Introduction: Navigating the Global Market for size of water bottle for dispenser

In an increasingly interconnected world, sourcing the right size of water bottle for dispensers poses a significant challenge for international B2B buyers. Whether you are catering to a bustling office in Nigeria or a remote work site in Vietnam, understanding the diverse range of bottle sizes and their applications is crucial for effective hydration solutions. This guide delves into the essential aspects of selecting water bottles, including common sizes such as 3-gallon, 5-gallon, and 1-liter options, alongside insights into their specific uses, from workplace hydration to event catering.

Navigating the complexities of supplier vetting, cost considerations, and compliance with local regulations can be daunting. This comprehensive resource empowers B2B buyers by providing actionable insights into the various types of water bottles available, their suitability for different environments, and tips for ensuring quality and sustainability. By equipping buyers with the knowledge needed to make informed decisions, this guide not only addresses the immediate challenges of sourcing water bottles but also supports long-term sustainability goals by promoting the use of reusable options.

As businesses across Africa, South America, the Middle East, and Europe strive to enhance their hydration strategies, understanding the nuances of water bottle sizes for dispensers becomes imperative. This guide is your roadmap to navigating the global market effectively, ensuring that your organization can provide clean, accessible water solutions that meet the needs of your customers and employees alike.

Article Navigation

- Top 5 Size Of Water Bottle For Dispenser Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for size of water bottle for dispenser

- Understanding size of water bottle for dispenser Types and Variations

- Key Industrial Applications of size of water bottle for dispenser

- 3 Common User Pain Points for ‘size of water bottle for dispenser’ & Their Solutions

- Strategic Material Selection Guide for size of water bottle for dispenser

- In-depth Look: Manufacturing Processes and Quality Assurance for size of water bottle for dispenser

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘size of water bottle for dispenser’

- Comprehensive Cost and Pricing Analysis for size of water bottle for dispenser Sourcing

- Alternatives Analysis: Comparing size of water bottle for dispenser With Other Solutions

- Essential Technical Properties and Trade Terminology for size of water bottle for dispenser

- Navigating Market Dynamics and Sourcing Trends in the size of water bottle for dispenser Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of size of water bottle for dispenser

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for size of water bottle for dispenser

Understanding size of water bottle for dispenser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Gallon Bottles | Compact size, suitable for smaller spaces | Offices, small businesses | Pros: Lightweight, easy to handle. Cons: Limited capacity for high-demand settings. |

| 5-Gallon Bottles | Standard size for most dispensers, versatile usage | Corporate offices, cafes, and restaurants | Pros: Economical, widely available. Cons: Bulkier than smaller options. |

| 1-Liter Bottles | Smaller size, often used for personal or shared use | Gyms, schools, and events | Pros: Convenient for individual use. Cons: Frequent refills needed for larger groups. |

| 2-Gallon Bottles | Intermediate size, good for moderate usage | Workshops, community centers | Pros: Balances size and weight. Cons: May still require multiple bottles for larger teams. |

| Reusable Water Jugs | Made from sustainable materials, various sizes | Eco-conscious businesses, event organizers | Pros: Environmentally friendly, customizable. Cons: Higher initial investment. |

What are the Characteristics and Suitability of 3-Gallon Bottles?

3-gallon bottles are designed for environments where space is limited but hydration needs are still significant. Their compact size makes them ideal for small offices or businesses with fewer employees, allowing for easy storage and handling. When considering a purchase, B2B buyers should evaluate the expected water consumption and whether the size will meet their needs, as these bottles may require more frequent replacements compared to larger options.

How Do 5-Gallon Bottles Serve Various B2B Applications?

The 5-gallon bottle is the industry standard for water dispensers, offering a balance between capacity and portability. They are widely used in corporate offices, cafes, and restaurants, where the demand for hydration is consistent but not overwhelming. Buyers should consider the logistics of delivery and storage, as well as the frequency of refills, when selecting this size. Their availability and cost-effectiveness make them a popular choice among B2B buyers.

Why Choose 1-Liter Bottles for Specific Settings?

1-liter bottles are perfect for personal or shared use in settings such as gyms, schools, and events. They provide a convenient option for hydration without the bulk of larger bottles. However, businesses should assess whether these smaller bottles will meet their hydration needs, especially in high-traffic environments where frequent refills may be necessary. Their compact size also allows for easy transport and storage.

What Advantages Do 2-Gallon Bottles Offer?

2-gallon bottles serve as a middle ground between smaller and larger options, making them suitable for workshops and community centers. They strike a balance between size and weight, allowing for moderate usage without excessive bulk. B2B buyers should consider the number of users and the expected consumption rates when opting for this size, as it may still necessitate multiple bottles for larger groups.

How Do Reusable Water Jugs Align with Eco-Conscious Initiatives?

Reusable water jugs are made from sustainable materials and come in various sizes, catering to eco-conscious businesses and event organizers. They not only help reduce plastic waste but can also be customized for branding purposes. Buyers should weigh the higher initial investment against long-term savings and environmental benefits. The choice of reusable jugs can enhance a company’s sustainability profile while meeting hydration needs effectively.

Key Industrial Applications of size of water bottle for dispenser

| Industry/Sector | Specific Application of Size of Water Bottle for Dispenser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Use of 5-gallon water bottles in hospitals and clinics | Ensures hydration for staff and patients, promoting health | Compliance with health regulations, BPA-free materials, easy handling |

| Hospitality | Water dispensers in hotels and restaurants | Enhances guest experience with convenient access to water | Aesthetic design, refillable options, and compatibility with existing dispensers |

| Education | Water stations in schools and universities | Promotes hydration among students, supports wellness programs | Durable materials, ease of cleaning, and child-safe designs |

| Corporate Offices | Water coolers in office spaces | Boosts employee morale and productivity through hydration | Delivery logistics, customizable branding options, and refill frequency |

| Events and Catering | Portable dispensers for outdoor events | Provides hydration solutions for large gatherings or festivals | Portability, ease of setup, and volume capacity for high demand |

How are Water Bottles for Dispensers Used in Healthcare Settings?

In healthcare facilities, large-capacity water bottles, typically 5 gallons, are essential for ensuring that both patients and staff have constant access to hydration. This is critical in promoting patient recovery and maintaining staff wellness. Buyers in this sector must prioritize BPA-free materials to ensure safety and compliance with health regulations. The bottles should also be designed for easy handling and refilling to facilitate quick service in busy environments.

What Role Do Water Bottles Play in the Hospitality Industry?

In the hospitality sector, water dispensers equipped with large bottles enhance the guest experience by providing easy access to fresh, clean water. Hotels and restaurants can improve their service offering and sustainability efforts by using refillable water bottles. Key considerations for sourcing include aesthetics to match the venue’s design, the ability to accommodate various bottle sizes, and ensuring efficient refill logistics to meet high demand during peak hours.

How Do Educational Institutions Benefit from Water Dispensers?

Schools and universities increasingly utilize water dispensers to promote hydration among students. These dispensers, often fitted with 5-gallon bottles, encourage healthier drinking habits and support wellness programs. Buyers need to consider the durability of materials to withstand heavy usage and the ease of cleaning to maintain hygiene standards. Additionally, designs that are child-safe and user-friendly are essential to ensure accessibility for all students.

Why Are Water Bottles Important in Corporate Offices?

In corporate environments, the presence of water coolers with large bottles significantly contributes to employee well-being and productivity. Access to hydration can enhance focus and morale, making it an important consideration for workplace health initiatives. When sourcing, companies should look for options that offer customizable branding, efficient delivery logistics, and a sustainable approach to reduce environmental impact through refillable solutions.

How Are Water Bottles Used in Events and Catering?

For events and catering, portable water dispensers with large bottles provide an effective hydration solution for large gatherings, festivals, and outdoor activities. These dispensers ensure that guests stay hydrated without the hassle of single-use plastic bottles, aligning with sustainability goals. Key sourcing considerations include the portability of the dispensers, ease of setup, and sufficient volume capacity to meet the demands of a large audience.

3 Common User Pain Points for ‘size of water bottle for dispenser’ & Their Solutions

Scenario 1: Choosing the Right Bottle Size for Diverse Work Environments

The Problem: In international markets, particularly in regions like Africa and South America, B2B buyers often face the challenge of selecting the appropriate size of water bottles for dispensers that cater to various environments—offices, factories, or remote sites. A mismatch in bottle size can lead to frequent refills, leading to operational inefficiencies and employee dissatisfaction. For instance, a smaller bottle might require more frequent changes, interrupting workflow, while an overly large bottle may not fit smaller dispensers, wasting valuable space.

The Solution: To navigate this issue, buyers should conduct a thorough assessment of their specific environment and the hydration needs of their workforce. Start by evaluating the number of employees and their daily water consumption. For offices, a standard 5-gallon bottle may suffice, while larger factories might benefit from 3 or 2-gallon bottles for ease of handling and storage. Engage with suppliers to understand the dimensions of dispensers and storage areas, ensuring that the chosen bottle sizes fit seamlessly. Additionally, consider the frequency of water delivery; establishing a reliable supply chain can help maintain optimal hydration levels without excessive refills.

Scenario 2: Balancing Cost-Effectiveness with Sustainability

The Problem: Many businesses are increasingly pressured to adopt sustainable practices while managing costs effectively. B2B buyers often grapple with the dilemma of choosing between cheaper single-use plastic bottles and more sustainable multi-gallon refillable bottles for their dispensers. The former may appear cost-effective initially but can lead to higher long-term expenses due to waste disposal and potential regulatory fines.

The Solution: B2B buyers should prioritize sourcing BPA-free, reusable 5-gallon water bottles that not only reduce waste but also lower costs over time. It is essential to analyze the total cost of ownership, which includes purchase price, delivery, and waste management costs. Partnering with suppliers who promote sustainability can provide discounts or incentives for bulk purchases, further driving down costs. Additionally, implementing an employee education program on the benefits of using refillable bottles can foster a culture of sustainability within the company, enhancing brand reputation and potentially attracting eco-conscious clients.

Scenario 3: Ensuring Compatibility with Existing Dispenser Models

The Problem: A significant pain point for B2B buyers is ensuring that the water bottles they choose are compatible with existing dispenser models. Incompatibility can lead to operational disruptions and wasted resources. For instance, a company may purchase a new brand of water bottle only to find that it does not fit the neck size of their dispensers, resulting in spills or the need for additional purchases of compatible dispensers.

The Solution: To avoid compatibility issues, buyers should meticulously document the specifications of their current dispensers, including neck sizes and bottle dimensions, before making a purchase. Engaging with suppliers who provide comprehensive product specifications and compatibility charts can streamline this process. Additionally, consider investing in adjustable dispensers that can accommodate a range of bottle sizes, providing flexibility for future purchases. Regular communication with suppliers about upcoming changes in bottle designs or new product releases can also ensure that buyers remain informed and prepared, minimizing the risk of purchasing incompatible products.

Strategic Material Selection Guide for size of water bottle for dispenser

What Are the Key Properties of Common Materials Used for Water Bottles for Dispensers?

When selecting materials for water bottles designed for dispensers, it is essential to evaluate their properties, advantages, and limitations. Here, we analyze four common materials: BPA-Free Plastic, Glass, Stainless Steel, and Copper. Each material has unique characteristics that can influence product performance and suitability for various applications.

BPA-Free Plastic: A Versatile Choice for Water Bottles

BPA-free plastic is widely used in the manufacturing of water bottles due to its lightweight nature and durability. It typically has a temperature rating of up to 100°C (212°F) and is resistant to impact, making it suitable for various environments. However, while it is generally resistant to corrosion, it can become scratched or scuffed over time, which may harbor bacteria.

Pros: The primary advantages include low manufacturing costs, ease of production, and a wide range of styles and sizes. BPA-free plastic is also recyclable, making it a more sustainable option compared to traditional plastics.

Cons: On the downside, it may not withstand extreme temperatures and can degrade over time, leading to potential leaching of chemicals if not properly maintained.

Impact on Application: This material is compatible with a variety of media, including purified and spring water. However, it is crucial to ensure compliance with international standards such as FDA regulations and local guidelines in regions like Africa and South America.

Glass: The Premium Option for Purity

Glass is often favored for its purity and aesthetic appeal. It does not leach chemicals and is resistant to staining, making it an excellent choice for high-quality water storage. Glass bottles can typically withstand temperatures up to 60°C (140°F) but are more prone to breakage.

Pros: Glass offers superior taste preservation and is environmentally friendly since it is fully recyclable. It also has a premium feel, which can enhance brand perception.

Cons: The primary limitation is its weight and fragility, which can lead to higher shipping costs and potential breakage during transport.

Impact on Application: Glass bottles are ideal for high-end markets and are often preferred in Europe, where consumers may prioritize sustainability and health. Compliance with EU standards for food safety is essential.

Stainless Steel: The Durable and Insulated Choice

Stainless steel is known for its durability and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for both hot and cold beverages. Stainless steel bottles often come with insulation options that help maintain temperature for extended periods.

Pros: The key advantages include long-lasting durability, resistance to rust, and a sleek appearance. They are also easy to clean and maintain.

Cons: Stainless steel bottles tend to be more expensive than plastic options, and their manufacturing process can be more complex, leading to higher initial costs.

Impact on Application: This material is compatible with a wide range of liquids, including alkaline and flavored waters. International buyers should ensure that products meet ASTM standards for food safety.

Copper: The Antimicrobial Alternative

Copper is gaining popularity due to its natural antimicrobial properties, which can inhibit bacterial growth. It is suitable for water storage but has specific temperature limitations, typically not exceeding 50°C (122°F).

Pros: The antimicrobial nature of copper makes it an excellent choice for health-conscious consumers. It also has a unique aesthetic appeal.

Cons: However, copper can react with certain liquids, which may limit its compatibility with flavored or acidic beverages. Additionally, it can be more expensive and requires careful handling to prevent tarnishing.

Impact on Application: Copper bottles are particularly appealing in markets that emphasize health and wellness, such as the Middle East. Compliance with local health regulations is crucial.

Summary Table of Material Selection for Water Bottles

| Material | Typical Use Case for size of water bottle for dispenser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| BPA-Free Plastic | General-purpose water dispensers | Lightweight and cost-effective | May degrade over time | Low |

| Glass | Premium water storage | Superior taste preservation | Fragile and heavier | High |

| Stainless Steel | Insulated water dispensers | Durable and temperature resistant | Higher manufacturing complexity | Med |

| Copper | Health-focused water storage | Antimicrobial properties | Limited compatibility with some liquids | High |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring that they can make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for size of water bottle for dispenser

What Are the Main Stages in the Manufacturing Process for Water Bottles Designed for Dispensers?

The manufacturing of water bottles for dispensers involves a series of systematic stages aimed at ensuring product quality and durability. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials such as BPA-free plastics, glass, or stainless steel. The raw materials undergo rigorous testing for purity and compliance with international safety standards. For instance, plastics must be free from harmful chemicals and must meet FDA regulations.

-

Forming: This stage involves shaping the materials into the desired bottle size and form. Techniques such as blow molding for plastics or glass molding are commonly used. These methods allow for the creation of bottles in various sizes (e.g., 3-gallon, 5-gallon) that fit standard dispensers. Precision in this stage is critical, as any imperfections can lead to leaks or breakage.

-

Assembly: After forming, components such as caps and handles are assembled. For example, a 5-gallon bottle might have a screw cap with a wide mouth for easy filling. Automated assembly lines are often employed to enhance efficiency and reduce human error.

-

Finishing: The final stage includes cleaning, labeling, and packaging. Bottles are subjected to sanitation processes to eliminate any contaminants. Labels must adhere to regulatory requirements, often including details about material safety and recycling instructions.

How Is Quality Assurance Implemented During the Manufacturing of Water Bottles?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets both industry standards and consumer expectations.

-

International Standards Compliance: Adhering to international quality standards such as ISO 9001 is essential for manufacturers targeting global markets. These standards establish a framework for consistent quality management practices.

-

Industry-Specific Certifications: Bottles meant for water dispensing must comply with specific industry standards such as CE (Conformité Européenne) and API (American Petroleum Institute) for certain materials. These certifications verify that products are safe and suitable for their intended use.

What Are the Key Quality Control Checkpoints in Bottle Manufacturing?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process to ensure that products meet the required standards.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Manufacturers verify that materials meet specified standards, conducting tests for chemical composition and physical properties.

-

In-Process Quality Control (IPQC): During the production process, continuous monitoring is conducted to ensure that manufacturing parameters remain within set limits. For example, temperature and pressure during molding processes are closely monitored to prevent defects.

-

Final Quality Control (FQC): Once production is complete, bottles undergo rigorous testing for leaks, strength, and overall integrity. This includes pressure testing and visual inspections to identify any surface flaws.

What Common Testing Methods Are Used to Ensure Water Bottle Quality?

To maintain high standards, manufacturers employ various testing methods during the QC process:

- Physical Testing: This includes drop tests to assess durability and stress tests to measure resistance to pressure.

- Chemical Testing: Bottles are tested for the presence of harmful substances to ensure compliance with safety standards. This may involve chromatography to identify any toxic compounds.

- Performance Testing: This involves simulating real-world conditions to evaluate how bottles perform under various temperatures and conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, QA processes, and overall compliance with international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for comprehensive quality reports, including details on testing methods, failure rates, and corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct independent tests and audits to ensure compliance with required standards.

What Are the Specific Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding specific quality nuances is crucial.

-

Regulatory Compliance: Different regions have varying regulations regarding materials and safety standards. Buyers must ensure that their suppliers are compliant with local regulations in their target markets.

-

Cultural Considerations: Communication barriers may arise due to cultural differences. Establishing clear expectations and guidelines in the contract can help mitigate misunderstandings.

-

Supply Chain Logistics: International shipping may introduce additional risks such as damage or contamination during transit. Buyers should collaborate with suppliers to implement robust logistics solutions that include proper packaging and handling procedures.

Conclusion

Understanding the manufacturing processes and quality assurance practices for water bottles designed for dispensers is essential for B2B buyers. By being aware of the key stages of production, quality control checkpoints, testing methods, and verification strategies, international buyers can make informed decisions when sourcing products. This knowledge not only helps in ensuring the quality and safety of the water bottles but also builds stronger partnerships with suppliers across various regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘size of water bottle for dispenser’

In today’s competitive market, selecting the right size of water bottle for dispensers is crucial for ensuring customer satisfaction and operational efficiency. This practical sourcing guide will help B2B buyers navigate the procurement process by outlining essential steps to consider when choosing the appropriate water bottle size for dispensers.

Step 1: Determine Your Capacity Requirements

Understanding the expected demand for water in your operation is the first step. Assess how many employees or customers will be using the dispenser and the frequency of usage. Common sizes include 3-gallon and 5-gallon bottles, which are popular for office and commercial settings, but make sure to align the capacity with your specific needs to avoid frequent changes or shortages.

Step 2: Evaluate Compatibility with Dispensers

Not all water bottles fit all dispensers. Confirm the dimensions of the bottles you are considering, including neck size and height, to ensure they are compatible with the dispensers you plan to use. This step is crucial to avoid operational disruptions caused by mismatched equipment.

Step 3: Assess Material Quality and Safety

Choose water bottles made from safe, durable materials. Look for BPA-free options to ensure that the bottles do not leach harmful chemicals into the water. Additionally, consider bottles made from materials that are resistant to breakage and wear, as this will reduce replacement costs and enhance safety.

Step 4: Consider Sustainability Practices

As environmental concerns grow, sourcing sustainable products is increasingly important. Opt for reusable water bottles that promote eco-friendliness and reduce plastic waste. Inquire about the supplier’s recycling programs or initiatives that align with sustainable practices, as this can enhance your brand’s reputation.

Step 5: Verify Supplier Certifications

Before finalizing any purchase, ensure that your chosen suppliers meet industry standards and have the necessary certifications. Look for certifications from recognized bodies such as the FDA or IBWA, which indicate compliance with safety and quality regulations. This verification can mitigate risks associated with product safety and quality.

Step 6: Request Samples for Testing

Always ask for product samples before placing a bulk order. Testing the samples for durability, usability, and compatibility with your dispensers allows you to assess whether they meet your quality expectations. This step can prevent costly mistakes and ensure that you are satisfied with your final choice.

Step 7: Evaluate Cost-Effectiveness

Lastly, consider the total cost of ownership, including initial purchase price, delivery fees, and potential maintenance costs. Compare different suppliers to identify the best value without compromising quality. A thorough cost analysis will help you make an informed decision that aligns with your budget while meeting operational needs.

By following this checklist, B2B buyers can confidently procure the appropriate water bottle sizes for dispensers, ensuring they meet customer demands while maintaining quality and sustainability standards.

Comprehensive Cost and Pricing Analysis for size of water bottle for dispenser Sourcing

What Are the Key Cost Components for Sourcing Water Bottles for Dispensers?

When considering the sourcing of water bottles for dispensers, it’s essential to break down the cost structure into its core components. The primary factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of material significantly impacts the cost. Common materials include BPA-free plastic, glass, and stainless steel. Each material varies in price, durability, and consumer perception regarding safety and environmental impact. For example, stainless steel bottles tend to be more expensive but are favored for their sustainability.

-

Labor: Labor costs can fluctuate based on geographic location. In regions like Africa or South America, labor costs may be lower, which can reduce overall production expenses. However, this must be balanced against potential quality concerns if the workforce lacks experience with specific manufacturing processes.

-

Manufacturing Overhead: This includes expenses related to the operation of the production facility, such as utilities, equipment maintenance, and facility management. Efficient production processes can help mitigate these costs.

-

Tooling: Custom molds and equipment for manufacturing specific bottle designs add a one-time expense. This cost is amortized over the production volume, meaning that larger orders can significantly reduce the per-unit cost.

-

Quality Control: Ensuring that the bottles meet safety and quality standards involves additional costs. This is particularly crucial for international buyers who must comply with their respective local regulations.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier, the shipping method, and current fuel prices. International shipments often involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers will add a profit margin, typically ranging from 10% to 30%, depending on their business model and market conditions.

How Do Price Influencers Affect the Cost of Water Bottles for Dispensers?

Several factors can influence the pricing of water bottles, especially in a B2B context. Understanding these can help buyers make more informed decisions.

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally receive better pricing due to economies of scale. It’s advisable to negotiate for lower prices based on projected volumes.

-

Specifications and Customization: Customized bottles (e.g., unique shapes, colors, branding) will incur additional costs. Buyers should evaluate whether customization adds significant value to their offering.

-

Material Quality and Certifications: Higher quality materials and certifications (like FDA approval for food-grade products) may increase costs but can enhance marketability. Buyers in regions with stringent regulations must prioritize compliance, potentially impacting costs.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge more due to their proven quality and service levels.

-

Incoterms: The terms of shipping and delivery (like FOB, CIF, etc.) can significantly affect overall costs. Understanding these terms can help buyers negotiate better shipping arrangements.

What Buyer Tips Should Be Considered for Cost-Efficiency in Water Bottle Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost-efficiency:

-

Negotiate Terms: Always negotiate terms with suppliers, including price, payment terms, and shipping costs. Building a relationship can also lead to better deals over time.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price to consider the entire lifecycle of the product, including shipping, storage, and potential waste management costs. This holistic view can lead to better long-term decisions.

-

Understand Pricing Nuances: Be aware of regional pricing variations, especially when importing goods. Costs can fluctuate due to currency exchange rates and local tariffs. Staying informed about these changes can lead to more strategic purchasing decisions.

-

Research Local Suppliers: Exploring local suppliers may yield more competitive pricing due to lower shipping costs and tariffs. Additionally, local manufacturers may have a better understanding of regional preferences and regulations.

-

Stay Informed on Market Trends: Keep an eye on trends in sustainability and consumer preferences, as these can influence both pricing and demand. Adapting to market changes can provide a competitive edge.

Conclusion

Sourcing water bottles for dispensers involves a complex interplay of costs and pricing influencers. By understanding the cost components and employing strategic purchasing practices, B2B buyers can optimize their sourcing decisions for better profitability and sustainability. Always remember that prices can vary significantly based on a multitude of factors, and it is prudent to conduct thorough market research and analysis before making purchasing commitments.

Alternatives Analysis: Comparing size of water bottle for dispenser With Other Solutions

Exploring Alternatives to the Size of Water Bottle for Dispenser

When it comes to providing hydration solutions in a business environment, the size of the water bottle for dispensers is just one of several options available. Companies must consider various alternatives that can meet their hydration needs effectively while also addressing factors such as cost, convenience, and sustainability. Below, we compare the size of water bottles for dispensers with two viable alternatives: water filtration systems and direct water delivery services.

| Comparison Aspect | Size Of Water Bottle For Dispenser | Water Filtration System | Direct Water Delivery Service |

|---|---|---|---|

| Performance | Reliable for high-volume usage; easy access to water. | Provides filtered water on demand; quality depends on filter type. | High-quality water available in various types (spring, purified). |

| Cost | Moderate initial investment; refills can add up over time. | Initial setup cost can be high; ongoing maintenance costs for filters. | Subscription model can be cost-effective; flexible based on consumption. |

| Ease of Implementation | Simple setup; requires space for dispenser and bottles. | Installation can be complex; may require plumbing adjustments. | Minimal setup; delivery schedule can be easily managed online. |

| Maintenance | Regular cleaning of bottles and dispensers; refilling logistics. | Regular filter changes needed; system maintenance required. | Minimal maintenance; company handles logistics and quality control. |

| Best Use Case | Ideal for offices with consistent water needs; promotes hydration culture. | Best for locations with access to tap water; eco-friendly option. | Suitable for businesses needing flexibility or those in areas with unreliable water supply. |

What Are the Pros and Cons of Water Filtration Systems?

Water filtration systems are an attractive alternative for businesses that want to provide clean drinking water without relying on bottled solutions. These systems filter tap water, removing impurities and ensuring a fresh taste. However, the initial investment can be significant, particularly for high-capacity systems. Additionally, ongoing maintenance costs for replacing filters and potential plumbing adjustments can add to the overall expense. They are best suited for locations with a reliable municipal water supply and can significantly reduce plastic waste, aligning with sustainability goals.

How Do Direct Water Delivery Services Compare?

Direct water delivery services offer a convenient option for businesses needing high-quality water without the hassle of managing bottles. Companies like Primo Water provide a variety of water types, including purified and spring water, delivered directly to the workplace. This method requires minimal setup and management, making it ideal for organizations that prioritize ease of use. However, costs can vary based on consumption patterns, and businesses need to establish a reliable delivery schedule. The flexibility of adjusting water quantities according to demand is a significant advantage for fluctuating office sizes.

Making the Right Choice for Your Business

In conclusion, B2B buyers must carefully evaluate their specific needs when selecting a hydration solution. The size of water bottles for dispensers provides a reliable and straightforward option for high-volume water needs, particularly in office environments. Alternatively, water filtration systems can offer sustainable, on-demand solutions, while direct water delivery services provide convenience and flexibility. By considering performance, costs, ease of implementation, maintenance, and the best use case for each option, businesses can choose the solution that best fits their operational requirements and sustainability goals.

Essential Technical Properties and Trade Terminology for size of water bottle for dispenser

What Are the Key Technical Properties of Water Bottles for Dispensers?

Understanding the technical properties of water bottles designed for dispensers is crucial for B2B buyers looking to source products that meet their specific operational needs. Here are several essential specifications to consider:

-

Material Grade

– Definition: This refers to the type of material used in manufacturing the water bottle, commonly plastic (BPA-free), glass, or stainless steel.

– B2B Importance: The choice of material affects not only the durability and weight of the bottle but also its safety and compliance with health regulations. For instance, BPA-free plastics are essential in markets sensitive to chemical leaching concerns. -

Capacity

– Definition: The volume the bottle can hold, typically measured in liters or gallons. Common sizes include 3-gallon, 5-gallon, and 1-liter.

– B2B Importance: Different businesses have varying water consumption needs. Understanding capacity helps companies select the right size for their operations, minimizing waste and ensuring adequate hydration. -

Neck Size

– Definition: The diameter of the bottle’s opening, usually specified in millimeters (e.g., 53mm for a standard 5-gallon bottle).

– B2B Importance: The neck size is critical for compatibility with dispensers. A mismatch can lead to leaks or operational inefficiencies, making it vital for procurement teams to ensure compatibility with existing systems. -

Weight

– Definition: This is the total weight of the filled water bottle, which varies based on the material and capacity.

– B2B Importance: Weight considerations are essential for logistics and handling. Heavier bottles may require special handling equipment, while lighter bottles can facilitate easier transportation and storage. -

Sustainability Features

– Definition: Attributes that enhance the environmental friendliness of the bottle, such as being reusable or made from recycled materials.

– B2B Importance: Increasingly, businesses are prioritizing sustainability in their supply chains. Bottles that reduce plastic waste or are recyclable can enhance a company’s brand reputation and meet consumer demand for eco-friendly products.

What Are Common Trade Terms in the Water Bottle Industry?

Familiarity with industry jargon can significantly aid B2B buyers in navigating negotiations and procurement processes. Here are some common terms relevant to the water bottle sector:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that manufactures products that may be marketed by another company under its brand name.

– Importance: Understanding OEM relationships helps businesses identify potential suppliers that can produce custom-branded water bottles, enhancing brand visibility in the market. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budget planning and inventory management. Buyers must ensure they can meet these quantities without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and other details for specific quantities of products.

– Importance: An RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define responsibilities of sellers and buyers.

– Importance: Understanding Incoterms is crucial for international trade, as they clarify who is responsible for shipping costs, insurance, and customs duties. -

Lead Time

– Definition: The amount of time between the initiation of a process and its completion, often referring to the time from order placement to delivery.

– Importance: Knowing the lead time helps businesses plan their operations and manage inventory levels effectively, ensuring they have adequate supplies when needed.

By grasping these technical specifications and industry terms, B2B buyers can make informed decisions that align with their operational requirements and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the size of water bottle for dispenser Sector

What Are the Key Market Dynamics Affecting the Size of Water Bottles for Dispensers?

The global market for water bottles for dispensers is experiencing significant growth driven by rising health consciousness, increasing demand for sustainable products, and the need for convenient hydration solutions. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are looking for reliable suppliers that can offer a variety of sizes, from 3-gallon to 5-gallon bottles, to cater to diverse consumer needs. Emerging trends include the adoption of smart water dispensers that monitor consumption and the growing popularity of BPA-free materials, which have become a standard expectation among consumers.

Moreover, as e-commerce continues to flourish, businesses are increasingly sourcing water bottles online, making it essential for suppliers to optimize their digital presence. The integration of technology in logistics, such as real-time tracking and automated inventory management, is also enhancing supply chain efficiency. Buyers are advised to look for vendors that provide detailed product specifications and transparent sourcing practices to ensure they meet local regulations and consumer expectations.

How Is Sustainability Shaping Sourcing Trends for Water Bottles?

Sustainability is no longer just a buzzword; it has become a critical factor in the B2B sourcing of water bottles for dispensers. Buyers are increasingly prioritizing products made from eco-friendly materials, such as recycled plastics and stainless steel, which not only reduce environmental impact but also appeal to a growing demographic of eco-conscious consumers. Certifications like FDA approval and ISO standards are vital for ensuring product safety and sustainability.

The shift towards reusable water bottles is further supported by the global movement against single-use plastics. Suppliers who offer refillable and recyclable options are likely to gain a competitive edge in the market. Additionally, businesses that can demonstrate a commitment to sustainable practices, such as reducing carbon footprints and engaging in responsible sourcing, are more likely to attract partnerships with socially responsible organizations. For B2B buyers, aligning with suppliers who prioritize sustainability can enhance brand reputation and customer loyalty.

How Has the Market for Water Bottles Evolved Over Time?

The market for water bottles, especially those used in dispensers, has undergone significant evolution over the past few decades. Initially dominated by single-use plastic bottles, the industry has shifted towards reusable options due to increasing awareness of environmental issues and health concerns associated with plastic consumption. The introduction of larger capacities, such as 3-gallon and 5-gallon bottles, has made it more convenient for businesses and households to access hydration solutions without the need for frequent replacements.

The advent of innovative materials and designs has also transformed the market. Suppliers now offer a wide range of options, including BPA-free plastics, glass, and stainless steel, catering to various consumer preferences and regulatory requirements. This evolution not only reflects changing consumer attitudes but also highlights the growing importance of sustainability in purchasing decisions. As the market continues to mature, B2B buyers must stay informed about emerging trends and innovations to remain competitive in the evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of size of water bottle for dispenser

-

How do I choose the right size of water bottle for my dispenser?

Choosing the right size of water bottle for your dispenser depends on your consumption needs and the space available. Common sizes include 3-gallon, 5-gallon, and 2-liter options. For businesses with high traffic, larger bottles like 5-gallon are ideal as they reduce the frequency of replacements. If space is limited, consider smaller bottles or countertop dispensers that accommodate 3-gallon bottles. Ensure your dispenser model is compatible with the chosen bottle size to avoid operational issues. -

What is the best material for a water bottle for dispensers?

The best materials for water bottles include BPA-free plastic, glass, and stainless steel. BPA-free plastic is lightweight and durable, making it suitable for high-volume use, while glass offers purity and taste but may be heavier and more prone to breakage. Stainless steel is excellent for insulation but can be more costly. Assess your specific needs, such as durability, weight, and environmental impact, when selecting the best material for your water bottles. -

What are the minimum order quantities (MOQ) for water bottles?

Minimum order quantities (MOQ) for water bottles can vary significantly among suppliers, typically ranging from 100 to 1,000 units. International buyers should communicate their requirements directly with suppliers to understand the MOQ and negotiate if necessary. Some manufacturers may offer flexibility on MOQs for initial orders or to encourage new partnerships. Always consider the potential for future orders when negotiating MOQ to ensure a sustainable supply chain. -

What payment terms should I expect when sourcing water bottles internationally?

Payment terms for international sourcing can include options like 30% upfront and 70% upon delivery, letters of credit, or payment through platforms like PayPal or Escrow. It’s essential to discuss and agree on payment methods upfront to avoid misunderstandings. Always ensure that payment terms are documented in your contract, and consider using secure payment methods to protect your investment, especially when dealing with new suppliers. -

How can I vet suppliers of water bottles for dispensers?

To vet suppliers effectively, start by researching their reputation through online reviews and industry references. Request samples to assess product quality and check for compliance with international standards, such as FDA or ISO certifications. Additionally, inquire about their production capacity, lead times, and after-sales support. Establishing clear communication can also help you gauge their professionalism and reliability before committing to a partnership. -

What customization options are available for water bottles?

Many suppliers offer customization options such as branding, labeling, and size variations for water bottles. Custom labeling can enhance your brand visibility and provide essential product information. Additionally, consider if you need specific features like ergonomic handles or color options. Discuss your needs with potential suppliers to determine their capabilities and any additional costs associated with customization. -

How do logistics impact the sourcing of water bottles for dispensers?

Logistics play a crucial role in the sourcing process, affecting delivery times and costs. When sourcing internationally, consider shipping methods (air vs. sea), customs clearance, and potential tariffs. Collaborating with suppliers who have experience in your target markets can streamline the logistics process. It’s advisable to factor in lead times for production and shipping to align with your inventory needs and avoid stock shortages. -

What quality assurance measures should I expect from suppliers?

Quality assurance (QA) measures can vary by supplier, but reputable manufacturers typically implement rigorous testing protocols to ensure product safety and compliance with standards. Ask about their QA processes, such as material testing, production inspections, and certifications. Request documentation of these measures to ensure that the bottles meet international safety standards. Regular audits and feedback loops can also help maintain quality throughout your partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Size Of Water Bottle For Dispenser Manufacturers & Suppliers List

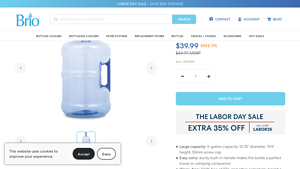

1. Briowater – 5-Gallon BPA-Free Water Bottle

Domain: briowater.com

Registered: 2015 (10 years)

Introduction: {“name”: “5-Gallon BPA-Free Water Bottle w/ Screw Cap”, “price”: “$39.99”, “msrp”: “$44.99”, “sku”: “BT505ET”, “capacity”: “5 gallons”, “dimensions”: {“diameter”: “10.75 inches”, “height”: “19.5 inches”}, “cap_type”: “53mm screw cap”, “features”: [“sturdy built-in handle for easy carrying”, “100% free of BPA and harmful chemicals”, “wide mouth for fitting ice cubes”, “reusable to eliminate single-…

2. The Water Bottle Store – Reusable Water Bottles

Domain: thewaterbottlestore.com

Registered: 2005 (20 years)

Introduction: Reusable water bottles available in various sizes including 1 Liter/32 oz, 13 oz, 20 oz, and larger options such as 64 oz/2 Liter, 1 Gallon, 2 Gallon, 3 Gallon, and 5 Gallon. Materials include BPA-free plastic, stainless steel, and glass. Categories include insulated, infuser, collapsible, and filtered water bottles. Brands featured include Asobu, Aquaovo, EarthLust, EcoVessel, KOR, and New Wave E…

3. WaterGuard – 5-Gallon Commercial Water Bottles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 5-gallon commercial water bottles for dispensers, suitable for emergency preparedness, long-lasting storage, and easy rotation. Ideal for families needing around 12 gallons of water. Can be refilled at water stations, and manual pumps are available for emergencies.

4. Topia Water – Premium Bottle Dispensers

Domain: topiawater.com

Registered: 2019 (6 years)

Introduction: Topia Water offers a range of premium water bottle dispensers that provide Still and Sparkling water on demand. Key features include: 1. Hot and Cold Water Options: The Topia Tap provides Still Chilled, Sparkling, and Hot water, eliminating the need for a kettle. 2. Filtration and Purification Systems: Filters water to 0.5 microns for clear, fresh, premium quality water. 3. Capacity and Size: Vari…

5. Water.com – Convenient Water Delivery Solutions

Domain: water.com

Registered: 1994 (31 years)

Introduction: Water Delivery: Convenient delivery of quality bottled water to your home or business. Water Refill: Refill empty 1-, 3-, or 5-gallon bottles at retail locations. Water Exchange: Exchange your bottle for purified Primo Water. Water Filtration: Direct tap water filtration systems with installation and maintenance. Commercial Services: Variety of products for organizational needs. Water Types: Purif…

Strategic Sourcing Conclusion and Outlook for size of water bottle for dispenser

In navigating the complexities of sourcing water bottles for dispensers, international B2B buyers must prioritize size, material, and sustainability to meet diverse market demands. The prevalent options, ranging from 3 to 5-gallon bottles, cater to both commercial and residential needs, offering convenience while promoting eco-friendly practices. Understanding the nuances of bottle specifications, such as neck sizes and compatibility with different dispensers, can enhance operational efficiency and customer satisfaction.

Strategic sourcing is not merely about procurement; it involves aligning product choices with sustainability goals and market trends. By opting for BPA-free materials and reusable options, companies can significantly reduce plastic waste, appealing to environmentally conscious consumers across regions, including Africa, South America, the Middle East, and Europe.

As the global market evolves, the demand for high-quality, responsibly sourced water bottles will only increase. International buyers are encouraged to leverage this opportunity by engaging with suppliers who prioritize quality and sustainability. This proactive approach will not only enhance brand reputation but also contribute to a healthier planet. Embrace the future of hydration solutions and position your business at the forefront of this essential industry.