Introduction: Navigating the Global Market for can you microwave a water bottle

In today’s fast-paced world, businesses often seek quick and efficient solutions, leading many to wonder, “Can you microwave a water bottle?” This question highlights a key challenge faced by international B2B buyers: ensuring the safety and functionality of products that are increasingly used for convenience. With the rising demand for practical hydration solutions across diverse markets—including Africa, South America, the Middle East, and Europe—understanding the nuances of microwaving water bottles is crucial for making informed purchasing decisions.

This comprehensive guide delves into various types of water bottles, their materials, and the safety implications of microwaving them. It provides actionable insights into applications for different sectors, from hospitality to healthcare, and outlines essential supplier vetting processes to ensure quality and compliance with international standards. Additionally, we will explore cost considerations, helping businesses strike a balance between affordability and safety.

By addressing these key areas, this guide empowers B2B buyers to navigate the complexities of sourcing water bottles that are not only functional but also safe for microwaving. With a focus on informed decision-making, readers will be equipped to enhance their product offerings and meet the growing expectations of their customers. Whether you’re sourcing for retail or wholesale, this guide is an invaluable resource in optimizing your procurement strategy.

Navigation dans les articles

- Top 9 Can You Microwave A Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for can you microwave a water bottle

- Understanding can you microwave a water bottle Types and Variations

- Key Industrial Applications of can you microwave a water bottle

- 3 Common User Pain Points for ‘can you microwave a water bottle’ & Their Solutions

- Strategic Material Selection Guide for can you microwave a water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for can you microwave a water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you microwave a water bottle’

- Comprehensive Cost and Pricing Analysis for can you microwave a water bottle Sourcing

- Alternatives Analysis: Comparing can you microwave a water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for can you microwave a water bottle

- Navigating Market Dynamics and Sourcing Trends in the can you microwave a water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of can you microwave a water bottle

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for can you microwave a water bottle

Understanding can you microwave a water bottle Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Polyethylene Terephthalate (PET) Bottles | Lightweight, clear, and often labeled as microwave-safe with recycling symbol #1. | Beverage packaging, personal hydration products. | Pour : Affordable, widely available. Cons : Limited heat resistance, potential chemical leaching if overheated. |

| Polycarbonate Bottles | Durable and impact-resistant but often not microwave-safe, may contain BPA. | Industrial use, reusable water containers. | Pour : Long-lasting, strong. Cons : Not microwave-safe, potential health concerns with BPA. |

| Hot Water Bottles | Designed specifically for heating, often made from rubber or silicone. | Healthcare, wellness products, home comfort. | Pour : Effective for heat retention, safe for microwaving if specified. Cons : Limited lifespan, may degrade with frequent heating. |

| Stainless Steel Bottles | Highly durable and insulated, but generally not microwave-safe. | Outdoor activities, corporate gifts, premium hydration solutions. | Pour : Long-lasting, environmentally friendly. Cons : Not suitable for microwaving, heavier than plastic options. |

| Glass Water Bottles | Reusable, often labeled as microwave-safe, provides no leaching risk. | Eco-friendly products, food service industry. | Pour : Non-toxic, maintains taste. Cons : Fragile, heavier than plastic. |

What Are Polyethylene Terephthalate (PET) Bottles and Their B2B Relevance?

Polyethylene Terephthalate (PET) bottles are commonly used for beverages and personal hydration products. They are lightweight and often feature the recycling symbol #1, indicating they are generally microwave-safe. However, these bottles can warp or leach harmful chemicals if overheated. For B2B buyers, sourcing PET bottles requires a balance between cost-effectiveness and safety, particularly in regions where consumer awareness about plastic safety is growing.

How Do Polycarbonate Bottles Differ in Microwave Safety?

Polycarbonate bottles are known for their durability and resistance to impact, making them suitable for industrial applications. However, they are often not microwave-safe and may contain BPA, raising health concerns. B2B buyers should consider these factors when selecting polycarbonate products for reusable water containers, especially in markets with stringent health regulations.

What Makes Hot Water Bottles a Unique Option for Heating?

Hot water bottles are specifically designed for heating and are typically made from rubber or silicone materials. They are popular in healthcare and wellness sectors for pain relief and comfort. When buying for B2B applications, it’s crucial to ensure that the hot water bottles can be safely microwaved, as this can enhance their usability in consumer markets. However, frequent heating may shorten their lifespan.

Why Choose Stainless Steel Bottles Despite Microwave Limitations?

Stainless steel bottles offer exceptional durability and insulation, making them ideal for outdoor activities and corporate gifts. However, they are generally not microwave-safe. B2B buyers should weigh the benefits of sustainability and long-term use against the limitations of microwave heating, particularly in regions where convenience and speed are prioritized.

What Are the Advantages of Glass Water Bottles in B2B Markets?

Glass water bottles are increasingly favored for their eco-friendly nature and safety in microwaving. They do not leach chemicals, ensuring product integrity. For B2B buyers, glass bottles represent a premium product offering, especially in food service and eco-conscious markets. However, their fragility and weight compared to plastic alternatives should be factored into purchasing decisions.

Key Industrial Applications of can you microwave a water bottle

| Industrie/secteur | Specific Application of can you microwave a water bottle | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Alimentation et boissons | Heating water for instant beverages | Enhances product convenience and customer satisfaction | Ensure bottles are microwave-safe and compliant with local regulations |

| Soins de santé | Preparing warm compresses for pain relief | Improves patient care and comfort | Source bottles that meet safety and durability standards for medical use |

| L'hospitalité | Quick beverage service in cafes and restaurants | Increases operational efficiency | Choose bottles that are durable and suitable for high-volume use |

| L'éducation | Providing quick access to warm water in schools | Supports student health and wellness | Look for eco-friendly materials that align with sustainability goals |

| Vente au détail | Offering microwave-safe water bottles for home use | Attracts health-conscious consumers | Consider branding and customization options for market differentiation |

How is ‘can you microwave a water bottle’ applied in the Food and Beverage Industry?

In the food and beverage industry, the ability to microwave water bottles is crucial for businesses offering instant beverages such as teas, coffees, and soups. By allowing customers to heat water quickly, establishments can enhance convenience and satisfaction, leading to repeat business. Buyers in this sector should prioritize sourcing microwave-safe bottles that meet local food safety regulations to ensure product integrity and customer safety.

What are the Healthcare Applications of Microwavable Water Bottles?

In healthcare settings, microwavable water bottles are often used to prepare warm compresses for pain relief and physical therapy. This application can significantly improve patient comfort and care quality. Healthcare providers must ensure that the bottles sourced are made from materials that are both durable and safe for repeated heating, adhering to strict medical safety standards.

How Does the Hospitality Sector Benefit from Microwaving Water Bottles?

In the hospitality industry, particularly in cafes and restaurants, the ability to quickly heat water using microwavable bottles can streamline service during peak hours. This efficiency not only enhances customer experience but also optimizes staff workflow. When sourcing these bottles, businesses should focus on durability and heat resistance to withstand high-volume usage.

Why is Access to Warm Water Important in Education?

Schools and educational institutions can benefit from microwavable water bottles by providing students with quick access to warm water for beverages or personal use, promoting health and wellness. Such facilities should consider eco-friendly materials that align with sustainability initiatives while ensuring safety standards are met to protect student health.

What Retail Opportunities Exist for Microwave-Safe Water Bottles?

Retailers can capitalize on the growing trend of health-conscious consumers by offering microwave-safe water bottles. These products cater to individuals seeking convenience in their busy lives. Buyers should look for customization options to differentiate their offerings in a competitive market, while ensuring that the materials used are safe for heating and comply with regional regulations.

3 Common User Pain Points for ‘can you microwave a water bottle’ & Their Solutions

Scenario 1: Misleading Product Labels Create Confusion

Le problème : B2B buyers often encounter products labeled as “microwave-safe,” yet the specifics of this designation can be ambiguous. For instance, a buyer may purchase a bulk order of water bottles for a corporate event, only to find that some bottles warp or leak when heated in a microwave. This not only leads to product loss but can also result in safety hazards, such as burns or chemical leaching, impacting the buyer’s reputation and customer satisfaction.

La solution : To mitigate this issue, buyers should prioritize sourcing from reputable manufacturers who provide clear, detailed labeling and specifications regarding microwave safety. Before finalizing purchases, request documentation that outlines the materials used in the water bottles and whether they have been tested for microwave compatibility. Implement a quality assurance process that includes testing a sample batch in a controlled environment to confirm performance under microwave conditions. By establishing strong supplier relationships and demanding transparency, buyers can confidently procure products that meet safety standards and customer expectations.

Scenario 2: Inadequate Knowledge Leads to Unsafe Practices

Le problème : Many businesses, particularly those in food service or hospitality, may lack adequate training on the safe use of water bottles in microwaves. Staff may assume that all water bottles are microwave-safe, leading to potentially dangerous practices such as microwaving bottles without removing caps, which can result in explosions or hot water spills. This oversight can cause injuries and increase liability for the business.

La solution : It is crucial for businesses to develop comprehensive training programs that educate employees on the safe handling of water bottles, including proper microwave use. This training should cover essential points such as identifying microwave-safe materials (like PET or HDPE), removing caps before microwaving, and adhering to recommended heating times. Additionally, creating easy-to-understand guidelines or checklists that staff can reference can help reinforce safe practices. Regular refresher courses and safety audits can further ensure that employees remain informed and vigilant, ultimately reducing the risk of accidents.

Scenario 3: Environmental Concerns Over Plastic Use

Le problème : With growing awareness of environmental issues, B2B buyers are increasingly scrutinizing the sustainability of products they source, including water bottles. Many traditional plastic bottles are not designed for repeated microwave use, leading to concerns about waste and the environmental impact of disposing of damaged or unsafe products. This can complicate purchasing decisions and affect a company’s sustainability initiatives.

La solution : Buyers should consider investing in eco-friendly, reusable water bottles specifically designed for microwave use. These products should be made from sustainable materials that can withstand high temperatures without degrading or leaching harmful chemicals. Furthermore, buyers can engage with suppliers who emphasize sustainability in their production processes, such as using recycled materials or offering take-back programs for end-of-life products. Promoting these environmentally-friendly alternatives within the organization not only aligns with corporate social responsibility goals but also appeals to increasingly eco-conscious consumers. Implementing a strategy to educate end-users about the benefits of sustainable products can further enhance the company’s reputation and encourage responsible consumption practices.

Strategic Material Selection Guide for can you microwave a water bottle

What Materials Are Commonly Used for Microwavable Water Bottles?

When selecting materials for water bottles intended for microwave use, it is crucial to consider the properties, advantages, and limitations of each material. This analysis focuses on four common materials: Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), Polypropylene (PP), and Borosilicate Glass. Each material has unique characteristics that impact performance, safety, and suitability for international markets.

1. Polyethylene Terephthalate (PET)

Key Properties: PET is lightweight and exhibits excellent clarity and strength. It has a temperature tolerance of up to 70°C (158°F), making it suitable for moderate heating.

Pros & Cons: PET is cost-effective and widely available, making it a popular choice for disposable water bottles. However, it is not recommended for repeated heating as it can deform and leach harmful chemicals when exposed to high temperatures.

Impact sur l'application: PET is compatible with cold and room-temperature liquids but poses risks when microwaved, especially if the bottle is sealed.

Considérations pour les acheteurs internationaux: Compliance with safety standards such as FDA regulations is essential. Buyers in regions like Africa and South America should ensure that local regulations regarding plastic safety are met.

2. High-Density Polyethylene (HDPE)

Key Properties: HDPE is known for its robustness and resistance to impact and chemicals. It can withstand temperatures up to 120°C (248°F) and has good resistance to corrosion.

Pros & Cons: This material is durable and suitable for repeated use, making it ideal for reusable water bottles. However, HDPE can be more expensive than PET and may require more complex manufacturing processes.

Impact sur l'application: HDPE is compatible with a wide range of liquids, including hot water, making it a viable option for microwavable bottles.

Considérations pour les acheteurs internationaux: Buyers should check for compliance with ASTM standards and local regulations. In regions like the Middle East, where high temperatures are common, HDPE’s heat resistance is a significant advantage.

3. Polypropylene (PP)

Key Properties: Polypropylene is a thermoplastic polymer known for its high melting point of approximately 160°C (320°F) and excellent chemical resistance.

Pros & Cons: PP is lightweight, flexible, and can be manufactured in various colors and designs. However, it may be less transparent than PET, which could impact consumer perception.

Impact sur l'application: Its high-temperature tolerance makes PP suitable for microwaving, especially for applications involving hot liquids.

Considérations pour les acheteurs internationaux: Compliance with international safety standards is crucial. In Europe, for instance, adherence to EU regulations on food contact materials is mandatory.

4. Borosilicate Glass

Key Properties: Borosilicate glass is known for its thermal resistance and ability to withstand sudden temperature changes. It can handle temperatures up to 500°C (932°F).

Pros & Cons: This material is highly durable and does not leach chemicals, making it safe for food and beverages. However, it is heavier and more fragile than plastic options, which can increase shipping costs.

Impact sur l'application: Ideal for microwaving, borosilicate glass is suitable for both hot and cold liquids, making it versatile.

Considérations pour les acheteurs internationaux: Buyers should be aware of the fragility of glass products and ensure compliance with safety standards in their respective markets, including potential shipping regulations.

Summary Table of Material Selection for Microwavable Water Bottles

| Matériau | Typical Use Case for can you microwave a water bottle | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Polyethylene Terephthalate (PET) | Disposable water bottles, single-use applications | Rentabilité et légèreté | Not suitable for repeated heating | Faible |

| High-Density Polyethylene (HDPE) | Reusable water bottles, suitable for hot liquids | Durable and impact-resistant | Coût plus élevé et fabrication plus complexe | Moyen |

| Polypropylène (PP) | Reusable containers for hot liquids | High-temperature tolerance | Less transparency than PET | Moyen |

| Borosilicate Glass | Microwavable containers for hot and cold liquids | Thermal resistance and safety | Heavier and more fragile | Haut |

This analysis provides a comprehensive overview of materials used in microwavable water bottles, enabling B2B buyers to make informed decisions based on their specific needs and market regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for can you microwave a water bottle

What Are the Key Stages in the Manufacturing Process of Microwave-Safe Water Bottles?

The manufacturing process for microwave-safe water bottles involves several critical stages that ensure the product’s safety, quality, and functionality. Each stage plays a pivotal role in determining whether the water bottle can withstand microwave heating without compromising the integrity of the material.

Material Preparation: What Materials Are Used for Microwave-Safe Water Bottles?

The first step in the manufacturing process is material preparation. Manufacturers typically use plastics known for their microwave safety, such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE). These materials are chosen for their ability to withstand high temperatures without releasing harmful chemicals.

Before production, raw materials undergo a quality check to verify their compliance with safety standards. This includes testing for toxicity, durability, and heat resistance. Suppliers must provide certifications that demonstrate the materials meet international safety regulations, which is particularly important for B2B buyers in regions like Africa, South America, the Middle East, and Europe.

Forming: How Are Water Bottles Shaped for Optimal Performance?

Once the materials are prepared, the next stage is forming. This process usually involves injection molding or blow molding, depending on the bottle design. Injection molding allows for precise control over the bottle’s shape and thickness, ensuring uniformity, while blow molding is typically used for larger, hollow structures.

During this stage, manufacturers must monitor temperature and pressure closely to ensure that the material melts correctly and fills the mold evenly. Any inconsistencies can lead to weak points in the product, which may fail under microwave conditions.

Assembly: What Steps Are Taken to Ensure Secure Construction?

After forming, the bottles undergo assembly. This stage includes attaching components such as caps and seals. Quality assurance during assembly is crucial; any leaks or structural weaknesses can lead to dangerous outcomes when the bottle is heated in a microwave.

Manufacturers often conduct functional tests to ensure that the caps fit securely and that the seals are airtight. This step is vital for international buyers, as products need to meet different regional specifications for safety and usability.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage involves surface treatments and labeling. Bottles may undergo processes like polishing to remove imperfections, while labeling includes essential information such as recycling codes, safety instructions, and microwave compatibility.

Quality checks at this stage ensure that all markings are clear and accurate, helping end-users understand how to use the product safely. This is particularly important for markets in Africa and the Middle East, where consumer education on product safety may vary.

What Quality Assurance Measures Are Essential for Microwave-Safe Water Bottles?

Quality assurance (QA) is a critical aspect of the manufacturing process for microwave-safe water bottles. It ensures that products are reliable and safe for consumer use, aligning with international standards.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with international standards such as ISO 9001, which specifies requirements for a quality management system. Compliance with ISO 9001 indicates that the manufacturer has a systematic approach to managing quality and continuous improvement.

Additionally, products sold in Europe must meet CE marking requirements, which confirm that the product complies with health and safety standards. In regions like Saudi Arabia, local regulations may also require compliance with specific safety norms.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity. These checkpoints include:

-

Contrôle de la qualité à l'arrivée (IQC) : This step involves inspecting raw materials before production begins. Suppliers must provide documentation proving that materials meet safety standards.

-

Contrôle de la qualité en cours de fabrication (IPQC) : During the manufacturing process, regular inspections and tests are conducted to identify defects early. This may include checking the temperature and pressure during forming and ensuring proper assembly.

-

Contrôle de qualité final (CQF) : At the end of the production line, finished products undergo thorough testing. This includes checks for leaks, structural integrity, and compliance with microwave safety standards.

Comment les acheteurs B2B peuvent-ils vérifier le contrôle de la qualité des fournisseurs ?

B2B buyers need to ensure that their suppliers maintain robust quality control processes. Here are several strategies for verifying supplier QC:

-

Conduct Supplier Audits: Regular audits can help buyers assess the manufacturer’s compliance with quality standards. These audits can focus on the manufacturing process, documentation, and adherence to safety regulations.

-

Demander des rapports de qualité : Suppliers should provide detailed reports on their quality control measures, including results from IQC, IPQC, and FQC. This documentation should reflect the frequency and results of various tests conducted throughout the manufacturing process.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can verify compliance with international standards and identify any areas for improvement.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate various nuances when it comes to quality control. Different regions may have unique safety requirements, and understanding these can help buyers make informed decisions.

For instance, in Africa and South America, regulatory frameworks may not be as stringent as in Europe or the Middle East. As such, buyers should prioritize suppliers that adhere to international quality standards, ensuring that the products are safe and compliant regardless of their market.

Furthermore, buyers should consider the logistics of importing products. Quality assurance processes should include checks for damage during transit and compliance with destination country regulations. This is especially relevant for markets in Nigeria and Saudi Arabia, where import regulations can be complex and stringent.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing microwave-safe water bottles, ensuring the products they offer meet safety standards and consumer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘can you microwave a water bottle’

To assist B2B buyers interested in procuring water bottles suitable for microwave use, this guide provides a practical checklist. By following these steps, you can ensure that you source high-quality products that meet safety and performance standards.

Étape 1 : Définir les spécifications techniques

Establish clear technical specifications for the water bottles you need. Consider factors such as size, material, and intended use (e.g., for hot beverages or baby formula). This clarity will help you communicate your requirements effectively to suppliers.

Étape 2 : Research Material Safety Standards

Understand the safety standards relevant to the materials used in water bottles. Look for bottles made from polyethylene terephthalate (PET), high-density polyethylene (HDPE), or other microwave-safe plastics. Compliance with international safety regulations, such as those from the FDA or EU standards, is essential to avoid potential health risks.

Étape 3 : Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with industry standards. Request documentation that proves their products meet safety and quality benchmarks. This step is crucial to ensure that you are sourcing from reputable manufacturers who prioritize safety.

Étape 4 : Inspect Product Design Features

Assess the design features of the water bottles. Look for bottles that are specifically labeled as microwave-safe and include features such as wide openings for easy filling and cleaning. Additionally, ensure that the design allows for safe heating, such as vented caps to prevent pressure buildup.

Étape 5 : Request Samples for Testing

Always request samples of the water bottles before placing a bulk order. Conduct your own tests to verify their microwave safety and performance under various conditions. Testing for heat resistance and durability will help you identify any potential issues early on.

Étape 6 : Gather Feedback from Other Buyers

Engage with other businesses that have purchased similar products. Collect feedback regarding their experiences with specific suppliers and product performance. This information can provide valuable insights into the reliability of the supplier and the quality of the water bottles.

Étape 7 : Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiate terms and conditions that align with your business needs. Discuss pricing, minimum order quantities, delivery timelines, and return policies. Establishing clear agreements upfront will help mitigate risks and ensure a smooth procurement process.

By following this checklist, B2B buyers can confidently source water bottles that are safe for microwave use, ensuring both quality and compliance with safety standards.

Comprehensive Cost and Pricing Analysis for can you microwave a water bottle Sourcing

What Are the Key Cost Components for Sourcing Water Bottles That Are Microwave-Safe?

When sourcing water bottles that can be microwaved, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Matériaux: The type of plastic used significantly influences the cost. Microwave-safe plastics, such as Polyethylene Terephthalate (PET) or High-Density Polyethylene (HDPE), are generally more expensive due to their durability and safety certifications.

-

Travail: Labor costs can vary by region and manufacturer. In countries with lower labor costs, such as some in Africa and South America, the overall manufacturing expenses may be reduced, allowing for competitive pricing.

-

Frais généraux de fabrication: This includes utilities, facility costs, and equipment maintenance. Manufacturers with advanced technology and efficient processes can minimize overhead, impacting the final pricing favorably.

-

Outillage: The initial investment in molds and machinery for creating specific bottle designs can be substantial. Custom designs or specific specifications often lead to higher tooling costs, which should be factored into the unit price.

-

Contrôle de la qualité (CQ): Ensuring that the bottles meet safety and quality standards is vital, especially for products intended for food and beverage use. Robust QC processes add to manufacturing costs but are essential for compliance and consumer safety.

-

Logistique: Transportation costs can vary significantly based on the sourcing location and destination. Incoterms also play a role here, influencing who bears the cost and risk during transit.

-

Marge: Suppliers typically add a margin to cover their business costs and profit. This can vary widely based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect the Sourcing of Microwave-Safe Water Bottles?

Several factors can influence the pricing of microwave-safe water bottles:

-

Volume/QMo (quantité minimale de commande): Bulk orders often lead to discounts, making it more cost-effective for buyers. Understanding the MOQ can help buyers negotiate better terms.

-

Spécifications et personnalisation: Customized designs or features can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Matériaux et certifications de qualité: Higher quality materials that meet specific safety certifications will generally cost more. Buyers should consider the long-term value of investing in higher-quality products.

-

Facteurs liés au fournisseur: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better quality assurance and after-sales support.

-

Incoterms: Understanding the shipping terms is crucial. Different Incoterms can change the total cost, as they define responsibilities for shipping, insurance, and tariffs.

What Buyer Tips Can Help in Negotiating Costs for Microwave-Safe Water Bottles?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Always negotiate pricing and payment terms. Suppliers may be willing to offer better rates for long-term contracts or larger orders.

-

Tenir compte du coût total de possession (CTP): Evaluate not only the purchase price but also the long-term costs associated with the product, including shipping, storage, and disposal.

-

Understand Regional Pricing Nuances: Pricing can vary significantly across regions due to local market conditions, tariffs, and economic factors. Buyers should be aware of these nuances to make informed decisions.

-

Leverage Local Partnerships: Establishing relationships with local suppliers can reduce logistics costs and enhance supply chain efficiency. Local suppliers may also better understand regional regulations and market needs.

-

Research and Compare Suppliers: Don’t settle for the first supplier. Conduct thorough research to compare prices, quality, and customer service. This can provide leverage in negotiations.

Clause de non-responsabilité

Prices and cost structures presented in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing can you microwave a water bottle With Other Solutions

Exploring Alternative Methods for Heating Water

In the quest for efficient water heating, many individuals consider using a microwave to heat water bottles. However, this method may not always be the best choice due to safety concerns and potential risks. In this section, we will explore alternative methods for heating water and compare them against the microwave approach to help B2B buyers make informed decisions.

| Aspect comparatif | Can You Microwave A Water Bottle | Electric Kettle | Stovetop Pot |

|---|---|---|---|

| Performance | Quick heating; risk of explosion if not monitored | Fast and efficient; consistent heating | Slower than kettle; requires more attention |

| Coût | Low (if you already own a microwave) | Moderate (price varies) | Low to moderate (depends on pot type) |

| Facilité de mise en œuvre | Easy but requires caution | Very easy; plug and go | Requires more setup (stove) |

| Maintenance | Minimal (just the microwave) | Moderate (cleaning kettle) | Moderate (cleaning pot) |

| Meilleur cas d'utilisation | Quick, small amounts of water | Large quantities; quick boils | Cooking alongside other food |

What Are the Advantages and Disadvantages of Using an Electric Kettle?

Electric kettles are known for their efficiency and speed in boiling water. They typically come with safety features like automatic shut-off, which mitigates the risk of overheating. Their ease of use makes them an attractive option for both personal and business settings. However, electric kettles can be more expensive than simple microwave use, and they require a power source. Additionally, they can accumulate mineral deposits over time, necessitating regular cleaning and maintenance.

How Does the Stovetop Pot Compare?

Using a stovetop pot is another traditional method for heating water. This method allows for larger quantities of water to be heated at once, making it ideal for situations where multiple servings are needed, such as in catering or food service. However, stovetop heating is generally slower and requires constant monitoring to prevent boiling over. The setup can also be less convenient, particularly in environments where stovetops are not readily available. Maintenance is comparable to that of electric kettles, as pots also require regular cleaning.

Conclusion : Choisir la bonne solution pour vos besoins

When deciding on the best method for heating water, B2B buyers should consider their specific needs, including volume requirements, safety concerns, and cost-effectiveness. While microwaving a water bottle can be a quick solution, it carries risks that may not justify its convenience. Electric kettles offer efficiency and safety features, making them suitable for businesses that prioritize speed and ease. Stovetop pots, while slower, can accommodate larger volumes and may be preferable in settings where multiple cooking processes occur simultaneously. Ultimately, the best choice will depend on the operational context and specific use cases within your business.

Essential Technical Properties and Trade Terminology for can you microwave a water bottle

What Are the Key Technical Properties to Consider When Microwaving a Water Bottle?

When evaluating the suitability of water bottles for microwaving, several critical technical properties come into play. Understanding these specifications is essential for B2B buyers, particularly when sourcing products for international markets.

1. Qualité des matériaux

The material grade of a water bottle significantly influences its microwave safety. Bottles made from polyethylene terephthalate (PET) are generally safe for microwaving, as they can withstand the heat without warping or leaching harmful chemicals. In contrast, polycarbonate (recycling symbol #7) may release bisphenol A (BPA) when heated, posing health risks. For B2B buyers, selecting the right material grade ensures compliance with safety regulations and enhances product reliability.

2. Résistance à la chaleur

Heat resistance refers to the maximum temperature a material can withstand without deforming. Water bottles intended for microwave use should be rated for high temperatures, typically above 100°C (212°F), as water can reach boiling points. This property is critical for manufacturers and distributors to ensure that the products can be safely used in consumer applications without risk of damage.

3. Microwave Safety Certification

Microwave safety certification indicates whether a product has been tested and approved for microwave use. Certifications from recognized organizations (like the FDA or other international bodies) are vital for B2B buyers to ensure consumer safety and product performance. This certification can also impact marketability, as products with safety endorsements often enjoy greater consumer trust.

4. Mécanisme de scellement

The design of the water bottle’s cap and sealing mechanism is crucial when microwaving. Bottles that seal too tightly can create pressure, leading to potential explosions or spills. B2B buyers should look for designs that allow steam to escape safely, reducing the risk of accidents. This consideration is particularly important for markets where safety regulations are stringent.

5. Recyclability

Recyclability of materials used in water bottles affects environmental sustainability and compliance with international regulations. Bottles made from recyclable plastics are increasingly favored in global markets, aligning with consumer preferences for eco-friendly products. B2B buyers should prioritize suppliers who offer sustainable options, which can also enhance brand reputation.

What Are the Common Trade Terms Related to Microwavable Water Bottles?

Understanding trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to sourcing microwavable water bottles.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For water bottles, an OEM may produce the bottles that are branded under another company’s label. This term is crucial for buyers looking to partner with manufacturers for private-label products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers to manage inventory costs and ensure they can meet consumer demand without overstocking. It also affects pricing structures and negotiation strategies.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This term is important for B2B buyers to initiate the procurement process, allowing them to compare prices, terms, and conditions from various suppliers.

4. Incoterms (termes commerciaux internationaux)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, insurance, and risk transfer. For B2B buyers, understanding Incoterms is essential for negotiating contracts and ensuring smooth logistics, especially when importing products like water bottles.

5. Délai d'exécution

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for planning inventory and ensuring timely product availability. This term can greatly impact supply chain efficiency and customer satisfaction.

By comprehensively understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing microwavable water bottles, ensuring safety, compliance, and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the can you microwave a water bottle Sector

What Are the Global Drivers Influencing the ‘Can You Microwave a Water Bottle’ Market?

The market for microwave-safe water bottles is rapidly evolving, driven by several global trends. Firstly, there is an increasing demand for convenience among consumers, particularly in regions such as Africa, South America, the Middle East, and Europe. This is reflected in the rising popularity of products that can be quickly heated, especially in urban areas where time is of the essence. Additionally, health and safety concerns have prompted a focus on materials that are both microwave-safe and free from harmful chemicals, pushing manufacturers to innovate in their product offerings.

Moreover, the surge in e-commerce has transformed how businesses source these products. International B2B buyers are increasingly turning to online platforms to procure microwave-safe water bottles, leading to a greater emphasis on digital marketing and supply chain efficiency. Emerging technologies such as IoT and smart packaging are also gaining traction, allowing companies to provide better consumer education regarding the safe use of these products. In regions like Nigeria and Saudi Arabia, where awareness of health-related issues is growing, this trend is particularly relevant.

How Is Sustainability Influencing the Sourcing of Microwave-Safe Water Bottles?

Sustainability is becoming a cornerstone of sourcing strategies in the water bottle sector. As environmental concerns rise globally, B2B buyers are increasingly prioritizing ethical sourcing practices. This includes selecting suppliers that utilize sustainable materials, such as recycled plastics and biodegradable options. Certifications such as ‘Green Seal’ or ‘Cradle to Cradle’ are becoming essential for companies looking to assure their customers of the environmental integrity of their products.

In the context of microwave-safe water bottles, the choice of materials plays a crucial role. Plastics that can withstand microwave heating without leaching harmful chemicals are vital, yet they must also be sourced responsibly. Buyers are encouraged to conduct thorough audits of their supply chains to ensure compliance with environmental standards and to seek partnerships with manufacturers committed to reducing their carbon footprint. This not only enhances brand reputation but also meets the growing consumer demand for environmentally friendly products.

What Is the Historical Context Behind Microwave-Safe Water Bottles?

The concept of microwave-safe water bottles has evolved significantly since the introduction of microwaves in the mid-20th century. Initially, most water bottles were made from materials like glass and metal, which posed limitations in terms of convenience and safety. As the market expanded, manufacturers began experimenting with various plastics, leading to the development of materials specifically designed to be microwave-safe, such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE).

Over the years, as consumer awareness regarding health and safety increased, manufacturers adapted by incorporating safety features and clear labeling to indicate microwave compatibility. This evolution has been particularly relevant in emerging markets, where the adoption of microwaves has increased rapidly, creating a need for products that align with modern lifestyles. Understanding this historical context can provide B2B buyers with insights into product development trends and consumer preferences, allowing for more informed sourcing decisions.

Through these insights, businesses can better navigate the complexities of the microwave-safe water bottle market, ensuring they meet both consumer expectations and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of can you microwave a water bottle

-

How can I determine if a water bottle is microwave-safe?

To determine if a water bottle is microwave-safe, first check for any labels or markings on the bottle that indicate microwave suitability. Look for symbols such as “microwave-safe” or specific recycling codes, particularly those indicating materials like polyethylene terephthalate (PET) or high-density polyethylene (HDPE). Additionally, review the manufacturer’s guidelines, as these often provide essential instructions regarding the safe usage of the bottle in microwaves. If in doubt, consult with your supplier for detailed product specifications. -

What materials are commonly used in microwave-safe water bottles?

Microwave-safe water bottles are typically made from specific types of plastics, such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), and certain polypropylene variants. These materials are designed to withstand microwave heating without releasing harmful chemicals. It’s crucial to avoid bottles made from polycarbonate (recycling symbol #7) or other non-microwave-safe plastics, as they can break down and leach toxins when heated. Always confirm the material composition with your supplier before making a purchase. -

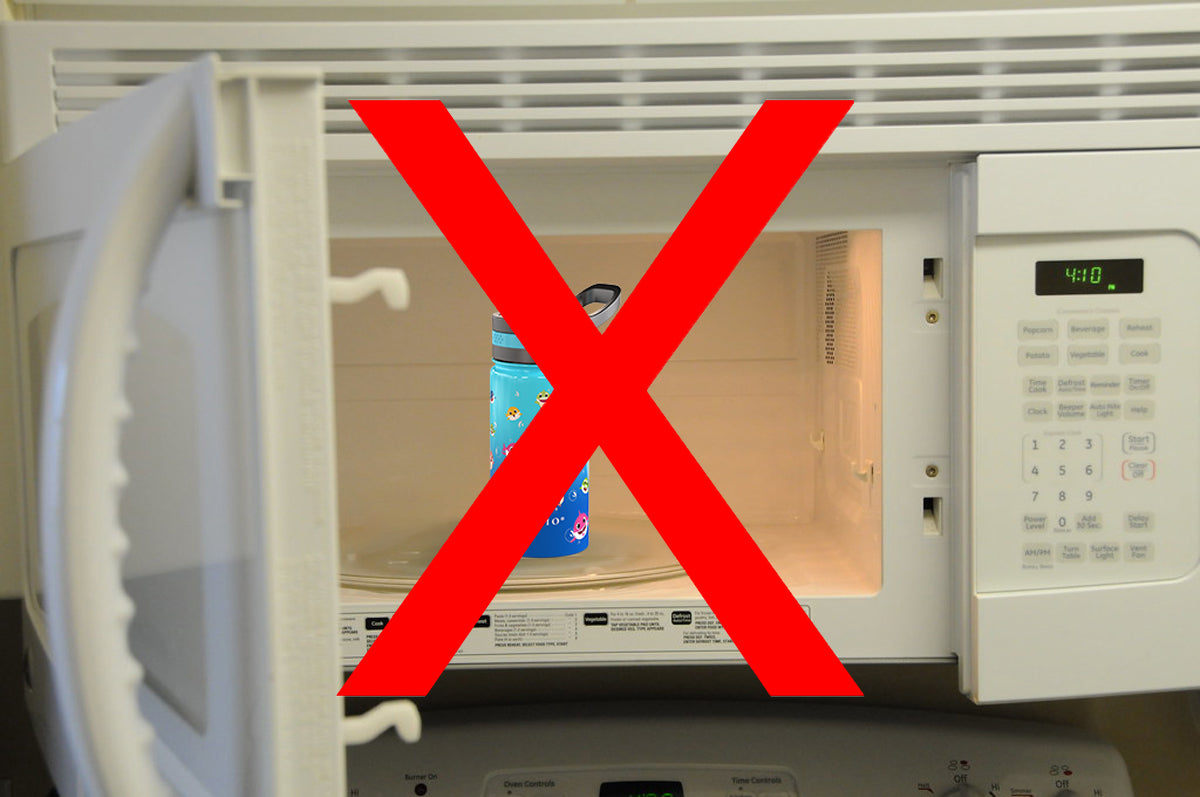

What are the risks of microwaving a water bottle?

Microwaving a water bottle can pose several risks, including the potential for the bottle to melt, warp, or even explode if it is not microwave-safe. If the bottle is sealed with a cap, pressure can build up, leading to leaks or bursts. Furthermore, overheating the water inside may cause scalding. To mitigate these risks, ensure the bottle is designed for microwave use, leave the cap off, and avoid heating water beyond two minutes. Always adhere to safety guidelines provided by the manufacturer. -

How can I vet suppliers for microwave-safe water bottles?

When vetting suppliers for microwave-safe water bottles, start by reviewing their certifications and quality assurance processes. Request samples to verify the materials and safety features. Investigate their manufacturing practices to ensure compliance with international safety standards, particularly for markets in Africa, South America, the Middle East, and Europe. Additionally, check for customer reviews and testimonials to gauge reliability and product quality. Engaging in direct communication with suppliers can also provide insights into their responsiveness and willingness to meet your specific requirements. -

What customization options are available for water bottles?

Customization options for water bottles can vary by supplier but may include choices for material, size, color, and branding elements such as logos or designs. Some suppliers offer eco-friendly materials or unique shapes tailored for specific market needs. Discussing your target audience’s preferences and the intended use of the bottles can help guide the customization process. Always confirm minimum order quantities (MOQs) for customized products to ensure they align with your procurement strategy. -

What are the typical payment terms for international water bottle suppliers?

Payment terms can vary widely among international suppliers, often depending on the region and the relationship established. Common payment methods include wire transfers, letters of credit, and PayPal, with terms ranging from upfront deposits (usually 30-50%) to net payment terms (30, 60, or 90 days) after delivery. It’s essential to clarify these terms before finalizing any agreements to ensure smooth transactions and avoid potential disputes. Always consider negotiating terms that provide you with sufficient cash flow while securing the supplier’s commitment. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have comprehensive quality assurance measures in place, including regular inspections of raw materials, in-process quality checks, and final product evaluations. Look for suppliers who adhere to international quality standards such as ISO certifications. Request detailed documentation of their QA processes, including testing methods for microwave safety and material integrity. Establishing clear communication regarding your quality expectations can also help ensure that the products meet your specifications and regulatory requirements. -

What logistics considerations should I keep in mind when sourcing water bottles?

When sourcing water bottles, logistics considerations include shipping methods, lead times, and customs regulations specific to your region. Evaluate the supplier’s ability to meet delivery schedules and manage inventory levels to avoid disruptions. Additionally, consider the total landed cost, including shipping fees, tariffs, and taxes. Collaborating with a logistics partner familiar with international trade can streamline the process, helping you navigate complex import/export regulations and ensuring timely delivery to your location.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 9 Can You Microwave A Water Bottle Manufacturers & Suppliers List

1. Reddit – Safety Concerns with Plastic Bottles

Domaine : reddit.com

Enregistré : 2005 (20 ans)

Introduction : This company, Reddit – Safety Concerns with Plastic Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Buzio – Microwave-Safe Water Bottles

Domaine : buziolife.com

Enregistré : 2017 (8 ans)

Introduction : Buzio water bottles are made of polyethylene terephthalate (PET), indicated by recycling symbol #1, which is microwave-safe. It is advised to remove the cap before microwaving to prevent pressure buildup, and not to heat for more than two minutes to avoid scalding. Overfilling should be avoided to allow for water expansion. The bottles should be placed in the center of the microwave for even heati…

3. Bearaby – Hot Water Bottles

Domaine : bearaby.com

Enregistré : 2018 (7 ans)

Introduction : Hot water bottles are versatile for warmth and pain relief. Whether you can microwave one depends on its specific design. Always check the manufacturer’s guidelines and heating instructions. Microwaving non-microwavable bottles can cause damage and safety hazards. For microwavable bottles, follow specific guidelines to avoid overheating and scalding.

4. Water Bottle – Microwave Safety

Domaine : waterbottle.tech

Enregistré : 2018 (7 ans)

Introduction : Hydro Flasks and Yeti Cups are not microwave safe. Both are made of stainless steel, which can reflect microwaves, causing sparks and potential fire hazards. Plastic components may also not be microwave safe. Microwaving can damage the containers and the microwave itself, leading to safety concerns such as superheating liquids. To heat beverages safely, use microwave-safe containers like glass or …

5. Samply – Hot Water Bottles UZhen 1.7L & 1.2L

Domaine : samply.com

Enregistré : 2006 (19 ans)

Introduction : Hot Water Bottle UZhen CAPACITY:1.7L, UZhen CAPACITY:1.2L

6. Pinterest – Microwave Safety Tips

Domaine : fr.pinterest.com

Enregistré : 2009 (16 ans)

Introduction : Can you microwave water bottles? While it may seem like a convenient solution, knowing whether it is safe to microwave water bottles is essential. Microwaving water bottles is not recommended.

7. Facebook – Safe Bottle Warming Tips

Domaine : facebook.com

Enregistré : 1997 (28 ans)

Introduction : Microwaves and baby bottles don’t mix. To safely warm a baby bottle, fill a mug halfway with water, microwave the mug in 30-second increments, place the bottle in the warm water for a few minutes, gently swirl the milk to heat evenly, and test the temperature on the inside of your wrist.

8. Healthline – Understanding Plastic Types

Domaine : healthline.com

Enregistré : 2004 (21 ans)

Introduction : Plastic is a synthetic or semi-synthetic material that is durable, lightweight, and flexible, used in various products including food storage containers and beverage containers. There are seven types of plastic, identified by a recycling triangle with a number from 1 to 7, which indicates the type of plastic: 1) PET or PETE, 2) HDPE, 3) PVC, 4) LDPE, 5) PP, 6) PS, and 7) Other. Concerns about micr…

9. Hotties – Microwave Safe Hot Water Bottles

Domaine : thenakedscientists.com

Enregistré : 2001 (24 ans)

Introduction : Hotties microwave hot water bottles are designed for safe use in microwaves, with a safety record of ten years in the UK and Europe, and no significant injuries reported. They are engineered to fail-safe in case of overheating, preventing dangerous ballooning or explosive failure. Hotties are particularly beneficial for the elderly, infirm, and disabled. They hold heat for approximately 45 minutes…

Strategic Sourcing Conclusion and Outlook for can you microwave a water bottle

What Are the Key Takeaways for B2B Buyers Regarding Microwave Safety for Water Bottles?

Understanding the nuances of microwave safety for water bottles is crucial for B2B buyers, especially those sourcing products for diverse markets. First and foremost, it’s essential to evaluate the materials used in water bottles, as not all plastics are microwave-safe. Buyers should prioritize products made from polyethylene terephthalate (PET) or high-density polyethylene (HDPE) and ensure they come with clear manufacturer guidelines. This not only safeguards consumer health but also mitigates potential liability issues.

How Can Strategic Sourcing Enhance Product Safety and Compliance?

Strategic sourcing plays a vital role in ensuring that suppliers adhere to safety standards and regulations. By collaborating closely with manufacturers, buyers can secure products that meet international safety certifications, which is particularly important in regions such as Africa, South America, the Middle East, and Europe. Leveraging strong supplier relationships can also facilitate better product innovation, ensuring that offerings remain competitive and compliant with local market demands.

What’s Next for International B2B Buyers?

As the demand for safe and efficient household products continues to grow, now is the time for B2B buyers to reassess their sourcing strategies. Prioritize partnerships with suppliers who demonstrate a commitment to product safety and transparency. By doing so, you can enhance your product offerings and meet the evolving needs of your customers. Embrace this opportunity to lead in your market by ensuring that your water bottle products are not only functional but also safe for consumer use.