Introduction: Navigating the Global Market for water bottle method

In today’s fast-paced global market, sourcing effective solutions for sustainable packaging, like the water bottle method, can be a daunting challenge for international B2B buyers. With increasing environmental regulations and consumer demand for eco-friendly practices, businesses in regions such as Africa, South America, the Middle East, and Europe must navigate a complex landscape of options. This comprehensive guide delves into the various types of water bottle methods, their applications across different sectors, and practical insights on supplier vetting processes.

Our aim is to equip B2B buyers with the knowledge needed to make informed purchasing decisions. From understanding the cost implications to evaluating the sustainability of materials, this guide addresses the critical factors that influence the selection of water bottle methods. It will also explore innovative applications that can enhance product offerings and meet market demands, ensuring that your business remains competitive.

By providing actionable insights and a clear framework for evaluating suppliers and products, this guide empowers businesses to embrace sustainable packaging solutions confidently. Whether you are a buyer in Germany seeking reliable suppliers or a manufacturer in Brazil looking to expand your product line, our guide serves as an essential resource for navigating the intricacies of the global market for water bottle methods.

Artículo Navegación

- Top 7 Water Bottle Method Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water bottle method

- Understanding water bottle method Types and Variations

- Key Industrial Applications of water bottle method

- 3 Common User Pain Points for ‘water bottle method’ & Their Solutions

- Strategic Material Selection Guide for water bottle method

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle method

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle method’

- Comprehensive Cost and Pricing Analysis for water bottle method Sourcing

- Alternatives Analysis: Comparing water bottle method With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle method

- Navigating Market Dynamics and Sourcing Trends in the water bottle method Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle method

- Descargo de responsabilidad y condiciones de uso

- Strategic Sourcing Conclusion and Outlook for water bottle method

Understanding water bottle method Types and Variations

| Tipo Nombre | Principales rasgos distintivos | Aplicaciones B2B principales | Breves pros y contras para los compradores |

|---|---|---|---|

| Water Bottle Bong | Simple design, uses a plastic bottle, cost-effective | Recreational product sales, DIY kits | Pros: Low cost, easy to make; Contras: Less durable, potential health concerns from materials. |

| Gravity Bong | Utilizes gravity for smoke filtration, larger hits | Specialty smoking shops, event rentals | Pros: Produces potent hits, unique experience; Contras: Requires practice, can be cumbersome. |

| Mason Jar Bong | Durable design, visually appealing, longer-lasting | Home decor, specialty cannabis shops | Pros: Attractive, reusable; Contras: More complex to create, higher initial cost. |

| Waterfall Bong | Uses gravity and water to create a waterfall effect | Novelty item sales, cannabis events | Pros: Unique smoking experience; Contras: Requires more setup, can be messy. |

| Portable Water Pipe | Compact and easy to transport, often made of silicone | Travel accessories, outdoor events | Pros: Convenient, durable; Contras: Limited water capacity, may not filter as effectively. |

What Are the Characteristics of a Water Bottle Bong?

The water bottle bong is the most accessible variation, making it an ideal choice for B2B buyers interested in low-cost, DIY smoking solutions. Typically made from a standard plastic bottle, this method is popular among novice users due to its straightforward assembly and effective smoke filtration. Businesses can capitalize on this trend by offering DIY kits or instructional materials, appealing to budget-conscious consumers who value both functionality and ease of use.

How Does a Gravity Bong Differ from Other Types?

Gravity bongs leverage the principles of gravity to enhance the smoking experience, delivering larger, more potent hits. This method is distinguished by its ability to produce a significant amount of smoke in a short time. B2B buyers in the recreational market can focus on selling gravity bong kits or accessories at events, catering to consumers looking for unique and intense experiences. However, the learning curve associated with its use may deter some customers.

Why Choose a Mason Jar Bong?

The mason jar bong combines aesthetic appeal with functionality, making it suitable for businesses that want to offer products that double as decor. Its robust construction ensures longevity, appealing to eco-conscious buyers who prefer reusable options. However, the complexity of crafting a mason jar bong may require additional customer education, which presents an opportunity for businesses to provide tutorials or workshops.

What Is the Appeal of a Waterfall Bong?

Waterfall bongs offer a distinctive smoking method that generates a unique experience through the use of gravity and water. This novelty can attract consumers looking for something different from traditional smoking methods. B2B buyers can leverage this by marketing waterfall bongs at cannabis events or festivals, but they should also consider the potential for messiness and the need for proper setup instructions.

How Do Portable Water Pipes Cater to On-the-Go Consumers?

Portable water pipes are designed for convenience, making them ideal for consumers who enjoy smoking while traveling. Often made from durable materials like silicone, these pipes offer a practical solution for outdoor events or on-the-go use. B2B businesses can tap into this market by providing portable options that emphasize ease of transport and durability, although they may need to address concerns regarding smoke filtration effectiveness compared to larger models.

Key Industrial Applications of water bottle method

| Industria/Sector | Specific Application of Water Bottle Method | Valor/beneficio para la empresa | Consideraciones clave para el aprovisionamiento de esta aplicación |

|---|---|---|---|

| Agricultura | Irrigation and Water Conservation Solutions | Efficient water use improves crop yield and reduces costs | Access to sustainable water sources and affordable bottles |

| Educación | Science Education Tools for Demonstrations | Engages students in practical science applications | Durable materials and safety certifications for school use |

| Environmental Services | Waste Management and Recycling Initiatives | Promotes recycling and reduces plastic waste | Partnerships with local recycling facilities and NGOs |

| Salud y bienestar | DIY Health and Fitness Tools (e.g., hydration tracking) | Encourages healthy habits and increases product engagement | Quality assurance of materials used for health applications |

| Construction and DIY | Customizable Water Filtration Systems | Enhances water quality for construction sites and homes | Compliance with local water quality standards and regulations |

How is the Water Bottle Method Used in Agriculture to Improve Irrigation?

In the agriculture sector, the water bottle method is utilized to create low-cost irrigation systems that enhance water conservation. By repurposing plastic bottles, farmers can develop drip irrigation setups that deliver water directly to plant roots, minimizing evaporation and runoff. This method addresses water scarcity issues prevalent in regions like Africa and South America, where efficient water usage is crucial for crop sustainability. Buyers should consider sourcing durable, UV-resistant bottles that withstand environmental conditions.

What Role Does the Water Bottle Method Play in Education?

Educational institutions leverage the water bottle method for hands-on science experiments and demonstrations. This approach allows students to learn about principles like buoyancy, filtration, and environmental science in a fun and interactive manner. The method fosters engagement and understanding of complex concepts, which is particularly valuable in regions where traditional resources may be limited. When sourcing materials, schools should prioritize safety and durability to ensure a secure learning environment.

How Does the Water Bottle Method Contribute to Environmental Services?

The environmental services industry employs the water bottle method to promote recycling initiatives and waste management programs. By encouraging the use of repurposed bottles, organizations can significantly reduce plastic waste while raising awareness about environmental sustainability. This application is particularly effective in urban areas across the Middle East and Europe, where waste management is a pressing concern. Businesses should focus on partnerships with local recycling facilities to ensure effective implementation and community engagement.

In What Ways Can the Water Bottle Method Support Health and Wellness Initiatives?

In the health and wellness sector, the water bottle method facilitates the creation of DIY hydration tracking tools, encouraging individuals to maintain proper hydration levels. This application is particularly useful in fitness centers and wellness programs across Europe and South America, where health consciousness is on the rise. Buyers should ensure that materials used are BPA-free and safe for regular use, as this can significantly enhance user trust and product effectiveness.

How Can the Water Bottle Method Enhance Construction and DIY Projects?

The construction industry can utilize the water bottle method to develop customizable water filtration systems that improve water quality on job sites. By repurposing bottles as part of DIY filtration setups, construction companies can ensure that their water sources meet health standards, which is especially vital in remote areas. Buyers should prioritize sourcing bottles that comply with local water quality regulations to ensure safety and effectiveness in their projects.

3 Common User Pain Points for ‘water bottle method’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Materials for Water Bottle Method

El problema: B2B buyers, especially those in emerging markets like Africa and South America, often face challenges when sourcing high-quality materials for the water bottle method. This could stem from limited access to reliable suppliers, fluctuating prices, and varying quality standards. Buyers may struggle to find bottles that are both affordable and safe for use, leading to concerns about product quality and consumer safety. Additionally, they may encounter difficulties in securing consistent supply chains, which can disrupt production schedules and affect customer satisfaction.

La solución: To effectively source materials for the water bottle method, buyers should establish partnerships with reputable suppliers who specialize in eco-friendly packaging and materials. Conducting thorough market research to identify local and international suppliers can help in finding high-quality plastic bottles that meet safety regulations. Additionally, buyers should consider bulk purchasing to negotiate better pricing and ensure a steady supply. Implementing a quality control process upon receipt of materials can help mitigate risks associated with subpar products. Finally, engaging in sustainable practices by choosing recyclable materials can enhance brand reputation and appeal to environmentally conscious consumers.

Scenario 2: Training Staff to Properly Utilize the Water Bottle Method

El problema: A common pain point for B2B buyers is the need for effective training of staff on the proper utilization of the water bottle method. Inadequate training can lead to improper use, resulting in wasted materials, inefficiencies, and potential safety hazards. This is particularly critical in businesses that rely on this method for manufacturing processes or product demonstrations. Without proper understanding, employees may struggle to achieve the desired results, ultimately affecting overall business productivity.

La solución: Implementing a structured training program is essential to ensure that all staff members are well-versed in the water bottle method. This program should include hands-on workshops, detailed instructional materials, and clear guidelines on best practices. Consider collaborating with industry experts to provide training sessions that cover both theoretical and practical aspects of the method. Additionally, creating a comprehensive resource library with video tutorials and FAQs can serve as a reference for employees. Regular assessments and feedback sessions can help identify knowledge gaps and reinforce learning, ensuring that the workforce is proficient and confident in using the method.

Scenario 3: Managing Regulatory Compliance for Water Bottle Use

El problema: B2B buyers often grapple with the complexities of regulatory compliance related to the use of water bottles in their products. Different regions, especially in Europe and the Middle East, have stringent regulations regarding plastic materials and consumer safety. Buyers may find it challenging to navigate these regulations, leading to potential legal issues, fines, or product recalls. The lack of clear guidelines can create confusion, especially for businesses looking to expand into new markets.

La solución: To manage regulatory compliance effectively, buyers should invest in understanding the specific regulations that apply to their market and product category. Engaging legal experts or consultants who specialize in compliance can provide valuable insights into local laws and regulations. Buyers should also stay updated on any changes in legislation that may affect their operations. Creating a compliance checklist that outlines required certifications, testing standards, and labeling information can streamline the process. Additionally, fostering relationships with industry associations can provide access to resources and support in navigating regulatory landscapes, ensuring that products are compliant and market-ready.

Strategic Material Selection Guide for water bottle method

What Materials Are Commonly Used in the Water Bottle Method?

When selecting materials for the water bottle method, particularly in the context of creating water bottles for various applications, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials: plastic (PET), glass, stainless steel, and aluminum.

How Does Plastic (PET) Perform in Water Bottle Applications?

Polyethylene terephthalate (PET) is widely used for producing water bottles due to its lightweight nature and excellent barrier properties. PET has a temperature rating of up to 70°C and is resistant to impact, making it suitable for various environments.

Pros: PET is cost-effective, easy to manufacture, and recyclable. It is also transparent, allowing consumers to see the contents, which can enhance market appeal.

Contras: However, PET has limitations regarding high-temperature exposure, which can lead to deformation or leaching of harmful chemicals. It is also less durable compared to glass or metal options.

Impacto en la aplicación: PET is compatible with cold and room-temperature liquids but may not be suitable for hot beverages.

Consideraciones para compradores internacionales: Compliance with local regulations, such as those set by the FDA in the U.S. or EFSA in Europe, is crucial. Buyers in regions like Africa and South America should also consider the recyclability of PET and local waste management practices.

¿Qué ventajas ofrece el vidrio para las botellas de agua?

Glass is another material commonly used for water bottles, known for its inert properties and ability to maintain the purity of the contents. Glass bottles can withstand temperatures up to 100°C, making them suitable for hot liquids.

Pros: Glass is non-reactive, does not leach chemicals, and is recyclable. It also provides a premium feel, which can enhance brand perception.

Contras: The primary drawback is its weight and fragility, making it less practical for on-the-go use. Additionally, glass production can be more complex and energy-intensive compared to plastic.

Impacto en la aplicación: Glass is ideal for beverages that require long shelf life and purity, such as juices and flavored waters.

Consideraciones para compradores internacionales: Buyers should ensure compliance with safety standards such as ASTM and DIN. In regions with high transportation risks, the fragility of glass may be a significant concern.

How Does Stainless Steel Compare in Water Bottle Manufacturing?

Stainless steel is gaining popularity for water bottles due to its durability and resistance to corrosion. It can handle a wide range of temperatures, making it suitable for both hot and cold liquids.

Pros: Stainless steel is highly durable, resistant to rust, and does not retain flavors or odors. It is also recyclable and has a long lifespan.

Contras: The initial cost of stainless steel bottles is higher than plastic or aluminum. Manufacturing processes can also be more complex, requiring specialized equipment.

Impacto en la aplicación: Stainless steel is excellent for both hot and cold beverages, making it versatile for various consumer needs.

Consideraciones para compradores internacionales: Compliance with food safety regulations is essential, as is understanding local preferences for materials. Buyers in Europe and the Middle East may prefer stainless steel for its sustainability credentials.

What Role Does Aluminum Play in Water Bottle Design?

Aluminum is often used for water bottles due to its lightweight nature and ability to be molded into various shapes. It has a temperature resistance of around 150°C when coated.

Pros: Aluminum is lightweight, durable, and can be easily recycled. It also allows for vibrant designs and branding opportunities through printing.

Contras: Aluminum can react with acidic beverages unless coated, which may complicate manufacturing. It is also less durable than stainless steel.

Impacto en la aplicación: Aluminum is suitable for cold beverages and is often used for sports drinks or flavored waters.

Consideraciones para compradores internacionales: Compliance with international standards, such as JIS in Japan and ASTM in the U.S., is crucial. Buyers should also consider the environmental impact of aluminum production and recycling in their regions.

Summary Table of Material Selection for Water Bottle Method

| Material | Typical Use Case for Water Bottle Method | Ventajas clave | Principales desventajas/limitaciones | Coste relativo (Bajo/Medio/Alto) |

|---|---|---|---|---|

| Plastic (PET) | Cold beverages, bottled water | Ligero y rentable | Limited temperature resistance | Bajo |

| Vidrio | Juices, flavored waters | Tacto no reactivo y de primera calidad | Frágil y pesado | Med |

| Acero inoxidable | Bebidas frías y calientes | Durable and corrosion-resistant | Mayor coste inicial | Alta |

| Aluminio | Sports drinks, flavored waters | Lightweight and easily moldable | Can react with acidic beverages | Med |

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle method

What Are the Main Stages of Manufacturing Processes for the Water Bottle Method?

The manufacturing process for the water bottle method involves several critical stages, each designed to ensure that the final product meets the necessary quality and functionality standards. These stages typically include material preparation, forming, assembly, and finishing.

How is Material Prepared for the Water Bottle Method?

The first step in the manufacturing process is material preparation. For water bottles, this usually involves sourcing high-quality plastics, such as polyethylene or PET, known for their durability and safety. Suppliers often conduct material testing to ensure compliance with food-grade standards, particularly important for products intended for beverages.

In addition to the primary materials, manufacturers may also prepare additives that enhance the properties of the bottles, such as UV stabilizers or antimicrobial agents. This preparation phase is crucial for ensuring that the materials used are suitable for both the intended use and regulatory compliance.

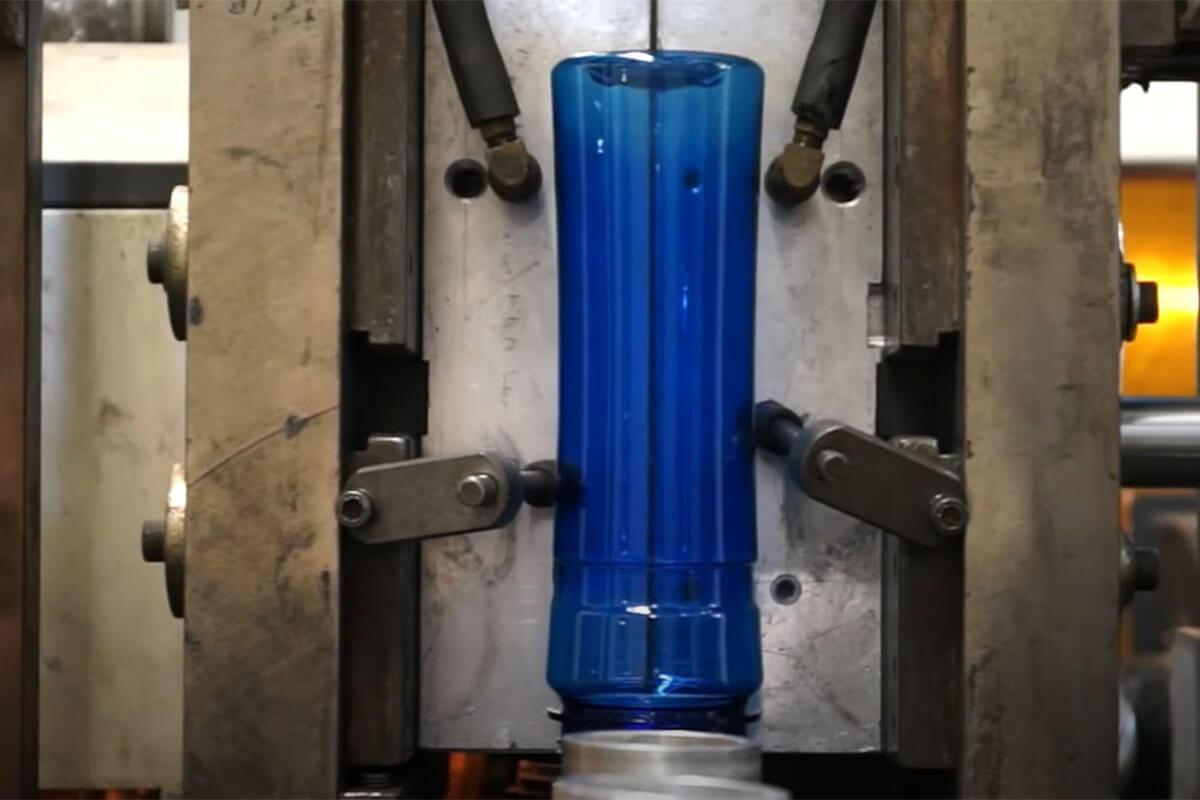

What Techniques Are Used in the Forming Process?

Once the materials are prepared, the next stage is forming. This stage typically employs techniques such as blow molding or injection molding. Blow molding is commonly used for creating hollow bottles, where heated plastic is inflated into a mold to form the bottle shape. Injection molding, on the other hand, is used for producing caps and other components.

Each technique has its advantages; for instance, blow molding allows for rapid production of lightweight bottles, while injection molding provides precision for parts like screw caps, ensuring a secure fit. Manufacturers must select the appropriate technique based on the design specifications and production volume.

How is Assembly Conducted in the Manufacturing Process?

Following forming, the assembly stage involves bringing together various components, such as the bottle body, cap, and any additional features like labels or handles. This stage is often automated to enhance efficiency and reduce labor costs. However, manual assembly may be employed for more complex designs or custom products.

Quality checks are integrated into the assembly line to ensure that components fit correctly and that there are no defects. This may include visual inspections and simple functional tests to verify that closures seal properly and that bottles can withstand typical handling and transportation conditions.

What Finishing Techniques Are Commonly Used?

The final stage in the manufacturing process is finishing. This may involve surface treatments, labeling, or printing logos and nutritional information directly onto the bottles. Finishing techniques can include screen printing, heat transfer, or labeling with adhesive-backed materials.

It is essential for manufacturers to ensure that the finishing processes do not compromise the integrity of the bottles. For example, inks and adhesives must be food-safe and resistant to washing and wear. Quality control during this stage ensures that the final product is both aesthetically pleasing and functional.

What Quality Assurance Standards Apply to the Water Bottle Method?

Quality assurance is paramount in the manufacturing of water bottles, particularly for international markets. Various standards govern the quality and safety of these products, including ISO 9001, which focuses on quality management systems, and CE marking, which indicates compliance with EU safety regulations.

How Do International Standards Like ISO 9001 Impact Quality Control?

ISO 9001 establishes a framework for quality management that can enhance customer satisfaction and operational efficiency. For B2B buyers, suppliers with ISO 9001 certification demonstrate a commitment to maintaining high-quality standards throughout their manufacturing processes. This includes regular internal audits, documentation of processes, and continuous improvement initiatives.

Adherence to ISO standards also facilitates smoother trade across borders, as many countries recognize these certifications. For buyers from regions like Africa, South America, and the Middle East, selecting suppliers with ISO certification can reduce risks associated with product quality and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

To ensure consistent quality, manufacturers implement several checkpoints throughout the production process, including:

-

Control de calidad entrante (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

-

Control de calidad durante el proceso (IPQC): During manufacturing, operators conduct regular checks to monitor the production process and identify any deviations from established parameters.

-

Control de calidad final (CCF): This final checkpoint occurs after assembly and finishing, where the finished products undergo rigorous testing for defects, functionality, and compliance with safety standards.

These checkpoints help to catch issues early, minimizing waste and ensuring that only products that meet quality standards reach the market.

¿Cómo pueden los compradores B2B verificar el control de calidad de los proveedores?

B2B buyers must be diligent in verifying the quality control practices of their suppliers. One effective method is to conduct audits, either internally or through third-party services, to assess compliance with quality standards and operational efficiency.

What Documentation Should Buyers Request?

Buyers should request relevant documentation that can provide insights into a supplier’s quality control processes, including:

- Quality Assurance Manuals: Outlining the company’s quality management system.

- Audit Reports: From internal or third-party audits that assess compliance with quality standards.

- Test Reports: Detailing the results of product testing, including material safety and performance metrics.

How Do QC and Certification Nuances Affect International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential. Different regions may have varying requirements for product safety and quality, which can affect market entry and compliance.

For example, European buyers may require CE marking for products sold within the EU, while buyers in Africa may prioritize suppliers who understand local regulations. It is crucial for buyers to communicate their requirements clearly and verify that suppliers are equipped to meet both local and international standards.

Conclusión

In summary, the manufacturing processes and quality assurance for the water bottle method involve meticulous attention to detail at every stage, from material preparation to finishing. For B2B buyers, understanding these processes and the relevant quality standards is critical to ensuring that they select reliable suppliers capable of delivering high-quality products that meet international regulations. By conducting thorough audits and requesting appropriate documentation, buyers can mitigate risks and foster successful business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle method’

In this practical sourcing guide, we aim to provide B2B buyers with a step-by-step checklist for effectively procuring materials and components related to the ‘water bottle method.’ This guide will help streamline your sourcing process, ensuring that you make informed decisions while meeting your business needs.

Primer paso: Identify Your Project Requirements

Before initiating any procurement, clearly define the specifications of the water bottle method you intend to implement. Consider factors such as capacity, material composition, and intended use. This step is vital as it lays the foundation for all subsequent decisions, ensuring that your sourcing aligns with your project goals.

Segundo paso: Buscar posibles proveedores

Conduct thorough research to compile a list of potential suppliers specializing in the materials needed for the water bottle method. Utilize industry directories, trade shows, and online platforms to identify reputable vendors. Pay attention to their experience, product range, and customer reviews, as these elements will help you gauge their reliability and expertise.

Tercer paso: Evaluar las certificaciones de los proveedores

Before finalizing any supplier, verify their certifications and compliance with international quality standards. This may include ISO certifications or specific industry-related qualifications. Ensuring that your suppliers adhere to these standards is crucial for maintaining product quality and minimizing risks associated with sourcing.

Paso 4: Solicitud de muestras para pruebas

Once you have shortlisted suppliers, request samples of the materials to assess their quality and suitability for your specific application. This step allows you to evaluate the performance and durability of the products before making a bulk order. Be sure to test the samples under conditions that closely mimic their intended use.

Paso 5: Negociar precios y condiciones

Engage in negotiations with your selected suppliers to secure the best pricing and payment terms. Consider factors such as bulk discounts, lead times, and payment flexibility. Effective negotiation can lead to significant cost savings and better overall terms, which are essential for maintaining your budget and project timeline.

Paso 6: Assess Logistics and Delivery Options

Evaluate the logistics capabilities of your suppliers, including their shipping methods, delivery timelines, and ability to handle customs clearance if sourcing internationally. This is particularly important for B2B buyers in regions like Africa and South America, where logistics can be complex. Ensure that your supplier can meet your delivery requirements to avoid project delays.

Paso 7: Establecer un plan de comunicación

Finally, set up a clear communication plan with your supplier. Define points of contact, preferred communication channels, and reporting schedules. A well-structured communication strategy helps ensure that both parties are aligned on expectations and can address any issues that may arise during the procurement process.

By following these steps, B2B buyers can effectively navigate the sourcing process for the water bottle method, ultimately leading to successful project outcomes and stronger supplier relationships.

Comprehensive Cost and Pricing Analysis for water bottle method Sourcing

What are the Key Cost Components in Sourcing Water Bottle Methods?

When sourcing water bottle methods, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materiales: The type of plastic or other materials used in manufacturing water bottles significantly impacts cost. High-quality, food-grade plastics will typically be more expensive than standard options, but they are crucial for compliance with safety regulations, especially in international markets.

-

Trabajo: Labor costs vary by region and can be influenced by local wage standards, skill levels, and the complexity of production processes. In countries like Germany, labor costs may be higher compared to regions in Africa or South America, affecting overall pricing.

-

Gastos generales de fabricación: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient production facilities can help reduce these costs, which can be a significant factor in pricing.

-

Herramientas: The initial investment in molds and machinery necessary for production can be substantial. Buyers should inquire about the tooling costs, especially if custom designs are required, as this can affect the final price.

-

Control de calidad: Implementing stringent QC processes ensures product reliability but can add to the overall costs. Certifications for quality assurance may also be necessary for certain markets, which can further influence pricing.

-

Logística: Shipping and handling costs are crucial, especially for international transactions. Factors such as distance, shipping method, and customs duties must be considered in the total cost of ownership.

-

Margen: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the typical margins in the industry can aid in negotiations.

How Do Price Influencers Affect Water Bottle Method Sourcing?

Several factors influence the pricing of water bottle methods:

-

Volumen/MOQ (Cantidad mínima de pedido): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should consider their consumption needs to optimize costs.

-

Especificaciones y personalización: Custom designs, sizes, or features can lead to increased costs. Buyers should balance the need for unique specifications with budget constraints.

-

Calidad del material y certificaciones: Higher-quality materials and certifications (e.g., BPA-free, ISO certifications) can increase costs. Buyers must assess the importance of these factors against their target market’s expectations.

-

Factores del proveedor: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may offer better quality assurance but at a premium price.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they define the responsibilities of buyers and sellers in shipping. This can affect overall costs, particularly in logistics.

What Buyer Tips Can Help Negotiate Better Prices for Water Bottle Methods?

-

Negociar con eficacia: Building a strong relationship with suppliers can lead to better pricing and terms. Consider long-term partnerships that can facilitate better deals.

-

Centrarse en la rentabilidad: Evaluate the total cost of ownership, which includes purchase price, shipping, and potential waste or loss during transit. A lower initial price may not always equate to overall savings.

-

Entender los matices de los precios en los mercados internacionales: Be aware of regional pricing trends and regulations. For instance, European markets may have stricter regulations on materials, impacting sourcing decisions.

-

Research Market Rates: Conduct thorough market research to understand competitive pricing and leverage that information in negotiations.

-

Evaluate Multiple Suppliers: Don’t settle for the first quote. Comparing multiple suppliers can provide leverage in negotiations and help identify the best value.

Conclusión

Understanding the comprehensive cost and pricing analysis for sourcing water bottle methods is vital for international B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. By considering the various cost components and price influencers, buyers can make informed decisions that align with their business objectives. Always remember to negotiate effectively and keep an eye on total cost implications to maximize value.

Alternatives Analysis: Comparing water bottle method With Other Solutions

Introduction to Alternative Solutions for the Water Bottle Method

When evaluating the effectiveness of the water bottle method, it is crucial to consider viable alternatives that may better suit specific business needs. Each method offers unique advantages and disadvantages, which can impact operational efficiency, cost-effectiveness, and user experience. This analysis provides a comprehensive comparison of the water bottle method against two alternative solutions, enabling B2B buyers to make informed decisions.

Cuadro comparativo

| Aspecto comparativo | Water Bottle Method | Gravity Bong | Mason Jar Bong |

|---|---|---|---|

| Rendimiento | Good filtration, smooth hits | Very high filtration, potent hits | High filtration, aesthetically pleasing |

| Coste | Low-cost, often DIY | Low-cost, often DIY | Moderate, requires more materials |

| Facilidad de aplicación | Very easy, minimal tools needed | Requires some practice | More complex, additional materials needed |

| Mantenimiento | Low, easy to clean | Low, easy to clean | Moderate, may require more thorough cleaning |

| El mejor caso de uso | Casual use, home settings | Group settings, potent effects | Decorative use, longer sessions |

Desglose detallado de alternativas

Gravity Bong

The gravity bong is an innovative alternative that leverages water and gravity to create a highly effective smoking device. It offers superior filtration and delivers potent hits due to the volume of smoke produced. However, it requires a learning curve for effective use, which may not be ideal for all users, particularly beginners. The materials needed are generally inexpensive, making it a budget-friendly option. Still, its complexity can deter casual users who prefer straightforward methods.

Mason Jar Bong

The mason jar bong combines functionality with aesthetics, making it a popular choice among users who appreciate a visually appealing smoking device. It offers high filtration, similar to traditional bongs, and can provide a smoother smoking experience. However, constructing a mason jar bong requires more materials and effort compared to the water bottle method, which may not be suitable for those seeking a quick and easy solution. Maintenance can also be slightly higher, as its design may require more thorough cleaning.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate smoking method hinges on understanding your specific requirements and user preferences. For businesses or individuals seeking a straightforward, cost-effective solution, the water bottle method remains a compelling option. However, for those who prioritize potency and filtration, exploring gravity bongs or mason jar bongs may yield better results. Ultimately, B2B buyers should weigh factors such as cost, ease of implementation, and user experience to determine the best fit for their operational needs and customer satisfaction.

Essential Technical Properties and Trade Terminology for water bottle method

What Are the Essential Technical Properties of the Water Bottle Method?

Understanding the technical specifications of the water bottle method is crucial for B2B buyers, particularly those engaged in the manufacturing and supply of smoking apparatus. Below are some critical properties that define the quality and functionality of water bottle bongs:

-

Calidad del material

– The most common material used in the construction of water bottle bongs is plastic, typically polyethylene or PET (Polyethylene Terephthalate). The material grade affects durability, safety, and the ability to withstand heat. High-grade plastics are less likely to leach harmful chemicals, making them safer for consumer use. For B2B buyers, selecting products with verified material grades ensures compliance with safety regulations and enhances brand reputation. -

Water Filtration Capacity

– The design of the water chamber is essential for effective smoke filtration. The size and shape of the chamber influence how much smoke is cooled and filtered before inhalation. A larger chamber can accommodate more water, improving the filtration process. For businesses, understanding filtration capacity can help in marketing products as superior smoking devices, appealing to health-conscious consumers. -

Niveles de tolerancia

– Tolerance refers to the allowable deviation in the dimensions of the bong components, such as the downstem and mouthpiece. Precise tolerances ensure that parts fit together seamlessly, preventing air leaks that could compromise the smoking experience. For manufacturers, maintaining tight tolerance levels is vital for quality control, reducing returns and enhancing customer satisfaction. -

Ergonomic Design

– The design of the mouthpiece and overall shape of the bong should allow for comfortable handling and ease of use. Ergonomic considerations may include the angle of the neck and the weight distribution of the device. For B2B buyers, products that prioritize user comfort can lead to higher sales and positive reviews, driving repeat business. -

Ease of Assembly and Disassembly

– Water bottle bongs should be easy to assemble and disassemble for cleaning and maintenance. Features such as screw-on caps or easily removable downstems are desirable. In the B2B context, offering products that are user-friendly can attract a wider customer base, including those who may be new to smoking devices.

What Are the Common Trade Terms Associated with the Water Bottle Method?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to the water bottle method:

-

OEM (fabricante de equipos originales)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of water bottle bongs, an OEM may produce the plastic components while a different brand sells the finished product. Understanding OEM partnerships can help businesses manage supply chains and product quality. -

MOQ (Cantidad mínima de pedido)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management. It can also affect pricing strategies, as larger orders typically lead to lower per-unit costs. -

RFQ (solicitud de presupuesto)

– An RFQ is a document used by buyers to solicit price bids from suppliers for specific products or services. When considering the water bottle method, submitting an RFQ can help buyers compare prices, quality, and delivery terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (Términos comerciales internacionales)

– Incoterms are a set of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B transactions involving water bottle bongs, as they dictate who is responsible for shipping, insurance, and tariffs, thereby minimizing risk and confusion. -

Plazos de entrega

– Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses dealing with water bottle bongs, short lead times can be a competitive advantage, allowing quicker market entry and better inventory management. -

Opciones de personalización

– Customization options refer to the ability to modify products according to specific requirements, such as size, color, or branding. For B2B buyers, understanding available customization options can enhance product differentiation in the market, attracting niche segments and boosting sales.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their product offerings and drive business success in the competitive market for water bottle smoking devices.

Navigating Market Dynamics and Sourcing Trends in the water bottle method Sector

What Are the Current Market Dynamics and Key Trends in the Water Bottle Method Sector?

The water bottle method sector has witnessed substantial growth, driven by increasing consumer demand for portable and eco-friendly alternatives to traditional smoking devices. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where innovative product designs cater to local preferences. The rise of social media platforms, especially TikTok, has further fueled interest in DIY smoking solutions, making water bottle bongs a popular choice among younger demographics. B2B buyers in these regions should note that this trend is not merely about aesthetics; it highlights a broader shift towards personalization and sustainability in product offerings.

Emerging technologies are also influencing sourcing trends. For instance, advancements in materials science have led to the development of safer, more durable plastics and biodegradable options that cater to environmentally conscious consumers. Additionally, the integration of e-commerce platforms has simplified the procurement process for B2B buyers, allowing them to source innovative products directly from manufacturers. As competition intensifies, suppliers that leverage data analytics to understand market preferences and forecast demand will have a competitive edge.

How Important Is Sustainability and Ethical Sourcing in the Water Bottle Method Sector?

Sustainability is becoming a crucial factor in the water bottle method sector, as consumers increasingly prioritize environmentally friendly products. The environmental impact of single-use plastics has prompted a shift towards sustainable alternatives, such as reusable and recyclable materials. For B2B buyers, this means sourcing products that align with their corporate social responsibility goals and meet the growing consumer demand for eco-friendly solutions.

Ethical sourcing practices are also gaining traction, as businesses are held accountable for their supply chains. Buyers should prioritize suppliers that demonstrate transparency in their sourcing processes, ensuring that materials are obtained responsibly and without harm to communities or ecosystems. Certifications like Fair Trade and Global Recycle Standard can serve as benchmarks for ethical sourcing, providing buyers with assurance that their products meet high environmental and social standards. By aligning with sustainable and ethical practices, businesses can enhance their brand reputation and foster customer loyalty.

What Is the Brief Evolution and History of the Water Bottle Method?

The water bottle method, commonly associated with DIY smoking devices, has its roots in the early days of smoking culture. Initially, makeshift bongs were crafted from various household items, with the water bottle emerging as a popular choice due to its accessibility and convenience. Over the years, the method has evolved from a simple DIY solution to a recognized product category, with manufacturers creating specialized designs that enhance user experience.

As the cannabis industry has matured, so too has the technology and materials used in these devices. Today, water bottle bongs are not only functional but also serve as a canvas for artistic expression, with a variety of shapes, colors, and materials available. This evolution reflects broader changes in consumer preferences, emphasizing the importance of innovation and adaptability in the marketplace. B2B buyers should consider these trends when sourcing products, as the market continues to evolve alongside consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle method

-

How do I solve quality control issues when sourcing water bottles?

To mitigate quality control issues, establish a clear set of quality standards and specifications before engaging suppliers. Conduct thorough research to identify reputable manufacturers with a proven track record. Request samples to assess material quality and functionality. Implement regular inspections during production and consider third-party quality assurance services to ensure compliance with your standards. Establish open communication with your suppliers to address any concerns promptly and ensure they understand your quality expectations. -

What is the best material for producing water bottles?

The best material for producing water bottles often depends on the intended use and market demands. Common materials include PET (Polyethylene Terephthalate) for single-use bottles, which are lightweight and recyclable, and BPA-free Tritan or stainless steel for reusable options. Each material has its benefits; for example, stainless steel offers durability and insulation, while PET is cost-effective for mass production. Consider your target market’s preferences and environmental regulations when choosing the material. -

How can I find reliable suppliers for the water bottle method?

To find reliable suppliers, utilize online B2B marketplaces like Alibaba or Global Sources, where you can filter suppliers by ratings and reviews. Attend trade shows related to packaging and consumer goods to network and discover potential partners. Verify suppliers by checking their certifications, production capabilities, and customer references. Conducting factory visits or requesting audits can also provide insight into their operations and reliability. -

What are the typical minimum order quantities (MOQs) for water bottles?

Minimum order quantities (MOQs) for water bottles can vary significantly based on the supplier and customization options. Generally, MOQs range from 1,000 to 10,000 units for standard designs, while custom orders may require higher quantities to justify setup costs. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business strategy and market demand. -

What payment terms should I expect when sourcing water bottles internationally?

Payment terms in international trade can vary widely among suppliers. Common practices include a 30% deposit upfront and the remaining 70% before shipping, or payment via Letter of Credit (L/C) for larger transactions. It’s essential to clarify payment methods accepted by the supplier, such as wire transfers or escrow services. Ensure you understand the implications of each payment method, including potential fees and security measures, to protect your investment. -

¿Qué consideraciones logísticas debo tener en cuenta al importar botellas de agua?

When importing water bottles, consider logistics factors such as shipping methods (air vs. sea freight), lead times, and customs regulations in your destination country. Work with a freight forwarder experienced in handling your product type to streamline the shipping process. Additionally, ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to facilitate a smooth customs clearance process. -

How can I customize water bottles to meet market demands?

Customization options for water bottles can include size, color, material, and branding elements such as logos and designs. Collaborate closely with your supplier to discuss available customization options and lead times. Conduct market research to identify trends and preferences in your target demographic, ensuring that your customized products align with consumer expectations. Additionally, consider eco-friendly materials or innovative designs to differentiate your product in the market. -

What are the best practices for ensuring sustainable sourcing of water bottles?

To ensure sustainable sourcing, prioritize suppliers that use eco-friendly materials and adhere to responsible manufacturing practices. Investigate certifications such as ISO 14001 for environmental management or BPA-free certifications for materials. Engage in transparent communication with suppliers about their sustainability policies and practices. Consider implementing a lifecycle assessment to evaluate the environmental impact of your products and explore options for recycling or reusing materials to minimize waste.

Descargo de responsabilidad y condiciones de uso

⚠️ Descargo de responsabilidad importante

La información facilitada en esta guía, incluido el contenido relativo a fabricantes, especificaciones técnicas y análisis de mercado, tiene únicamente fines informativos y educativos. No constituye asesoramiento profesional en materia de adquisiciones, asesoramiento financiero ni asesoramiento jurídico.

Aunque hemos hecho todo lo posible por garantizar la exactitud y actualidad de la información, no nos hacemos responsables de posibles errores, omisiones o información obsoleta. Las condiciones del mercado, los detalles de las empresas y las normas técnicas están sujetos a cambios.

Los compradores B2B deben llevar a cabo su propia diligencia debida independiente y exhaustiva antes de tomar cualquier decisión de compra. Esto incluye ponerse en contacto directamente con los proveedores, verificar las certificaciones, solicitar muestras y buscar asesoramiento profesional. El riesgo de confiar en la información contenida en esta guía es responsabilidad exclusiva del lector.

Top 7 Water Bottle Method Manufacturers & Suppliers List

1. Reddit – Bottle Modification Guide

Dominio: reddit.com

Matriculado: 2005 (20 años)

Introducción: This company, Reddit – Bottle Modification Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. WikiHow – Basic Water Bottle Bong

Dominio: wikihow.com

Inscrito: 2004 (21 años)

Introducción: Basic Water Bottle Bong:

– Material: 17 oz (0.5 L) plastic water bottle, aluminum foil

– Aluminum foil size: 2.5 in (5 cm) square

– Features:

– Foil bowl shape created by pressing down in the center

– 5-6 needle-sized holes poked in the foil for airflow

– Side hole for inhalation, approximately 1 inch (2.5 cm) in diameter

– Instructions:

1. Remove lid from the water bottle.

2. C…

3. ScrapingDog – Instagram Data Solutions

Dominio: instagram.com

Inscrito: 2004 (21 años)

Introducción: Contact us at info@scrapingdog.com for scraping Instagram. Let us know how many pages you want to scrape per month.

4. Space Needle – DIY Water Bottle Bowl

Dominio: ftp.spaceneedle.com

Matriculado: 1995 (30 años)

Introducción: This company, Space Needle – DIY Water Bottle Bowl, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. House of Borel – Water Bottle Method

Dominio: houseofborel.com

Registrado: 2014 (11 años)

Introducción: The water bottle method is a stress-reduction technique that involves using a clear water bottle with a secure lid. It helps manage anxiety by utilizing visualization, breathing synchronization, and tactile sensation. Steps include selecting a suitable bottle, finding a quiet space, filling the bottle with water, focusing on the water, breathing in sync, tilting the bottle to observe water movemen…

6. Weedmaps – Water Bottle Bong

Dominio: weedmaps.com

Registered: 2008 (17 years)

Introducción: Water Bottle Bong: A makeshift smoking device made from a plastic water bottle, typically a standard 17-ounce size. It requires a few materials: a plastic water bottle, scissors or a knife, a pen or marker, aluminum foil or a small metal pipe bowl, a needle or toothpick, water, and a lighter or match. The process involves preparing the bottle, creating a downstem from a pen or marker, making a bow…

7. Instructables – Mastering the Water Bottle Flip

Dominio: instructables.com

Matriculado: 2005 (20 años)

Introducción: The Art of the Water Bottle Flip involves selecting the right water bottle, preparing it with the correct amount of water (approximately 1/3 full), finding an ideal flat surface for flipping, executing the flip with proper technique, and celebrating the successful flip. The best water bottles for flipping are those with a large, flat, circular base, like generic Iowa State Cyclone bottles, and mad…

Strategic Sourcing Conclusion and Outlook for water bottle method

In conclusion, the water bottle method presents a unique opportunity for international B2B buyers to explore innovative solutions that are both cost-effective and environmentally friendly. By leveraging strategic sourcing, businesses can tap into sustainable practices that not only enhance product offerings but also resonate with a growing consumer base that values eco-consciousness.

This method exemplifies how simple materials can be transformed into valuable products, enabling suppliers to differentiate themselves in competitive markets across Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil. As businesses continue to seek ways to optimize their supply chains, the adaptability and simplicity of the water bottle method can serve as a model for innovation.

Looking ahead, international buyers are encouraged to engage with suppliers who prioritize sustainability and creativity in their offerings. By fostering partnerships that emphasize strategic sourcing, companies can position themselves for future growth while meeting the demands of an increasingly discerning market. Embrace the potential of the water bottle method to unlock new avenues for success in your business endeavors.