Introduction: Navigating the Global Market for types of water bottle lids

Navigating the complex landscape of water bottle lids presents a significant challenge for international B2B buyers looking to optimize their product offerings. With a diverse range of options, from standard screw caps to sophisticated flip-top designs, understanding the nuances of each type is crucial for sourcing the right lids that meet consumer demands and regulatory standards. This comprehensive guide delves into various types of water bottle lids, their specific applications, and the implications for packaging machinery, ensuring that you can make informed decisions for your business.

In addition to exploring the different lid types, this guide will provide insights on supplier vetting processes, cost considerations, and the latest trends shaping the global market. Whether you are sourcing for a startup in South America, a manufacturing firm in Africa, or a distribution company in Europe, the information contained herein is tailored to empower your purchasing decisions. By understanding the characteristics and functionalities of water bottle lids, you can enhance your product line while ensuring compliance with safety regulations and sustainability practices.

As you navigate this guide, expect to gain actionable insights that will not only streamline your procurement process but also position your business advantageously in the competitive landscape. Equip yourself with the knowledge to select the most suitable water bottle lids that resonate with your target market and drive sales.

Navigation dans les articles

- Top 7 Types Of Water Bottle Lids Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for types of water bottle lids

- Understanding types of water bottle lids Types and Variations

- Key Industrial Applications of types of water bottle lids

- 3 Common User Pain Points for ‘types of water bottle lids’ & Their Solutions

- Strategic Material Selection Guide for types of water bottle lids

- In-depth Look: Manufacturing Processes and Quality Assurance for types of water bottle lids

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of water bottle lids’

- Comprehensive Cost and Pricing Analysis for types of water bottle lids Sourcing

- Alternatives Analysis: Comparing types of water bottle lids With Other Solutions

- Essential Technical Properties and Trade Terminology for types of water bottle lids

- Navigating Market Dynamics and Sourcing Trends in the types of water bottle lids Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of types of water bottle lids

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for types of water bottle lids

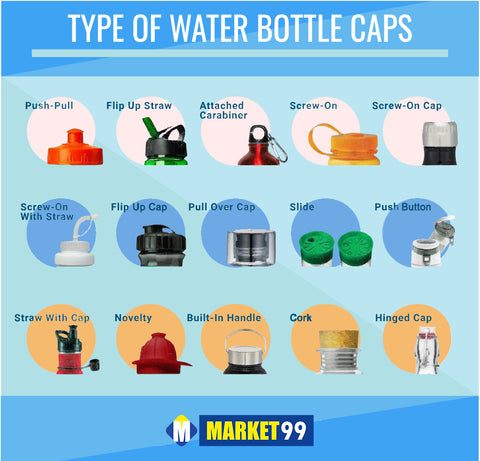

Understanding types of water bottle lids Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Standard Screw Cap | Commonly used, allows easy access; may include tamper-proof seal | Beverages, chemicals, food products | Pour : Versatile, widely available. Cons : Risk of leakage if not sealed properly. |

| Flip Top Cap | Features a hinged lid for easy dispensing; ideal for squeezable products | Personal care, condiments, cleaning products | Pour : Convenient for consumers. Cons : Can be less secure than screw caps. |

| Sports Cap | Pull-to-open design with a nozzle; designed for on-the-go use | Sports drinks, hydration products | Pour : User-friendly for active consumers. Cons : Limited to specific beverage types. |

| Pump Cap | Dispenses liquid or cream with a press; often includes a locking mechanism | Hand sanitizers, lotions, shampoos | Pour : Minimizes contamination. Cons : Can be cumbersome for capping machines. |

| Childproof Cap | Safety mechanism prevents child access; requires specific opening method | Pharmaceuticals, household chemicals | Pour : Essential for safety compliance. Cons : Can be challenging for adults to open. |

What are the Key Characteristics of Standard Screw Caps?

Standard screw caps are the most prevalent type of water bottle lid, known for their straightforward design that allows users to easily open and close the bottle. Often made from plastic or aluminum, these caps can include tamper-proof seals to enhance product safety. For B2B buyers, these caps are ideal for a wide range of applications, including beverages, chemicals, and food products. When purchasing, consider the compatibility of the cap with your capping machines and the potential for leakage if not sealed correctly.

How Do Flip Top Caps Enhance User Experience?

Flip top caps feature a hinged lid that allows for quick and easy dispensing, making them particularly suitable for products like sauces, personal care items, and cleaning solutions. Their design enables users to access the product without fully removing the cap, which can be beneficial for maintaining product freshness. B2B buyers should assess the balance between convenience and security, as flip tops may not provide the same level of sealing as standard screw caps, potentially affecting product integrity during transportation.

What Makes Sports Caps Ideal for Active Consumers?

Sports caps are designed for convenience, allowing users to pull open a nozzle for quick hydration, making them a popular choice for sports drinks and other on-the-go beverages. Their user-friendly design appeals to active consumers who require easy access to hydration during physical activities. When sourcing sports caps, B2B buyers should consider the material durability and the cap’s ability to prevent leaks, especially during transit, to ensure customer satisfaction.

Why are Pump Caps Popular in Personal Care Products?

Pump caps are ideal for dispensing liquids or creams with minimal contact, making them a preferred choice for products like hand sanitizers, lotions, and shampoos. Their design often includes a locking mechanism to prevent accidental dispensing, which is crucial for maintaining product integrity. For B2B buyers, it’s important to evaluate the compatibility of pump caps with existing capping machinery and the potential challenges they may pose during production, as their complexity can lead to operational inefficiencies.

What are the Safety Benefits of Childproof Caps?

Childproof caps are specifically designed to prevent children from easily accessing potentially hazardous products, making them essential for pharmaceuticals and household chemicals. These caps require a specific opening method, which enhances safety but can also pose challenges for adult users. B2B buyers must consider the regulatory requirements for safety in their markets when selecting childproof caps, as well as the implications for customer satisfaction if the caps are perceived as difficult to use.

Key Industrial Applications of types of water bottle lids

| Industrie/secteur | Specific Application of types of water bottle lids | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Beverage Manufacturing | Use of sports caps for functional hydration products | Enhances consumer convenience and promotes brand loyalty | Durability, compatibility with bottling equipment, and ease of use |

| Pharmaceutique | Child-proof caps for medicinal liquids | Ensures safety for children and compliance with regulations | Certification standards, material safety, and tamper-evidence |

| Alimentation et boissons | Flip top lids for sauces and condiments | Provides easy dispensing and maintains product freshness | Leak-proof design, compatibility with various viscosities, and user-friendliness |

| Personal Care Products | Pump caps for lotions and shampoos | Reduces waste and enhances user experience | Dispensing accuracy, material quality, and ease of operation |

| Water Bottling | ROPP caps for premium bottled water | Offers a tamper-proof seal and preserves product integrity | Sourcing for specific bottle neck sizes and sealing technology |

How Are Water Bottle Lids Applied in Beverage Manufacturing?

In the beverage manufacturing industry, sports caps are commonly used for functional hydration products like energy drinks and flavored waters. These lids provide convenience, allowing consumers to easily drink while on the move. For international buyers, especially in regions like Africa and South America where outdoor activities are prevalent, sourcing durable and easy-to-use caps can significantly enhance product appeal and brand loyalty. Businesses must consider the compatibility of these caps with their bottling equipment to ensure smooth production processes.

What Role Do Child-Proof Caps Play in Pharmaceuticals?

Child-proof caps are crucial in the pharmaceutical industry, particularly for products like liquid medications that could pose risks to children. These lids incorporate safety mechanisms that prevent accidental opening, thus ensuring compliance with safety regulations. International buyers, particularly in the Middle East and Europe, should prioritize sourcing caps that meet stringent certification standards and material safety requirements. This focus not only safeguards children but also protects the brand from liability issues.

How Do Flip Top Lids Benefit Food and Beverage Products?

Flip top lids are widely utilized in the food and beverage sector for products such as sauces and condiments. These lids facilitate easy dispensing while maintaining product freshness, which is essential for consumer satisfaction. Buyers from regions with diverse culinary practices, like Africa and South America, should consider sourcing lids that are leak-proof and compatible with various product viscosities. This ensures that the end product remains appealing and functional, catering to local tastes and preferences.

What Advantages Do Pump Caps Provide for Personal Care Products?

In the personal care industry, pump caps are favored for products like lotions and shampoos due to their ability to minimize waste and enhance user experience. These caps allow for controlled dispensing, which is particularly important for high-value products. International buyers, especially in Europe, should focus on sourcing pump caps that offer dispensing accuracy and high-quality materials to ensure durability and consumer satisfaction. This focus can significantly improve product perception in competitive markets.

Why Are ROPP Caps Important for Premium Water Bottling?

ROPP caps are essential in the premium bottled water sector as they provide a tamper-proof seal, ensuring product integrity and safety. These caps are particularly appealing to international buyers looking to enhance the quality perception of their bottled water products. Businesses must source ROPP caps that fit specific bottle neck sizes and utilize effective sealing technologies to guarantee a secure closure. This attention to detail can elevate brand reputation and consumer trust in the product.

3 Common User Pain Points for ‘types of water bottle lids’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with Water Bottle Lids

Le problème : B2B buyers often struggle with ensuring that the lids they source are compatible with their existing water bottle designs. Inconsistent measurements and variations in design can lead to wasted inventory and increased costs. For instance, a buyer may order a large shipment of flip-top lids only to discover they do not fit their specific bottles, resulting in delays and potential loss of sales. This situation creates frustration as it affects production timelines and overall business operations.

La solution : To mitigate compatibility issues, buyers should prioritize sourcing lids from suppliers who provide detailed specifications, including dimensions, materials, and compatibility charts. Before placing bulk orders, it’s advisable to request samples to test against their bottles. Additionally, collaborating with suppliers who offer customization options can ensure that the lids meet unique specifications. Establishing clear communication regarding design requirements and conducting thorough testing can help prevent these costly mistakes.

Scenario 2: Ensuring Safety Features in Water Bottle Lids

Le problème : In markets where safety regulations are stringent, such as in Europe or North America, buyers face the challenge of ensuring that the water bottle lids they procure meet safety standards, particularly for products intended for children. A lack of proper safety features, such as child-proof mechanisms or non-toxic materials, can lead to compliance issues and damage brand reputation. This concern is heightened in regions where consumers are increasingly aware of product safety and environmental impact.

La solution : Buyers should conduct comprehensive research on the safety certifications required for water bottle lids in their target markets. Partnering with manufacturers that specialize in safety-compliant products can provide peace of mind. It’s also beneficial to request certifications and testing reports for the lids, confirming that they meet the necessary safety standards. Implementing a quality assurance process during the procurement stage can further ensure that all lids are regularly tested and certified, reducing the risk of compliance issues.

Scenario 3: Addressing Environmental Sustainability Concerns

Le problème : With the growing emphasis on sustainability, B2B buyers are increasingly pressured to source eco-friendly water bottle lids. Traditional plastic lids can contribute to environmental degradation, and consumers are becoming more discerning about the sustainability practices of the brands they support. Buyers may find it challenging to identify suppliers who offer biodegradable or recyclable options, leading to potential backlash from environmentally-conscious customers.

La solution : To address these sustainability concerns, buyers should prioritize suppliers who specialize in eco-friendly products. This includes exploring options such as lids made from recycled materials or biodegradable plastics. Engaging in conversations with suppliers about their sustainability practices can provide insights into their production processes and the environmental impact of their products. Additionally, buyers can consider implementing a take-back program for used lids, encouraging customers to return them for recycling. By clearly communicating their commitment to sustainability, brands can enhance their market position and attract a more environmentally conscious customer base.

Strategic Material Selection Guide for types of water bottle lids

When selecting materials for water bottle lids, it’s essential to consider the properties, advantages, and limitations of the most common materials used in the industry. This analysis will focus on four prevalent materials: plastic, stainless steel, aluminum, and silicone. Each material offers unique characteristics that can significantly impact product performance and suitability for various applications.

What Are the Key Properties of Plastic Water Bottle Lids?

Plastic, particularly polypropylene and polyethylene, is the most widely used material for water bottle lids. These plastics boast excellent temperature resistance, typically rated between -40°C to 120°C, making them suitable for both hot and cold beverages. They are also resistant to corrosion and chemical reactions, which is vital for maintaining the integrity of the contents.

Pros & Cons: Plastic lids are lightweight and cost-effective, making them an attractive option for mass production. However, they may not offer the same durability as metal options and can be prone to wear and tear over time. Additionally, environmental concerns regarding plastic waste may deter some consumers.

Impact sur l'application: Plastic lids are compatible with a variety of liquids, including water, juices, and sports drinks. However, they may not be suitable for high-temperature applications, such as hot beverages, unless specifically designed for such use.

Considérations pour les acheteurs internationaux: Compliance with international standards such as FDA regulations in the U.S. or EU food safety standards is crucial. Buyers from regions like Africa and South America should also consider local regulations regarding plastic use and recycling.

How Does Stainless Steel Compare for Water Bottle Lids?

Stainless steel is another popular choice for water bottle lids, particularly for premium products. Known for its exceptional durability and corrosion resistance, stainless steel can withstand extreme temperatures and pressures, making it ideal for both hot and cold beverages.

Pros & Cons: The primary advantage of stainless steel lids is their longevity and resistance to impact and wear. However, they are heavier and more expensive than plastic alternatives, which can affect shipping costs and retail pricing.

Impact sur l'application: Stainless steel lids are particularly suited for insulated water bottles, maintaining temperature for extended periods. They are also compatible with a wide range of liquids, including carbonated beverages.

Considérations pour les acheteurs internationaux: Buyers should ensure that the stainless steel used complies with standards such as ASTM A240 for corrosion resistance. Countries in Europe, like Germany, have stringent regulations regarding food-grade materials, which must be adhered to.

What Are the Benefits of Aluminum Lids for Water Bottles?

Aluminum is often used for water bottle lids due to its lightweight nature and recyclability. Aluminum lids can be coated to enhance their resistance to corrosion and can handle moderate temperature variations.

Pros & Cons: The lightweight nature of aluminum makes it a cost-effective choice for shipping. However, aluminum lids can be prone to dents and may not withstand high-pressure conditions as effectively as stainless steel.

Impact sur l'application: Aluminum lids are commonly used in conjunction with beverages that require a lightweight solution, such as flavored waters or energy drinks. They are not ideal for hot liquids unless specifically designed with insulation.

Considérations pour les acheteurs internationaux: Buyers should verify that the aluminum used meets industry standards, such as JIS H 4040 in Japan or DIN EN 573 in Europe. Environmental regulations regarding recycling and material sourcing may also impact purchasing decisions.

What Role Does Silicone Play in Water Bottle Lids?

Silicone is increasingly being used for water bottle lids, particularly in applications requiring flexibility and a tight seal. Silicone can withstand a wide temperature range, typically from -50°C to 200°C, making it suitable for various beverages.

Pros & Cons: Silicone lids provide excellent sealing capabilities and are resistant to UV light and ozone, which enhances their longevity. However, they can be more expensive than plastic and may not be as rigid, which could affect their usability in some designs.

Impact sur l'application: Silicone lids are particularly effective for products requiring a leak-proof design, such as travel mugs or sports bottles. They are compatible with both hot and cold beverages, making them versatile.

Considérations pour les acheteurs internationaux: Compliance with food safety standards is crucial, particularly in regions with strict regulations like Europe. Buyers should also consider the availability of silicone products and their environmental impact, as silicone is often viewed as a more sustainable option.

Summary Table of Material Selection for Water Bottle Lids

| Matériau | Typical Use Case for types of water bottle lids | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Plastique | Standard water bottles, sports drinks | Léger et rentable | Less durable, environmental concerns | Faible |

| Acier inoxydable | Insulated water bottles, premium products | Exceptional durability | Heavier, higher cost | Haut |

| Aluminium | Flavored waters, energy drinks | Léger et recyclable | Prone to dents, moderate pressure | Moyen |

| Silicone | Travel mugs, leak-proof bottles | Excellent sealing, temperature resistant | Higher cost, less rigidity | Moyen |

This comprehensive analysis provides B2B buyers with actionable insights into the strategic selection of materials for water bottle lids, ensuring they can make informed decisions that align with their product goals and market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for types of water bottle lids

What Are the Key Stages in the Manufacturing Process of Water Bottle Lids?

The manufacturing process for water bottle lids typically involves several main stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring that the final product meets quality standards and is suitable for its intended use.

Préparation du matériel

The process begins with selecting the appropriate materials, which often include plastics such as polypropylene (PP), polyethylene (PE), or thermoplastic elastomers (TPE). For metal lids, aluminum or tinplate is commonly used. Suppliers must ensure that materials meet safety and regulatory standards, particularly for food and beverage applications. This phase also involves quality checks on raw materials to confirm they are free from defects and contaminants.

Formation

During the forming stage, the prepared materials are shaped into the desired lid configuration. This can involve various techniques, including injection molding, blow molding, or stamping for metal caps. Each technique has specific advantages; for example, injection molding allows for complex shapes and fine details, while blow molding is ideal for hollow forms. The choice of technique depends on the lid design, production volume, and material properties.

Assemblée

Once the individual components of the lid are formed, they are assembled. This may include adding seals, gaskets, or other functional elements that enhance the lid’s performance, such as preventing leaks or improving user convenience. Automated assembly lines are often employed to ensure consistency and efficiency, although manual assembly may be necessary for more complex designs.

Finition

The final stage involves finishing processes that enhance the lid’s aesthetics and functionality. This can include surface treatments like coatings or printing, which may involve applying logos or instructions. Quality checks are critical in this phase to ensure that the lids meet the required specifications for appearance and functionality.

How Is Quality Assurance Implemented in the Production of Water Bottle Lids?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that the final products meet both international and industry-specific standards. For B2B buyers, understanding the QA processes can help in selecting reliable suppliers.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international standards such as ISO 9001, which outlines a framework for quality management systems. This standard emphasizes a process approach and continuous improvement, ensuring that products consistently meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) are crucial for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

Quels sont les principaux points de contrôle de la qualité ?

Quality control (QC) typically involves several key checkpoints throughout the manufacturing process, including:

-

Contrôle de la qualité à l'arrivée (IQC) : This initial checkpoint verifies the quality of raw materials before they enter the production process. Suppliers should provide documentation proving that materials meet specified standards.

-

Contrôle de la qualité en cours de fabrication (IPQC) : During production, periodic checks are performed to monitor the manufacturing processes. This includes assessing equipment performance and ensuring that production parameters remain within specified limits.

-

Contrôle de qualité final (CQF) : Once the lids are produced, final inspections ensure that they meet all design specifications and quality standards. This may involve testing for dimensional accuracy, leak-proof performance, and aesthetic quality.

What Common Testing Methods Are Used in Quality Control?

To ensure that water bottle lids meet safety and performance requirements, various testing methods are employed. These can include:

-

Mechanical Testing: Assessing the strength, flexibility, and durability of the lid under various conditions.

-

Test d'étanchéité : Conducting tests to ensure that the lids maintain an airtight seal, which is crucial for preserving product integrity.

-

Chemical Testing: Evaluating the material’s resistance to chemicals, especially for lids intended for beverages or food products.

-

Test thermique : Checking how lids perform under extreme temperature conditions, which is essential for products like insulated water bottles.

Comment les acheteurs B2B peuvent-ils vérifier le contrôle de la qualité des fournisseurs ?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are some strategies:

-

Audits des fournisseurs : Conducting on-site audits can provide insights into a supplier’s manufacturing processes, quality control measures, and adherence to standards. This can help assess their capability to deliver consistent quality.

-

Documentation and Reports: Requesting quality control reports, including IQC, IPQC, and FQC data, can help buyers understand the supplier’s commitment to quality.

-

Inspections par des tiers : Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product performance.

Quelles sont les particularités du contrôle de la qualité pour les acheteurs internationaux B2B ?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, navigating quality control can involve additional complexities:

-

Understanding Local Regulations: Different regions may have specific regulations regarding the safety and quality of packaging materials. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Cultural and Communication Barriers: Clear communication regarding quality expectations is crucial. Buyers should ensure that suppliers understand their requirements, which may involve providing detailed specifications and documentation.

-

Considérations logistiques : Quality control extends beyond manufacturing to include transportation and storage conditions. Buyers must verify that suppliers have protocols in place to maintain product integrity throughout the supply chain.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for water bottle lids is essential for B2B buyers. By prioritizing quality, conducting due diligence, and fostering strong supplier relationships, buyers can ensure that they receive products that meet their needs and comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of water bottle lids’

When sourcing water bottle lids, it is essential for B2B buyers to approach the procurement process methodically. This guide provides a clear checklist to ensure that you select the right types of lids tailored to your product specifications and market requirements.

Étape 1 : Définir les spécifications techniques

Establishing precise technical specifications is crucial to ensure that the lids you select meet your product’s needs. Consider factors such as material (plastic, metal, or composite), size compatibility with your bottles, and any specific functionalities like child-proof designs or resealable features. This clarity will help streamline the sourcing process and avoid costly mismatches later on.

Étape 2 : Research Different Lid Types

Understanding the various types of water bottle lids available is essential for making an informed decision. Familiarize yourself with options such as screw caps, flip tops, chug lids, and sports caps, each serving different purposes and user experiences. For instance, sports caps are ideal for active consumers, while screw caps provide a traditional sealing method for liquid preservation.

Étape 3 : Évaluer les fournisseurs potentiels

Before finalizing any supplier, it is critical to conduct thorough evaluations. Request documentation such as company profiles, case studies, and references from other buyers in your industry. This information will provide insights into their reliability, quality standards, and ability to meet your specific requirements.

- Consider certifications: Look for certifications such as ISO, FDA approval, or other relevant standards that ensure product safety and quality.

- Assess production capacity: Confirm that the supplier can meet your volume demands without compromising quality.

Étape 4 : Compare Pricing Models

Once you have shortlisted potential suppliers, compare their pricing models to find the best value for your investment. Keep in mind that the cheapest option is not always the best; consider the total cost of ownership, which includes shipping, customs duties, and potential tariffs. Ensure that you understand the terms of payment and any discounts for bulk orders.

Étape 5 : Request Samples for Testing

Before placing a large order, it is wise to request samples of the water bottle lids you are considering. Testing these samples will allow you to evaluate their quality, functionality, and compatibility with your existing products. Pay attention to aspects such as the ease of use, durability, and how well they seal the bottle.

Étape 6 : Assess Lead Times and Delivery Reliability

Understanding the lead times for production and delivery is crucial for effective inventory management. Ask potential suppliers about their typical turnaround times and their policies on expedited orders. Reliable suppliers should provide clear timelines and options for urgent requests to prevent disruptions in your supply chain.

Étape 7 : Negotiate Terms and Finalize Agreements

Once you’ve selected a supplier, engage in negotiations to finalize terms that are favorable to both parties. This includes pricing, payment terms, delivery schedules, and warranty conditions. A well-drafted agreement will protect your interests and establish a clear understanding of expectations, paving the way for a successful partnership.

By following this structured checklist, B2B buyers can navigate the sourcing process for water bottle lids effectively, ensuring they select the right products for their market needs while establishing reliable supplier relationships.

Comprehensive Cost and Pricing Analysis for types of water bottle lids Sourcing

What Are the Key Cost Components in Sourcing Water Bottle Lids?

When sourcing water bottle lids, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Matériaux: The choice of materials—be it plastic, metal, or silicone—significantly affects pricing. For instance, aluminum lids may be more expensive than standard plastic caps due to their durability and recyclability. The quality of materials used can also influence costs; high-grade materials may lead to a higher upfront price but can offer better performance and longevity.

-

Travail: Labor costs vary by region and can be influenced by local wage standards. Countries with lower labor costs may provide more competitive pricing, but this can come at the expense of quality control. In contrast, regions with higher labor costs often have stricter regulations and may produce higher-quality products.

-

Frais généraux de fabrication: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Buyers should inquire about a supplier’s operational efficiency, as this can impact overall pricing.

-

Outillage: Custom tooling for specialized lid designs can be a significant upfront investment. However, for large orders, this cost can be amortized over time, making it a worthy consideration for buyers looking to differentiate their products in the market.

-

Contrôle de la qualité (CQ): Implementing rigorous QC processes adds to manufacturing costs but is essential for maintaining product consistency and safety, particularly for lids used in food and beverage applications.

-

Logistique: Shipping costs can vary widely depending on the mode of transport, distance, and import duties. Buyers must consider these expenses in their total cost of ownership (TCO).

-

Marge: Supplier profit margins can differ based on market conditions and competition. Understanding the typical margins in your target market can provide leverage during negotiations.

What Influences the Pricing of Water Bottle Lids?

Several factors can influence the pricing of water bottle lids, particularly for international buyers:

-

Volume et quantité minimale de commande (QMC): Larger orders often result in lower unit costs. Suppliers may offer significant discounts for bulk purchases, making it beneficial for companies looking to scale.

-

Spécifications et personnalisation: Custom designs or specific technical requirements can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Qualité des matériaux et certifications: Higher quality materials and certifications (such as BPA-free or food-safe compliance) may result in higher prices. However, they can enhance product appeal and consumer trust.

-

Facteurs liés au fournisseur: The reputation and reliability of a supplier can impact pricing. Established suppliers with proven track records may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the overall cost.

How Can Buyers Negotiate for Better Pricing?

-

Volume Leverage: Buyers should aim to consolidate orders to meet MOQ requirements, enabling them to negotiate better pricing based on volume.

-

Coût total de possession (TCO): When evaluating suppliers, consider not just the purchase price but also logistics, quality, and potential returns or defects. A lower initial price may lead to higher costs in the long run if product quality is compromised.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends. This knowledge can empower buyers during negotiations.

-

Building Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Suppliers may offer loyalty discounts or other incentives to repeat customers.

-

Flexibility on Specifications: Being open to alternative materials or designs can provide opportunities for cost savings. Suppliers may have more cost-effective solutions that meet your needs without compromising quality.

Conclusion

Sourcing water bottle lids involves navigating a complex cost structure influenced by various factors. By understanding these elements and employing strategic negotiation tactics, B2B buyers can optimize their purchasing decisions and achieve favorable pricing, ensuring a competitive edge in their respective markets. Remember, prices can vary significantly based on region, supplier, and market conditions, so always approach negotiations with comprehensive knowledge and flexibility.

Alternatives Analysis: Comparing types of water bottle lids With Other Solutions

Understanding Alternatives in Water Bottle Lid Solutions

In the competitive landscape of beverage packaging, selecting the right water bottle lid is crucial for functionality, user experience, and overall product integrity. However, there are alternative solutions that can serve similar purposes, each with its unique advantages and disadvantages. This analysis will compare various types of water bottle lids with alternative solutions such as reusable straws and bottle pumps to provide B2B buyers with comprehensive insights into their options.

Tableau de comparaison

| Aspect comparatif | Types Of Water Bottle Lids | Reusable Straws | Bottle Pumps |

|---|---|---|---|

| Performance | Effective sealing, various designs for different uses | Convenient for drinking, reusable | Controlled dispensing of liquid |

| Coût | Moderate initial investment; varies by design | Low cost for bulk purchase | Higher initial investment, but long-term savings |

| Facilité de mise en œuvre | Straightforward; requires compatible bottles | Easy to integrate; fits most bottles | Installation needed; may require specific bottle types |

| Maintenance | Minimal; usually dishwasher safe | Requires cleaning after each use | Regular cleaning required to prevent clogging |

| Meilleur cas d'utilisation | Ideal for single-use or multi-purpose hydration | Suitable for casual use and eco-conscious consumers | Best for liquid dispensing in kitchens or commercial settings |

Analyse détaillée des alternatives

Reusable Straws

Reusable straws offer a convenient and eco-friendly option for hydration. They are typically made from materials like silicone, stainless steel, or bamboo and can fit into a variety of bottle openings. The main advantage is their low cost and ease of use, appealing to consumers focused on sustainability. However, they may not provide the same level of sealing as traditional lids, which can lead to spills if not used correctly.

Bottle Pumps

Bottle pumps are designed to dispense liquid in a controlled manner, making them ideal for products like soaps, lotions, or beverages that require precise pouring. While they have a higher initial investment compared to standard bottle lids, they can reduce product waste and enhance user convenience, especially in commercial settings. However, they require regular maintenance to prevent clogging and may not be compatible with all bottle designs, limiting their versatility.

Conclusion: How to Choose the Right Solution

When determining the best solution for your hydration needs, B2B buyers should consider the specific requirements of their target market. Types of water bottle lids are versatile and effective for a wide range of products, while reusable straws present an eco-friendly alternative that appeals to environmentally conscious consumers. Bottle pumps, on the other hand, are suited for controlled dispensing in commercial applications. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, businesses can make informed decisions that align with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for types of water bottle lids

What Are the Key Technical Properties of Water Bottle Lids?

When selecting water bottle lids for your products, understanding the essential technical properties is crucial for ensuring functionality, safety, and consumer satisfaction. Here are several critical specifications to consider:

1. Material Grade

The material used for water bottle lids significantly impacts durability, safety, and usability. Common materials include high-density polyethylene (HDPE), polypropylene (PP), and aluminum. HDPE is known for its robustness and resistance to impact, making it suitable for outdoor use. In contrast, PP is often used for its lightweight and recyclable properties. Choosing the right material is essential for meeting safety standards and consumer preferences, particularly in diverse markets.

2. Tolerance

Tolerance refers to the allowable variations in dimensions during manufacturing. For bottle lids, precise tolerances are critical to ensure a proper seal with the bottle neck, preventing leaks and contamination. Tolerances of +/- 0.1mm are standard, but understanding the specific requirements for your product can help avoid costly production errors and ensure compatibility with capping machines.

3. Closure Type

Different closure types, such as screw caps, flip-top lids, or pump caps, serve various functional needs. For instance, screw caps provide a secure seal for carbonated beverages, while flip-top lids offer convenience for personal care products. Understanding the closure type helps in aligning your product’s functionality with consumer expectations and market demands.

4. Seal Integrity

The integrity of the seal is vital for preserving the product’s freshness and preventing leaks. Lids may incorporate features like tamper-evident seals or induction seals to enhance security. For B2B buyers, assessing the seal integrity ensures compliance with regulatory standards and minimizes the risk of product spoilage during transport.

5. Compatibility with Capping Machines

The design of the lid must be compatible with automated capping machines to ensure efficient production processes. Features like the cap’s neck size and closure mechanism can affect how well it integrates with machinery. Understanding these specifications can help streamline production and reduce downtime.

What Common Trade Terminology Should B2B Buyers Know?

Navigating the B2B landscape involves familiarizing oneself with industry-specific jargon. Here are several key terms that are essential for effective communication and negotiation:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are then sold under another company’s brand. For water bottle lids, understanding OEM relationships can help buyers identify reliable suppliers who can meet specific quality and design requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ can help businesses plan purchases and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. In the context of water bottle lids, an RFQ helps buyers gauge pricing and availability, making it an essential tool for informed purchasing decisions.

4. Incoterms (conditions commerciales internationales)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to clarify logistics and avoid disputes related to shipping responsibilities.

5. Délai d'exécution

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring timely product launches, particularly in regions with varying supply chain dynamics.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their business objectives and market demands.

Navigating Market Dynamics and Sourcing Trends in the types of water bottle lids Sector

What Are the Current Market Dynamics and Key Trends in Water Bottle Lids?

The water bottle lid market is witnessing significant growth driven by an increasing global demand for reusable and environmentally friendly packaging solutions. As consumer preferences shift towards sustainable products, international B2B buyers are focusing on innovative lid designs that enhance functionality and user experience. Key trends include the rise of multi-functional lids, such as those with integrated straws and spouts, catering to active lifestyles. Additionally, technological advancements in capping machinery are making it easier for manufacturers to accommodate diverse lid types, thereby improving operational efficiency.

In regions like Africa and South America, there is a growing emphasis on locally sourced materials that reflect cultural preferences, while buyers in Europe and the Middle East prioritize quality and sustainability. The emergence of smart lids equipped with sensors for tracking hydration levels is also gaining traction, especially in health-conscious markets. Overall, international B2B buyers must stay attuned to these trends to ensure they are sourcing products that meet evolving consumer demands.

How Does Sustainability and Ethical Sourcing Influence the Water Bottle Lid Market?

Sustainability is a critical consideration in the sourcing of water bottle lids. The environmental impact of plastic waste has prompted manufacturers to explore alternative materials, such as biodegradable plastics and recycled resources. Buyers are increasingly looking for suppliers who can provide eco-friendly options that align with their corporate social responsibility goals. Certifications like FSC (Forest Stewardship Council) for wood-based materials or ISO 14001 for environmental management systems are becoming essential for verifying the sustainability of sourcing practices.

Ethical supply chains are also paramount, particularly in regions with stringent regulations regarding labor practices. Buyers must ensure their suppliers adhere to fair labor standards and sustainable practices, as this not only mitigates risk but also enhances brand reputation. As the market evolves, the demand for ‘green’ certifications and materials will likely grow, making it imperative for B2B buyers to prioritize sustainability in their sourcing strategies.

How Have Water Bottle Lids Evolved Over Time?

The evolution of water bottle lids reflects broader shifts in consumer behavior and technological advancements. Initially, simple screw caps dominated the market, primarily designed for functionality. However, as the demand for convenience and versatility increased, manufacturers began to innovate, introducing a variety of lid types like flip tops, sports caps, and pump dispensers.

In recent years, the focus has shifted towards creating lids that enhance user experience and promote sustainability. This includes the integration of smart technology and the use of eco-friendly materials. The historical context of water bottle lids illustrates the industry’s adaptability in response to changing consumer needs, positioning it for continued growth in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of types of water bottle lids

-

How do I choose the right type of water bottle lid for my product?

Selecting the appropriate lid depends on your product’s specific needs, target market, and intended use. Consider factors such as user convenience, safety features, and compatibility with your packaging. For instance, if you’re targeting sports enthusiasts, a sports cap may be ideal for ease of use. For products like cleaning solutions or chemicals, child-proof caps are essential. Additionally, assess your brand’s image; premium products may benefit from sleek, high-quality lids, while eco-friendly options can enhance sustainability messaging. -

What are the advantages of using custom water bottle lids?

Custom water bottle lids allow for differentiation in a competitive market. They can be designed to enhance user experience, such as ergonomic designs or unique opening mechanisms. Customization also offers branding opportunities, as lids can be printed with logos or colors that resonate with your brand identity. Furthermore, tailored lids can meet specific regulatory requirements, especially for products that require safety features or tamper-evident designs, thus ensuring compliance in various international markets. -

What is the typical minimum order quantity (MOQ) for water bottle lids?

MOQs can vary significantly based on the manufacturer and the complexity of the lid design. Generally, standard lids may have an MOQ of 1,000 to 5,000 units, while custom designs might require larger quantities, often starting at 10,000 units or more. It’s essential to communicate your needs with suppliers to negotiate favorable terms. Keep in mind that larger orders can reduce per-unit costs, making it more economical in the long run. -

What payment terms should I expect when sourcing water bottle lids internationally?

Payment terms vary by supplier and region, but common arrangements include payment in advance, 30% deposit with the balance before shipment, or payment upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify terms upfront and ensure they align with your cash flow requirements. Building a solid relationship with your supplier can also lead to more flexible payment arrangements in the future. -

How can I ensure the quality of water bottle lids from suppliers?

To ensure quality, conduct thorough supplier vetting before placing orders. Request samples to assess material durability, functionality, and design. Additionally, inquire about quality control processes, certifications (e.g., ISO standards), and testing procedures. Establish clear quality specifications in your purchase agreements and consider on-site inspections or third-party quality assurance services, especially for large orders. Maintaining open communication with your supplier is crucial for addressing any quality issues promptly. -

What logistics considerations should I keep in mind when importing water bottle lids?

Logistics can significantly impact your supply chain efficiency. Consider factors like shipping methods, lead times, and customs regulations in your target market. Choose reliable freight forwarders who can navigate complex international shipping processes. It’s also vital to understand the tariffs and duties applicable to water bottle lids in your importing country. Properly labeling your shipments and ensuring all documentation is in order will help avoid delays in customs clearance. -

How do different water bottle lid types impact user experience?

The type of lid can greatly influence user satisfaction and product usability. For example, sports caps allow for easy sipping during physical activities, while flip-top lids offer convenience for everyday use. Safety features, such as child-proof caps, enhance user confidence for products aimed at families. Additionally, lids designed for specific applications, like pump caps for hand sanitizers, can improve functionality and customer satisfaction, ultimately influencing repeat purchases and brand loyalty. -

What trends are emerging in the water bottle lid market?

Current trends include the growing demand for eco-friendly materials, such as biodegradable plastics and recycled materials. Consumers are increasingly concerned about sustainability, prompting brands to adopt more responsible packaging solutions. Additionally, innovations in lid designs, such as multi-functional caps and those with built-in filters, are gaining popularity. Customization options are also on the rise, allowing brands to differentiate their products and enhance consumer engagement through personalized designs and features.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 7 Types Of Water Bottle Lids Manufacturers & Suppliers List

1. Asset Packaging – Screw Caps & Child Proof Caps

Domaine : assetpackaging.com.au

Introduction : 1. Standard Screw Cap: Commonly used for various products, made from plastic or aluminium, often includes a pilfer proof seal and inner foil or plastic seal.

2. Child Proof Caps: Designed for dangerous products, requires a specific opening mechanism to prevent children from accessing the contents.

3. Flip Top Caps: Used for squeezable containers, includes a small hole for product flow and a flip l…

2. MyThermoFlask – Water Bottle Lids

Domaine : mythermoflask.com

Enregistré : 2014 (11 ans)

Introduction : {“collection_name”: “Water Bottle Lids”, “products”: [{“name”: “Swivel Handle Straw Lid”, “color”: “Black”, “price”: “$9.99”}, {“name”: “Wide Swivel Handle Straw Lid”, “color”: “Black”, “price”: “$9.99”}, {“name”: “Fixed Handle Straw Lid”, “color”: “Black”, “price”: “$9.99”}, {“name”: “Spout Lid”, “color”: “Black”, “price”: “$9.99”}, {“name”: “Spout Lid With Wide Loop”, “color”: “Black”, “price”: …

3. Maps of India – Water Bottle Cap Guide

Domaine : mapsofindia.com

Enregistré : 1998 (27 ans)

Introduction : The colour-coding of water bottle caps indicates the type of water contained within:

– Black Caps: Alkaline Water (high pH, potential health benefits)

– Blue Caps: Spring Water (pure, mineral-rich, sourced from natural springs)

– White Caps: Processed Water (filtered, crisp taste, lacks mineral profile)

– Green Caps: Flavored Water (natural flavors, appealing to diverse tastes)

– Clear Caps: Natu…

4. Hydro Flask – Wide Mouth Straw Lid

Domaine : hydroflask.com

Enregistré : 2009 (16 ans)

Introduction : Wide Mouth Straw Lid – Black: $7.46 (originally $9.95, 25% off)

Stainless Steel Straw Set: $9.95 (originally $7.46, 25% off)

Tea Infuser: $16.95 (originally $12.71, 25% off)

3-Pack Replacement Straw Pack: $4.95 (originally $3.71, 25% off)

Wide Mouth Flex Chug Cap: $12.95 (originally $9.71, 25% off)

Wide Mouth Flex Straw Cap: $14.95 (originally $11.21, 25% off)

Standard Mouth Flex Cap: $9.95 (origi…

5. HydraPeak – Chug Lids

Domaine : hydrapeak.com

Enregistré : 2017 (8 ans)

Introduction : This company, HydraPeak – Chug Lids, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Great Eastern Life – Water Bottle Cap Colors Explained

Domaine : greateasternlife.com

Enregistré : 2005 (20 ans)

Introduction : The article discusses the significance of water bottle cap colors in Singapore, where bottled water consumption is high. It explains the meanings of different cap colors:

– Clear/White: Regular or purified drinking water, safe but lacks beneficial substances like fluoride.

– Blue: Spring or mineral water, rich in minerals but can be costly.

– Green: Flavored water, may contain added sugars or a…

7. Snopes – Water Bottle Cap Myths

Domaine : snopes.com

Enregistré : 1997 (28 ans)

Introduction : The claim that plastic water bottle caps are color coded based on the type of water is false. Viral posts suggest: blue caps indicate spring water, black caps signify alkaline water, green caps signal flavored water, and white caps mean processed water. However, there are no regulations from the FDA or EPA regarding color-coded caps. Some brands may use caps that match these claims, but many do no…

Strategic Sourcing Conclusion and Outlook for types of water bottle lids

In navigating the diverse landscape of water bottle lids, international B2B buyers must prioritize strategic sourcing to enhance product functionality and consumer appeal. The wide range of options—from standard screw caps to advanced sports caps and child-proof lids—provides opportunities for differentiation in competitive markets. Understanding the unique features and applications of each lid type is crucial for aligning product offerings with consumer preferences and regulatory requirements.

As buyers evaluate their sourcing strategies, they should consider factors such as material sustainability, manufacturing capabilities, and compatibility with existing capping systems. This holistic approach not only improves operational efficiency but also fosters innovation in product design, catering to evolving consumer demands across regions like Africa, South America, the Middle East, and Europe.

Looking ahead, the trend toward personalized and functional products suggests that investing in versatile and innovative lid solutions will be key to capturing market share. By embracing these developments, B2B buyers can position themselves for success in an increasingly dynamic global marketplace. Engage with suppliers who are committed to quality and innovation, ensuring your product lines are not only competitive but also resonate with consumers worldwide.