástico | Single-use and reusable water bottles | Ligero y rentable | Less durable, potential leaching | Bajo |

| Acero inoxidable | Reusable water bottles for outdoor use | Duradero y conserva la temperatura | Higher cost, heavier weight | Alta |

| Aluminio | Lightweight promotional water bottles | Easy to carry | Prone to dents, moderate durability | Medio |

| Vidrio | Aesthetic and safe home use | No chemical leaching | Frágil y pesado | Medio |

This guide provides a comprehensive overview of material options for average water bottles, highlighting essential factors for B2B buyers across various regions. Understanding these materials will aid in making informed purchasing decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for average water bottle oz

What Are the Main Stages of Manufacturing Processes for Average Water Bottle Sizes?

The manufacturing of average water bottles, particularly those ranging from 8 oz to 64 oz, involves several critical stages. Understanding these processes is essential for B2B buyers looking for quality products.

1. Material Preparation: What Materials Are Used in Water Bottle Production?

The first stage in the manufacturing process is material preparation. Most water bottles are made from plastic (such as PET, HDPE, or PP) or glass. The selection of material significantly impacts the bottle’s durability, safety, and environmental footprint.

- Plastic Bottles: Polyethylene Terephthalate (PET) is commonly used for its lightweight and recyclable properties. High-Density Polyethylene (HDPE) is also popular due to its strength and resistance to impact.

- Glass Bottles: Glass is preferred for premium products, as it is non-reactive and preserves the taste of the water. However, it is heavier and more fragile.

Once the materials are selected, they undergo quality checks to ensure they meet international safety standards.

2. Forming: How Are Water Bottles Shaped?

The forming process typically involves one of two techniques: blow molding or injection molding.

- Blow Molding: This method is predominantly used for plastic bottles. In blow molding, pre-formed plastic is heated and inflated into a mold to create the desired bottle shape. This technique is efficient for mass production and allows for various bottle sizes, including the popular 16.9 oz variant.

- Injection Molding: This technique is often used for creating caps and sometimes bottles with complex shapes. The molten plastic is injected into molds, where it cools and solidifies into the final product.

What Are the Key Steps in the Assembly and Finishing Processes?

Following the forming stage, the bottles move to assembly and finishing processes, which ensure they are ready for packaging.

3. Assembly: What Components Are Included?

The assembly process involves attaching various components like caps and labels. For bottles that require insulation, additional layers may be added during this stage.

- Cap Production: Caps are typically produced through injection molding and may include features like child safety mechanisms or tamper-evident seals.

- Labeling: Labels are applied either through direct printing or adhesive application. Custom branding options are often available for B2B buyers, enhancing marketing efforts.

4. Finishing: How Is Quality Enhanced?

Finishing processes include inspection and cleaning. Bottles are often rinsed and sanitized before packaging. This step is crucial for ensuring that the bottles are free from contaminants and safe for use.

How Is Quality Assurance Conducted in Water Bottle Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet both customer expectations and regulatory standards.

Relevant International Standards for Water Bottle Quality

For B2B buyers, understanding the applicable international standards is vital. ISO 9001 is the benchmark for quality management systems, ensuring manufacturers consistently meet customer and regulatory requirements.

- Marcado CE: In Europe, CE marking signifies compliance with safety, health, and environmental protection standards.

- API Standards: For bottles used in specific industries, such as pharmaceuticals, adherence to API (American Petroleum Institute) standards may be required.

What Are the Key QC Checkpoints in the Production Process?

Quality Control (QC) checkpoints are established at various stages to ensure product integrity.

1. Incoming Quality Control (IQC)

Before production begins, materials undergo IQC. This step involves verifying the quality of raw materials, ensuring they meet predefined specifications.

2. In-Process Quality Control (IPQC)

During manufacturing, IPQC checks are performed at various intervals. This includes monitoring the forming process, ensuring dimensions and weights of the bottles conform to specifications.

3. Final Quality Control (FQC)

Upon completion of production, FQC involves a thorough inspection of the finished products. This includes testing for leaks, checking label alignment, and ensuring that caps fit securely.

What Testing Methods Are Commonly Used in Water Bottle Quality Assurance?

Several testing methods are used to evaluate the quality of water bottles.

- Pruebas de estanqueidad: Ensures that bottles do not leak under pressure, which is essential for maintaining product integrity during transport and storage.

- Pruebas de materiales: Involves assessing the physical and chemical properties of the materials used to ensure they meet safety standards.

- Pruebas de durabilidad: Bottles are subjected to stress tests to evaluate their resistance to impact and temperature variations.

¿Cómo pueden los compradores B2B verificar las prácticas de control de calidad de los proveedores?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier QC practices is crucial.

1. Supplier Audits

Conducting supplier audits allows buyers to assess manufacturing processes and quality control measures firsthand. Audits should focus on compliance with international standards and the effectiveness of the QA system.

2. Quality Reports

Requesting quality reports can provide insights into past performance and adherence to standards. These reports often include data on defect rates, test results, and corrective actions taken.

3. Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate manufacturing facilities and processes, ensuring compliance with international quality standards.

¿Cuáles son los matices del control de calidad y la certificación para los compradores B2B internacionales?

When sourcing water bottles globally, understanding the nuances of QC and certifications is essential.

- Cultural and Regulatory Differences: Different regions may have varying regulations regarding product safety and quality. Familiarity with local standards can help avoid compliance issues.

- Sustainability Certifications: As sustainability becomes increasingly important, buyers may want to look for suppliers with certifications like ISO 14001, which focuses on effective environmental management systems.

In conclusion, understanding the manufacturing processes and quality assurance practices for average water bottle sizes equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on material quality, manufacturing techniques, and rigorous quality control, businesses can ensure they are sourcing high-quality products that meet market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘average water bottle oz’

Introducción

When sourcing average water bottles, especially for international markets, it’s essential to have a clear and organized approach. This guide provides a practical checklist to help B2B buyers navigate the complexities of procuring water bottles in various sizes, ensuring that the products meet their specific needs while adhering to local regulations and market preferences.

Primer paso: Determine Your Target Market Needs

Understanding the preferences and requirements of your target market is crucial. Different regions may have varying standards for bottle sizes, materials, and labeling. For instance, while 16.9 oz (500 ml) bottles are common in many markets, some areas may favor larger or smaller sizes. Conduct market research to identify the most popular bottle sizes in your target regions, such as Africa or South America.

Segundo paso: Defina sus especificaciones técnicas

Clearly outline the specifications of the water bottles you wish to procure. This includes the size (e.g., 8 oz, 16.9 oz), material (plastic, glass, stainless steel), and design features (e.g., insulated, collapsible). Having a well-defined specification helps streamline communication with suppliers and ensures that the products meet your quality standards.

- Consider Regulatory Compliance: Different countries have specific regulations regarding food safety and packaging. Ensure your specifications align with these requirements.

Tercer paso: Evaluar posibles proveedores

Before finalizing a supplier, it’s essential to conduct a thorough evaluation. Look for suppliers with a proven track record in the industry, especially those experienced in exporting to your target regions. Request documentation such as company profiles, certifications, and customer references.

- Evaluar la capacidad de producción: Ensure the supplier can meet your order volumes and delivery timelines, especially during peak demand periods.

Paso 4: Solicitud de muestras para la evaluación de la calidad

Always request samples before placing a bulk order. This step allows you to evaluate the quality, durability, and design of the bottles. Pay attention to the labeling options, as custom branding can significantly enhance your product’s marketability.

- Test for Compliance: Check that the samples comply with local health and safety standards, ensuring they are safe for consumer use.

Paso 5: Negociar precios y condiciones de pago

Once you have identified a suitable supplier, engage in negotiations regarding pricing, minimum order quantities, and payment terms. It’s essential to achieve a balance between cost-effectiveness and quality.

- Consider Long-term Partnerships: Building a long-term relationship with suppliers can lead to better pricing and more favorable terms in future transactions.

Paso 6: Finalize Logistics and Shipping Arrangements

Planning logistics is vital to ensure timely delivery and cost efficiency. Discuss shipping options with your supplier, considering factors like freight costs, delivery times, and customs regulations.

- Include Packaging Specifications: Ensure that the bottles are packaged in a manner that prevents damage during transit, which can be particularly important for international shipments.

Paso 7: Establish a Feedback Loop

After the products have been delivered, establish a feedback mechanism to assess customer satisfaction and product performance. This information is invaluable for making future sourcing decisions and improving product offerings.

- Monitor Market Trends: Stay updated on changing consumer preferences and market dynamics to adjust your sourcing strategy accordingly.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing average water bottles, ensuring they meet market demands while maintaining quality and compliance.

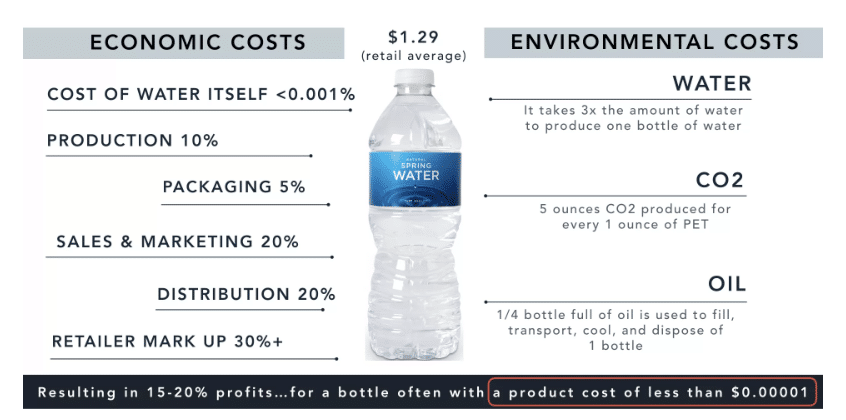

Comprehensive Cost and Pricing Analysis for average water bottle oz Sourcing

What Are the Key Cost Components in Sourcing Average Water Bottles?

Understanding the cost structure for sourcing average water bottles in various sizes is crucial for B2B buyers looking to make informed purchasing decisions. The primary cost components include:

-

Materiales: The choice of materials significantly impacts the overall cost. Common materials for water bottles include PET (Polyethylene Terephthalate) for disposable bottles and stainless steel or BPA-free plastics for reusable options. The price of raw materials can fluctuate based on market demand and availability.

-

Trabajo: Labor costs encompass wages for factory workers involved in the production process. These costs vary by region, with labor being generally more affordable in developing countries compared to industrialized nations.

-

Gastos generales de fabricación: This includes expenses related to utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce these overheads, thus lowering the overall production cost.

-

Herramientas: Initial costs for molds and other tooling necessary for bottle production can be substantial. These costs are typically amortized over large production runs, making it important to consider minimum order quantities (MOQs) to spread out these expenses.

-

Control de calidad: Ensuring that the water bottles meet safety and quality standards is essential. QC processes may add to the cost, but they are critical for minimizing defects and ensuring customer satisfaction.

-

Logística: Shipping and handling costs must be factored in, especially for international buyers. These costs can vary significantly based on the shipping method, distance, and Incoterms selected.

-

Margen: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and perceived value.

What Influences Pricing for Average Water Bottles?

Several factors can influence the pricing of average water bottles, particularly for international B2B buyers:

-

Volumen/MOQ: Larger orders often lead to reduced per-unit costs. Suppliers are generally more willing to negotiate favorable pricing for bulk purchases, making it essential to understand your demand to leverage better deals.

-

Especificaciones y personalización: Custom labels, unique designs, or specific materials can increase costs. Buyers should weigh the benefits of customization against the additional expenses incurred.

-

Materials Quality and Certifications: Higher-quality materials or certifications (e.g., FDA approval, ISO standards) may come at a premium but can enhance the product’s marketability and safety.

-

Factores del proveedor: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the costs and risks during shipping. Terms such as FOB (Free on Board) or CIF (Cost Insurance and Freight) can significantly affect the total landed cost of the bottles.

What Tips Can Help Buyers Negotiate Better Prices?

International B2B buyers can adopt several strategies to enhance cost-efficiency and achieve better pricing:

-

Negotiate with Multiple Suppliers: Request quotes from various suppliers to gain insights into market pricing. This competitive approach can provide leverage during negotiations.

-

Considerar el coste total de propiedad (TCO): Evaluate not just the upfront costs but also potential ongoing expenses such as logistics, storage, and disposal. Understanding TCO can lead to more informed decisions.

-

Centrarse en la rentabilidad: Look for suppliers who offer efficient logistics solutions or bulk discounts. This can help minimize shipping costs, especially for international buyers facing high freight charges.

-

Be Aware of Pricing Nuances in Different Regions: Pricing structures can vary widely across regions due to local economic conditions, tariffs, and regulations. Understanding these nuances can help buyers make more strategic sourcing decisions.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and other variables. Always conduct thorough research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing average water bottle oz With Other Solutions

Introducción a las soluciones alternativas para la hidratación

When it comes to hydration solutions in the B2B market, understanding the nuances of different options is vital. While average water bottle sizes, particularly the common 16.9 oz (500 ml) bottle, are widely used, various alternatives can cater to specific business needs, such as sustainability, cost efficiency, and convenience. This analysis compares average water bottle ounces against two viable alternatives: reusable water bottles and water dispensers, helping businesses make informed decisions.

Cuadro comparativo

| Aspecto comparativo | Average Water Bottle Oz | Reusable Water Bottles | Water Dispensers |

|---|---|---|---|

| Rendimiento | Standard hydration, typically 16.9 oz | Customizable sizes (16 oz to 64 oz) | High capacity (up to 5 gallons) |

| Coste | Low initial cost, but recurring for single-use | Higher upfront cost, but cost-effective over time | Higher initial investment; lower ongoing costs |

| Facilidad de aplicación | Widely available; minimal setup | Requires education on usage; may need cleaning | Requires installation and maintenance |

| Mantenimiento | Minimal; disposable after use | Needs regular cleaning and refilling | Requires regular maintenance and filter changes |

| El mejor caso de uso | Events, quick service, single-use | Office environments, gyms, outdoor activities | High-traffic areas, workplaces, schools |

Desglose detallado de alternativas

Reusable Water Bottles

Reusable water bottles are designed for long-term use, typically available in a variety of sizes ranging from 16 oz to 64 oz. They offer significant advantages in sustainability, reducing plastic waste compared to single-use bottles. While the upfront cost is higher, they can be more economical in the long run, especially for companies that promote eco-friendly practices. However, they require regular cleaning and can be cumbersome to carry when filled to capacity, making them less ideal for all scenarios.

Water Dispensers

Water dispensers serve as a robust hydration solution, especially in high-traffic environments such as offices, schools, and gyms. They can hold large amounts of water (up to 5 gallons), reducing the frequency of refills compared to smaller bottles. While the initial investment may be significant, the ongoing costs for water refills can be lower than purchasing single-use bottles. However, they require installation and routine maintenance, including filter changes and cleaning, which could be a consideration for businesses with limited resources or time.

Conclusiones: Elegir la solución de hidratación adecuada

For B2B buyers, the decision on the right hydration solution should align with their specific operational needs, budget constraints, and sustainability goals. If the priority is quick, convenient hydration for events or short-term use, average water bottles remain a practical choice. Conversely, for organizations looking to promote sustainability and reduce waste, investing in reusable bottles or water dispensers can provide long-term benefits and enhance employee health and satisfaction. By carefully evaluating the pros and cons of each option, businesses can select the solution that best meets their hydration needs while aligning with their overall operational strategy.

Essential Technical Properties and Trade Terminology for average water bottle oz

What Are the Key Technical Properties of Average Water Bottle Sizes?

When evaluating water bottles for B2B purchasing, understanding their technical properties is essential. Here are several critical specifications that influence product quality and usability:

-

Volume Capacity (oz)

The volume capacity of water bottles is typically measured in ounces (oz). Common sizes include 8 oz, 10 oz, 12 oz, 16.9 oz, and larger variants like 32 oz and 64 oz. This specification is crucial for determining how much water can be carried, which affects user convenience and hydration needs. For example, a standard 16.9 oz bottle is often preferred for single-use and portability, making it a staple in many markets. -

Calidad del material

Water bottles are made from various materials, including PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and stainless steel. Each material has different properties such as durability, weight, and recyclability. For B2B buyers, selecting the right material is vital for cost-effectiveness, safety compliance, and environmental impact, particularly in regions with stringent regulations. -

Dimensions and Weight

The physical dimensions (height, diameter) and weight of the bottles are significant for shipping and storage considerations. Bottles must fit into standard packaging sizes for efficient transportation, and lighter bottles can reduce shipping costs. Understanding the dimensions also helps in determining how many bottles can be efficiently palletized and shipped, impacting logistics and inventory management. -

Label Area Specifications

The size and material of the label area are important for branding and marketing. Each bottle size typically has specific label dimensions that can be customized. A durable, high-gloss vinyl label can enhance visibility and appeal, which is essential for retail environments. B2B buyers should consider how branding can influence consumer choices, especially in competitive markets. -

Packaging Configuration

Water bottles are usually sold in cases or pallets, with configurations depending on the bottle size. For instance, 48 bottles of 8 oz may be packaged differently than 24 bottles of 16.9 oz. Understanding packaging configurations helps in calculating shipping costs and managing warehouse space, making it a critical factor for efficient supply chain operations.

What Are Common Trade Terms Related to Water Bottles?

Familiarity with industry terminology can streamline communication and negotiation processes in B2B transactions. Here are some common terms you should know:

-

OEM (fabricante de equipos originales)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of water bottles, an OEM might produce bottles for various brands. Understanding OEM relationships can help buyers identify reliable suppliers. -

MOQ (Cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for companies looking to maintain adequate stock levels without overcommitting financially. -

RFQ (solicitud de presupuesto)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. For B2B buyers, issuing an RFQ can provide competitive pricing and help in evaluating different suppliers based on cost and quality. -

Incoterms (Términos comerciales internacionales)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial for effective logistics management and ensuring that both parties are aware of their obligations regarding shipping, insurance, and tariffs. -

Plazos de entrega

Lead time refers to the time taken from placing an order to receiving the goods. It is essential for supply chain planning, as longer lead times can affect inventory levels and customer satisfaction. Buyers should factor in lead times when negotiating contracts and placing orders. -

Cumplimiento de la sostenibilidad

This term refers to adherence to environmental standards and regulations regarding the production and disposal of products. As sustainability becomes increasingly important, B2B buyers should consider suppliers’ compliance with eco-friendly practices, which can also enhance brand reputation in environmentally conscious markets.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing water bottles, ensuring they meet both operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the average water bottle oz Sector

What Are the Key Market Trends in the Average Water Bottle Oz Sector?

The global market for average water bottles, particularly in the 8 oz to 64 oz range, is experiencing notable growth driven by increasing consumer awareness of health and hydration. In regions like Africa, South America, the Middle East, and Europe, there is a rising demand for convenient and portable hydration solutions. The adoption of reusable bottles is also gaining momentum, as consumers seek eco-friendly alternatives to single-use plastics. Technological advancements in manufacturing and design are enabling companies to produce lighter, more durable bottles that cater to diverse needs.

Furthermore, the trend toward customization is shaping sourcing strategies. B2B buyers are increasingly looking for suppliers who offer personalized labeling and design options, which are crucial for branding in competitive markets. E-commerce platforms are facilitating easier access to a broader range of suppliers, enabling buyers to compare prices and product features efficiently. This is particularly relevant in emerging markets where online purchasing is becoming more prevalent. Additionally, the rise of health-conscious lifestyles is driving demand for larger capacity bottles, such as 32 oz and above, as consumers aim to meet their daily hydration goals with fewer refills.

How Does Sustainability Impact Sourcing Trends in the Average Water Bottle Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the average water bottle sector. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility. This includes sourcing materials that are recyclable or made from recycled content, such as PET or bioplastics. The demand for ‘green’ certifications, such as the Global Recycled Standard or Cradle to Cradle certification, is on the rise, as these credentials provide assurance to buyers about the sustainability of their products.

Moreover, ethical sourcing practices are gaining traction, particularly in regions sensitive to social issues. Buyers are seeking suppliers who maintain transparent supply chains and ensure fair labor practices. This trend is especially pertinent in markets like Nigeria and Brazil, where local regulations may dictate sustainability standards. For B2B buyers, partnering with suppliers who prioritize sustainability not only mitigates environmental impact but also enhances brand reputation and consumer loyalty in an increasingly eco-conscious marketplace.

How Has the Average Water Bottle Sector Evolved Over Time?

The evolution of the average water bottle sector reflects broader changes in consumer behavior and environmental awareness. In the early 2000s, bottled water was primarily sold in single-use plastic containers, often in 16.9 oz sizes. However, as awareness of plastic pollution grew, the market began shifting towards reusable options. This led to innovations in materials and designs, offering consumers a variety of sizes and functionalities tailored to specific activities, from gym use to outdoor adventures.

Today, B2B buyers benefit from a rich array of options that cater to diverse hydration needs, with sizes ranging from compact 8 oz bottles to large 64 oz containers. The focus has also expanded beyond functionality to include aesthetics and branding opportunities, reflecting the growing importance of product differentiation in a competitive landscape. As sustainability continues to shape consumer preferences, the evolution of the sector is likely to prioritize eco-friendly materials and ethical sourcing practices, positioning businesses that adapt swiftly at the forefront of the market.

Frequently Asked Questions (FAQs) for B2B Buyers of average water bottle oz

-

How many ounces are in a standard water bottle?

The most common size for a standard water bottle is 16.9 ounces (500 ml). This size is frequently used for single-use plastic bottles and is also popular among reusable options. Understanding this standard helps B2B buyers gauge inventory needs, as it is widely recognized and preferred by consumers for its balance between portability and hydration capacity. When sourcing bottles, consider this size for promotional products or events where convenience and brand visibility are essential. -

What is the best size of water bottle for corporate events?

For corporate events, the ideal water bottle size typically ranges from 16 to 20 ounces. This size is manageable for attendees and can be easily branded with company logos. It provides enough hydration for short to medium-duration events without being cumbersome. If the event lasts longer, consider offering refill stations alongside larger bottles (e.g., 32 oz) to ensure guests stay hydrated while promoting sustainability by reducing single-use plastic. -

How can I customize water bottles for my brand?

Customizing water bottles can enhance brand visibility and customer engagement. Most suppliers offer options for label design, color choices, and even bottle shapes. You can usually submit your artwork or logo to be printed on the bottle’s label. When selecting a supplier, inquire about their customization capabilities, minimum order quantities (MOQs), and lead times to ensure your promotional products align with your marketing strategy. -

What are the typical minimum order quantities (MOQs) for water bottles?

Minimum order quantities for water bottles can vary widely based on the supplier and the type of customization required. Generally, MOQs for standard bottles range from 24 to 100 units, while custom designs may start at 500 units or more. When sourcing, it’s essential to discuss MOQs with potential suppliers to ensure they align with your project needs, budget, and inventory management strategies. -

How do I ensure quality when sourcing water bottles internationally?

To ensure product quality when sourcing water bottles from international suppliers, conduct thorough due diligence. Request samples to assess material quality and craftsmanship before placing a bulk order. Additionally, review supplier certifications, such as ISO or food safety standards, and consider arranging factory visits or audits. Establishing clear quality assurance (QA) protocols in your purchase agreements can also mitigate risks and ensure that the final products meet your specifications. -

What payment terms should I negotiate with water bottle suppliers?

When negotiating payment terms with suppliers, consider options like a deposit upfront, followed by the balance upon delivery or net 30/60 days terms. These terms help manage cash flow while ensuring that suppliers are committed to fulfilling orders. Be cautious of suppliers demanding full payment in advance, especially for large orders, and always verify their credibility and track record before proceeding. -

¿Qué consideraciones logísticas debo tener en cuenta al importar botellas de agua?

Logistics plays a critical role in the successful importation of water bottles. Key considerations include shipping methods (air vs. sea), customs regulations, and lead times. Ensure you have a reliable freight forwarder familiar with your target market’s import regulations. Additionally, consider warehousing options and distribution strategies to streamline the supply chain and minimize delays in getting products to your customers. -

How can I find reliable suppliers for water bottles in Africa or South America?

Finding reliable suppliers in regions like Africa or South America involves researching trade directories, attending industry trade shows, and leveraging local business networks. Platforms such as Alibaba or Global Sources can also connect you with manufacturers. It’s crucial to assess supplier credentials, request references, and initiate small trial orders to evaluate product quality and service reliability before committing to larger purchases.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 3 Average Water Bottle Oz Manufacturers & Suppliers List

1. Embotella tu marca - Botella de agua de 8oz

Dominio: botellatumarca.com

Inscrito: 2004 (21 años)

Introducción: {“8oz_water_bottle”:{“capacity”:”8 fluid ounces”,”dimensions”:{“height”:”5 inches”,”diameter”:”2.25 inches”},”label_size”:{“length”:”6.375 inches”,”height”:”2.25 inches”},”label_material”:”durable, high gloss vinyl”,”sold_in”:”multiples of 48 bottles”,”box_size”:{“length”:”16.75 inches”,”width”:”10.25 inches”,”height”:”10.75 inches”},”weight”:”30 lbs per box”,”pallet_capacity”:”120 cases”},”10oz_w…

2. Owala – 40 oz FreeSip Water Bottle

Dominio: owalife.com

Matriculado: 2019 (6 años)

Introducción: Owala’s 40 oz FreeSip water bottle is designed for convenience and sustainability, allowing users to drink a gallon of water daily without frequent refills. The bottle is priced at $37.99, making it a cost-effective alternative to single-use 16.9 oz water bottles, which average $0.87 each. Drinking 7.5 of these bottles daily would cost approximately $6.525 per day, $45.68 per week, and $2,375.36 a…

3. WaterBottle.Tech – Hydration Insights

Dominio: waterbottle.tech

Registrado: 2018 (7 años)

Introducción: In the United States, a typical disposable plastic water bottle has a capacity of 16.9 fluid ounces. Other common capacities mentioned include 17 oz, 25 oz, 32 oz, and 64 oz. The blog discusses the importance of hydration and the environmental impact of using single-use plastic bottles compared to reusable stainless steel water bottles or tumblers.

Strategic Sourcing Conclusion and Outlook for average water bottle oz

In the evolving landscape of water bottle sourcing, understanding the nuances of average water bottle sizes is crucial for international B2B buyers. The predominant sizes—ranging from 8 oz to 64 oz—serve different market needs, from small, portable options for children to larger bottles designed for athletes and outdoor enthusiasts. Recognizing these variations allows businesses to strategically align their inventory with customer preferences, ensuring they meet hydration demands across diverse regions, particularly in Africa, South America, the Middle East, and Europe.

Strategic sourcing not only optimizes supply chain efficiency but also enhances brand differentiation through customized offerings. By investing in quality and appropriate sizes, businesses can establish stronger connections with their target markets, driving customer loyalty and sales growth.

Looking ahead, as consumer preferences shift towards sustainability and convenience, now is the time for B2B buyers to evaluate their sourcing strategies. Embracing innovative bottle designs and eco-friendly materials will position businesses favorably in an increasingly competitive market. Engage with suppliers today to explore how tailored water bottle solutions can elevate your brand and meet the hydration needs of your clients effectively.