Introduction: Navigating the Global Market for best material for water bottle

In today’s competitive landscape, international B2B buyers face the critical challenge of sourcing the best material for water bottles that not only meets safety standards but also appeals to a diverse consumer base. With a plethora of options—ranging from stainless steel to glass and eco-friendly alternatives—making the right choice can be overwhelming. This comprehensive guide delves into the various materials available, their applications, and the implications of each for quality, sustainability, and cost-effectiveness.

Throughout this guide, we will explore the intricacies of each water bottle material, providing insights into their durability, insulation properties, and potential health impacts. We will also address supplier vetting processes to ensure you partner with reputable manufacturers who prioritize quality and compliance. By equipping B2B buyers, especially those from Africa, South America, the Middle East, and Europe—countries like Nigeria and Vietnam—with actionable information, this resource empowers informed purchasing decisions that align with market demands and consumer expectations.

Understanding the nuances of water bottle materials is essential for businesses aiming to enhance their product offerings and meet consumer preferences. Whether your focus is on sustainability, safety, or aesthetics, this guide will serve as your roadmap to navigating the global market for the best water bottle materials, ensuring you make choices that resonate with your target audience and drive business success.

Artículo Navegación

- Top 7 Best Material For Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best material for water bottle

- Understanding best material for water bottle Types and Variations

- Key Industrial Applications of best material for water bottle

- 3 Common User Pain Points for ‘best material for water bottle’ & Their Solutions

- Strategic Material Selection Guide for best material for water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for best material for water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best material for water bottle’

- Comprehensive Cost and Pricing Analysis for best material for water bottle Sourcing

- Alternatives Analysis: Comparing best material for water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for best material for water bottle

- Navigating Market Dynamics and Sourcing Trends in the best material for water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best material for water bottle

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for best material for water bottle

Understanding best material for water bottle Types and Variations

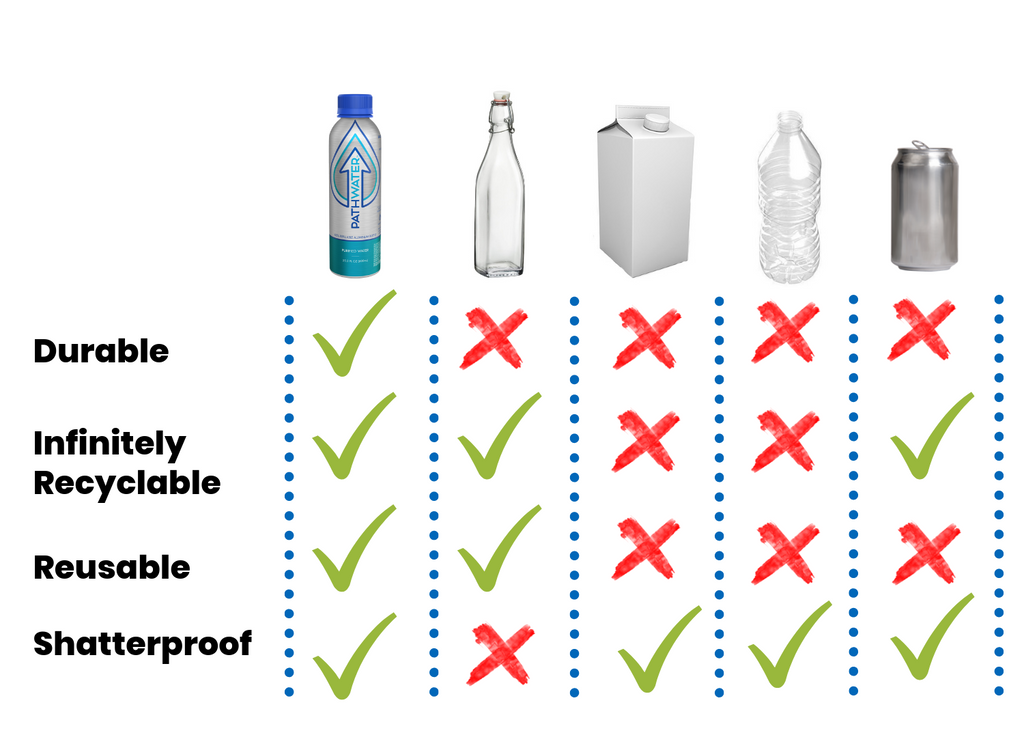

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Acero inoxidable | Durable, insulated, and resistant to leaching | Corporate gifts, outdoor activities | Pros: Long-lasting, easy to clean. Contras: Heavier than plastic. |

| Vidrio | Non-reactive, preserves taste, and aesthetically pleasing | Health-focused brands, premium products | Pros: Pure taste, no chemical leaching. Contras: Fragile and heavier. |

| Plástico sin BPA | Lightweight, cost-effective, and versatile | Mass-market products, promotional items | Pros: Asequible, ligero. Contras: Potential for scratching and leaching if not high-quality. |

| Aluminio | Lightweight, often insulated, and customizable | Sports events, branded merchandise | Pros: Lightweight, good for branding. Contras: Can dent easily, may require lining to prevent leaching. |

| Silicona | Flexible, collapsible, and easy to transport | Travel products, children’s items | Pros: Portable, versatile. Contras: Menos duradero, puede retener olores. |

What are the Characteristics and Suitability of Stainless Steel Water Bottles?

Stainless steel water bottles are favored for their durability and excellent insulation properties. They often feature double-wall vacuum insulation, keeping beverages hot or cold for extended periods. This makes them ideal for outdoor activities and corporate gifts, appealing to companies looking to promote a robust, sustainable image. When sourcing stainless steel bottles, B2B buyers should consider the weight and insulation quality, as these factors influence user experience and brand perception.

Why Choose Glass Water Bottles for Your Business?

Glass water bottles are celebrated for their purity and aesthetic appeal, making them suitable for health-focused brands and premium products. They do not leach chemicals, ensuring the water tastes fresh and untainted. However, their fragility can be a concern, particularly for businesses targeting active consumers. B2B buyers should assess the balance between glass’s premium feel and the potential for breakage, particularly in high-volume distribution scenarios.

What Makes BPA-Free Plastic Water Bottles a Popular Choice?

BPA-free plastic bottles are lightweight, cost-effective, and versatile, making them suitable for mass-market applications and promotional items. They are easier to transport and typically more affordable than metal or glass alternatives. However, lower-quality plastics can scratch easily, leading to potential leaching. B2B buyers should prioritize high-quality, BPA-free materials to ensure safety and durability, particularly for products aimed at families or health-conscious consumers.

How Does Aluminum Compare as a Water Bottle Material?

Aluminum water bottles are lightweight and often feature custom branding opportunities, making them popular for sports events and promotional merchandise. While they can be insulated, they are prone to dents and may require a lining to prevent leaching of metals. B2B buyers should consider the branding potential versus the durability of aluminum bottles, ensuring that the choice aligns with their marketing strategy and target audience preferences.

What are the Benefits and Drawbacks of Silicone Water Bottles?

Silicone water bottles are flexible and collapsible, making them easy to transport and ideal for travel products or children’s items. They are resistant to breaking and can be produced in various colors and designs. However, silicone can retain odors and may not be as durable as other materials. B2B buyers should evaluate the target market’s needs, weighing the convenience and portability of silicone against its long-term usability and potential odor retention.

Key Industrial Applications of best material for water bottle

| Industria/Sector | Specific Application of Best Material for Water Bottle | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Alimentación y bebidas | Reusable Water Bottles for Restaurants and Cafés | Enhances brand image through eco-friendly practices; reduces waste. | Compliance with food safety standards; durability and ease of cleaning. |

| Sports and Recreation | Hydration Solutions for Outdoor Activities | Improves customer satisfaction and health; promotes active lifestyles. | Lightweight and insulated options; BPA-free materials. |

| Educación | School Water Bottles for Students | Encourages hydration among students; reduces single-use plastic. | Safety certifications; affordability for bulk purchasing. |

| Bienestar empresarial | Branded Water Bottles for Employee Programs | Promotes health and wellness; strengthens corporate branding. | Customization options; material safety for daily use. |

| Travel and Tourism | Eco-friendly Bottles for Tour Operators | Attracts eco-conscious travelers; reduces environmental impact. | Lightweight and durable for travel; compliance with international regulations. |

How is the Best Material for Water Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, reusable water bottles made from stainless steel or glass are increasingly adopted by restaurants and cafés. These materials not only enhance the aesthetic appeal of establishments but also promote sustainability by reducing reliance on single-use plastics. For international buyers, particularly in regions like Africa and South America, compliance with local food safety standards is critical. Ensuring that the bottles are easy to clean and maintain is essential for food service businesses looking to uphold hygiene standards.

What are the Applications in Sports and Recreation?

Hydration solutions utilizing the best materials for water bottles are vital in the sports and recreation sector. Companies producing gear for outdoor activities often choose insulated stainless steel bottles to keep beverages at optimal temperatures. This not only enhances user experience but also promotes a healthy lifestyle. For B2B buyers in the Middle East and Europe, lightweight options are crucial for portability, while ensuring that materials are BPA-free is essential for safety and health compliance.

Why are Reusable Water Bottles Important in Education?

In educational institutions, providing students with reusable water bottles encourages hydration and reduces the environmental impact of single-use plastics. Schools are increasingly sourcing bottles made from safe, durable materials like Tritan or stainless steel. For international buyers, especially in developing regions, affordability is a key consideration. Safety certifications are also critical to ensure that products meet health regulations, fostering a safe environment for students.

How Can Corporate Wellness Programs Benefit from Water Bottles?

Corporate wellness initiatives often incorporate branded water bottles to promote healthy habits among employees. Using high-quality materials like stainless steel or glass enhances the perceived value of these items, aligning with corporate sustainability goals. For international B2B buyers, customization options for branding are important, alongside ensuring that the materials used are safe for daily use. This not only boosts employee morale but also strengthens corporate identity.

What Role do Water Bottles Play in Travel and Tourism?

In the travel and tourism sector, eco-friendly water bottles are a significant draw for environmentally-conscious travelers. Tour operators are increasingly sourcing lightweight and durable bottles made from sustainable materials. For international buyers, particularly in regions with growing eco-tourism, compliance with international regulations regarding materials and safety is essential. Offering insulated options can enhance customer satisfaction by providing convenience during travel.

3 Common User Pain Points for ‘best material for water bottle’ & Their Solutions

Scenario 1: Navigating Health Concerns in Water Bottle Materials

El problema: B2B buyers are increasingly aware of health implications associated with different water bottle materials. For example, plastic bottles, despite being popular due to their lightweight and cost-effectiveness, often come with concerns about chemical leaching, particularly substances like BPA. Buyers, especially those in regions like Africa and South America where regulations may vary, face the dilemma of balancing cost with the need to provide safe products. This uncertainty can lead to reluctance in choosing certain materials, ultimately affecting product offerings and customer trust.

La solución: To address these health concerns, buyers should prioritize sourcing BPA-free plastic options, such as those made from Tritan or other safe alternatives. When evaluating suppliers, request certifications that confirm the absence of harmful chemicals in their products. Additionally, consider offering a diverse range of materials, including stainless steel and glass, which are generally recognized as safer choices. For effective product marketing, provide transparent information to end-users about the materials used, emphasizing their safety features and the testing processes they have undergone. This proactive approach not only mitigates health concerns but also builds customer confidence in your brand.

Scenario 2: Balancing Durability and Weight in Water Bottle Choices

El problema: Many B2B buyers are tasked with selecting water bottles that must withstand heavy use, especially in demanding environments like construction sites or outdoor events. Buyers often struggle with the trade-off between durability and portability; for instance, while stainless steel bottles are robust and insulated, they tend to be heavier than plastic counterparts. This creates a challenge when catering to customers who value both resilience and ease of transport, particularly in regions where mobility is crucial.

La solución: To effectively balance durability and weight, buyers should conduct a thorough market analysis to identify hybrid solutions that offer the best of both worlds. For instance, investing in stainless steel bottles with a lightweight design or aluminum options could meet the durability requirement while reducing weight. Additionally, consider incorporating ergonomic designs that enhance portability, such as built-in handles or collapsible features. Offering a range of products tailored to different use cases—such as lightweight bottles for hiking and robust options for industrial use—can attract a broader customer base. Highlight these features in your marketing materials to help buyers make informed decisions.

Scenario 3: Aesthetic Appeal vs. Functional Integrity in Water Bottle Design

El problema: In a competitive market, B2B buyers often face pressure to choose aesthetically pleasing products that can attract consumers. However, many stylish options may compromise on functionality, such as insulation performance or ease of cleaning. This creates a conflict where buyers may be tempted to prioritize design over the practical benefits of a water bottle, risking customer dissatisfaction when the product fails to perform as expected.

La solución: To navigate this challenge, buyers should seek suppliers that provide water bottles designed with both aesthetics and functionality in mind. Emphasize the importance of features like double-wall insulation for maintaining beverage temperatures, as well as materials that are easy to clean and resistant to scratches. Conduct focus groups or surveys with end-users to understand their preferences, ensuring that the products align with both aesthetic desires and functional needs. Furthermore, consider offering customization options that allow businesses to brand bottles with their logos while maintaining high-performance standards. This approach can enhance customer satisfaction and brand loyalty while still meeting market demands for visually appealing products.

Strategic Material Selection Guide for best material for water bottle

What Are the Best Materials for Water Bottles in B2B Markets?

When selecting materials for water bottles in a B2B context, it is essential to consider not only the properties of the materials but also their suitability for specific markets and compliance with international standards. Below, we analyze four common materials used in water bottles: stainless steel, glass, plastic, and aluminum.

How Does Stainless Steel Perform as a Water Bottle Material?

Stainless steel is renowned for its durability and insulation properties. It typically has a high-temperature rating and excellent corrosion resistance, making it suitable for a variety of liquids. The most common grades used for water bottles are 304 and 316 stainless steel, both of which offer high resistance to oxidation and staining.

Pros: Stainless steel bottles are highly durable, resistant to impact, and easy to clean. They can maintain the temperature of liquids for extended periods due to their insulating properties.

Contras: The primary drawback is their weight, which can be a disadvantage for consumers seeking lightweight options. Additionally, stainless steel can be more expensive than other materials, which may affect pricing strategies in cost-sensitive markets.

Impacto en la aplicación: Stainless steel is compatible with a wide range of beverages, including acidic and alkaline solutions, without leaching harmful chemicals.

Consideraciones para compradores internacionales: Compliance with standards such as ASTM and ISO is crucial. In regions like Africa and South America, buyers should consider local preferences for durability and temperature retention, particularly in hotter climates.

¿Qué ventajas ofrece el vidrio para las botellas de agua?

Glass is often considered the gold standard for water bottle materials due to its non-reactive nature. It does not leach chemicals into liquids, ensuring the purity of the contents. Glass bottles can handle high temperatures but are sensitive to impact.

Pros: Glass provides an excellent taste experience, as it does not impart any flavors. It is also easy to clean and can be recycled.

Contras: The fragility of glass makes it less suitable for rugged environments. Moreover, the weight of glass bottles can be a concern for transport and handling.

Impacto en la aplicación: Glass is ideal for water and other non-carbonated beverages. However, it is not suitable for carbonated drinks due to the risk of breakage under pressure.

Consideraciones para compradores internacionales: Buyers should ensure compliance with local safety standards, especially in regions prone to high temperatures. In markets like Europe, glass is often preferred for its aesthetic appeal and sustainability.

How Does Plastic Compare in the B2B Water Bottle Market?

Plastic, particularly BPA-free variants like Tritan, is widely used due to its lightweight and cost-effective nature. It can withstand moderate temperatures and is generally resistant to impact.

Pros: The affordability and versatility of plastic make it a popular choice for mass production. It is also lightweight, making it easy to transport.

Contras: Concerns about chemical leaching, particularly with lower-quality plastics, can deter consumers. Additionally, plastic bottles may not maintain temperature as effectively as stainless steel.

Impacto en la aplicación: Plastic bottles are suitable for a variety of beverages but may not hold up well against hot liquids.

Consideraciones para compradores internacionales: Compliance with regulations regarding BPA and other chemicals is essential. In developing markets, the cost-effectiveness of plastic can be a significant advantage, but buyers should be wary of quality variations.

What Role Does Aluminum Play in Water Bottle Manufacturing?

Aluminum is lightweight and offers good thermal conductivity, making it a practical choice for insulated bottles. It is often coated to prevent leaching and enhance durability.

Pros: Aluminum bottles are lightweight and can be manufactured in various designs. They are also recyclable, appealing to environmentally conscious consumers.

Contras: Aluminum can dent easily and may not be as durable as stainless steel. Additionally, the coating can wear off over time, potentially leading to leaching concerns.

Impacto en la aplicación: Aluminum is suitable for cold beverages and can be used for carbonated drinks if properly coated.

Consideraciones para compradores internacionales: Buyers should ensure that aluminum bottles meet local health and safety standards. In regions like the Middle East, where temperature fluctuations are common, the insulation properties of aluminum can be particularly beneficial.

Summary Table of Material Selection for Water Bottles

| Material | Typical Use Case for best material for water bottle | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Acero inoxidable | Insulated water bottles for outdoor activities | Excelente durabilidad y aislamiento | Heavier than other materials | Alta |

| Vidrio | Premium water bottles for health-conscious consumers | Pure taste, non-reactive | Frágil y pesado | Medio |

| Plástico | Everyday use bottles, budget-friendly options | Ligero y rentable | Potential chemical leaching | Bajo |

| Aluminio | Lightweight bottles for sports and travel | Ligero y reciclable | Less durable, potential leaching | Medio |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for water bottles, considering both performance and market-specific requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for best material for water bottle

What Are the Main Stages of Manufacturing Water Bottles from the Best Materials?

The manufacturing process for water bottles varies significantly depending on the chosen material. Understanding these stages can help B2B buyers assess the quality and reliability of their suppliers. The typical manufacturing process includes the following main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Water Bottle Manufacturing?

Material preparation is crucial, as the quality of the input materials directly affects the final product. For stainless steel bottles, high-grade stainless steel (often 304 or 316) is selected for its corrosion resistance and strength. In the case of glass bottles, silica sand, soda ash, and limestone are the primary raw materials. Each material undergoes rigorous testing to ensure it meets industry standards before moving to the next stage.

For plastic bottles, manufacturers often use BPA-free Tritan or polyethylene, requiring careful selection to avoid harmful chemicals. Materials are typically sourced from certified suppliers who comply with international safety standards to ensure the materials are free from toxins.

What Techniques Are Used in Forming Water Bottles?

Forming techniques differ significantly by material:

-

Stainless Steel: The process usually involves cutting, stamping, or spinning the steel into shape. Advanced techniques such as hydroforming or deep drawing may be employed for complex shapes. Stainless steel bottles often undergo a process of double-wall vacuum insulation, where two layers of steel are formed with an airless space in between, enhancing thermal retention.

-

Glass: Glass bottles are generally manufactured through blow molding or press molding. The molten glass is shaped into bottles and then annealed to relieve internal stresses. This process ensures a robust and stable product, minimizing the risk of breakage.

-

Plastic: Plastic forming techniques include injection molding and blow molding. Injection molding is often used for the bottle cap and components, while blow molding shapes the bottle itself. This process allows for mass production of lightweight bottles, essential for consumer convenience.

What Does the Assembly Process Involve for Water Bottles?

After forming, the assembly stage brings together all the components of the water bottle. For stainless steel and glass bottles, this often involves attaching lids, straws, or insulation layers. The assembly process is usually automated but may also involve manual labor for quality assurance.

For plastic bottles, assembly might include adding labels or printing designs directly onto the bottle. In this stage, manufacturers often conduct inspections to ensure that components fit correctly and that the product meets specified standards.

How Is Finishing Conducted in Water Bottle Manufacturing?

Finishing processes enhance the aesthetic and functional qualities of the water bottle. This includes polishing stainless steel for a sleek finish, applying coatings to glass for added durability, or printing designs on plastic bottles. Manufacturers may also apply anti-bacterial coatings or UV protection, especially for outdoor and sports bottles.

Quality checks are vital during the finishing stage to ensure that all products are free from defects. This may involve visual inspections and automated systems that detect flaws in appearance or functionality.

What Quality Assurance Practices Are Essential for Water Bottle Manufacturers?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for B2B buyers concerned about safety and compliance. International standards, such as ISO 9001, are commonly adopted in the manufacturing of water bottles to ensure consistency and reliability.

Which International Standards Should B2B Buyers Consider?

B2B buyers should look for manufacturers that comply with international standards, including:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring that manufacturers maintain high-quality production processes.

- Marcado CE: Required for products sold in the European Economic Area, CE marking ensures that a product meets safety and environmental requirements.

- API Standards: For bottles intended for oil or gas applications, the American Petroleum Institute (API) standards may be relevant.

What Are the Key Quality Control Checkpoints in Water Bottle Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Control de calidad entrante (IQC): This initial stage involves inspecting raw materials for defects or inconsistencies before they enter the production line.

- Control de calidad durante el proceso (IPQC): During manufacturing, ongoing checks ensure that processes are within specifications, minimizing the risk of defects.

- Control de calidad final (CCF): Once production is complete, the final product undergoes thorough inspections, including dimensional checks, leak tests, and performance evaluations.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers must conduct due diligence to ensure their suppliers maintain rigorous quality control processes. Here are effective strategies to verify supplier QC:

- Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request access to audit reports and certifications.

- Inspecciones de terceros: Engaging third-party inspection services can provide unbiased evaluations of product quality and compliance with international standards.

- Documentation: Suppliers should provide detailed documentation of their QC processes, including test results and compliance certifications. This transparency can build trust and ensure that suppliers adhere to high standards.

What QC and Certification Nuances Should International B2B Buyers Be Aware Of?

When sourcing from manufacturers in different regions, international B2B buyers should be aware of local regulations and certification requirements. For example, products entering the EU must comply with stringent regulations concerning material safety and environmental impact, while buyers in Africa and South America may face different standards.

Understanding these nuances is crucial for successful sourcing and can help mitigate risks associated with non-compliance. Buyers should work with local representatives or consultants who can navigate these regulations effectively.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices is essential for B2B buyers looking to source the best materials for water bottles. By focusing on these aspects, buyers can ensure they partner with reliable suppliers who prioritize safety, quality, and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best material for water bottle’

When sourcing the best materials for water bottles, it’s essential to navigate a complex landscape of options, standards, and supplier capabilities. This guide outlines a practical checklist to help B2B buyers make informed decisions that align with their business needs and consumer expectations.

Primer paso: Identify Your Target Market’s Preferences

Understanding the preferences of your target market is crucial for selecting the right materials. Conduct market research to determine what consumers in your region prioritize—be it sustainability, safety, or design. Consider factors like local health regulations and cultural attitudes towards different materials.

Segundo paso: Defina sus especificaciones técnicas

Clearly outline the technical specifications required for your water bottles. This includes material type (e.g., stainless steel, glass, plastic), size, weight, and insulation properties. Defining these parameters will help streamline the sourcing process and ensure that the final product meets your quality standards.

Tercer paso: Evaluar posibles proveedores

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, certifications, and references from buyers in a similar industry or region. Look for suppliers who have experience with the specific materials you are interested in, as this can significantly impact product quality and compliance.

- Subbala: Ensure the supplier adheres to international standards, such as ISO certifications.

- Subbala: Check for reviews or testimonials from previous clients to gauge reliability.

Paso 4: Assess Material Safety and Compliance

Safety is paramount when selecting materials for water bottles. Investigate whether the materials are BPA-free and comply with relevant health regulations in your target markets. This will not only safeguard consumer health but also enhance your brand’s reputation.

Paso 5: Solicitud de muestras para pruebas

Before finalizing your order, request samples of the materials or finished products. Testing these samples will allow you to evaluate factors such as durability, insulation performance, and ease of cleaning. Conduct taste tests if applicable, especially for glass and stainless steel bottles, to ensure there are no adverse flavors.

Paso 6: Consider Sustainability and Environmental Impact

Sustainability is increasingly important in consumer purchasing decisions. Assess the environmental impact of the materials you are considering, including their recyclability and carbon footprint. Partner with suppliers who prioritize sustainable practices, as this can enhance your brand’s marketability.

Paso 7: Negotiate Terms and Establish Quality Control Processes

Once you’ve selected a supplier, negotiate terms that align with your business objectives, including pricing, lead times, and minimum order quantities. Establish clear quality control processes to ensure that the products received meet your specifications consistently. This step is critical to maintaining product integrity and customer satisfaction.

By following this checklist, B2B buyers can make informed decisions about sourcing the best materials for water bottles, ensuring that their products meet both market demands and regulatory standards.

Comprehensive Cost and Pricing Analysis for best material for water bottle Sourcing

What Are the Key Cost Components in Water Bottle Material Sourcing?

When sourcing materials for water bottles, understanding the cost structure is essential. The primary cost components include:

-

Materiales: The type of material significantly impacts costs. Stainless steel and glass generally command higher prices due to their durability and safety features. In contrast, plastic materials, especially those that are BPA-free like Tritan, can be more cost-effective but may have varying quality levels.

-

Trabajo: Labor costs vary by region. Countries with lower labor costs, such as Vietnam, may provide a competitive edge in manufacturing. However, it’s crucial to consider the skill level of the workforce, which can affect the quality of the final product.

-

Gastos generales de fabricación: This includes costs associated with factory operations, utilities, and maintenance. Efficient production processes can minimize these overheads, impacting the overall cost.

-

Herramientas: Custom molds and tools for specific bottle designs can incur substantial upfront costs. However, these costs can be amortized over larger production runs, making them more manageable for bulk orders.

-

Control de calidad: Ensuring product safety and quality is paramount, especially for materials that come into direct contact with beverages. Implementing stringent QC measures may add to costs but can prevent costly recalls and damage to brand reputation.

-

Logística: Shipping costs can vary based on the origin and destination of the materials. Factors such as distance, shipping methods, and tariffs play a significant role in logistics costs.

-

Margen: Suppliers typically add a profit margin to their costs, which can vary widely based on market conditions and competition.

How Do Price Influencers Affect Water Bottle Sourcing?

Several factors can influence the pricing of water bottle materials:

-

Volumen/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Larger orders typically yield lower per-unit costs due to economies of scale. International buyers should negotiate MOQs to optimize their pricing strategy.

-

Especificaciones/Personalización: Customized designs or specifications can increase costs. Buyers should evaluate whether custom features are necessary or if standard models suffice.

-

Material Quality/Certifications: Higher quality materials or those with specific certifications (e.g., food-grade, BPA-free) may come at a premium. Understanding the certification requirements in your market can help avoid unexpected costs.

-

Factores del proveedor: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more but offer better quality assurance and service, reducing risks in the long run.

-

Incoterms: The International Commercial Terms (Incoterms) dictate responsibilities between buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers manage costs effectively.

What Buyer Tips Should International B2B Buyers Consider?

-

Negotiate Wisely: Leverage volume and long-term contracts to negotiate better prices. Building relationships with suppliers can also lead to favorable terms and pricing structures.

-

Focus on Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential warranty claims. A cheaper upfront price may lead to higher long-term costs.

-

Entender los matices de los precios: For buyers in Africa, South America, the Middle East, and Europe, be aware of regional pricing trends and currency fluctuations. Local market conditions can affect the availability and cost of materials.

-

Tenga en cuenta a los proveedores locales: Sourcing from local suppliers can reduce shipping costs and lead times. Additionally, local suppliers may better understand regional regulations and certifications.

-

Manténgase informado sobre las tendencias del mercado: Keeping abreast of changes in raw material prices and market demands can help buyers make informed purchasing decisions.

Descargo de responsabilidad sobre los precios indicativos

Prices for water bottle materials can fluctuate based on market conditions, supplier negotiations, and changing regulations. It’s advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing best material for water bottle With Other Solutions

Exploring Alternatives to the Best Material for Water Bottles

When selecting the optimal material for water bottles, it’s essential to consider alternatives that offer similar functionalities. This analysis compares the best materials—primarily stainless steel, glass, and plastic—against innovative solutions such as hydration packs and water filtration systems. Each alternative presents unique advantages and challenges, allowing B2B buyers to make informed decisions tailored to their specific requirements.

| Aspecto comparativo | Best Material For Water Bottle | Hydration Pack | Water Filtration System |

|---|---|---|---|

| Rendimiento | Excellent insulation and durability; ideal for all temperatures. | Convenient for outdoor activities; holds a large volume of water. | Provides safe drinking water from various sources but requires a separate container. |

| Coste | Moderate to high; varies by brand and features. | Generally lower cost; includes a bladder and tube. | Varies widely; initial purchase can be low, but filters require replacement. |

| Facilidad de aplicación | Simple to use; ready-to-fill design. | Quick to fill and use; designed for portability. | Requires set-up and knowledge of filtration methods; more complex for casual users. |

| Mantenimiento | Requires regular cleaning to prevent bacteria buildup; durable. | Needs frequent cleaning of the bladder and tube; susceptible to mold if not dried properly. | Filters need periodic replacement; system requires maintenance to function effectively. |

| El mejor caso de uso | Ideal for everyday hydration, travel, and outdoor adventures. | Best for hiking, biking, and other outdoor activities requiring hands-free hydration. | Suitable for outdoor adventures where water sources are questionable, or for emergency situations. |

How Do Hydration Packs Compare as an Alternative?

Hydration packs have gained popularity for their practicality in outdoor sports and activities. They consist of a water reservoir (bladder) and a tube for easy sipping on the go. One significant advantage of hydration packs is their hands-free design, which allows users to stay hydrated without stopping. However, they can be challenging to clean thoroughly, especially if not dried properly, which can lead to mold growth. Additionally, while they can carry a larger volume of water, they do not offer insulation, which may be a disadvantage in extreme temperatures.

What About Water Filtration Systems?

Water filtration systems provide an essential solution for ensuring safe drinking water, particularly in areas where water quality is questionable. These systems can filter out contaminants, making water from rivers or lakes safe to consume. Their flexibility allows users to source water from various locations, but they require a separate container for drinking. The maintenance aspect is critical, as filters need to be replaced regularly to ensure efficacy. While they are excellent for emergencies or outdoor scenarios, they may not be as convenient for everyday use compared to traditional water bottles.

Conclusión: ¿Cómo deben elegir los compradores B2B la solución adecuada?

When deciding on the best material for water bottles or considering alternatives, B2B buyers must evaluate their specific use cases and the environments in which the products will be employed. For regular hydration needs, stainless steel or glass bottles are superior due to their durability and insulation properties. In contrast, hydration packs are excellent for active lifestyles, while filtration systems are crucial for ensuring water safety in unpredictable environments. Ultimately, understanding the trade-offs between performance, cost, maintenance, and intended use will guide buyers to make the most suitable choice for their needs.

Essential Technical Properties and Trade Terminology for best material for water bottle

What Are the Key Technical Properties of Water Bottle Materials?

When selecting the best material for water bottles, understanding critical technical properties is essential for B2B buyers. These specifications not only influence product performance but also affect safety, durability, and consumer satisfaction.

1. Material Grade

Material grade refers to the specific classification of a material based on its composition and properties. For example, stainless steel water bottles may be made from grades like 304 or 316. Grade 304 is widely used due to its excellent corrosion resistance and suitability for food contact. B2B buyers must consider material grade as it directly impacts the longevity and safety of the product, ensuring compliance with health regulations.

2. Thermal Conductivity

Thermal conductivity measures how well a material conducts heat. This property is particularly vital for insulated water bottles, where double-wall vacuum insulation is preferred to maintain the temperature of beverages. A lower thermal conductivity means better insulation, keeping drinks hot or cold for extended periods. B2B buyers should prioritize materials with low thermal conductivity to enhance customer satisfaction and brand reputation.

3. Leaching Potential

Leaching potential refers to the risk of harmful chemicals migrating from the container into the liquid it holds. This is a significant concern with materials like plastics, where BPA (bisphenol A) can leach into water. Understanding leaching potential is crucial for buyers, as it affects consumer health and can lead to liability issues. Opting for BPA-free plastics or safer materials like glass or stainless steel mitigates these risks.

4. Impact Resistance

Impact resistance indicates a material’s ability to withstand physical stress without breaking or deforming. Stainless steel and certain high-grade plastics exhibit high impact resistance, making them suitable for active lifestyles. For B2B buyers, selecting materials with strong impact resistance is essential to reduce returns and enhance customer loyalty.

5. Weight-to-Strength Ratio

This property measures the strength of a material relative to its weight. Lightweight materials, such as aluminum, offer ease of transport without compromising durability. A favorable weight-to-strength ratio is particularly appealing for outdoor and sports applications, influencing purchasing decisions for B2B buyers focused on active consumer markets.

¿Cuáles son los términos comerciales habituales en el sector de las botellas de agua?

Understanding industry terminology is crucial for effective communication and negotiations in the B2B space.

1. OEM (fabricante de equipos originales)

OEM refers to companies that produce parts or products that are then sold under another company’s brand. In the water bottle industry, an OEM may manufacture bottles for a brand that designs and markets them. B2B buyers should consider OEM partnerships to leverage manufacturing expertise while focusing on branding and marketing.

2. MOQ (Cantidad mínima de pedido)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cost efficiency. Understanding MOQ helps buyers plan their procurement strategies effectively and avoid overstock or stockouts.

3. RFQ (solicitud de oferta)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific quantities of products. It is an essential tool for B2B buyers to compare offers and negotiate better deals. Crafting a clear RFQ ensures that suppliers provide accurate quotes based on the buyer’s specifications.

4. Incoterms (Términos comerciales internacionales)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms dictate who is responsible for shipping, insurance, and tariffs. B2B buyers should familiarize themselves with Incoterms to minimize misunderstandings and ensure smooth cross-border transactions.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing water bottles, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the best material for water bottle Sector

What Are the Global Drivers Influencing the Best Material for Water Bottles?

The global water bottle market is undergoing a significant transformation driven by increasing health awareness, sustainability concerns, and technological advancements. As consumers become more conscientious about their health and the environment, materials like stainless steel and glass are gaining popularity due to their safety and durability compared to traditional plastic options. In regions such as Africa, South America, the Middle East, and Europe, the demand for reusable water bottles is rising, fueled by urbanization and a growing middle class seeking quality products.

Emerging technologies in manufacturing are also reshaping sourcing trends. Innovations such as advanced recycling processes and the development of BPA-free plastics are making it easier for manufacturers to meet safety standards and consumer preferences. Additionally, the rise of e-commerce platforms is enabling international B2B buyers to access a wider range of products and suppliers, facilitating competitive pricing and better sourcing strategies.

Furthermore, market dynamics are shifting as regulations tighten around single-use plastics, pushing brands to innovate and pivot towards more sustainable materials. This evolution is particularly evident in regions like Europe, where stringent environmental policies encourage businesses to adopt eco-friendly practices.

How Is Sustainability and Ethical Sourcing Shaping the Best Material for Water Bottles?

Sustainability has become a crucial consideration for B2B buyers in the water bottle sector. The environmental impact of materials used in production—especially concerning plastic pollution—has prompted a shift towards more sustainable alternatives. Materials such as stainless steel and glass are not only recyclable but also have a longer lifespan, reducing the need for frequent replacements.

Ethical sourcing practices are gaining traction as consumers demand transparency in supply chains. B2B buyers are increasingly looking for suppliers that can demonstrate commitment to sustainable practices, including the use of renewable energy, responsible sourcing of raw materials, and fair labor practices. Certifications like ISO 14001 (Environmental Management) and Cradle to Cradle can serve as indicators of a supplier’s commitment to sustainability.

In addition, brands that prioritize eco-friendly materials and ethical sourcing often enjoy a competitive advantage. They can leverage these practices in their marketing strategies to appeal to environmentally conscious consumers, ultimately driving sales and fostering brand loyalty.

What Is the Evolution of Water Bottle Materials and Its Significance for B2B Buyers?

The evolution of water bottle materials reflects broader trends in consumer behavior and health consciousness. Initially dominated by single-use plastic, the market began shifting towards more durable and safer materials in response to health concerns over BPA and other harmful chemicals. The introduction of BPA-free plastics marked a significant turning point, addressing safety concerns while maintaining affordability.

Stainless steel emerged as a leading alternative due to its durability, insulation properties, and ease of cleaning. This material not only meets health and safety standards but also aligns with the growing demand for reusable products. Glass, while heavier, gained favor for its purity and taste, appealing to health-conscious consumers.

For B2B buyers, understanding this evolution is essential for making informed sourcing decisions. The shift towards sustainable materials is not merely a trend but a reflection of changing consumer values. By prioritizing suppliers that offer safe, durable, and eco-friendly options, businesses can position themselves favorably in a competitive market while meeting the demands of today’s conscientious consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of best material for water bottle

-

How do I choose the safest water bottle material for my business needs?

When selecting the safest water bottle material, prioritize options that are BPA-free and have a proven track record for safety. Stainless steel is highly regarded for its durability, insulation properties, and ease of cleaning, making it ideal for reusable bottles. Glass is another excellent choice, known for its purity and lack of chemical leaching. Consider your target market’s preferences and any local regulations regarding materials to ensure compliance and safety. -

What is the best material for a sustainable water bottle?

Stainless steel is often considered the best material for sustainable water bottles due to its long lifespan and recyclability. Unlike plastic, it doesn’t contribute to environmental pollution, and many stainless steel bottles are insulated, enhancing their usability. Glass bottles, while heavier, are also a sustainable option as they are reusable and recyclable. When sourcing, look for suppliers that emphasize eco-friendly practices in their manufacturing processes. -

What are the minimum order quantities (MOQs) for water bottles from international suppliers?

Minimum order quantities can vary significantly among suppliers, typically ranging from 100 to 10,000 units depending on the material and customization options. It’s essential to communicate your specific needs upfront to gauge whether a supplier can meet your requirements. Some suppliers may offer lower MOQs for initial orders, especially if you’re willing to build a long-term partnership, so consider negotiating based on your business potential. -

How can I ensure the quality of water bottles when sourcing internationally?

To ensure the quality of water bottles, conduct thorough supplier vetting by reviewing certifications, customer testimonials, and product samples. Request detailed information about their manufacturing processes and quality control measures. Consider partnering with a third-party inspection service to perform quality assurance checks before shipment. This proactive approach can help mitigate risks associated with international sourcing. -

What customization options are available for water bottles?

Customization options for water bottles can include branding (logos and colors), size variations, and additional features such as insulation or built-in filtration systems. Many suppliers offer flexible customization packages to cater to different market needs. Discuss your vision with potential suppliers to explore their capabilities and ensure that the final product aligns with your brand identity and customer expectations. -

What payment terms should I consider when sourcing water bottles internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit (typically 30-50%) before production and the remaining balance before shipment. Consider using secure payment methods that offer buyer protection, such as letters of credit or escrow services, especially for larger orders. Negotiate favorable terms that align with your cash flow and risk management strategies. -

How do I handle logistics and shipping for international water bottle orders?

When managing logistics for international orders, collaborate with experienced freight forwarders who understand the nuances of shipping water bottles, including packaging requirements and customs regulations. Choose between air and sea freight based on your budget and delivery timelines. Ensure you account for duties and taxes in your overall cost structure and maintain clear communication with your supplier regarding shipping schedules. -

What are the common certifications to look for when sourcing water bottles?

When sourcing water bottles, look for certifications such as FDA approval for food safety, ISO certifications for quality management, and BPA-free labeling for plastics. If you are targeting markets in Europe, ensure compliance with EU regulations regarding materials used in food contact items. These certifications not only assure product safety but also enhance your brand’s credibility in the competitive B2B landscape.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 7 Best Material For Water Bottle Manufacturers & Suppliers List

1. BottlePro – Water Bottle Safety Guide

Dominio: bottlepro.net

Registrado: 2014 (11 años)

Introducción: The article discusses the safety of various water bottle materials, ranking seven types: plastic, stainless steel, glass, aluminum, copper, silicone, and titanium. It emphasizes the importance of regular cleaning to prevent bacteria buildup and mentions leaching concerns, particularly with plastics containing BPA. It highlights that most modern plastic bottles are BPA-free, recommending Tritan as …

2. Reddit – Best Water Bottle Materials

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: The discussion revolves around the best materials for water bottles, with key mentions of stainless steel, copper, glass, and plastic. Stainless steel is favored for its durability and insulation properties, while glass is appreciated for its purity but noted for being heavy and fragile. Copper is debated due to concerns about potential toxicity versus its antimicrobial properties. Plastic is ment…

3. Hydro Flask – 32 oz. Stainless Steel Water Bottle

Dominio: waterbottleadvisor.com

Registered: 2024 (1 years)

Introducción: 1st Place: Stainless Steel – Recommendation: Hydro Flask 32 oz. Pros: Amazing insulation, durable, good taste, no odors, healthy, versatile, no condensation in premium bottles. Cons: Heavier than other materials, can be loud, not always dishwasher-safe, no clear walls. 2nd Place: Glass – Recommendation: Waterdrop Glass Bottle. Pros: Superior taste, purity, healthiest material to drink from, clear …

4. Fellow Products – Aluminum Water Bottles

Dominio: fellowproducts.com

Registrado: 2014 (11 años)

Introducción: This company, Fellow Products – Aluminum Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Washington Post – Best Materials for Reusable Water Bottles

Dominio: washingtonpost.com

Matriculado: 1995 (30 años)

Introducción: The article discusses the best materials for reusable water bottles: glass, metal, and plastic. It highlights that reusable water bottles can save carbon emissions and reduce plastic waste. Drinking from reusable bottles is considered healthier and more sustainable compared to single-use bottles, which often contain microplastics and are rarely recycled, leading to environmental issues.

6. Allrecipes – Top Water Bottles

Dominio: allrecipes.com

Inscrito: 1998 (27 años)

Introducción: Top Picks: My Top Pick: Yeti Rambler Water Bottle at Amazon $32; Best Budget: Contigo AutoSeal Chill 2.0 Water Bottle, 24-Ounce at Amazon $40; Best Lightweight: S’well 17-Ounce Stainless Steel Water Bottle at Amazon $39; Best Tumbler: Stanley Quencher H2.0 at Amazon $48; Best Design: Owala Water Bottle at Amazon $30; Most Versatile: Hydro Flask Wide Mouth Water Bottle at Amazon $45; Best Straw Lid…

7. Hydro Flask – Sustainable Drinkware

Dominio: hydroflask.com

Inscrito: 2009 (16 años)

Introducción: Hydro Flask offers sustainable and refillable water bottles and drinkware. They have a Labor Day Sale with 25% off select items. Free shipping is available on orders over $39. The product range includes limited edition collections, travel bottles, tumblers, coolers, lunch boxes, kitchenware, and accessories. Notable products include a 5 c Stainless Steel Food Container ($22.46), Flatware Set ($18….

Strategic Sourcing Conclusion and Outlook for best material for water bottle

In the competitive landscape of reusable water bottles, strategic sourcing of materials is essential for international B2B buyers. As highlighted, stainless steel, glass, and BPA-free plastics each present unique advantages. Stainless steel is favored for its durability and insulation properties, making it ideal for a diverse range of climates. Glass offers unparalleled purity and taste, while modern plastics like Tritan provide lightweight options without compromising safety.

Understanding these material characteristics can enhance product offerings and meet evolving consumer demands across regions such as Africa, South America, the Middle East, and Europe. Buyers should prioritize sourcing from manufacturers who adhere to stringent safety standards and sustainable practices, thereby aligning with global trends toward eco-friendliness and health consciousness.

As we look ahead, the demand for high-quality, safe, and sustainable water bottles will only increase. Now is the time for B2B buyers to leverage insights from this guide to make informed sourcing decisions. By investing in the best materials, businesses can not only enhance their product lines but also foster brand loyalty in a market that values health and sustainability. Engage with suppliers who prioritize innovation and quality to stay ahead in this dynamic industry.