Introduction: Navigating the Global Market for 2.5 liter bottle

Navigating the global market for 2.5 liter bottles presents a unique set of challenges for international B2B buyers. Sourcing quality products that meet diverse regional requirements can be daunting, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The growing demand for sustainable packaging solutions, along with the need for reliable suppliers, necessitates a comprehensive understanding of the various types of 2.5 liter bottles available in the market, including plastic, aluminum, and insulated options.

This guide is designed to empower B2B buyers by providing a detailed exploration of the 2.5 liter bottle landscape. It covers essential aspects such as product types, applications in industries ranging from beverages to chemicals, and best practices for supplier vetting. Additionally, the guide addresses cost considerations, shipping logistics, and compliance with international safety standards, ensuring that buyers can make informed purchasing decisions that align with their business goals.

By equipping buyers with actionable insights and a thorough understanding of the market dynamics, this guide aims to streamline the procurement process and foster successful partnerships. Whether you are a distributor, retailer, or manufacturer, understanding the nuances of the 2.5 liter bottle market will enable you to meet consumer demands effectively while navigating the complexities of global trade.

Artículo Navegación

- Top 7 2.5 Liter Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 2.5 liter bottle

- Understanding 2.5 liter bottle Types and Variations

- Key Industrial Applications of 2.5 liter bottle

- 3 Common User Pain Points for ‘2.5 liter bottle’ & Their Solutions

- Strategic Material Selection Guide for 2.5 liter bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 2.5 liter bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.5 liter bottle’

- Comprehensive Cost and Pricing Analysis for 2.5 liter bottle Sourcing

- Alternatives Analysis: Comparing 2.5 liter bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 2.5 liter bottle

- Navigating Market Dynamics and Sourcing Trends in the 2.5 liter bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 2.5 liter bottle

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for 2.5 liter bottle

Understanding 2.5 liter bottle Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Aluminum Bottle | UN-rated, leak-proof, food-grade material | Chemical storage, hazardous material transport | Pros: Lightweight, durable, recyclable; Contras: Higher cost, limited insulation. |

| Insulated Stainless Steel Jug | Double-wall vacuum insulation, BPA-free, customizable designs | Beverage service, outdoor events | Pros: Excellent temperature retention, durable; Contras: Heavier, higher price point. |

| PETG Water Bottle | BPA-free, large capacity, practical measurement markings | Retail, fitness, promotional giveaways | Pros: Affordable, lightweight; Contras: Less durable than metal, limited insulation. |

| Botella de vidrio | Eco-friendly, aesthetically pleasing, reusable | High-end retail, premium brands | Pros: Non-toxic, retains taste; Contras: Fragile, heavier, requires careful handling. |

| Sports Water Jug | Wide mouth for ice, ergonomic handle, various lid options | Sports teams, fitness centers, outdoor activities | Pros: Easy to clean, versatile lid options; Contras: May not be suitable for all liquids, bulkier design. |

What Are the Key Characteristics of Aluminum Bottles?

Aluminum bottles are designed to be lightweight and durable, making them ideal for transporting liquids, especially hazardous materials. Their UN-rated certification ensures compliance with international safety standards, allowing for secure shipping of chemicals. These bottles typically feature leak-proof caps, which prevent spillage and contamination. For B2B buyers, the primary considerations include shipping costs, as larger orders may benefit from freight options, and the necessity for food-grade certification depending on the intended use.

How Do Insulated Stainless Steel Jugs Stand Out?

Insulated stainless steel jugs are crafted for temperature retention, keeping beverages hot or cold for extended periods. Their double-wall construction and BPA-free materials cater to health-conscious consumers and businesses. Customization options, including logos and colors, make them appealing for branding purposes at events or corporate gifts. B2B buyers should consider the weight and cost, as these jugs tend to be pricier but offer long-term durability and functionality.

What Makes PETG Water Bottles a Practical Choice?

PETG water bottles are favored for their affordability and lightweight nature. They are BPA-free and often come with practical measurement markings, making them suitable for fitness enthusiasts and everyday hydration. These bottles are commonly used in retail settings or as promotional items due to their cost-effectiveness. However, B2B buyers should be aware of their limitations in terms of durability compared to metal options, as they may not withstand heavy use.

Why Choose Glass Bottles for Your Business Needs?

Glass bottles are an eco-friendly choice that appeals to premium brands looking to emphasize sustainability. They offer a clean taste and do not leach chemicals, making them ideal for beverages. However, their fragility can pose challenges in transportation and storage. B2B buyers should weigh the aesthetic and health benefits against the potential for breakage and the need for careful handling during distribution.

What Are the Advantages of Sports Water Jugs?

Sports water jugs are designed for convenience, featuring wide mouths for easy filling and cleaning, along with ergonomic handles for portability. They cater to various activities, from sports teams to outdoor events, and often come with multiple lid options to suit different preferences. While these jugs are versatile, B2B buyers should consider their size and suitability for specific liquids, as some designs may not be ideal for all applications.

Key Industrial Applications of 2.5 liter bottle

| Industria/Sector | Specific Application of 2.5 liter bottle | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Alimentación y bebidas | Bulk beverage packaging for water, juices, and soft drinks | Cost-effective storage and distribution solution | Compliance with food safety regulations, material quality |

| Chemical Manufacturing | Safe storage and transportation of chemicals and solvents | Prevents contamination and ensures compliance | UN-rated containers for hazardous materials, durability |

| Agriculture and Horticulture | Fertilizer and nutrient solution application | Efficient delivery of liquid fertilizers to crops | Resistance to UV and chemical exposure, ease of handling |

| Salud y bienestar | Personal hydration solutions in fitness and wellness industries | Promotes hydration among consumers, brand visibility | BPA-free materials, customizable branding options |

| Venta al por menor y comercio electrónico | Eco-friendly packaging for personal care and cleaning products | Enhances brand image and sustainability efforts | Sourcing from certified suppliers, ensuring recyclability |

How is the 2.5 Liter Bottle Used in the Food and Beverage Industry?

In the food and beverage sector, 2.5 liter bottles serve as bulk packaging solutions for a variety of liquids, including water, juices, and soft drinks. These bottles allow businesses to efficiently store and transport large quantities, reducing packaging waste and overall costs. Buyers should ensure that the bottles comply with food safety standards, are made from high-quality materials, and offer a reliable sealing mechanism to prevent leaks and contamination.

What Role Does the 2.5 Liter Bottle Play in Chemical Manufacturing?

Chemical manufacturers utilize 2.5 liter bottles for the safe storage and transport of various chemicals and solvents. These bottles are often UN-rated, ensuring they meet international safety standards for hazardous materials. This application provides businesses with peace of mind regarding environmental safety and compliance. Buyers must focus on sourcing bottles that feature leak-proof designs and are constructed from durable materials to withstand harsh conditions.

How is the 2.5 Liter Bottle Beneficial for Agriculture and Horticulture?

In agriculture, 2.5 liter bottles are used for dispensing liquid fertilizers and nutrient solutions directly to crops. This application allows for precise delivery and minimizes waste, thus enhancing crop yield. Buyers in this sector should consider bottles that are resistant to UV rays and chemical exposure, ensuring longevity and effectiveness in the field. Additionally, ease of handling is crucial for efficient application.

How Can the 2.5 Liter Bottle Support Health and Wellness Industries?

The health and wellness sector leverages 2.5 liter bottles as personal hydration solutions, particularly in gyms and fitness centers. These bottles encourage consumers to stay hydrated throughout their workouts, while also serving as a marketing tool for brands. Buyers should prioritize BPA-free materials and explore customization options for branding purposes, which can significantly enhance customer engagement and loyalty.

What Are the Advantages of Using 2.5 Liter Bottles in Retail and E-commerce?

In retail and e-commerce, 2.5 liter bottles are increasingly favored for packaging personal care and cleaning products. Their eco-friendly design aligns with consumer preferences for sustainable products, enhancing brand image. Businesses should focus on sourcing bottles from certified suppliers that ensure recyclability and compliance with environmental regulations, which can further attract eco-conscious consumers and improve market competitiveness.

3 Common User Pain Points for ‘2.5 liter bottle’ & Their Solutions

Scenario 1: Difficulty in Ensuring Product Quality During Transport

El problema: International B2B buyers often face challenges in maintaining the quality of their products during shipping, especially when dealing with liquid contents in 2.5-liter bottles. Factors such as temperature fluctuations, pressure changes, and potential leaks can compromise the integrity of the contents, leading to product spoilage or contamination. Buyers in regions like Africa or South America may find it particularly challenging due to less reliable shipping infrastructure and environmental conditions.

La solución: To mitigate these risks, it is essential to select bottles designed specifically for durability and leak prevention. Opt for UN-rated aluminum or high-quality food-grade plastic bottles that offer robust protection against external elements. Ensure that the closure systems are tamper-evident and leak-proof, as seen with the foam/aluminum liner and LDPE plug options available in some aluminum bottles. Additionally, consider sourcing bottles that are insulated to maintain temperature stability during transit. Collaborating with suppliers who specialize in logistics for hazardous materials can also provide added assurance that your products will arrive intact and in optimal condition.

Scenario 2: Challenges in Managing Inventory and Storage Space

El problema: B2B buyers frequently struggle with managing inventory for 2.5-liter bottles, particularly when dealing with multiple sizes and types of bottles. Limited warehouse space can lead to overstocking or understocking issues, complicating supply chain management. Buyers in regions with fluctuating demand patterns may find it especially difficult to predict inventory needs, leading to unnecessary costs or missed sales opportunities.

La solución: Implementing a just-in-time (JIT) inventory strategy can help buyers manage their stock levels effectively. This approach minimizes storage costs by ordering products only as needed. To facilitate this, work closely with suppliers to establish flexible order quantities and delivery schedules. Utilize inventory management software that integrates demand forecasting based on historical sales data and market trends. This can help ensure that you maintain optimal stock levels of 2.5-liter bottles, reducing the need for large storage spaces while meeting customer demand promptly.

Scenario 3: Difficulty in Customization and Branding

El problema: Many B2B buyers find it challenging to differentiate their products in a crowded marketplace, particularly when it comes to bottled liquids. Customization options for 2.5-liter bottles, such as labeling and design, are often limited, making it difficult for brands to establish a unique identity. This can be a significant disadvantage for businesses looking to attract customers in competitive regions like Europe and the Middle East.

La solución: To stand out, buyers should seek suppliers that offer extensive customization options for 2.5-liter bottles. Look for manufacturers that allow for various surface treatments—such as powder coating, silk screening, or laser engraving—and offer multiple cap and lid choices. This can enhance both functionality and aesthetic appeal. Additionally, consider partnering with suppliers who can assist in designing custom packaging solutions that reflect your brand identity. Engaging in collaborative design sessions with suppliers can yield innovative solutions that align with market trends and consumer preferences, ultimately strengthening your brand presence in the marketplace.

Strategic Material Selection Guide for 2.5 liter bottle

When selecting materials for 2.5-liter bottles, it’s essential to consider various factors that influence performance, compliance, and market preferences. Below, we analyze four common materials used in the production of 2.5-liter bottles, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Plastic Bottles for 2.5-liter Applications?

Tereftalato de polietileno (PET) is a widely used plastic for beverage containers. It boasts excellent clarity, strength, and resistance to impact. PET is lightweight and can handle moderate temperatures, making it suitable for both cold and room-temperature liquids. However, it has limited resistance to high temperatures and can deform if exposed to heat.

Pros: PET bottles are cost-effective and recyclable, appealing to environmentally conscious consumers. They are also lightweight, reducing shipping costs.

Contras: PET is not suitable for high-temperature liquids and can be prone to leaching chemicals if not properly managed.

Impacto en la aplicación: PET is ideal for water and soft drinks, but its limitations make it less suitable for hot beverages or products requiring extended shelf life.

Consideraciones para compradores internacionales: Compliance with food safety regulations (such as FDA in the U.S. or EFSA in Europe) is crucial. Buyers should ensure that the PET used is food-grade and meets local recycling standards.

How Does Aluminum Compare as a Material for 2.5-liter Bottles?

Aluminio is another popular choice, particularly for its lightweight and durability. It offers excellent resistance to corrosion and is capable of withstanding high pressures, making it suitable for carbonated beverages. Aluminum bottles can be coated internally to prevent reactions with the contents.

Pros: Aluminum bottles are highly durable and can be recycled indefinitely without loss of quality. They also provide a barrier against light and oxygen, enhancing product shelf life.

Contras: The initial cost of aluminum is generally higher than that of plastic. Additionally, the manufacturing process can be more complex, requiring specialized equipment.

Impacto en la aplicación: Aluminum is well-suited for beverages that are sensitive to light and oxygen, such as juices and flavored waters.

Consideraciones para compradores internacionales: Buyers must ensure that aluminum bottles comply with international shipping regulations and standards, such as UN ratings for hazardous materials. Familiarity with local recycling practices is also beneficial.

What Are the Benefits of Using Stainless Steel for 2.5-liter Bottles?

Acero inoxidable, particularly food-grade stainless steel (like 18/8), is increasingly popular for reusable water bottles. It offers outstanding durability, corrosion resistance, and is capable of maintaining temperature due to its insulating properties.

Pros: Stainless steel bottles are highly durable and can keep liquids hot or cold for extended periods. They are also BPA-free and environmentally friendly.

Contras: The higher cost of stainless steel compared to plastic can be a barrier for some buyers. Additionally, they are heavier than both PET and aluminum, which may affect shipping costs.

Impacto en la aplicación: Stainless steel is ideal for both hot and cold beverages, making it versatile for various markets, including outdoor and fitness sectors.

Consideraciones para compradores internacionales: Buyers should confirm that the stainless steel meets international standards for food safety and durability, such as ASTM or ISO certifications.

Why Choose Glass for 2.5-liter Bottles?

Vidrio is a traditional material known for its inert properties, meaning it doesn’t interact with its contents. It is an excellent choice for preserving the taste and quality of beverages.

Pros: Glass is recyclable and provides an airtight seal that protects against contamination. It is also free from chemicals found in some plastics.

Contras: Glass bottles are heavier and more fragile than other materials, which can lead to higher shipping costs and breakage during transport.

Impacto en la aplicación: Glass is suitable for premium beverages, including juices, wines, and spirits, where quality is paramount.

Consideraciones para compradores internacionales: Compliance with international shipping regulations is essential, especially regarding breakage and safety standards.

Summary Table of Material Selection for 2.5-Liter Bottles

| Material | Typical Use Case for 2.5 liter bottle | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| PET | Water, soft drinks | Ligero y rentable | Limited heat resistance | Bajo |

| Aluminio | Carbonated beverages, juices | Durable and excellent barrier | Higher initial cost, complex mfg | Medio |

| Acero inoxidable | Bebidas frías y calientes | Insulating and durable | Mayor coste, mayor peso | Alta |

| Vidrio | Premium beverages (juices, wines) | Inert and recyclable | Pesado y frágil | Medio |

This guide provides a comprehensive overview of the materials available for 2.5-liter bottles, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for 2.5 liter bottle

What Are the Main Stages of Manufacturing a 2.5 Liter Bottle?

The manufacturing of a 2.5-liter bottle involves several key stages that ensure both efficiency and quality. The primary stages include material preparation, forming, assembly, and finishing.

Preparación del material

The first stage of the manufacturing process begins with material selection. Depending on the intended use, manufacturers may opt for various materials such as PET, aluminum, or stainless steel. Each material presents unique benefits: PET is lightweight and recyclable, aluminum offers durability and resistance to corrosion, while stainless steel is known for its longevity and health safety.

Once the material is chosen, it undergoes preparation, which includes drying and pelletizing for plastics or alloying for metals. This process ensures that the materials are in optimal condition for the next stage, minimizing defects that could affect the final product’s quality.

How Are 2.5 Liter Bottles Formed?

The forming stage involves shaping the prepared materials into the desired bottle structure. Different techniques are used based on the material:

-

Moldeo por soplado: This is commonly used for plastic bottles. The process begins with heating the plastic and molding it into a preform. The preform is then placed in a mold, and air is blown into it, expanding it into the final shape.

-

Aluminum Extrusion: For aluminum bottles, the metal is heated and forced through a die to create a tube, which is then cut to length and shaped.

-

Stamping and Welding: Stainless steel bottles are often created through stamping sheets of metal and welding them together. This method ensures a robust and leak-proof structure.

What Is Involved in the Assembly and Finishing Processes?

After forming, the bottles undergo assembly, where components such as caps and labels are added. This can include:

-

Cap Installation: Depending on the design, caps can be screw-on, snap-on, or tamper-evident, which is crucial for maintaining the integrity of the contents, especially for food and beverage applications.

-

Labeling: Labels are applied for branding and information, often using automated systems to ensure precision and consistency.

The finishing stage includes surface treatments such as polishing for metal bottles or applying coatings to enhance durability and aesthetic appeal. This may involve powder coating for stainless steel bottles, which adds a protective layer and can be customized for branding purposes.

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance is critical in the manufacturing of 2.5-liter bottles, particularly for international markets. Buyers should look for suppliers who adhere to relevant international standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications may apply, such as:

- Marcado CE: Indica el cumplimiento de las normas europeas de salud, seguridad y protección del medio ambiente.

- API Certification: Relevant for bottles used in hazardous material transport, ensuring they meet specific safety and quality standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process, ensuring that each bottle meets the required specifications. Key QC checkpoints include:

-

Control de calidad entrante (IQC): This initial inspection checks raw materials for compliance with quality standards before they enter the production line.

-

Control de calidad durante el proceso (IPQC): During manufacturing, random samples are tested to ensure ongoing compliance with quality standards. This can include dimensional checks, weight inspections, and surface quality assessments.

-

Control de calidad final (CCF): Once the bottles are completed, a final inspection is conducted. This includes testing for leaks, visual inspections for defects, and compliance with labeling requirements.

What Common Testing Methods Are Used for Quality Assurance?

Various testing methods are employed to ensure the quality of 2.5-liter bottles. Common techniques include:

-

Pressure Testing: For bottles intended to hold carbonated beverages, pressure testing is crucial to ensure they can withstand internal pressure without failure.

-

Pruebas de estanqueidad: Bottles are subjected to tests that simulate real-world conditions to ensure they do not leak. This can involve filling the bottles with water and applying pressure or using vacuum testing methods.

-

Pruebas de materiales: This includes assessing the mechanical properties of the materials used, such as tensile strength and impact resistance, to ensure they meet industry standards.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers should implement several strategies to verify the quality control processes of potential suppliers. These include:

-

Auditorías de proveedores: Conducting on-site audits allows buyers to assess the manufacturing processes and QC measures firsthand. This can reveal the commitment of suppliers to maintaining high standards.

-

Requesting QC Reports: Buyers should ask for detailed QC reports that outline the testing methods used, results obtained, and any corrective actions taken for non-compliance.

-

Inspecciones de terceros: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing and QC processes. These agencies can conduct random inspections and testing to ensure compliance with international standards.

¿Cuáles son los matices del control de calidad y la certificación para los compradores B2B internacionales?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding QC and certification. These include:

-

Regional Standards Compliance: Different regions may have varying standards for materials and product safety. Buyers should ensure that their suppliers are compliant with both local regulations and international standards.

-

Documentation Requirements: Import/export regulations often require specific documentation, including certificates of compliance and quality assurance reports. Buyers should ensure that suppliers can provide these documents.

-

Consideraciones culturales: Understanding the cultural and business practices of suppliers in different regions can facilitate better communication and negotiation regarding quality expectations.

By being informed about the manufacturing processes and quality assurance standards for 2.5-liter bottles, B2B buyers can make more educated decisions, ensuring they partner with reliable suppliers that meet their quality requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.5 liter bottle’

Introducción

Sourcing a 2.5-liter bottle requires careful consideration of various factors that can impact product quality, compliance, and cost-effectiveness. This checklist is designed to guide B2B buyers through the essential steps in procuring 2.5-liter bottles, ensuring that you make informed decisions that meet your business needs and regulatory requirements.

Primer paso: Defina sus especificaciones técnicas

Before initiating the sourcing process, clearly outline the technical specifications of the 2.5-liter bottle you need. This includes material types (e.g., PETG, aluminum, stainless steel), closure types, and any specific certifications required for your market.

- Considerations: Determine if the bottles need to be food-grade, BPA-free, or insulated, based on the intended use and target market.

Segundo paso: Buscar posibles proveedores

Conduct thorough research to identify potential suppliers who specialize in 2.5-liter bottles. Utilize online directories, trade shows, and industry forums to compile a list of reputable manufacturers.

- Tip: Look for suppliers with a proven track record in your target market regions, such as Africa, South America, or Europe, to ensure they understand local regulations and preferences.

Tercer paso: Evaluar las certificaciones de los proveedores

Verify that potential suppliers hold the necessary certifications that comply with international standards. This includes ISO certifications, food safety certifications, and any regional compliance marks.

- Why It Matters: Certifications ensure that the bottles meet safety and quality standards, which is crucial for maintaining your brand reputation and regulatory compliance.

Paso 4: Solicitud de muestras para la evaluación de la calidad

Once you have narrowed down your list of suppliers, request samples of the 2.5-liter bottles for quality assessment. Examine the materials, design, and closure mechanisms to ensure they meet your specifications.

- Key Focus: Test the samples for durability, leak-proof capabilities, and overall aesthetic appeal, as these factors can influence customer satisfaction.

Paso 5: Analyze Pricing Structures

Request detailed pricing from shortlisted suppliers, considering not just the unit price but also shipping costs, bulk order discounts, and payment terms. Compare these factors across suppliers to identify the best value.

- Considerations: Keep in mind that the cheapest option may not always provide the best quality or service; balance cost with reliability and product quality.

Paso 6: Confirm Shipping and Lead Times

Discuss shipping options and lead times with your selected suppliers to ensure they can meet your delivery requirements. Understand the logistics involved, including potential customs and import duties for international shipments.

- Importance: Timely delivery is crucial for maintaining your supply chain, especially if you have specific project timelines or seasonal demands.

Paso 7: Establecer un plan de comunicación

Establish clear lines of communication with your chosen supplier to facilitate ongoing collaboration. Regular updates on production, shipping, and any potential issues can help build a strong partnership.

- Best Practices: Schedule regular check-ins and provide feedback to ensure that your supplier understands your evolving needs and can adapt accordingly.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing 2.5-liter bottles, ensuring that they select the right products and suppliers for their business needs.

Comprehensive Cost and Pricing Analysis for 2.5 liter bottle Sourcing

What Are the Key Cost Components in Sourcing 2.5 Liter Bottles?

When sourcing 2.5-liter bottles, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materiales: The type of material significantly impacts the price. Common materials for 2.5-liter bottles include plastic (PETG, HDPE), aluminum, and stainless steel. For example, a food-grade aluminum bottle may cost around $23.10, while a BPA-free PETG bottle could be priced at $26.99.

-

Trabajo: Labor costs vary based on the manufacturing location. Countries with lower labor costs, such as those in Africa or South America, may offer more competitive pricing. However, quality assurance and skilled labor can increase costs.

-

Gastos generales de fabricación: This encompasses costs associated with factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Herramientas: Custom molds or tooling for specific bottle designs can incur significant one-time costs. Buyers should factor these into their total expenditure, especially for customized orders.

-

Control de calidad: Ensuring product quality can add to the costs, particularly if certifications (like FDA or CE) are required. Regular inspections and testing contribute to the overall price.

-

Logística: Shipping costs, which can vary based on the Incoterms agreed upon, play a crucial role. For larger orders, opting for Freight LCL can be more economical. Additionally, international shipping fees may fluctuate based on geopolitical factors.

-

Margen: Suppliers will include a profit margin that varies based on competition and market demand. Understanding local market conditions can help buyers negotiate better deals.

What Influences the Pricing of 2.5 Liter Bottles?

Several factors can influence the pricing of 2.5-liter bottles in the B2B market:

-

Volumen/MOQ: Minimum order quantities (MOQ) significantly affect the unit price. Higher volumes typically lead to discounted rates, making bulk purchasing more cost-effective.

-

Especificaciones y personalización: Customized bottles with specific designs, sizes, or features (like insulated options) often come at a premium. Buyers should evaluate the necessity of these customizations against their budget.

-

Materiales y certificaciones de calidad: The choice of material and the presence of quality certifications can drive up costs. For instance, food-grade materials and environmentally friendly options might be pricier but are often preferred for health and sustainability reasons.

-

Factores del proveedor: Supplier reputation, reliability, and their operational efficiencies can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The agreed shipping terms can affect total costs. DDP (Delivered Duty Paid) might seem more expensive upfront but can simplify logistics, particularly for international buyers unfamiliar with local customs regulations.

What Are Essential Tips for B2B Buyers When Sourcing 2.5 Liter Bottles?

-

Negociación: Don’t hesitate to negotiate prices. Suppliers often have flexibility, especially on larger orders. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Centrarse en la rentabilidad: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, and maintenance costs over the product’s lifespan. Sometimes, a higher initial price can lead to lower long-term costs.

-

Conozca los matices de los precios: International buyers should consider currency fluctuations, tariffs, and regional price variations, especially in markets like Brazil and Nigeria. Researching local market trends can provide insights into fair pricing.

-

Solicitud de muestras: Before committing to a large order, ask for samples to assess quality. This can prevent costly mistakes and ensure the product meets your standards.

-

Understand Payment Terms: Clarify payment terms upfront. Favorable payment conditions can help manage cash flow, especially for larger orders.

In conclusion, a comprehensive understanding of the cost structure and pricing influences for 2.5-liter bottles will empower B2B buyers to make informed sourcing decisions, ultimately leading to better value and profitability in their operations.

Alternatives Analysis: Comparing 2.5 liter bottle With Other Solutions

When considering packaging solutions for liquids, particularly in the B2B sector, it’s essential to explore various alternatives to the standard 2.5-liter bottle. Different industries have unique requirements, and understanding these alternatives can help buyers make informed decisions tailored to their specific needs.

| Aspecto comparativo | 2.5 Liter Bottle | Alternative 1: 2.5L Aluminum Bottle | Alternative 2: Insulated Stainless Steel Jug |

|---|---|---|---|

| Rendimiento | Suitable for storing and transporting various liquids. | Excellent for chemical and hazardous liquid storage, leak-proof. | Superior thermal insulation for hot and cold beverages. |

| Coste | Typically low-cost, varying by material and brand. | Moderate cost, generally higher due to material and safety ratings. | Higher initial investment but offers long-term durability. |

| Facilidad de aplicación | Easy to source and use across various industries. | Requires understanding of UN packaging regulations for hazardous materials. | Slightly more complex due to insulation technology and maintenance needs. |

| Mantenimiento | Minimal; generally disposable or recyclable. | Low maintenance; durable and reusable. | Requires careful cleaning to maintain insulation performance. |

| El mejor caso de uso | General liquid storage for beverages and non-hazardous liquids. | Ideal for shipping and storing hazardous materials. | Best for outdoor activities and situations requiring temperature control. |

What Are the Advantages of Using an Aluminum Bottle as an Alternative?

The 2.5-liter aluminum bottle offers several advantages, particularly for industries that require the storage of chemicals or hazardous liquids. Its UN rating ensures compliance with international shipping regulations, making it a safe choice for transporting dangerous goods. The leak-proof cap design protects both the product and the environment, reducing the risk of contamination. However, the cost is generally higher than that of standard plastic bottles, which may be a consideration for budget-conscious businesses.

How Does an Insulated Stainless Steel Jug Compare?

Insulated stainless steel jugs, particularly those with a 2.5-liter capacity, provide excellent temperature retention, keeping beverages cold for up to 36 hours or hot for 12 hours. This feature makes them ideal for outdoor events or for industries that require their products to maintain temperature. While the initial cost is higher than traditional plastic or aluminum options, the durability and effectiveness can lead to long-term savings. Maintenance can be a bit more involved, as these jugs require thorough cleaning to preserve insulation properties, which may not be suitable for all operational environments.

Conclusion: How Can B2B Buyers Choose the Right Liquid Storage Solution?

Selecting the right liquid storage solution depends on various factors, including the nature of the liquid, regulatory requirements, budget constraints, and the intended use case. Buyers should carefully evaluate the performance, cost, and maintenance needs of each option. For businesses dealing with hazardous materials, the aluminum bottle may be the best choice due to its safety features. Conversely, for those needing temperature control for beverages, the insulated stainless steel jug is unmatched. Ultimately, understanding the unique demands of your industry and the specific use cases will guide you toward the most effective solution for your operations.

Essential Technical Properties and Trade Terminology for 2.5 liter bottle

What Are the Key Technical Properties of a 2.5 Liter Bottle?

When considering the procurement of 2.5-liter bottles, it is essential to evaluate specific technical properties that influence performance, safety, and usability. Here are several critical specifications:

-

Calidad del material

The material used in manufacturing 2.5-liter bottles significantly affects their durability and application. Common materials include PETG (Polyethylene Terephthalate Glycol) for its lightweight and clarity, aluminum for its strength and recyclability, and stainless steel for insulation properties. Each material has unique benefits; for instance, aluminum bottles are ideal for hazardous materials due to their UN rating, while stainless steel is preferred for thermal insulation. -

Closure Type

The type of closure used (e.g., tamper-evident, screw cap, or flip lid) is vital for maintaining product integrity. A tamper-evident cap ensures safety by indicating if the bottle has been opened, which is particularly important in markets concerned with health and safety regulations. The closure design should also facilitate ease of use, especially in high-volume consumption scenarios. -

Tolerancia de capacidad

Understanding the tolerance levels in capacity is critical for B2B buyers. Tolerance refers to the acceptable range of variation in the bottle’s stated volume, which can impact packaging and shipping efficiency. For instance, a 2.5-liter bottle with a tolerance of ±5% allows for some variation, ensuring that manufacturers can maintain consistency while accommodating minor discrepancies in production. -

Propiedades del aislamiento

For bottles designed for thermal retention, insulation performance is crucial. Double-wall vacuum insulation can keep liquids hot or cold for extended periods, which is beneficial for end-users in both consumer and industrial markets. This property is particularly appealing in regions with extreme temperatures, enhancing the product’s usability. -

Normas de cumplimiento

Compliance with international safety and quality standards, such as FDA or EU regulations, is non-negotiable for B2B buyers. These standards ensure that the bottles are safe for food and beverage use, especially in markets where health regulations are stringent. Ensuring compliance can also facilitate smoother import/export processes across regions. -

Customizability

The ability to customize bottle designs, including size, color, and branding, is a significant factor for B2B buyers. Customization allows companies to differentiate their products in competitive markets, enhancing brand recognition and consumer loyalty.

What Are Common Trade Terms Used in the 2.5 Liter Bottle Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B sector. Here are several key terms:

-

OEM (fabricante de equipos originales)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of 2.5-liter bottles, an OEM might manufacture the bottles according to specifications provided by a brand, allowing for tailored designs that meet specific market needs. -

MOQ (Cantidad mínima de pedido)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory and cash flow efficiently, especially when entering new markets or testing product demand. -

RFQ (solicitud de presupuesto)

An RFQ is a document that a buyer submits to suppliers to request pricing and terms for a specific quantity of goods. In the bottle industry, an RFQ would detail the required specifications, such as material, capacity, and customization options, facilitating better pricing negotiations. -

Incoterms (Términos comerciales internacionales)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. For 2.5-liter bottles, understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for managing shipping costs and responsibilities effectively. -

Plazos de entrega

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the bottle manufacturing industry, lead times can vary significantly based on material availability, production schedules, and shipping methods. Buyers should factor in lead times when planning inventory and product launches. -

Sin BPA

BPA (Bisphenol A) is a chemical often found in plastics that has raised health concerns. Bottles labeled as BPA-free are manufactured without this chemical, appealing to health-conscious consumers and meeting regulatory demands in many markets. Understanding this term is essential for B2B buyers focusing on safety and compliance.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right 2.5-liter bottles for their specific needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the 2.5 liter bottle Sector

What Are the Current Market Dynamics and Key Trends in the 2.5 Liter Bottle Sector?

The global market for 2.5-liter bottles is experiencing dynamic shifts driven by several key factors. Increasing consumer awareness regarding health and hydration is propelling demand for larger capacity bottles, particularly in regions like Africa and South America, where access to clean water remains a challenge. B2B buyers are focusing on sourcing solutions that not only meet immediate hydration needs but also ensure product quality and safety.

Emerging technologies in manufacturing and logistics are revolutionizing the sourcing landscape. Automation and smart supply chain management systems are enhancing efficiency and reducing costs. Additionally, innovations such as lightweight materials and recyclable options are gaining traction, catering to both manufacturers and consumers seeking sustainable alternatives. For international buyers, particularly from Brazil and Nigeria, the emphasis on local sourcing and partnerships with regional manufacturers is becoming crucial. This trend not only mitigates shipping costs but also fosters community engagement and supports local economies.

Furthermore, the rise of e-commerce platforms is reshaping how B2B transactions occur in this sector. Buyers are increasingly leveraging online marketplaces to access a broader range of suppliers, facilitating competitive pricing and faster delivery times. As the market evolves, staying attuned to these trends will be essential for B2B buyers looking to optimize their supply chains and meet the growing demand for 2.5-liter bottles.

How Can Sustainability and Ethical Sourcing Impact the 2.5 Liter Bottle Sector?

Sustainability is no longer a mere trend but a necessity in the 2.5-liter bottle sector. The environmental impact of plastic waste has prompted both consumers and businesses to prioritize eco-friendly solutions. B2B buyers are increasingly seeking suppliers who utilize recycled materials or biodegradable alternatives in their product offerings. Certifications such as ISO 14001 for environmental management and the Global Recycle Standard are becoming essential criteria for supplier selection.

Ethical sourcing is equally important, particularly as global awareness of labor practices and supply chain transparency grows. Buyers from regions like the Middle East and Europe are demanding that their suppliers adhere to fair labor practices and provide transparency in their sourcing processes. This not only enhances brand reputation but also aligns with the values of environmentally and socially conscious consumers.

Furthermore, companies are exploring innovative materials such as aluminum and glass, which offer both durability and recyclability, reducing the overall environmental footprint. As sustainability becomes a pivotal factor in purchasing decisions, B2B buyers must evaluate potential suppliers based on their commitment to environmental stewardship and ethical sourcing practices.

What is the Brief Evolution and History of the 2.5 Liter Bottle Sector?

The evolution of the 2.5-liter bottle sector can be traced back to the growing demand for convenient and portable hydration solutions. Initially dominated by single-use plastic bottles, the sector has witnessed a significant shift towards reusable and eco-friendly options in response to environmental concerns and changing consumer preferences.

The introduction of alternative materials, such as aluminum and stainless steel, has expanded the market, offering businesses innovative solutions that cater to both functionality and sustainability. Over the past decade, the rise of e-commerce has transformed how these products are marketed and sold, enabling manufacturers to reach a broader audience while streamlining the purchasing process for B2B buyers.

As the market continues to evolve, understanding this historical context allows buyers to make informed decisions that align with current trends and consumer expectations, ensuring they remain competitive in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of 2.5 liter bottle

-

How do I ensure the quality of 2.5 liter bottles before purchasing?

To ensure the quality of 2.5 liter bottles, request samples from potential suppliers before committing to a bulk order. Evaluate the material quality, durability, and safety certifications such as FDA or LFGB compliance, especially if the bottles are intended for food or beverage use. Additionally, consider conducting third-party quality assurance inspections during production and before shipment. Establish clear quality control standards and communicate them to your suppliers to mitigate risks of receiving subpar products. -

What are the best materials for 2.5 liter bottles?

The best materials for 2.5 liter bottles depend on your intended use. For food and beverage applications, food-grade PETG or stainless steel are excellent choices due to their safety and durability. Aluminum bottles are also popular for their lightweight nature and resistance to corrosion. If sustainability is a priority, consider recyclable materials or those with low environmental impact. Always verify that the chosen material meets international safety standards relevant to your market. -

What customization options are available for 2.5 liter bottles?

Customization options for 2.5 liter bottles can include material choice, color, size, and branding features such as logos and patterns. Many manufacturers offer various caps and lids to enhance functionality, such as spout lids or tamper-evident caps. You can also choose surface finishes like powder coating or stainless steel brushing. Discuss your specific requirements with suppliers to explore available options and ensure that the final product aligns with your brand identity. -

What are the typical minimum order quantities (MOQs) for 2.5 liter bottles?

Minimum order quantities (MOQs) for 2.5 liter bottles can vary significantly by supplier and material type. Generally, MOQs can range from a few hundred to several thousand units. When negotiating with suppliers, clarify the MOQ and explore options for reducing it through bulk purchasing or shared container shipments. Some suppliers may offer flexibility for new customers or for specific product lines, so it’s worth discussing your needs directly. -

What payment terms should I expect when sourcing 2.5 liter bottles?

Payment terms for sourcing 2.5 liter bottles can vary, but common practices include a deposit (usually 30% to 50%) upfront with the balance due before shipment. Some suppliers may offer payment upon delivery or after receipt of goods. Consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms in advance and ensure they are documented in your purchase agreement to avoid misunderstandings. -

How can I vet potential suppliers for 2.5 liter bottles?

To vet potential suppliers, start by researching their reputation in the industry through online reviews and ratings. Request references from previous clients and assess their production capabilities by reviewing certifications and compliance with international standards. Conduct factory visits, if feasible, or arrange virtual tours to inspect their operations. Additionally, ensure they have robust quality control measures and the ability to meet your specific needs, including customization and delivery timelines. -

What are the shipping options for 2.5 liter bottles?

Shipping options for 2.5 liter bottles typically include air freight for quicker delivery and sea freight for cost-effective bulk shipping. The choice of shipping method depends on your budget, urgency, and the size of your order. Discuss logistics with your supplier, as they may have preferred carriers or shipping partners. Always factor in customs duties and taxes when calculating total costs, especially for international shipments to regions like Africa, South America, and the Middle East. -

How can I handle potential import regulations for 2.5 liter bottles?

Handling import regulations for 2.5 liter bottles involves understanding the specific requirements of your target market. Research the necessary certifications, such as safety and health regulations, that your products must meet to enter the country. Engage with customs brokers or import/export consultants familiar with the regulations in your region to ensure compliance. Additionally, prepare accurate documentation, including invoices and certificates of origin, to facilitate smooth customs clearance upon arrival.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 7 2.5 Liter Bottle Manufacturers & Suppliers List

1. Air Sea Containers – 2.5L UN Rated Aluminum Bottle

Dominio: airseacontainers.com

Inscrita: 1997 (28 años)

Introducción: {“name”:”2.5L (84.54oz) UN Rated Aluminum Bottle with Cap”,”item_number”:”IP3A-2500-U”,”price”:”$23.10″,”capacity”:”2.5L (84.54oz)”,”material”:”Aluminum”,”features”:”UN Rated (1B1/Y), Food Grade, Leak proof cap”,”closure”:”White tamper evident plastic cap with foam/aluminum liner and LDPE plug”,”quantity_per_case”:20,”case_weight”:”18 lbs”,”case_dimensions”:”26″ x 21″ x 13″”,”shipping_time”:”Ships…

2. WaterBottle – Insulated Stainless Steel Water Jug

Dominio: waterbottle.tech

Registrado: 2018 (7 años)

Introducción: Product Name: Insulated Stainless Steel Water Jug 1.5L 2.5L Big Bottle with Handle 50oz 85oz Gallon Capacity

Model Number / SKU: S11150051

Capacity / Size: 85 oz (2.5 L), 50 oz (1.5 L)

Bottle Diameter: 86mm

Height (w/o cap): Not specified

Bottle Material: 18/8 food grade stainless steel (SUS304 stainless steel)

Lid Material: PP + Silicone

Surface Decoration Technical: Powder coating

Insulation Per…

3. Unbranded – 2.5 Liter Large Capacity Water Bottle

Dominio: ebay.es

Matriculado: 1995 (30 años)

Introducción: {“title”:”2.5 Liter 85 Oz Large Capacity Water Bottle With Time Marker Reusable Hydration”,”price”:”$24.99″,”condition”:”Used”,”item_number”:”236064298637″,”brand”:”Unbranded”,”dimensions”:”10\” tall and 5\” wide”,”features”:”Leak-proof design, suitable for camping, hiking, and outdoor activities”,”seller”:”C Corn Bread s Cubby Hole”,”seller_feedback”:”100% positive feedback”,”shipping_estimate”:”…

4. Etsy – Personalizable Water Bottles

Dominio: etsy.com

Inscrito: 2004 (21 años)

Introducción: 2.5 Litre Water Bottle, Personalizable, Ships from United States, Free shipping, Various sellers and prices, Includes options like 5 Gallon Water Dispenser, SANGER LONGI rubber hot water bottle, Personalized Owala FreeSip Water Bottle, Chakra Tamba Water Bottle, Indian Pure Copper Jumbo Water Bottle.

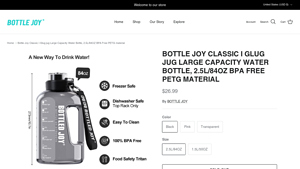

5. Bottle Joy – Classic Glug Jug

Dominio: bottlejoy.com

Inscrito: 2017 (8 años)

Introducción: Bottle Joy Classic I Glug jug Large Capacity Water Bottle, 2.5L/84OZ, BPA Free PETG material, Price: $26.99, Available Colors: Black, Pink, Transparent, Sizes: 2.5L/84OZ, 1.5L/50OZ, Features: All day water tracking from 7am to 7pm, practical measurement markings, leak proof, matching carry strap, flip top lid for easy drinking, wide mouth for adding ice or fruit, reusable material, smash-proof des…

6. Stanley – Classic Legendary Bottle

Dominio: stanley1913.com

Matriculado: 2019 (6 años)

Introducción: {“product_name”: “Classic Legendary Bottle”, “capacity”: “2.5 qt”, “material”: “stainless steel”, “insulation”: “double-wall vacuum insulation”, “features”: [“keeps drinks cold for 24 hours”, “keeps drinks hot for 12 hours”, “wide mouth opening”, “durable and rust-proof”, “dishwasher safe”]}

7. BLUEGO – 2.5L Borosilicate Glass Bottle

Dominio: amazon.ie

Matriculado: 2000 (25 años)

Introducción: {“Brand”:”BLUEGO”,”Material”:”Borosilicate Glass”,”Bottle Type”:”wide mouth”,”Color”:”Black”,”Capacity”:”2.5L (84oz)”,”Special Features”:”Wide Mouth, Time and Volume Marker, BPA Free”,”Age Range Description”:”Adult”,”Item Dimensions”:”15.6W x 29H cm”,”Product Care Instructions”:”Dishwasher Safe”,”Model Name”:”B-84oz-Black”,”Key Features”:[“Updated Stainless Steel Handle with silicone anti-slip sle…

Strategic Sourcing Conclusion and Outlook for 2.5 liter bottle

What Are the Key Takeaways for Sourcing 2.5 Liter Bottles?

In conclusion, strategic sourcing of 2.5 liter bottles presents an array of opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The demand for versatile, high-quality containers—ranging from aluminum to insulated stainless steel—highlights the importance of selecting suppliers who prioritize durability, safety, and customization options.

Buyers should consider factors such as material quality, shipping logistics, and the environmental impact of their choices. Leveraging bulk purchasing and establishing strong supplier relationships can lead to significant cost savings and enhanced product offerings. Furthermore, the growing focus on sustainability and health-conscious materials, such as BPA-free and food-grade options, aligns with evolving consumer preferences.

How Can B2B Buyers Prepare for Future Trends?

Looking ahead, the market for 2.5 liter bottles is poised for growth, driven by increasing consumer awareness around hydration and eco-friendly packaging solutions. B2B buyers are encouraged to stay informed about market trends and innovations in bottle design and functionality.

Now is the time to take action: evaluate your sourcing strategies, engage with suppliers who share your values, and explore customization options that can set your brand apart in a competitive landscape. By doing so, you can secure a robust supply chain that not only meets current demands but also anticipates future market shifts.