Introducción: Navegando por el mercado mundial de onzas líquidas en una botella de vino

Comprender las onzas líquidas de una botella de vino es crucial para los compradores B2B que navegan por el mercado mundial del vino, especialmente cuando se abastecen de productos para mercados diversos como África, Sudamérica, Oriente Medio y Europa. Dado que la botella de vino estándar contiene aproximadamente 750 mililitros (25,4 onzas líquidas), los compradores deben tener en cuenta los distintos tamaños de botella y sus implicaciones para el precio, el almacenamiento y las preferencias de los consumidores. Esta guía ofrece una visión completa de los distintos tipos de botellas de vino, sus capacidades y el contexto histórico en el que se basan estas medidas, para que los compradores internacionales puedan tomar decisiones de compra con conocimiento de causa.

A medida que el vino va ganando popularidad en las distintas regiones, resulta esencial comprender las aplicaciones de los distintos tamaños de botella -desde el compacto Piccolo hasta el gran Jeroboam- para adaptar la oferta a los mercados locales. Además, la guía profundiza en los procesos de selección de proveedores, las consideraciones de costes y las mejores prácticas para abastecerse de vinos de alta calidad. Al proporcionar información y datos procesables, esta guía permite a los compradores B2B optimizar su inventario y satisfacer las demandas cambiantes de su clientela. Tanto si es un distribuidor en Brasil como un minorista en Nigeria, dominar los matices de las onzas líquidas en las botellas de vino mejorará su ventaja competitiva en este dinámico sector.

Artículo Navegación

- Lista de los 9 mejores fabricantes y proveedores de oz líquidas en una botella de vino

- Introducción: Navegando por el mercado mundial de onzas líquidas en una botella de vino

- Tipos y variaciones de onzas líquidas en una botella de vino

- Principales aplicaciones industriales de las oz líquidas en una botella de vino

- 3 puntos débiles habituales de los usuarios de "onzas líquidas en una botella de vino" y sus soluciones

- Guía estratégica de selección de materiales para las onzas líquidas de una botella de vino

- Mirada en profundidad: Procesos de fabricación y garantía de calidad de las onzas líquidas de una botella de vino

- Guía práctica de aprovisionamiento: Una lista de comprobación paso a paso para 'onzas líquidas en una botella de vino'

- Análisis exhaustivo de costes y precios de las onzas líquidas en una botella de vino Sourcing

- Análisis de alternativas: Comparación de las onzas líquidas de una botella de vino con otras soluciones

- Propiedades técnicas esenciales y terminología comercial de las onzas líquidas de una botella de vino

- Dinámica del mercado y tendencias de abastecimiento en el sector de las onzas líquidas en una botella de vino

- Preguntas frecuentes (FAQ) para compradores B2B de onzas líquidas en una botella de vino

- Descargo de responsabilidad y condiciones de uso

- Conclusiones y perspectivas de la contratación estratégica de oz líquidas en una botella de vino

Tipos y variaciones de onzas líquidas en una botella de vino

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Botella estándar | 750 ml (25,4 oz), formato universal para la mayoría de los vinos | Comercios, restaurantes, eventos | Pros: Amplia disponibilidad, tamaño de ración estándar. Contras: Cantidad limitada para grandes eventos. |

| Magnum | 1500ml (50.7 oz), equivalente a dos botellas estándar | Venta de vinos premium, eventos | Pros: Mejor potencial de envejecimiento, presentación impresionante. Contras: Más difícil de encontrar, mayor coste. |

| Jeroboam | 3L (101.4 oz), tiene capacidad para cuatro botellas estándar | Ocasiones especiales, mercados de lujo | Pros: Llamativo, adecuado para grandes reuniones. Contras: Requiere mucho espacio de almacenamiento. |

| Piccolo (Split) | 187 ml, ideal para raciones individuales o degustaciones | Catas de vino, vuelos, pequeños eventos | Pros: Conveniente para la toma de muestras, menos residuos. Contras: Volumen limitado, no rentable para grandes reuniones. |

| Demi (Mitad) | 375 ml, la mitad que una botella normal | Cena de lujo, maridaje de vinos | Pros: Perfecto para porciones más pequeñas, versátil. Contras: Precio más alto por onza, menos común. |

¿Qué características tienen las botellas de vino estándar?

La botella de vino estándar, de 750 ml o 25,4 onzas líquidas, es el formato más reconocido en el sector del vino. Este tamaño es ideal para entornos minoristas, restaurantes y eventos, por lo que es un elemento básico para los compradores B2B. Ofrece cinco medidas estándar, lo que facilita los cálculos a la hora de planificar reuniones. La amplia disponibilidad y familiaridad de este tamaño lo convierten en una elección fiable, aunque puede no ser suficiente para eventos más grandes en los que se necesiten varias botellas.

¿Cómo mejoran las Magnums la experiencia del vino?

Las botellas Magnum, que contienen 1.500 ml o 50,7 onzas líquidas, son populares entre los vendedores de vino de calidad y los organizadores de eventos. Llaman la atención visualmente y son conocidas por su mayor potencial de envejecimiento debido a la menor proporción de oxígeno en relación con el vino. Los compradores B2B deberían considerar las magnums para eventos de alto nivel o para presentar vinos de alta calidad. Sin embargo, su escasez y su elevado precio pueden plantear dificultades a la hora de adquirirlas, lo que las convierte en una inversión única pero valiosa.

¿Por qué elegir las botellas Jeroboam para las grandes reuniones?

Las botellas Jeroboam tienen capacidad para 3 litros (101,4 onzas líquidas) de vino, equivalente a cuatro botellas estándar. Son especialmente adecuadas para ocasiones especiales y mercados de lujo, ya que constituyen un impresionante centro de mesa para grandes reuniones. El atractivo visual de un Jeroboam puede elevar la experiencia gastronómica, pero los compradores deben tener en cuenta la necesidad de un espacio de almacenamiento adecuado y las posibles dificultades logísticas a la hora de adquirir estos formatos más grandes.

¿Cuáles son las ventajas de las botellas Piccolo?

Las botellas Piccolo, o splits, contienen 187 ml de vino, lo que las hace ideales para degustaciones o raciones individuales. Suelen utilizarse en vuelos de vino o en eventos en los que se fomenta la degustación. Los compradores B2B aprecian la comodidad de las botellas Piccolo, que minimizan el desperdicio y permiten una oferta variada sin comprometerse con una botella completa. Sin embargo, su volumen limitado puede no ser rentable para grandes reuniones.

¿Cómo encajan las botellas Demi en las estrategias de maridaje?

Las botellas Demi, de 375 ml (12,7 onzas líquidas), tienen la mitad de tamaño que las botellas estándar y son adecuadas para cenas de lujo y maridajes de vinos. Ofrecen una opción equilibrada para quienes desean explorar diferentes vinos sin abrumar a sus invitados. Aunque las botellas demi ofrecen versatilidad, los compradores B2B deben ser conscientes de que su precio por onza es más elevado y de la posible dificultad para conseguirlas en comparación con los tamaños estándar.

Principales aplicaciones industriales de las oz líquidas en una botella de vino

| Industria/Sector | Aplicación específica de oz líquidas en una botella de vino | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Hostelería | Diseño de cartas de vinos y control de raciones | Mejora la experiencia del cliente y optimiza la gestión del inventario | Comprender las preferencias locales y las normas sobre raciones |

| Venta al por menor | Envasado y etiquetado para el consumidor | Aumenta las ventas gracias a un marketing y un cumplimiento eficaces | Cumplimiento de la normativa local y las normas de etiquetado |

| Alimentación y bebidas | Maridaje con ofertas culinarias | Mejora la experiencia de las comidas y fomenta la venta | Conocimiento de las características de los vinos y sus maridajes |

| Gestión de eventos | Catering y organización de eventos | Garantiza un suministro adecuado y minimiza los residuos | Estimación precisa de las preferencias y el consumo de los huéspedes |

| Exportación e importación | Comercio y distribución internacionales | Facilita el cumplimiento de las normas internacionales | Conocimiento de la normativa de importación y exportación y de los requisitos de envasado |

¿Cómo se utilizan las onzas líquidas de una botella de vino en la hostelería?

En el sector de la hostelería, las onzas líquidas de una botella de vino son cruciales para el diseño del menú y el control de las raciones. Los establecimientos suelen estandarizar sus raciones de vino para mejorar la experiencia de los clientes y, al mismo tiempo, gestionar eficazmente el inventario. Al conocer las preferencias locales en cuanto al tamaño de las raciones, las empresas pueden optimizar sus ofertas, garantizando que los clientes disfruten de una experiencia agradable sin un desperdicio excesivo. Los compradores B2B internacionales deben conocer las variaciones regionales en los tamaños de las raciones y las expectativas de los consumidores para adaptar sus selecciones de vino en consecuencia.

¿Qué papel desempeñan las onzas líquidas en el envasado y etiquetado del vino al por menor?

En el comercio minorista, la medición de onzas líquidas es fundamental para el envasado y el etiquetado. Un etiquetado preciso no sólo cumple la normativa, sino que también influye en las decisiones de compra de los consumidores. Los minoristas pueden comercializar eficazmente sus productos destacando el volumen específico en onzas líquidas, atendiendo así a las preferencias de los consumidores en cuanto al tamaño de las porciones. Para los compradores internacionales, comprender los requisitos locales de etiquetado y asegurarse de que el envase cumple estas normas puede tener un impacto significativo en las ventas y la aceptación en el mercado.

¿Cómo facilita el oz fluido los maridajes culinarios en el sector de la alimentación y las bebidas?

El sector de la alimentación y las bebidas aprovecha las onzas líquidas de una botella de vino para mejorar los maridajes culinarios. Al conocer el volumen exacto, los chefs y propietarios de restaurantes pueden crear experiencias gastronómicas a medida que complementen su oferta de menús. Este enfoque fomenta las ventas y mejora la satisfacción del cliente. Para los compradores B2B, familiarizarse con las características del vino y su maridaje con diferentes alimentos es esencial para tomar decisiones de compra informadas que se ajusten a las tendencias culinarias de sus mercados objetivo.

¿Por qué es importante el oz fluido para la gestión de eventos y el catering?

Los profesionales de la organización de eventos utilizan las onzas líquidas de las botellas de vino para garantizar un suministro adecuado durante los eventos con servicio de catering. Saber cuántas porciones pueden obtenerse de una botella estándar permite planificar con precisión, minimizar el desperdicio y garantizar la satisfacción de los invitados. Para los compradores internacionales, las estimaciones precisas basadas en las preferencias culturales y los patrones de consumo son vitales para el éxito de la ejecución del evento y la satisfacción del cliente.

¿Cómo influye el oz fluido en los procesos de exportación e importación del sector vitivinícola?

En el sector de la exportación y la importación, las onzas líquidas en botellas de vino son importantes para el cumplimiento de las normas del comercio internacional. Los compradores deben conocer la normativa sobre envasado, etiquetado y especificaciones de volumen de los distintos países. Comprender estos requisitos puede facilitar las transacciones y reducir el riesgo de incumplimiento. Para las empresas que operan en diversos mercados, el conocimiento de las preferencias y normativas locales mejorará su capacidad para navegar con eficacia por las complejidades de la distribución internacional de vino.

3 puntos débiles habituales de los usuarios de "onzas líquidas en una botella de vino" y sus soluciones

Situación 1: Confusión sobre los tamaños de las botellas y las onzas líquidas

El problema: Los compradores B2B a menudo se encuentran con confusiones sobre los distintos tamaños de las botellas de vino y sus onzas líquidas correspondientes, sobre todo cuando se abastecen de productos para eventos o inventarios. Por ejemplo, un comprador en Nigeria puede asumir erróneamente que una botella de vino estándar es de 1 litro en lugar de los 750 ml reales (25,4 onzas). Este malentendido puede dar lugar a pedidos excesivos o insuficientes, con las consiguientes pérdidas económicas y problemas logísticos, especialmente en temporadas altas o grandes eventos.

La solución: Para mitigar este problema, los compradores B2B deberían invertir en una formación exhaustiva para sus equipos de compras, centrada en los tamaños de las botellas de vino y las conversiones. La creación de una guía de referencia estandarizada que incluya los tamaños habituales de las botellas de vino, las onzas líquidas y el número de jarras estándar puede ser una herramienta muy valiosa. Además, aprovechar los sistemas digitales de gestión de inventario que convierten y muestran automáticamente los tamaños de las botellas en unidades métricas e imperiales puede agilizar el proceso de pedido. Colaborar con los proveedores para recibir especificaciones claras sobre el etiquetado de los productos también puede mejorar la claridad, garantizando que todas las partes tengan la misma comprensión de los volúmenes de vino.

Escenario 2: Cálculos inexactos de los eventos vinícolas

El problema: Calcular el número de botellas necesarias para los eventos puede resultar desalentador, sobre todo para los compradores que organizan grandes reuniones en regiones como Sudamérica, donde las preferencias de los invitados pueden variar mucho. Un comprador puede equivocarse al calcular la cantidad necesaria, lo que puede dar lugar a una escasez de vino o a un exceso de existencias, dos situaciones que pueden repercutir negativamente en la experiencia del evento y en los resultados financieros. Por ejemplo, si un comprador planifica un evento para 100 invitados y supone que cada uno consumirá dos copas de vino, pero no tiene en cuenta la cantidad estándar de 5 onzas, podría acabar teniendo demasiado o demasiado poco vino.

La solución: Para mejorar la precisión en los cálculos de vino, los compradores B2B deben adoptar un enfoque sistemático. Utilizar una herramienta de cálculo de vinos que tenga en cuenta el número de invitados, el consumo medio y el tamaño de las botellas puede proporcionar estimaciones precisas. Además, los compradores deberían considerar la posibilidad de organizar una sesión de cata con un grupo selecto de invitados para evaluar las preferencias y los hábitos de consumo. Estos datos pueden orientar futuras decisiones de compra y ayudar a ajustar las estimaciones en consecuencia. Establecer una relación con un distribuidor de vino local también puede proporcionar información sobre las opciones más populares en la región, lo que permite realizar pedidos mejor informados que se ajusten a las expectativas de los clientes.

Escenario 3: Control de calidad y coherencia en las botellas de vino

El problema: Garantizar la calidad y la coherencia de las distintas botellas de vino es un reto importante para los compradores B2B, especialmente para los que se abastecen de varios proveedores. Las variaciones en los tamaños de las botellas y las onzas líquidas pueden dar lugar a ofertas de productos incoherentes, lo que puede confundir a los clientes finales y dañar la reputación de la marca. Por ejemplo, un comprador en Europa puede recibir un envío de vinos en el que algunas botellas están etiquetadas como estándar pero contienen volúmenes diferentes debido a discrepancias en la producción, lo que puede causar problemas con el precio y la satisfacción del cliente.

La solución: Para mantener el control de calidad, los compradores B2B deben establecer estrictas directrices de abastecimiento que den prioridad a los proveedores con reputación de coherencia en sus procesos de embotellado. Las auditorías periódicas y los controles de calidad de los envíos entrantes pueden ayudar a identificar las discrepancias en una fase temprana. Además, la aplicación de un sistema de etiquetado normalizado que incluya información clara sobre el tamaño de la botella y las onzas líquidas puede aumentar la transparencia para los clientes. Establecer relaciones sólidas con los proveedores y entablar una comunicación periódica sobre las expectativas de calidad también puede fomentar la responsabilidad y dar lugar a prácticas de abastecimiento más fiables. Al centrarse en estas estrategias, los compradores pueden garantizar un producto coherente y de calidad que satisfaga las necesidades de los clientes.

Guía estratégica de selección de materiales para las onzas líquidas de una botella de vino

¿Cuáles son los materiales habituales de las botellas de vino y sus propiedades?

A la hora de seleccionar los materiales para las botellas de vino, las empresas deben tener en cuenta diversos factores que influyen en el rendimiento del producto, el coste y las preferencias del mercado. A continuación se analizan cuatro materiales habituales en la producción de botellas de vino: vidrio, aluminio, PET (tereftalato de polietileno) y corcho.

¿Cómo se comporta el vidrio como material para las botellas de vino?

El vidrio es el material tradicional de las botellas de vino y es ampliamente reconocido por sus propiedades inertes, que no reaccionan con el vino. Entre sus principales propiedades se encuentran su excelente capacidad de barrera frente al oxígeno y la luz, que son cruciales para preservar la calidad del vino a lo largo del tiempo. El vidrio puede soportar altas temperaturas durante el proceso de embotellado, lo que lo hace adecuado para la esterilización.

Pros: Las botellas de vidrio son duraderas, reciclables y pueden moldearse de diversas formas, lo que mejora la estética de la marca. También proporcionan una sensación de calidad superior, esencial para los vinos de gama alta.

Contras: El principal inconveniente es el peso del vidrio, que puede incrementar los costes de envío. Además, el vidrio es frágil y puede romperse con facilidad, lo que conlleva posibles pérdidas durante el transporte.

Impacto en la aplicación: Las botellas de vidrio son compatibles con todo tipo de vinos, incluidos tintos, blancos y espumosos, lo que las hace versátiles para los productores.

Consideraciones para compradores internacionales: El cumplimiento de normas internacionales como ASTM y DIN es crucial. Los compradores de regiones como África y Sudamérica deben tener en cuenta las capacidades locales de reciclado y el impacto medioambiental de la producción de vidrio.

¿Cuáles son las ventajas de utilizar aluminio para las botellas de vino?

El aluminio está ganando popularidad como alternativa al vidrio, especialmente para determinados segmentos del vino. Sus principales propiedades son su construcción ligera, que reduce los costes de transporte, y su excelente resistencia a la corrosión.

Pros: Las botellas de aluminio son irrompibles, lo que las hace ideales para eventos al aire libre y reduce el riesgo de pérdida de producto. Además, ofrecen una barrera total contra la luz y el oxígeno, preservando la calidad del vino.

Contras: El proceso de fabricación de las botellas de aluminio puede ser más complejo y costoso que el del vidrio. Además, algunos consumidores pueden percibir el aluminio como menos premium en comparación con el vidrio.

Impacto en la aplicación: El aluminio es adecuado tanto para vinos tranquilos como espumosos, aunque se utiliza más en ambientes informales o al aire libre.

Consideraciones para compradores internacionales: Los compradores deben asegurarse de que se cumplen las normativas locales sobre reciclaje y sostenibilidad del aluminio. En mercados como Oriente Medio, donde el consumo al aire libre es habitual, el aluminio puede resultar especialmente atractivo.

¿Cómo se compara el PET como material para botellas de vino?

El PET es un plástico ligero que ofrece flexibilidad y durabilidad. Sus principales propiedades son la resistencia al impacto y una buena barrera contra el oxígeno, aunque es menos eficaz que el vidrio o el aluminio para bloquear la luz ultravioleta.

Pros: Las botellas de PET son mucho más ligeras que las de vidrio, lo que reduce los costes de transporte. También son inastillables, lo que las hace más seguras en diversos entornos.

Contras: El PET no es tan eficaz como el vidrio a la hora de preservar la calidad del vino durante largos periodos de tiempo, especialmente en el caso de los vinos de guarda. Además, es posible que no transmita la misma imagen de calidad que el vidrio.

Impacto en la aplicación: El PET se utiliza a menudo para vinos de bajo precio y es ideal para formatos de una sola porción.

Consideraciones para compradores internacionales: Los compradores deben conocer la capacidad de reciclaje local y la normativa sobre el uso del plástico. En regiones como Brasil y Nigeria, donde la sostenibilidad es una preocupación creciente, la percepción del PET puede variar.

¿Qué papel desempeña el corcho en el cierre de las botellas de vino?

El corcho no es un material propio de las botellas, pero es esencial para sellar las botellas de vino. Sus principales propiedades son la elasticidad natural y la capacidad de permitir la microoxigenación, que puede beneficiar el proceso de envejecimiento de determinados vinos.

Pros: El corcho es biodegradable y ofrece una estética tradicional que muchos consumidores valoran. Además, permite que los vinos respiren, lo que favorece el desarrollo de su sabor con el paso del tiempo.

Contras: El corcho puede ser propenso a problemas como el sabor a corcho, que puede estropear el vino. Además, la producción de corcho puede ser menos sostenible que las alternativas sintéticas.

Impacto en la aplicación: El corcho se utiliza principalmente para vinos de calidad, sobre todo tintos y algunos blancos, en los que se desea el envejecimiento.

Consideraciones para compradores internacionales: Los compradores deben tener en cuenta el origen del corcho y su sostenibilidad. En Europa, donde se valoran las prácticas tradicionales, el corcho sigue siendo la opción preferida, mientras que las opciones sintéticas pueden ser más aceptadas en otras regiones.

Tabla resumen de selección de materiales para botellas de vino

| Material | Caso típico de uso de las onzas líquidas en una botella de vino | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Vidrio | Vinos de calidad, tintos y blancos | Excelentes propiedades de barrera | Pesado y frágil | Alta |

| Aluminio | Vinos informales, eventos al aire libre | Ligero e irrompible | Percibido como menos caro | Medio |

| PET | Vinos más baratos, formatos monodosis | Inastillable y ligero | Menos eficaz para preservar la calidad | Bajo |

| Corcho | Vinos de calidad que requieren envejecimiento | Estética natural y microoxigenación | Propenso a la contaminación del corcho | Medio |

Este exhaustivo análisis proporciona a los compradores B2B información práctica sobre el proceso de selección de materiales para botellas de vino, garantizando la toma de decisiones informadas que se ajusten a las demandas del mercado y a las preferencias regionales.

Mirada en profundidad: Procesos de fabricación y garantía de calidad de las onzas líquidas de una botella de vino

¿Cuáles son las etapas clave del proceso de fabricación de botellas de vino?

El proceso de fabricación de botellas de vino implica varias etapas críticas que garantizan que el producto final cumpla las especificaciones de calidad y diseño. Comprender estas etapas puede ayudar a los compradores B2B a evaluar las capacidades de los proveedores y asegurarse de que están adquiriendo productos que se ajustan a sus estándares de calidad.

-

Preparación del material

El primer paso en la fabricación de botellas de vino es la preparación de las materias primas. El principal material utilizado es el vidrio, que suele fabricarse a partir de arena de sílice, ceniza de sosa y piedra caliza. Estos componentes se mezclan y funden en un horno a altas temperaturas (alrededor de 1.700°C o 3.092°F). En el caso de las botellas de vino especializadas, pueden incluirse materiales adicionales para mejorar las propiedades del vidrio, como colorantes o aditivos para la protección contra los rayos UV. -

Formando

Una vez que el vidrio fundido está listo, se le da forma de botella mediante diversas técnicas. El método más común es el moldeo por soplado, en el que se insufla aire en un parison (una forma de vidrio preformada) para crear la botella. Otros métodos son el moldeo por presión y soplado y el moldeo por estirado y soplado, que se utilizan para formas y tamaños de botella específicos. El proceso de moldeado es fundamental, ya que determina el volumen, la forma y el grosor finales de la botella, lo que afecta directamente tanto a la estética como a la funcionalidad. -

Montaje

Tras el conformado, las botellas se someten a un proceso de enfriamiento para aliviar las tensiones internas. A continuación se realizan controles de calidad para garantizar que cumplen las especificaciones exigidas. En esta fase también se preparan los componentes adicionales, como los tapones (de corcho o rosca) y las etiquetas. El proceso de montaje es vital para garantizar que todas las piezas encajen correctamente y funcionen según lo previsto. -

Acabado

La última fase consiste en los toques finales, que incluyen el pulido, la decoración y la aplicación de etiquetas. Las técnicas de acabado pueden variar mucho en función de la estética deseada. Por ejemplo, algunos fabricantes pueden utilizar serigrafía o etiquetado para la marca, mientras que otros pueden optar por diseños en relieve. La garantía de calidad durante esta fase es crucial, ya que cualquier imperfección puede afectar a la comerciabilidad.

¿Cómo se aplica la garantía de calidad en la fabricación de botellas de vino?

El control de calidad es parte integrante del proceso de fabricación de botellas de vino. Garantiza que los productos cumplan las normas internacionales y las expectativas de los clientes. He aquí algunos aspectos clave de la garantía de calidad en esta industria:

-

Normas internacionales y específicas del sector

Muchos fabricantes de botellas de vino se adhieren a normas de calidad internacionales como la ISO 9001, que establece los criterios de un sistema de gestión de la calidad. El cumplimiento de las normas ISO ayuda a garantizar una calidad constante y una mejora continua. Además, pueden aplicarse certificaciones específicas del sector como CE (Conformité Européenne) y API (American Petroleum Institute) en función de la región y los requisitos del mercado. Estas certificaciones ayudan a los compradores B2B a identificar proveedores reputados. -

Puntos de control de calidad

Los puntos de control de calidad (CC) se establecen en varias fases del proceso de fabricación para garantizar el cumplimiento de las especificaciones. Los puntos de control más comunes son:

– Control de calidad entrante (IQC): Esto implica inspeccionar las materias primas a su llegada a las instalaciones para garantizar que cumplen unas normas predefinidas.

– Control de calidad durante el proceso (IPQC): Durante la producción, se toman muestras a diferentes intervalos para evaluar la calidad de las botellas que se están formando.

– Control de calidad final (CCF): Una vez finalizada la producción, los productos acabados se someten a rigurosas pruebas para garantizar que cumplen todas las especificaciones antes de ser enviados. -

Métodos de ensayo habituales

Para garantizar la calidad se emplean diversos métodos de ensayo, entre ellos:

– Inspección visual: Comprobación de defectos como grietas, burbujas o superficies irregulares.

– Pruebas dimensionales: Medir las botellas para garantizar que cumplen las especificaciones de tamaño.

– Pruebas de resistencia: Evaluar la durabilidad del vidrio bajo variaciones de presión y temperatura.

– Análisis químico: Garantizar que los materiales utilizados no filtren sustancias nocivas al vino.

¿Cómo pueden los compradores B2B verificar los procesos de control de calidad de los proveedores?

Para los compradores B2B internacionales, sobre todo de regiones como África, Sudamérica, Oriente Medio y Europa, verificar los procesos de control de calidad de los proveedores es esencial para garantizar la integridad del producto. He aquí varias estrategias para evaluar eficazmente la calidad de los proveedores:

-

Realización de auditorías

Las auditorías periódicas de los proveedores pueden aportar información sobre sus procesos de fabricación y sus medidas de control de calidad. Durante una auditoría, los compradores deben evaluar la conformidad de las instalaciones con las normas internacionales y la eficacia de sus procesos de control de calidad. Esto incluye el examen de la documentación, la observación de las prácticas de producción y la evaluación de la formación del personal implicado en la garantía de calidad. -

Solicitud de informes de control de calidad

Los proveedores deben facilitar informes detallados de control de calidad que describan sus procedimientos de ensayo, los resultados y el cumplimiento de las normas. Estos informes pueden ayudar a los compradores a comprender cómo supervisa y mantiene la calidad el proveedor a lo largo de todo el proceso de producción. -

Utilización de servicios de inspección de terceros

Contratar servicios de inspección de terceros puede proporcionar una evaluación imparcial de las medidas de control de calidad de un proveedor. Estas organizaciones pueden realizar inspecciones en varias fases de la producción y certificar que los productos cumplen las normas especificadas. Esto es especialmente beneficioso para los compradores que no disponen de los recursos necesarios para llevar a cabo inspecciones exhaustivas.

¿Cuáles son los matices del control de calidad para los compradores B2B internacionales?

Cuando se abastecen de botellas de vino a escala internacional, los compradores B2B deben sortear diversos matices de control de calidad que pueden influir en sus decisiones de compra:

-

Cumplimiento de la normativa

Los distintos países tienen normativas específicas sobre el envasado y etiquetado de los productos vinícolas. Los compradores deben asegurarse de que sus proveedores cumplen tanto la normativa local como la internacional para evitar complicaciones legales. -

Consideraciones culturales

Las preferencias culturales pueden influir en la percepción de la calidad. Por ejemplo, los compradores de Europa pueden dar prioridad a la estética y la artesanía, mientras que los de Sudamérica pueden centrarse más en la durabilidad y la funcionalidad. Comprender estos matices puede ayudar a los compradores a seleccionar proveedores que se ajusten a sus expectativas de mercado. -

Transparencia de la cadena de suministro

La transparencia en la cadena de suministro es fundamental para mantener la calidad. Los compradores deben informarse sobre el origen de las materias primas, los procesos de fabricación y los métodos de distribución. Los proveedores con prácticas transparentes tienen más probabilidades de ofrecer una calidad constante.

En conclusión, comprender los procesos de fabricación y las medidas de garantía de calidad de las botellas de vino es crucial para los compradores B2B. Al centrarse en estos aspectos, los compradores pueden tomar decisiones informadas, asegurándose de que se asocian con proveedores de confianza que cumplen sus estándares de calidad y las necesidades del mercado.

Guía práctica de aprovisionamiento: Una lista de comprobación paso a paso para 'onzas líquidas en una botella de vino'

Para ayudar a los compradores B2B en la adquisición de vino basado en onzas líquidas en una botella, esta lista de comprobación describe los pasos esenciales para garantizar un aprovisionamiento informado y eficaz. Comprender el volumen y las especificaciones de las botellas de vino es crucial para una gestión precisa del inventario, la planificación de eventos y la satisfacción de las demandas de los clientes.

Primer paso: Determine sus necesidades de volumen

Establezca los requisitos específicos de onzas líquidas para su aprovisionamiento de vino. Conocer el volumen le ayudará a ajustarse a las expectativas de los clientes y a las normas del mercado, sobre todo en regiones como África, Sudamérica, Oriente Medio y Europa, donde las preferencias pueden variar considerablemente. Los tamaños más comunes son la botella estándar de 750 ml (aproximadamente 25,4 onzas) y formatos más grandes como los magnums (1,5 L o 50,7 onzas).

Segundo paso: Diferentes tamaños de botellas de vino y sus usos

Familiarícese con los distintos tamaños de botellas de vino y sus onzas líquidas correspondientes. Este conocimiento es esencial para calcular con precisión cuántas raciones o copas puedes servir de cada tipo de botella. Por ejemplo, una botella estándar rinde unas cinco raciones de 5 onzas, mientras que una magnum proporciona diez raciones, lo que la hace ideal para grandes reuniones.

Tercer paso: Evaluar las certificaciones y la conformidad de los proveedores

Antes de seleccionar a los proveedores, verifique sus certificaciones y el cumplimiento de las normas internacionales. Esto es especialmente importante en regiones con normativas estrictas sobre la distribución de alcohol. Asegúrese de que los proveedores pueden aportar documentación sobre garantía de calidad y cumplimiento de las normas de salud y seguridad.

- Certificaciones clave que debe buscar:

- ISO 9001 para sistemas de gestión de la calidad.

- APPCC para la gestión de la seguridad alimentaria.

Paso 4: Evaluar la calidad y variedad de la oferta

Investigue la calidad y variedad de la oferta de vinos de los posibles proveedores. Los vinos de alta calidad pueden mejorar la reputación de su marca y la satisfacción de sus clientes. Solicite muestras y reseñas de clientes existentes para evaluar los perfiles de sabor, que pueden diferir significativamente en función de la región vinícola y la variedad de uva.

Paso 5: Negociar precios y condiciones de pago

Entable conversaciones para negociar precios y condiciones de pago que se ajusten a su presupuesto y flujo de caja. Comprender el coste por onza líquida puede ayudarle a determinar su estrategia de precios para la reventa. Tenga en cuenta las cantidades mínimas de pedido y los descuentos por volumen que pueden repercutir en los costes totales.

Paso 6: Establecer opciones fiables de logística y entrega

Asegúrese de que sus proveedores disponen de sólidos sistemas logísticos y de entrega. La puntualidad en las entregas es crucial para mantener los niveles de inventario y satisfacer las demandas de los clientes, especialmente en sectores como la hostelería o el comercio minorista. Confirme los plazos de entrega y los métodos de transporte para evitar posibles interrupciones.

Paso 7: Seguir las tendencias del mercado y las preferencias de los clientes

Manténgase al día de las tendencias del mercado y las preferencias de los clientes en cuanto al consumo de vino. Comprender las variaciones regionales en cuanto a gustos y preferencias de botellas puede orientar sus decisiones de compra. Considere la posibilidad de realizar encuestas o entablar conversaciones con los clientes para recabar información sobre sus elecciones de vino y sus necesidades de volumen.

Siguiendo estos pasos, los compradores B2B pueden abastecerse eficazmente de vino basándose en onzas líquidas, garantizando que satisfacen las demandas del mercado al tiempo que mantienen la calidad y la conformidad.

Análisis exhaustivo de costes y precios de las onzas líquidas en una botella de vino Sourcing

¿Cuáles son los principales componentes del coste de una botella de vino en onzas líquidas?

Comprender la estructura de costes asociada al abastecimiento de onzas líquidas en una botella de vino es crucial para los compradores B2B. Los principales componentes son los materiales, la mano de obra, los gastos generales de fabricación, las herramientas, el control de calidad, la logística y los márgenes de beneficio deseados.

- Materiales: Incluye el coste de las botellas de vidrio, los corchos, las etiquetas y el propio vino. La elección de la calidad del vidrio (por ejemplo, estándar frente a premium) puede influir significativamente en los costes.

- Trabajo: Los costes de mano de obra incluyen tanto la mano de obra directa que interviene en el proceso de embotellado como la mano de obra indirecta de las funciones administrativas y de supervisión.

- Gastos generales de fabricación: Incluye servicios públicos, alquiler, mantenimiento de equipos y otros costes operativos asociados al funcionamiento de una bodega o instalación de embotellado.

- Herramientas: La inversión en maquinaria especializada para el embotellado y el etiquetado puede afectar a los costes iniciales, pero puede generar eficiencias a largo plazo.

- Control de calidad: Garantizar que el vino cumple las normas reglamentarias y las expectativas de calidad conlleva costes adicionales, pero es esencial para mantener la reputación de la marca.

- Logística: Los costes de transporte y almacenamiento, especialmente en envíos internacionales, pueden variar mucho en función de la distancia, el modo de transporte y el embalaje utilizado.

- Margen: Los proveedores suelen añadir un margen basado en sus costes operativos y la demanda del mercado.

¿Cómo influyen los precios en el coste de las botellas de vino?

Varios factores influyen en el precio del vino por onzas líquidas. Entre ellos, el volumen o las cantidades mínimas de pedido (MOQ), las especificaciones y peticiones de personalización, la calidad del material, las certificaciones, la fiabilidad del proveedor y los Incoterms.

- Volumen/MOQ: Los pedidos más grandes suelen reducir los costes por unidad. Los compradores deben negociar para encontrar el equilibrio adecuado entre sus necesidades y las capacidades del proveedor.

- Especificaciones/Personalización: Las etiquetas personalizadas o las formas únicas de las botellas pueden aumentar los costes. Los compradores deben evaluar si el gasto añadido se ajusta a su estrategia de marketing.

- Materiales: La calidad del vidrio y los tapones puede influir significativamente en el coste total. Los materiales de primera calidad pueden mejorar la comerciabilidad del vino, pero a un precio más elevado.

- Calidad/Certificaciones: Los vinos que cumplen determinadas certificaciones (por ejemplo, ecológicos o biodinámicos) pueden tener un precio superior. Los compradores deben evaluar las preferencias del mercado objetivo al considerar estos factores.

- Factores del proveedor: La fiabilidad y reputación de los proveedores puede influir en los costes, ya que los proveedores establecidos pueden cobrar más por su calidad y servicio percibidos.

- Incoterms: Comprender las condiciones comerciales puede ayudar a los compradores a calcular el coste total en destino, incluidos aranceles e impuestos, que pueden variar considerablemente según la región.

¿Qué consejos pueden utilizar los compradores para negociar mejores precios?

Para los compradores B2B internacionales, especialmente los de regiones como África, Sudamérica, Oriente Medio y Europa, varias estrategias de negociación pueden suponer un ahorro de costes.

- Coste total de propiedad (TCO): Evalúe el coste total del aprovisionamiento más allá del precio de compra. Esto incluye el envío, los aranceles, el almacenamiento y los posibles costes de deterioro.

- Aprovechar las relaciones: Establecer relaciones sólidas con los proveedores puede mejorar los precios y las condiciones. Piensa en asociaciones a largo plazo que beneficien a ambas partes.

- Estudios de mercado: Conozca los precios y las tendencias del mercado en su región. Este conocimiento facilitará las negociaciones y ayudará a identificar precios justos.

- Sea flexible: Si es posible, sea flexible con las especificaciones o el tamaño de los pedidos para aprovechar descuentos o condiciones favorables.

- Considere el aprovisionamiento local: En determinados mercados, el aprovisionamiento local puede reducir los costes de envío y los plazos de entrega, mejorando la eficiencia general de los costes.

¿Qué deben tener en cuenta los compradores sobre los matices de los precios?

Los compradores B2B deben ser conscientes de los matices de los precios, que pueden variar según la región. Por ejemplo, los impuestos y aranceles de importación pueden afectar drásticamente al coste de desembarque del vino, sobre todo para los compradores de África y Sudamérica. Además, las fluctuaciones monetarias pueden afectar a la estabilidad de los precios, por lo que es esencial tener en cuenta los tipos de cambio a la hora de negociar.

Descargo de responsabilidad sobre los precios indicativos

Los precios mencionados en este análisis son indicativos y pueden variar ampliamente en función de numerosos factores, como las condiciones del mercado, las negociaciones con los proveedores y los requisitos específicos del comprador. Se recomienda a los compradores que lleven a cabo una investigación exhaustiva del mercado y se pongan en contacto directo con los proveedores para obtener precios exactos.

Análisis de alternativas: Comparación de las onzas líquidas de una botella de vino con otras soluciones

Introducción: Alternativas a las onzas líquidas en las botellas de vino

En el sector del vino, la medida estándar de onzas líquidas de una botella de vino, concretamente la omnipresente botella de 750 ml, desempeña un papel crucial en la gestión de inventarios, la fijación de precios y el servicio. Sin embargo, a medida que evolucionan los mercados mundiales, los compradores B2B exploran cada vez más soluciones de envasado alternativas para satisfacer las diversas preferencias de los consumidores y las necesidades operativas. Este análisis compara la medida tradicional de la onza líquida en las botellas de vino con otras soluciones innovadoras, como los sistemas de vino en grifo y los vinos en lata, con el fin de proporcionar información práctica a los compradores internacionales.

Cuadro comparativo

| Aspecto comparativo | Oz líquido en una botella de vino | Sistema Wine-On-Tap | Vino en lata |

|---|---|---|---|

| Rendimiento | Medición estandarizada; fácil de servir y compartir. | Mantiene la frescura; permite vertidos personalizados. | Portátil; ideal para raciones individuales. |

| Coste | Moderado; el precio varía según la calidad y la región. | Mayores costes iniciales de instalación; menores costes de servicio a largo plazo. | Coste generalmente inferior; precios competitivos. |

| Facilidad de aplicación | Ampliamente aceptada y conocida; requiere una formación mínima. | Requiere instalación; puede necesitar formación del personal. | Fácil de almacenar y servir; requiere una formación mínima. |

| Mantenimiento | Baja; se necesitan comprobaciones ocasionales del inventario. | Moderada; requiere limpieza y mantenimiento regulares. | Bajo; requiere un mantenimiento mínimo. |

| El mejor caso de uso | Experiencias y eventos gastronómicos tradicionales. | Restaurantes, bares y eventos que buscan frescura. | Entornos informales, eventos al aire libre y festivales. |

Desglose detallado de alternativas

Sistema Wine-On-Tap

Los sistemas de vino de barril son cada vez más populares en restaurantes y bares, ya que ofrecen vino en formato de barril. Este método permite un vertido preciso y minimiza los residuos, ya que los vinos pueden mantenerse frescos durante semanas si se almacenan adecuadamente. La inversión inicial en equipos puede ser considerable, pero el ahorro a largo plazo en envases y gestión de residuos suele justificar los costes. Además, este sistema resulta atractivo para los consumidores concienciados con el medio ambiente, ya que reduce el uso de vidrio. Sin embargo, requiere formación del personal y un mantenimiento regular, lo que puede ser un inconveniente para los locales más pequeños.

Vino en lata

El vino en lata se ha convertido en una alternativa viable, especialmente atractiva para los consumidores más jóvenes y los que buscan comodidad. Las latas son ligeras, portátiles y reciclables, lo que las hace ideales para eventos al aire libre y entornos informales. El coste del vino en lata suele ser inferior al del vino embotellado, lo que permite un precio competitivo en el mercado. Sin embargo, la percepción de la calidad puede ser motivo de preocupación para algunos tradicionalistas, y la gama de variedades disponibles puede ser limitada en comparación con las opciones embotelladas. A pesar de ello, la creciente aceptación de los vinos en lata indica un cambio en las preferencias de los consumidores que los compradores deberían tener en cuenta.

Conclusión: ¿Cómo deben elegir los compradores B2B la solución adecuada?

A la hora de seleccionar la solución de envasado de vino adecuada, los compradores B2B deben evaluar sus necesidades específicas, las tendencias del mercado y las preferencias de los consumidores. Las onzas líquidas tradicionales en botellas de vino ofrecen un formato familiar y ampliamente aceptado, especialmente para cenas y eventos formales. Sin embargo, alternativas innovadoras como los sistemas de vino en grifo y el vino en lata ofrecen claras ventajas en términos de frescura, comodidad y rentabilidad. Analizando detenidamente el rendimiento, el coste, la facilidad de implantación y el mantenimiento, los compradores pueden tomar decisiones informadas que se ajusten a sus objetivos empresariales y mejoren su oferta en un mercado competitivo.

Propiedades técnicas esenciales y terminología comercial de las onzas líquidas de una botella de vino

¿Cuáles son las principales propiedades técnicas de las onzas líquidas en las botellas de vino?

Comprender las especificaciones técnicas asociadas a las onzas líquidas de las botellas de vino es crucial para los compradores B2B, sobre todo cuando se abastecen de productos para mercados internacionales. He aquí algunas propiedades esenciales que deben tenerse en cuenta:

-

Especificación de volumen

El volumen estándar de una botella de vino es de 750 ml, lo que equivale aproximadamente a 25,36 onzas líquidas. Reconocer este estándar es fundamental para la gestión de inventarios, las estrategias de fijación de precios y el cumplimiento de la normativa local en materia de etiquetado y tamaño de las raciones. -

Calidad del material

La mayoría de las botellas de vino son de vidrio, lo que afecta a su conservación y calidad. Los compradores deben conocer el grado del vidrio, ya que un vidrio de mayor calidad puede proporcionar una mejor protección contra los rayos UV y reducir el riesgo de rotura durante el transporte. Esto es especialmente importante en regiones con condiciones climáticas variables. -

Niveles de tolerancia

La tolerancia se refiere a la variación admisible del volumen de vino dentro de una botella. En la industria vinícola, suele aceptarse una tolerancia de ±5%. Comprender estas tolerancias es vital para el control de calidad y para garantizar que los clientes reciban el volumen esperado, lo que puede influir en la satisfacción del cliente y en la reputación de la marca. -

Requisitos de etiquetado

El cumplimiento de las normas internacionales de etiquetado es esencial. Esto incluye no sólo el volumen (en onzas y mililitros), sino también información sobre el contenido de alcohol, el origen y las advertencias sanitarias. Conocer estas normas puede evitar costosas multas y facilitar la entrada en el mercado. -

Forma y diseño de la botella

Aunque la botella estándar de 750 ml tiene un volumen uniforme, su forma puede afectar al almacenamiento y el transporte. Diferentes formas, como las botellas de Burdeos o Borgoña, pueden tener pesos y capacidades de apilamiento diferentes, lo que repercute en la logística del transporte. Los compradores deben tener en cuenta estos factores a la hora de tomar decisiones de compra.

¿Qué términos comerciales comunes deben entender los compradores B2B?

Familiarizarse con la jerga del sector puede agilizar la comunicación y las negociaciones. Estos son algunos términos clave relacionados con la compra de botellas de vino:

-

OEM (fabricante de equipos originales)

Este término se refiere a las empresas que fabrican piezas o productos que se utilizan en el producto final de otra empresa. En el sector vinícola, podría referirse a los fabricantes de botellas que ofrecen diseños personalizados a las bodegas. Entender las relaciones con los OEM puede ayudar a los compradores a conseguir mejores precios y productos a medida. -

MOQ (Cantidad mínima de pedido)

El MOQ especifica el menor número de unidades que un proveedor está dispuesto a vender. Conocer el MOQ es esencial para la elaboración de presupuestos y la planificación de inventarios, especialmente para las empresas que pueden no necesitar grandes cantidades pero que, aun así, quieren garantizar la rentabilidad. -

RFQ (solicitud de presupuesto)

Una petición de oferta es un documento que un comprador envía a los proveedores para solicitar precios y condiciones para productos específicos. Elaborar una petición de oferta exhaustiva puede facilitar las negociaciones y garantizar que se tengan en cuenta todos los costes potenciales antes de tomar una decisión de compra. -

Incoterms (Términos comerciales internacionales)

Se trata de términos comerciales estandarizados que definen las responsabilidades de compradores y vendedores en las transacciones internacionales. Estar familiarizado con los Incoterms ayuda a mitigar los riesgos relacionados con el envío, el seguro y la entrega, lo que resulta especialmente vital para las operaciones B2B que abarcan varios países. -

Plazos de entrega

Este término hace referencia al tiempo que transcurre desde que se realiza un pedido hasta la entrega del producto. Comprender los plazos de entrega es crucial para la gestión y planificación de inventarios, ya que permite a las empresas alinear sus cadenas de suministro con la demanda del mercado.

Al comprender estas propiedades técnicas y términos comerciales, los compradores B2B pueden tomar decisiones más informadas, optimizar sus estrategias de compra y mejorar su eficiencia operativa general en la industria del vino.

Dinámica del mercado y tendencias de abastecimiento en el sector de las onzas líquidas en una botella de vino

¿Cuáles son las principales tendencias que impulsan el mercado de la onza líquida en el sector vitivinícola?

El mercado mundial del vino está experimentando cambios dinámicos, impulsados por diversos factores que los compradores B2B internacionales deben tener en cuenta. Uno de los principales es la creciente demanda de vino en los mercados emergentes de África, Sudamérica, Oriente Medio y Europa. Países como Brasil y Nigeria son testigos de una creciente clase media con una renta disponible cada vez mayor, lo que conduce a un mayor consumo de vino. Además, la proliferación de plataformas de venta de vino en línea está cambiando la forma en que los compradores adquieren los productos, permitiendo el acceso a una amplia gama de marcas y tamaños de botella.

Las tendencias actuales también indican un creciente interés por los vinos de calidad y ecológicos, en consonancia con la preferencia de los consumidores por la calidad frente a la cantidad. Este cambio está impulsando a las bodegas a diversificar su oferta en términos de tamaños de botella, incluyendo formatos más grandes como magnums y opciones de envasado únicas que se adaptan tanto a los sectores minoristas como a la hostelería. Además, los avances tecnológicos en la gestión de la cadena de suministro, como blockchain para la trazabilidad y los sistemas de gestión de inventarios, están mejorando la eficiencia operativa para los compradores B2B.

Los mercados emergentes también están mostrando un gran interés por la educación y el turismo del vino, lo que puede influir aún más en las decisiones de compra. A medida que estos mercados evolucionan, los compradores B2B deben mantenerse en sintonía con las preferencias de los consumidores locales y las tendencias en el consumo de vino para aprovechar las oportunidades de crecimiento.

¿Qué impacto pueden tener la sostenibilidad y el abastecimiento ético en la industria vitivinícola?

La sostenibilidad se está convirtiendo en una piedra angular de la industria vitivinícola, impulsada por la creciente concienciación de los consumidores sobre los problemas medioambientales y la demanda de productos de origen ético. Los compradores B2B internacionales dan cada vez más prioridad a los proveedores que se adhieren a prácticas sostenibles, como el uso responsable del agua, los métodos de agricultura ecológica y la reducción de la huella de carbono en la producción y el transporte.

Nunca se insistirá lo suficiente en la importancia de unas cadenas de suministro éticas. Los compradores buscan certificaciones como "orgánico", "comercio justo" y otras etiquetas "verdes" que señalan el compromiso con la sostenibilidad. Estas certificaciones no sólo mejoran la reputación de la marca, sino que también se alinean con los valores de los consumidores concienciados con el medio ambiente, creando una ventaja competitiva en el mercado.

Además, el sector del vino está adoptando soluciones de envasado ecológicas, como botellas de vidrio ligeras y materiales alternativos que reducen el impacto medioambiental. Los compradores B2B deben buscar proveedores que estén innovando en este espacio, ya que estas prácticas no solo apoyan la sostenibilidad, sino que también pueden suponer un ahorro de costes en logística y producción.

¿Cuál es el contexto histórico de los tamaños de las botellas de vino y su relevancia para los compradores B2B?

La estandarización de los tamaños de las botellas de vino, en particular el formato de 750 ml, tiene sus raíces en prácticas históricas que se remontan al Imperio Romano. Aunque los formatos más grandes han ganado popularidad en los últimos años, la botella de 750 ml sigue siendo el estándar de la industria debido a su equilibrio entre comodidad y manejabilidad. Comprender la evolución de los tamaños de botella es crucial para los compradores B2B, ya que este conocimiento puede informar las decisiones de compra basadas en las preferencias de los consumidores y la demanda del mercado.

La diversidad de tamaños de botella, desde piccolos a dobles magnums, refleja una tendencia más amplia de personalización en la industria vinícola. Los compradores deben tener en cuenta cómo los distintos formatos de botella pueden atender a diversos segmentos del mercado, incluidos los consumidores ocasionales y los coleccionistas de alto nivel. Este contexto histórico no sólo enriquece los conocimientos de los compradores, sino que también les ayuda en el aprovisionamiento estratégico y la gestión de inventarios, garantizando que satisfacen las diversas necesidades de su clientela.

Preguntas frecuentes (FAQ) para compradores B2B de onzas líquidas en una botella de vino

-

¿Cuántas onzas líquidas hay en una botella de vino normal?

Una botella de vino estándar contiene 750 mililitros, lo que equivale aproximadamente a 25,4 onzas líquidas. Este tamaño está ampliamente reconocido y se utiliza tanto en el comercio minorista como en la hostelería. Comprender esta medida es crucial para que los compradores B2B planifiquen con precisión el inventario y proporcionen cantidades suficientes para eventos o ventas. Además, conocer el tamaño estándar de consumo (normalmente unas 5 onzas) ayuda a calcular el número de raciones por botella, lo que resulta esencial para la planificación de eventos y las expectativas de los clientes. -

¿Cuáles son los distintos tamaños de las botellas de vino y sus equivalentes en onzas líquidas?

Las botellas de vino se presentan en varios tamaños, cada uno de ellos con diferentes capacidades de onzas líquidas. Por ejemplo, una media botella contiene unas 12,7 onzas, una magnum contiene 50,7 onzas, y los formatos más grandes, como el Jeroboam, pueden contener hasta 101,4 onzas. Los compradores B2B deben familiarizarse con estos tamaños para satisfacer las distintas necesidades y preferencias de los clientes, ya que los formatos más grandes suelen buscarse para eventos y celebraciones, mientras que las botellas más pequeñas pueden ser ideales para degustaciones o consumo ocasional. -

¿Cómo se determina el número de botellas necesarias para un evento?

Para calcular el número de botellas necesarias para un evento, primero hay que estimar el número de invitados y el consumo previsto por persona. Por lo general, una botella estándar (25,4 onzas) rinde unas cinco copas de 5 onzas. Por ejemplo, si espera 100 invitados y calcula dos copas por persona, necesitará aproximadamente 40 botellas. Este método garantiza un suministro suficiente sin exceso de existencias, lo que puede inmovilizar capital innecesariamente. -

¿Qué debo tener en cuenta al abastecerme de vino para el comercio internacional?

Al abastecerse de vino para el comercio internacional, tenga en cuenta factores como la normativa de importación, los aranceles aduaneros y la logística de envío. Es esencial verificar los requisitos legales para la importación de alcohol en su mercado objetivo, incluidas las normas de etiquetado y calidad. Además, evalúe la fiabilidad de los proveedores, sus certificaciones y su capacidad para ofrecer una calidad constante. Establecer una buena comunicación y comprender los matices de las preferencias del mercado local también puede mejorar significativamente su estrategia de abastecimiento. -

¿Cómo puedo investigar eficazmente a los posibles proveedores de vino?

Investigar a los posibles proveedores de vino implica evaluar su reputación, la calidad de sus productos y su fiabilidad. Empiece por consultar las reseñas y testimonios de otros compradores B2B. Solicite muestras para evaluar la calidad del vino de primera mano. Además, infórmese sobre sus procesos de producción, certificaciones (como orgánico o comercio justo) y cumplimiento de las normas internacionales. Establecer una conexión personal mediante visitas a las instalaciones también puede proporcionar información sobre sus operaciones y ayudar a generar confianza. -

¿Cuáles son las cantidades mínimas de pedido habituales para las botellas de vino?

Las cantidades mínimas de pedido (MOQ) de botellas de vino pueden variar mucho según el proveedor y el tipo de vino. Por lo general, las cantidades mínimas de pedido pueden variar desde unas pocas cajas hasta varios palés para pedidos a granel. Es esencial aclarar estos términos antes de hacer un pedido para asegurarse de que sus requisitos de compra coinciden con las capacidades del proveedor. Considere la posibilidad de negociar las CMP si está probando nuevos productos o entrando en un nuevo mercado para minimizar el riesgo. -

¿Qué condiciones de pago son habituales en las transacciones B2B del sector vitivinícola?

Las condiciones de pago habituales en las transacciones B2B del sector vinícola incluyen el pago neto a 30, neto a 60 o por adelantado, en función de las políticas del proveedor y de la relación del comprador con él. Es fundamental negociar unas condiciones favorables que se ajusten a sus necesidades de tesorería y, al mismo tiempo, garanticen la confianza del proveedor en la transacción. Utilizar métodos de pago seguros y establecer procesos de facturación claros también puede agilizar las transacciones y reducir el riesgo de disputas. -

¿Cómo puedo garantizar la calidad de los productos vitivinícolas?

Garantizar la calidad de los productos vitivinícolas implica aplicar un planteamiento sistemático para evaluar y controlar la calidad del vino en distintas fases. Esto incluye la verificación de las certificaciones de los proveedores, la realización de controles de calidad periódicos tras la recepción y el mantenimiento de registros de muestras de productos. Además, establecer un canal de comunicación claro con los proveedores sobre las normas y expectativas de calidad puede ayudar a abordar cualquier problema de forma proactiva. Establecer un circuito de retroalimentación con los clientes también puede proporcionar información sobre el rendimiento del producto y las áreas de mejora.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Lista de los 9 mejores fabricantes y proveedores de oz líquidas en una botella de vino

1. KJ - Tamaños estándar de las botellas de vino

Dominio: kj.com

Matriculado: 1995 (30 años)

Introducción: Tamaño estándar de la botella de vino: 750 ml (25,4 onzas). Otros tamaños de botella son: Cuarto (187ml, 6.03oz), Media (375ml, 12.07oz), Vinos Dulces (500ml, 16.09oz), Magnum (1500ml, 50.07oz), Jeroboam (3L, 100oz), Rehoboam (4.5L, 152oz), Jeroboam Bordelais (5L, 169oz), Imperial (6L, 203oz), Matusalén (6L, 203oz), Salmanazar (9L, 304oz), Baltasar (12L, 406oz), Nabucodonosor (15L, 507oz), Melchor (18L, 608o...

2. Reddit - Tamaños de las raciones de vino

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: En Estados Unidos, la ración estándar de una copa de vino es de 147 ml (5 onzas), lo que significa que en una botella de vino estándar caben cinco copas de 5 onzas. Sin embargo, muchos restaurantes sirven copas de 6 onzas. En Australia, la bebida estándar oficial son 100 ml de vino tinto, pero la media en los restaurantes ronda los 150 ml.

3. Coravin - Soluciones para la conservación del vino

Dominio: coravin.com

Inscrito: 2012 (13 años)

Introducción: Una botella de vino estándar contiene 750 mililitros (ml) o 25,4 onzas. Normalmente proporciona cinco copas de vino de 5 onzas. Las copas más pequeñas (4 onzas) dan hasta 6 copas, mientras que las más grandes (6 onzas) dan unas 4 copas. Los vinos espumosos en botellas de 750 ml suelen proporcionar 6 copas. Los tamaños de botella de vino más comunes son: Media botella (375 ml): 2-3 copas; Botella estándar (750 ml): 5 copas; Ma...

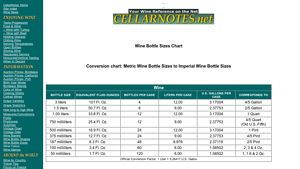

4. Notas de bodega - Conversión del tamaño de las botellas de vino

Dominio: cellarnotes.net

Matriculado: 1999 (26 años)

Introducción: Tabla de conversión de tamaños de botellas de vino: Medidas métricas de botellas de vino a medidas imperiales de botellas de vino. Tamaño de botella de vino: 3 litros, Equivalente: 101 Fl. Oz, Botellas por Caja: 4, Litros por Caja: 12.00, Galones EE.UU. por Caja: 3.17004, Corresponde a: 4/5 Galones. Tamaño de la botella de vino: 1,5 litros, Equivalente: 50,7 Fl. Oz., Botellas por Caja: 6, Litros por Caja: 9.00, Galones EE.UU. por Caja: 2.37753, Corresponde ...

5. Almacenamiento experto del vino - Tamaños de las botellas de vino

Dominio: expertwinestorage.es

Matriculado: 2020 (5 años)

Introducción: Una botella de vino estándar es de 750 ml (25,4 onzas líquidas). Otros tamaños son: Copa de vino estándar (125 ml) - 4,4 onzas, Copa de vino mediana (175 ml) - 6,1 onzas, Copa de vino grande (250 ml) - 8,8 onzas, Media botella (375 ml) - algo menos de 13 onzas, Magnum (1,5 litros) - 51 onzas, Jeroboam (3 litros) - 102 onzas. Las raciones de vino con bajo contenido alcohólico oscilan entre 6 y 11 onzas, las de vino con alto contenido alcohólico entre 4,5 y 5 onzas y las de vino con alto contenido...

6. Vinos habituales - Botellas estándar y de postre

Dominio: usualwines.com

Registrado: 2018 (7 años)

Introducción: Las botellas de vino estándar contienen 750 ml de vino, lo que equivale a 25 onzas líquidas o 1,31 pintas. Por lo general, hay cinco vasos de vino por botella estándar, suponiendo una ración estándar de 5 onzas. Los vinos de postre suelen venderse en botellas de 375 ml, que rinden unos ocho vasos debido a su menor tamaño. Los vinos espumosos tienen botellas de distintos tamaños: una botella estándar tiene capacidad para cinco copas, una magnum...

7. Batch Mead - Tamaños de las botellas de hidromiel

Dominio: batchmead.com

Inscrito: 2015 (10 años)

Introducción: Batch Mead ofrece tres tamaños de botella para su hidromiel: 375 ml (Demi), 500 ml (2/3 del tamaño de una botella estándar) y 750 ml (estándar). La botella estándar de 750 ml contiene 5 copas de vino, mientras que la botella Demi de 375 ml sirve de 2 a 3 copas. El hidromiel no contiene gluten y puede ser tradicional o fermentado con frutas o especias. Batch Mead se centra en pequeños lotes que utilizan miel e ingredientes de origen local, pro...

8. Math.Tools - Conversor de botellas de vino a onzas líquidas estadounidenses

Dominio: herramientas.matemáticas

Introducción: Conversor de botella de vino a onza líquida US. 1 botella de vino = 25.993283059955 fl oz US. Tabla de conversión disponible para hasta 20 botellas de vino. Conversión inversa: 1 onza líquida US = 0.038471477331026 botella de vino.

9. KWAF - Pack aireador de vino

Dominio: kwafwineaerators.com

Inscrito: 2021 (4 años)

Introducción: El pack de aireadores de vino KWAF incluye 2 aireadores de un solo uso que se adaptan a todas las botellas de vino. El precio normal es de $14.99, actualmente en oferta por $11.99. Disfrute de envío gratuito dentro de EE.UU. para pedidos superiores a $25.

Conclusiones y perspectivas de la contratación estratégica de oz líquidas en una botella de vino

¿Cuáles son las claves para los compradores B2B del sector vitivinícola?

Comprender las onzas líquidas de una botella de vino es crucial para los compradores B2B internacionales, sobre todo en mercados emergentes como África, Sudamérica, Oriente Medio y Europa. La botella estándar de 750 ml, que equivale aproximadamente a 25,4 onzas, es la piedra angular de las decisiones de compra de vino. Este conocimiento no sólo ayuda a gestionar con precisión el inventario, sino que también facilita una mejor planificación de los eventos y la demanda de los consumidores.

¿Cómo puede el aprovisionamiento estratégico mejorar sus compras de vino?

El aprovisionamiento estratégico desempeña un papel vital en la optimización de costes y la garantía de calidad. Al establecer relaciones sólidas con proveedores que puedan suministrar botellas de distintos tamaños y formatos, los compradores pueden satisfacer las diversas preferencias del mercado y maximizar la rentabilidad. Considere la posibilidad de abastecerse en regiones conocidas por estilos de vino o formatos de botella específicos, aprovechando los conocimientos locales para obtener una ventaja competitiva.

¿Qué les espera a los compradores internacionales de vino?

A medida que el mercado mundial del vino siga evolucionando, será esencial mantenerse informado sobre los tamaños de las botellas y las tendencias del sector. Los compradores deben adoptar estrategias de abastecimiento innovadoras y mantener la flexibilidad para adaptarse a las cambiantes preferencias de los consumidores. Trabaje con proveedores de confianza, explore nuevos formatos y tenga en cuenta la creciente demanda de experiencias enológicas únicas. Tomar estas medidas puede posicionar a su empresa para el éxito en un panorama cada vez más competitivo.