Introduction: Navigating the Global Market for types of bottles

Navigating the diverse landscape of bottle types presents a significant challenge for international B2B buyers seeking reliable and efficient sourcing solutions. From water bottles designed for outdoor adventures to specialized baby bottles catering to nutritional needs, the sheer variety can be overwhelming. This guide provides a comprehensive overview of the most common types of bottles, their unique applications, and crucial considerations such as supplier vetting and cost analysis.

By delving into the intricacies of different bottle styles—from insulated tumblers to eco-friendly options—this resource aims to empower buyers from regions such as Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and Nigeria. Understanding the specific features and benefits of each bottle type allows businesses to make informed purchasing decisions that align with their operational needs and customer preferences.

Whether you’re looking to optimize hydration solutions for your workforce or seeking the latest innovations in baby feeding products, this guide serves as your roadmap. It will help you navigate through the complexities of sourcing bottles, ensuring that you not only select the right products but also establish partnerships with reputable suppliers who can meet your quality and delivery standards. Your journey to effective bottle sourcing starts here, where informed choices lead to enhanced business outcomes.

Navigation dans les articles

- Top 3 Types Of Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for types of bottles

- Understanding types of bottles Types and Variations

- Key Industrial Applications of types of bottles

- 3 Common User Pain Points for ‘types of bottles’ & Their Solutions

- Strategic Material Selection Guide for types of bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for types of bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of bottles’

- Comprehensive Cost and Pricing Analysis for types of bottles Sourcing

- Alternatives Analysis: Comparing types of bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for types of bottles

- Navigating Market Dynamics and Sourcing Trends in the types of bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of types of bottles

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for types of bottles

Understanding types of bottles Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Cold Cups | Triple-walled insulation, straw included | Beverage retail, fitness centers | Pour : Keeps drinks cold for hours; customizable designs. Cons : May be bulkier than other options. |

| Tumblers | Durable stainless steel, hot and cold insulation | Food service, outdoor events | Pour : Versatile for various beverages; easy to clean. Cons : Higher cost compared to plastic alternatives. |

| Canteens | Triple insulated, ergonomic carry handle | Outdoor recreation, travel retail | Pour : Excellent temperature retention; durable design. Cons : Heavier than lighter plastic options. |

| Commuter Cups | Spill-proof design, 360-degree sip lid | Corporate gifting, commuter services | Pour : Convenient for on-the-go hydration; fits standard cup holders. Cons : Limited capacity. |

| Baby Bottles | Anti-colic features, various nipple options | Healthcare, childcare products | Pour : Promotes healthy feeding; trusted brand recognition. Cons : Requires careful selection based on age and needs. |

What Are the Characteristics of Cold Cups and Their B2B Suitability?

Cold cups are designed with triple-walled insulation, allowing beverages to remain cold for extended periods, making them ideal for fitness centers and beverage retail. Their inclusion of straws enhances user experience, especially in casual settings. B2B buyers should consider customization options for branding purposes, as these cups can be personalized in various colors and designs. However, their bulkiness may pose storage challenges.

How Do Tumblers Stand Out in the Market?

Tumblers are crafted from durable stainless steel and are suitable for both hot and cold beverages, making them a popular choice in food service and outdoor events. Their versatility allows businesses to cater to different customer preferences. Easy to clean and maintain, tumblers can also be branded for promotional purposes. However, their higher price point compared to plastic alternatives may deter cost-sensitive buyers.

Why Are Canteens Ideal for Outdoor Activities?

Canteens feature triple insulation and ergonomic designs, making them perfect for outdoor recreation and travel retail. Their ability to keep drinks cold for up to 25 hours is a significant advantage for outdoor enthusiasts and athletes. B2B buyers should prioritize durability and size when selecting canteens for resale or corporate gifting. While they are heavier than plastic bottles, their robust construction ensures longevity.

What Makes Commuter Cups a Smart Choice for Businesses?

Commuter cups are designed with a spill-proof lid and a 360-degree sipping mechanism, catering to busy professionals who value convenience. They are commonly used in corporate gifting and commuter services, fitting easily into standard cup holders. B2B buyers can benefit from their practicality, but should be mindful of their limited capacity, which may not meet all hydration needs.

How Do Baby Bottles Cater to Healthcare and Childcare Needs?

Baby bottles, particularly those with anti-colic features, are essential in healthcare and childcare sectors. They promote healthy feeding practices and are often recommended by pediatricians, making them a trusted option for parents. When purchasing, B2B buyers should consider the age appropriateness of different nipple options and materials. While they are highly valued in the market, careful selection is crucial to meet diverse customer needs.

Key Industrial Applications of types of bottles

| Industrie/secteur | Specific Application of Types of Bottles | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Alimentation et boissons | Beverage Packaging (e.g., water, juices, soft drinks) | Enhances brand visibility and customer convenience; reduces waste | Quality of materials, customization options, regulatory compliance |

| Soins de santé | Medical and Pharmaceutical Bottles | Ensures safe storage and dispensing of medications; promotes patient safety | Sterilization processes, durability, and child-proof features |

| Personal Care and Cosmetics | Cosmetic and Personal Care Packaging | Protects product integrity; enhances shelf appeal and user experience | Material compatibility with contents, eco-friendliness, design flexibility |

| Sports and Outdoor Equipment | Hydration Solutions (e.g., sports bottles, canteens) | Supports active lifestyles; encourages hydration; brand promotion | Insulation properties, portability, and ease of cleaning |

| Baby Products | Baby Bottles and Feeding Accessories | Promotes infant health; reduces colic and feeding issues; builds brand loyalty | Safety standards, ease of use for parents, and sterilization capabilities |

How Are Types of Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, bottles are essential for packaging liquids like water, juices, and soft drinks. They serve to enhance brand visibility while providing convenience to consumers. For international buyers, sourcing bottles must consider quality materials that comply with food safety regulations, customization options for branding, and sustainability practices to meet growing consumer demands for eco-friendly packaging.

What Role Do Bottles Play in Healthcare Applications?

In healthcare, bottles are crucial for storing and dispensing medications and other medical liquids. They ensure that products remain uncontaminated and safe for patient use. Buyers in this sector should prioritize sourcing bottles with robust sterilization processes and child-proof features to enhance safety. Additionally, the durability of materials is vital to withstand various handling conditions in medical environments.

How Are Types of Bottles Utilized in the Personal Care and Cosmetics Industry?

Cosmetic and personal care products rely heavily on specialized bottles for packaging. These bottles protect product integrity and enhance aesthetic appeal, which is critical in a competitive market. Buyers should focus on material compatibility to ensure product stability and consider eco-friendly options to align with sustainability trends. Design flexibility is also important to cater to diverse product lines and branding strategies.

Why Are Hydration Solutions Important in Sports and Outdoor Equipment?

Hydration solutions, such as sports bottles and canteens, are designed for outdoor enthusiasts and athletes. These bottles encourage hydration during physical activities while providing brand promotion opportunities. Buyers should look for features like insulation properties to maintain beverage temperatures, portability for ease of transport, and ease of cleaning, as these factors significantly influence consumer satisfaction.

What Are the Key Considerations for Baby Bottle Sourcing?

In the baby products sector, bottles play a pivotal role in infant feeding, requiring designs that promote health and reduce colic. Buyers must ensure that the bottles comply with stringent safety standards and are easy for parents to use. Additionally, the ability to sterilize these bottles easily is crucial for maintaining hygiene and ensuring the health of infants, making sourcing decisions critical for success in this market.

3 Common User Pain Points for ‘types of bottles’ & Their Solutions

Scenario 1: Navigating Diverse Bottle Options for Different Markets

Le problème :

B2B buyers often face the challenge of selecting the right type of bottle that suits various markets, especially when dealing with international clients from regions like Africa, South America, and the Middle East. Each region may have unique preferences regarding materials, sizes, and functionalities. For instance, buyers in Africa may prioritize durability and affordability due to local economic conditions, while European markets may lean towards premium designs with advanced features. This diversity can lead to confusion and potential misalignment with customer expectations, resulting in unsold inventory or loss of business.

La solution :

To effectively navigate this challenge, B2B buyers should conduct comprehensive market research that includes consumer preferences, local regulations, and competitive analysis. Utilizing surveys and focus groups can yield valuable insights into what consumers in each region value most in bottle design and functionality. Additionally, collaborating with local distributors can provide on-the-ground knowledge of market trends and preferences. Once you have gathered this data, prioritize sourcing bottles that can be easily customized to meet the specific needs of each market, whether that means adjusting the bottle size, material, or adding features like insulation or spill-proof lids. This tailored approach not only increases customer satisfaction but also enhances the likelihood of repeat purchases.

Scenario 2: Ensuring Product Safety and Compliance

Le problème :

Another significant pain point for B2B buyers is ensuring that the types of bottles they procure meet safety and regulatory standards, which can vary drastically by region. For example, food-grade materials must comply with strict safety regulations in the European Union, while other regions might have more lenient requirements. Failure to adhere to these standards can result in costly recalls, legal liabilities, and damage to brand reputation.

La solution :

To mitigate this risk, B2B buyers should implement a robust supplier vetting process that includes checking for compliance certifications and safety standards relevant to the target market. It’s crucial to request documentation from suppliers that confirms their products meet local regulations, such as FDA approval in the U.S. or EU regulations for food contact materials. Additionally, establishing a relationship with a compliance consultant or legal expert can provide ongoing guidance about regulatory changes in different markets. Finally, consider investing in third-party testing for your products, as this not only ensures compliance but also builds trust with your customers, showcasing your commitment to quality and safety.

Scenario 3: Addressing Environmental Sustainability Concerns

Le problème :

With increasing awareness of environmental issues, B2B buyers are often pressured to source bottles that are environmentally friendly. Many businesses, particularly in Europe, are prioritizing sustainability in their procurement processes. This demand can create a challenge for buyers who may struggle to find suitable options that are both eco-friendly and cost-effective. Moreover, the lack of transparency in the supply chain regarding the environmental impact of bottle production can complicate decision-making.

La solution :

To effectively address sustainability concerns, buyers should focus on partnering with suppliers who prioritize eco-friendly practices, such as using recycled materials, minimizing packaging waste, and ensuring energy-efficient manufacturing processes. Look for certifications such as Cradle to Cradle or FSC (Forest Stewardship Council) to verify the sustainability claims of your suppliers. Additionally, consider implementing a lifecycle assessment (LCA) approach to evaluate the environmental impact of the bottles you source, from production through disposal. By prioritizing sustainable sourcing and transparently communicating these efforts to your customers, you can not only meet market demand but also enhance your brand’s reputation as a responsible and forward-thinking business.

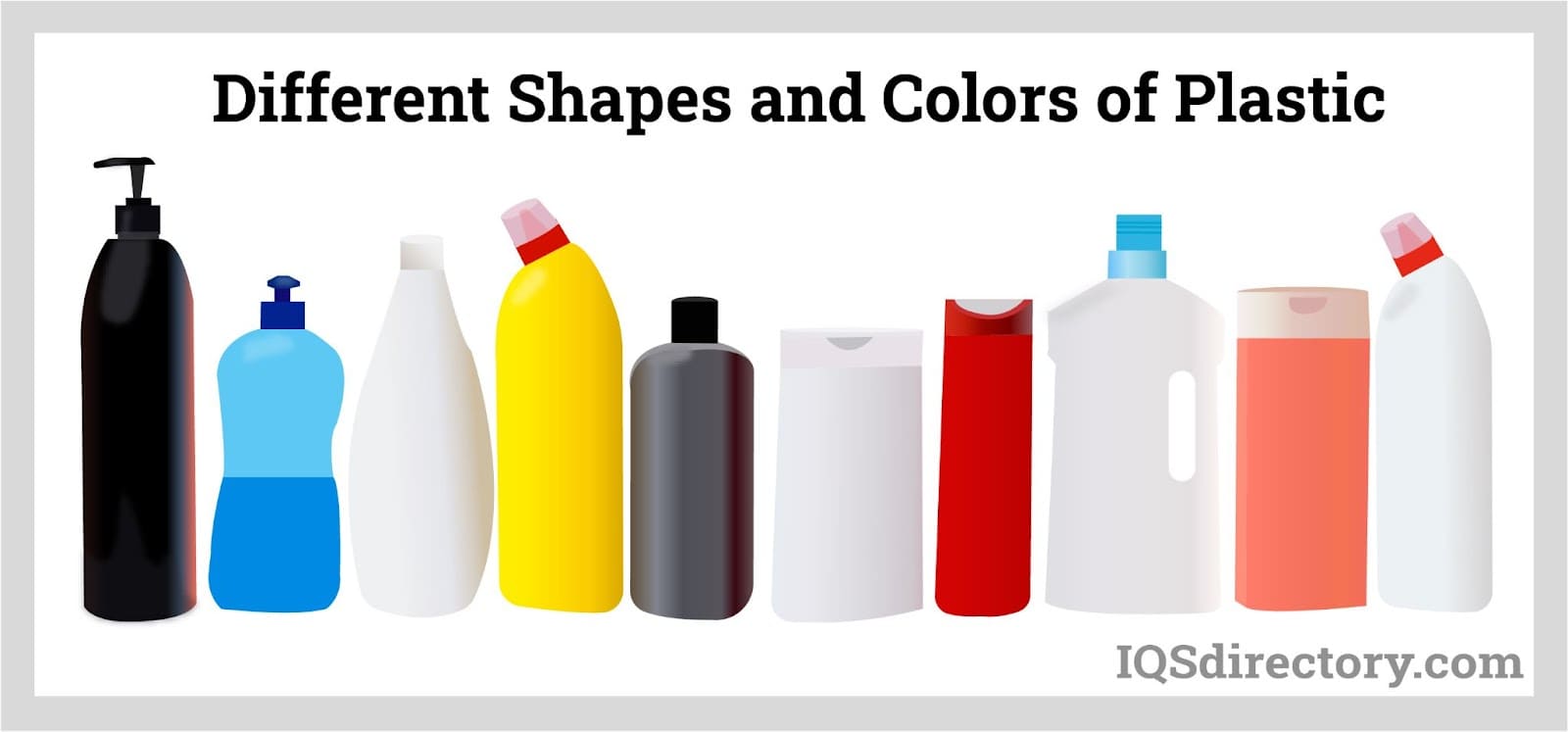

Strategic Material Selection Guide for types of bottles

What Are the Key Materials Used in Bottle Manufacturing?

When selecting the appropriate material for bottle manufacturing, it is crucial for B2B buyers to consider the unique properties, advantages, and limitations of each material. This analysis will focus on four common materials: plastic, glass, stainless steel, and aluminum. Each material has distinct characteristics that can significantly influence product performance, cost, and suitability for various applications.

How Does Plastic Perform in Bottle Applications?

Plastic, particularly high-density polyethylene (HDPE) and polyethylene terephthalate (PET), is widely used in bottle manufacturing due to its lightweight nature and versatility. Key properties include excellent impact resistance and good chemical compatibility, making it suitable for a range of liquids, including beverages and household products. However, plastic bottles typically have a lower temperature and pressure rating compared to other materials, which can limit their use in high-temperature applications.

Pour: Plastic bottles are generally cost-effective, lightweight, and resistant to shattering. They can be produced in various shapes and sizes, making them highly customizable.

Cons: The primary drawbacks include environmental concerns related to plastic waste and potential leaching of chemicals into the contents, especially when exposed to heat. Additionally, plastics may not provide the same level of barrier protection against oxygen and moisture as other materials.

For international buyers, compliance with regulations such as FDA standards for food-grade plastics and recycling guidelines is essential, especially in regions with strict environmental policies.

What Are the Advantages of Glass Bottles?

Glass bottles are renowned for their superior barrier properties, making them ideal for preserving the quality of beverages and other sensitive contents. They can withstand high temperatures and are non-reactive, ensuring that the contents remain untainted. Glass also offers a premium feel, which can enhance brand perception.

Pour: Glass is recyclable, durable, and provides an excellent barrier against gases and moisture. It is also chemically inert, making it suitable for a wide range of products.

Cons: The main limitations of glass include its weight and fragility. Glass bottles can be more expensive to manufacture and transport, especially in regions where breakage during shipping is a concern.

International buyers should consider compliance with safety standards, such as those set by ASTM or ISO, particularly in markets where glass packaging is prevalent.

How Does Stainless Steel Compare for Bottle Use?

Stainless steel bottles are increasingly popular due to their durability and resistance to corrosion. They can handle extreme temperatures, making them suitable for both hot and cold beverages. Key properties include high tensile strength and excellent thermal insulation, especially when double-walled.

Pour: Stainless steel is highly durable, reusable, and resistant to rust and corrosion. It is also easy to clean and can be recycled at the end of its life cycle.

Cons: The primary drawback is the higher cost compared to plastic and aluminum. Additionally, stainless steel bottles can be heavier, which may not be ideal for all applications.

For buyers in regions like Africa and South America, where durability is essential due to varying transport conditions, stainless steel offers a robust solution. Compliance with international food safety standards is also critical.

What Role Does Aluminum Play in Bottle Manufacturing?

Aluminum bottles are lightweight and highly recyclable, making them an attractive option for beverage packaging. They provide a good barrier against light and oxygen, which helps preserve the quality of the contents. Aluminum can also be produced in various colors and finishes, enhancing branding opportunities.

Pour: Aluminum is lightweight, cost-effective, and offers a high degree of customization. It is also fully recyclable, which appeals to environmentally conscious consumers.

Cons: One limitation is that aluminum bottles may require a lining to prevent chemical reactions with acidic beverages. Additionally, they may not provide the same level of insulation as stainless steel.

International buyers should be aware of compliance with standards such as the EU’s food contact regulations and local recycling practices, particularly in regions with growing environmental awareness.

Summary Table of Material Selection for Bottles

| Matériau | Typical Use Case for types of bottles | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| Plastique | Soft drinks, household products | Léger et rentable | Environmental concerns, lower barrier | Faible |

| Verre | Premium beverages, pharmaceuticals | Excellent barrier properties | Lourd et fragile | Haut |

| Acier inoxydable | Sports drinks, outdoor products | Durable and reusable | Higher cost, heavier | Méd. |

| Aluminium | Soft drinks, energy drinks | Lightweight and highly recyclable | May require lining for acidic contents | Méd. |

This strategic material selection guide provides essential insights for B2B buyers looking to choose the right type of bottle for their specific applications, ensuring compliance with international standards and addressing market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for types of bottles

What Are the Main Stages of Bottle Manufacturing Processes?

Understanding the manufacturing process of bottles is essential for B2B buyers who seek quality products. The production of bottles typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques that ensure the final product meets both functionality and aesthetic requirements.

How Is Material Prepared for Bottle Manufacturing?

Material preparation is the first stage in bottle manufacturing. Depending on the type of bottle—plastic, glass, or metal—the materials will vary. For plastic bottles, resin pellets are often used, which are heated until they melt and can be molded. Glass bottles start with raw materials such as silica sand, soda ash, and limestone, which are mixed and melted in a furnace. Metal bottles, on the other hand, typically utilize aluminum or stainless steel sheets.

Quality checks begin here, ensuring that materials meet specifications. For example, suppliers may need to provide certifications confirming that their materials are free from harmful substances. This is particularly important for products intended for food and beverage use.

What Techniques Are Used in Bottle Forming?

The forming stage is critical, as it shapes the raw materials into bottles. There are several techniques employed depending on the material:

-

Injection Molding: Commonly used for plastic bottles, this method involves injecting molten plastic into a mold, allowing it to cool and harden into the desired shape.

-

Blow Molding: This technique is often used for hollow bottles, where air is blown into a heated plastic preform to expand it into the mold.

-

Glass Blowing: In glass manufacturing, molten glass is shaped using a blowpipe to form the bottle, ensuring uniform thickness and design.

-

Stamping and Drawing: For metal bottles, sheets of metal are stamped and drawn into shape, which ensures durability and a clean finish.

Each technique has its own set of quality control measures to verify that the bottles are formed correctly, including dimensional inspections and visual checks for defects.

What Happens During the Assembly Process of Bottle Manufacturing?

The assembly process involves adding components such as caps, labels, and any additional features required for the bottle’s functionality. For example, baby bottles might require specialized nipples, while insulated bottles need additional layers for thermal protection.

During assembly, quality checks are essential. Automated systems can be employed to ensure that caps fit securely and labels are applied correctly. Manual inspections may also be conducted to catch any assembly-related defects.

How Is Finishing Executed in Bottle Manufacturing?

Finishing involves the final touches that enhance the bottle’s appearance and functionality. This can include:

-

Coatings: Applying protective coatings to prevent scratches and improve aesthetics.

-

Printing: Using techniques like screen printing or digital printing for branding and labeling.

-

Testing for Functionality: For bottles designed for specific uses, such as insulated bottles, tests for thermal retention are conducted.

Quality assurance during this stage is critical, as it not only impacts the product’s appearance but also its performance in the marketplace.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance in bottle manufacturing is governed by various international standards, which are essential for B2B buyers to understand. The most relevant include:

-

ISO 9001: This standard ensures that the manufacturer has a quality management system in place, focusing on customer satisfaction and continuous improvement.

-

CE Marking: For products sold in Europe, the CE mark indicates conformity with health, safety, and environmental protection standards.

-

API Standards: For bottles used in pharmaceutical applications, adherence to standards set by the American Petroleum Institute (API) is crucial.

These certifications not only guarantee quality but also facilitate smoother trade across borders, particularly for buyers in Africa, South America, the Middle East, and Europe.

What Are the QC Checkpoints in Bottle Manufacturing?

Quality control checkpoints are crucial throughout the manufacturing process. Key checkpoints include:

-

Contrôle de la qualité à l'arrivée (IQC) : This stage checks raw materials upon arrival to ensure they meet required specifications.

-

Contrôle de la qualité en cours de fabrication (IPQC) : Continuous monitoring during manufacturing ensures that processes are followed correctly and that the product remains within specified parameters.

-

Contrôle de qualité final (CQF) : This is the last line of defense before products are shipped. It includes comprehensive testing for defects, dimensional accuracy, and performance.

By implementing these checkpoints, manufacturers can significantly reduce the risk of defective products reaching the market.

What Testing Methods Are Common in Bottle Quality Control?

Testing methods are diverse and depend on the type of bottle being produced. Common testing methods include:

-

Dimensional Testing: Ensures that the bottle meets specified size and shape requirements.

-

Pressure Testing: For bottles designed to hold carbonated beverages, pressure tests verify that they can withstand internal pressures without failure.

-

Thermal Cycling Tests: For insulated bottles, these tests evaluate how well the bottle maintains temperature over time.

-

Essais de résistance chimique : For bottles that will hold various substances, testing ensures that materials do not react adversely with the contents.

These tests provide critical data that can be shared with B2B buyers, establishing trust in the product’s quality.

Comment les acheteurs B2B peuvent-ils vérifier le contrôle de la qualité des fournisseurs ?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some effective methods:

-

Audits des fournisseurs : Regular audits of the supplier’s facilities can provide insights into their quality control processes and compliance with international standards.

-

Rapports de contrôle de la qualité : Requesting detailed reports on quality control measures, including results from testing and inspections, can help buyers assess supplier reliability.

-

Inspections par des tiers : Engaging third-party inspection services can add an additional layer of assurance, providing unbiased evaluations of product quality.

Buyers in emerging markets, like those in Africa and South America, should also consider the local regulatory landscape, as compliance may vary significantly between regions.

What Nuances Should International B2B Buyers Be Aware Of?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, several nuances come into play:

-

Regulatory Compliance: Different countries have varying regulations regarding materials, safety, and environmental impact. It’s crucial to understand these regulations to ensure compliance and avoid potential fines or product recalls.

-

Cultural Considerations: Packaging preferences can vary greatly by region. Understanding local consumer preferences can guide decisions on bottle design and functionality.

-

Supply Chain Logistics: International shipping can introduce challenges such as longer lead times and potential customs issues. Working with suppliers who have experience in international trade can mitigate these risks.

By keeping these factors in mind, B2B buyers can make informed decisions when sourcing bottles, ensuring they select suppliers who not only provide high-quality products but also align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of bottles’

In the competitive landscape of bottle sourcing, understanding the various types of bottles available and the specific needs of your business is crucial. This practical sourcing guide provides a step-by-step checklist tailored for B2B buyers looking to procure different types of bottles, ensuring you make informed decisions that align with your operational requirements and market demands.

Étape 1 : Identify Your Target Market Needs

Understanding the specific needs of your target market is the first step in sourcing bottles effectively. Consider factors such as the demographics of your customers, regional preferences, and the intended use of the bottles. For instance, bottles for outdoor activities might require durability and insulation, while baby bottles would need to focus on safety and ease of use.

- Market Research: Conduct surveys or focus groups to gather insights on customer preferences.

- Competitive Analysis: Review what similar businesses are offering to identify gaps in the market.

Étape 2 : Définir les spécifications techniques

Establishing clear technical specifications is essential for ensuring that the bottles meet your quality standards and use cases. This includes material selection (e.g., plastic, glass, stainless steel), size, capacity, and any specific features like insulation or spill-proof designs.

- Material Considerations: Assess the sustainability and safety of materials, especially for products intended for children or food and beverage use.

- Feature Requirements: Determine if additional features, like custom branding or unique lid designs, are necessary for your product offering.

Étape 3 : Évaluer les fournisseurs potentiels

Before committing, thoroughly vet potential suppliers to ensure they can meet your specifications. Request company profiles, product samples, and references from buyers in similar industries or regions.

- Quality Assurance: Ask about quality control processes and certifications, such as ISO or FDA compliance, to ensure product safety and reliability.

- Supplier Reputation: Look for reviews or testimonials to gauge their reliability and service quality.

Étape 4 : Assess Production Capabilities

Understanding a supplier’s production capabilities is vital for ensuring they can meet your order volume and timelines. Inquire about their manufacturing processes, lead times, and flexibility to accommodate large or custom orders.

- Scalability: Ensure the supplier can scale production if your demand increases.

- Technology and Innovation: Look for suppliers who utilize advanced manufacturing technologies for better quality and efficiency.

Étape 5 : Négocier les prix et les conditions

Once you have identified potential suppliers, negotiate pricing and terms to secure the best deal. Consider not only the unit price but also shipping costs, payment terms, and return policies.

- Remises en vrac : Ask about pricing tiers for larger orders to maximize your budget.

- Contract Clarity: Ensure that all terms are clearly outlined in a contract to avoid misunderstandings.

Étape 6 : Verify Compliance and Certifications

Ensure that the bottles you are sourcing comply with relevant regulations and standards in your target markets. This step is crucial for avoiding legal issues and ensuring product safety.

- Regulatory Compliance: Check if the bottles meet local health and safety regulations, especially for food and beverage applications.

- Sustainability Certifications: If applicable, verify any sustainability certifications that may enhance your product’s marketability.

Étape 7 : Plan for Quality Control and Testing

Establish a quality control process to ensure the bottles meet your standards before distribution. This may involve testing samples for durability, safety, and performance.

- Sample Testing: Request samples from suppliers and conduct independent testing if necessary.

- Inspection Protocols: Develop a checklist for quality inspections upon receipt of goods to ensure all specifications are met.

By following this checklist, B2B buyers can streamline the sourcing process for various types of bottles, ensuring that their procurement aligns with business objectives and market demands.

Comprehensive Cost and Pricing Analysis for types of bottles Sourcing

What Are the Key Cost Components in Bottle Sourcing?

When sourcing bottles, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

-

Matériaux: The choice of materials significantly impacts costs. Common materials for bottles include plastic (e.g., PET, HDPE), glass, and stainless steel. Plastic is generally less expensive, while glass and stainless steel may incur higher material costs but offer better durability and aesthetics.

-

Travail: Labor costs can vary based on the region and the complexity of the manufacturing process. Regions with lower labor costs can offer significant savings, but this may come at the expense of quality or compliance with international standards.

-

Frais généraux de fabrication: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce these costs, which is essential for competitive pricing.

-

Outillage: Custom tooling for unique bottle designs can be a substantial initial investment. For B2B buyers, understanding the tooling costs associated with their specific requirements is vital. These costs may be amortized over larger order volumes.

-

Contrôle de la qualité (CQ): Ensuring product quality is non-negotiable, especially for international markets. QC processes add to the cost but are essential for maintaining brand reputation and meeting regulatory standards.

-

Logistique: Shipping costs can vary significantly based on distance, mode of transport, and Incoterms. Understanding the logistics chain is crucial to avoid unexpected expenses that could erode margins.

-

Marge: Suppliers will typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand and competition.

What Influences Bottle Pricing for International Buyers?

Several factors influence the pricing of bottles in the B2B marketplace, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can greatly affect pricing. Ordering in bulk often leads to lower per-unit costs, making it essential for buyers to negotiate favorable terms based on anticipated demand.

-

Spécifications et personnalisation: Custom designs, sizes, or features will typically increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Matériaux et certifications de qualité: Higher quality materials and certifications (e.g., FDA, ISO) can raise costs but are crucial for compliance and market acceptance. Buyers must balance the need for quality with budget constraints.

-

Facteurs liés au fournisseur: The supplier’s reputation, reliability, and geographic location play roles in pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

What Buyer Tips Can Enhance Cost-Efficiency in Bottle Sourcing?

International buyers should consider several strategies to optimize costs when sourcing bottles.

-

Negotiate Terms: Engaging in negotiations can lead to better pricing, especially for larger orders. Establishing a relationship with suppliers can also yield favorable terms over time.

-

Évaluer le coût total de possession (TCO): Beyond the purchase price, consider the total cost of ownership, including shipping, handling, storage, and disposal costs. A lower upfront cost may not always translate to overall savings.

-

Comprendre les nuances de la tarification: Be aware that prices may fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Keeping abreast of these elements can help buyers time their purchases effectively.

-

Effectuer des audits des fournisseurs: Regularly assessing suppliers for quality, efficiency, and compliance can prevent costly mistakes and ensure that your sourcing strategy remains competitive.

In conclusion, a comprehensive understanding of the cost structure, pricing influencers, and strategic purchasing tips can empower B2B buyers to make informed decisions in the competitive landscape of bottle sourcing. Always remember to request indicative prices and conduct thorough market research before finalizing any agreements.

Alternatives Analysis: Comparing types of bottles With Other Solutions

Exploring Alternatives to Types of Bottles

When it comes to beverage packaging and storage, various solutions exist beyond traditional bottles. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific operational needs. This section compares different types of bottles with alternative solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Aspect comparatif | Types of Bottles | Alternative 1: Tetra Paks | Alternative 2: Cans |

|---|---|---|---|

| Performance | Versatile for various beverages; excellent insulation options available. | Good for shelf-stability and long shelf life; limited insulation. | Lightweight, highly portable; less effective for temperature control. |

| Coût | Moderate to high, depending on materials and design. | Generally lower production cost; cost-efficient for bulk purchases. | Low-cost production; competitive pricing for high-volume orders. |

| Facilité de mise en œuvre | Easy to source and customize; requires storage space for empty bottles. | Requires specialized packaging equipment; less flexibility in customization. | Simple to produce; widely available; easy to store. |

| Maintenance | Reusable options may require cleaning and care; single-use bottles create waste. | Low maintenance; recyclable but not reusable. | Minimal maintenance; recyclable but usually single-use. |

| Meilleur cas d'utilisation | Ideal for premium brands wanting to emphasize quality; suitable for diverse markets. | Best for long-term storage of liquids; often used for juices and dairy. | Excellent for carbonated beverages and on-the-go consumption. |

What Are the Pros and Cons of Tetra Paks?

Tetra Paks offer a unique packaging solution, particularly for liquids like juices and dairy products. Their aseptic design allows for long shelf life without refrigeration, making them a practical choice for regions with limited access to cold storage. However, they require specialized machinery for filling, which can be a significant investment for businesses. Additionally, customization options are more limited compared to traditional bottles, potentially affecting brand differentiation.

How Do Cans Compare as an Alternative?

Cans are a popular choice for beverage packaging due to their lightweight and recyclable nature. They are cost-effective to produce and widely accepted in various markets, making them an attractive option for B2B buyers. Cans excel in portability and are ideal for carbonated drinks, but they do not offer the same insulation properties as some bottles. Furthermore, once opened, cans are less effective at maintaining beverage quality compared to insulated bottle options.

How Should B2B Buyers Choose the Right Solution?

When selecting between types of bottles and their alternatives, B2B buyers should consider their specific operational needs and target market. Factors such as cost efficiency, branding requirements, and the nature of the beverage play crucial roles in decision-making. For example, premium brands may prefer bottles to convey quality, while companies focusing on bulk distribution might opt for Tetra Paks or cans to reduce costs. Ultimately, understanding the advantages and disadvantages of each option will empower businesses to choose the most suitable packaging solution for their products.

Essential Technical Properties and Trade Terminology for types of bottles

What Are the Key Technical Properties to Consider for Different Types of Bottles?

When sourcing bottles for your business, understanding the technical properties that define their quality and performance is crucial. Here are several critical specifications that can influence your purchasing decisions:

-

Qualité des matériaux

The grade of material used in bottle production (such as PET, glass, stainless steel, or HDPE) significantly affects durability, safety, and environmental impact. For example, food-grade plastics are essential for beverage containers to ensure safety and compliance with health regulations. B2B buyers should prioritize material certifications that align with their product applications and regional regulations. -

Capacity and Dimensions

Bottles come in various sizes, typically measured in liters or ounces. Understanding the volume is vital for meeting consumer demand and logistics. Additionally, dimensions (height, diameter) determine compatibility with packaging and shipping containers. Accurate sizing ensures that products fit well within shipping and retail displays, optimizing space and reducing costs. -

Thermal Insulation Properties

For bottles designed to maintain temperature (like insulated tumblers or canteens), thermal insulation performance is a key property. This is often measured in terms of how long a bottle can keep liquids hot or cold. B2B buyers should consider the insulation technology (e.g., double-walled vacuum insulation) to ensure that products meet customer expectations for temperature retention. -

Closure Type and Sealing Mechanism

The closure type (e.g., screw cap, flip-top, or straw lid) can influence usability and leakage prevention. A reliable sealing mechanism is essential to prevent spills during transport and storage. Buyers should evaluate closure designs based on target markets, such as outdoor activities where durability and spill-proof features are critical. -

Compliance and Certifications

Bottles may require compliance with various international standards, such as FDA regulations for food safety or ISO certifications for manufacturing processes. Ensuring that products meet these standards is crucial for market entry and customer trust. B2B buyers should request documentation of compliance to mitigate risks associated with non-compliance.

Which Trade Terms Are Essential for Understanding Bottle Purchases?

Familiarity with industry terminology can streamline negotiations and purchasing processes. Here are some common trade terms relevant to bottle sourcing:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of bottles, an OEM can provide customized designs or branding for your specific needs. Understanding OEM relationships can enhance product uniqueness and brand identity. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. It is crucial for B2B buyers to understand MOQ as it impacts inventory management and cash flow. Negotiating favorable MOQs can allow businesses to maintain lower inventory levels while still meeting customer demand. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. It is an essential step in the procurement process, helping buyers compare costs and terms across different vendors. Utilizing RFQs effectively can lead to better pricing and supplier relationships. -

Incoterms (termes commerciaux internationaux)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for determining who is responsible for shipping costs, insurance, and risk during transit. Clear agreements based on Incoterms can prevent misunderstandings and facilitate smoother transactions. -

Délai d'exécution

Lead time refers to the amount of time it takes from placing an order to receiving the product. It encompasses production and shipping times and is critical for inventory planning. B2B buyers should discuss lead times with suppliers to align delivery with their operational needs.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions that optimize their procurement processes, ensuring the selection of the right bottles for their market needs.

Navigating Market Dynamics and Sourcing Trends in the types of bottles Sector

What Are the Key Drivers and Current Trends in the Global Bottles Market?

The global bottles market is experiencing dynamic shifts driven by consumer preferences, environmental concerns, and technological advancements. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate this landscape, they should be aware of several key trends. The demand for reusable bottles, especially those designed for hydration and convenience, has surged as consumers prioritize sustainability and functionality. Innovations in materials, such as stainless steel and BPA-free plastics, are becoming increasingly popular, offering durability and safety.

Moreover, the rise of e-commerce platforms has transformed sourcing strategies, allowing buyers to access a wider range of products and suppliers globally. Digital tools and B2B marketplaces facilitate efficient procurement processes, enabling businesses to compare prices and features seamlessly. Additionally, the emphasis on personalization and branding is reshaping product offerings, with custom designs and colors catering to niche markets. Understanding these trends is crucial for B2B buyers aiming to make informed purchasing decisions in the ever-evolving bottles sector.

How Is Sustainability Influencing Sourcing Trends in the Bottles Sector?

Sustainability is no longer just a buzzword; it is a fundamental aspect of sourcing strategies in the bottles sector. The environmental impact of single-use plastics has led to a significant shift towards eco-friendly alternatives. B2B buyers are increasingly seeking suppliers that prioritize ethical sourcing and sustainable materials. This includes bottles made from recycled plastics, biodegradable materials, and glass, which not only reduce waste but also appeal to environmentally conscious consumers.

Furthermore, certifications such as FSC (Forest Stewardship Council) and ISO 14001 are becoming essential criteria for B2B buyers. These certifications ensure that the products are sourced responsibly and comply with environmental standards. Establishing ethical supply chains not only enhances brand reputation but also meets the growing regulatory demands for sustainability. For international buyers, understanding the environmental policies of suppliers in different regions can provide a competitive edge and foster long-term partnerships that align with global sustainability goals.

What Is the Historical Context of Bottles and Their Evolution in the B2B Market?

The evolution of bottles can be traced back thousands of years, from primitive vessels made of clay and animal skins to the sophisticated designs we see today. Initially, glass was the material of choice for durability and preservation, particularly in beverage packaging. The introduction of plastic in the mid-20th century revolutionized the industry, offering lightweight and versatile options that led to the proliferation of single-use bottles.

In recent years, however, the focus has shifted back to reusable and sustainable options, as awareness of environmental issues has grown. This historical context is essential for B2B buyers to understand market dynamics, as it highlights the cyclical nature of consumer preferences and the ongoing quest for innovation in the bottle sector. As buyers look to the future, recognizing the lessons of the past can guide sourcing strategies that balance functionality, sustainability, and market demand.

Frequently Asked Questions (FAQs) for B2B Buyers of types of bottles

-

How do I select the right type of bottle for my business needs?

Choosing the right type of bottle depends on your specific requirements such as the intended use, target market, and branding needs. Consider factors such as material (plastic, glass, stainless steel), insulation properties, and size. Additionally, evaluate whether you need features like spill-proof lids or customization options. Conducting market research to understand consumer preferences in your target region can also guide your decision. Engage with suppliers who can provide samples for testing before finalizing your choice. -

What is the best bottle type for eco-friendly packaging?

For businesses prioritizing sustainability, glass and stainless steel bottles are excellent options due to their recyclability and longevity. Reusable bottles not only appeal to environmentally conscious consumers but also align with global trends towards reducing plastic waste. Consider sourcing from suppliers who offer eco-friendly manufacturing processes and materials. Additionally, explore options for biodegradable plastics if you require a lightweight solution, ensuring your packaging aligns with your brand’s sustainability goals. -

What customization options are available for bottles?

Many suppliers offer a range of customization options for bottles, including color, size, logo printing, and labeling. Some manufacturers allow for unique design features such as ergonomic grips or multi-functional lids. When sourcing bottles, discuss your specific branding requirements with potential suppliers to understand their capabilities. Be sure to review minimum order quantities (MOQs) and lead times for customized products to ensure they align with your project timelines. -

How can I vet suppliers for bottle sourcing?

To effectively vet suppliers, start by researching their reputation and experience in the industry. Check for certifications, such as ISO or FDA compliance, which ensure product quality and safety. Request references from previous clients and assess their responsiveness during initial communications. Additionally, consider visiting manufacturing facilities if feasible, or request virtual tours to evaluate their operational standards. Finally, review their terms for quality assurance and after-sales support. -

What are the common minimum order quantities (MOQs) for bottles?

MOQs for bottles can vary significantly based on material, design complexity, and supplier capabilities. Generally, plastic bottles have lower MOQs compared to glass or metal due to the production processes involved. It’s crucial to discuss MOQs upfront with potential suppliers to ensure they align with your business needs. Some suppliers may offer flexibility on MOQs for first-time orders or sample runs, allowing you to test market demand before committing to larger quantities. -

What payment terms should I expect when sourcing bottles internationally?

Payment terms can vary widely among suppliers, but common practices include upfront deposits ranging from 30% to 50%, with the balance due before shipment. Some suppliers may offer net payment terms (e.g., net 30 days) for established relationships. When negotiating payment terms, consider using secure methods such as letters of credit or escrow services to protect your investment. It’s essential to clarify any additional costs, such as shipping or customs duties, to avoid unexpected expenses. -

How do I ensure quality assurance for the bottles I source?

Implementing a robust quality assurance process is essential when sourcing bottles. Start by establishing clear specifications and standards that the products must meet. Request samples for testing before placing larger orders. Consider conducting third-party inspections during production and prior to shipment to ensure compliance with your quality standards. Additionally, maintaining open communication with your supplier throughout the production process can help address any potential issues early on. -

What logistics considerations should I keep in mind when importing bottles?

When importing bottles, consider logistics factors such as shipping methods, lead times, and customs regulations specific to your region. Select a reliable freight forwarder who can navigate international shipping complexities and provide accurate cost estimates. It’s also important to factor in storage and distribution capabilities upon arrival. Understanding local import duties and taxes can help you budget effectively. Finally, ensure that your supplier provides adequate documentation to facilitate smooth customs clearance.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

Top 3 Types Of Bottles Manufacturers & Suppliers List

1. Dr. Brown’s – Natural Flow Anti-Colic Options+

Domaine : drbrownsbaby.com

Registered: 2010 (15 years)

Introduction : Dr. Brown’s offers a variety of baby bottles, including the Natural Flow Anti-Colic Options+ in both narrow and wide-neck designs. Key features include:

– Pediatrician recommended, used in hospitals for over 20 years.

– Available in glass and plastic options.

– Comes with Level 1 Slow Flow Nipples.

– Sizes include 5oz/150mL and 9oz/270mL.

– Options for 2-packs and individual bottles.

– Addit…

2. Paramount Global – Wholesale Packaging Bottles

Domaine : paramountglobal.com

Enregistré : 1999 (26 ans)

Introduction : Your Guide to Wholesale Packaging Bottles includes various types of bottles with unique features tailored for specific needs and industries. Key bottle types include: 1. Boston Round – Rounded shoulders, narrow neck, wide body; used for liquids, essential oils, beverages, personal care; available in glass (clear, cobalt blue, amber) and plastic (clear, white). 2. Bullet Round – Rounded shoulders, …

3. The Bottle Depot – Glass Bottle Varieties

Domaine : thebottledepot.co

Enregistré : 2019 (6 ans)

Introduction : Different types of glass bottles and their uses include: 1. Amber Glass Bottles – Ideal for light-sensitive products like essential oils, pharmaceuticals, cosmetics, and food products. 2. Clear Glass Bottles – Versatile for beverages, sauces, and cosmetics. 3. Green Glass Bottles – Used for wine, spirits, and olive oils. 4. Blue Glass Bottles – Common in high-end cosmetics and essential oils. 5. F…

Strategic Sourcing Conclusion and Outlook for types of bottles

Why Is Strategic Sourcing Essential for Bottle Procurement?

In the diverse landscape of bottle types, understanding the nuances—from insulated tumblers to specialized baby bottles—can significantly enhance your procurement strategy. Each bottle type offers unique features tailored to specific market needs, whether for hydration, convenience, or specialized applications. Strategic sourcing empowers international B2B buyers to identify reliable suppliers, negotiate favorable terms, and secure high-quality products that align with their operational requirements.

How Can You Leverage Bottle Variability for Market Growth?

As markets in Africa, South America, the Middle East, and Europe evolve, the demand for innovative and sustainable bottle solutions is on the rise. Buyers should focus on sourcing products that not only meet current consumer preferences but also anticipate future trends, such as eco-friendly materials and multifunctional designs. By staying ahead of these trends, businesses can enhance their competitive edge and cater to a broader audience.

What Steps Should You Take Next?

Engage with suppliers who demonstrate a commitment to quality and sustainability while exploring new product innovations. Consider forming strategic partnerships that facilitate access to emerging bottle technologies and materials. Now is the time to reassess your sourcing strategies to ensure your offerings resonate with evolving market demands. The future of bottle procurement is bright—act decisively to capitalize on it.