Introduction: Navigating the Global Market for microwave water bottle

In the evolving landscape of consumer goods, sourcing microwave water bottles presents a unique challenge for international B2B buyers. As companies strive to meet the growing demand for versatile and convenient hydration solutions, understanding the nuances of microwave-safe products is essential. This guide offers a comprehensive exploration of the microwave water bottle market, detailing various types available, their applications across different industries, and critical factors to consider when vetting suppliers.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in markets like Brazil and Saudi Arabia—will benefit from insights into material safety, design considerations, and compliance with international standards. Additionally, the guide delves into cost analysis, helping purchasers to make informed decisions that align with budget constraints while ensuring product quality.

By equipping buyers with the necessary knowledge to navigate this complex market, this guide empowers businesses to enhance their product offerings and address consumer needs effectively. Whether aiming to provide innovative solutions for health and wellness or seeking eco-friendly options, understanding the dynamics of the microwave water bottle sector is crucial for success in today’s competitive environment.

Navigation dans les articles

- Top 7 Microwave Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microwave water bottle

- Understanding microwave water bottle Types and Variations

- Key Industrial Applications of microwave water bottle

- 3 Common User Pain Points for ‘microwave water bottle’ & Their Solutions

- Strategic Material Selection Guide for microwave water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for microwave water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microwave water bottle’

- Comprehensive Cost and Pricing Analysis for microwave water bottle Sourcing

- Alternatives Analysis: Comparing microwave water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for microwave water bottle

- Navigating Market Dynamics and Sourcing Trends in the microwave water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microwave water bottle

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for microwave water bottle

Understanding microwave water bottle Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Traditional Rubber Bottles | Made from flexible rubber; classic design | Healthcare, wellness products | Pour : Cost-effective, widely available. Cons : Limited durability, may wear out over time. |

| Microwave-Safe Plastic Bottles | Lightweight, often BPA-free; designed specifically for microwaving | Educational institutions, fitness centers | Pour : Safe for microwave use, lightweight. Cons : May not retain heat as long as rubber. |

| Insulated Microwave Bottles | Double-walled construction for temperature retention | Outdoor events, corporate gifting | Pour : Keeps liquids hot/cold longer, durable materials. Cons : Higher cost, may be heavier. |

| Gel-Filled Microwave Bottles | Contains gel that retains heat longer; flexible design | Pain relief products, home care | Pour : Effective for localized heat therapy, reusable. Cons : Initial cost can be higher, requires specific heating instructions. |

| Ceramic Microwave Bottles | Made from ceramic materials, often stylish designs | Specialty retailers, home goods | Pour : Aesthetic appeal, good heat retention. Cons : Heavier, potential for breakage. |

What Are the Characteristics of Traditional Rubber Bottles?

Traditional rubber microwave water bottles are a staple in many households and healthcare settings. They are flexible, allowing for easy filling and sealing, and are often used for pain relief and warmth. When considering B2B purchases, buyers should note their cost-effectiveness and widespread availability. However, these bottles may not last as long as other materials, and their susceptibility to wear over time could necessitate more frequent replacements.

How Do Microwave-Safe Plastic Bottles Stand Out?

Microwave-safe plastic bottles are specifically engineered for safe heating in microwaves. They are lightweight and often BPA-free, making them suitable for various applications, from schools to fitness centers. For B2B buyers, the primary consideration should be the product’s safety certifications and durability. While these bottles provide convenience and ease of use, they may lack the heat retention capabilities of traditional rubber options.

What Are the Advantages of Insulated Microwave Bottles?

Insulated microwave bottles feature a double-walled design, allowing them to maintain the temperature of liquids for extended periods. This makes them ideal for outdoor events or corporate gifts where presentation and functionality matter. Buyers in B2B sectors should consider the durability and quality of materials used, as these factors affect both performance and customer satisfaction. While they offer excellent heat retention, the higher price point and added weight can be downsides.

How Do Gel-Filled Microwave Bottles Function?

Gel-filled microwave bottles are designed to provide localized heat therapy, making them popular in home care and wellness markets. The gel inside retains heat longer than water, providing effective relief for aches and pains. B2B buyers should evaluate the specific heating instructions and the bottle’s reusability. Although they may come with a higher upfront cost, their therapeutic benefits can justify the investment for health-focused businesses.

Why Consider Ceramic Microwave Bottles?

Ceramic microwave bottles add an element of style to functionality, often featuring attractive designs that appeal to consumers. They are good at retaining heat and are suitable for specialty retailers and home goods markets. B2B buyers should be aware of the fragility of ceramic materials, which can lead to breakage during shipping or handling. While they offer aesthetic appeal, their weight and potential for damage may limit their practicality in some applications.

Key Industrial Applications of microwave water bottle

| Industrie/secteur | Specific Application of Microwave Water Bottle | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Soins de santé | Pain relief for patients | Provides effective, non-pharmaceutical pain relief | Ensure compliance with health regulations and safety standards. |

| L'hospitalité | Guest amenities in hotels | Enhances guest experience with convenient heating options | Focus on durability and ease of cleaning for high-traffic use. |

| L'éducation | Student wellness programs | Supports student comfort during cold weather or illness | Consider bulk purchasing options for cost-effectiveness. |

| Sports et remise en forme | Recovery tools for athletes | Aids in muscle recovery and relaxation post-exercise | Look for lightweight and portable designs for easy transport. |

| Home Care Products | Consumer wellness products | Meets growing demand for self-care and wellness solutions | Prioritize eco-friendly materials and sustainable sourcing. |

How Can Microwave Water Bottles Benefit the Healthcare Industry?

In healthcare settings, microwave water bottles serve as effective tools for pain relief, particularly for patients dealing with chronic pain or muscle soreness. These bottles can be heated quickly in a microwave, offering a convenient and safe method to provide warmth without the need for electricity, making them ideal for hospital use or home care. Buyers in this sector should prioritize products that comply with health regulations and ensure safety features to prevent burns or leaks, especially in environments with vulnerable patients.

What Role Do Microwave Water Bottles Play in the Hospitality Sector?

In the hospitality industry, microwave water bottles can be offered as part of guest amenities, enhancing the overall experience by providing a simple solution for warmth and comfort. Hotels can place these bottles in rooms or wellness areas, allowing guests to heat them easily for relaxation or comfort during their stay. When sourcing, businesses should focus on durability and ease of cleaning, as these products will undergo frequent use and require maintenance to uphold hygiene standards.

How Are Microwave Water Bottles Integrated into Educational Institutions?

Educational institutions can utilize microwave water bottles in student wellness programs, particularly during colder months or flu seasons. These bottles can be distributed to students for personal use, promoting comfort and self-care practices. Bulk purchasing options can be a cost-effective solution for schools aiming to provide these wellness tools to a larger student body. Buyers should consider the materials used, ensuring they are safe and suitable for young users.

Why Are Microwave Water Bottles Valuable in Sports and Fitness?

In the sports and fitness industry, microwave water bottles can be used by athletes for muscle recovery and relaxation after intense training sessions. The ability to heat these bottles quickly provides athletes with a convenient way to apply heat therapy, reducing muscle tension and promoting blood flow. Sourcing lightweight and portable designs is essential for teams and fitness centers that require easy transport to various locations, ensuring athletes can access recovery tools wherever they train.

What Are the Considerations for Home Care Product Buyers?

As consumer wellness trends rise, microwave water bottles are increasingly popular in the home care product sector. These bottles cater to individuals seeking self-care solutions, offering a simple way to alleviate discomfort at home. When sourcing, businesses should prioritize eco-friendly materials and sustainable sourcing practices to meet the growing consumer demand for environmentally responsible products. This approach not only enhances brand reputation but also aligns with the values of a conscientious consumer base.

3 Common User Pain Points for ‘microwave water bottle’ & Their Solutions

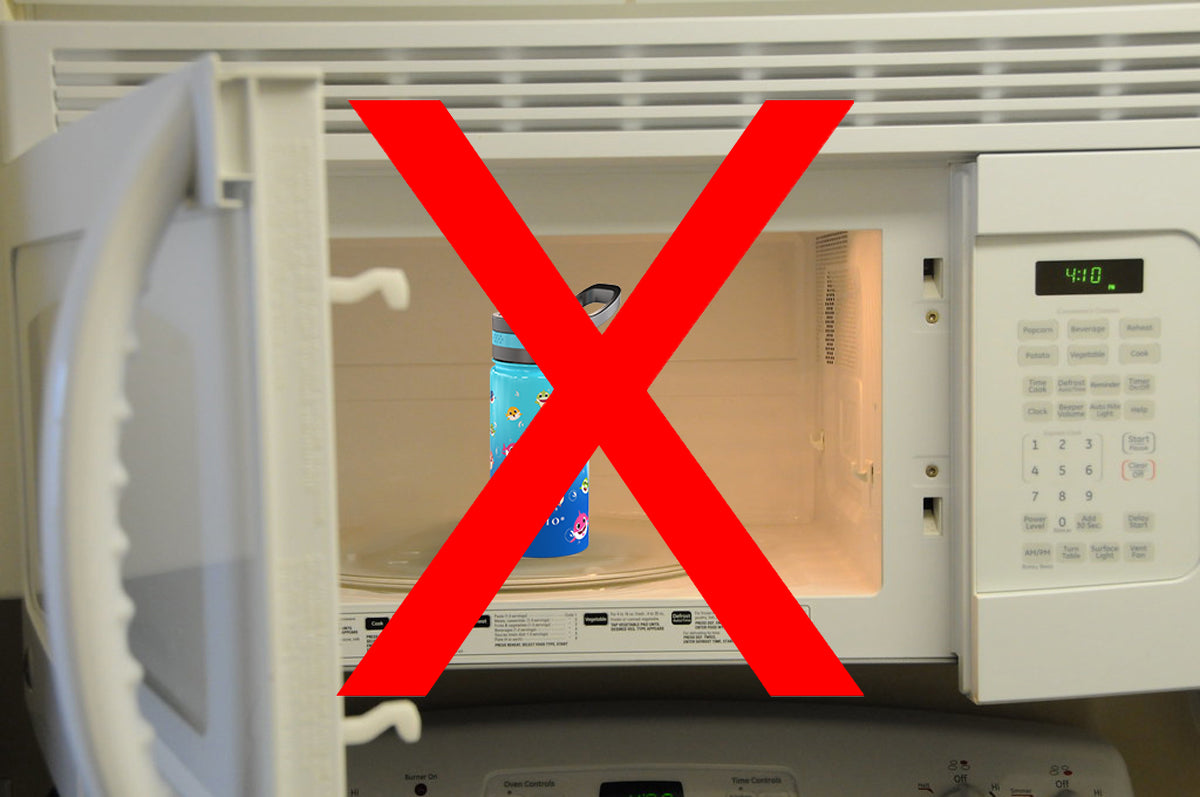

Scenario 1: Ensuring Microwave Safety Compliance for Different Markets

Le problème : B2B buyers often face the challenge of ensuring that the microwave water bottles they source comply with varying safety standards across different regions. For instance, products that are deemed microwave-safe in one country may not meet the regulatory requirements in another, potentially leading to legal liabilities or product recalls. This is particularly pertinent in diverse markets such as Africa, South America, and the Middle East, where regulations can be inconsistent and complex.

La solution : To navigate this issue effectively, B2B buyers should conduct thorough research on the regulatory landscape of each target market. This includes understanding specific certifications required for microwave safety, such as the FDA in the United States or CE marking in Europe. Collaborating with local legal experts or compliance consultants can provide insights into regional standards. Additionally, sourcing products from manufacturers that have a proven track record of compliance in multiple markets can significantly reduce risk. Buyers should also request comprehensive documentation and testing results from suppliers, ensuring that all products are tested for microwave safety and labeled accordingly. Implementing a compliance checklist tailored to each market can streamline this process and ensure that all products meet local regulations.

Scenario 2: Managing Customer Expectations for Product Versatility

Le problème : Many B2B buyers encounter customer dissatisfaction due to misconceptions about the versatility of microwave water bottles. Buyers often assume that all water bottles labeled as microwave-safe can be used interchangeably for heating water, but the reality is that designs and materials vary significantly. This can lead to customer complaints regarding product performance, safety issues, or even injuries from improper use.

La solution : To manage customer expectations effectively, B2B buyers should prioritize clear communication and education regarding product specifications. This involves providing comprehensive product descriptions that detail the materials used, heating instructions, and limitations of each microwave water bottle. Developing informative marketing materials or product guides that explain how to safely use and care for the bottles can help mitigate misunderstandings. Additionally, offering training sessions or webinars for retailers and end-users can empower them with knowledge about the products, enhancing their confidence in the items being sold. By establishing a robust customer education program, buyers can foster loyalty and reduce the incidence of returns or complaints.

Scenario 3: Sourcing High-Quality and Durable Microwave Water Bottles

Le problème : A significant pain point for B2B buyers is sourcing high-quality microwave water bottles that are both durable and safe for repeated use. Many products on the market may be marketed as microwave-safe but lack the durability needed for long-term use, resulting in leaks or material degradation over time. This issue is critical for businesses that aim to build a reputable brand image based on reliable products.

La solution : To address this challenge, B2B buyers should establish strict quality control criteria when selecting suppliers. This includes requesting samples to assess the material quality and durability before placing bulk orders. Engaging with manufacturers who provide third-party testing certifications can also serve as a guarantee of product quality. Buyers should look for microwave water bottles made from high-grade materials, such as BPA-free plastics or reinforced silicone, which are known for their resilience and safety. Furthermore, implementing a feedback loop with customers can help in identifying any recurring issues with product quality, allowing buyers to make informed decisions when selecting future suppliers. By prioritizing quality and durability in the sourcing process, buyers can enhance customer satisfaction and reduce the likelihood of product failure.

Strategic Material Selection Guide for microwave water bottle

What Are the Key Materials Used in Microwave Water Bottles?

When selecting materials for microwave water bottles, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: silicone, glass, BPA-free plastic, and rubber. Each material presents unique characteristics that can influence product performance and marketability.

How Does Silicone Perform as a Material for Microwave Water Bottles?

Silicone is a popular choice for microwave water bottles due to its flexibility and heat resistance. It can withstand temperatures ranging from -40°C to 230°C, making it suitable for various heating applications. Silicone is also non-toxic and does not leach chemicals when heated, ensuring safety for consumers.

Pour : Silicone is highly durable, resistant to wear, and can be molded into various shapes, which enhances design versatility. It is also lightweight and easy to clean, making it a practical option for consumers.

Cons : The initial cost of silicone can be higher than traditional materials like rubber or plastic. Additionally, silicone may not be as rigid, which can affect the bottle’s stability when filled with hot water.

Impact sur l'application : Silicone is compatible with a wide range of liquids and is particularly effective for storing hot water. Its flexibility allows for easy pouring and handling, which is advantageous for users.

Considérations pour les acheteurs internationaux : Buyers should ensure that silicone products meet international safety standards, such as FDA regulations and European Union directives. Understanding local preferences for material safety and durability is also crucial.

What Advantages Does Glass Offer for Microwave Water Bottles?

Glass is another viable option for microwave water bottles, known for its excellent thermal resistance and chemical inertness. It can typically withstand temperatures up to 300°C, making it suitable for microwave use.

Pour : Glass is non-reactive, ensuring that it does not impart any flavors or chemicals into the water. It is also easy to clean and can be recycled, appealing to environmentally conscious consumers.

Cons : While glass is durable, it is also heavy and can break easily, posing safety concerns. Manufacturing glass bottles can be more complex and expensive compared to other materials.

Impact sur l'application : Glass is ideal for applications where purity and taste are paramount, such as in gourmet or health-focused markets. Its aesthetic appeal can also enhance brand perception.

Considérations pour les acheteurs internationaux : Buyers should verify compliance with international standards like ASTM and EN for glass safety. Additionally, understanding local market preferences for aesthetics and functionality can guide purchasing decisions.

What Role Does BPA-Free Plastic Play in Microwave Water Bottles?

BPA-free plastic has gained popularity due to its safety and versatility. Common types include polypropylene and polyethylene, which can withstand moderate temperatures (up to 120°C) and are often labeled as microwave-safe.

Pour : BPA-free plastics are lightweight, cost-effective, and available in various colors and designs. They are also less prone to breaking compared to glass, making them suitable for active lifestyles.

Cons : While BPA-free plastics are safer than traditional plastics, they may still leach chemicals at high temperatures. Their durability can also be lower than silicone or glass, leading to potential wear over time.

Impact sur l'application : These plastics are suitable for everyday use, appealing to a broad consumer base. They are often used in budget-friendly products aimed at families and children.

Considérations pour les acheteurs internationaux : It is crucial to ensure that BPA-free plastics comply with local regulations regarding food safety and materials. Buyers should also be aware of recycling capabilities in their regions to promote sustainability.

How Does Rubber Compare as a Material for Microwave Water Bottles?

Rubber, particularly natural rubber, has been a traditional choice for hot water bottles. It can withstand moderate temperatures but has limitations in microwave applications.

Pour : Rubber is flexible, durable, and provides excellent insulation, making it effective for retaining heat. It is also relatively inexpensive compared to other materials.

Cons : Rubber can degrade over time, especially when exposed to high temperatures or chemicals. Additionally, not all rubber products are microwave-safe, which can limit their application.

Impact sur l'application : Rubber is suitable for traditional hot water bottles but may not be ideal for modern microwave applications. It is often used in markets where traditional methods are preferred.

Considérations pour les acheteurs internationaux : Buyers should confirm that rubber products meet safety standards and are labeled appropriately for microwave use. Understanding local market trends toward modern materials can also influence purchasing decisions.

Summary of Material Selection for Microwave Water Bottles

| Matériau | Typical Use Case for Microwave Water Bottle | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Silicone | Versatile, flexible designs | High durability and heat resistance | Coût initial plus élevé | Moyen |

| Verre | Premium, health-focused applications | Non-reactive and aesthetic appeal | Heavy and breakable | Haut |

| Plastique sans BPA | Everyday use and family-friendly products | Léger et rentable | Potential chemical leaching | Faible |

| Caoutchouc | Traditional hot water bottles | Excellent insulation | Degrades over time | Faible |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on material properties, market trends, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for microwave water bottle

What Are the Main Stages of Manufacturing a Microwave Water Bottle?

Manufacturing a microwave water bottle involves a series of well-defined stages that ensure the final product is safe, durable, and effective for consumer use. Understanding these stages is crucial for B2B buyers looking for reliable suppliers.

Préparation du matériel

The first step in the manufacturing process is material preparation. Common materials for microwave water bottles include various types of plastics, such as High-Density Polyethylene (HDPE) and polypropylene, as well as silicone and sometimes glass. These materials are selected for their microwave-safe properties, durability, and resistance to heat.

During this stage, raw materials are sourced and tested for quality. Suppliers often conduct initial assessments to ensure that materials meet industry standards. For instance, materials may be tested for BPA content and overall safety, which is crucial for consumer trust.

Techniques de formage

Once the materials are prepared, the next stage involves forming the bottle. This process can vary depending on the material used. For plastics, techniques such as injection molding or blow molding are common.

-

Moulage par injection: This method involves injecting molten plastic into a mold to create the desired shape of the water bottle. It allows for high precision and is suitable for producing large quantities.

-

Moulage par soufflage: This technique is often used for hollow bottles. A plastic tube is heated and then inflated to fill a mold, creating a seamless design that can be lightweight yet sturdy.

For silicone products, molding techniques are employed to ensure flexibility and durability, which are essential characteristics for microwave safety.

Processus d'assemblage

The assembly stage involves bringing together various components of the microwave water bottle, such as the cap, seals, and any additional features like handles or insulation. This stage may involve manual assembly or automated processes, depending on the production scale.

Quality checks are integrated throughout the assembly process. For instance, seals are tested for leak resistance, ensuring that the final product will not create hazards during use.

Finishing Touches

Finishing involves adding any necessary surface treatments or coatings to enhance the product’s aesthetic appeal and functionality. This may include applying colors, logos, or other branding elements.

Additionally, the bottles may undergo processes like polishing or sanding to remove any imperfections. At this stage, final inspections are crucial to ensure that the product meets the specified standards before it is packaged for shipment.

How Is Quality Assurance Implemented in Microwave Water Bottle Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for microwave water bottles. It ensures that products meet both international safety standards and customer expectations.

What International Standards Are Relevant for Microwave Water Bottles?

B2B buyers should look for manufacturers that adhere to recognized international quality standards. Key standards include:

-

ISO 9001: This standard focuses on quality management systems and ensures that companies consistently provide products that meet customer and regulatory requirements.

-

Marquage CE: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

-

Normes API: Although more common in the petroleum industry, certain API standards can apply to materials used in water bottles, particularly regarding safety and manufacturing practices.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any defects early. These checkpoints typically include:

-

Contrôle de la qualité à l'arrivée (IQC): This initial checkpoint assesses the raw materials upon delivery. Tests may include checking for material certifications and conducting random sample tests.

-

Contrôle de la qualité en cours de fabrication (IPQC): During the manufacturing stages, samples are taken at various points to ensure that the processes are operating within defined parameters. This may include monitoring temperature settings during molding.

-

Contrôle de qualité final (CQF): At the end of the assembly line, finished products are subjected to rigorous testing. This includes leak tests, thermal stability tests, and visual inspections to check for defects.

What Testing Methods Are Commonly Used for Microwave Water Bottles?

Various testing methods are employed to ensure microwave water bottles are safe and reliable. These methods include:

-

Essais thermiques: This assesses how the bottle performs under extreme temperatures, ensuring that it does not warp or leak when heated in a microwave.

-

Material Testing: This includes tests for chemical leaching, which is vital to ensure that no harmful substances are released when the bottle is heated.

-

Essais de durabilité: Drop tests and pressure tests are conducted to evaluate the bottle’s resilience to everyday use.

Comment les acheteurs B2B peuvent-ils vérifier le contrôle de la qualité des fournisseurs ?

B2B buyers should conduct thorough due diligence when selecting suppliers. Here are actionable steps to verify a supplier’s quality control processes:

-

Audits: Request an audit of the supplier’s manufacturing facility. This can be done by a third-party organization to ensure unbiased results.

-

Quality Control Reports: Ask for detailed reports on the supplier’s QC processes, including any certifications they hold.

-

Inspections par des tiers: Consider hiring third-party inspection services to conduct checks on the products before they are shipped. These inspectors can provide insights into the manufacturing processes and overall quality.

Quelles sont les nuances en matière de contrôle qualité et de certification pour les acheteurs internationaux B2B ?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, it’s essential to understand the specific QC and certification requirements that may vary by region.

-

Regional Standards: Different regions may have unique requirements for product safety and quality. For example, the European Union has stringent regulations regarding plastics, while certain countries in Africa may have less formalized standards.

-

Import Regulations: Understanding the import regulations for each target market is crucial. This includes ensuring that products meet local health and safety standards, which may necessitate additional testing or certification.

-

Considérations culturelles: Awareness of cultural preferences and safety concerns can also play a role in product acceptance. Tailoring products to meet these needs can enhance marketability.

By understanding the manufacturing processes and quality assurance practices in place for microwave water bottles, B2B buyers can make informed decisions and establish partnerships with suppliers that prioritize safety and quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microwave water bottle’

Introduction

When sourcing microwave water bottles for your business, it’s essential to follow a systematic approach to ensure quality, safety, and compliance with local regulations. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively, ensuring that the products meet consumer needs while aligning with business goals.

Étape 1 : Définir les spécifications techniques

Before reaching out to suppliers, clearly outline the technical specifications for the microwave water bottles you intend to procure. This includes dimensions, materials (e.g., BPA-free plastics, silicone), and whether the bottles should have specific features like insulation or safety lids. Defining these specifications helps streamline your sourcing process and ensures you communicate your needs effectively to potential suppliers.

Step 2: Research Regulatory Compliance

Understanding the regulations surrounding microwave-safe products in your target markets is crucial. Different regions may have specific safety standards or certifications that products must meet. Research the necessary compliance requirements for countries like Brazil, Saudi Arabia, or those in Europe, as this will prevent potential legal issues and ensure your products are safe for consumers.

Étape 3 : Évaluer les fournisseurs potentiels

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of delivering quality products and can provide certifications that align with your regulatory requirements. Don’t just rely on their website; conduct interviews or factory visits if possible.

Step 4: Verify Product Safety Features

Ensure that the microwave water bottles are designed with safety features that prevent overheating and leaks. Look for products that include user guidelines for safe microwave use and any certifications related to thermal safety. This step is important not only for consumer safety but also for minimizing the risk of product returns and complaints.

Step 5: Assess Material Quality and Durability

Evaluate the materials used in the construction of the microwave water bottles. Opt for high-quality, durable materials that can withstand repeated heating and cooling cycles without degrading. Materials such as high-density polyethylene (HDPE) or silicone are often preferred. Request samples if possible to conduct your own quality assessments.

Step 6: Consider Eco-Friendly Options

Sustainability is increasingly important to consumers and businesses alike. When sourcing microwave water bottles, consider options that are reusable, made from recycled materials, or designed for eco-friendliness. This not only appeals to environmentally conscious consumers but can also enhance your brand reputation in the marketplace.

Step 7: Negotiate Terms and Review Contracts

Once you have identified potential suppliers and verified their products, it’s time to negotiate terms. Discuss pricing, minimum order quantities, lead times, and payment terms. Ensure that all agreements are documented in a contract that clearly outlines expectations, responsibilities, and remedies for non-compliance. This protects your interests and helps maintain a healthy supplier relationship.

By following these steps, you will be better equipped to make informed decisions when sourcing microwave water bottles, ultimately leading to successful procurement and satisfied customers.

Comprehensive Cost and Pricing Analysis for microwave water bottle Sourcing

What Are the Key Cost Components in Sourcing Microwave Water Bottles?

When sourcing microwave water bottles, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Matériaux: The choice of materials significantly impacts the overall cost. Microwave-safe plastics such as High-Density Polyethylene (HDPE) or Polypropylene (PP) are commonly used and can vary in price based on quality and supplier. Eco-friendly materials may come at a premium, appealing to sustainability-conscious buyers.

-

Travail: Labor costs can fluctuate based on geographic location. Regions with lower labor costs, such as certain parts of Asia, may offer competitive pricing, but this can also affect quality and lead times.

-

Frais généraux de fabrication: This includes costs related to utilities, facility maintenance, and other operational expenses. Buyers should consider suppliers who can demonstrate efficient manufacturing processes to minimize these costs.

-

Outillage: Custom designs or molds for unique shapes and sizes of water bottles can involve significant tooling costs. This is an essential consideration for buyers looking to differentiate their products in the market.

-

Contrôle de la qualité (CQ): Implementing stringent QC processes ensures that the products meet safety and performance standards, which can incur additional costs. However, investing in QC can prevent costly recalls and enhance brand reputation.

-

Logistique: Shipping and handling costs are influenced by the distance from the manufacturing site to the buyer’s location, as well as the chosen shipping method. International buyers must also account for customs duties and taxes.

-

Marge: Suppliers will typically add a markup to cover their costs and ensure profitability. This margin can vary depending on the supplier’s market position and the competitiveness of the industry.

How Do Price Influencers Affect the Cost of Microwave Water Bottles?

Several factors influence the pricing of microwave water bottles, particularly for international B2B transactions:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Bulk purchases often lead to discounts, making it essential for buyers to negotiate favorable terms based on their expected sales volume.

-

Spécifications et personnalisation: Tailored specifications, such as custom branding or unique designs, can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Matériaux et certifications de qualité: Higher-quality materials or certifications (like BPA-free or eco-friendly labels) can raise production costs. Buyers should assess whether these certifications align with their target market’s demands.

-

Facteurs liés au fournisseur: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more, but they often provide better assurance of product consistency and service.

-

Incoterms: The choice of Incoterms can affect the overall cost of acquiring microwave water bottles. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping and insurance costs, impacting the final price.

What Buyer Tips Should Be Considered for Cost-Efficiency?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Négociation: Leverage volume commitments to negotiate better pricing. Building a long-term relationship with suppliers can also yield more favorable terms over time.

-

Coût total de possession (TCO): Consider the TCO, which includes purchase price, shipping, duties, and operational costs over the product’s lifespan. A lower upfront cost may lead to higher long-term expenses if the product quality is subpar.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers. Evaluate their production capabilities, quality control processes, and past client reviews to ensure they meet your standards.

-

Comprendre les nuances de la tarification: Be aware of regional pricing differences. Factors like local economic conditions, currency fluctuations, and trade agreements can significantly impact costs.

-

Rester informé des tendances du marché: Keeping abreast of trends in materials and manufacturing processes can provide insights into potential cost savings and innovations that could enhance product offerings.

Avertissement sur les prix indicatifs

Prices for microwave water bottles can vary widely based on the factors outlined above. Buyers should conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing microwave water bottle With Other Solutions

When considering hydration and heating solutions for diverse applications, the microwave water bottle stands out, but it is essential to evaluate other viable alternatives. This comparison will provide B2B buyers with insights into various options available in the market, helping them make informed decisions based on performance, cost, and practicality.

| Aspect comparatif | Microwave Water Bottle | Electric Hot Water Dispenser | Traditional Stovetop Kettle |

|---|---|---|---|

| Performance | Quick heating, portable | Rapid boiling, consistent temperature | Slower heating, less precise |

| Coût | Moderate (varies by brand) | Higher initial investment, lower long-term cost | Low initial cost, but less energy efficient |

| Facilité de mise en œuvre | Simple to use, requires microwave | Requires electrical outlet, easy to operate | Requires manual operation, no electricity needed |

| Maintenance | Minimal, easy to clean | Requires descaling and maintenance | Regular cleaning needed, especially if used with hard water |

| Meilleur cas d'utilisation | Personal use, travel, quick relief | Office settings, high-demand environments | Home use, traditional cooking |

What Are the Benefits and Drawbacks of Using an Electric Hot Water Dispenser as an Alternative?

Electric hot water dispensers are an excellent alternative for environments where rapid and consistent hot water supply is needed. They can heat water in seconds and maintain it at a desired temperature, making them ideal for offices, cafes, or facilities that require frequent hot water access. However, they come with a higher initial investment and require an electrical outlet, which may not be feasible in every location. Moreover, regular maintenance is necessary to prevent mineral build-up, especially in areas with hard water.

How Does a Traditional Stovetop Kettle Compare to a Microwave Water Bottle?

Traditional stovetop kettles offer a simple and cost-effective solution for heating water. They can be used on various heat sources, including gas and electric stoves, and do not require electricity, making them useful in remote locations. However, they have slower heating times compared to microwave water bottles and lack the convenience of portability. Users must monitor the kettle to prevent overboiling, which can lead to safety hazards. This method is best suited for home use or situations where precise temperature control is not critical.

Comment les acheteurs B2B peuvent-ils choisir la bonne solution pour leurs besoins ?

When evaluating the best solution for heating water, B2B buyers should consider the specific use case and environment. If rapid heating and portability are priorities, a microwave water bottle is a suitable option. In contrast, if the need is for a consistent hot water supply in a high-demand setting, an electric hot water dispenser may be more appropriate despite the higher upfront cost. For traditional settings where electricity is not accessible or where low cost is a priority, a stovetop kettle remains a reliable choice. Ultimately, the right solution will depend on balancing performance, cost, and user requirements.

Essential Technical Properties and Trade Terminology for microwave water bottle

What Are the Key Technical Properties of Microwave Water Bottles?

When considering microwave water bottles for B2B procurement, understanding their technical properties is crucial for ensuring safety, durability, and market competitiveness. Here are several critical specifications to consider:

-

Composition du matériau: The primary materials used in microwave water bottles include high-density polyethylene (HDPE), polypropylene, and silicone. HDPE is known for its durability and resistance to impact, while polypropylene is often labeled as microwave-safe. Understanding the material helps in assessing the bottle’s heat resistance, safety, and compliance with health regulations.

-

Capacité: The volume of water a bottle can hold is a key specification. Common capacities range from 500ml to 2 liters. This is important for B2B buyers as it influences customer satisfaction and usability. Larger bottles may be marketed for family use, while smaller sizes can appeal to individuals.

-

Microwave Safety Rating: It’s essential to verify if the bottle has a microwave-safe label. This indicates that the product has undergone testing to ensure it can withstand microwave heating without deforming or releasing harmful substances. B2B buyers should prioritize sourcing products with clear safety certifications to mitigate liability risks.

-

Temperature Tolerance: This property refers to the maximum temperature the bottle can safely withstand during microwave heating. Many microwave-safe bottles can handle temperatures up to 120°C (248°F). Knowing this specification helps buyers ensure that their products meet consumer safety expectations, especially in regions with stringent regulations.

-

Design Features: Features such as insulated walls, ergonomic grips, and leak-proof lids enhance user experience. For B2B buyers, understanding these design elements can help in marketing the product effectively, as they contribute to usability and customer satisfaction.

-

Durability and Lifespan: The expected lifespan of a microwave water bottle can vary based on its material and construction quality. Bottles made from high-grade plastics or silicone tend to have a longer lifespan. B2B buyers should consider the durability of products to reduce return rates and enhance brand reputation.

What Are Common Trade Terms Related to Microwave Water Bottles?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B sector. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of microwave water bottles, OEMs often provide custom branding options for businesses looking to create private-label products.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet their inventory needs without overcommitting to excessive stock.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products. For buyers of microwave water bottles, sending an RFQ allows them to compare offers and negotiate better deals.

-

Incoterms (termes commerciaux internationaux): These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is vital for B2B buyers to understand shipping costs and liabilities.

-

Normes de certification: These refer to the compliance measures that products must meet to be deemed safe for use in various markets. For microwave water bottles, certifications like FDA approval (in the U.S.) or CE marking (in Europe) assure buyers of product safety and quality.

-

Délai d'exécution: This is the period between placing an order and receiving the product. Understanding lead times is essential for B2B buyers to effectively manage inventory and meet customer demand.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing microwave water bottles, ensuring they align with market needs and safety standards.

Navigating Market Dynamics and Sourcing Trends in the microwave water bottle Sector

What Are the Key Trends Shaping the Microwave Water Bottle Market?

The global microwave water bottle market is experiencing significant growth, driven by rising consumer demand for convenience and multifunctionality in everyday products. As urbanization accelerates, particularly in regions like Africa and South America, consumers are increasingly seeking products that offer quick solutions for daily challenges, such as relieving aches or providing warmth. Additionally, the growing awareness of health and wellness is pushing consumers to invest in products that contribute to their overall well-being, such as microwave-safe water bottles that can be used for therapeutic purposes.

Technological advancements are also influencing sourcing trends. Manufacturers are increasingly integrating smart technology into product designs, offering features like temperature control and safety sensors that prevent overheating. This innovation not only enhances user experience but also aligns with the preferences of tech-savvy consumers. Furthermore, international B2B buyers should be aware of the shifting dynamics in global supply chains due to geopolitical factors and trade regulations, particularly in markets like Brazil and Saudi Arabia, which can affect sourcing strategies.

Sustainability is another critical factor. Buyers are gravitating towards products made from eco-friendly materials, as consumers become more environmentally conscious. This trend is further reinforced by regulatory pressures in Europe and the Middle East, where compliance with sustainability standards is becoming mandatory. As a result, B2B buyers must stay abreast of these trends to make informed sourcing decisions that not only meet market demands but also contribute positively to their brand image.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Microwave Water Bottles?

The environmental impact of manufacturing processes for microwave water bottles is a growing concern among B2B buyers. As consumers increasingly demand transparency and sustainability, it is crucial for businesses to prioritize ethical sourcing practices. This includes assessing the entire supply chain, from raw material extraction to production methods, to ensure that operations adhere to environmental regulations and social responsibility standards.

Buyers should look for suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management or certifications related to sustainable materials, like recycled plastics or BPA-free products. These certifications not only demonstrate a commitment to sustainability but also enhance product credibility in the eyes of consumers. Additionally, sourcing from manufacturers that implement eco-friendly practices, such as reducing water usage and minimizing carbon footprints, can further bolster a company’s environmental credentials.

Moreover, ethical sourcing extends beyond environmental considerations to encompass fair labor practices. Ensuring that workers in the supply chain are treated fairly and paid living wages is essential for maintaining brand integrity and consumer trust. By prioritizing sustainability and ethical sourcing, B2B buyers can meet market expectations while contributing to a more responsible global economy.

What Is the Historical Context of Microwave Water Bottles in the B2B Market?

The concept of using water bottles for heat therapy dates back several centuries, with early versions made from materials like metal and glass. However, the introduction of microwave-safe materials in the late 20th century revolutionized the industry, allowing consumers to heat water bottles conveniently without the risk of burns or leaks. This evolution has significantly shaped the current B2B landscape, where manufacturers are now focused on creating products that combine safety, efficiency, and comfort.

As consumer preferences evolved, so did the designs of microwave water bottles, leading to a variety of shapes, sizes, and materials tailored to different markets. This adaptability has enabled businesses to cater to diverse consumer needs across regions, particularly in emerging markets in Africa and South America, where the demand for affordable and multifunctional products is on the rise. As a result, understanding the historical context of microwave water bottles provides valuable insights into current market dynamics and future opportunities for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of microwave water bottle

-

1. How do I determine if a microwave water bottle is suitable for my market?

To determine the suitability of a microwave water bottle for your market, begin by evaluating local regulations regarding product safety and material standards. Research consumer preferences in your region, as well as any specific requirements, such as BPA-free materials or eco-friendly designs. Engaging with local distributors or conducting surveys can provide insights into market demand. Additionally, assess the competition to identify gaps in the current offerings that your product could fill, ensuring that it aligns with the needs of your target audience. -

2. What is the best material for microwave water bottles?

The best materials for microwave water bottles typically include high-density polyethylene (HDPE), glass, and certain types of ceramic. These materials are known for their microwave safety and durability. When sourcing, prioritize bottles labeled as “microwave-safe” to ensure compliance with safety standards. Avoid materials like stainless steel or aluminum, which can pose safety hazards in microwaves. It’s also beneficial to assess the insulation properties of the materials, as this can enhance user experience by maintaining temperature longer. -

3. What customization options should I consider for microwave water bottles?

When considering customization options for microwave water bottles, think about branding, colors, and designs that resonate with your target market. Custom shapes or ergonomic designs can enhance usability and attract customers. Additionally, consider personalized packaging that reflects your brand’s identity. Functionality features such as integrated handles, spouts, or easy-grip surfaces can also be appealing. Collaborate with suppliers to explore available customization processes and ensure they can meet your design specifications within your budget. -

4. How can I ensure the quality of microwave water bottles from suppliers?

To ensure the quality of microwave water bottles from suppliers, implement a comprehensive vetting process. Start by reviewing supplier certifications, such as ISO or CE markings, which indicate adherence to international quality standards. Request samples to assess material quality, durability, and microwave safety. Establish clear quality assurance protocols, including third-party testing for safety compliance. Regular audits and feedback loops with suppliers can also help maintain quality over time, ensuring that products meet your expectations and customer requirements. -

5. What are common minimum order quantities (MOQ) for microwave water bottles?

Minimum order quantities (MOQ) for microwave water bottles can vary significantly based on the supplier and the specific product. Typically, MOQs range from 500 to 10,000 units, depending on factors such as production capabilities and material sourcing. It’s crucial to discuss your needs directly with suppliers to negotiate favorable terms, especially if you are testing market demand with a new product. Some suppliers may offer flexible MOQs for custom designs or smaller initial orders, which can be advantageous for startups. -

6. What payment terms are standard when sourcing microwave water bottles internationally?

Standard payment terms for international sourcing of microwave water bottles often include options such as a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the goods. It’s essential to clarify payment methods accepted (e.g., wire transfer, credit card, or letters of credit) and ensure that the terms are documented in your purchase agreement. Additionally, consider the impact of currency exchange rates on your pricing and budgeting. -

7. How do I handle logistics and shipping for microwave water bottles?

Handling logistics and shipping for microwave water bottles involves several key steps. First, choose a reliable freight forwarder experienced in international shipping. Decide on the shipping method (air, sea, or land) based on your budget and delivery timeline. Ensure that all necessary documentation, such as customs declarations and invoices, is accurately prepared to avoid delays. Additionally, discuss insurance options with your freight forwarder to protect your investment during transit. Finally, plan for customs clearance in the destination country to facilitate smooth delivery. -

8. What are the safety regulations for microwave water bottles in different regions?

Safety regulations for microwave water bottles vary by region and can include specific guidelines on materials used, labeling, and manufacturing processes. In Europe, for instance, products must comply with the EU’s REACH regulations, while in the U.S., the Consumer Product Safety Commission (CPSC) oversees product safety. In regions like Africa and South America, regulations may differ significantly, often requiring local certifications. Research the specific regulations applicable to your target markets and ensure that your products meet all necessary compliance standards to avoid legal issues and enhance market acceptance.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 7 Microwave Water Bottle Manufacturers & Suppliers List

1. Reddit – Safety of Microwaving Disposable Plastic Water Bottles

Domaine : reddit.com

Enregistré : 2005 (20 ans)

Introduction : Disposable plastic water bottles are not safe for microwaving beverages, as heating can cause the plastic to leach harmful substances into the drink.

2. Target – Microwave-Safe Water Bottles

Domaine : target.com

Enregistré : 1997 (28 ans)

Introduction : Microwave-Safe Water Bottles available at Target. Key products include: 1. Team USA 24oz Peanuts Snoopy Venture Lite Water Bottle – $24.99 2. NFL Philadelphia Eagles 24oz All Over Venture Lite Water Bottle – $29.99 3. NCAA Kentucky Wildcats 24oz Primary Logo Venture Lite Water Bottle – $29.99 4. NFL Las Vegas Raiders 24oz All Over Venture Lite Water Bottle – $29.99 5. NBA Los Angeles Lakers 24oz P…

3. Walmart – Silicone Hot Water Bottle

Domaine : walmart.com

Enregistré : 1995 (30 ans)

Introduction : This company, Walmart – Silicone Hot Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Bearaby – Hot Water Bottles

Domaine : bearaby.com

Enregistré : 2018 (7 ans)

Introduction : Hot water bottles are versatile for warmth and pain relief. Whether you can microwave a hot water bottle depends on its specific design. Always check the manufacturer’s guidelines and heating instructions to avoid burns and overheating. Microwaving non-microwavable bottles can cause damage and safety hazards. Inspect materials, design, and labels to determine if your water bottle is microwavable.

5. Buzio – Microwave-Safe Water Bottles

Domaine : buziolife.com

Enregistré : 2017 (8 ans)

Introduction : Buzio water bottles are made of polyethylene terephthalate (PET), indicated by recycling symbol #1, which is microwave-safe. It is advised to remove the cap before microwaving to prevent pressure build-up, and not to heat the water for more than two minutes to avoid scalding. The bottles should not be overfilled and should be placed in the center of the microwave for even heating.

6. Samply – Hot Water Bottles UZhen 1.7L & 1.2L

Domaine : samply.com

Enregistré : 2006 (19 ans)

Introduction : Hot Water Bottle UZhen CAPACITY:1.7L, UZhen CAPACITY:1.2L

7. LIPPA – Hot Water Bottle Microwave Safe

Domaine : ebay.com

Enregistré : 1995 (30 ans)

Introduction : {“Product Name”: “Hot Water Bottle Microwave Safe”, “Condition”: “New”, “Brand”: “LIPPA”, “Type”: “Hot Water Bottle & Cover”, “Color”: “Yellow”, “Theme”: “Home & Garden”, “Features”: “With Cover”, “Material”: “Silicone”, “Price”: “$39.99”, “Shipping”: “Free Economy Shipping from outside US”, “Returns”: “30 days returns, Seller pays for return shipping”, “Seller Feedback”: “100% positive”, “Locatio…

Strategic Sourcing Conclusion and Outlook for microwave water bottle

As the market for microwave water bottles continues to expand, strategic sourcing becomes essential for B2B buyers aiming to capitalize on this growing demand. Understanding the diverse materials, designs, and safety features associated with these products is crucial for making informed purchasing decisions. By prioritizing quality and compliance with safety standards, businesses can not only mitigate risks but also enhance customer satisfaction and brand loyalty.

Furthermore, the increasing global emphasis on sustainability presents an opportunity for suppliers to innovate with eco-friendly materials and designs, appealing to environmentally conscious consumers across regions such as Africa, South America, the Middle East, and Europe. As international buyers, it is vital to establish partnerships with manufacturers who prioritize both functionality and environmental responsibility.

Looking ahead, the microwave water bottle market is poised for significant growth, driven by rising consumer awareness and evolving lifestyle preferences. Now is the time for international B2B buyers to engage with reliable suppliers and explore innovative product offerings that meet the needs of a dynamic consumer base. Take the next step in your sourcing strategy and position your business for success in this promising market.