Introduction: Navigating the Global Market for bottle size

Navigating the diverse landscape of bottle sizes can be a daunting task for international B2B buyers, especially those sourcing packaging solutions for the vibrant markets of Africa, South America, the Middle East, and Europe. The myriad of options available—from standard sizes like the 750 ml to unique offerings such as magnums—can complicate purchasing decisions. This comprehensive guide aims to demystify the complexities of bottle sizes, covering various types, applications across different industries, supplier vetting processes, and cost considerations.

By understanding the nuances of bottle sizes, businesses can better align their products with consumer preferences, optimize their supply chains, and enhance their market presence. Whether you are a distiller seeking to elevate your spirits brand, a winery looking to showcase your vintage, or a retailer aiming to meet customer demands, this guide empowers you to make informed purchasing decisions. The insights provided will help you navigate the global market effectively, ensuring that your selections not only meet regulatory standards but also resonate with your target audience.

Armed with this knowledge, B2B buyers can strategically position themselves in competitive markets, ensuring that their packaging solutions enhance product appeal and drive sales. Join us as we explore the essential elements of bottle sizes to equip your business for success in the international marketplace.

Navigation dans les articles

- Top 4 Bottle Size Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle size

- Understanding bottle size Types and Variations

- Key Industrial Applications of bottle size

- 3 Common User Pain Points for ‘bottle size’ & Their Solutions

- Strategic Material Selection Guide for bottle size

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle size

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle size’

- Comprehensive Cost and Pricing Analysis for bottle size Sourcing

- Alternatives Analysis: Comparing bottle size With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle size

- Navigating Market Dynamics and Sourcing Trends in the bottle size Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle size

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for bottle size

Understanding bottle size Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

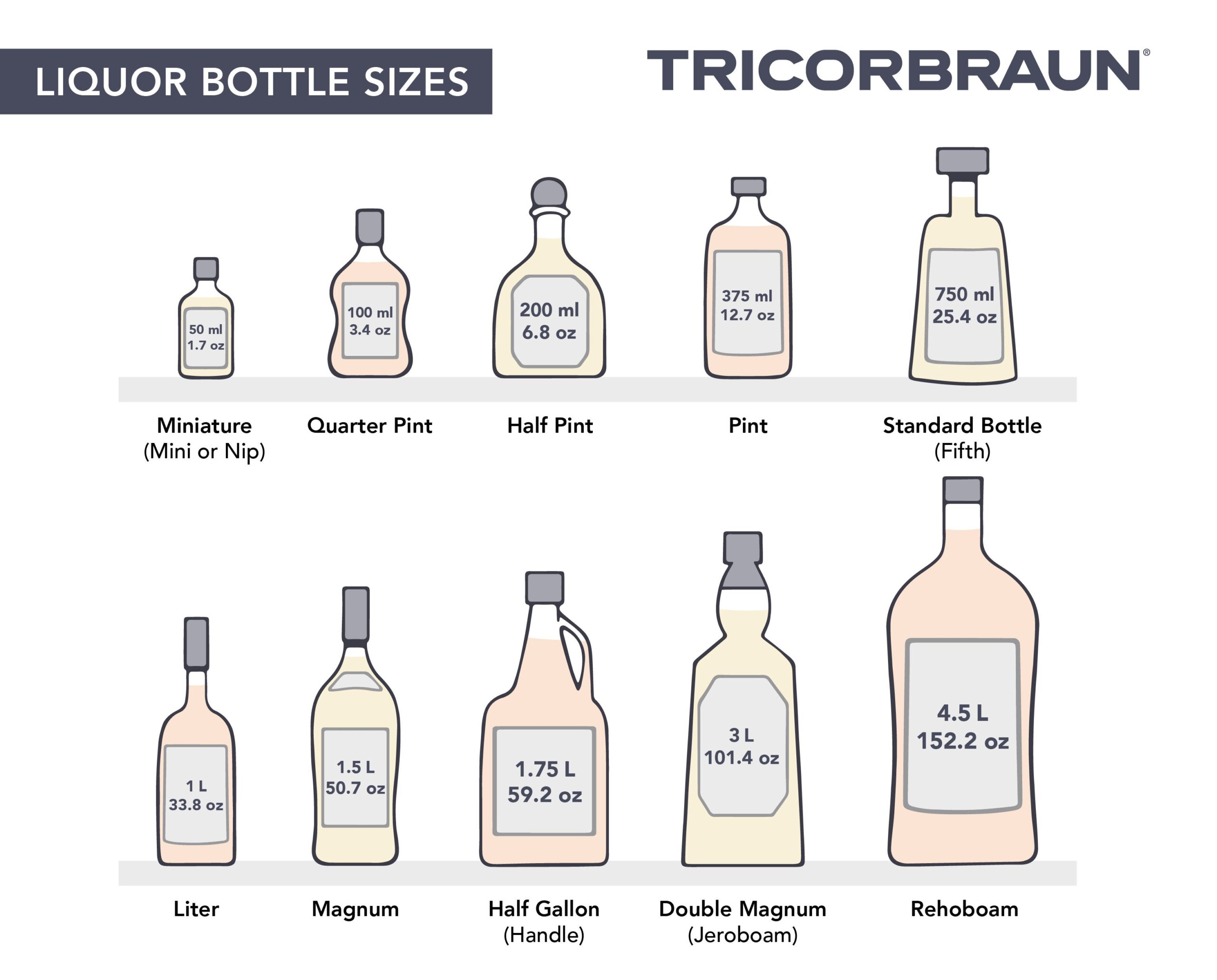

| Standard Size | Commonly 750 ml, suitable for most spirits and wines | Retail, distribution, direct-to-consumer | Pour : Widely accepted; easy to source. Cons : May lack uniqueness in a crowded market. |

| Miniature | Typically 50 ml or 200 ml; ideal for sampling | Promotions, travel retail, gifts | Pour : Low investment; great for marketing. Cons : Limited profit margins due to small size. |

| Magnum | 1.5 liters, equivalent to two standard bottles | High-end events, gifts, premium products | Pour : Appeals to luxury market; enhances brand prestige. Cons : Higher cost and storage needs. |

| Jeroboam | 3 liters, suitable for special occasions | Catering, events, wine clubs | Pour : Excellent for large gatherings; eye-catching. Cons : Difficult to handle and pour. |

| Custom Design | Tailored sizes and shapes to fit brand identity | Niche markets, unique product lines | Pour : Differentiates brand; can command premium pricing. Cons : Higher development costs and lead times. |

What Are the Characteristics of Standard Size Bottles?

Standard size bottles, typically 750 ml, are the most common choice for spirits and wines globally. Their widespread acceptance makes them ideal for retail and distribution channels, allowing businesses to easily source and stock inventory. When purchasing standard bottles, B2B buyers should consider factors such as bottle weight, material (glass or plastic), and neck finish, which can impact the overall aesthetic and functionality. While standard sizes offer convenience, they may lack the distinctive appeal needed to stand out in competitive markets.

How Do Miniature Bottles Serve B2B Needs?

Miniature bottles, usually ranging from 50 ml to 200 ml, are perfect for promotions, travel retail, and gifting purposes. Their small size allows brands to offer samples or trial sizes, making them an effective marketing tool to attract new customers. For B2B buyers, the key considerations include the cost-effectiveness of small packaging and the potential for higher turnover rates. However, the limited volume may lead to lower profit margins, which is a crucial factor for brands looking to maintain profitability.

What Advantages Do Magnum Bottles Provide?

Magnum bottles, holding 1.5 liters, are often associated with luxury and special occasions. These bottles are particularly appealing for high-end events, catering, and gifting, allowing brands to enhance their prestige and visibility in the market. B2B buyers should evaluate the storage and handling challenges associated with magnums, as they can be cumbersome. While they can command higher prices, the investment must be justified by the potential for increased brand awareness and customer engagement.

Why Choose Jeroboam Bottles for Special Occasions?

Jeroboam bottles, which contain 3 liters of liquid, are designed for large gatherings and special events. They serve as a striking centerpiece and facilitate serving multiple guests at once, making them popular among caterers and wine clubs. When considering jeroboam bottles, B2B buyers should assess the logistics of handling and transportation due to their size. Although they provide a unique selling point, the challenges in pouring and storage should also be factored into purchasing decisions.

How Can Custom Design Bottles Enhance Brand Identity?

Custom-designed bottles allow brands to create unique packaging solutions tailored to their identity and target market. This approach is particularly beneficial for niche markets or products aiming to stand out in a saturated industry. B2B buyers should consider the initial investment and lead times associated with custom designs, as they may be higher than standard options. However, the potential for premium pricing and enhanced brand loyalty can make custom bottles a worthwhile investment for businesses looking to differentiate themselves.

Key Industrial Applications of bottle size

| Industrie/secteur | Specific Application of bottle size | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Alimentation et boissons | Standardization of packaging sizes | Ensures consistency in branding and customer experience | Compliance with local regulations and sustainability standards |

| Pharmaceutique | Precision in dosage packaging | Enhances safety and efficacy of medicinal products | Material compatibility and tamper-evident features |

| Cosmetics and Personal Care | Custom bottle sizes for product lines | Differentiates products and enhances shelf appeal | Availability of unique designs and customization options |

| E-commerce and Retail | Flexible bottle sizes for shipping | Reduces shipping costs and improves inventory management | Supplier reliability and logistical capabilities |

| Hospitality and Events | Large format bottles for special occasions | Increases customer engagement and enhances experience | Availability of bulk purchasing options and seasonal variations |

How Is Bottle Size Utilized in the Food and Beverage Industry?

In the food and beverage sector, bottle size standardization is crucial for ensuring consistent branding and a reliable customer experience. Companies often utilize specific sizes, such as 750 ml for wines and 1 liter for spirits, to meet consumer expectations and regulatory requirements. International B2B buyers, especially in regions like Africa and South America, must consider local market preferences and compliance with food safety standards when sourcing packaging solutions.

What Role Does Bottle Size Play in Pharmaceutical Applications?

In the pharmaceutical industry, precise bottle sizes are essential for accurate dosage and medication safety. Bottles are designed to hold specific volumes, reducing the risk of dosing errors. B2B buyers in this sector must prioritize sourcing bottles that meet stringent regulatory requirements, including child-resistant and tamper-evident features. Additionally, compatibility with various medicinal substances is critical, necessitating careful material selection.

How Do Custom Bottle Sizes Enhance Cosmetics and Personal Care Products?

Cosmetics and personal care brands often leverage unique bottle sizes to differentiate their products on retail shelves. Custom sizes can create a luxurious feel or cater to specific market segments, such as travel-size products. For international buyers, sourcing options should include a variety of designs and materials that align with brand identity while also considering sustainability practices, especially in Europe and the Middle East.

Why Is Bottle Size Important for E-commerce and Retail?

In the e-commerce and retail sectors, flexible bottle sizes can significantly impact shipping costs and inventory management. Smaller or more compact packaging can lead to reduced shipping fees, while larger formats may cater to bulk buyers. Businesses must evaluate suppliers based on their ability to provide reliable logistics solutions and responsiveness to changing market demands, particularly in emerging markets across Africa and South America.

How Do Large Format Bottles Benefit the Hospitality Industry?

In hospitality and event management, large format bottles are often used for special occasions, enhancing the guest experience and creating memorable moments. These bottles, such as magnums or jeroboams, not only serve a practical purpose but also elevate the aesthetic appeal of events. B2B buyers should consider suppliers who offer bulk purchasing options and seasonal variations to meet the dynamic demands of the hospitality sector.

3 Common User Pain Points for ‘bottle size’ & Their Solutions

Scenario 1: Struggling with Inconsistent Bottle Sizes Across Markets

Le problème : B2B buyers often face the challenge of inconsistent bottle sizes when distributing products across different international markets. For instance, a company might source a standard 750 ml bottle for its spirits in Europe, only to find that South American regulations favor a 1-liter bottle. This discrepancy can lead to logistical issues, increased shipping costs, and potential regulatory fines, complicating market entry and damaging brand reputation.

La solution : To navigate this challenge, B2B buyers should conduct thorough market research before finalizing their packaging decisions. Engage with local distributors and regulatory bodies to understand the specific size requirements for each target market. It’s also beneficial to work with a packaging supplier who offers a variety of bottle sizes and can provide guidance on compliance. Establishing a flexible packaging strategy that allows for quick adjustments to bottle sizes based on regional needs can significantly enhance operational efficiency and market adaptability.

Scenario 2: Difficulty in Meeting Consumer Preferences for Bottle Sizes

Le problème : Understanding consumer preferences regarding bottle sizes can be a significant pain point for B2B buyers, particularly in sectors like wine and spirits. Buyers may find themselves offering a product in a bottle size that doesn’t resonate with their target audience, leading to poor sales performance. For example, a distillery might produce a high-quality spirit in a 1-liter bottle, but if consumers in a specific market prefer smaller sizes for sampling or gifting, the product may not sell as expected.

La solution : To align product offerings with consumer preferences, B2B buyers should invest in consumer research and market analysis. Utilize surveys, focus groups, and sales data to determine the most popular bottle sizes within the target demographic. Additionally, consider offering a range of sizes to cater to different market segments. For instance, introducing miniatures for sampling alongside standard sizes can attract a broader audience. Collaborating with marketing experts to develop targeted campaigns around these offerings can also help in effectively positioning products in the market.

Scenario 3: Managing Packaging Costs While Ensuring Quality

Le problème : B2B buyers often grapple with the balance between managing packaging costs and ensuring the quality of bottle sizes. In an effort to reduce expenses, some buyers might opt for cheaper materials or less durable sizes, which can compromise product integrity and lead to customer dissatisfaction. For example, using lower-quality glass for a premium spirit can result in breakage during transport or an inferior perception of the brand.

La solution : To effectively manage packaging costs while maintaining quality, B2B buyers should conduct a cost-benefit analysis of various packaging options. Evaluate the total cost of ownership, including production, shipping, and potential returns due to damaged goods. Engage with reputable suppliers who can offer a range of materials that meet both budgetary constraints and quality standards. Consider investing in technology that enables precise forecasting and inventory management, which can help reduce waste and optimize purchasing decisions. Additionally, establishing long-term partnerships with suppliers can lead to better pricing and increased reliability in maintaining product quality across all bottle sizes.

Strategic Material Selection Guide for bottle size

What are the Key Properties of Common Bottle Materials?

When selecting the appropriate material for bottle sizes, it is essential to consider the key properties that influence product performance. The most common materials used for bottle manufacturing include glass, PET (polyethylene terephthalate), HDPE (high-density polyethylene), and aluminum. Each material presents unique characteristics that can significantly impact the suitability of the final product for various applications.

How Does Glass Perform as a Bottle Material?

Glass is a traditional choice for bottle manufacturing, particularly in the beverage industry. Its key properties include excellent barrier resistance to gases and moisture, allowing for extended shelf life. Glass can withstand high temperatures, making it suitable for hot-fill applications. However, it is fragile and can break easily under impact or stress.

Pour : Glass bottles are highly durable against chemical reactions, making them ideal for storing a wide range of liquids, including spirits and wines. They also provide a premium feel, which can enhance brand perception.

Cons : The primary disadvantages of glass include higher manufacturing costs and weight, which can increase shipping expenses. Additionally, glass bottles require careful handling during transportation and storage.

Impact sur l'application : Glass is compatible with a variety of media, including alcoholic beverages, juices, and oils. However, its weight may limit its use in markets where shipping costs are a significant concern.

Considérations pour les acheteurs internationaux : Buyers from regions like Africa and South America should be aware of the fragility of glass and consider local transport conditions. Compliance with international standards such as ASTM and DIN is also critical to ensure quality and safety.

What are the Advantages of PET Bottles?

PET is a lightweight, flexible plastic widely used for beverage bottles. Its key properties include high impact resistance and excellent clarity, making it visually appealing. PET bottles can be produced in various shapes and sizes, accommodating diverse branding needs.

Pour : The lightweight nature of PET reduces transportation costs, and its recyclability aligns with growing sustainability trends. Additionally, PET can be produced at a lower cost compared to glass.

Cons : PET has a lower barrier to oxygen compared to glass, which may affect the shelf life of certain products. It is also less resistant to high temperatures, limiting its use for hot-fill applications.

Impact sur l'application : PET is suitable for carbonated beverages, juices, and water but may not be ideal for products requiring long shelf life without preservatives.

Considérations pour les acheteurs internationaux : Buyers in Europe and the Middle East should consider local recycling capabilities for PET, as regulations regarding plastic waste vary significantly by region.

How Does HDPE Compare in Bottle Manufacturing?

HDPE is another plastic option known for its strength and resistance to impact and chemicals. It is often used for bottles containing household products, detergents, and some food items.

Pour : HDPE is highly durable and resistant to many chemicals, making it suitable for a variety of applications. Its lower cost compared to glass and PET makes it an economical choice.

Cons : While HDPE is resistant to impact, it has a lower aesthetic appeal compared to glass or PET. It also has a less favorable oxygen barrier, which can affect product quality over time.

Impact sur l'application : HDPE is commonly used for non-food applications but can also be suitable for certain food products. Its resistance to chemicals makes it a good choice for cleaning products.

Considérations pour les acheteurs internationaux : Buyers should ensure compliance with food safety standards, particularly in Europe, where regulations are stringent. Understanding local market preferences for packaging aesthetics is also essential.

What Role Does Aluminum Play in Bottle Design?

Aluminum bottles are increasingly popular for beverages due to their lightweight and recyclable nature. They provide excellent barrier properties against light and oxygen, making them suitable for products sensitive to these elements.

Pour : Aluminum is lightweight and highly durable, making it ideal for transportation. It also offers a unique branding opportunity with customizable designs.

Cons : The manufacturing process for aluminum can be more complex and costly than plastic options. Additionally, aluminum may not be suitable for all beverage types, particularly those that require a longer shelf life.

Impact sur l'application : Aluminum is commonly used for soft drinks and alcoholic beverages, particularly in markets focused on sustainability.

Considérations pour les acheteurs internationaux : Buyers should be aware of local recycling practices and regulations regarding aluminum packaging, particularly in Europe, where recycling rates are high.

Summary Table

| Matériau | Typical Use Case for bottle size | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Verre | Spirits, wines, juices | Excellent barrier properties, premium feel | Fragile, higher shipping costs | Haut |

| PET | Carbonated beverages, juices | Lightweight, lower cost, recyclable | Lower oxygen barrier, not suitable for hot-fill | Moyen |

| PEHD | Household products, detergents | Durable, resistant to chemicals | Less aesthetic appeal, lower oxygen barrier | Faible |

| Aluminium | Soft drinks, alcoholic beverages | Lightweight, excellent barrier properties | Higher manufacturing complexity, limited use for some beverages | Moyen |

In-depth Look: Manufacturing Processes and Quality Assurance for bottle size

What Are the Key Stages in the Manufacturing Process of Bottles?

The manufacturing process for bottles, particularly in the liquor and beverage industry, involves several critical stages that ensure the final product meets quality and safety standards. Understanding these stages helps B2B buyers assess potential suppliers effectively.

Material Preparation: What Materials Are Used in Bottle Production?

The primary materials used in bottle manufacturing are glass and plastic. For glass bottles, raw materials such as silica sand, soda ash, and limestone are mixed and melted at high temperatures. For plastic bottles, resins like PET (Polyethylene Terephthalate) are utilized. The choice of material impacts the bottle’s durability, weight, and aesthetic appeal, which are crucial for brand positioning.

How Are Bottles Formed During Manufacturing?

Once the materials are prepared, the next step is forming. This can be accomplished through various techniques, including:

- Moulage par soufflage: Commonly used for plastic bottles, this technique involves heating and inflating the plastic into a mold.

- Glass Blowing: In this traditional method, molten glass is inflated into a bubble and shaped into the desired bottle form.

- Press-and-Blow: This hybrid technique is often used for high-volume glass bottle production, combining pressing and blowing to achieve uniformity.

These forming techniques are crucial in achieving the desired bottle size and shape, which can vary significantly depending on the product requirements.

What Does the Assembly Process Involve?

After forming, bottles may undergo an assembly process where additional components, such as closures and labels, are added. This stage is essential for ensuring that the bottles are functional and visually appealing. The assembly line must be efficient to maintain production speed while ensuring quality control.

How Are Bottles Finished to Meet Quality Standards?

Finishing processes involve surface treatment, decoration, and quality checks. For glass bottles, this may include polishing and applying protective coatings. For plastic bottles, UV protection can be added to prevent degradation. Additionally, labeling is a crucial aspect, as it provides branding and regulatory information.

What Quality Assurance Measures Are Essential for Bottle Manufacturing?

Quality assurance (QA) is critical in the bottle manufacturing process to ensure that the products meet international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for suppliers that comply with international quality management standards, such as ISO 9001. This standard ensures that the manufacturer has a quality management system in place that focuses on continual improvement and customer satisfaction. In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific applications can indicate a supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints in Bottle Manufacturing?

Quality control (QC) involves systematic processes throughout the manufacturing stages. Key checkpoints include:

- Contrôle de la qualité à l'arrivée (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- Contrôle de la qualité en cours de fabrication (IPQC): This stage monitors the manufacturing process to catch defects as they occur.

- Contrôle de qualité final (CQF): This final inspection ensures that the finished bottles meet all specifications before they are shipped.

Each checkpoint serves to minimize defects and ensure compliance with established quality standards.

What Common Testing Methods Are Used to Ensure Bottle Quality?

B2B buyers should be familiar with common testing methods that manufacturers employ to ensure bottle quality:

- Dimensional Testing: Ensures that the bottle meets size specifications.

- Pressure Testing: Particularly important for beverage bottles, this tests the bottle’s ability to withstand internal pressure.

- Drop Testing: Assesses the durability of bottles by simulating real-world handling.

- Chemical Resistance Testing: For plastic bottles, this checks for degradation when in contact with various substances.

These tests provide valuable data on the durability and safety of the bottles.

Comment les acheteurs B2B peuvent-ils vérifier le contrôle de la qualité des fournisseurs ?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

- Effectuer des audits des fournisseurs: Regular audits can help assess a supplier’s adherence to quality standards.

- Demander des rapports de qualité: Suppliers should provide documentation of their quality control processes and testing results.

- Faire appel à des inspecteurs tiers: Independent inspections can provide an objective assessment of the supplier’s quality control measures.

These steps are essential for mitigating risks associated with product quality, particularly in international markets.

Quelles sont les particularités du contrôle de la qualité pour les acheteurs internationaux B2B ?

When dealing with international suppliers, B2B buyers must be aware of certain nuances related to quality control:

- Regulatory Compliance: Different regions may have varying requirements for packaging materials, especially concerning food and beverage safety.

- Considérations culturelles: Understanding the local manufacturing culture can provide insights into potential quality issues.

- Logistics and Shipping: Ensure that quality is maintained throughout the shipping process, as transportation can impact product integrity.

B2B buyers from regions like Africa, South America, the Middle East, and Europe must navigate these complexities to ensure they partner with reliable suppliers.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Important?

For international B2B buyers, a deep understanding of the manufacturing processes and quality assurance measures in bottle production is crucial. It not only aids in selecting reliable suppliers but also ensures that the products meet the necessary standards for market entry. By focusing on material preparation, forming techniques, and stringent quality control measures, buyers can secure high-quality packaging solutions that align with their brand’s values and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle size’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively procuring the right bottle sizes for their products. Understanding the diverse bottle sizes available in the market and aligning them with your business needs is crucial for enhancing brand appeal, ensuring compliance, and optimizing logistics. Follow this checklist to streamline your sourcing process and make informed decisions.

Étape 1 : Identify Your Product Type

Understanding the type of product you are packaging is the first step in selecting the appropriate bottle size. Different beverages, such as spirits, wines, or non-alcoholic drinks, have standard bottle sizes associated with them. For instance, a standard wine bottle is typically 750 ml, while spirits may range from 200 ml to 1.75 liters. Knowing your product type helps narrow down the options and ensures you meet market expectations.

Étape 2 : Define Your Target Market

Your target market influences not only the bottle size but also the design and material of the bottle. For example, markets in Africa may favor larger quantities for communal consumption, while European markets may lean towards standard sizes for individual servings. Conduct market research to understand preferences and cultural nuances, which can help tailor your product to meet customer expectations effectively.

Étape 3 : Determine Regulatory Compliance

Ensure that the bottle sizes you consider comply with local and international regulations. Different countries have specific labeling and packaging laws, especially for alcoholic beverages. Familiarize yourself with the regulations in your target regions, such as the EU’s stringent packaging laws or labeling requirements in Brazil, to avoid costly penalties and ensure smooth market entry.

Étape 4 : Evaluate Material Options

The choice of material—glass, plastic, or alternative materials—affects not only the aesthetic appeal but also the cost and sustainability of your packaging. Glass is often preferred for premium products due to its perceived quality, while plastic may be more economical for mass production. Assess your brand positioning and sustainability goals to choose the right material that aligns with your business strategy.

Étape 5 : Assess Supplier Capabilities

Before finalizing a supplier, evaluate their capabilities regarding bottle size options and customization. Request samples to assess quality and ensure they can meet your specifications in terms of size, shape, and material. It’s also beneficial to inquire about their production capacity and lead times to avoid potential delays in your supply chain.

Étape 6 : Calculate Total Cost of Ownership

When selecting bottle sizes, consider not just the unit price but the total cost of ownership, which includes shipping, storage, and handling costs. Larger bottles may have a lower cost per unit but could incur higher shipping fees. Analyze the complete cost structure to make an informed decision that aligns with your budget and profit margins.

Étape 7 : Test Market with Prototypes

Before full-scale production, conduct a test market with prototypes of your selected bottle sizes. Gather feedback from consumers and distributors to assess the appeal and functionality of the packaging. This step can provide valuable insights into consumer preferences and help you make necessary adjustments before launching your product.

By following this checklist, B2B buyers can navigate the complexities of bottle size sourcing more effectively, ensuring that their products meet market demands while optimizing costs and compliance.

Comprehensive Cost and Pricing Analysis for bottle size Sourcing

What Are the Key Cost Components in Bottle Sourcing?

When sourcing bottles, several cost components come into play that international B2B buyers must consider. These include:

-

Matériaux: The type of materials used, such as glass or plastic, significantly impacts cost. Glass is generally more expensive due to its weight and fragility, while plastic offers a cost-effective alternative. Furthermore, the quality of the materials can influence both the price and the perceived value of the product.

-

Travail: The labor costs associated with manufacturing bottles vary by region and can be affected by local wage rates and labor laws. Countries with lower labor costs may present attractive sourcing options, but it’s essential to assess the quality of workmanship.

-

Frais généraux de fabrication: This includes the costs related to factory operations, such as utilities, rent, and maintenance. High overhead can lead to increased prices, so it’s crucial to evaluate potential suppliers on this front.

-

Outillage: Custom bottle designs may require specialized tooling, which adds to upfront costs. Buyers should factor in these expenses when considering bespoke designs versus standard offerings.

-

Contrôle de la qualité (CQ): Rigorous quality control processes ensure that bottles meet the required standards. Suppliers that invest in QC may charge higher prices, but this can result in better overall product quality and reduced returns.

-

Logistique: Transportation costs can significantly affect the total cost of ownership (TCO). Factors such as distance, shipping methods, and customs duties should all be taken into account.

-

Marge: Suppliers will add their profit margin to the cost structure, which can vary widely based on market conditions and competition.

How Do Price Influencers Affect Bottle Sourcing?

Several factors can influence pricing when sourcing bottles:

-

Volume/QMo (quantité minimale de commande): Larger orders typically result in lower per-unit costs. Understanding suppliers’ MOQs can help buyers negotiate better pricing.

-

Spécifications et personnalisation: Custom designs or specifications can lead to higher costs due to increased tooling and manufacturing complexities. Buyers should weigh the benefits of customization against the additional costs.

-

Qualité des matériaux et certifications: Bottles that meet certain quality standards or certifications may carry a premium price. Buyers should consider whether these certifications are necessary for their market.

-

Facteurs liés au fournisseur: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is essential. Different Incoterms can affect the total cost by shifting responsibilities for shipping and insurance.

What Are the Best Practices for Negotiating Bottle Prices?

International B2B buyers, especially from diverse regions like Africa, South America, the Middle East, and Europe, can benefit from specific strategies:

-

Réaliser une étude de marché: Understand the typical price ranges for the required bottle sizes in your target markets. This knowledge will empower you during negotiations.

-

Évaluer le coût total de possession: Look beyond initial pricing and consider all associated costs, including shipping, tariffs, and potential returns. A lower initial price may not always equate to a better deal.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet MOQs and negotiate for volume discounts. This strategy can significantly reduce costs.

-

Be Transparent About Your Needs: Clear communication about your specifications and requirements can foster a collaborative relationship with suppliers, leading to better pricing options.

-

Understand Regional Pricing Nuances: Pricing may vary significantly across different regions due to local economic conditions, currency fluctuations, and demand. Tailor your negotiation strategies based on these factors.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s important to note that prices for bottles can fluctuate based on market conditions, material costs, and supplier pricing strategies. Always seek multiple quotes and remain flexible in your negotiations to adapt to these variations. By understanding the comprehensive cost structure and pricing dynamics, B2B buyers can make informed decisions that align with their business objectives and market needs.

Alternatives Analysis: Comparing bottle size With Other Solutions

Understanding Alternative Solutions to Bottle Size

When evaluating packaging solutions in the beverage industry, particularly for liquor and wine, understanding the various alternatives to traditional bottle sizes is essential. While standard bottle sizes are widely recognized for their functionality and consumer familiarity, several alternative solutions can offer unique benefits. This analysis compares the traditional concept of bottle size with two viable alternatives: bag-in-box packaging and bulk dispensing systems.

Tableau de comparaison

| Aspect comparatif | Bottle Size | Bag-in-Box Packaging | Bulk Dispensing System |

|---|---|---|---|

| Performance | Reliable shelf life, user-friendly | Extended freshness, reduced oxidation | High capacity, less waste |

| Coût | Moderate to high, based on material | Generally lower due to reduced packaging | Initial investment high, but cost-effective long-term |

| Facilité de mise en œuvre | Simple, established process | Requires training for staff | Complex setup, needs regular maintenance |

| Maintenance | Minimal maintenance required | Moderate; check for leaks | High; regular cleaning and calibration needed |

| Meilleur cas d'utilisation | Retail sales, events, gifts | Home use, small gatherings | Commercial settings, high-volume sales |

Analyse détaillée des alternatives

What are the Advantages and Disadvantages of Bag-in-Box Packaging?

Bag-in-box packaging is increasingly popular for both wine and spirits. This solution consists of a flexible bag housed within a cardboard box, which allows for easy pouring while minimizing air exposure. One of the primary advantages is its ability to maintain product freshness for extended periods after opening, significantly reducing oxidation. This makes it ideal for consumers who may not finish a bottle in one sitting. However, bag-in-box solutions may not carry the same brand prestige as glass bottles, which can impact consumer perception in high-end markets.

How Does a Bulk Dispensing System Compare?

Bulk dispensing systems are designed for high-volume environments, such as bars or restaurants, where beverages are stored in larger containers and dispensed as needed. This method significantly reduces packaging waste and offers cost efficiencies, especially for businesses with high turnover rates. However, the initial investment in equipment can be substantial, and the complexity of setup requires specialized training for staff. Furthermore, regular maintenance is necessary to ensure cleanliness and functionality, which can add to operational overhead.

Conclusion: How to Choose the Right Packaging Solution

For B2B buyers in the beverage industry, selecting the appropriate packaging solution hinges on understanding specific operational needs and market positioning. While traditional bottle sizes offer familiarity and established consumer trust, alternatives like bag-in-box and bulk dispensing systems present innovative ways to enhance product freshness and reduce costs. Buyers should consider their target market, volume requirements, and budget constraints when evaluating these options. By aligning packaging solutions with business goals, companies can enhance their competitive edge in a dynamic marketplace.

Essential Technical Properties and Trade Terminology for bottle size

What Are the Key Technical Properties of Bottle Sizes That B2B Buyers Should Consider?

When selecting bottles for your products, understanding the technical properties is essential for ensuring quality, compliance, and consumer satisfaction. Here are some critical specifications to consider:

-

Qualité des matériaux

The choice of material—glass, plastic, or metal—affects the bottle’s durability, weight, and compatibility with various contents. Glass is often favored for premium products due to its non-reactive nature and ability to preserve flavor. In contrast, PET plastic is lightweight and shatter-resistant, making it suitable for bulk shipping. Choosing the right material can enhance brand perception and reduce shipping costs. -

Capacity and Volume Tolerance

Bottle sizes are typically measured in milliliters (ml) or ounces, with common sizes including 750 ml (fifth) and 1,000 ml (liter). Understanding volume tolerance—how much variation is acceptable from the stated capacity—is crucial. For instance, a tolerance of ±5% ensures that your product meets regulatory standards while maintaining consumer trust. Inconsistencies can lead to financial loss and reputational damage. -

Neck Finish and Closure Compatibility

The neck finish refers to the design of the bottle’s opening, which impacts the type of closure used, such as corks or screw caps. Ensuring compatibility is vital for both functionality and aesthetics. For example, a bar top neck finish is often used for spirits, while a standard 28-400 finish is common for sauces. Proper closure not only preserves the product but also influences the ease of use for consumers. -

Weight and Dimensional Specifications

The weight of the bottle can influence shipping costs and consumer handling. Heavier bottles may convey a sense of quality but can increase shipping expenses. Dimensional specifications—height, width, and diameter—are also important for storage and shelf display. Buyers should consider how these factors align with their logistics and marketing strategies. -

Labeling Surface Area

The surface area available for labeling is a key consideration for branding and regulatory compliance. Adequate space allows for clear product information, branding elements, and legal requirements, such as ingredient lists and alcohol content. A well-designed label can enhance marketability and attract consumers.

What Are the Common Trade Terms Related to Bottle Sizes That B2B Buyers Should Know?

Understanding trade terminology can streamline communication and negotiations in the B2B landscape. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or products that are sold by another company under its brand name. In the context of bottle manufacturing, an OEM might produce custom-designed bottles that align with a brand’s specifications. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest number of units a supplier is willing to sell. This term is critical for budgeting and inventory management. Understanding MOQ helps buyers align their purchasing decisions with production capabilities and financial constraints. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For bottle sizes, an RFQ can help buyers obtain competitive pricing and understand the supplier’s capabilities and lead times. -

Incoterms (termes commerciaux internationaux)

These are predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can aid in understanding shipping logistics, cost allocation, and risk management. -

Délai d'exécution

Lead time refers to the time it takes from placing an order to receiving the goods. In the context of bottle sizes, understanding lead times can help businesses plan their inventory and marketing strategies effectively. -

Customs Duty

This is a tariff or tax imposed on goods when transported across international borders. Being aware of customs duties related to imported bottles can impact the total cost and pricing strategy for B2B buyers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that optimize their product offerings and supply chain operations.

Navigating Market Dynamics and Sourcing Trends in the bottle size Sector

What Are the Key Market Dynamics and Trends Impacting the Bottle Size Sector?

The global bottle size market is witnessing dynamic shifts driven by various factors, including consumer preferences, regulatory changes, and technological advancements. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Brazil) navigate these complexities, understanding market dynamics becomes crucial. Key trends include a growing demand for diverse bottle sizes to cater to specific consumer segments, such as miniatures for sampling and larger formats for events. The rise of e-commerce has also accelerated the need for efficient packaging solutions that protect products during transit while appealing to online shoppers.

Emerging technologies are playing a significant role in sourcing and production. Innovations such as automated manufacturing processes and smart packaging solutions enhance efficiency and reduce lead times. Buyers are increasingly looking for suppliers who can provide flexibility in order quantities and rapid prototyping capabilities to meet the fast-paced market demands. Furthermore, the growth of the craft beverage sector, particularly in regions like South America and Africa, has led to an increased focus on unique bottle designs that enhance brand identity and consumer engagement.

How Important Is Sustainability and Ethical Sourcing in the Bottle Size Sector?

Sustainability is becoming a cornerstone in the bottle size sector, particularly as consumers and businesses alike prioritize environmental responsibility. The environmental impact of packaging is under scrutiny, with a growing demand for sustainable materials and practices. B2B buyers are increasingly seeking suppliers that offer eco-friendly options, such as bottles made from recycled materials or biodegradable alternatives. This shift not only addresses consumer concerns but also aligns with regulatory trends aimed at reducing plastic waste.

Ethical sourcing is equally important, as buyers are more aware of the social implications of their procurement choices. Ensuring that suppliers adhere to fair labor practices and have transparent supply chains is essential for maintaining brand integrity. Certifications such as FSC (Forest Stewardship Council) for paper products and ISO standards for environmental management can serve as indicators of a supplier’s commitment to sustainability. By prioritizing these factors, B2B buyers can enhance their brand reputation and appeal to a growing demographic that values ethical consumption.

What Is the Historical Evolution of Bottle Sizes and Its Relevance Today?

The evolution of bottle sizes has deep historical roots, often reflecting cultural practices and consumer behavior over centuries. Initially, bottle sizes were largely determined by the type of beverage they contained, with standard sizes emerging for spirits, wines, and other beverages. The naming conventions for these sizes, such as “fifth” for 750 ml bottles, have persisted, influencing modern packaging standards.

Today, this historical context is relevant for B2B buyers as it informs the market’s current preferences and trends. Understanding the origins of bottle sizes can provide insight into consumer expectations and the importance of consistency in packaging. As the market continues to evolve, the interplay between tradition and innovation will shape future developments, requiring buyers to stay informed about emerging formats that could redefine the landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle size

-

1. How do I choose the right bottle size for my product?

Choosing the right bottle size depends on various factors, including your target market, product type, and pricing strategy. For spirits, standard sizes like 750 ml or 1 liter are widely accepted, while unique sizes can differentiate your brand. Consider consumer preferences in your region; for instance, smaller bottles may appeal in markets where premium pricing is prevalent. Additionally, assess your distribution channels, as larger sizes might be more suited for wholesale or special events. Engaging with local market research can provide insights into popular sizes in your target demographic. -

2. What is the best bottle size for exporting spirits internationally?

The best bottle size for exporting spirits often aligns with international standards, such as 750 ml for wine and spirits. This size is familiar to consumers globally and complies with regulations in many countries. Additionally, consider the packaging materials, as lightweight options can reduce shipping costs and environmental impact. It’s also crucial to evaluate your target market’s preferences; regions may have unique trends regarding bottle sizes. Engaging with local distributors can provide valuable insights into the most appealing sizes for your intended audience. -

3. How can I customize bottle sizes for my brand?

Customizing bottle sizes involves collaborating with packaging suppliers who offer design and manufacturing flexibility. Start by defining your brand identity and target market to inform your bottle design. Many manufacturers provide options for unique shapes, colors, and sizes that can enhance brand recognition. Be sure to discuss minimum order quantities (MOQs) with suppliers, as custom bottles often require larger runs. Additionally, consider the cost implications of customization, ensuring it aligns with your overall budget and marketing strategy. -

4. What are the minimum order quantities (MOQs) for bottle sizes?

Minimum order quantities (MOQs) for bottle sizes can vary significantly based on the supplier and the complexity of the order. Typically, standard sizes have lower MOQs, while custom designs may require higher quantities to justify production costs. When sourcing bottles, inquire about MOQs upfront to avoid unexpected expenses. Additionally, some suppliers may offer flexibility with MOQs if you are open to a mix of sizes or colors. It’s also wise to factor in future demand when deciding on quantities to ensure you meet market needs without overstocking. -

5. How do I ensure quality assurance for my bottle orders?

To ensure quality assurance for your bottle orders, establish clear specifications and standards with your supplier. Request samples before placing large orders to evaluate materials, finishes, and overall quality. Implement a quality control process that includes inspections at various stages of production, including pre-shipment checks. Additionally, consider working with suppliers who have third-party certifications, as these can indicate adherence to international quality standards. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

6. What payment terms should I expect when sourcing bottles internationally?

Payment terms for international bottle sourcing can vary widely, but common options include upfront payment, net 30/60/90 days, or a letter of credit. Many suppliers may require a deposit (usually 30-50%) before production begins, with the balance due upon shipment. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Additionally, consider using secure payment methods that offer buyer protection, such as escrow services or PayPal. Always ensure that terms are documented in your contract to avoid misunderstandings. -

7. What logistics considerations should I keep in mind when importing bottles?

When importing bottles, logistics considerations include shipping methods, customs regulations, and storage conditions. Choose a shipping method that balances cost and delivery speed; sea freight is often more economical for larger shipments, while air freight offers faster delivery. Ensure compliance with customs regulations in your destination country, including labeling and documentation requirements. Additionally, consider the storage conditions for your bottles upon arrival, as temperature and humidity can affect product integrity. Partnering with a logistics provider experienced in international shipping can streamline this process. -

8. How can I vet suppliers for bottle sizes effectively?

Vetting suppliers for bottle sizes involves conducting thorough research and due diligence. Start by reviewing their reputation through online reviews and industry references. Request samples to assess quality and craftsmanship. Engage in direct communication to gauge their responsiveness and customer service quality. Additionally, verify their production capabilities, certifications, and compliance with international standards. Attending trade shows or industry events can also provide insights into potential suppliers and allow for face-to-face discussions, fostering stronger business relationships.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 4 Bottle Size Manufacturers & Suppliers List

1. Architecture Intérieure du Vin – Wine Bottle Sizes Guide

Domaine : architectureinterieureduvin.com

Enregistré : 2020 (5 ans)

Introduction : A Complete Guide to Different Wine Bottle Sizes: 1. Small Wine Bottles: – Miniature (0.05 L): Smallest wine bottle, used for spirits and liqueurs, rare and sought after by collectors. – Piccolo (0.20 L): Holds enough for a large glass or two small glasses. – Chopine (0.25 L): Similar to piccolo, slightly larger. – Demi (0.375 L): Half a standard bottle, ideal for sharing. – Half-litre (0.5 L)…

2. Roetell – Liquor Bottle Sizes

Domaine : roetell.com

Enregistré : 2019 (6 ans)

Introduction : Different sizes of liquor bottles include: Miniature (50 ml / 1.5-1.7 oz), Quarter Pint (100 ml / 3.4 oz), Half Pint (200 ml / 6.8 oz), Pint (375 ml / 12.6 oz), Fifth (750 ml / 25.4 oz), Liter (1000 ml / 33.8 oz), Magnum (1500 ml / 50.7 oz), Handle (1750 ml / 60 oz), Rehoboam (4500 ml / 152.1 oz). A 750 ml bottle of gin provides 16 standard serves, while a 1 liter vodka bottle has 23 servings. The…

3. SKS Bottle – Custom Containers & Labels

Domaine : sks-bottle.com

Enregistré : 1997 (28 ans)

Introduction : Size Comparison Info, Custom Labels, Caps, Metal Tins, Cans, Plastic Jars, Plastic Bottles, Glass Vials, Glass Jars, Glass Bottles. Categories include: Glass Containers (Clear, Blue, Green, Amber, Frosted), Plastic Containers (Bottles by Color, Shape, Material, Size), Metal Containers (Aluminum Bottles, Cans, Tins), Paperboard Containers, Bulk Containers, Caps/Closures (Brush Caps, Child Resistant…

4. Outshinery – Wine Bottle Sizes Explained

Domaine : outshinery.com

Registered: 2015 (10 years)

Introduction : The article discusses 17 different wine bottle sizes and their names, highlighting the significance of each size in the wine industry. Key sizes mentioned include:

– Piccolo: 187ml, ideal for single servings of sparkling wines.

– Half-Size Bottle: 375ml, convenient for trying new flavors without commitment.

– Standard Bottle: 750ml, the most common size for wine.

– Magnum: 1.5L, suitable for s…

Strategic Sourcing Conclusion and Outlook for bottle size

How Can Strategic Sourcing Enhance Your Bottle Size Selection?

In the competitive landscape of beverage packaging, understanding the nuances of bottle sizes is crucial for businesses aiming to optimize their product offerings. The diverse range of sizes—from standard 750 ml to larger formats like magnums—allows brands to cater to varying consumer preferences and market demands. Strategic sourcing enables companies to align their packaging choices with their branding, ensuring that they not only meet regulatory standards but also resonate with their target audience.

By leveraging insights into regional trends, such as the increasing popularity of eco-friendly materials and unique bottle designs, international buyers can make informed decisions that enhance their market position. For instance, while European markets may favor traditional sizes, emerging markets in Africa and South America might present opportunities for innovative packaging solutions that appeal to local tastes.

As you consider your sourcing strategies, prioritize partnerships with suppliers who offer both variety and customization options. This proactive approach will not only streamline your procurement process but also elevate your brand’s presence in a crowded marketplace. Embrace the future of beverage packaging—explore new bottle sizes and materials that can set your products apart and captivate consumers worldwide.