Introduction: Navigating the Global Market for plastic flask bottles

In an increasingly interconnected global market, sourcing the right plastic flask bottles can pose significant challenges for B2B buyers. These versatile containers, traditionally associated with liquor, are now making waves in various industries—from food and beverage to personal care and pharmaceuticals. As demand surges, understanding the nuances of plastic flask bottles becomes critical. This guide delves into the diverse types, applications, and features of these containers, equipping international buyers from regions such as Africa, South America, the Middle East, and Europe with the knowledge they need to make informed purchasing decisions.

Navigating the complexities of supplier vetting, cost analysis, and compliance with regional regulations can be daunting. This guide aims to simplify that process by providing actionable insights into selecting high-quality plastic flask bottles that meet both functional and aesthetic requirements. Whether you are considering lightweight PET options for their shatter resistance or exploring customizable designs for branding purposes, our comprehensive overview will help you identify suitable suppliers and negotiate favorable terms.

Ultimately, this resource empowers B2B buyers to confidently source plastic flask bottles that align with their operational needs and market demands, ensuring a competitive edge in their respective industries. By leveraging the insights shared in this guide, you can enhance product offerings and streamline supply chain operations, facilitating growth and sustainability in your business.

Article Navigation

- Top 5 Plastic Flask Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for plastic flask bottles

- Understanding plastic flask bottles Types and Variations

- Key Industrial Applications of plastic flask bottles

- 3 Common User Pain Points for ‘plastic flask bottles’ & Their Solutions

- Strategic Material Selection Guide for plastic flask bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for plastic flask bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic flask bottles’

- Comprehensive Cost and Pricing Analysis for plastic flask bottles Sourcing

- Alternatives Analysis: Comparing plastic flask bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for plastic flask bottles

- Navigating Market Dynamics and Sourcing Trends in the plastic flask bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of plastic flask bottles

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for plastic flask bottles

Understanding plastic flask bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear PET Plastic Flasks | Lightweight, shatter-resistant, glass-like clarity | Liquor, syrups, marinades, personal care products | Pros: Cost-effective, BPA-free, recyclable. Cons: Limited heat resistance compared to other plastics. |

| Tamper-Evident Plastic Flasks | Secure closure to prevent contamination | Food service, pharmaceuticals, personal care | Pros: Enhances product safety, user-friendly. Cons: Slightly higher cost due to added features. |

| Square Plastic Flask Containers | Unique square design, often with aluminum lids | Catering, events, oils, syrups | Pros: Eye-catching design, stackable. Cons: May not be suitable for all liquid types. |

| Multi-Size PET Plastic Bottles | Available in various sizes (200 ml to 500 ml) | Beverage, condiments, personal care | Pros: Versatile, portable, customizable. Cons: Larger sizes may increase shipping costs. |

| High-Pressure Resistant Flasks | Engineered for high-pressure processing | Food and beverage, pharmaceuticals | Pros: Suitable for sterilization, durable. Cons: May require specific caps for optimal performance. |

What Are the Characteristics of Clear PET Plastic Flasks?

Clear PET plastic flasks are a popular choice for businesses looking for lightweight and shatter-resistant packaging solutions. Their glass-like clarity makes them ideal for showcasing products such as liquors, syrups, and marinades. B2B buyers should consider the cost-effectiveness of shipping these bottles due to their lightweight nature. However, it is important to note that while PET is durable, it may not withstand extreme heat as effectively as other materials.

Why Choose Tamper-Evident Plastic Flasks?

Tamper-evident plastic flasks are essential for businesses focused on safety and consumer trust. These bottles feature secure closures that prevent unauthorized access, making them suitable for food service and pharmaceutical applications. B2B buyers appreciate the user-friendly design that balances safety with convenience. The only downside is that these flasks may come at a slightly higher price point due to the additional safety features.

How Do Square Plastic Flask Containers Stand Out?

Square plastic flask containers offer a unique aesthetic that appeals to event planners and caterers. Their design allows for efficient stacking and storage, while aluminum lids enhance both style and functionality. These containers are often used for oils and syrups, making them a versatile option for various applications. However, their specialized design may not be suitable for all types of liquids, which is something buyers should consider.

What Benefits Do Multi-Size PET Plastic Bottles Provide?

Multi-size PET plastic bottles cater to a variety of business needs, offering capacities ranging from 200 ml to 500 ml. This versatility makes them suitable for beverages, condiments, and personal care products. B2B buyers benefit from the ability to customize sizes based on their specific requirements, although larger sizes may incur higher shipping costs. It’s crucial for businesses to assess their product volume needs when selecting sizes.

Why Are High-Pressure Resistant Flasks Important?

High-pressure resistant flasks are engineered for applications that require sterilization and durability, making them ideal for food and beverage industries as well as pharmaceuticals. These bottles can withstand autoclaving, ensuring that products remain safe and uncontaminated. While they offer significant advantages in terms of safety and performance, buyers must ensure compatibility with specific caps to maintain optimal functionality.

Key Industrial Applications of plastic flask bottles

| Industry/Sector | Specific Application of plastic flask bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Packaging for sauces, syrups, and marinades | Lightweight and shatter-resistant, reducing shipping costs | Ensure FDA compliance and recyclability of materials |

| Personal Care & Cosmetics | Storage for lotions, oils, and fragrances | Clear visibility enhances product appeal and branding opportunities | Tamper-evident features for safety and compliance |

| Pharmaceuticals | Dispensing liquid medications and health products | Durable and leak-proof design ensures safe storage and transport | Look for certifications that meet international health standards |

| Hospitality & Catering | Serving sauces and dressings at events | Attractive design enhances customer experience | Consider bulk purchasing options for cost efficiency |

| Retail & E-commerce | Customized packaging for promotional items | Flexible design allows for branding and easy identification | Assess the adaptability for e-commerce logistics |

How Are Plastic Flask Bottles Used in the Food & Beverage Industry?

In the food and beverage sector, plastic flask bottles are increasingly used for packaging sauces, syrups, and marinades. Their lightweight and shatter-resistant properties significantly reduce shipping costs, making them ideal for international distribution. Buyers in this industry should prioritize sourcing bottles made from FDA-compliant materials to ensure safety and quality, as well as consider the recyclability of the product to align with sustainability goals.

What Role Do Plastic Flask Bottles Play in Personal Care & Cosmetics?

Plastic flask bottles serve as effective storage solutions for lotions, oils, and fragrances in the personal care and cosmetics industry. Their clear visibility allows consumers to appreciate the product’s color and texture, enhancing marketing appeal. For international buyers, tamper-evident features are crucial to ensure product safety and compliance with local regulations, which can vary significantly across regions such as Africa, South America, and Europe.

How Are Plastic Flask Bottles Utilized in Pharmaceuticals?

In the pharmaceutical sector, plastic flask bottles are used for dispensing liquid medications and health products. Their durable and leak-proof design is essential for safe storage and transport, especially when dealing with sensitive substances. Buyers should look for products that meet international health standards and certifications, ensuring that they comply with regulations in their respective markets, particularly in the Middle East and Europe.

How Do Plastic Flask Bottles Enhance Hospitality & Catering Services?

In the hospitality and catering industry, plastic flask bottles are ideal for serving sauces and dressings at events. Their attractive designs not only enhance the customer experience but also facilitate easy handling during service. When sourcing these bottles, businesses should consider bulk purchasing options to improve cost efficiency, especially when catering to large events across diverse regions.

What Are the Advantages of Using Plastic Flask Bottles in Retail & E-commerce?

Retailers and e-commerce businesses leverage plastic flask bottles for customized packaging of promotional items. Their flexible design allows for branding opportunities and easy identification of products on shelves or online platforms. International buyers should assess how well these bottles adapt to e-commerce logistics, including shipping and storage requirements, to optimize their supply chain operations.

3 Common User Pain Points for ‘plastic flask bottles’ & Their Solutions

Scenario 1: Struggling with Leakage During Transport

The Problem: B2B buyers often face significant issues with leakage when transporting liquids in plastic flask bottles. This is particularly critical for businesses in the food and beverage industry, where a leak can lead to product contamination, financial losses, and a damaged reputation. For instance, a catering company might find that their bottles of sauces or dressings have leaked during transit, resulting in messy deliveries and customer complaints. This not only affects immediate sales but can also impact long-term relationships with clients.

The Solution: To mitigate leakage issues, buyers should prioritize sourcing high-quality plastic flask bottles that are specifically designed for leak-proof performance. Look for features such as tamper-evident caps and specialized sealing mechanisms that ensure a secure fit. When placing an order, verify the manufacturer’s testing standards to ensure the bottles have been rigorously evaluated for leak resistance. Additionally, consider using protective packaging solutions, such as padded containers or dividers, to further safeguard the bottles during transport. Implementing these strategies will help maintain product integrity and enhance customer satisfaction.

Scenario 2: Limited Customization Options for Branding

The Problem: Many B2B buyers struggle with finding plastic flask bottles that allow for effective branding. In competitive markets, the ability to customize packaging can significantly influence consumer choices. For businesses that produce gourmet sauces, spirits, or health products, a lack of branding options can lead to missed marketing opportunities and a weaker brand presence. Buyers may find that the standard bottles available do not fit their branding aesthetic or provide the visibility they desire for their products.

The Solution: Buyers should seek suppliers that offer customizable plastic flask bottles in various shapes, sizes, and colors. Look for manufacturers that provide options for label printing, embossing, or color customization. Additionally, consider exploring eco-friendly materials, as sustainability can enhance brand image and appeal to environmentally conscious consumers. When negotiating with suppliers, inquire about minimum order quantities for custom designs and lead times to ensure that your branding needs align with your production schedule. By investing in personalized packaging, businesses can create a distinctive identity that resonates with their target audience.

Scenario 3: Difficulty in Sourcing Sustainable Options

The Problem: Increasingly, B2B buyers are under pressure to adopt sustainable practices, including the sourcing of eco-friendly packaging. However, many buyers encounter challenges in finding plastic flask bottles that are not only functional but also environmentally responsible. This can be particularly frustrating for businesses that wish to appeal to a market segment that prioritizes sustainability, such as consumers in Europe and North America who are increasingly favoring recyclable or biodegradable materials.

The Solution: To address sustainability concerns, buyers should focus on sourcing plastic flask bottles made from recyclable materials like PET (Polyethylene Terephthalate), which is known for its recyclability and lower environmental impact. Engage with suppliers who provide detailed information about their materials and manufacturing processes, ensuring compliance with environmental regulations. Additionally, consider working with suppliers who have certifications, such as those from the National Sanitation Foundation (NSF) or other reputable organizations that verify sustainable practices. Implementing a recycling program for your packaging can also enhance your brand’s sustainability profile and attract eco-conscious customers. By prioritizing sustainable sourcing, companies can not only meet regulatory demands but also foster goodwill among their consumers.

Strategic Material Selection Guide for plastic flask bottles

What Are the Key Materials Used in Plastic Flask Bottles?

When selecting plastic flask bottles for various applications, the choice of material is crucial. Different plastics offer unique properties that can significantly affect performance, cost, and suitability for specific media. Below, we analyze four common materials used in the manufacturing of plastic flask bottles, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyethylene Terephthalate (PET) Perform in Plastic Flask Bottles?

Key Properties: PET is known for its excellent clarity, gloss, and impact resistance. It can withstand temperatures up to 70°C (158°F) and is suitable for high-pressure processing.

Pros & Cons: PET is lightweight and shatter-resistant, making it an ideal alternative to glass. It is also cost-effective for shipping due to its lower weight. However, PET can be less durable than other plastics when exposed to extreme temperatures for prolonged periods.

Impact on Application: PET is compatible with a wide range of liquids, including beverages, personal care products, and pharmaceuticals. Its clarity allows consumers to see the product inside, enhancing visual appeal.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding food safety and recyclability. Standards such as ASTM and DIN may apply, and it’s essential to verify that the PET used is BPA-free.

What Advantages Does High-Density Polyethylene (HDPE) Offer?

Key Properties: HDPE is known for its excellent chemical resistance and can withstand temperatures up to 120°C (248°F). It is also highly resistant to impact and does not degrade under UV light.

Pros & Cons: The material is durable and provides a good barrier against moisture and chemicals, making it suitable for a variety of liquids. However, HDPE is generally less transparent than PET, which may not appeal to all consumers.

Impact on Application: HDPE is particularly well-suited for storing chemicals, cleaning agents, and some food products. Its robustness makes it a preferred choice for industrial applications.

Considerations for International Buyers: Buyers in the Middle East and Europe should be aware of specific regulations surrounding chemical storage and transportation. Compliance with EU regulations and local standards is critical.

Why Choose Polypropylene (PP) for Plastic Flask Bottles?

Key Properties: Polypropylene offers a high melting point (up to 130°C or 266°F) and is resistant to fatigue and stress. It is also resistant to many solvents, making it versatile.

Pros & Cons: PP is lightweight and has a good balance of strength and flexibility. However, it can be more expensive than PET and HDPE, which may affect cost-sensitive projects.

Impact on Application: PP is suitable for a variety of applications, including food storage and personal care products. Its chemical resistance makes it ideal for containing oils and other corrosive substances.

Considerations for International Buyers: Buyers should consider the specific regulations in their regions regarding food-grade materials. Compliance with standards such as JIS in Japan or ASTM in the U.S. is essential for ensuring product safety.

What Are the Benefits of Using Polyvinyl Chloride (PVC)?

Key Properties: PVC is known for its excellent chemical resistance and can withstand temperatures up to 60°C (140°F). It is also highly durable and resistant to environmental degradation.

Pros & Cons: PVC is cost-effective and can be easily molded into various shapes. However, it is less flexible than other plastics and can become brittle over time, especially when exposed to UV light.

Impact on Application: PVC is commonly used for non-food applications, such as industrial chemicals and cleaning agents. Its durability makes it suitable for long-term storage.

Considerations for International Buyers: Buyers should be aware of the environmental regulations regarding PVC, as its production and disposal can pose environmental challenges. Compliance with local standards is crucial for market acceptance.

Summary Table of Material Selection for Plastic Flask Bottles

| Material | Typical Use Case for plastic flask bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Terephthalate (PET) | Beverages, personal care products, pharmaceuticals | Lightweight and shatter-resistant | Less durable under extreme temperatures | Low |

| High-Density Polyethylene (HDPE) | Chemicals, cleaning agents, some food products | Excellent chemical resistance | Less transparency than PET | Low |

| Polypropylene (PP) | Food storage, personal care products | High melting point and flexibility | More expensive than PET and HDPE | Medium |

| Polyvinyl Chloride (PVC) | Industrial chemicals, cleaning agents | Cost-effective and durable | Can become brittle over time | Low |

This strategic material selection guide provides essential insights for B2B buyers seeking to make informed decisions regarding plastic flask bottles. Understanding the properties and implications of each material will facilitate better product choices tailored to specific applications and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic flask bottles

What Are the Main Stages of Manufacturing Plastic Flask Bottles?

The manufacturing of plastic flask bottles involves several key stages, each critical to ensuring the final product meets quality and safety standards. The process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary material used for manufacturing plastic flask bottles is polyethylene terephthalate (PET). This thermoplastic is favored for its clarity, strength, and recyclability. The process begins with the procurement of high-quality PET resin, which is then dried to remove moisture and ensure optimal processing. The resin is often blended with additives to enhance properties such as UV resistance or impact strength, depending on the intended use of the flask.

-

Forming: The forming stage is where the actual shape of the flask is created. Common techniques include blow molding and injection molding. In blow molding, heated PET is extruded into a parison, which is then inflated into a mold to form the flask shape. Injection molding involves injecting molten PET into a mold where it cools and solidifies. This stage is crucial as it defines the structural integrity and aesthetic appeal of the final product.

-

Assembly: After forming, the components of the flask, such as caps and labels, are assembled. Caps may be manufactured separately, often with features like tamper-evident designs to enhance safety. During this stage, additional features like child-resistant mechanisms can also be integrated. This assembly process can be manual or automated, depending on the scale of production.

-

Finishing: The final stage involves quality checks, surface finishing, and packaging. Flasks may undergo additional treatments to improve surface gloss or add coatings that provide resistance to chemicals or scratches. Once finished, the products are packaged in bulk for shipping, often using environmentally friendly materials to appeal to sustainability-conscious buyers.

How Is Quality Assurance Implemented in the Manufacturing of Plastic Flask Bottles?

Quality assurance (QA) is integral to the production of plastic flask bottles, ensuring that each product meets both international standards and specific customer requirements.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, a globally recognized standard for quality management systems. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific standards such as the CE mark for European markets or the American National Standards Institute (ANSI) standards may apply, particularly for products intended for food and beverage use.

-

Quality Control Checkpoints: Quality control (QC) is typically implemented at several critical checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken to monitor the production process, checking for defects or inconsistencies.

– Final Quality Control (FQC): Before packaging, each batch undergoes comprehensive testing to verify that finished products meet safety and quality standards. -

Common Testing Methods: To ensure compliance with standards, various testing methods are employed. These may include:

– Visual Inspection: Checking for defects in appearance, such as clarity and color consistency.

– Dimensional Testing: Using calipers and gauges to verify that the flasks meet specified dimensions.

– Leak Testing: Assessing the integrity of seals and closures to prevent leaks during transport.

– Chemical Resistance Testing: Evaluating the flasks’ ability to withstand various substances, ensuring they are safe for intended use.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure product reliability.

-

Conducting Supplier Audits: One effective method is to conduct regular audits of potential suppliers. These audits assess compliance with quality standards and operational practices. Buyers can request documentation of previous audits and certifications to verify adherence to international standards.

-

Requesting Quality Control Reports: Suppliers should be able to provide detailed quality control reports, including data on testing results, compliance certifications, and records of any non-conformities. Buyers can analyze these reports to gauge the supplier’s commitment to quality.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality control measures. These services can conduct inspections during production, providing reports that highlight compliance with safety and quality standards.

-

Understanding QC and Certification Nuances: Different regions may have varying requirements for certifications and quality assurance. For example, products intended for the European market must comply with EU regulations, while those for the U.S. market may need to meet FDA guidelines. B2B buyers should familiarize themselves with these regional differences to ensure compliance and avoid potential legal issues.

What Are the Key Considerations for International Buyers When Sourcing Plastic Flask Bottles?

When sourcing plastic flask bottles internationally, buyers should consider several factors to ensure they select the right supplier and product.

-

Sustainability Practices: As global awareness of environmental issues increases, B2B buyers should prioritize suppliers that demonstrate sustainable practices in their manufacturing processes. This includes using recyclable materials, minimizing waste, and adhering to environmentally friendly production methods.

-

Customization Options: Buyers often seek suppliers that offer customization options for their products. This may include variations in size, color, and design features such as branding or labeling. Suppliers that can accommodate specific requests are typically more valuable partners.

-

Supply Chain Reliability: Assessing the reliability of a supplier’s supply chain is crucial, especially for international transactions. Buyers should inquire about lead times, shipping methods, and contingency plans for potential disruptions.

-

Communication and Support: Effective communication is vital in international trade. Buyers should ensure that suppliers have robust customer support systems in place to address inquiries, resolve issues, and facilitate smooth transactions.

By understanding the manufacturing processes and quality assurance measures in place for plastic flask bottles, B2B buyers can make informed decisions that align with their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic flask bottles’

When sourcing plastic flask bottles for your business, it’s essential to approach the process methodically to ensure you select the right products and suppliers. This guide offers a step-by-step checklist to help international B2B buyers streamline their procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, outline the specific requirements for your plastic flask bottles. Consider factors such as size, material (e.g., PET), design, and intended use (e.g., food, beverage, or personal care). Having clear specifications will help you communicate your needs effectively and avoid any misunderstandings during the sourcing process.

Step 2: Research Potential Suppliers

Identify and compile a list of potential suppliers that specialize in plastic flask bottles. Look for manufacturers with a proven track record, especially those who have experience supplying to your target market regions like Africa, South America, the Middle East, or Europe. Utilize platforms like trade directories, industry forums, and trade shows to gather information and insights.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that your chosen suppliers meet relevant industry standards and certifications. Check for certifications such as FDA compliance for food contact materials, ISO standards, and sustainability certifications. This step ensures that the products you receive are safe, high-quality, and environmentally friendly.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of their plastic flask bottles. Testing samples allows you to evaluate the quality, durability, and suitability of the products for your specific applications. Pay attention to factors like clarity, weight, and leak-proof capabilities.

Step 5: Compare Pricing and Terms

After assessing the quality of samples, compare the pricing and terms from different suppliers. Look beyond the base price; consider shipping costs, minimum order quantities, payment terms, and bulk discounts. This comprehensive evaluation helps you identify the best overall value for your procurement needs.

Step 6: Review Supplier Reputation and References

Conduct thorough background checks on your shortlisted suppliers. Look for reviews and testimonials from previous clients, and request references, especially from businesses in your industry. A supplier with a solid reputation will be more reliable in terms of product quality, delivery times, and customer service.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful sourcing relationship. Establish clear channels for ongoing communication with your supplier, including contact points for order updates, inquiries, and issue resolution. Ensure that all agreements, specifications, and expectations are documented to avoid potential disputes.

By following this checklist, B2B buyers can navigate the complexities of sourcing plastic flask bottles with confidence, ultimately ensuring they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for plastic flask bottles Sourcing

What Are the Key Cost Components in Sourcing Plastic Flask Bottles?

When analyzing the cost structure for sourcing plastic flask bottles, several components must be taken into account. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The most significant component of the cost structure is the raw materials, predominantly PET (Polyethylene Terephthalate) plastic, which is known for its clarity and durability. Prices can fluctuate based on global petroleum prices, as PET is derived from oil. Additionally, if a supplier offers customized colors or specialized features (like tamper-evident caps), this can increase material costs.

-

Labor: Labor costs vary by region. In countries with lower labor costs, such as some in Africa or South America, manufacturers may offer more competitive pricing. Conversely, European manufacturers may have higher labor costs, which can influence overall pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and general factory operations. Efficient production processes can help minimize these costs, allowing suppliers to offer better prices.

-

Tooling: The initial investment in molds and tools for producing specific flask designs can be substantial. This cost is typically amortized over large production runs, making it crucial for buyers to consider minimum order quantities (MOQs) to ensure cost-effectiveness.

-

Quality Control (QC): Ensuring that products meet safety and quality standards, especially for food and beverage applications, requires a robust QC process. This adds to the overall cost but is essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can significantly impact total expenses, particularly for international buyers. Factors such as distance, shipping method, and packaging can affect logistics costs. Additionally, understanding Incoterms is crucial for clarifying responsibilities and costs associated with shipping.

-

Margin: Supplier margins can vary widely. Established suppliers with strong reputations may charge a premium, while emerging suppliers might offer lower margins to gain market share.

How Do Price Influencers Affect the Cost of Plastic Flask Bottles?

Several factors can influence the pricing of plastic flask bottles. Understanding these can help buyers negotiate better terms and optimize their purchasing strategy.

-

Volume/MOQ: Suppliers often provide discounts based on the volume of orders. Higher MOQs can lead to lower per-unit costs, making bulk purchasing a cost-efficient strategy for B2B buyers.

-

Specifications and Customization: Custom designs, sizes, or features can significantly affect pricing. Buyers should consider their specific needs and whether a standard product could suffice to minimize costs.

-

Materials and Quality Certifications: The choice of material impacts pricing, as does the level of certification required (e.g., FDA compliance for food-grade bottles). Higher quality materials may come at a premium but can offer better performance and customer satisfaction.

-

Supplier Factors: The reliability, reputation, and location of suppliers can influence pricing. Buyers should assess potential suppliers not only on price but also on their ability to deliver quality products consistently.

-

Incoterms: Understanding the terms of shipping and delivery is vital. Incoterms define the responsibilities of buyers and sellers, affecting overall costs, including insurance, duties, and transportation.

What Are the Best Practices for Negotiating Prices and Ensuring Cost Efficiency?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can help in negotiating better prices and achieving cost efficiency.

-

Leverage Volume Discounts: Buyers should aim to consolidate orders to meet or exceed MOQs, which can yield significant savings.

-

Conduct Total Cost of Ownership (TCO) Analysis: Beyond the initial purchase price, consider factors such as durability, shipping, and storage costs. A lower upfront price may lead to higher long-term costs if the product has a shorter lifespan.

-

Understand Pricing Nuances: Recognizing the regional differences in pricing and supplier capabilities can provide a strategic advantage. For instance, sourcing from regions with lower production costs may be beneficial, but ensure that quality standards are not compromised.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, preferential treatment, and improved service levels. Regular communication can also help in understanding market trends and pricing dynamics.

-

Be Aware of Market Trends: Staying informed about fluctuations in raw material prices, labor costs, and global supply chain issues can empower buyers to make timely purchasing decisions.

Disclaimer on Pricing

Prices for plastic flask bottles can vary widely based on the factors discussed above. The figures mentioned in this analysis are indicative and should be verified with suppliers during negotiations. Always conduct thorough research and obtain multiple quotes to ensure the best value for your investment.

Alternatives Analysis: Comparing plastic flask bottles With Other Solutions

Exploring Alternatives to Plastic Flask Bottles

When considering packaging solutions, B2B buyers often explore various alternatives to plastic flask bottles. Each option presents unique benefits and challenges that can significantly influence operational efficiency and cost-effectiveness. This analysis focuses on comparing plastic flask bottles with two viable alternatives: glass bottles and aluminum containers.

Comparison Table

| Comparison Aspect | Plastic Flask Bottles | Glass Bottles | Aluminum Containers |

|---|---|---|---|

| Performance | Lightweight, shatter-resistant, good visibility | Heavy, breakable, excellent barrier properties | Lightweight, recyclable, good thermal resistance |

| Cost | Generally low cost | Higher initial investment | Moderate cost, potential for higher recycling costs |

| Ease of Implementation | Easy to source and customize | Requires careful handling and storage | Simple to implement, but may require specialized sealing |

| Maintenance | Low maintenance, recyclable | Fragile, requires careful cleaning | Low maintenance, easy to recycle |

| Best Use Case | Liquids, sauces, personal care | Premium products, beverages | Beverages, ready-to-drink products |

Detailed Breakdown of Alternatives

Glass Bottles

Glass bottles are often viewed as a premium packaging option, particularly for high-end products like spirits and gourmet sauces. They provide an excellent barrier against oxygen and moisture, ensuring product integrity. However, their weight and fragility make them less suitable for applications requiring transportation over long distances or in bulk. While they offer excellent aesthetic appeal, the higher costs associated with glass, along with the need for careful handling, can deter some businesses from using them.

Aluminum Containers

Aluminum containers serve as a robust alternative, particularly in the beverage industry. They are lightweight, recyclable, and provide good protection against light and oxygen, which can help extend shelf life. Additionally, aluminum is highly durable and resistant to corrosion. However, the initial costs can be moderate, and manufacturers may need to invest in specialized equipment for sealing and filling. Aluminum containers are ideal for ready-to-drink products and can be a sustainable choice for brands focused on eco-friendliness.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the most suitable packaging solution involves a careful assessment of your specific business needs, target market, and product characteristics. Plastic flask bottles offer a cost-effective and versatile option, particularly for businesses looking to minimize shipping costs while maintaining product visibility. In contrast, glass bottles may enhance brand perception and product quality but come with higher costs and handling challenges. Aluminum containers provide a balance of durability and sustainability, making them an excellent choice for beverage manufacturers. Ultimately, B2B buyers should evaluate each option against their operational goals and product requirements to determine the best fit for their packaging needs.

Essential Technical Properties and Trade Terminology for plastic flask bottles

What Are the Essential Technical Properties of Plastic Flask Bottles?

When sourcing plastic flask bottles, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications that B2B buyers should consider:

-

Material Grade: What Type of Plastic is Used?

– Most plastic flask bottles are made from Polyethylene Terephthalate (PET) due to its excellent clarity, durability, and lightweight nature. PET is also BPA-free, making it safer for food and beverage storage. The choice of material directly impacts the product’s performance, safety, and appeal in the market. -

Capacity: How Much Liquid Can It Hold?

– Plastic flasks come in various sizes, typically ranging from 200 ml to 500 ml. Understanding the capacity is essential for meeting customer needs, whether for personal use, catering events, or retail distribution. Buyers should align flask capacities with their target market’s preferences. -

Closure Type: How Is the Bottle Sealed?

– Common closure types include tamper-evident caps and leak-resistant lids. Tamper-evident closures enhance product security and safety, making them particularly important for food and beverage applications. The choice of closure affects not only product safety but also customer trust and satisfaction. -

Recyclability: What Is the Environmental Impact?

– Many plastic flasks are designed to be 100% recyclable, an essential consideration for businesses aiming to improve their sustainability profiles. This property can significantly influence purchasing decisions, especially in markets where environmental concerns are paramount. -

Temperature Resistance: Can It Withstand Extreme Conditions?

– Some plastic flasks are engineered to resist degradation under high temperatures and can be used in microwaves or dishwashers. This versatility adds value, especially for consumers who prioritize convenience and safety in their products. -

Impact Resistance: How Durable Is the Bottle?

– Shatter-resistant properties are crucial for minimizing breakage during transport and handling. This durability not only reduces costs associated with product loss but also enhances consumer confidence in the product’s reliability.

What Are Common Trade Terminologies in the Plastic Flask Bottle Industry?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer): What Does It Mean?

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of plastic flasks, OEMs can provide customized products tailored to specific client needs, which is essential for businesses looking to differentiate their offerings. -

MOQ (Minimum Order Quantity): Why Is It Important?

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budget planning and inventory management. Lower MOQs can be beneficial for startups or smaller businesses looking to test a market. -

RFQ (Request for Quotation): How to Get Pricing?

– An RFQ is a document sent to suppliers requesting a quote for specific products. It’s an essential tool for comparing prices and terms across different suppliers, helping buyers make informed decisions based on cost and quality. -

Incoterms (International Commercial Terms): What Are They?

– Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping costs and liabilities effectively, reducing the risk of unexpected expenses. -

Lead Time: How Long Will It Take?

– Lead time refers to the time taken from placing an order to receiving it. Knowing the lead time is vital for inventory planning and ensuring that supply meets demand, particularly in seasonal markets. -

Sustainability Certifications: Why Do They Matter?

– Certifications related to environmental impact, such as FDA compliance and recycling standards, are increasingly important for buyers focused on sustainability. These certifications can enhance brand reputation and consumer trust in a market that values eco-friendly practices.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the plastic flask bottle market more effectively, ensuring they choose products that meet their operational needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the plastic flask bottles Sector

What Are the Current Market Dynamics for Plastic Flask Bottles?

The global plastic flask bottles market is experiencing notable growth driven by several factors. Increasing demand for lightweight, shatter-resistant packaging solutions across various industries, including food and beverage, personal care, and pharmaceuticals, is a primary driver. As businesses seek to minimize shipping costs while maximizing product safety, materials like polyethylene terephthalate (PET) are becoming increasingly popular due to their glass-like clarity and durability.

Emerging trends in B2B technology are also shaping sourcing strategies. The rise of e-commerce has led to a demand for e-commerce-ready packaging solutions, enabling manufacturers to meet the needs of online retailers and enhance customer satisfaction. Furthermore, advancements in production techniques, such as high-pressure processing and autoclaving, allow for greater versatility in product applications, catering to diverse market segments.

International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, must remain vigilant about local regulations and consumer preferences. The trend towards smaller, portable packaging formats is particularly pronounced in these markets, driven by a younger consumer base and increasing urbanization. This demographic shift presents an opportunity for suppliers to innovate and adapt their offerings to align with evolving consumption patterns.

How Can Sustainability and Ethical Sourcing Impact Your Business in the Plastic Flask Bottles Sector?

Sustainability is no longer just a buzzword; it is a critical factor influencing purchasing decisions in the plastic flask bottles sector. The environmental impact of plastic waste is prompting buyers to prioritize products that are not only recyclable but also manufactured using sustainable practices. For instance, sourcing from suppliers who utilize recycled PET or biodegradable materials can significantly enhance a company’s sustainability profile.

Moreover, ethical supply chains are becoming increasingly important. Buyers should consider the entire lifecycle of plastic flask bottles, from raw material extraction to production and disposal. Certifications such as ISO 14001 for environmental management and the Forest Stewardship Council (FSC) for sustainable sourcing can serve as indicators of a supplier’s commitment to ethical practices.

Incorporating ‘green’ certifications into procurement strategies not only enhances brand reputation but also aligns with global sustainability goals. As consumers become more environmentally conscious, B2B buyers must adapt to these shifts to remain competitive and meet regulatory demands.

How Has the Plastic Flask Bottle Market Evolved Over Time?

The evolution of plastic flask bottles can be traced back to the early adoption of PET in the 1970s, which revolutionized the packaging industry. Initially used predominantly for beverage containers, PET’s advantages, including lightweight construction and resistance to shattering, quickly led to its application in various sectors, including food service and personal care.

Over the decades, the versatility of plastic flasks has expanded, with innovations leading to features such as tamper-evident caps and designs tailored for specific uses, such as syrups and sauces. The ongoing push for sustainability has further influenced product development, prompting manufacturers to focus on creating recyclable and environmentally friendly options. As market demands continue to evolve, the future of plastic flask bottles will likely be shaped by advancements in materials technology and changing consumer preferences, ensuring their relevance in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic flask bottles

-

How do I ensure the quality of plastic flask bottles from suppliers?

To ensure the quality of plastic flask bottles, it’s essential to conduct thorough supplier vetting. Request samples to assess the material quality and manufacturing standards. Look for suppliers with relevant certifications, such as FDA compliance for food-grade materials. Engage in discussions regarding their quality assurance processes, including inspections and testing procedures. Consider visiting the manufacturing facility if feasible, or utilize third-party inspection services to verify the quality before bulk orders. -

What is the best type of plastic for beverage storage?

Polyethylene terephthalate (PET) is considered the best type of plastic for beverage storage due to its durability, clarity, and resistance to impact. PET is lightweight and shatter-resistant, making it ideal for shipping and handling. It is also FDA-compliant, ensuring safety for food and beverage contact. Furthermore, PET is recyclable, aligning with sustainability goals that are increasingly important to consumers and businesses alike. -

What are the minimum order quantities (MOQ) for plastic flask bottles?

Minimum order quantities (MOQ) for plastic flask bottles vary by supplier and can range from a few hundred to several thousand units. It’s advisable to inquire directly with potential suppliers about their MOQ, as they may offer flexibility based on your specific needs or order frequency. Additionally, consider negotiating terms that might allow for smaller initial orders, especially if you’re testing new products or entering new markets. -

How can I customize plastic flask bottles for my brand?

Customization options for plastic flask bottles often include printing your logo, choosing specific colors, and selecting unique cap designs. Many suppliers offer various printing techniques, such as screen printing or labeling, to create branded packaging. When discussing customization, provide clear specifications and inquire about minimum quantities required for custom orders. Additionally, request mock-ups or prototypes to ensure the final product aligns with your brand vision. -

What payment terms should I expect when sourcing internationally?

Payment terms for international sourcing can vary significantly based on supplier policies and negotiation. Common terms include upfront deposits (usually 30-50%) with the balance due before shipment or upon delivery. Some suppliers may also offer payment through letters of credit for added security. Always clarify the payment method, currency, and any associated fees upfront to avoid misunderstandings later in the transaction process. -

What logistics considerations should I be aware of when importing plastic flask bottles?

When importing plastic flask bottles, consider logistics aspects such as shipping methods, customs regulations, and import tariffs. Choose between air freight for faster delivery or ocean freight for cost-effectiveness, depending on your urgency and budget. Ensure compliance with local regulations regarding packaging and labeling. Collaborating with a reputable freight forwarder can streamline the import process and help navigate complex customs procedures. -

How do I verify a supplier’s compliance with international standards?

To verify a supplier’s compliance with international standards, request documentation such as ISO certifications, FDA approvals, or other relevant certifications. Conduct online research to check the supplier’s reputation and reviews from previous clients. Additionally, consider third-party audits or inspections to assess their manufacturing processes and adherence to safety and quality standards. Engaging in direct communication with the supplier about their compliance practices can also provide valuable insights. -

What are the typical uses for plastic flask bottles in various industries?

Plastic flask bottles are versatile and can be used across multiple industries. In the food and beverage sector, they are commonly used for sauces, syrups, and beverages due to their lightweight and shatter-resistant properties. In the personal care industry, they serve for lotions and mouthwashes. Additionally, industries like pharmaceuticals utilize PET bottles for liquid medications. Understanding the specific needs of your target market can help you choose the right bottle type and features for your products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Plastic Flask Bottles Manufacturers & Suppliers List

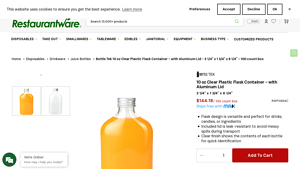

1. Bottle Tek – 10 oz Clear Plastic Flask Container

Domain: restaurantware.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Bottle Tek 10 oz Clear Plastic Flask Container”, “material”: “Plastic”, “lid_material”: “Aluminum”, “dimensions”: “3 1/4\” x 1 3/4\” x 6 1/4\””, “capacity”: “10 oz”, “packaging”: “100 count box”}

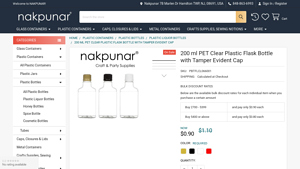

2. Nakpunar – 200 ml PET Clear Plastic Flask Bottle

Domain: nakpunar.com

Registered: 2008 (17 years)

Introduction: {‘name’: ‘200 ml PET Clear Plastic Flask Bottle with Tamper Evident Cap’, ‘sku’: ‘PBTFLCL066001’, ‘upc’: ”, ‘mpn’: ”, ‘shipping’: ‘Calculated at Checkout’, ‘bulk_discount_rates’: [{‘quantity_range’: ‘2700 – 5399’, ‘price_each’: 0.9}, {‘quantity_range’: ‘5400 or above’, ‘price_each’: 0.8}], ‘msrp’: ‘$1.10’, ‘current_price’: ‘$0.90’, ‘color_options’: [‘Gold’, ‘Black’, ‘White’, ‘Red’], ‘capacity_ml…

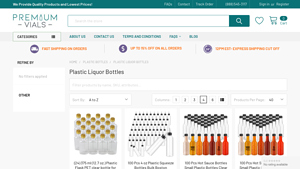

3. Premium Vials – PET Clear Bottles with Tamper Evident Lids

Domain: premiumvials.com

Registered: 2013 (12 years)

Introduction: This company, Premium Vials – PET Clear Bottles with Tamper Evident Lids, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Oberk – Flask Shaped Bottles

Domain: oberk.com

Registered: 1997 (28 years)

Introduction: Flask shaped bottles are available in glass and plastic, suitable for liquid beverages or spirits/liquor products.

5. Pellah Goods – Flask Bottles

Domain: pellahgoods.com

Registered: 2019 (6 years)

Introduction: {“collection”:”Flask Bottles”,”products”:[{“name”:”Pellah 200 ml Flask Bottle with Caps”,”size”:”200 ml (6.7 oz)”,”features”:”Leak-Proof, Tamper-Evident”,”price”:”$48.00 USD”,”availability”:”Sold out”},{“name”:”PELLAH GOODS 200 ml Flask Bottles with Caps”,”size”:”200 ml (6.7 oz)”,”features”:”Leak Proof, Tamper Evident Lids, Compact Small Plastic Container for Liquid Beverage Sauce Alcohol Liquor”,…

Strategic Sourcing Conclusion and Outlook for plastic flask bottles

In the competitive landscape of plastic flask bottles, strategic sourcing emerges as a critical component for B2B buyers aiming to optimize their supply chains. Key takeaways highlight the growing versatility of PET plastic flasks, which are not only ideal for spirits but also increasingly utilized for sauces, dressings, and personal care products. Their lightweight and shatter-resistant properties make them a cost-effective choice, especially for international shipping.

Investing in high-quality PET flasks ensures compliance with safety standards, while the option for customization—such as tamper-evident caps and various sizes—enhances brand differentiation. Buyers should prioritize suppliers who demonstrate a commitment to sustainability and recyclability, aligning with the global shift towards eco-friendly practices.

Looking ahead, the demand for innovative and functional packaging solutions will continue to rise. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to explore diverse sourcing options and partnerships that can provide a competitive edge. Embrace this opportunity to enhance your product offerings and meet the evolving needs of your customers by leveraging the advantages of strategic sourcing in the plastic flask bottle market.