Introduction: Navigating the Global Market for shaker bottle ball

In the competitive landscape of fitness and wellness, sourcing high-quality shaker bottle balls presents a unique challenge for international B2B buyers. As the demand for effective and durable mixing solutions grows, understanding the nuances of shaker bottle ball manufacturing becomes crucial. This guide delves into the diverse types of shaker balls available, their various applications, and the critical factors to consider when vetting suppliers. With a focus on cost analysis and quality assurance, we aim to equip businesses across Africa, South America, the Middle East, and Europe—such as Nigeria and Germany—with the insights needed to make informed purchasing decisions.

Navigating the global market for shaker bottle balls involves more than just identifying products; it requires a strategic approach to sourcing and supplier relationships. Whether you are looking to enhance your product line or secure reliable materials for production, this comprehensive guide serves as a roadmap. By addressing key considerations—from material quality and design features to supplier reliability and pricing strategies—we empower B2B buyers to confidently choose the best shaker bottle balls for their specific needs. Your investment in this guide could lead to significant improvements in product offerings and customer satisfaction, ensuring your business thrives in a rapidly evolving market.

Navigation dans les articles

- Top 9 Shaker Bottle Ball Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for shaker bottle ball

- Understanding shaker bottle ball Types and Variations

- Key Industrial Applications of shaker bottle ball

- 3 Common User Pain Points for ‘shaker bottle ball’ & Their Solutions

- Strategic Material Selection Guide for shaker bottle ball

- In-depth Look: Manufacturing Processes and Quality Assurance for shaker bottle ball

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘shaker bottle ball’

- Comprehensive Cost and Pricing Analysis for shaker bottle ball Sourcing

- Alternatives Analysis: Comparing shaker bottle ball With Other Solutions

- Essential Technical Properties and Trade Terminology for shaker bottle ball

- Navigating Market Dynamics and Sourcing Trends in the shaker bottle ball Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shaker bottle ball

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for shaker bottle ball

Understanding shaker bottle ball Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Stainless Steel Ball | Durable, rust-resistant, and often insulated | Fitness and nutrition product manufacturers | Pour : Long-lasting, maintains temperature; Cons : Heavier and may be more expensive. |

| Plastic Blender Ball | Lightweight and typically made of BPA-free plastic | Health supplement brands | Pour : Affordable, easy to clean; Cons : Less durable, can warp over time. |

| Whisk Ball | Features a whisk-like design for enhanced mixing | Smoothie and protein drink producers | Pour : Excellent mixing capability; Cons : Noisy during use, potential for rust. |

| Silicone Mixing Ball | Made from flexible silicone, quieter and eco-friendly | Eco-conscious brands | Pour : Non-toxic, easy to clean; Cons : May not mix as thoroughly as metal options. |

| Electric Mixing Mechanism | Built-in battery-operated mixing for effortless blending | High-end fitness product lines | Pour : Consistent mixing, user-friendly; Cons : Requires charging, higher initial investment. |

What Are the Characteristics of Stainless Steel Balls in Shaker Bottles?

Stainless steel balls are favored for their durability and rust resistance, making them ideal for long-term use in various environments. They often provide insulation, keeping beverages cold or hot for extended periods. B2B buyers in the fitness and nutrition sectors benefit from their robustness, ensuring that products maintain quality over time. However, they are heavier than their plastic counterparts and may come at a higher price point, which can impact bulk purchasing decisions.

Why Choose Plastic Blender Balls for Your Business?

Plastic blender balls are lightweight and typically made from BPA-free materials, appealing to health-conscious consumers. Their affordability and ease of cleaning make them popular among health supplement brands. However, their longevity can be a concern, as they may warp or degrade with frequent use. B2B buyers should weigh the cost savings against potential replacement needs when considering bulk orders.

What Advantages Do Whisk Balls Offer for Mixing?

Whisk balls feature a unique design that enhances mixing efficiency, making them suitable for smoothie and protein drink producers. They provide excellent blending capabilities, ensuring that ingredients are thoroughly mixed. However, the noise generated during use can be a drawback in quieter environments. B2B buyers should consider the target market’s preferences for noise levels when selecting this type of shaker ball.

How Do Silicone Mixing Balls Stand Out?

Silicone mixing balls are an eco-friendly option, made from non-toxic materials that appeal to environmentally conscious brands. They are quieter during use, which can be a significant advantage in settings where noise is a concern. While they are easy to clean and maintain, their mixing efficiency may not match that of metal alternatives. B2B buyers focused on sustainability will find these an attractive option, but should also assess their effectiveness in meeting consumer expectations.

Why Invest in Electric Mixing Mechanisms?

Electric mixing mechanisms represent a premium choice for those looking to offer cutting-edge solutions in the shaker bottle market. These devices provide effortless blending at the touch of a button, ensuring consistent results every time. They are particularly appealing for high-end fitness product lines. However, they require regular charging and represent a higher initial investment, which may affect pricing strategies in competitive markets. B2B buyers should evaluate the potential return on investment when considering incorporating electric options into their product offerings.

Key Industrial Applications of shaker bottle ball

| Industrie/secteur | Specific Application of shaker bottle ball | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Fitness et sports | Mixing protein shakes and supplements | Enhances product offering with effective mixing tools | Quality materials, durability, and compliance with health standards |

| Alimentation et boissons | Beverage preparation in cafes and restaurants | Streamlines drink preparation, improving efficiency | Customization options, branding potential, and bulk pricing |

| Health & Wellness | Nutritional supplement packaging | Adds value to product lines, encouraging consumer trust | Sourcing eco-friendly materials and ensuring product safety |

| Education & Training | Use in physical education programs | Promotes healthy habits among students | Affordability, ease of cleaning, and availability in bulk |

| Plein air et aventure | Portable mixing solutions for hiking and camping | Attracts outdoor enthusiasts with convenience | Lightweight design, resistance to harsh conditions, and size options |

How is the shaker bottle ball used in the Fitness & Sports industry?

In the fitness and sports sector, shaker bottle balls are essential for mixing protein shakes, smoothies, and other supplements. These balls enhance the blending process, ensuring a smooth consistency that is critical for athletes and fitness enthusiasts. Buyers in this sector should prioritize durable materials that can withstand frequent use and are easy to clean. Additionally, understanding regional preferences for colors and designs can help brands cater to diverse markets, particularly in Africa and Europe.

What role does the shaker bottle ball play in the Food & Beverage industry?

In cafes and restaurants, shaker bottle balls facilitate the preparation of beverages, including cocktails and smoothies. They help mix ingredients thoroughly, improving the quality of the final product and enhancing customer satisfaction. Businesses in this sector should consider sourcing shaker balls that allow for customization, enabling branding opportunities. Ensuring compliance with food safety regulations is also crucial, especially for international buyers in regions like South America and the Middle East.

How does the Health & Wellness industry benefit from shaker bottle balls?

The health and wellness industry utilizes shaker bottle balls in nutritional supplement packaging, providing consumers with a tool for effective mixing. This feature adds value to products, increasing consumer trust and satisfaction. B2B buyers should focus on sourcing eco-friendly materials to align with growing consumer preferences for sustainability. Additionally, ensuring that products meet health and safety standards is vital for market acceptance, especially in Europe and Africa.

In what ways are shaker bottle balls beneficial for Education & Training programs?

In educational settings, particularly physical education programs, shaker bottle balls promote healthy habits by making nutritional drinks more accessible and appealing to students. They serve as an engaging tool for teaching about nutrition and fitness. Buyers in this sector should look for affordable options that can be purchased in bulk, ensuring that they remain within budget while providing quality products. Ease of cleaning is also a significant consideration to maintain hygiene standards.

How do shaker bottle balls enhance outdoor and adventure activities?

For outdoor enthusiasts, shaker bottle balls provide a portable solution for mixing drinks while hiking or camping. They offer convenience by enabling users to prepare shakes on-the-go, catering to the active lifestyle of this demographic. When sourcing for this application, businesses should focus on lightweight designs that can withstand harsh conditions. Additionally, offering various size options can attract a broader customer base, particularly in markets with a strong outdoor culture, like South America.

3 Common User Pain Points for ‘shaker bottle ball’ & Their Solutions

Scenario 1: Concerns About Durability and Quality of Shaker Bottle Balls

Le problème : B2B buyers often face the challenge of sourcing shaker bottle balls that withstand rigorous use without compromising on quality. In regions such as Africa and South America, where access to high-quality materials may be limited, many suppliers may offer subpar products that rust, break, or wear out quickly. This not only affects customer satisfaction but can also lead to increased costs from frequent replacements, impacting the overall bottom line for businesses.

La solution : To mitigate this issue, buyers should prioritize sourcing shaker bottle balls made from high-grade stainless steel or BPA-free plastic. Conduct thorough supplier evaluations by requesting product samples and reviewing certifications for material quality and durability. Additionally, consider establishing long-term partnerships with manufacturers that specialize in fitness and health products, as they often have better quality control processes. Implementing a return policy for defective products can also safeguard your investment and ensure customer trust.

Scenario 2: Ineffective Mixing Performance Leading to Customer Dissatisfaction

Le problème : Many B2B buyers encounter shaker bottle balls that do not effectively mix the contents, resulting in clumps or unevenly blended drinks. This is particularly problematic for businesses in the fitness and health sector, where customers expect a smooth and consistent shake, especially when dealing with protein powders or nutritional supplements. Poor mixing performance can lead to dissatisfaction and damage the brand’s reputation.

La solution : To address this, buyers should look for shaker bottle balls specifically designed with features that enhance mixing efficiency, such as a whisk-style design or those with multiple fins. When selecting products, consider the size and weight of the shaker ball; a heavier ball may create more agitation, resulting in better mixing. Testing different designs through product trials can help determine which option yields the best performance. Additionally, educate customers on the proper usage techniques, such as shaking vigorously for a specified duration, to optimize mixing results.

Scenario 3: Environmental Concerns and Sustainability of Materials

Le problème : As global awareness of environmental issues increases, B2B buyers face pressure to offer products that align with sustainability goals. Traditional shaker bottle balls made from plastic or low-grade materials may not meet eco-friendly standards, causing concern among environmentally conscious consumers. This can pose a significant dilemma for businesses aiming to enhance their brand image while still providing functional products.

La solution : Buyers can alleviate these concerns by sourcing shaker bottle balls made from sustainable materials, such as recycled plastics or biodegradable substances. Partnering with manufacturers committed to sustainable practices can also enhance brand reputation. To further this initiative, consider implementing a take-back program for old shaker balls or offering discounts for customers who return used products for recycling. This not only positions the business as environmentally responsible but also fosters customer loyalty through shared values.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their product offerings and meet customer expectations while maintaining operational efficiency.

Strategic Material Selection Guide for shaker bottle ball

What Are the Key Properties of Common Materials Used for Shaker Bottle Balls?

When selecting materials for shaker bottle balls, several options are commonly used, each with distinct properties that affect performance, durability, and suitability for various applications. Below, we analyze four prevalent materials: stainless steel, plastic, silicone, and glass.

How Does Stainless Steel Perform as a Material for Shaker Bottle Balls?

Stainless steel is a popular choice due to its excellent durability and resistance to corrosion. It can withstand a wide range of temperatures and pressures, making it suitable for both hot and cold beverages. The key properties of stainless steel include high tensile strength and a non-reactive surface, which prevents any metallic taste from leaching into the drink.

Pros and Cons: Stainless steel balls are highly durable and can last for years without significant wear. However, they tend to be more expensive than plastic alternatives and may require more complex manufacturing processes. Additionally, their weight could be a consideration for users who prefer lighter shaker bottles.

Impact sur l'application: Stainless steel is compatible with a variety of media, including acidic and alkaline solutions, making it versatile for different types of beverages.

Considérations pour les acheteurs internationaux: Buyers from regions like Africa and South America should be aware of local regulations regarding food safety and material compliance. Standards such as ASTM or DIN may apply, and ensuring that the stainless steel meets these standards is crucial for market acceptance.

What Are the Advantages of Using Plastic for Shaker Bottle Balls?

Plastic, particularly high-density polyethylene (HDPE) or polypropylene, is another common material for shaker bottle balls. These plastics are lightweight and can be produced at a lower cost compared to metals. They are also resistant to impact and can handle a range of temperatures.

Pros and Cons: The primary advantage of plastic shaker balls is their affordability and ease of manufacturing. However, they may not be as durable as stainless steel and can degrade over time, especially under high temperatures or when exposed to certain chemicals.

Impact sur l'application: Plastic is generally suitable for non-corrosive media, but it may not be ideal for acidic drinks, which can lead to leaching of harmful substances.

Considérations pour les acheteurs internationaux: Compliance with food safety standards is essential. Buyers in Europe, for instance, must ensure that the plastic used is BPA-free and adheres to EU regulations regarding food contact materials.

How Does Silicone Compare as a Material for Shaker Bottle Balls?

Silicone offers a unique alternative due to its flexibility and non-toxic properties. It is highly durable and resistant to both heat and cold, making it suitable for various beverage types.

Pros and Cons: Silicone balls are easy to clean and do not retain odors, which is a significant advantage for users concerned about hygiene. However, they may not provide the same level of mixing efficiency as metal balls and can be more expensive than plastic options.

Impact sur l'application: Silicone is compatible with most media, including hot beverages, and is particularly appealing for health-conscious consumers due to its non-toxic nature.

Considérations pour les acheteurs internationaux: Buyers should verify that the silicone meets relevant international standards for food safety. In regions like the Middle East, where there is a growing emphasis on health and safety, silicone’s non-toxic properties can be a selling point.

What Role Does Glass Play in Shaker Bottle Ball Design?

Glass is less common but offers a unique aesthetic and functional benefits. It is completely inert, meaning it won’t leach any substances into the drink, and is easy to clean.

Pros and Cons: Glass balls can provide excellent mixing without any risk of contamination. However, they are fragile and can break easily, making them less practical for active lifestyles. Additionally, glass is heavier than other materials, which can be a drawback for portability.

Impact sur l'application: Glass is suitable for all types of beverages but may not be practical for on-the-go use due to its weight and fragility.

Considérations pour les acheteurs internationaux: Buyers should consider the logistics of shipping glass products, especially in regions prone to breakage during transit. Compliance with safety standards is also critical, particularly in markets with stringent regulations.

Summary of Material Properties for Shaker Bottle Balls

| Matériau | Typical Use Case for shaker bottle ball | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Acier inoxydable | Premium shaker bottles | Highly durable and corrosion-resistant | Higher cost and heavier weight | Haut |

| Plastique | Budget-friendly shaker bottles | Léger et rentable | Less durable and may leach chemicals | Faible |

| Silicone | Health-focused shaker bottles | Non-toxic and easy to clean | May not mix as efficiently | Moyen |

| Verre | Aesthetic and premium shaker bottles | Inert and easy to clean | Fragile et lourd | Moyen |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials available for shaker bottle balls, enabling informed decisions that align with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shaker bottle ball

What Are the Key Stages in the Manufacturing Process of Shaker Bottle Balls?

The manufacturing process of shaker bottle balls involves several critical stages, each ensuring that the final product meets the durability and functionality required by end-users. The typical stages are as follows:

-

Préparation du matériel:

The primary materials used for shaker bottle balls are stainless steel and high-density polyethylene (HDPE). For stainless steel balls, manufacturers start by sourcing high-grade stainless steel, which is then cut into appropriate sizes for forming. HDPE materials are also processed to ensure they meet specific health and safety standards. Quality control begins at this stage, where incoming materials are assessed for compliance with international standards. -

Formation:

This stage involves shaping the balls through various techniques. Stainless steel balls are often manufactured using a process called metal forming, which may include techniques such as forging or machining. For HDPE balls, injection molding is the preferred method, allowing for high precision and efficiency. This phase is crucial as it determines the strength and performance of the shaker ball. -

Assemblée:

While shaker bottle balls are generally standalone products, some designs may include additional features such as whisking mechanisms or integrated lids. During assembly, manufacturers ensure that all components fit securely and function as intended. This stage may involve automated assembly lines or manual assembly, depending on the complexity of the product design. -

Finition:

After forming and assembly, shaker bottle balls undergo finishing processes, which can include polishing, coating, and surface treatment. For stainless steel, this may involve buffing to enhance appearance and corrosion resistance. HDPE balls may receive treatments to improve durability and resistance to odors. The finishing stage significantly affects the aesthetic appeal and longevity of the product.

How is Quality Assurance Implemented in the Manufacturing of Shaker Bottle Balls?

Quality assurance (QA) is integral to ensuring that shaker bottle balls meet the required standards for safety and performance. Several international and industry-specific standards guide these processes:

-

Normes internationales:

Compliance with ISO 9001, which outlines the requirements for a quality management system, is essential for manufacturers. This certification indicates that a company consistently provides products that meet customer and regulatory requirements. For shaker bottle balls, adherence to ISO standards ensures that manufacturing processes are efficient and that products are reliable. -

Certifications spécifiques à l'industrie:

Certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, especially if the products are intended for specific markets or applications. CE marking indicates compliance with EU safety, health, and environmental protection standards. These certifications can significantly enhance marketability in regions such as Europe and the Middle East. -

Points de contrôle de la qualité:

The manufacturing process incorporates several quality control checkpoints:

– Contrôle de la qualité à l'arrivée (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specifications.

– Contrôle de la qualité en cours de fabrication (IPQC): Conducted during the manufacturing stages, IPQC focuses on monitoring processes to prevent defects. This may include checking the dimensions and weight of the balls during forming.

– Contrôle de qualité final (CQF): After finishing, each batch of shaker bottle balls undergoes rigorous testing to verify compliance with quality standards. This includes visual inspections and functionality tests.

What Common Testing Methods Are Used for Shaker Bottle Balls?

Manufacturers employ various testing methods to ensure the quality and performance of shaker bottle balls:

-

Essais de durabilité:

This involves subjecting the balls to stress tests to evaluate their resilience under typical usage conditions. Stainless steel balls may undergo drop tests, while HDPE balls are tested for impact resistance. -

Essai d'étanchéité:

Since shaker bottles are often used for liquids, ensuring that balls do not leak is crucial. Manufacturers typically perform water immersion tests to check for any leaks or failures in sealing. -

Chemical Resistance Testing:

Given that shaker bottles may contain various liquids, testing the material’s resistance to chemicals is essential. This ensures that no harmful substances leach into the liquid.

Comment les acheteurs B2B peuvent-ils vérifier les processus de contrôle de la qualité des fournisseurs ?

B2B buyers must ensure that their suppliers maintain rigorous quality control processes. Here are some actionable steps:

-

Audits des fournisseurs:

Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes reviewing production lines, quality control checkpoints, and compliance with international standards. -

Demande de rapports de qualité:

Buyers should request detailed quality assurance reports from suppliers. These reports typically include results from various tests conducted on the shaker bottle balls, demonstrating compliance with relevant standards. -

Inspections par des tiers:

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can evaluate the manufacturing processes and verify compliance with international and industry-specific standards.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

-

Regulatory Compliance:

Different regions have varying regulatory requirements. For instance, the EU has stringent regulations concerning product safety and environmental impact. B2B buyers must ensure that suppliers are compliant with these regulations to avoid legal issues. -

Considérations culturelles:

Understanding cultural differences in manufacturing practices and quality expectations can impact supplier relationships. Buyers should engage in open communication with suppliers to address any concerns and align expectations. -

Logistical Challenges:

Buyers must consider the logistical aspects of sourcing products internationally, including shipping times, customs regulations, and potential tariffs. Ensuring that quality control measures are in place throughout the supply chain is essential for maintaining product integrity.

In summary, the manufacturing and quality assurance processes for shaker bottle balls are multifaceted, requiring attention to detail at every stage. By understanding these processes, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shaker bottle ball’

To assist B2B buyers in procuring shaker bottle balls, this guide provides a comprehensive checklist to ensure effective sourcing. Whether you’re targeting markets in Africa, South America, the Middle East, or Europe, following these steps will help streamline your procurement process and secure high-quality products.

Étape 1 : Définir les spécifications techniques

Clearly outline the technical requirements for the shaker bottle balls you intend to source. This includes material preferences (e.g., stainless steel, plastic), size, weight, and design features such as ball type (whisk vs. traditional). Having a precise specification will help you communicate effectively with suppliers and ensure that the final product meets your needs.

Étape 2 : Réaliser une étude de marché

Investigate the current market landscape for shaker bottle balls. Identify leading manufacturers and emerging players in various regions, especially in your target markets. Understanding market trends will give you insight into pricing, quality standards, and innovative features that can set your products apart.

Étape 3 : Évaluer les fournisseurs potentiels

Before making any commitments, thoroughly vet potential suppliers. Request detailed company profiles, certifications, and case studies that demonstrate their experience in manufacturing shaker bottle balls. Look for reviews or references from other businesses that have sourced similar products to ensure reliability and quality.

- Check for industry certifications: Ensure suppliers comply with relevant quality and safety standards (e.g., ISO, FDA).

- Assess production capabilities: Confirm that the supplier can handle your volume requirements and has the necessary equipment and technology.

Étape 4 : Demande d'échantillons

Always request samples before placing a bulk order. This allows you to evaluate the quality, performance, and compatibility of the shaker bottle balls with your products. Pay attention to aspects such as durability, mixing efficiency, and ease of cleaning.

- Test for functionality: Ensure the balls mix effectively without clumping or leaving residue.

- Inspect for safety: Verify that materials are non-toxic and safe for food contact.

Étape 5 : Négocier les conditions et les prix

Once you’ve identified a suitable supplier, engage in negotiations to secure favorable terms. Discuss pricing, payment methods, delivery schedules, and minimum order quantities. Be clear about your expectations regarding quality and timelines to avoid misunderstandings later on.

Étape 6 : Confirm Logistics and Delivery Options

Evaluate the logistics capabilities of your chosen supplier. Ensure they can deliver to your target regions efficiently. Discuss shipping options, lead times, and costs to ensure they align with your business needs.

- Consider customs and import regulations: Be aware of any tariffs or regulations that might affect your procurement process, particularly if sourcing internationally.

Étape 7 : Establish a Quality Control Process

Implement a quality control system to monitor the production and shipment of shaker bottle balls. Define inspection protocols and criteria for acceptance. Regular communication with your supplier during production can help address any issues promptly.

- Schedule regular check-ins: Maintain an open line of communication for updates and potential adjustments.

- Plan for post-delivery inspections: Verify that the received products meet your specifications and quality standards upon arrival.

By following this detailed checklist, B2B buyers can ensure a smooth and successful sourcing process for shaker bottle balls, ultimately leading to better product offerings and satisfied customers.

Comprehensive Cost and Pricing Analysis for shaker bottle ball Sourcing

What Are the Key Cost Components in Shaker Bottle Ball Sourcing?

Understanding the cost structure of shaker bottle balls is vital for B2B buyers aiming to maximize profitability. The primary cost components include:

-

Matériaux: The choice of materials significantly impacts costs. Common materials for shaker balls include stainless steel, plastic, and silicone. Stainless steel offers durability and a premium feel but comes at a higher price compared to plastic alternatives.

-

Travail: Labor costs vary by region and manufacturing method. Automated production can lower labor costs, while hand-crafted options might be more expensive. It is essential to consider the labor market in the supplier’s location, especially for buyers in Africa and South America, where labor costs can fluctuate.

-

Frais généraux de fabrication: This encompasses utilities, rent, and equipment depreciation. Overhead costs can be higher in regions with increased energy costs or stringent regulations. Buyers should assess how these factors influence overall pricing.

-

Outillage: Initial setup costs for molds and tools can be significant, especially for custom designs. For buyers requiring unique specifications, understanding tooling costs is crucial for accurate budgeting.

-

Contrôle de la qualité (CQ): Implementing robust QC processes adds to costs but ensures product reliability. Buyers should inquire about a supplier’s QC measures, as this can affect long-term satisfaction and reduce the risk of returns.

-

Logistique: Shipping and transportation costs can vary widely based on distance, volume, and chosen Incoterms. Buyers must factor in these costs when evaluating total expenses.

-

Marge: Suppliers typically add a profit margin that can vary based on competition, market demand, and brand reputation. Understanding the expected margin can help buyers negotiate better deals.

What Influences Pricing for Shaker Bottle Balls?

Several factors influence the pricing of shaker bottle balls, which B2B buyers should consider:

-

Volume et quantité minimale de commande (QMC): Ordering in bulk can lead to significant discounts. Suppliers often offer tiered pricing based on order volume, so buyers should strategize their purchasing to maximize cost savings.

-

Spécifications et personnalisation: Unique designs or additional features (like insulation or specific colors) can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Matériaux et certifications de qualité: High-quality materials and certifications (like BPA-free or food-grade compliance) can raise costs. Buyers must assess the importance of these factors for their target market.

-

Facteurs liés au fournisseur: A supplier’s reputation, experience, and production capabilities can affect pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Different Incoterms can shift responsibility and risk, impacting overall expenses.

What Are Effective Negotiation and Cost-Efficiency Tips for Buyers?

For B2B buyers, particularly those operating in diverse markets like Nigeria, Germany, and other regions, employing strategic negotiation techniques can enhance cost-efficiency:

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, more favorable terms, and priority service.

-

Tenir compte du coût total de possession (CTP): Instead of focusing solely on unit price, evaluate the TCO, which includes shipping, handling, and potential warranty or replacement costs. A slightly higher upfront cost might lead to lower long-term expenses.

-

Rester informé des tendances du marché: Understanding regional market dynamics can help buyers negotiate effectively. For example, fluctuations in raw material prices or changes in trade policies can impact pricing.

-

Explorer plusieurs fournisseurs: Soliciting quotes from various suppliers can provide leverage in negotiations. It also allows buyers to compare different offerings and terms.

What Should International Buyers Be Aware of in Pricing Nuances?

International buyers should be aware of various pricing nuances when sourcing shaker bottle balls:

-

Fluctuations monétaires: Exchange rate changes can significantly impact costs, particularly for buyers in Africa and South America. It may be beneficial to lock in prices or use hedging strategies.

-

Import Duties and Tariffs: Understanding applicable tariffs for importing goods into specific countries is crucial. These additional costs can affect the final price significantly.

-

Cultural Differences in Negotiation Styles: Different regions have varying negotiation practices. Familiarizing oneself with local customs can facilitate smoother discussions and better outcomes.

Avertissement sur les prix indicatifs

Prices for shaker bottle balls can vary widely based on the factors discussed above. It is advisable for buyers to obtain specific quotes from suppliers to ensure accurate pricing tailored to their needs.

Alternatives Analysis: Comparing shaker bottle ball With Other Solutions

In the competitive landscape of beverage mixing solutions, B2B buyers often seek alternatives to traditional shaker bottle balls that can enhance performance, reduce costs, or improve user experience. Understanding the strengths and weaknesses of various mixing technologies is essential for making informed purchasing decisions.

| Aspect comparatif | Shaker Bottle Ball | Stainless Steel Whisk Ball | Electric Protein Shaker Bottle |

|---|---|---|---|

| Performance | Effective mixing of powders and liquids | Excellent mixing; quieter than metal balls | Consistent mixing at the touch of a button |

| Coût | Generally low-cost; varies by brand | Moderate price; durable | Higher initial investment; rechargeable |

| Facilité de mise en œuvre | Simple to use; drops into bottle | Easy to replace existing balls | Requires charging and setup |

| Maintenance | Minimal maintenance; rinsing required | Facile à nettoyer ; passe au lave-vaisselle | Needs battery maintenance and occasional cleaning |

| Meilleur cas d'utilisation | Everyday protein shakes and smoothies | Noise-sensitive environments; durability-focused users | Users seeking convenience and efficiency |

What are the Pros and Cons of Using a Stainless Steel Whisk Ball as an Alternative?

The stainless steel whisk ball serves as a viable alternative to the traditional shaker bottle ball. It provides excellent mixing capabilities and is durable, making it suitable for frequent use. Its quieter operation is particularly beneficial in settings where noise is a concern, such as gyms or offices. However, it may still produce some noise during mixing and can be susceptible to rust if not maintained properly.

How Does an Electric Protein Shaker Bottle Compare?

Electric protein shaker bottles represent a modern solution for mixing beverages without the manual effort required by traditional shaker balls. These devices offer consistent mixing at the touch of a button, making them ideal for busy professionals or athletes who need quick results. While they do come with a higher price tag and require regular charging, their convenience and efficiency can justify the investment for many users. However, the dependence on a battery and the need for occasional maintenance might deter some buyers.

Conclusion: Which Mixing Solution is Right for Your Business Needs?

When choosing the right mixing solution, B2B buyers should consider their specific operational needs, budget constraints, and user preferences. Traditional shaker bottle balls are cost-effective and straightforward, making them suitable for everyday use. In contrast, stainless steel whisk balls offer durability and quieter operation, while electric shaker bottles provide unmatched convenience and efficiency. By assessing these alternatives against their requirements, businesses can select a solution that optimally aligns with their objectives, enhancing both user satisfaction and operational efficiency.

Essential Technical Properties and Trade Terminology for shaker bottle ball

What Are the Key Technical Properties of Shaker Bottle Balls?

When sourcing shaker bottle balls, understanding their technical properties is crucial for ensuring product quality and customer satisfaction. Here are several key specifications to consider:

-

Qualité des matériaux

Shaker balls are typically made from stainless steel or high-grade plastic. Stainless steel offers durability, resistance to rust, and ease of cleaning, making it a preferred choice in many markets. High-grade plastics, like Tritan, provide a lightweight and shatter-resistant alternative. Understanding the material grade is essential for B2B buyers to ensure the longevity and safety of the product. -

Diameter

The diameter of the shaker ball typically ranges from 1.5 to 2 inches. This size is critical as it affects the mixing efficiency within the bottle. A ball that is too small may not mix effectively, while one that is too large may not fit properly. For manufacturers and suppliers, ensuring the correct diameter is vital for compatibility with various shaker bottle designs. -

Poids

The weight of the shaker ball can influence the overall functionality of the shaker bottle. A heavier ball may provide better mixing action, while a lighter one may be preferred for ease of handling. Buyers should consider the weight specifications to align with consumer preferences and market trends. -

Finish and Coating

The finish of a shaker ball can impact its aesthetic appeal and functionality. Options include matte, glossy, or powder-coated finishes. A powder-coated finish may enhance grip and resistance to scratches. For B2B buyers, understanding the finish can help in selecting products that align with branding and consumer expectations. -

Odor Resistance

Odor resistance is a property of materials like Tritan or specialized coatings that prevent the absorption of smells. This feature is particularly important for shaker bottles used with protein powders or flavored drinks. For manufacturers, highlighting odor resistance can be a strong selling point in competitive markets.

What Trade Terminology Should Buyers Know When Sourcing Shaker Bottle Balls?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to shaker bottle balls:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. For shaker bottle balls, working with an OEM can ensure that the balls are manufactured to specific standards and can be branded by the buyer. This is critical for maintaining quality control and brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For shaker bottle balls, MOQs can vary significantly based on the manufacturer. Understanding MOQ is essential for buyers to manage inventory and ensure cost-effectiveness. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and other details for a specific quantity of goods. This is a standard practice in B2B transactions, allowing buyers to compare options before making purchasing decisions. -

Incoterms (termes commerciaux internationaux)

Incoterms are international rules that define the responsibilities of buyers and sellers in shipping goods. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) are commonly used. Understanding Incoterms is vital for buyers to manage shipping costs and liabilities effectively. -

Délai d'exécution

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This is particularly important for B2B buyers who need to manage inventory levels and meet customer demand. Knowing the lead time can help in planning and logistics.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shaker bottle balls, ultimately enhancing their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the shaker bottle ball Sector

What Are the Current Market Dynamics and Key Trends in the Shaker Bottle Ball Sector?

The global shaker bottle ball market is experiencing robust growth, driven by increasing health consciousness and the rise of fitness culture across diverse regions, particularly in Africa, South America, the Middle East, and Europe. B2B buyers are leveraging this trend to explore new sourcing opportunities, especially as consumers demand high-quality, versatile products that cater to various dietary and fitness needs. The market is witnessing a shift towards innovative designs, including insulated bottles and those with enhanced mixing mechanisms, which appeal to the modern consumer’s lifestyle.

Emerging B2B technologies, such as advanced manufacturing processes and customization capabilities, are reshaping sourcing strategies. Buyers are increasingly interested in products that offer unique features, such as odor resistance and eco-friendly materials. Additionally, the proliferation of e-commerce platforms allows for easier access to international suppliers, facilitating cross-border transactions and enabling buyers to source products that meet specific market demands.

In terms of market dynamics, competition is intensifying as brands strive to differentiate themselves through product innovation and branding. International buyers, particularly from emerging markets, are prioritizing suppliers that can provide not only quality products but also reliable delivery timelines and competitive pricing. Understanding local market preferences and regulatory requirements is crucial for successful sourcing in these regions.

How Important Is Sustainability and Ethical Sourcing in the Shaker Bottle Ball Sector?

Sustainability and ethical sourcing are becoming paramount considerations in the shaker bottle ball sector. As consumers increasingly prioritize environmentally friendly products, B2B buyers must align their sourcing strategies with sustainable practices. This includes selecting suppliers that utilize recyclable materials, such as stainless steel and BPA-free plastics, which minimize environmental impact.

Furthermore, the importance of ethical supply chains cannot be overstated. International buyers are now more vigilant about the labor practices of their suppliers, seeking transparency and accountability. Certifications such as Fair Trade and ISO 14001 can serve as indicators of a supplier’s commitment to sustainability and ethical practices, providing buyers with confidence in their sourcing decisions.

The environmental impact of manufacturing processes is another critical factor. Companies that adopt green manufacturing techniques, reduce waste, and implement energy-efficient practices are likely to resonate with conscientious buyers. By prioritizing sustainability and ethical sourcing, B2B buyers not only meet consumer demand but also contribute to a more sustainable future, enhancing their brand reputation in the process.

What Is the Brief Evolution of the Shaker Bottle Ball?

The shaker bottle ball has evolved significantly since its inception. Originally designed as a simple tool to mix protein powders and supplements, the introduction of the stainless steel ball provided a more effective mixing solution compared to traditional methods. Over the years, the design has expanded to include various materials, such as BPA-free plastics and insulated options, catering to a wider range of consumer preferences.

The rise of health and fitness trends in the late 20th century catalyzed the popularity of shaker bottles, transforming them from a niche product into a mainstream accessory for fitness enthusiasts. As awareness of nutrition and wellness has grown, so too has the demand for high-quality shaker bottles that enhance the mixing process and offer added functionalities. This evolution reflects broader market trends towards health, wellness, and sustainability, positioning the shaker bottle ball as a key player in the fitness and lifestyle sectors.

In summary, understanding market dynamics, prioritizing sustainability, and recognizing the evolution of products are crucial for international B2B buyers in the shaker bottle ball sector. By staying attuned to these trends, buyers can make informed sourcing decisions that align with both consumer expectations and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of shaker bottle ball

-

How do I ensure the quality of shaker bottle balls from suppliers?

To ensure quality when sourcing shaker bottle balls, conduct thorough supplier vetting. Request samples to evaluate the materials and manufacturing processes used. Look for certifications such as ISO or quality assurance standards specific to your region. Additionally, consider third-party quality inspections, especially for international shipments, to mitigate risks of defects or discrepancies in product specifications. -

What is the best material for shaker bottle balls?

The best materials for shaker bottle balls typically include stainless steel, plastic, and silicone. Stainless steel is durable and resistant to rust, making it ideal for long-term use. Plastic options, often lighter, can be more economical but may wear out faster. Silicone balls are eco-friendly and provide a quieter mixing experience. Your choice should align with your brand’s values and target market preferences. -

What are common minimum order quantities (MOQs) for shaker bottle balls?

Minimum order quantities (MOQs) for shaker bottle balls vary by supplier, typically ranging from 500 to 5,000 units. When negotiating with suppliers, inquire about their flexibility on MOQs, especially if you’re a smaller business or testing a new market. Some manufacturers may offer lower MOQs for initial orders or allow mixed product orders to meet MOQ requirements. -

What payment terms should I expect when sourcing shaker bottle balls internationally?

International suppliers usually offer payment terms ranging from 30% upfront and 70% upon shipment to net 30 or net 60 days after delivery. It’s essential to establish clear payment terms before finalizing contracts. Using secure payment methods like letters of credit or escrow services can provide additional protection for both parties involved in the transaction. -

How can I customize shaker bottle balls for my brand?

Customization options for shaker bottle balls often include colors, sizes, and branding elements like logos or designs. When discussing customization with suppliers, specify your requirements clearly. Many manufacturers offer options such as screen printing, embossing, or even unique shapes. Be sure to ask about lead times and any additional costs associated with custom designs. -

What logistics considerations should I keep in mind when importing shaker bottle balls?

When importing shaker bottle balls, consider logistics factors such as shipping methods, customs clearance, and delivery times. Choose a reliable freight forwarder with experience in your target market. Understand the import regulations, tariffs, and taxes applicable in your country to avoid unexpected costs. Lastly, plan for potential delays by allowing extra time in your supply chain schedule. -

How do I handle potential disputes with suppliers?

To handle disputes with suppliers effectively, establish clear communication channels and terms in your contract regarding quality, delivery timelines, and payment. If issues arise, try to resolve them amicably through discussions. If necessary, consider mediation or arbitration as a means to settle disputes without resorting to litigation, which can be costly and time-consuming. -

What trends should I be aware of in the shaker bottle market?

Key trends in the shaker bottle market include a growing preference for eco-friendly materials, innovative designs, and multifunctional products. Many consumers now seek products that align with their sustainability values, such as BPA-free plastics or stainless steel options. Additionally, the rise of fitness and health consciousness has driven demand for customized and branded shaker bottles, providing opportunities for B2B buyers to differentiate their offerings in competitive markets.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 9 Shaker Bottle Ball Manufacturers & Suppliers List

1. BlenderBottle – Insulated Stainless Sport Shaker

Domaine : blenderbottle.com

Enregistré : 1999 (26 ans)

Introduction : Best Shaker Cups & Protein Shaker Bottles | BlenderBottle®

– Insulated Stainless Shakers

– Plastic Shakers

– Classic – #1 Shaker Bottle in the World

– Free US Shipping on Orders $50+

– Product Variants:

– Insulated Stainless Sport: $27.99, 4.5 (739 reviews), Colors: Cobalt, Cranberry, Nightshade, Grapefruit

– Stainless Sleek Sport: $29.99, 4.4 (113 reviews), Colors: Sherbet, Seafoam, Lavender…

2. Reddit – Shake Bottle with Metal Wire Ball

Domaine : reddit.com

Enregistré : 2005 (20 ans)

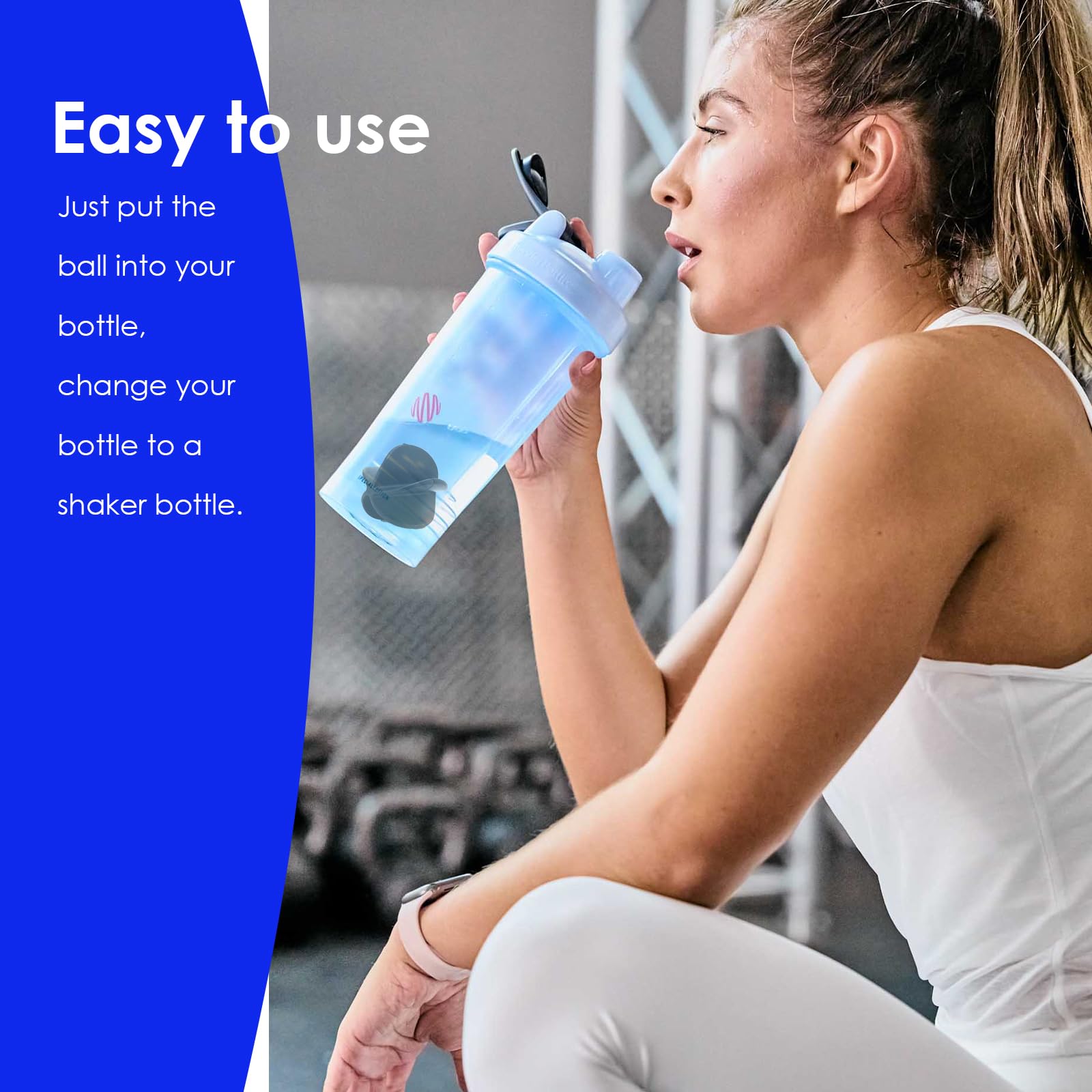

Introduction : Shake bottles with metal wire balls are effective for mixing protein powder, providing a smoother result than stirring with a spoon. They are versatile for other mixing tasks, such as pancake batter. Cleanup is easy by shaking with water and soap. Users recommend washing them after each use to avoid unpleasant odors, especially when used with dairy-based protein powders.

3. Target – Premium Protein Shaker Balls & Cups

Domaine : target.com

Enregistré : 1997 (28 ans)

Introduction : This company, Target – Premium Protein Shaker Balls & Cups, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Everich – Shaker Bottles

Domaine : everich.com

Registered: 2010 (15 years)

Introduction : Everich offers a range of shaker bottles designed for optimal mixing of protein shakes. Key features include: 1. Mixing Ball: A small spherical component that helps eliminate clumps and ensures a smooth consistency in beverages. 2. Types of Mixing Balls: – Stainless Steel Balls: Durable, resistant to wear, and effective for thick protein powders. – Plastic Mixing Balls: Lightweight and affordable,…

5. ProScoop – Mixer Ball

Domaine : proscoop.com.au

Introduction : Mixer Ball Properties: Material: 100% food grade 304 stainless steel. Overall Dimensions: Ø55.0mm x 50.0mm H. Wire diameter: Ø1.5mm. Properties: Highly durable and resistant to corrosion or rust.

6. Dugout – Pack Big Protein Shaker Ball

Domaine : dugoutnorthbrook.com

Enregistré : 2016 (9 ans)

Introduction : {“product_name”: “Pack Big Protein Shaker Ball”, “material”: “304 Stainless Steel”, “color”: “Jamaica”}

7. BlenderBottle – Whisk Ball

Domaine : blenderbottles.nl

Enregistré : 2014 (11 ans)

Introduction : Whisk Ball by BlenderBottle; made from electropolished 316 grade stainless steel; designed for superior mixing; free floating and springy nature allows it to mix powders and liquids effectively; can handle thick ingredients like peanut butter and ice cream; rust, chip, and peel resistant; unique multistage manufacturing process for safety and quality; recognized by fitness publications and profess…

8. AliExpress – Easy Mix Drink Bottle

Domaine : aliexpress.com

Enregistré : 2006 (19 ans)

Introduction : This company, AliExpress – Easy Mix Drink Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. Hydro Flask – 24 oz Insulated Shaker Bottle

Domaine : hydroflask.com

Enregistré : 2009 (16 ans)

Introduction : 24 oz Insulated Shaker Bottle, Leakproof, Keeps drinks cold for 24 hours, Whisk ball for quick and easy mixing, Dishwasher safe, Available in multiple colors: Reef, Surf, Trillium, Agave, Black, Indigo, Dew, Price: $26.21 – $34.95, Currently on sale with discounts up to 35%.

Strategic Sourcing Conclusion and Outlook for shaker bottle ball

What Are the Key Takeaways for B2B Buyers in the Shaker Bottle Ball Market?

In summary, strategic sourcing in the shaker bottle ball market can significantly enhance your product offerings and operational efficiency. Buyers should prioritize high-quality materials, such as stainless steel and odor-resistant plastics, to ensure durability and customer satisfaction. Additionally, understanding regional preferences—such as designs and functionalities—can help tailor products for diverse markets, from Africa to Europe.

How Can International Buyers Leverage Trends for Competitive Advantage?

As the demand for shaker bottles continues to rise, integrating innovative features like leak-proof designs and eco-friendly alternatives will not only meet consumer expectations but also differentiate your brand in a competitive landscape. Emphasizing sustainability and functionality can resonate well with health-conscious and environmentally aware consumers across various regions.

What Are the Future Directions for Shaker Bottle Ball Sourcing?

Looking ahead, international B2B buyers should capitalize on emerging trends and technologies, including electric mixing mechanisms and customizable options. Engaging with suppliers who offer these advancements will position your business favorably in the marketplace.

In conclusion, now is the time to reassess your sourcing strategies and explore new opportunities within the shaker bottle ball segment. Strengthening partnerships with innovative manufacturers can drive growth and elevate your brand’s presence in the global market.