Introduction: Navigating the Global Market for water bottle insulators

In the ever-evolving landscape of global commerce, sourcing effective water bottle insulators presents a unique challenge for international B2B buyers. With growing demand for hydration solutions that maintain beverage temperatures across varying climates, understanding the nuances of this product category is essential for successful procurement. This guide delves into the diverse types of water bottle insulators available in the market, from neoprene sleeves to high-performance insulated covers, tailored for various applications and environments.

Buyers will gain insights into the critical factors influencing purchasing decisions, such as material quality, insulation capabilities, and compatibility with popular bottle sizes. Additionally, we explore the importance of supplier vetting, highlighting how to identify reliable manufacturers from regions such as Africa, South America, the Middle East, and Europe, including notable markets like Brazil and Germany.

By equipping international B2B buyers with actionable intelligence on cost considerations, industry trends, and product specifications, this guide empowers organizations to make informed purchasing decisions. Understanding these elements not only enhances operational efficiency but also ensures that businesses can meet the hydration needs of their customers effectively, regardless of geographic location.

Navigation dans les articles

- Top 6 Water Bottle Insulators Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water bottle insulators

- Understanding water bottle insulators Types and Variations

- Key Industrial Applications of water bottle insulators

- 3 Common User Pain Points for ‘water bottle insulators’ & Their Solutions

- Strategic Material Selection Guide for water bottle insulators

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle insulators

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle insulators’

- Comprehensive Cost and Pricing Analysis for water bottle insulators Sourcing

- Alternatives Analysis: Comparing water bottle insulators With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle insulators

- Navigating Market Dynamics and Sourcing Trends in the water bottle insulators Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle insulators

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for water bottle insulators

Understanding water bottle insulators Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Neoprene Sleeves | Flexible, lightweight, and water-resistant; available in various sizes and colors. | Outdoor gear retailers, fitness centers | Pour : Affordable, customizable; Cons : Less durable in extreme conditions. |

| Insulated Bottle Covers | Thick insulation, often with features to prevent freezing; designed for specific bottle sizes. | Specialty outdoor stores, expedition suppliers | Pour : Excellent temperature retention; Cons : Higher price point, specific fit. |

| Foldable Insulators | Compact, lightweight, and easy to store; suitable for various bottle shapes. | Travel accessory retailers, event organizers | Pour : Space-saving, versatile; Cons : May offer less insulation than rigid options. |

| Koozies | Typically made from foam or fabric; designed to prevent condensation. | Beverage distributors, promotional items | Pour : Cost-effective, lightweight; Cons : Limited thermal insulation capacity. |

| Customizable Insulators | Options for branding and personalization; made from various materials. | Corporate gifts, promotional merchandise | Pour : Enhances brand visibility; Cons : Minimum order quantities may apply. |

What Are Neoprene Sleeves and Their B2B Applications?

Neoprene sleeves are popular for their flexibility and lightweight properties, making them a practical choice for B2B buyers in outdoor gear and fitness sectors. Available in various sizes and colors, they can accommodate different bottle shapes, catering to diverse customer preferences. When purchasing, consider factors such as durability against wear and tear and the potential for customization, which can enhance brand appeal in retail settings.

How Do Insulated Bottle Covers Benefit Businesses?

Insulated bottle covers are designed with thick insulation materials that excel in maintaining beverage temperatures, making them ideal for outdoor and adventure retailers. They often fit specific bottle sizes, ensuring a snug fit. B2B buyers should evaluate the price point against the performance benefits, especially for high-end markets where customers expect superior quality and functionality.

What Advantages Do Foldable Insulators Offer?

Foldable insulators are designed for convenience and portability, making them an excellent choice for travel accessory retailers and event organizers. Their compact nature allows for easy storage and transport, appealing to customers who prioritize space-saving solutions. Buyers should assess the insulation performance, as these may not provide the same level of temperature retention as more rigid options.

How Do Koozies Fit into the Market?

Koozies, typically made from foam or fabric, are designed to prevent condensation and keep beverages at a comfortable temperature. They are often used as promotional items, making them suitable for beverage distributors and companies looking to enhance brand visibility. When considering a purchase, businesses should weigh the cost-effectiveness against the limited thermal insulation capabilities of these products.

Why Choose Customizable Insulators for Promotional Use?

Customizable insulators allow businesses to incorporate branding and personalization, making them ideal for corporate gifts and promotional merchandise. They can be made from various materials, catering to different market segments. Buyers should be mindful of minimum order quantities and production times, as these factors can influence inventory management and marketing strategies.

Key Industrial Applications of water bottle insulators

| Industrie/secteur | Specific Application of Water Bottle Insulators | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Loisirs de plein air | Insulating bottles for hiking and camping | Enhances hydration experience in extreme temperatures | Durability, weight, insulation effectiveness, compatibility with various bottle sizes |

| Alimentation et boissons | Insulated bottles for catering and events | Maintains beverage temperatures, improves customer satisfaction | Material safety, customization options, bulk pricing, lead times |

| Sports et remise en forme | Insulated bottles for gyms and sports teams | Keeps drinks at optimal temperatures for athletes | Size variations, branding opportunities, ease of cleaning |

| Soins de santé | Insulated water bottles for hospitals and clinics | Encourages hydration among patients and staff | Compliance with health regulations, ease of use, insulation performance |

| L'éducation | Insulated bottles for schools and universities | Promotes hydration among students, reduces waste from disposable bottles | Cost-effectiveness, branding potential, environmental sustainability |

How Are Water Bottle Insulators Used in Outdoor Recreation?

In the outdoor recreation industry, water bottle insulators play a crucial role in enhancing the hydration experience during activities like hiking and camping. They are designed to maintain the temperature of liquids, ensuring that water remains cold in hot climates or warm in freezing conditions. This is particularly important for outdoor enthusiasts who often face extreme weather. Buyers in this sector must consider factors such as durability, weight, and compatibility with various bottle sizes to ensure that their products meet the needs of adventurers.

What Benefits Do Insulated Bottles Offer in Food and Beverage Industries?

In the food and beverage sector, insulated bottles are essential for catering and event management. They help maintain the temperature of beverages, ensuring that drinks stay cold or hot for extended periods, which significantly enhances customer satisfaction. Businesses sourcing these products should focus on material safety, customization options for branding, and bulk pricing to optimize costs. Additionally, understanding lead times for delivery can be crucial for event planning.

How Do Sports and Fitness Industries Utilize Insulated Bottles?

Sports teams and fitness centers use insulated bottles to keep athletes’ drinks at the ideal temperature during workouts and competitions. This not only aids in hydration but also enhances performance. When sourcing insulated bottles for this sector, businesses should look for size variations that cater to different sports and activities, as well as branding opportunities that allow for team logos. Ease of cleaning is also a critical factor, as these bottles are used frequently.

Why Are Insulated Water Bottles Important in Healthcare Settings?

In healthcare environments, insulated water bottles encourage hydration among patients and staff, which is vital for overall health. These bottles must comply with health regulations and be easy to use, especially for individuals with mobility challenges. Buyers in this sector should prioritize insulation performance to ensure beverages remain at safe drinking temperatures. Additionally, the ease of cleaning and sterilization is essential for maintaining hygiene standards.

What Role Do Insulated Bottles Play in Educational Institutions?

Educational institutions are increasingly adopting insulated water bottles to promote hydration among students while reducing reliance on disposable plastic bottles. These bottles not only support environmental sustainability but also foster a culture of health and wellness. When sourcing for schools and universities, buyers should consider cost-effectiveness and the potential for branding, as well as the environmental impact of the materials used in the products.

3 Common User Pain Points for ‘water bottle insulators’ & Their Solutions

Scenario 1: Struggling with Temperature Retention in Extreme Conditions

Le problème : B2B buyers in regions with extreme temperatures, such as the Middle East or Southern Africa, often face challenges with maintaining the temperature of beverages in water bottles. In hot climates, water can heat up rapidly, while in colder regions, there’s a risk of liquids freezing. This inconsistency can affect the quality of the product they provide, especially if the insulators fail to perform adequately, leading to customer dissatisfaction.

La solution : To combat this issue, buyers should seek water bottle insulators that specifically emphasize temperature retention features. Products made from high-density neoprene or closed-cell foam can significantly enhance insulation performance. When sourcing, consider manufacturers that provide detailed specifications on the insulation properties, including the thickness of the material and its temperature resistance capabilities. It’s also beneficial to choose insulators with a secure fit for a variety of bottle sizes, ensuring comprehensive coverage and minimal heat transfer. Additionally, advising end-users to pre-chill or pre-heat their bottles before filling them can further enhance performance.

Scenario 2: Concerns Over Material Durability and Safety

Le problème : Buyers are increasingly cautious about the materials used in water bottle insulators, especially regarding durability and safety standards. Concerns over toxic materials, particularly in regions with strict regulatory compliance, can create hesitance to purchase or distribute certain products. B2B buyers need to ensure that the insulators meet international safety standards while also being robust enough for repeated use in demanding environments.

La solution : When sourcing insulated products, prioritize suppliers who can provide certifications regarding material safety and durability. Look for insulators made from BPA-free and non-toxic materials that comply with European or American safety regulations. Request samples to test for wear and tear in real-world conditions, ensuring that the insulators maintain their integrity after extended use. Establishing partnerships with reputable manufacturers who prioritize sustainability and ethical practices can also enhance brand reputation and customer trust.

Scenario 3: Managing Inventory and Meeting Customer Expectations

Le problème : B2B buyers often struggle with inventory management when it comes to seasonal products like water bottle insulators. As demand fluctuates with changes in weather, buyers may find themselves either overstocked or underprepared, leading to lost sales opportunities or increased storage costs. This challenge is particularly acute in regions where outdoor activities peak in specific seasons, creating a need for timely availability.

La solution : Implementing a just-in-time (JIT) inventory strategy can significantly alleviate these issues. Work closely with suppliers to establish flexible ordering systems that allow for quick restocking based on real-time sales data. Use predictive analytics to forecast demand more accurately, considering factors like seasonal trends and local events that may influence sales. Additionally, consider offering a diverse range of insulator styles and sizes to cater to different customer preferences, ensuring that your offerings remain attractive and relevant throughout the year. This approach not only optimizes inventory levels but also enhances customer satisfaction by providing the right products at the right time.

Strategic Material Selection Guide for water bottle insulators

What Are the Key Properties of Common Materials Used in Water Bottle Insulators?

When selecting materials for water bottle insulators, several options stand out due to their unique properties and performance characteristics. Understanding these materials can help international B2B buyers make informed decisions that align with their market needs.

Neoprene: A Versatile Insulation Material

Neoprene is a synthetic rubber that offers excellent thermal insulation properties. It can withstand a temperature range of -40°F to 200°F (-40°C to 93°C) and is resistant to water, oils, and UV light. The flexibility of neoprene allows it to fit snugly around various bottle shapes, making it suitable for diverse applications.

Pour : Neoprene is durable and provides a good balance between insulation and weight, making it ideal for outdoor use. It is also relatively cost-effective, which is advantageous for bulk purchases.

Cons : While neoprene is resistant to many substances, it can degrade over time when exposed to harsh chemicals. Additionally, its production process can be complex, impacting manufacturing timelines.

Impact sur l'application : Neoprene is compatible with a wide range of liquids, including hot and cold beverages, making it versatile for different climates and activities.

Considérations pour les acheteurs internationaux : Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider local preferences for eco-friendly materials, as neoprene is synthetic and may not align with sustainability goals in some regions.

Foam Insulation: Lightweight and Effective

Foam insulation, particularly closed-cell foam, is another popular choice for water bottle insulators. This material is lightweight and provides excellent thermal resistance, keeping beverages at their desired temperatures for extended periods.

Pour : The lightweight nature of foam makes it easy to transport, and its insulating properties are highly effective in both hot and cold conditions. It is also generally less expensive than other materials.

Cons : Foam can be less durable than other options, particularly in rugged environments. It may also be susceptible to compression over time, reducing its insulating effectiveness.

Impact sur l'application : Foam insulation is ideal for casual use, such as picnics or day hikes, but may not be suitable for extreme outdoor conditions where durability is critical.

Considérations pour les acheteurs internationaux : Buyers should verify the foam’s compliance with safety and environmental regulations in their respective regions. The demand for recyclable or biodegradable materials is increasing, especially in Europe.

Stainless Steel: A Premium Choice for Durability

Stainless steel is renowned for its strength and resistance to corrosion, making it a premium choice for water bottle insulators. It can handle high temperatures and is generally safe for various beverages.

Pour : Stainless steel offers exceptional durability and is resistant to rust and staining. It is also easy to clean and maintain, making it a long-lasting option for consumers.

Cons : The higher cost of stainless steel can be a barrier for some buyers, especially when compared to more affordable materials like neoprene or foam. Additionally, it is heavier than other insulating materials, which may not appeal to all consumers.

Impact sur l'application : Stainless steel is particularly suitable for high-end markets and eco-conscious consumers who prioritize durability and sustainability.

Considérations pour les acheteurs internationaux : Compliance with food safety standards (e.g., FDA, EU regulations) is crucial. Buyers should also be aware of the varying preferences for stainless steel grades in different markets.

Polyester: Cost-Effective and Stylish

Polyester is often used in water bottle insulators due to its affordability and versatility. It can be blended with other materials to enhance its properties, making it a popular choice for various applications.

Pour : Polyester is lightweight, cost-effective, and available in a wide range of colors and designs, allowing for customization. It also dries quickly and is resistant to shrinking and stretching.

Cons : While polyester is durable, it may not provide the same level of insulation as neoprene or foam. Its performance can vary significantly based on the specific blend and manufacturing process.

Impact sur l'application : Polyester is suitable for casual use and promotional products, appealing to brands looking for budget-friendly options.

Considérations pour les acheteurs internationaux : Buyers should ensure that polyester products meet local environmental regulations, as there is a growing emphasis on sustainability and the use of recycled materials.

Summary Table of Material Selection for Water Bottle Insulators

| Matériau | Typical Use Case for water bottle insulators | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Neoprene | Outdoor activities, sports | Durable et flexible | Degrades with harsh chemicals | Moyen |

| Foam Insulation | Casual outings, picnics | Lightweight and effective | Less durable in rugged conditions | Faible |

| Acier inoxydable | High-end markets, eco-conscious consumers | Exceptional durability | Higher cost and heavier | Haut |

| Polyester | Promotional items, casual use | Cost-effective and customizable | Varies in insulation performance | Faible |

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle insulators

What Are the Main Stages in the Manufacturing Process of Water Bottle Insulators?

The manufacturing process for water bottle insulators typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensure the final product meets quality and performance standards.

-

Préparation du matériel: The first step involves sourcing high-quality materials, such as neoprene, silicone, or other insulated fabrics. Suppliers often need to provide certifications that guarantee the materials are safe and meet international standards. This stage includes cutting the materials to specific dimensions based on the design requirements, ensuring consistency across batches.

-

Formation: In this stage, the prepared materials are shaped into the desired form. Techniques such as molding, sewing, or heat sealing are employed depending on the design specifications. For example, neoprene is often stitched together to create sleeves that fit various bottle sizes. Manufacturers may utilize computer-aided design (CAD) software to ensure precision in the forming process, which is critical for achieving a snug fit.

-

Assemblée: After forming, the components are assembled. This could involve attaching zippers, straps, or other functional elements. Assembly lines are typically organized to maximize efficiency, with trained workers overseeing the process. Automation may be used for repetitive tasks, but skilled labor remains essential, especially for quality-sensitive operations.

-

Finition: The final stage includes quality checks and any necessary finishing touches, such as adding branding, labels, or protective coatings. Products may undergo additional processes like washing or drying to remove any residues from manufacturing. This stage is crucial for ensuring that the insulators are ready for consumer use and can withstand the rigors of outdoor activities.

How Do Quality Assurance Standards Impact the Production of Water Bottle Insulators?

Quality assurance (QA) is paramount in manufacturing, especially for products that interact with consumers and the environment. Compliance with international standards such as ISO 9001 ensures that manufacturers implement systematic processes to maintain quality throughout production.

-

Normes internationales: ISO 9001 focuses on consistent quality management systems, which help manufacturers identify areas for improvement and ensure customer satisfaction. In addition to ISO, other certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can be relevant, particularly for products intended for specific markets or uses.

-

Points de contrôle de la qualité: Implementing quality control (QC) checkpoints throughout the manufacturing process is essential. Common QC checkpoints include:

– Contrôle de la qualité à l'arrivée (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

– Contrôle de la qualité en cours de fabrication (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

– Contrôle de qualité final (CQF): Comprehensive testing of the finished product before it is packaged for shipment. -

Testing Methods: Various testing methods are employed to evaluate the insulators’ performance, such as thermal resistance tests, durability assessments, and water resistance evaluations. Manufacturers may use both in-house testing labs and third-party testing facilities to validate their products against industry standards.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is vital to ensure product reliability and compliance with local regulations.

-

Audits des fournisseurs: Conducting on-site audits of suppliers can provide insights into their manufacturing processes, quality management systems, and compliance with international standards. Buyers should look for evidence of certifications and ask about the supplier’s history with QA practices.

-

Quality Reports: Requesting regular quality reports can help buyers track the supplier’s performance over time. These reports should include metrics such as defect rates, customer complaints, and corrective actions taken. Transparent reporting can build trust between buyers and suppliers.

-

Inspections par des tiers: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s operations. These inspections can occur at various stages of production, from raw material sourcing to final product testing.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is crucial for international B2B buyers. Different regions may have specific regulations and standards that must be adhered to.

-

Regional Standards: Buyers should familiarize themselves with the local quality standards applicable in their region. For instance, European buyers may prioritize CE certification, while those in Africa may need to comply with local safety regulations.

-

Cultural Differences in Quality Expectations: Cultural perceptions of quality can vary significantly across regions. Buyers should communicate their expectations clearly and ensure that suppliers understand the specific quality criteria required for their market.

-

Documentation and Compliance: Maintaining proper documentation is essential for both buyers and suppliers. This includes product specifications, test reports, and compliance certificates. Having these documents readily available can facilitate smoother transactions and help resolve disputes more efficiently.

Conclusion

Navigating the manufacturing processes and quality assurance for water bottle insulators requires a keen understanding of the stages involved and the standards that govern them. By implementing robust verification methods and staying informed about regional regulations, B2B buyers can ensure that they partner with reliable suppliers who deliver high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle insulators’

In today’s competitive market, sourcing high-quality water bottle insulators is essential for businesses looking to meet customer demands and enhance their product offerings. This guide provides a practical checklist to ensure that B2B buyers can make informed decisions when procuring these products.

Étape 1 : Définir les spécifications techniques

Understanding your specific needs is crucial before engaging with suppliers. Consider factors such as insulation material (e.g., neoprene, foam), size compatibility (e.g., 16oz, 32oz), and intended use (e.g., outdoor activities, winter hiking). Clearly defined specifications will streamline the sourcing process and help you communicate effectively with potential suppliers.

Étape 2 : Research Market Trends and Competitors

Staying informed about current market trends and competitor offerings can provide valuable insights into what products are in demand. Look for popular features, such as eco-friendliness or unique designs, and analyze pricing strategies. This information will help you position your products competitively and identify gaps in the market.

Étape 3 : Évaluer les fournisseurs potentiels

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control processes, and experience in the market to ensure they can meet your demands reliably.

- Check for Certifications: Verify if suppliers hold relevant quality certifications (e.g., ISO, CE) that demonstrate compliance with international standards.

- Assess Communication Responsiveness: A supplier’s willingness to communicate effectively is vital for addressing issues and ensuring smooth transactions.

Étape 4 : Demande d'échantillons pour l'évaluation de la qualité

Once you’ve shortlisted potential suppliers, request samples of their water bottle insulators. This step allows you to evaluate the quality, durability, and functionality of the products firsthand. Pay attention to details such as stitching, insulation effectiveness, and overall design.

Étape 5 : Negotiate Terms and Conditions

Negotiating favorable terms can significantly impact your overall procurement costs. Discuss pricing, minimum order quantities, lead times, and payment terms. Ensure that you have clarity on shipping costs and return policies to avoid any surprises down the line.

Étape 6 : Consider Logistics and Supply Chain Factors

Understanding the logistics involved in sourcing water bottle insulators is essential. Evaluate the supplier’s location, shipping options, and estimated delivery times. Efficient logistics can reduce lead times and ensure that you can meet customer demands promptly.

Étape 7 : Establish a Long-term Partnership

Once you’ve chosen a supplier, focus on building a strong, long-term relationship. Regular communication and feedback can foster collaboration and lead to better pricing, exclusive products, or improved service over time. A reliable supplier partnership can be a significant asset for your business as you navigate market changes.

By following this checklist, B2B buyers can effectively navigate the sourcing process for water bottle insulators, ensuring they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for water bottle insulators Sourcing

What Are the Key Cost Components in Sourcing Water Bottle Insulators?

When analyzing the cost structure for water bottle insulators, several key components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Matériaux: The choice of insulation material significantly impacts costs. Common materials such as neoprene or closed-cell foam vary in price based on quality and supplier availability. Higher-quality materials that offer better insulation and durability typically command higher prices.

-

Travail: Labor costs will depend on the manufacturing location. Countries with lower labor costs can provide cost advantages, but this must be balanced against potential quality issues. Skilled labor may be necessary for high-quality manufacturing processes, impacting overall pricing.

-

Frais généraux de fabrication: This encompasses utilities, rent, equipment maintenance, and other indirect costs related to production. Efficient manufacturing processes can help reduce overhead costs, which can be beneficial for B2B buyers seeking lower prices.

-

Outillage: Initial tooling costs for creating molds and production equipment can be significant, especially for customized designs. These costs are typically amortized over the production run, so larger orders can benefit from lower per-unit costs.

-

Contrôle de la qualité: Ensuring the products meet international standards often involves additional QC processes. Investing in robust QC can lead to higher upfront costs but may reduce returns and increase customer satisfaction in the long run.

-

Logistique: Shipping costs and delivery timelines vary based on the supplier’s location and the buyer’s destination. International logistics can introduce complexities such as customs duties and tariffs, which must be factored into the total cost.

-

Marge: The supplier’s margin will vary based on their market position, brand reputation, and competitive landscape. Understanding this component can help buyers negotiate better terms.

How Do Price Influencers Affect Water Bottle Insulator Costs?

Several factors influence the pricing of water bottle insulators, particularly in the B2B market:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing structures. Larger orders typically lead to discounts, making it crucial for buyers to assess their needs accurately.

-

Spécifications et personnalisation: Custom designs or specific features may increase costs. Buyers should determine the essential specifications to balance quality with budget constraints.

-

Materials and Quality: The type of insulation and material quality directly affect prices. Buyers should evaluate whether premium materials are necessary for their target market to avoid overpaying.

-

Facteurs liés au fournisseur: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is vital for pricing negotiations. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and risk allocation.

What Buyer Tips Can Help Optimize Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Négociation: Effective negotiation with suppliers can yield better pricing, especially for larger orders. Buyers should be prepared to discuss terms and explore various options.

-

Coût total de possession: Assess the total cost of ownership rather than just the initial purchase price. This includes shipping, customs, and potential return costs. A lower upfront price may result in higher overall expenses.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have different pricing structures compared to those in South America, influenced by local demand and competition.

-

Quality vs. Price Balance: Striking a balance between quality and price is essential. Investing in better-quality insulators can enhance brand reputation and customer loyalty, leading to long-term savings.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Regular communication and feedback can foster collaboration and mutual benefits.

Clause de non-responsabilité

The prices mentioned in the referenced materials serve as indicative figures and may vary based on supplier negotiations, market fluctuations, and specific buyer requirements. Always conduct thorough market research and engage with multiple suppliers to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing water bottle insulators With Other Solutions

Exploring Alternatives to Water Bottle Insulators: A Comparative Analysis

When selecting solutions for maintaining beverage temperatures, businesses have several options beyond traditional water bottle insulators. Understanding these alternatives can help B2B buyers make informed decisions based on their specific operational needs, regional preferences, and budget constraints.

| Aspect comparatif | Water Bottle Insulators | Vacuum-Sealed Bottles | Traditional Thermoses |

|---|---|---|---|

| Performance | Excellent thermal retention; prevents condensation. | Superior insulation; keeps drinks hot or cold for extended periods. | Good for hot beverages but can lead to overheating. |

| Coût | Generally affordable ($5 – $40). | Mid-range pricing ($20 – $50). | Higher initial cost ($30 – $100). |

| Facilité de mise en œuvre | Easy to use; simply slip over the bottle. | Requires selection of compatible bottles. | Requires understanding of maintenance and usage. |

| Maintenance | Minimal; machine washable or hand wash. | Low; typically hand wash only. | Moderate; requires careful handling to avoid damage. |

| Meilleur cas d'utilisation | Ideal for outdoor activities and casual use. | Best for long trips where temperature maintenance is crucial. | Suitable for short outings or specific beverage types. |

Vacuum-Sealed Bottles: Are They Worth It?

Vacuum-sealed bottles, such as those offered by brands like Hydro Flask, provide exceptional insulation by creating a vacuum between two walls. This technology allows beverages to maintain their temperature for longer periods, making them ideal for outdoor adventures or extended travel. However, their higher price point and bulkiness may deter some users. Additionally, they can become too hot or too cold, making it difficult to consume liquids comfortably, especially in extreme temperatures.

Traditional Thermoses: A Tried-and-True Solution

Traditional thermoses are a classic choice for keeping beverages hot. They work well for short-term use, particularly in scenarios like camping or day trips. While they can maintain heat effectively, they are not ideal for hydration purposes as they may keep water too hot to drink, which is counterproductive for hydration needs. Furthermore, they can be more fragile and require careful handling to prevent damage. Their design may not cater well to modern aesthetics, which could be a consideration for businesses focused on brand image.

Conclusion: How to Choose the Right Beverage Temperature Solution

For B2B buyers, the decision on which beverage temperature solution to adopt hinges on several factors including cost, intended use, and user preferences. Water bottle insulators offer a budget-friendly, practical solution for day-to-day hydration needs, while vacuum-sealed bottles excel in situations requiring long-term temperature maintenance. Traditional thermoses may appeal to buyers looking for a classic solution for specific types of beverages. By carefully evaluating the performance and practicality of each option in relation to their operational needs, businesses can choose the most effective solution for their audience.

Essential Technical Properties and Trade Terminology for water bottle insulators

What Are the Key Technical Properties of Water Bottle Insulators?

Understanding the technical specifications of water bottle insulators is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential properties to consider:

-

Composition du matériau

The material used in water bottle insulators greatly affects their performance. Common materials include neoprene, nylon, and closed-cell foam. Neoprene, for instance, is valued for its durability and thermal insulation properties, making it ideal for extreme temperatures. Buyers should assess the material grade to ensure it meets their specific needs for insulation and durability. -

Insulation Thickness

Insulation thickness is a critical factor in determining how well a bottle insulator maintains temperature. A thickness of 6.5mm to 10mm is typically effective for preventing heat transfer, whether in hot or cold conditions. This specification is vital for products intended for outdoor activities, where temperature control can significantly affect user experience. -

Size Compatibility

Insulators are designed to fit specific bottle sizes. Common sizes include 16oz, 24oz, and 32oz. Ensuring a proper fit is essential for optimal thermal performance and user convenience. B2B buyers should verify that the products they are considering are compatible with the water bottles they plan to offer. -

Poids

The weight of the insulator can affect its usability, especially for outdoor enthusiasts. Lightweight materials are preferred for easy transport, while heavier materials may provide better insulation but at the cost of portability. Buyers must weigh the trade-offs based on their target market’s needs. -

Water Resistance

Many water bottle insulators are designed to be water-resistant or waterproof. This feature prevents moisture from being absorbed into the insulation material, which can degrade performance over time. Buyers should look for products that explicitly state their water resistance capabilities to ensure longevity and effectiveness. -

Closure Mechanism

The design of the closure mechanism—such as Velcro, zippers, or elastic bands—impacts ease of use and functionality. A secure closure ensures that the insulator stays in place during use, while a user-friendly design allows for quick access, making it essential for on-the-go hydration.

What Are Common Trade Terms Related to Water Bottle Insulators?

Familiarity with industry jargon can enhance communication and negotiation processes for B2B buyers. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are marketed under another company’s brand name. For water bottle insulators, buyers may engage with OEMs to customize products that fit their branding and specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers to ensure that they can meet their inventory needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. This process helps buyers compare costs and make informed purchasing decisions. It’s an essential step in securing the best deals. -

Incoterms

International Commercial Terms (Incoterms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in the shipping process, which is particularly important for international transactions involving water bottle insulators. -

Thermal Performance

This term refers to the effectiveness of an insulator in maintaining the temperature of its contents. Buyers should look for insulators that demonstrate strong thermal performance in both hot and cold conditions, as this directly impacts customer satisfaction. -

Options de personnalisation

Many suppliers offer customization options for water bottle insulators, including color, size, and branding. Understanding these options can help B2B buyers tailor products to meet specific market demands and enhance brand visibility.

By grasping these technical properties and trade terms, B2B buyers can navigate the market for water bottle insulators more effectively, ensuring they select products that align with their operational needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the water bottle insulators Sector

What Are the Current Market Dynamics and Key Trends in the Water Bottle Insulators Sector?

The global market for water bottle insulators is experiencing significant growth, driven by increasing health consciousness, outdoor activities, and an emphasis on sustainability. Consumers across diverse regions, including Africa, South America, the Middle East, and Europe, are becoming more aware of the importance of hydration, particularly in hot climates or during physical activities. As a result, there is a rising demand for effective insulation products that keep beverages at optimal temperatures, whether hot or cold.

Technological advancements are reshaping sourcing trends within this sector. For instance, the use of eco-friendly materials like neoprene and recycled plastics is gaining traction, appealing to environmentally conscious consumers. Additionally, innovations in design, such as lightweight and foldable options, are becoming popular among outdoor enthusiasts. The shift towards e-commerce has also transformed how B2B buyers source these products, with a growing number of suppliers offering online catalogs and direct shipping options, catering to international buyers looking for convenience and variety.

In terms of market dynamics, competition is intensifying as new entrants focus on niche segments, such as insulated sleeves for specific bottle types or targeted outdoor activities. For international buyers, particularly in Brazil and Germany, understanding local preferences and regulations surrounding product safety and material usage is crucial for successful sourcing. This evolving landscape requires B2B buyers to stay agile and informed about emerging trends and consumer preferences to make strategic purchasing decisions.

How Does Sustainability and Ethical Sourcing Impact the Water Bottle Insulators Sector?

Sustainability is becoming a cornerstone of purchasing decisions in the water bottle insulator market. The environmental impact of production processes and materials used in these products is under scrutiny, prompting manufacturers to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to reducing their carbon footprint, using recyclable materials, and ensuring ethical labor practices throughout their supply chains.

Certifications such as ISO 14001 (Environmental Management) and Fair Trade can enhance a supplier’s credibility in the eyes of international buyers. Moreover, the growing consumer demand for “green” products has led to innovations in materials, such as biodegradable insulators and those made from recycled plastics. This trend is particularly relevant for buyers in Europe, where regulatory frameworks increasingly favor environmentally friendly products.

In regions like Africa and South America, the emphasis on sustainability is also tied to local economic development, as ethical sourcing can support community growth and foster partnerships that benefit both suppliers and consumers. For B2B buyers, aligning with suppliers who prioritize sustainability not only enhances brand reputation but also meets the rising expectations of consumers who demand accountability from businesses.

What Is the Brief Evolution and History of Water Bottle Insulators?

The concept of insulating containers dates back centuries, but the modern water bottle insulator has evolved significantly over the last few decades. Initially designed for outdoor enthusiasts, early models primarily utilized simple materials such as foam or fabric to provide minimal insulation. As outdoor activities gained popularity, the demand for more effective insulation solutions increased, leading to innovations in materials and design.

In the early 2000s, the introduction of neoprene and other synthetic materials revolutionized the sector, offering superior thermal insulation and durability. Today, water bottle insulators are not only practical but also come in a variety of styles and colors, catering to personal preferences and branding opportunities for B2B buyers. The evolution continues as manufacturers seek to balance functionality with sustainability, aiming to create products that meet the needs of an increasingly eco-conscious consumer base.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle insulators

-

How do I solve the issue of water freezing in insulated bottles during winter hikes?

To prevent water from freezing in insulated bottles during winter activities, consider using high-quality insulated bottle sleeves specifically designed for extreme cold. These sleeves are typically made from thick neoprene or similar materials that provide superior insulation. Additionally, filling your bottle with warm or hot water before heading out can help maintain a drinkable temperature for longer periods. Ensure the sleeve fits your bottle size snugly for optimal performance and check for features like a low-profile design that allows for easy handling with gloves. -

What is the best material for water bottle insulators?

The best materials for water bottle insulators include neoprene and closed-cell foam. Neoprene offers excellent thermal insulation, flexibility, and durability, making it ideal for outdoor activities. Closed-cell foam provides high insulation efficiency while being lightweight and resistant to moisture absorption. When sourcing insulators, prioritize products with quality stitching and reinforced seams to ensure longevity, especially for B2B markets where durability is crucial for customer satisfaction. -

How can I ensure the quality of water bottle insulators from suppliers?

To ensure the quality of water bottle insulators from suppliers, conduct thorough due diligence. Request samples to assess material quality, insulation performance, and durability. Verify the supplier’s manufacturing processes and certifications, such as ISO standards, which indicate adherence to quality management practices. Additionally, consider seeking reviews or testimonials from other businesses that have previously sourced from the supplier, providing insight into their reliability and product performance. -

What customization options are available for water bottle insulators?

Many suppliers offer customization options for water bottle insulators, including size, color, branding, and design. You can request specific dimensions to fit various bottle types or add your logo and branding elements for promotional purposes. Discuss these options during your initial communication with potential suppliers to understand their capabilities. Additionally, inquire about the minimum order quantities (MOQ) for customized products, as these can vary widely between manufacturers. -

What are the typical minimum order quantities (MOQ) for B2B purchases of water bottle insulators?

Minimum order quantities for water bottle insulators can vary significantly based on the supplier and the type of product. Generally, MOQs can range from 100 to 1000 units. It’s crucial to clarify the MOQ with potential suppliers during negotiations, especially if you’re testing a new product line or entering a new market. Some suppliers may offer flexibility with lower MOQs for first-time orders or samples, which can be beneficial for businesses looking to assess market demand. -

What payment terms should I expect when sourcing water bottle insulators internationally?

Payment terms for international sourcing can vary, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer more favorable terms for larger orders or long-term partnerships. It’s essential to establish clear payment terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods, such as letters of credit or escrow services, which can provide protection for both parties during the transaction. -

How can I manage logistics and shipping for my water bottle insulator orders?

Managing logistics for water bottle insulator orders involves choosing the right shipping method based on cost, speed, and reliability. Options may include air freight for faster delivery or sea freight for larger volumes at a lower cost. Work closely with your supplier to understand their shipping capabilities and preferred carriers. Additionally, consider hiring a freight forwarder to streamline customs clearance and ensure compliance with international shipping regulations, especially when importing goods into regions like Africa or South America. -

What should I know about the international trade regulations for importing water bottle insulators?

When importing water bottle insulators, familiarize yourself with the international trade regulations that apply to your target markets. This includes understanding tariffs, import duties, and compliance with safety standards or certifications required in your region. Each country may have specific regulations regarding materials used in products, especially those intended for food and beverage use. Consulting with a trade expert or customs broker can help navigate these complexities and ensure compliance, minimizing the risk of delays or fines during the import process.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 6 Water Bottle Insulators Manufacturers & Suppliers List

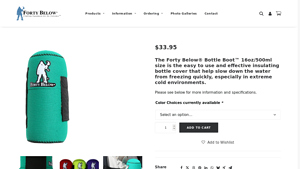

1. Forty Below – Bottle Boot™ 16oz/500ml

Domaine : 40below.com

Enregistré : 1997 (28 ans)

Introduction : {“product_name”:”Forty Below® Bottle Boot™ 16oz/500ml”,”price”:”$33.95″,”description”:”The Forty Below® Bottle Boot™ is an insulating bottle cover designed to slow down the freezing of water in extreme cold environments. It is easy to use and fits most 16oz (500ml) water bottles, including Nalgene. The product has been trusted for over 40 years on various outdoor trips, from winter hikes to high a…

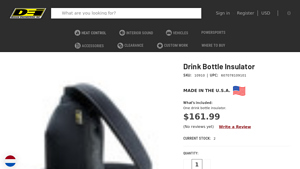

2. DEI – Drink Bottle Insulator

Domaine : designengineering.com

Enregistré : 1997 (28 ans)

Introduction : {“product_name”: “Drink Bottle Insulator”, “sku”: “10910”, “upc”: “607078109101”, “price”: “$161.99”, “description”: “The DEI Drink Bottle Insulation Cover keeps your drink cooler longer. Designed to fit the Longacre 22551 Drink Bottle, it covers the entire bottle and holder as well as the drink tube.”, “material”: “Premium Neoprene”, “features”: [“Keeps drinks cooler longer”, “Covers entire bottl…

3. SectionHiker – Insulated Water Bottle Solutions

Domaine : sectionhiker.com

Registered: 2007 (18 years)

Introduction : 1. Nalgene Water Bottle Sleeve: Insulated with reflective insulation, compatible with 32 oz Nalgene Wide Mouth Bottles, zipper closure, includes a strap for hand gripping and a webbing strap for attachment to a pack.

2. Forty Below Bottle Boots: Made with Neoprene, available in multiple sizes, no zippers for easy access with mittens or gloves, compatible with 32 oz Nalgene Bottles and German Hun…

4. Outdoor Research – Nalgene Bottle Insulator

Domaine : reddit.com

Enregistré : 2005 (20 ans)

Introduction : The test compared three Nalgene bottle insulators: Outdoor Research, Nalgene, and Forty Below (32 oz Nalgene wide mouth). The bottles were filled with water and left at room temperature overnight before being placed in a garage freezer set to 2 degrees. The Outdoor Research insulator performed the best, while all insulators held up well initially but froze quickly. The Forty Below insulator underp…

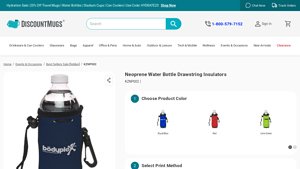

5. Discount Mugs – Custom Neoprene Water Bottle Insulators

Domaine : discountmugs.com

Registered: 2002 (23 years)

Introduction : {“product_name”:”Custom Neoprene Water Bottle Drawstring Insulators #KZNP002″,”price”:”$1.04″,”material”:”3mm Neoprene”,”dimensions”:”Fits 12 oz. Longneck Bottles”,”imprint_area”:”3”W x 3”H”,”case_pack”:”200″,”weight”:”5.9″,”available_colors”:[“Camouflage”,”Lime Green”,”Blue”,”Navy Blue”,”Orange”,”Red”],”features”:[“Drawstring Closure”,”Keeps drinks cool”,”Prevents spills”,”Stylish design”],”descr…

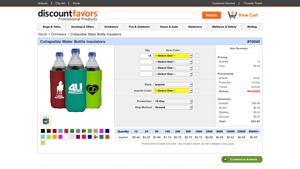

6. Discount Favors – Collapsible Water Bottle Insulators

Domaine : discountfavors.com

Enregistré : 2003 (22 ans)

Introduction : Product Name: Collapsible Water Bottle Insulators

Item Number: #10040

Material: Polyurethane Foam

Fits: 16oz – 20oz Bottle

Imprint Dimension: 5.25″H x 3.5″W

Color Options: Black, Brown, Burgundy, Carolina Blue, Crimson Red, Forest Green, Gray, Green Camo, Kelly Green, Khaki, Magenta, Navy Blue, Neon Blue, Neon Green, Neon Orange, Neon Pink, Off White, Pale Pink, Purple, Red, Royal Blue, Tan Camo, …

Strategic Sourcing Conclusion and Outlook for water bottle insulators

As the demand for water bottle insulators continues to rise across various global markets, strategic sourcing becomes paramount for international B2B buyers. Key considerations include product versatility, material quality, and the ability to cater to diverse climates—from the heat of South America to the cold winters in Europe. Buyers should prioritize suppliers who offer innovative designs and durable materials that enhance user experience, such as neoprene and closed-cell foam insulation, which effectively regulate temperatures while minimizing condensation.

Furthermore, understanding regional preferences and environmental conditions can significantly influence purchasing decisions. For instance, insulators designed for outdoor activities in the Middle East may differ from those suited for urban environments in Germany. Collaborating with manufacturers who have a proven track record in adapting to these needs can enhance supply chain efficiency and customer satisfaction.

Looking ahead, the market for water bottle insulators presents significant growth opportunities. B2B buyers should actively seek partnerships with suppliers that offer customization and sustainability in their products. By aligning sourcing strategies with market trends and consumer demands, businesses can ensure they remain competitive in this evolving landscape. Engage with potential suppliers today to explore innovative solutions that meet your business needs.