Introduction: Navigating the Global Market for plastic shaker bottle

Navigating the global market for plastic shaker bottles presents a unique challenge for international B2B buyers, especially those seeking reliable and quality products across diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality plastic shaker bottles that meet specific industry standards while ensuring cost-effectiveness can be daunting. This comprehensive guide addresses these challenges by exploring various types of shaker bottles, their applications across different industries, and the criteria for vetting suppliers effectively.

As the demand for fitness and health products continues to rise, understanding the nuances of the plastic shaker bottle market becomes essential. This guide will delve into the latest trends, material innovations, and design features that enhance user experience and product longevity. Additionally, it will provide insights into pricing strategies, helping buyers navigate their budget constraints while maximizing value.

By equipping B2B buyers with essential knowledge about sourcing, quality assurance, and supplier evaluation, this guide empowers informed purchasing decisions. Whether you are based in Nigeria, Vietnam, or any other region, this resource is tailored to help you identify and partner with the right suppliers, ensuring that your business remains competitive in an increasingly dynamic marketplace. Explore the world of plastic shaker bottles and unlock the potential for growth and success in your procurement strategies.

Artículo Navegación

- Top 6 Plastic Shaker Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for plastic shaker bottle

- Understanding plastic shaker bottle Types and Variations

- Key Industrial Applications of plastic shaker bottle

- 3 Common User Pain Points for ‘plastic shaker bottle’ & Their Solutions

- Strategic Material Selection Guide for plastic shaker bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for plastic shaker bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic shaker bottle’

- Comprehensive Cost and Pricing Analysis for plastic shaker bottle Sourcing

- Alternatives Analysis: Comparing plastic shaker bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for plastic shaker bottle

- Navigating Market Dynamics and Sourcing Trends in the plastic shaker bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of plastic shaker bottle

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for plastic shaker bottle

Understanding plastic shaker bottle Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Botella agitadora clásica | Simple design, often with a screw-on lid and mixing ball | Fitness, nutrition supplements | Pros: Asequible, ligero. Contras: Limited insulation, potential for odors. |

| Insulated Shaker Bottle | Double-wall construction for temperature retention | Sports teams, outdoor activities | Pros: Keeps drinks cold/hot longer. Contras: Heavier, higher price point. |

| Tritan Shaker Bottle | Made from BPA-free Tritan, offering durability and clarity | Food service, health clubs | Pros: Sturdy, dishwasher safe. Contras: Not completely odor-resistant. |

| Multi-Compartment Shaker | Features separate compartments for powder storage | Meal prep services, fitness classes | Pros: Convenient for on-the-go use. Contras: Bulkier design, more complex cleaning. |

| Specialty Shaker Bottle | Unique designs with features like built-in storage or mixers | Health and wellness brands | Pros: Innovative, tailored for specific uses. Contras: Higher cost, niche market. |

What are the characteristics of Classic Shaker Bottles?

Classic shaker bottles are typically straightforward in design, featuring a screw-on lid and a mixing ball to facilitate the blending of powders. They are widely used in fitness and nutrition industries due to their affordability and lightweight nature. When sourcing these bottles, B2B buyers should consider the material quality, as some variants may retain odors over time. While they are budget-friendly, buyers must be aware of the limitations in insulation, which could affect the temperature of the contents.

How do Insulated Shaker Bottles differ from other types?

Insulated shaker bottles utilize double-wall construction to maintain the temperature of beverages, making them ideal for outdoor sports and team activities. Their ability to keep drinks cold or hot for extended periods makes them a popular choice among B2B buyers in the sports and recreation sectors. However, the added insulation makes them heavier and typically more expensive than classic models. Buyers should assess their specific needs regarding portability versus temperature retention when considering these options.

Why choose Tritan Shaker Bottles for B2B purchases?

Tritan shaker bottles are made from BPA-free plastic known for its durability and clarity. This type of bottle is favored in food service and health club environments where hygiene is paramount. Tritan’s resistance to staining and odors makes it a practical choice for B2B buyers focused on long-term use. While these bottles are dishwasher safe and sturdy, they may not be completely odor-resistant, which is an important consideration for buyers concerned about maintaining product integrity over time.

What advantages do Multi-Compartment Shaker Bottles offer?

Multi-compartment shaker bottles come equipped with separate sections for storing powders and supplements, catering to meal prep services and fitness classes. These bottles provide convenience for users who need to mix their drinks on-the-go, enhancing their appeal in the health and wellness market. However, the bulkier design can complicate cleaning, and potential buyers should weigh the benefits of convenience against the increased size and complexity of maintenance.

What makes Specialty Shaker Bottles unique for specific markets?

Specialty shaker bottles are designed with unique features such as built-in storage compartments or innovative mixing mechanisms, targeting niche markets like health and wellness brands. These bottles can offer tailored solutions for specific consumer needs, making them attractive to B2B buyers looking to differentiate their product offerings. While they often come with a higher price tag, their innovative designs can justify the cost for brands aiming to provide exceptional value to their customers.

Key Industrial Applications of plastic shaker bottle

| Industria/Sector | Specific Application of plastic shaker bottle | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Alimentación y bebidas | Mixing and storing powdered ingredients like spices and protein | Enhances product consistency and quality, reduces preparation time | Ensure BPA-free materials, durability, and easy cleaning |

| Fitness and Nutrition | Protein shakes and supplement mixing for gyms and fitness centers | Provides convenience for customers, encourages repeat purchases | Look for leak-proof designs, various sizes, and customization options |

| Pharmaceutical | Compounding and storing powdered medications | Ensures accurate dosing and minimizes contamination risks | Compliance with health regulations, sterilization capabilities |

| Cosmetics and Personal Care | Mixing and dispensing powdered beauty products | Facilitates precise application and enhances user experience | Consider material compatibility with various formulations, ease of use |

| Craft and Hobby Supplies | Storing and mixing materials like glitter, paint, or powders | Offers versatility for various crafts, improving organization | Look for transparent designs for easy identification, secure lids |

How are Plastic Shaker Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, plastic shaker bottles are primarily used for mixing and storing powdered ingredients such as spices, protein powders, and flavor enhancers. They provide a reliable solution for ensuring product consistency and quality, which is crucial in maintaining customer satisfaction. Businesses in this industry must prioritize sourcing BPA-free materials to ensure safety and comply with food regulations. Additionally, durability and ease of cleaning are essential considerations to ensure long-term use.

What Role Do Plastic Shaker Bottles Play in Fitness and Nutrition?

Plastic shaker bottles are integral to gyms and fitness centers, where they are used for mixing protein shakes and other dietary supplements. They enhance customer convenience, allowing for quick preparation of drinks that support fitness goals. This encourages repeat purchases and brand loyalty. When sourcing these bottles, businesses should focus on leak-proof designs and various sizes to accommodate different customer preferences. Customization options, such as branding, can also add value.

How Are Plastic Shaker Bottles Utilized in the Pharmaceutical Sector?

In the pharmaceutical industry, plastic shaker bottles are employed for compounding and storing powdered medications. Their design helps ensure accurate dosing while minimizing contamination risks. For international buyers, especially in regions with strict health regulations, sourcing bottles that comply with these standards is critical. Additionally, the ability to sterilize the bottles is a key consideration to maintain product integrity and safety.

What Benefits Do Plastic Shaker Bottles Offer in Cosmetics and Personal Care?

In the cosmetics and personal care industry, plastic shaker bottles are used for mixing and dispensing powdered beauty products, such as foundations and exfoliants. They facilitate precise application and enhance the overall user experience. Buyers in this sector should consider the compatibility of materials with various cosmetic formulations, as well as the ease of use for consumers. Customizable designs can also attract a broader customer base.

How Are Plastic Shaker Bottles Applied in Craft and Hobby Supplies?

Plastic shaker bottles are increasingly popular in the craft and hobby supplies sector for storing and mixing materials like glitter, paint, and powders. They provide versatility, helping users keep their supplies organized and accessible. When sourcing these bottles, businesses should look for transparent designs that allow for easy identification of contents and secure lids to prevent spills. This functionality can significantly enhance user satisfaction and promote repeat sales.

3 Common User Pain Points for ‘plastic shaker bottle’ & Their Solutions

Scenario 1: Concerns About Durability and Breakage During Shipping

El problema: B2B buyers often face issues with the durability of plastic shaker bottles, especially when sourcing products internationally. The bottles can easily break during transit, leading to losses and potential damage claims. In regions with rough shipping conditions, such as parts of Africa and South America, this problem is exacerbated by inadequate packaging and handling processes. Buyers worry about the quality of products they receive, which can affect their reputation and customer satisfaction.

La solución: To mitigate these concerns, buyers should prioritize sourcing from manufacturers who offer robust packaging solutions and conduct thorough quality control checks. Engaging suppliers with a proven track record in shipping can ensure that plastic shaker bottles arrive intact. Additionally, buyers can specify the use of thicker plastic materials or reinforced designs in their purchase agreements. When discussing shipments with suppliers, it is beneficial to request samples to assess durability before placing larger orders. Leveraging technology such as real-time tracking can also help monitor shipments to avoid potential breakage during transit.

Scenario 2: Odor Retention and Cleaning Difficulties

El problema: Another common pain point for B2B buyers is the issue of odor retention in plastic shaker bottles. Many low-quality bottles absorb smells from protein powders and other ingredients, which can be off-putting for end users. This not only affects the user experience but also leads to increased returns and customer dissatisfaction. In markets where health and hygiene are paramount, such as in the Middle East and Europe, this issue can significantly impact brand loyalty.

La solución: To address odor retention, buyers should focus on sourcing shaker bottles made from high-quality, BPA-free plastics designed to resist odor absorption. When negotiating with suppliers, it is advisable to inquire about the materials used in production and request information on cleaning recommendations. Providing end users with proper care instructions can also enhance the lifespan and cleanliness of the shaker bottles. Buyers might also consider offering a variety of designs that facilitate easier cleaning, such as wide-mouth openings or dishwasher-safe options, to encourage proper maintenance and reduce odor issues.

Scenario 3: Inconsistent Mixing Performance

El problema: B2B buyers frequently encounter dissatisfaction from end users regarding the mixing performance of plastic shaker bottles. Users expect a smooth blend of powders and liquids, but many cheaper models fail to deliver, leaving clumps that detract from the drinking experience. This inconsistency can lead to negative reviews and diminished sales, especially in competitive markets where quality is a key differentiator.

La solución: To ensure consistent mixing performance, buyers should invest in shaker bottles with innovative mixing mechanisms, such as built-in agitators or specially designed blending balls. When selecting suppliers, it’s important to evaluate product specifications and request performance testing results. Additionally, conducting market research to understand user preferences can guide product selection. Educating end users about the proper shaking technique and the importance of adding liquids before powders can also enhance the mixing experience. By focusing on these features, buyers can better meet consumer expectations and improve overall satisfaction with their shaker bottles.

Strategic Material Selection Guide for plastic shaker bottle

What Are the Key Properties of Common Materials for Plastic Shaker Bottles?

When selecting materials for plastic shaker bottles, it’s essential to consider the properties that directly impact performance, safety, and user experience. The most common materials used in the manufacture of these bottles include Polyethylene Terephthalate (PET), Polypropylene (PP), Tritan™, and Polycarbonate (PC). Each material has distinct characteristics that can affect the final product’s functionality and marketability.

How Does Polyethylene Terephthalate (PET) Perform in Shaker Bottles?

PET is widely recognized for its excellent clarity and strength, making it a popular choice for shaker bottles. It has a temperature rating of up to 70°C (158°F) and is resistant to impact and moisture. However, PET is less suitable for hot liquids and can warp under high temperatures.

Pros: PET is lightweight, cost-effective, and recyclable, appealing to environmentally conscious consumers. Its clarity allows for attractive designs and branding visibility.

Contras: While durable, PET can be less resistant to scratches and may absorb odors over time. It is also not suitable for microwave use, limiting its versatility.

Impacto en la aplicación: PET is ideal for cold beverages and protein shakes but may not be the best choice for hot liquids or high-pressure applications.

Consideraciones para compradores internacionales: Compliance with FDA and EU regulations for food safety is crucial. Buyers in regions like Africa and South America should ensure that suppliers meet local standards for recycling and material safety.

What Are the Advantages of Using Polypropylene (PP)?

Polypropylene is another common material known for its high resistance to heat, making it suitable for hot liquids. It has a temperature resistance of up to 100°C (212°F) and offers excellent chemical resistance.

Pros: PP is durable, lightweight, and has a low cost of production. It is also microwave-safe, making it versatile for various applications.

Contras: While resistant to chemicals, PP can become brittle over time, especially when exposed to UV light. It is also less transparent than PET, which may affect branding visibility.

Impacto en la aplicación: PP is ideal for shaker bottles designed for both hot and cold beverages, particularly in fitness and health markets.

Consideraciones para compradores internacionales: Buyers should verify compliance with ASTM and ISO standards. In regions with high UV exposure, such as parts of Africa, UV stabilization may be necessary to enhance durability.

Why Choose Tritan™ for Shaker Bottles?

Tritan™ is a copolyester known for its clarity and toughness, often marketed as a BPA-free alternative to polycarbonate. It has a temperature resistance of up to 90°C (194°F) and is highly resistant to odors and stains.

Pros: Tritan™ is dishwasher-safe, shatter-resistant, and retains its clarity over time. It provides a premium feel, appealing to higher-end markets.

Contras: The cost of Tritan™ is generally higher than that of PET and PP, which may impact pricing strategies.

Impacto en la aplicación: Tritan™ is suitable for a wide range of beverages, including those with strong flavors or odors, making it ideal for protein shakes and flavored drinks.

Consideraciones para compradores internacionales: Ensure compliance with global safety standards, as Tritan™ is often marketed in regions with strict regulations regarding food contact materials.

What About Polycarbonate (PC) for Shaker Bottles?

Polycarbonate is a strong, durable plastic with high impact resistance and a temperature rating of up to 120°C (248°F). It is often used in industrial applications due to its robustness.

Pros: PC is highly durable and can withstand extreme conditions, making it suitable for heavy-duty applications.

Contras: The primary concern with polycarbonate is the potential for BPA leaching, which has led to a decline in its popularity for food and beverage containers.

Impacto en la aplicación: While PC can handle hot liquids and is very durable, concerns about health risks may limit its acceptance in the consumer market.

Consideraciones para compradores internacionales: Buyers must ensure that products made from polycarbonate are BPA-free and comply with health regulations in their respective markets, particularly in Europe and North America.

Summary Table of Material Selection for Plastic Shaker Bottles

| Material | Typical Use Case for plastic shaker bottle | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Tereftalato de polietileno (PET) | Cold beverages, protein shakes | Ligero y reciclable | Not suitable for hot liquids | Bajo |

| Polipropileno (PP) | Hot and cold beverages, versatile use | High heat resistance | Can become brittle over time | Bajo |

| Tritan | Premium shaker bottles, flavored drinks | Shatter-resistant and BPA-free | Higher cost than PET and PP | Alta |

| Polycarbonate (PC) | Heavy-duty applications, industrial use | Extremely durable | Potential BPA leaching | Med |

This strategic material selection guide provides B2B buyers with insights to make informed decisions regarding the materials used in plastic shaker bottles, considering performance, compliance, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic shaker bottle

What Are the Key Stages in the Manufacturing Process of Plastic Shaker Bottles?

The manufacturing of plastic shaker bottles involves several critical stages, each contributing to the final product’s quality and usability. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used in Plastic Shaker Bottle Production?

The first step in manufacturing plastic shaker bottles is selecting the right materials. Commonly used plastics include Polyethylene Terephthalate (PET), Polypropylene (PP), and Tritan, a copolyester known for its durability and clarity. These materials are chosen for their lightweight properties, resistance to impact, and food safety compliance.

Before processing, raw materials are often pelletized, which involves breaking down large plastic pieces into smaller pellets. This ensures uniformity in the melting process and allows for better control over the final product’s characteristics.

2. How Are Plastic Shaker Bottles Formed?

Once the materials are prepared, the next stage is forming, which can be achieved through various techniques:

-

Moldeo por inyección: This is the most common method used for producing plastic shaker bottles. In this process, heated plastic pellets are injected into a mold cavity, where they cool and solidify into the desired shape. Injection molding allows for high precision and repeatability, making it ideal for mass production.

-

Moldeo por soplado: This technique is often used for producing hollow containers. A tube of molten plastic is inflated inside a mold to form the bottle’s shape. Blow molding is particularly useful for creating lightweight bottles with a smooth finish.

-

Rotational Molding: Although less common, this technique is used for larger shaker bottles. In rotational molding, the plastic is placed in a mold that rotates while heated, allowing the material to coat the inside of the mold evenly.

3. What Does the Assembly Process Involve?

After forming, the bottles undergo an assembly process that may include the addition of components like caps, seals, and mixing elements. These components are typically manufactured separately and may involve:

-

Cap Production: Caps are often made from PP or other food-safe materials. They may include features like flip-top openings or built-in mixing balls, which help blend contents effectively.

-

Seal Installation: Many shaker bottles feature silicone or rubber seals to ensure leak-proof performance. These seals are fitted into the cap or lid to prevent spills during transport.

-

Quality Checks During Assembly: As components are assembled, manufacturers perform initial quality checks to ensure correct fit and function.

4. How Is the Finishing Process Conducted?

The finishing stage involves several steps to enhance the shaker bottle’s functionality and aesthetic appeal:

-

Surface Treatment: Bottles may undergo processes such as polishing or coating to improve scratch resistance and enhance visual appeal. Some manufacturers apply UV-resistant coatings to prevent discoloration from sunlight.

-

Labeling and Branding: Custom labels or prints are often added at this stage, allowing brands to showcase their identity on the product.

-

Final Inspection: Before packaging, each bottle is inspected for defects, ensuring that only products meeting quality standards proceed to distribution.

What Are the Quality Assurance Measures in Place for Plastic Shaker Bottles?

Quality assurance (QA) is critical in the manufacturing of plastic shaker bottles to ensure they meet international safety and performance standards. This is especially important for B2B buyers seeking reliable suppliers.

1. What International Standards Should Buyers Be Aware Of?

Several international standards govern the manufacturing of plastic products:

-

ISO 9001: This standard specifies requirements for a quality management system, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

-

Marcado CE: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

-

Food Safety Standards: Compliance with regulations such as the FDA in the United States or EFSA in Europe is crucial for products intended for food and beverage use.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) in the manufacturing process typically involves several checkpoints:

-

Control de calidad entrante (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they enter the production process.

-

Control de calidad durante el proceso (IPQC): During production, regular checks are conducted to monitor the manufacturing process and ensure that products meet predefined quality standards.

-

Control de calidad final (CCF): Once production is complete, a thorough inspection is performed on finished products to identify any defects or inconsistencies.

3. What Common Testing Methods Are Employed?

Manufacturers utilize various testing methods to assess product quality:

-

Mechanical Testing: This includes tests for tensile strength, impact resistance, and flexibility to ensure the bottles can withstand regular use.

-

Pruebas de estanqueidad: Bottles are often subjected to pressure tests to verify that seals and closures are effective.

-

Pruebas químicas: This ensures that materials used in the bottle do not leach harmful substances, particularly when in contact with food or beverages.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, verifying a supplier’s quality assurance processes is crucial for ensuring product reliability. Here are several strategies:

1. Conducting Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include on-site visits to evaluate facilities, equipment, and practices.

2. Reviewing Quality Reports

Requesting quality assurance reports from suppliers can help buyers understand their compliance with international standards and internal quality metrics.

3. Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of product quality. These services can conduct inspections at various stages of production, ensuring adherence to specifications.

What Are the Unique QC Considerations for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is essential.

-

Customs Regulations: Different countries have varying import regulations, which may require additional certifications or documentation. Familiarizing oneself with these requirements can prevent delays and compliance issues.

-

Cultural Expectations: Awareness of cultural preferences regarding product design and functionality can enhance buyer-supplier relationships. For example, preferences for color, size, and usability may differ across regions.

-

Prácticas de sostenibilidad: Increasingly, buyers are looking for suppliers who adhere to sustainable manufacturing practices. Suppliers who can demonstrate environmental responsibility through certifications or eco-friendly materials may have a competitive edge.

By understanding the manufacturing processes and quality assurance measures involved in plastic shaker bottle production, B2B buyers can make more informed decisions, ensuring they partner with reliable suppliers that meet their quality and compliance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic shaker bottle’

In the competitive landscape of B2B procurement, sourcing high-quality plastic shaker bottles requires a strategic approach. This guide provides a step-by-step checklist to help international buyers effectively navigate the sourcing process, ensuring they select the best products for their needs.

Primer paso: Defina sus especificaciones técnicas

Establishing clear technical specifications is crucial to ensure that the shaker bottles meet your intended use. Consider factors such as size, material (e.g., BPA-free plastic), and design features like leak-proof lids or built-in mixing mechanisms. Defining these parameters helps streamline supplier selection and reduces the risk of receiving unsuitable products.

Segundo paso: Investigar las tendencias del mercado y la demanda

Understanding current market trends can provide insights into popular designs and features that resonate with consumers. Investigate regional preferences and cultural factors, especially in markets like Africa, South America, and the Middle East. This knowledge can guide your purchasing decisions and ensure you align with customer expectations.

Tercer paso: Identify and Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough due diligence. Look for manufacturers with a proven track record in producing plastic shaker bottles. Request samples to assess quality and performance, and check for certifications (e.g., ISO, FDA) that indicate compliance with health and safety standards.

- Tip: Utilize online platforms and trade shows to connect with potential suppliers and gather reviews from other B2B buyers.

Paso 4: Request Quotations and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotations that outline pricing, minimum order quantities, and delivery timelines. Comparing these factors helps you identify the best value while ensuring that quality is not compromised for cost. Be mindful of potential hidden costs, such as shipping and customs duties.

Paso 5: Negociar las condiciones

Effective negotiation can significantly impact your procurement success. Discuss payment terms, return policies, and warranties to protect your investment. Ensure that all agreements are documented and clearly outline responsibilities on both sides to prevent misunderstandings later.

Paso 6: Assess Logistics and Supply Chain Reliability

Evaluate the logistical capabilities of your selected suppliers. Reliable suppliers should have efficient processes in place for production, quality control, and timely delivery. Consider their ability to scale production based on your demand fluctuations, especially if you plan to expand your product line in the future.

Paso 7: Conduct a Final Quality Inspection

Before finalizing your order, arrange for a quality inspection of the shaker bottles. This step is vital to confirm that the products meet your specifications and quality standards. Engaging a third-party inspection service can provide additional assurance, especially when dealing with overseas suppliers.

By following this checklist, B2B buyers can navigate the complexities of sourcing plastic shaker bottles with confidence, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for plastic shaker bottle Sourcing

What Are the Key Cost Components in Sourcing Plastic Shaker Bottles?

Sourcing plastic shaker bottles involves several critical cost components that B2B buyers should understand to make informed purchasing decisions. The primary cost elements include:

-

Materiales: The choice of plastic (e.g., BPA-free, Tritan, or recycled materials) significantly impacts costs. Higher-quality materials may lead to increased durability and safety, but they also raise the initial price.

-

Trabajo: Labor costs can vary greatly based on the country of manufacture. Regions with lower labor costs may provide more competitive pricing but could compromise quality. It’s essential to assess not only the cost but the skill level of the workforce involved in production.

-

Gastos generales de fabricación: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, which can be a significant part of the total cost structure.

-

Herramientas: Initial tooling costs for molds and production equipment can be substantial. Buyers should inquire about these costs upfront, especially if they require custom designs or unique features.

-

Control de calidad (CC): Implementing stringent QC measures ensures product reliability and compliance with health standards. However, rigorous QC processes can add to the overall cost.

-

Logística: Shipping and handling costs can vary based on the shipping method, distance, and Incoterms. International buyers should factor in customs duties, taxes, and potential delays during transit.

-

Margen: Suppliers typically add a profit margin to their costs, which can vary based on the supplier’s market position and the perceived value of their products.

How Do Price Influencers Affect the Cost of Plastic Shaker Bottles?

Several factors can influence the pricing structure of plastic shaker bottles:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can be beneficial for businesses planning to resell or distribute the products.

-

Specifications and Customization: Custom designs, colors, or features can significantly increase costs. Buyers should weigh the benefits of customization against the additional expenses it incurs.

-

Materials and Quality Certifications: Bottles made from higher-grade materials or those that comply with specific certifications (e.g., FDA-approved, ISO-certified) may command higher prices. These factors can enhance the perceived value and safety of the product.

-

Factores del proveedor: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total cost.

What Tips Can Help Buyers Negotiate Better Prices for Plastic Shaker Bottles?

B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to negotiate better prices:

-

Negotiate Terms: Don’t hesitate to discuss pricing, payment terms, and delivery schedules. Establishing a good rapport with suppliers can lead to favorable terms.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like shipping, handling, and potential product failures. A lower upfront cost may lead to higher long-term expenses if the product quality is subpar.

-

Research Market Prices: Conduct thorough market research to understand the prevailing prices for similar products. This knowledge can serve as leverage during negotiations.

-

Leverage Volume Discounts: If you anticipate consistent demand, negotiating volume discounts can lead to significant savings. Building a long-term relationship with suppliers can also yield better pricing over time.

-

Understand Regional Pricing Nuances: Be aware of regional market conditions, including currency fluctuations, import/export regulations, and trade agreements that may affect pricing.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and due diligence before making procurement decisions.

Alternatives Analysis: Comparing plastic shaker bottle With Other Solutions

Exploring Alternatives to Plastic Shaker Bottles in B2B Markets

In the quest for efficient mixing solutions, plastic shaker bottles have long been a staple for various industries, including fitness, food services, and pharmaceuticals. However, as environmental concerns rise and consumer preferences shift, it’s essential for B2B buyers to explore alternative options. This analysis will compare plastic shaker bottles with two viable alternatives: stainless steel shaker bottles and electric mixing devices.

| Aspecto comparativo | Botella agitadora de plástico | Stainless Steel Shaker Bottle | Electric Mixing Device |

|---|---|---|---|

| Rendimiento | Good for mixing powders and liquids; potential for odor retention | Excellent mixing capabilities; retains temperature | Superior mixing efficiency, especially for thick substances |

| Coste | Generally low-cost ($2 – $30) | Moderate cost ($20 – $40) | Higher upfront cost ($50 – $150) |

| Facilidad de aplicación | Easy to use and lightweight | Slightly heavier, but easy to handle | Requires charging or batteries; may need user training |

| Mantenimiento | Easy to clean but may stain or retain odors | Simple cleaning, often dishwasher safe | Requires more maintenance; cleaning can be complex |

| El mejor caso de uso | Ideal for casual use in fitness and food settings | Best for professionals needing durability and temperature retention | Perfect for commercial settings needing consistent and thorough mixing |

Ventajas e inconvenientes de cada alternativa

Stainless Steel Shaker Bottles

Stainless steel shaker bottles present a robust alternative to their plastic counterparts. They excel in performance, offering superior mixing capabilities without retaining odors or flavors. Their durability and insulation properties mean they can keep beverages hot or cold for extended periods. However, they come at a higher price point, which might deter budget-conscious businesses. Additionally, their weight can be a drawback for users accustomed to lighter plastic bottles.

Electric Mixing Devices

Electric mixing devices represent the most advanced option available. They provide unparalleled mixing efficiency, making them ideal for thicker substances such as protein powders and nutritional supplements. Their capability to achieve a smooth blend in seconds is a significant advantage for businesses that prioritize quality. However, the higher cost and the need for charging or battery replacements may be prohibitive for some. Moreover, users may require training to operate these devices effectively, which can add to the overall implementation time and cost.

La elección correcta para las necesidades de su empresa

When considering the best solution for your mixing needs, B2B buyers should evaluate their specific requirements. If budget constraints are a primary concern, plastic shaker bottles may still be the most viable option, offering decent performance and low maintenance. Conversely, if durability, temperature control, and long-term sustainability are top priorities, stainless steel shaker bottles can offer significant advantages despite the higher initial investment. For businesses requiring high efficiency and consistency in mixing, electric devices may be the ultimate solution, provided they can accommodate the associated costs and training.

In conclusion, the decision between plastic shaker bottles and their alternatives hinges on balancing performance, cost, and the specific needs of your operations. By thoroughly assessing these factors, B2B buyers can make informed choices that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for plastic shaker bottle

What Are the Key Technical Properties of Plastic Shaker Bottles?

When sourcing plastic shaker bottles for B2B purposes, understanding the essential technical properties can significantly influence purchasing decisions and supply chain management. Here are some critical specifications to consider:

1. Material Grade

The material used in the production of shaker bottles typically includes BPA-free plastics such as Tritan, polypropylene, or polyethylene. Tritan, for instance, is known for its durability and clarity, making it a popular choice. B2B buyers should prioritize material grades that ensure safety, durability, and resistance to odors or staining, which can affect customer satisfaction and brand reputation.

2. Capacidad

Shaker bottles come in various sizes, commonly ranging from 400 ml to 1000 ml. The capacity is crucial for determining the usability of the product for different customer segments, such as fitness enthusiasts or culinary professionals. Buyers should assess their target market’s needs to select appropriate sizes that maximize sales opportunities.

3. Leak Resistance

A reliable shaker bottle must offer effective leak-proof technology, often achieved through silicone seals or threaded caps. This property is vital for ensuring customer satisfaction and minimizing product returns. B2B buyers should inquire about testing standards and certifications related to leak resistance to ensure product reliability.

4. Dishwasher Safety

Many manufacturers promote their shaker bottles as dishwasher-safe, which adds value for end-users who prioritize convenience. Understanding whether the materials used can withstand high temperatures without deforming is essential for quality assurance. Buyers should also consider how this feature can influence customer loyalty and repeat purchases.

5. Odor Resistance

Odor resistance is a significant property for shaker bottles, especially when used for protein shakes or flavored beverages. Materials like Tritan are engineered to resist retaining odors, ensuring that the product remains fresh and appealing over time. B2B buyers should look for bottles that are marketed as odor-resistant, as this can be a strong selling point.

6. Customization Options

Customization capabilities, such as branding or color variations, are increasingly important in the B2B sector. Buyers should inquire about minimum order quantities (MOQ) and lead times for customized products, as this can affect marketing strategies and inventory planning.

Which Trade Terms Are Essential for Sourcing Plastic Shaker Bottles?

Understanding common trade terminology is crucial for effective communication with suppliers and ensuring smooth transactions. Here are some key terms to be familiar with:

1. OEM (fabricante de equipos originales)

An OEM refers to a company that manufactures products that are then sold under another company’s brand. For B2B buyers, partnering with an OEM can provide opportunities for private labeling and customization, enhancing brand differentiation in the market.

2. MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest number of units that a supplier is willing to sell in a single order. Understanding MOQ is essential for inventory management and cost-effectiveness. Buyers should negotiate MOQs to align with their sales forecasts and avoid excess inventory.

3. RFQ (solicitud de oferta)

An RFQ is a document that buyers send to suppliers to solicit pricing and terms for specific products. It is a fundamental step in the procurement process, enabling buyers to compare offers and make informed purchasing decisions.

4. Incoterms (Términos comerciales internacionales)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is critical for B2B transactions, especially when dealing with international suppliers, as they help clarify cost responsibilities and delivery conditions.

5. 5. Plazo de entrega

Lead time refers to the time it takes from placing an order until the goods are delivered. Understanding lead times is vital for inventory planning and ensuring that stock levels meet customer demand without interruption.

6. Compliance Standards

Compliance standards pertain to regulations that products must meet, such as FDA approval for food-safe materials. For B2B buyers, ensuring that products adhere to local and international compliance standards is crucial for legal and safety considerations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing plastic shaker bottles, ultimately enhancing their procurement strategies and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the plastic shaker bottle Sector

Global demand for plastic shaker bottles is witnessing significant growth, driven by a surge in fitness and health consciousness among consumers across various regions. This trend is particularly pronounced in markets such as Africa, South America, the Middle East, and Europe, where an increasing number of individuals are integrating protein supplements and meal replacements into their diets. As a result, B2B buyers should be aware that the market is becoming increasingly competitive, with a plethora of options available for sourcing.

Emerging technologies are reshaping the sourcing landscape, with innovations such as 3D printing enabling custom designs and rapid prototyping. This technology allows manufacturers to create unique shaker bottles tailored to specific customer needs, enhancing brand differentiation. Additionally, e-commerce platforms are facilitating direct procurement channels, enabling international buyers to access a broader range of suppliers and products from different regions, including emerging markets in Nigeria and Vietnam.

Another key trend is the focus on functionality and design. Modern shaker bottles are incorporating features like odor resistance, easy-to-clean designs, and multi-purpose functionality, catering to the evolving preferences of consumers. B2B buyers must stay attuned to these trends to make informed decisions that align with market demands.

How is Sustainability Influencing the Sourcing of Plastic Shaker Bottles?

Sustainability is becoming a cornerstone of sourcing strategies in the plastic shaker bottle sector. The environmental impact of plastic waste is prompting businesses to seek alternatives that minimize ecological footprints. Ethical sourcing practices are gaining traction, as buyers increasingly demand transparency in supply chains. This shift is particularly relevant for international buyers who are keen to align with global sustainability goals.

Manufacturers are responding by adopting eco-friendly materials, such as biodegradable plastics and recycled materials, to produce shaker bottles. Certifications like ISO 14001 (Environmental Management) and the use of materials that meet standards for food safety and recyclability are becoming essential for suppliers aiming to appeal to environmentally conscious buyers.

Moreover, the emergence of ‘green’ certifications is providing B2B buyers with a framework to evaluate suppliers. By choosing partners committed to sustainable practices, companies can enhance their brand reputation and meet the growing consumer demand for responsible products.

What is the Historical Evolution of the Plastic Shaker Bottle?

The plastic shaker bottle has evolved significantly since its inception in the late 20th century. Initially designed for simple mixing of protein powders, these bottles have transformed into multifunctional tools that cater to various dietary needs and lifestyle preferences. The introduction of materials like BPA-free plastics and innovations in design have improved the functionality and safety of shaker bottles.

As health trends gained momentum in the 2000s, the demand for shaker bottles surged, leading manufacturers to innovate further. Today, the market features a diverse range of options, from basic models to advanced designs equipped with features like built-in storage compartments and ergonomic grips. This evolution highlights the importance of adaptability in the B2B landscape, as suppliers must continuously innovate to meet changing consumer demands and preferences.

In summary, international B2B buyers in the plastic shaker bottle sector must navigate a dynamic market characterized by technological advancements, a strong emphasis on sustainability, and an evolving understanding of consumer needs. By staying informed and proactive, buyers can leverage these trends to make strategic sourcing decisions that align with market demands and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic shaker bottle

-

How do I choose the right plastic shaker bottle for my business needs?

Choosing the right plastic shaker bottle involves considering factors such as material quality, capacity, and design. Look for BPA-free options to ensure safety and durability. Assess your target market’s preferences; for example, colors and sizes that appeal to specific demographics. Additionally, consider whether you need features like leak-proof lids, mixing mechanisms, or easy-to-clean designs. Request samples from suppliers to evaluate their product quality firsthand before making bulk purchases. -

What are the key features to look for in a high-quality plastic shaker bottle?

When sourcing high-quality plastic shaker bottles, focus on features such as material composition, functionality, and ease of use. Look for bottles made from durable, BPA-free plastic that can withstand daily use. Ensure they have secure, leak-proof lids and mixing mechanisms like a ball or mesh screen for optimal blending. Additionally, consider bottles that are dishwasher safe for easy cleaning. A transparent design can also enhance usability by allowing users to see contents clearly. -

What is the minimum order quantity (MOQ) for plastic shaker bottles?

MOQs for plastic shaker bottles can vary significantly depending on the supplier and customization options. Generally, MOQs range from 500 to 5,000 units. If you require specific branding or custom designs, the MOQ may be higher. Always inquire about the supplier’s MOQ policies, as some may offer flexibility for first-time orders or provide samples at a lower quantity. Establishing a good relationship with suppliers may also lead to better terms in future orders. -

How do I vet potential suppliers for plastic shaker bottles?

Vetting suppliers is crucial to ensure product quality and reliability. Start by researching their reputation through online reviews and testimonials from other B2B buyers. Verify their certifications, such as ISO or GMP, which indicate adherence to quality standards. Request product samples to evaluate quality firsthand and inquire about their production capabilities and lead times. Additionally, assess their communication responsiveness and willingness to provide references from existing clients to gauge their reliability. -

What payment terms should I expect when sourcing plastic shaker bottles?

Payment terms can vary by supplier, but typical arrangements include a deposit (usually 30% upfront) with the balance due before shipment. Some suppliers may offer net terms (e.g., net 30 or net 60) for established relationships. It’s essential to clarify payment methods accepted, such as wire transfers, letters of credit, or online payment platforms. Consider negotiating favorable terms based on order size and your payment history to enhance cash flow management. -

What quality assurance measures should I implement when sourcing shaker bottles?

Implementing quality assurance (QA) measures is vital to ensure the shaker bottles meet your specifications. Establish clear product specifications, including material standards and performance criteria. Request certifications from suppliers that confirm compliance with safety regulations. Conduct regular inspections during production and consider third-party quality audits to verify product consistency. Additionally, set up a robust return policy for defective items to mitigate risks associated with poor-quality products. -

How can I customize plastic shaker bottles for my brand?

Customizing plastic shaker bottles can enhance brand visibility and appeal to your target market. Discuss options with your supplier, such as printing your logo, selecting specific colors, or altering the bottle shape. Many suppliers offer various customization techniques, including screen printing, pad printing, or labeling. Ensure you provide high-resolution artwork and understand the additional costs and lead times associated with customization. A well-defined design brief will help streamline the process and achieve your desired outcome. -

What logistics considerations should I keep in mind when importing plastic shaker bottles?

When importing plastic shaker bottles, logistics play a critical role in ensuring timely delivery and cost efficiency. Assess shipping methods (air vs. sea) based on urgency and budget constraints. Understand the customs regulations and duties applicable in your region to avoid unexpected costs. Collaborate with a reliable freight forwarder to navigate international shipping complexities and ensure compliance with import regulations. Additionally, track shipments closely to manage inventory levels effectively upon arrival.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 6 Plastic Shaker Bottle Manufacturers & Suppliers List

1. BlenderBottle - Coctelera deportiva aislada de acero inoxidable

Dominio: blenderbottle.com

Matriculado: 1999 (26 años)

Introducción: Mejores Vasos Mezcladores y Botellas Mezcladoras de Proteínas | BlenderBottle

Key Products:

1. Insulated Stainless Sport Shaker – Sale Price: $27.99, Rating: 4.5 (739 reviews)

– Variants: Cobalt, Cranberry, Nightshade, Grapefruit

2. Stainless Sleek Sport Shaker – Sale Price: $29.99, Rating: 4.4 (113 reviews)

– Variants: Sherbet, Seafoam, Lavender, Sangria

3. Tritan Sport Shaker – Sale Price: From $18.99, Ra…

2. Smoke N Deal – Plastic Shaker Bottle w/Red Cap

Dominio: smokindealbbq.com

Registrado: 2014 (11 años)

Introducción: {“name”: “Plastic Shaker Bottle w/Red Cap”, “size”: “5.5 oz.”, “material”: “BPA Free”, “price”: “$2.99”, “availability”: “In stock”, “SKU”: “221224”, “description”: “Premium Quality: Our plastic spice containers are made of high quality plastic, durable and lightweight, not easily broken. Multi Purpose: Our clear plastic jars are perfect for storing dried spices, salt, peppers, seasonings, herb bl…

3. BOLDE® - Botella agitadora totalmente de acero

Dominio: boldebottle.com

Registrado: 2018 (7 años)

Introducción: BOLDE® Bottle es una botella agitadora totalmente de acero diseñada para ser duradera, inodora e higiénica. Sus principales características son:

– Made with 304 Stainless Steel in the inner lid, spout, mixer, and bottle.

– Patented all-steel interior prevents odor and bacteria absorption.

– No microplastics, making it a healthier option compared to plastic shaker bottles.

- Fácil de limpiar y apto para lavavajillas.

– Premium silicone…

4. BlenderBottle - Botella mezcladora Classic V2

Dominio: garagegymreviews.com

Registrado: 2014 (11 años)

Introducción: Mejor Botella Mezcladora en General: BlenderBottle Classic V2 Shaker Bottle

GGR Score: 4.65

Product Highlights: New and improved V2 BlenderBall Classic with rounded base and Spoutguard.

Features: Measurement markings, rounded base, adjustable carry loop, classic BlendBall wire whisk, spout guard.

Pros: More affordable than competitors, top rack dishwasher safe, available in multiple sizes (20-45 oz), very…

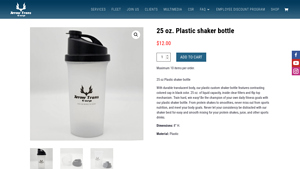

5. Arrow Trans – 25 oz. Plastic Shaker Bottle

Dominio: arrowtrans.net

Inscrito: 2015 (10 años)

Introducción: {“name”: “25 oz. Plastic shaker bottle”, “price”: “$12.00”, “capacity”: “25 oz.”, “dimensions”: “8” H”, “material”: “Plastic”, “features”: [“durable translucent body”, “contrasting colored cap in black”, “inside clear filters”, “flip top mechanism”], “usage”: [“protein shakes”, “smoothies”, “sports nutrition”, “juice”, “other sports drinks”], “slogan”: “Train hard, win easy!”}

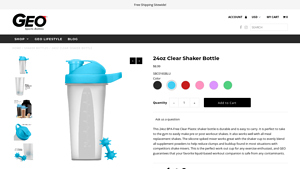

6. GeoBottles – 24oz Clear Shaker Bottle

Dominio: geobottles.com

Inscrito: 2016 (9 años)

Introducción: {“name”:”24oz Clear Shaker Bottle”,”price”:”$8.99″,”sku”:”SBC016SBLK”,”colors”:[“Black”,”Light Blue”,”Red”,”Pink”,”Purple”,”Green”],”capacity”:”24oz”,”material”:”BPA-Free Clear Plastic”,”features”:[“Durable”,”Easy to carry”,”Perfect for gym use”,”Works with meal replacement shakes”,”Silicone spiked mixer for even blending”,”Reduces clumps and buildup”],”target_audience”:”Exercise enthusiasts”,”gua…

Strategic Sourcing Conclusion and Outlook for plastic shaker bottle

In summary, the strategic sourcing of plastic shaker bottles presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Buyers should prioritize high-quality materials, such as BPA-free plastics, and consider innovative designs that enhance functionality—like odor resistance and ease of cleaning. Understanding consumer preferences for customization and sustainability can also inform sourcing decisions, as these factors are increasingly influencing purchasing behavior.

The value of strategic sourcing lies not only in cost savings but also in fostering long-term partnerships with reliable suppliers. This approach ensures access to a diverse range of products that meet the evolving demands of your customer base. As the market for shaker bottles continues to expand, staying ahead of trends and consumer expectations will be crucial.

Looking forward, we encourage B2B buyers to leverage these insights and engage with reputable suppliers who align with their strategic goals. By doing so, you can position your business to capitalize on the growing demand for high-quality shaker bottles, ultimately driving sales and enhancing brand loyalty in your target markets.