Introduction: Navigating the Global Market for average cost of water bottles

In the dynamic landscape of international trade, sourcing bottled water at competitive prices poses a significant challenge for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the average cost of water bottles is essential for making informed purchasing decisions that align with budget constraints and market expectations. This comprehensive guide delves into the intricacies of the bottled water market, exploring various types, applications, and pricing strategies that can influence your procurement process.

From understanding the differences between sparkling and non-sparkling options to evaluating bulk purchasing versus retail pricing, this guide equips international buyers with the knowledge needed to navigate the complexities of bottled water sourcing. We will also discuss supplier vetting processes, ensuring that you can identify reliable partners who meet your quality and sustainability standards.

By addressing the key factors that affect bottled water pricing, including regional market variations and consumer purchasing trends, this guide empowers B2B buyers to make strategic decisions that enhance their operational efficiency and cost-effectiveness. Whether you are based in Brazil, Germany, or elsewhere, this resource will serve as your roadmap to successfully sourcing bottled water that meets your business needs while fostering responsible consumption practices.

Navigation dans les articles

- Top 5 Average Cost Of Water Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for average cost of water bottles

- Understanding average cost of water bottles Types and Variations

- Key Industrial Applications of average cost of water bottles

- 3 Common User Pain Points for ‘average cost of water bottles’ & Their Solutions

- Strategic Material Selection Guide for average cost of water bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for average cost of water bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘average cost of water bottles’

- Comprehensive Cost and Pricing Analysis for average cost of water bottles Sourcing

- Alternatives Analysis: Comparing average cost of water bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for average cost of water bottles

- Navigating Market Dynamics and Sourcing Trends in the average cost of water bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of average cost of water bottles

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for average cost of water bottles

Understanding average cost of water bottles Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Single-Serve Bottles | Typically 500ml to 1L, convenient for on-the-go consumption | Corporate events, hospitality, retail | Pour : Easy distribution, high consumer demand; Cons : Higher cost per liter. |

| Bulk Bottled Water | Large containers (e.g., 5-gallon jugs) used for dispensers | Offices, schools, gyms | Pour : Cost-effective for large quantities; Cons : Requires storage space and delivery logistics. |

| Sparkling Water Bottles | Carbonated options, often marketed as premium | Restaurants, hotels, upscale events | Pour : Appeals to niche markets; Cons : Higher price point, limited audience. |

| Flavored Water | Infused with natural flavors, low-calorie options | Health-focused businesses, cafes | Pour : Attracts health-conscious consumers; Cons : Higher production costs, potential for shorter shelf life. |

| Eco-Friendly Bottles | Made from biodegradable or recycled materials | Sustainability-focused companies | Pour : Aligns with eco-friendly branding; Cons : May have higher upfront costs. |

What Are the Key Features of Single-Serve Bottles for B2B Buyers?

Single-serve bottles are usually available in sizes ranging from 500ml to 1 liter, making them ideal for events, corporate functions, and retail settings. Their convenience and portability cater to the fast-paced lifestyles of consumers. B2B buyers should consider the higher cost per liter compared to bulk options, but the ease of distribution and strong consumer demand can justify the expense.

How Do Bulk Bottled Water Options Benefit Businesses?

Bulk bottled water, particularly in 5-gallon jugs, is a popular choice for offices, schools, and gyms. This type of water is more cost-effective for businesses that require hydration for a large number of users. However, buyers must account for logistics, such as delivery schedules and storage space, as well as the need for dispensers.

Why Choose Sparkling Water Bottles for Premium Events?

Sparkling water bottles are often marketed as a premium product, suitable for upscale restaurants, hotels, and events. They can enhance the dining experience and appeal to specific consumer preferences. While they cater to a niche market, B2B buyers should be mindful of the higher price point, which may limit their audience.

What Are the Advantages of Offering Flavored Water?

Flavored water options attract health-conscious consumers and can be a great addition to cafés and health-focused businesses. These products often have lower calories and can be marketed as refreshing alternatives to sugary beverages. However, buyers should consider the higher production costs and potentially shorter shelf life when opting for flavored varieties.

How Do Eco-Friendly Bottles Align with Corporate Sustainability Goals?

Eco-friendly bottled water options are increasingly popular among sustainability-focused companies. These bottles are made from biodegradable or recycled materials, appealing to environmentally conscious consumers. While they may come with higher upfront costs, the alignment with eco-friendly branding can enhance a company’s reputation and customer loyalty.

Key Industrial Applications of average cost of water bottles

| Industrie/secteur | Specific Application of Average Cost of Water Bottles | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| L'hospitalité | Providing bottled water in hotels and restaurants | Enhances guest experience and satisfaction | Assess local suppliers for pricing, quality, and delivery |

| Corporate Offices | Supplying bottled water for employee hydration | Improves employee productivity and wellness | Evaluate bulk purchasing options and delivery schedules |

| Events and Catering | Offering bottled water at conferences and events | Boosts event quality and attendee satisfaction | Consider logistics for high-volume orders and sourcing costs |

| Vente au détail | Selling bottled water in supermarkets and convenience stores | Generates additional revenue and attracts customers | Analyze market trends and competitor pricing |

| Soins de santé | Providing bottled water in hospitals and clinics | Ensures patient hydration and comfort | Ensure compliance with health regulations and sourcing quality |

How is the Average Cost of Water Bottles Utilized in the Hospitality Industry?

In the hospitality sector, the average cost of water bottles plays a crucial role in enhancing guest experiences in hotels and restaurants. Offering bottled water can significantly improve customer satisfaction, especially in regions where tap water is not safe to drink. B2B buyers in this industry must consider sourcing from local suppliers to ensure competitive pricing and timely delivery, as well as the quality of the water, which can vary widely.

What Benefits Does Bottled Water Provide to Corporate Offices?

Corporate offices increasingly recognize the importance of hydration for employee productivity and overall wellness. The average cost of water bottles is a key consideration for businesses looking to supply their staff with convenient hydration options. B2B buyers should explore bulk purchasing agreements to reduce costs and ensure a steady supply. Additionally, evaluating the environmental impact of bottled water versus sustainable alternatives can be a significant factor in sourcing decisions.

How is Bottled Water Essential for Events and Catering?

Events and catering services heavily rely on the average cost of bottled water to enhance the quality of their offerings. Providing bottled water at conferences or social gatherings not only meets hydration needs but also contributes to a positive attendee experience. Buyers in this sector must consider logistics for high-volume orders, including sourcing costs and delivery timelines, to ensure they meet the demands of their events.

What Role Does Bottled Water Play in Retail?

In retail, the average cost of water bottles is critical for generating additional revenue. Supermarkets and convenience stores can attract customers by offering a variety of bottled water options at competitive prices. B2B buyers should analyze market trends and competitor pricing to establish their pricing strategy, ensuring they remain competitive while maximizing profit margins.

How is Bottled Water Used in Healthcare Settings?

In healthcare environments, the provision of bottled water is essential for patient comfort and hydration. The average cost of water bottles must be carefully managed to ensure that healthcare facilities can provide this service without incurring excessive costs. Compliance with health regulations and the sourcing of high-quality bottled water are paramount considerations for B2B buyers in this sector, as patient health and safety are always the top priority.

3 Common User Pain Points for ‘average cost of water bottles’ & Their Solutions

Scenario 1: Fluctuating Prices Create Budgeting Challenges

Le problème : B2B buyers often face the challenge of fluctuating prices for bottled water, making it difficult to create accurate budgets. For companies that rely on bottled water for employee hydration or customer service, unexpected price increases can lead to overspending or unplanned budget reallocations. This volatility is particularly acute for businesses operating in regions where import tariffs, currency fluctuations, or supply chain disruptions affect the cost of bottled water. Buyers need a reliable pricing structure to ensure they can maintain their hydration needs without compromising their financial stability.

La solution : To mitigate the impact of fluctuating prices, B2B buyers should establish long-term contracts with suppliers that guarantee fixed pricing over a specified period. This can help lock in prices and provide predictability in budgeting. Additionally, buyers can conduct market research to identify suppliers with competitive pricing structures and reliable supply chains. Utilizing online platforms to compare prices across different vendors can also be beneficial. Buyers should consider bulk purchasing options, as buying in larger quantities can lead to significant savings. Establishing a relationship with local manufacturers may also yield lower costs due to reduced shipping fees and tariffs.

Scenario 2: Quality Concerns with Low-Cost Options

Le problème : While seeking cost-effective solutions, B2B buyers may encounter low-priced bottled water that compromises quality. This is particularly concerning in industries where the reputation for providing safe and healthy products is paramount. Using inferior-quality water can lead to negative customer experiences, potential health risks, and damage to the brand’s reputation. Buyers must navigate the trade-off between cost and quality to ensure they are providing a safe product without overspending.

La solution : To address quality concerns, buyers should prioritize sourcing bottled water from reputable suppliers with transparent quality assurance processes. Requesting certifications and third-party testing results can help verify the quality of the water being purchased. Establishing criteria for selecting suppliers based on their production standards, sourcing methods, and environmental sustainability practices can ensure that buyers get high-quality water at a reasonable cost. Furthermore, implementing a trial period where smaller quantities of water are tested for quality and taste before committing to larger purchases can help mitigate risks associated with low-cost options.

Scenario 3: Sustainability and Environmental Impact of Bottled Water

Le problème : B2B buyers are increasingly pressured to consider the environmental impact of their purchasing decisions, particularly when it comes to bottled water. The reliance on single-use plastic bottles not only contributes to environmental degradation but can also harm a company’s reputation, especially among environmentally conscious consumers. Buyers may struggle to find a balance between providing hydration solutions and adhering to sustainability goals.

La solution : To align bottled water purchases with sustainability goals, buyers should explore alternative solutions such as refillable water stations or bottleless water coolers that filter tap water on-site. These options significantly reduce plastic waste and the carbon footprint associated with bottled water delivery. Additionally, buyers can partner with suppliers that prioritize sustainable practices, such as using recycled materials for packaging or adopting eco-friendly production methods. Incorporating sustainability metrics into the supplier evaluation process will help ensure that the chosen vendors align with the company’s environmental goals. Promoting the use of reusable bottles among employees can further enhance sustainability efforts while also reducing long-term costs associated with bottled water purchases.

Strategic Material Selection Guide for average cost of water bottles

What Are the Common Materials for Bottled Water and Their Costs?

When selecting materials for bottled water, international B2B buyers must consider various factors that influence both cost and performance. The most common materials used in bottled water production include plastic (PET), glass, aluminum, and biodegradable options. Each material has distinct properties, advantages, and limitations that can affect the overall cost and suitability for different markets.

How Does Plastic (PET) Perform in Bottled Water Applications?

Polyethylene terephthalate (PET) is the most widely used material for bottled water due to its lightweight nature and excellent barrier properties. PET bottles can withstand temperatures up to 60°C and are resistant to moisture and gases, making them ideal for preserving the quality of water.

Pour : PET is cost-effective, with low manufacturing complexity. It is also recyclable, appealing to environmentally conscious consumers.

Cons : However, PET bottles can degrade when exposed to high temperatures over time, potentially leaching harmful substances. Additionally, their environmental impact, particularly in regions with inadequate recycling facilities, can be a concern.

Considerations for Buyers: Buyers in Africa and South America should be aware of local recycling capabilities and regulations regarding plastic use. Compliance with international standards like ASTM and DIN is crucial, especially in Europe, where sustainability is increasingly prioritized.

What Advantages Does Glass Offer for Bottled Water?

Glass is another popular choice for bottled water, particularly premium brands. It is highly resistant to chemical leaching and can maintain the taste and purity of the water.

Pour : Glass bottles are reusable and recyclable, which aligns with sustainability initiatives. They also provide a premium feel, enhancing brand perception.

Cons : The primary drawback is the higher cost of production and transportation due to weight. Glass is also more fragile, posing risks during shipping and handling.

Considerations for Buyers: In Europe, where glass recycling is well-established, buyers may find glass bottles more appealing. However, in regions like the Middle East and parts of Africa, the cost and fragility may limit their practicality.

How Does Aluminum Compare for Bottled Water?

Aluminum is emerging as an alternative for bottled water, especially in the context of sustainability. It offers excellent barrier properties and is lightweight, making it easy to transport.

Pour : Aluminum is infinitely recyclable, which can significantly reduce its environmental footprint. It also provides a unique branding opportunity, as many consumers are attracted to innovative packaging.

Cons : The cost of aluminum production can be higher than that of plastic, and it may not be as widely accepted in all markets. Additionally, aluminum can react with certain beverages if not properly coated.

Considerations for Buyers: Buyers in Europe may find aluminum bottles appealing due to their sustainability credentials, while those in regions like South America may need to assess local acceptance and infrastructure for recycling.

What Are the Benefits of Biodegradable Materials?

Biodegradable materials, such as PLA (polylactic acid), are gaining traction as eco-friendly alternatives to traditional plastics. These materials can decompose under specific conditions, reducing environmental impact.

Pour : They cater to the growing demand for sustainable packaging solutions and can enhance brand image.

Cons : The cost of biodegradable materials is generally higher, and they may not perform as well in terms of durability and shelf life compared to PET or glass.

Considerations for Buyers: Buyers should evaluate the market demand for sustainable products in their regions, especially in Europe, where environmental regulations are stringent.

Summary Table of Material Selection for Bottled Water

| Matériau | Typical Use Case for average cost of water bottles | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Plastic (PET) | Standard bottled water for mass consumption | Léger et rentable | Potential leaching at high temps | Faible |

| Verre | Premium bottled water brands | Maintains purity and taste | Higher cost and fragile | Haut |

| Aluminium | Eco-friendly bottled water | Infinitely recyclable | Higher production cost | Moyen |

| Biodegradable | Sustainable bottled water solutions | Reduces environmental impact | Higher cost and limited durability | Haut |

Understanding the properties, advantages, and limitations of these materials will empower B2B buyers to make informed decisions that align with market demands and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for average cost of water bottles

What Are the Main Stages of the Manufacturing Process for Bottled Water?

The manufacturing process for bottled water involves several critical stages that ensure the final product is safe, high-quality, and compliant with international standards. Understanding these stages can help B2B buyers evaluate suppliers more effectively.

1. Material Preparation

The first step in the manufacturing process is sourcing and preparing the raw materials. This includes the selection of high-quality water sources, which can vary depending on the type of bottled water being produced, such as spring, mineral, or purified water. Additionally, the materials for the bottles, typically PET (Polyethylene Terephthalate), are sourced. Quality checks are essential at this stage to ensure that both the water and the materials meet regulatory standards.

2. Forming

Once materials are prepared, the next stage involves forming the bottles. This process typically includes extrusion and blow molding techniques, where the PET material is melted and shaped into preforms before being blown into the desired bottle shape. The precision of this process is crucial for maintaining the structural integrity of the bottles and ensuring they can withstand transportation and handling.

3. Assembly

In the assembly stage, various components such as caps and labels are added to the bottles. This step may involve automated systems for efficiency and consistency. Quality control is vital here, as any defects in the caps or labels can lead to leaks or misbranding, which could result in regulatory issues.

4. Finishing

The final stage involves the cleaning and sanitization of the filled bottles. This is done to eliminate any potential contaminants that may have been introduced during the manufacturing process. Bottles are typically subjected to high-pressure rinsing and UV treatment to ensure they are sterile before packaging.

How Is Quality Assurance Integrated into the Bottled Water Manufacturing Process?

Quality assurance (QA) is an integral component of the bottled water manufacturing process, ensuring compliance with both international and industry-specific standards.

Relevant International Standards for Bottled Water Quality

B2B buyers should be aware of various international standards that govern the bottled water industry, including ISO 9001, which focuses on quality management systems, and ISO 22000, which pertains to food safety management. Compliance with these standards signifies that the manufacturer adheres to a consistent quality control process.

Quels sont les principaux points de contrôle de la qualité ?

Quality control (QC) checkpoints are established at various stages throughout the manufacturing process:

-

Contrôle de la qualité à l'arrivée (IQC) : This involves inspecting raw materials upon arrival to ensure they meet specified quality standards. For bottled water, this includes testing the water source and bottle materials for contaminants.

-

Contrôle de la qualité en cours de fabrication (IPQC) : During the manufacturing process, regular checks are conducted to monitor the production line for any deviations from quality standards. This includes monitoring the temperatures during bottle formation and ensuring the correct filling levels.

-

Contrôle de qualité final (CQF) : Before the products are packaged and shipped, a final inspection is conducted. This may include checks for bottle integrity, cap sealing, and label accuracy. Common testing methods include pressure testing, microbiological testing, and chemical analyses.

Comment les acheteurs B2B peuvent-ils vérifier les pratiques de contrôle de la qualité des fournisseurs ?

B2B buyers need to ensure that their suppliers have robust quality control measures in place. Here are actionable steps to verify supplier QC practices:

Conducting Audits and Reviews

One effective way to verify a supplier’s QC processes is through on-site audits. These audits can assess the supplier’s adherence to quality standards, their manufacturing processes, and their overall commitment to quality. Buyers should request access to quality management system documentation and audit reports to gauge compliance.

Requesting Quality Assurance Reports

Suppliers should be willing to provide detailed reports on their QC processes, including test results from various stages of production. These documents can provide insights into how often they test their products and the outcomes of those tests.

Utilizing Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing processes and QC practices. These firms can conduct random checks and provide detailed reports on compliance with international standards.

Quelles sont les particularités du contrôle de la qualité pour les acheteurs internationaux B2B ?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, there are several nuances to consider regarding quality control:

Understanding Regional Regulations

Different regions may have varying regulations concerning bottled water quality. For example, European Union regulations may differ significantly from those in South America. B2B buyers must ensure that suppliers comply with both local and international standards to avoid legal issues.

Language Barriers and Documentation

Language differences can pose challenges when reviewing quality control documentation. Buyers should ensure that all critical documents are available in a language they understand to effectively assess compliance with quality standards.

Cultural Differences in Quality Assurance Practices

Cultural perceptions of quality and safety can differ across regions. B2B buyers should be aware of these differences and communicate their quality expectations clearly to suppliers.

Conclusion: The Importance of Quality in Bottled Water Manufacturing

Understanding the manufacturing processes and quality assurance practices associated with bottled water is crucial for B2B buyers. By evaluating suppliers based on their adherence to international standards, their QC checkpoints, and their willingness to provide detailed quality documentation, buyers can make informed decisions that ensure they receive a safe, high-quality product. As the demand for bottled water continues to rise globally, maintaining high-quality standards will be essential for sustaining customer trust and market competitiveness.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘average cost of water bottles’

To effectively navigate the procurement of bottled water, particularly in the context of average costs, this guide provides a structured checklist for international B2B buyers. Understanding the nuances of pricing and supplier selection can lead to significant cost savings and enhanced supplier relationships.

Étape 1 : Determine Your Requirements

Identify the specific types of bottled water you need, such as still, sparkling, or flavored varieties. This step is crucial as different types may come with varying costs and supplier availability. Consider your target market and consumer preferences to ensure you meet demand effectively.

Étape 2 : Research Market Prices

Conduct thorough research on the average prices of bottled water in your target regions. Utilize resources like industry reports and local supplier quotes to understand current pricing trends. Being informed about the typical price range will empower you to negotiate effectively with suppliers.

Étape 3 : Evaluate Supplier Certifications

Before engaging with suppliers, verify their certifications and compliance with local regulations. This includes checking for food safety standards and sustainability practices. Suppliers with recognized certifications not only ensure product quality but also align with growing consumer expectations for responsible sourcing.

Étape 4 : Demande d'échantillons

Always request product samples before finalizing a supplier. This allows you to assess the quality of the bottled water and its packaging. Pay attention to factors such as taste, packaging integrity, and branding, as these elements can significantly impact customer satisfaction and your brand’s reputation.

Étape 5 : Analyze Total Cost of Ownership

Look beyond the unit price of bottled water and consider the total cost of ownership (TCO). This includes delivery fees, storage costs, and potential wastage. Understanding the TCO will provide a more accurate picture of what you will spend in the long run, aiding in budget planning.

Étape 6 : Negotiate Terms and Conditions

Once you have selected potential suppliers, engage in negotiations to secure favorable terms. Discuss pricing, payment terms, delivery schedules, and return policies. Strong negotiation can lead to better pricing and more flexible arrangements, which are essential for maintaining cash flow.

Étape 7 : Establish a Long-term Relationship

After selecting a supplier, focus on building a long-term partnership. Regular communication and feedback will help ensure that your supplier meets your ongoing needs and can adapt to changes in demand or pricing. A strong relationship can also lead to better service and potential discounts in the future.

By following this checklist, B2B buyers can streamline their procurement process for bottled water, ensuring that they not only secure competitive pricing but also foster beneficial supplier relationships.

Comprehensive Cost and Pricing Analysis for average cost of water bottles Sourcing

What Are the Key Cost Components in Bottled Water Sourcing?

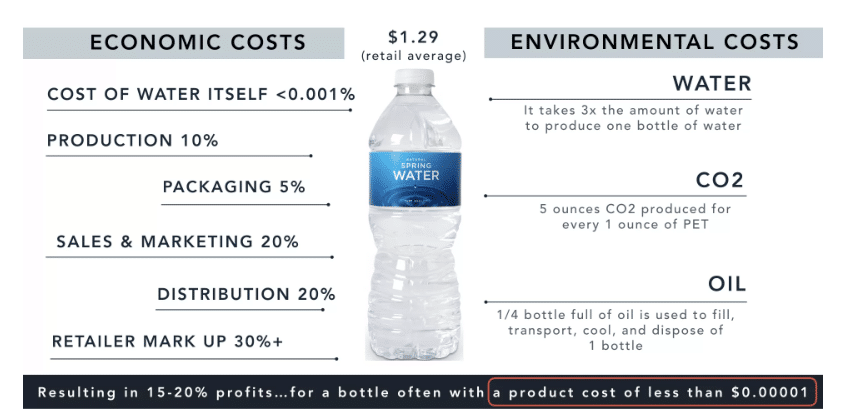

Understanding the cost structure of bottled water is essential for B2B buyers, particularly when sourcing for international markets. The average cost of bottled water includes several critical components:

-

Matériaux: The primary material for bottled water is plastic (PET) or glass, which significantly influences the overall cost. The price of resin can fluctuate based on market conditions, impacting the final product price. Additionally, the quality of the water itself (spring, mineral, or purified) can affect sourcing costs.

-

Travail: Labor costs vary by region and the complexity of the production process. For instance, countries with lower labor costs may yield cheaper bottled water, but this could also reflect on the product quality. Skilled labor for bottling operations and quality control can add to the cost.

-

Frais généraux de fabrication: This includes expenses related to utilities, maintenance of machinery, and other operational costs. Efficient manufacturing processes can help reduce overhead, allowing companies to offer competitive pricing.

-

Tooling and Equipment: Initial setup costs for bottling machinery can be substantial. These costs are amortized over the production volume, so larger orders can help in reducing the per-unit cost.

-

Contrôle de la qualité (CQ): Ensuring that bottled water meets safety and quality standards is vital. This involves additional costs for testing and compliance with local regulations, which can vary greatly between countries.

-

Logistique: Transportation costs are significant, especially for international shipping. Factors such as distance, mode of transport, and local infrastructure can impact logistics costs. The choice of Incoterms also plays a crucial role in determining who bears these costs.

-

Marge: Suppliers typically mark up prices to ensure profitability. Understanding the standard margins in your target market can help in negotiations and budgeting.

How Do Price Influencers Affect Bottled Water Costs?

Several factors influence the pricing of bottled water, particularly for B2B buyers looking for cost-effective solutions:

-

Volume et quantité minimale de commande (QMC): Buying in bulk often leads to lower prices per unit. Suppliers may offer discounts for higher volumes, making it essential to assess your needs accurately.

-

Spécifications et personnalisation: Custom labels or specific bottle designs can increase costs. Standardization can reduce expenses, so consider whether customization is necessary for your brand.

-

Matériaux et certifications de qualité: Premium materials or certifications (e.g., organic, non-GMO) can raise costs. Buyers should weigh the benefits of premium products against budget constraints.

-

Facteurs liés au fournisseur: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer greater assurance of quality and service.

-

Incoterms: The choice of Incoterms affects who is responsible for shipping costs, insurance, and risks during transit. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Practices for Negotiating Bottled Water Prices?

Effective negotiation strategies can significantly enhance cost efficiency for B2B buyers:

-

Comprendre le coût total de possession (TCO): Consider not just the purchase price but all associated costs, including logistics, storage, and handling. This holistic view can inform better purchasing decisions.

-

Leverage Market Research: Knowledge of current market prices and trends can provide leverage in negotiations. Being informed about competitor pricing can help you negotiate better deals.

-

Établir des relations avec les fournisseurs: Long-term partnerships can lead to better terms and pricing. Trust and reliability often yield favorable pricing adjustments.

-

Explore Alternative Suppliers: Diversifying your supplier base can create competition, prompting existing suppliers to offer better prices to retain your business.

-

Be Aware of Pricing Nuances in International Markets: Different regions have unique market dynamics. For example, bottled water may be cheaper in Egypt compared to Germany. Understanding these differences can guide sourcing strategies.

Conclusion

While the average cost of bottled water can vary significantly based on a multitude of factors, B2B buyers can navigate this landscape effectively by focusing on the key cost components, understanding pricing influencers, and employing strategic negotiation tactics. By doing so, companies can make informed decisions that align with their budgetary constraints and quality requirements.

Clause de non-responsabilité: The prices mentioned are indicative and can fluctuate based on market conditions, supplier negotiations, and local economic factors. Always conduct thorough research and obtain quotes from multiple suppliers before finalizing any agreements.

Alternatives Analysis: Comparing average cost of water bottles With Other Solutions

Exploring Alternative Water Solutions Beyond Bottled Water

In the pursuit of efficient hydration solutions, businesses often evaluate the average cost of bottled water against alternative methods. As sustainability and cost-effectiveness become increasingly important in B2B procurement, understanding these alternatives can provide significant advantages. Below, we compare bottled water with two viable alternatives: bottleless water coolers and water delivery services.

| Aspect comparatif | Average Cost Of Water Bottles | Bottleless Water Cooler | Water Delivery Service |

|---|---|---|---|

| Performance | Good for individual consumption | High capacity for multiple users, consistent quality | Varies by supplier, often good |

| Coût | $1.44 per gallon (wholesale) | Installation ~$199; monthly fees lower than bottled | Varies, often higher than bottleless |

| Facilité de mise en œuvre | Simple to purchase and use | Requires installation but low ongoing effort | Requires scheduling and management |

| Maintenance | None | Regular filter changes needed | Regular delivery coordination |

| Meilleur cas d'utilisation | Small offices, events | Larger offices with consistent water needs | Remote locations or occasional events |

What Are the Advantages and Disadvantages of Bottleless Water Coolers?

Bottleless water coolers connect directly to the existing water supply, filtering and providing fresh water on demand. This solution is particularly beneficial for larger offices where hydration needs are high.

Pour :

– Cost-Effective: Over time, the cost savings from not purchasing bottled water can be substantial. The average bottled water costs about $1.29 per bottle, while a bottleless system significantly reduces per-gallon costs.

– Sustainability: These systems help reduce plastic waste and carbon emissions associated with bottled water transportation.

Cons :

– Initial Setup Cost: The upfront installation fee may deter some businesses, although long-term savings usually outweigh this initial investment.

– Maintenance Requirements: Regular maintenance and filter changes are necessary to ensure water quality, adding to the operational workload.

How Does Water Delivery Service Compare to Bottled Water?

Water delivery services provide bottled water directly to your location, typically on a scheduled basis. This method is often preferred by businesses in remote areas or those with sporadic hydration needs.

Pour :

– Convenience: Delivery services handle logistics, making it easy for businesses to maintain hydration without managing inventory.

– Flexibility: Companies can order various sizes and types of bottled water, catering to specific tastes and requirements.

Cons :

– Higher Costs: Regular delivery can become expensive over time, especially compared to the lower long-term costs of bottleless systems.

– Logistical Challenges: Managing delivery schedules and ensuring timely replenishments can be an operational hassle.

How Should B2B Buyers Decide on the Best Water Solution?

When choosing the right hydration solution, B2B buyers should assess their specific needs, including the size of their workforce, budget constraints, and sustainability goals. For companies looking for a cost-effective, eco-friendly solution with minimal maintenance, bottleless water coolers are an excellent choice. Conversely, businesses in remote locations or those needing flexibility in their water supply may benefit more from a reliable water delivery service. Evaluating these aspects will enable businesses to make informed decisions that align with their operational goals and values.

Essential Technical Properties and Trade Terminology for average cost of water bottles

What Are the Key Technical Properties of Water Bottles That Affect Their Average Cost?

When considering the average cost of water bottles, several technical properties play a crucial role. Understanding these specifications can help B2B buyers make informed purchasing decisions.

1. Material Grade

Water bottles are commonly made from materials such as PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and glass. The material grade influences the bottle’s durability, weight, and recyclability. PET is lightweight and widely used for single-use bottles, whereas HDPE is more robust, making it suitable for reusable options. Buyers should assess material grades to align with their sustainability goals and cost constraints.

2. Capacity

The capacity of water bottles typically ranges from 500ml to 5 gallons. Understanding capacity is essential for bulk purchasing, especially for businesses aiming to meet the hydration needs of employees or customers. Larger capacity bottles often offer a lower cost per liter, making them a cost-effective solution for businesses.

3. Closure Type

The closure of a water bottle—whether it is a screw cap, flip-top, or sports cap—affects usability and customer satisfaction. A secure closure prevents leaks during transport, which is vital for suppliers and distributors. The choice of closure can also impact production costs, as certain types may require specialized machinery or materials.

4. Tolerance

Tolerance refers to the acceptable variations in dimensions during manufacturing. For example, a tolerance of ±0.5mm might be specified for bottle necks. High tolerance levels ensure that bottles fit securely with closures, reducing the likelihood of leaks or breakage. This is particularly important for bulk buyers who require uniformity for efficient packing and shipping.

5. Labeling and Branding Options

The ability to customize labels and branding directly impacts a bottle’s marketability and cost. Options may include shrink sleeves, pressure-sensitive labels, or direct printing. Custom branding can enhance product visibility but may also increase production costs. Buyers should evaluate the balance between branding needs and overall budget.

What Are Common Trade Terms Related to Water Bottle Costs That Buyers Should Know?

Understanding industry terminology can streamline negotiations and procurement processes for B2B buyers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. In the bottled water industry, an OEM may manufacture bottles for various brands. Knowing about OEMs can help buyers identify potential suppliers and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For bottled water, MOQs can vary significantly based on the supplier’s production capabilities. Understanding MOQs is essential for B2B buyers to plan inventory and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. B2B buyers use RFQs to compare costs, delivery times, and terms from various suppliers. This process is vital for ensuring competitive pricing and securing favorable conditions.

4. Incoterms (conditions commerciales internationales)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B buyers to understand shipping costs and risk management.

5. Sustainability Certifications

Many buyers are now looking for sustainability certifications (e.g., ISO 14001) that indicate a supplier’s commitment to environmentally friendly practices. Understanding these certifications can help businesses align their procurement strategies with corporate social responsibility goals.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of the bottled water market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the average cost of water bottles Sector

What Are the Key Trends Influencing the Average Cost of Water Bottles?

The bottled water market is experiencing significant shifts influenced by various global drivers, particularly for B2B buyers from regions like Africa, South America, the Middle East, and Europe. The average wholesale price for non-sparkling bottled water is currently around $1.44 per gallon, reflecting a competitive landscape where mass merchandisers and online platforms dominate sales channels, accounting for over 37% of purchases. Buyers are increasingly looking for cost-effective sourcing options, emphasizing bulk purchases to leverage economies of scale.

Emerging trends in technology, such as the rise of e-commerce platforms, are reshaping how businesses source bottled water. Companies are utilizing data analytics and AI-driven solutions to track pricing, forecast demand, and optimize inventory management. Additionally, businesses are increasingly leaning towards suppliers that offer flexible pricing models and transparent supply chain practices, which are critical for maintaining profitability in a fluctuating market.

As global concerns regarding water scarcity and pollution grow, B2B buyers are also seeking suppliers who can demonstrate resilience and adaptability in their operations. This includes diversifying sourcing strategies to mitigate risks associated with climate change and geopolitical tensions that can disrupt supply chains.

How Is Sustainability Shaping Sourcing Decisions in the Bottled Water Sector?

Sustainability has emerged as a pivotal factor in the sourcing of bottled water, particularly among B2B buyers who are increasingly aware of their environmental impact. The bottled water industry faces scrutiny for its reliance on single-use plastics, which contribute significantly to pollution. Consequently, businesses are prioritizing suppliers that adopt sustainable practices, such as using recycled materials or offering bottleless water cooler solutions that reduce plastic waste.

Ethical sourcing is becoming a key differentiator in supplier selection. Buyers are looking for certifications that guarantee environmentally friendly practices, such as ISO certification for sustainable manufacturing processes or certifications from recognized environmental organizations. These credentials not only enhance brand reputation but also align with the growing consumer demand for corporate social responsibility.

Moreover, the transition to more sustainable packaging options, such as biodegradable or reusable containers, is gaining traction. Companies that proactively engage in these practices are not only reducing their carbon footprint but also appealing to a broader audience that values sustainability, ultimately influencing their market positioning and pricing strategies.

What Is the Historical Context of the Bottled Water Industry?

The bottled water industry has undergone a remarkable transformation since its inception in the early 20th century. Initially considered a luxury item, bottled water has evolved into a staple consumer product. The 1970s marked a significant turning point with the introduction of mass-produced bottled water, making it accessible to a wider audience.

By the late 1990s and early 2000s, the industry saw exponential growth fueled by rising health consciousness and lifestyle changes, leading to increased demand for convenient hydration options. Today, the sector is characterized by intense competition, with numerous brands vying for market share, making it crucial for B2B buyers to stay informed about pricing trends and sourcing options to navigate this dynamic landscape effectively.

Understanding these historical shifts provides valuable insights into current market dynamics, helping international buyers make informed decisions when sourcing bottled water.

Frequently Asked Questions (FAQs) for B2B Buyers of average cost of water bottles

-

How do I determine the average cost of bottled water for bulk purchases?

To determine the average cost of bottled water for bulk purchases, consider factors such as the source, packaging, and local market conditions. Research wholesale prices, which can average around $1.44 per gallon in many markets. Additionally, suppliers often offer discounts for larger orders. Engage with multiple suppliers to compare prices and ask for quotes that include shipping and handling to get a clearer picture of total costs. -

What is the best way to source bottled water suppliers internationally?

The best way to source bottled water suppliers internationally is to utilize trade platforms such as Alibaba or Global Sources, where you can filter suppliers by region and product type. Attend industry trade shows to network and establish direct relationships with manufacturers. Additionally, verify suppliers through references and certifications, ensuring they meet quality standards and can handle the logistical requirements of international shipping. -

What are the minimum order quantities (MOQs) for bottled water?

Minimum order quantities (MOQs) for bottled water can vary significantly by supplier and region. Typically, MOQs range from 500 to 5,000 bottles depending on the supplier’s production capabilities and your specific requirements. It is advisable to discuss MOQs directly with potential suppliers to negotiate terms that align with your business needs, especially if you are looking to test the market before committing to larger orders. -

What customization options are available for bottled water?

Many suppliers offer customization options for bottled water, including label design, bottle shape, and size. Custom labeling allows businesses to enhance brand recognition and marketing efforts. Depending on the supplier, you may also have the option to choose different water sources, such as spring or mineral water. Ensure you discuss these options upfront and obtain samples to evaluate the quality of custom products before placing a bulk order. -

What payment terms should I expect when sourcing bottled water internationally?

Payment terms when sourcing bottled water internationally can vary widely based on the supplier’s policies and your negotiation skills. Common terms include a deposit of 30-50% upfront with the balance due upon delivery or shipment. Some suppliers may offer credit terms for established buyers. It’s crucial to establish clear payment methods, such as wire transfers or letters of credit, to protect your interests and ensure a smooth transaction. -

How can I ensure quality assurance for bottled water products?

To ensure quality assurance for bottled water products, request certifications such as ISO or NSF from suppliers, which indicate adherence to international quality standards. Conduct regular audits or inspections of the manufacturing facilities if possible. Additionally, consider requesting product samples for testing in your own quality control processes before committing to larger orders. Establishing a strong communication channel with suppliers can also help address any quality concerns promptly. -

What are the logistics considerations for importing bottled water?

Logistics considerations for importing bottled water include understanding shipping costs, customs regulations, and local distribution methods. Assess the best shipping options (air, sea, or land) based on urgency and budget. Familiarize yourself with import duties and taxes that may apply in your country. Collaborating with a freight forwarder can streamline the process, helping you navigate documentation and ensuring timely delivery of your products. -

How do regional pricing differences affect bottled water sourcing?

Regional pricing differences can significantly affect bottled water sourcing due to factors like local demand, supply chain costs, and regulatory environments. For instance, bottled water may be cheaper in regions with abundant natural springs. Conversely, areas with stricter regulations or higher transportation costs may see increased prices. Conduct thorough market research to understand these dynamics and consider sourcing from regions with favorable pricing while maintaining quality standards.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 5 Average Cost Of Water Bottles Manufacturers & Suppliers List

1. Water – 0.5L Bottles

Domaine : reddit.com

Enregistré : 2005 (20 ans)

Introduction : 0.5 L bottle of water; prices vary by location and purchase method; bulk pricing example: 35-pack for $4.99 (~$0.14 per bottle); single bottles typically around $1; preference for chilled drinks in convenience stores; room temperature options available at grocery stores.

2. Global Bottled Water Prices – Key Insights

Domaine : statista.com

Enregistré : 2005 (20 ans)

Introduction : A 1.5-liter bottle of water costs an average of $0.70 globally. The most expensive markets are Australia and the Philippines, at $2.02 per bottle. Other high-priced countries include Singapore, Uruguay, Puerto Rico, and Norway, with prices ranging from $1.59 to $1.74. The lowest prices are found in Egypt and Tunisia, at $0.

3. Culligan – Bottleless Water Coolers

Domaine : quench.culligan.com

Enregistré : 1997 (28 ans)

Introduction : Culligan Quench offers bottleless water coolers that connect to existing water lines and filter water on-site. Key features include:

– Built-in advanced filtration technology (reverse osmosis, touchless dispensing)

– Cost savings on bottled water and delivery services

– Installation fees starting at $199

– Monthly service fees

– Reduction of carbon emissions by 53% when switching from jug del…

4. Green Dispatch – Bottled Water Insights

Domaine : greendispatch.substack.com

Registered: 2010 (15 years)

Introduction : Bottled water is expensive, costing about $1.50 for a 16-ounce bottle, which equates to $12.00 per gallon, while tap water costs approximately $0.02 per gallon. Bottled water may not be safer than tap water, as studies show bacterial growth can be higher in bottled water stored at warm temperatures. The FDA sets lower standards for bottled water compared to the EPA’s standards for tap water. Most …

5. Drink Optimum – Workplace Water Solutions

Domaine : drinkoptimum.com

Enregistré : 2016 (9 ans)

Introduction : Workplace water costs associated with bottled water and alternatives. Bottled water options include a 40-pack from Walmart costing approximately $5.36, with monthly costs for teams ranging from $26.80 for a 2-person team to $241.20 for an 18-person team. 5-gallon water jugs cost around $7.49 each, with monthly costs from $37.45 for a 2-person team to $337.05 for an 18-person team. Alternatives sug…

Strategic Sourcing Conclusion and Outlook for average cost of water bottles

In navigating the complex landscape of bottled water pricing, international B2B buyers must strategically assess sourcing options to optimize costs while ensuring quality. The average wholesale price of bottled water has reached approximately $1.44 per gallon, influenced by factors such as market demand, geographical variations, and purchasing volumes. Bulk purchases from mass merchandisers can yield significant savings, highlighting the importance of understanding local market dynamics, particularly in regions like Africa, South America, the Middle East, and Europe.

Strategic sourcing not only aids in cost management but also enhances supply chain efficiency and sustainability. As companies increasingly face pressure to adopt eco-friendly practices, exploring alternatives such as bottleless water solutions can significantly reduce both financial and environmental footprints.

Looking ahead, international buyers are encouraged to evaluate their current water sourcing strategies and consider innovative solutions that align with their operational goals and sustainability commitments. By leveraging market insights and prioritizing strategic partnerships, businesses can navigate pricing fluctuations and position themselves for long-term success in the bottled water market.