Introduction: Navigating the Global Market for 3d printer water bottle

Navigating the complexities of sourcing high-quality 3D printer water bottles can be a daunting challenge for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. As businesses increasingly seek innovative solutions to enhance their product offerings, understanding the nuances of 3D printing technology becomes essential. This comprehensive guide delves into the various types of 3D printer water bottles available, their applications in different industries, and critical insights into supplier vetting processes.

By exploring factors such as material compatibility, production efficiency, and customization options, this resource equips international buyers with the knowledge to make informed purchasing decisions. We will also address cost considerations, ensuring that businesses can effectively balance quality with budget constraints. Additionally, we highlight emerging trends in 3D printing, including sustainable practices and consumer preferences, which are shaping the future of product design.

For B2B buyers in regions like Saudi Arabia and Vietnam, this guide serves as a vital tool to navigate the global market, ensuring that you can confidently select suppliers who align with your strategic goals. Whether you’re looking to enhance your product line or explore new manufacturing techniques, understanding the market dynamics of 3D printed water bottles will empower your business to thrive in a competitive landscape.

Navigation dans les articles

- Top 8 3D Printer Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 3d printer water bottle

- Understanding 3d printer water bottle Types and Variations

- Key Industrial Applications of 3d printer water bottle

- 3 Common User Pain Points for ‘3d printer water bottle’ & Their Solutions

- Strategic Material Selection Guide for 3d printer water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 3d printer water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printer water bottle’

- Comprehensive Cost and Pricing Analysis for 3d printer water bottle Sourcing

- Alternatives Analysis: Comparing 3d printer water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 3d printer water bottle

- Navigating Market Dynamics and Sourcing Trends in the 3d printer water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 3d printer water bottle

- Avis de non-responsabilité et conditions d'utilisation

- Strategic Sourcing Conclusion and Outlook for 3d printer water bottle

Understanding 3d printer water bottle Types and Variations

| Nom du type | Principales caractéristiques | Applications primaires B2B | Avantages et inconvénients pour les acheteurs |

|---|---|---|---|

| Customizable Plastic Bottles | Made from PLA or ABS, allowing for intricate designs and logos | Promotional products, Corporate branding | Pour : High customization; Cons : Less durable than metal. |

| Stainless Steel Bottles | Durable, insulated options with high resistance to wear | High-end retail, Corporate gifts | Pour : Long-lasting; Cons : Higher production costs. |

| Flexible Silicone Bottles | Soft, collapsible design for easy transport | Outdoor activities, Travel accessories | Pour : Lightweight; Cons : Limited design options. |

| Miniature Models | Scale models for display or educational purposes | Educational tools, Collectibles | Pour : Unique appeal; Cons : Not functional for drinking. |

| Eco-friendly Biodegradable | Made from sustainable materials that decompose | Eco-conscious brands, Sustainable marketing | Pour : Environmentally friendly; Cons : May lack durability. |

What Are the Characteristics of Customizable Plastic Bottles?

Customizable plastic bottles are primarily made from materials like PLA or ABS, enabling businesses to create intricate designs and logos through 3D printing. These bottles are particularly suitable for promotional products and corporate branding, allowing companies to convey their identity effectively. When considering a purchase, B2B buyers should evaluate the balance between customization potential and the durability of plastic compared to other materials.

How Do Stainless Steel Bottles Stand Out in the Market?

Stainless steel bottles are recognized for their durability and insulation properties, making them ideal for high-end retail and corporate gifts. These bottles can maintain beverage temperatures and are resistant to wear and tear, appealing to businesses looking to invest in quality products. Buyers should weigh the higher production costs against the long-term benefits of offering a premium product that can enhance their brand image.

What Are the Advantages of Flexible Silicone Bottles?

Flexible silicone bottles are designed for easy transport and are perfect for outdoor activities and travel accessories. Their collapsible nature makes them lightweight and convenient, catering to a growing market of on-the-go consumers. However, B2B buyers should consider the limited design options available, which may restrict branding opportunities compared to more rigid materials.

Why Are Miniature Models Important for B2B Applications?

Miniature models serve as scale representations for display or educational purposes, making them valuable tools in industries like education and collectibles. These models can attract attention and engage customers effectively. B2B buyers should recognize that while these products may not be functional for drinking, their unique appeal can enhance brand visibility and customer engagement.

How Do Eco-friendly Biodegradable Bottles Fit into Sustainable Practices?

Eco-friendly biodegradable bottles are crafted from sustainable materials that decompose over time, appealing to eco-conscious brands and businesses focused on sustainability. These bottles enable companies to align their products with environmentally responsible practices, enhancing their marketability. However, buyers should be mindful of potential durability issues, as these bottles may not perform as well as traditional materials in certain applications.

Key Industrial Applications of 3d printer water bottle

| Industrie/secteur | Specific Application of 3D Printer Water Bottle | Valeur/bénéfice pour l'entreprise | Principales considérations en matière d'approvisionnement pour cette application |

|---|---|---|---|

| Custom Merchandise | Production of branded water bottles for promotional events | Enhances brand visibility and customer engagement | Evaluate printing capabilities, material choices, and design flexibility |

| Outdoor and Sports Equipment | Customizable hydration solutions for athletes | Tailored products meet specific athlete needs | Assess durability, material safety, and customization options |

| Education and Training | 3D printed educational models for water conservation | Promotes sustainability awareness among students | Ensure compliance with educational standards and safety regulations |

| Soins de santé | Personalized water bottles for patients | Supports hydration needs and encourages health compliance | Consider ergonomics, material safety, and ease of cleaning |

| Hospitality and Events | Unique, themed water bottles for events | Creates memorable experiences and enhances event branding | Focus on design creativity, production speed, and cost-effectiveness |

How Can Custom Merchandise Benefit from 3D Printed Water Bottles?

In the custom merchandise sector, businesses can utilize 3D printed water bottles to create unique, branded products for promotional events. This application allows companies to enhance brand visibility while providing a functional item that resonates with consumers. The ability to customize designs quickly and affordably with 3D printing technology enables businesses to respond to market trends and customer preferences effectively. International buyers should consider the supplier’s printing capabilities and the range of materials available to ensure high-quality outputs.

What Advantages Do Outdoor and Sports Equipment Industries Gain from 3D Printed Water Bottles?

The outdoor and sports equipment sectors can leverage 3D printing technology to produce personalized hydration solutions tailored to athletes’ specific needs. Customization options may include size, shape, and ergonomic features that enhance usability during physical activities. This targeted approach not only improves athlete performance but also promotes brand loyalty among sports enthusiasts. Buyers in this field must evaluate the durability of materials used and the safety of designs to meet rigorous outdoor conditions.

How Does 3D Printing Support Education and Training Initiatives?

In education, 3D printed water bottles can serve as practical tools for teaching students about water conservation and environmental responsibility. By integrating these models into curricula, educators can foster discussions around sustainability while providing tangible examples. The customization of these bottles can also reflect educational branding or messages. International buyers should ensure that the products meet educational standards and safety regulations for use in schools.

What Role Do 3D Printed Water Bottles Play in Healthcare?

In healthcare, personalized water bottles can be designed to meet individual patient needs, promoting hydration and encouraging adherence to health guidelines. These bottles can be tailored for ease of use, taking into account factors such as grip and accessibility for patients with disabilities. For healthcare providers, sourcing considerations should include the safety of materials and the ease of cleaning to maintain hygiene standards.

How Can Hospitality and Events Use 3D Printed Water Bottles for Unique Experiences?

The hospitality and events industry can benefit significantly from 3D printed water bottles by creating unique, themed designs that enhance the guest experience. Custom bottles can serve as memorable takeaways, reinforcing brand identity and event themes. This application allows for rapid production and a high degree of creativity. When sourcing, businesses should focus on design innovation, production speed, and overall cost-effectiveness to maximize the return on investment.

3 Common User Pain Points for ‘3d printer water bottle’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality STL Files for Water Bottles

Le problème : B2B buyers often struggle with finding high-quality STL files for 3D printing water bottles. Many available models are either subpar in design or do not meet specific material requirements, which can lead to poor print quality and functionality. This issue is particularly pronounced for buyers looking to customize bottles for branding purposes. A substandard model can result in wasted materials, increased costs, and delays in product delivery, all of which can significantly impact business operations and customer satisfaction.

La solution : To overcome this challenge, buyers should leverage reputable platforms like Cults3D and Printables.com that specialize in high-quality 3D models. These platforms provide a vast collection of STL files, complete with user reviews and ratings to help buyers assess quality. When selecting a model, ensure it aligns with the intended use—whether it’s for promotional branding or functional everyday use. Additionally, consider engaging with designers on these platforms to request custom designs that meet specific branding requirements, thereby ensuring that the final product not only looks professional but also functions effectively.

Scenario 2: Managing Production Costs and Time Efficiency

Le problème : Another common pain point for B2B buyers is the high cost and time consumption associated with traditional water bottle manufacturing methods. Buyers often find themselves caught between the need for quality and the budget constraints imposed by lengthy production cycles. This can lead to frustration, especially when quick turnarounds are required for seasonal promotions or events.

La solution : 3D printing technology can be an effective solution for managing production costs and enhancing time efficiency. By opting for 3D printed water bottles, businesses can significantly reduce the time from design to production, as this method eliminates many of the traditional manufacturing steps. For B2B buyers, investing in a reliable 3D printer capable of using various materials—such as biodegradable plastics—can further optimize costs. Collaborating with a local 3D printing service can also be beneficial, as they may offer competitive pricing and faster turnaround times. Furthermore, utilizing software that integrates with 3D printers for real-time adjustments can streamline the production process.

Scenario 3: Ensuring Product Compliance and Safety Standards

Le problème : Compliance with health and safety regulations is a critical concern for B2B buyers in the water bottle industry. Many materials used in 3D printing can be unsuitable for food contact, leading to potential health risks and legal implications. Buyers may feel overwhelmed by the need to ensure that the materials they choose not only meet aesthetic and functional standards but also comply with local and international safety regulations.

La solution : To address this concern, buyers should prioritize sourcing materials that are certified for food safety, such as FDA-approved plastics. When selecting a 3D printing service or supplier, inquire specifically about their material certifications and compliance with relevant regulations. Additionally, consider investing in third-party testing for products to validate safety claims. Educating staff on the importance of compliance and regularly reviewing material safety data sheets (MSDS) can further mitigate risks. By taking these proactive steps, businesses can confidently provide safe and compliant products to their customers, enhancing their brand reputation and reducing liability concerns.

Strategic Material Selection Guide for 3d printer water bottle

What Are the Most Common Materials for 3D Printed Water Bottles?

When selecting materials for 3D printed water bottles, it is crucial to consider properties such as temperature resistance, durability, and chemical compatibility. Below, we analyze four common materials used in this application, focusing on their advantages, disadvantages, and specific considerations for international B2B buyers.

Which Materials Are Best for 3D Printed Water Bottles?

1. PLA (Polylactic Acid)

Propriétés principales :

PLA is a biodegradable thermoplastic derived from renewable resources like corn starch. It has a melting temperature of approximately 180-220°C and offers good rigidity.

Avantages et inconvénients :

PLA is easy to print and has a low cost, making it a popular choice for prototypes and low-volume production. However, its lower temperature resistance (around 60°C) limits its suitability for hot liquids. Additionally, while it is biodegradable, it may not be as durable as other materials in outdoor conditions.

Impact sur l'application :

PLA is compatible with cold beverages but may deform when exposed to heat. Its eco-friendly nature appeals to environmentally conscious consumers.

Considérations pour les acheteurs internationaux :

Buyers should ensure compliance with local food safety regulations, as PLA may not always meet stringent standards in certain regions. Certifications like ASTM can help verify material safety.

2. PETG (Polyethylene Terephthalate Glycol-Modified)

Propriétés principales :

PETG is a strong, impact-resistant thermoplastic with a melting temperature of 220-250°C. It is known for its excellent chemical resistance and clarity.

Avantages et inconvénients :

PETG offers a balance between durability and ease of printing. It is more heat-resistant than PLA and can handle a wider range of temperatures. However, it can be more expensive and may require more precise printing conditions to avoid stringing.

Impact sur l'application :

Ideal for both cold and warm beverages, PETG is suitable for applications requiring durability and chemical resistance, making it a versatile choice for various markets.

Considérations pour les acheteurs internationaux :

Compliance with food safety standards is critical, especially in regions with strict regulations. Buyers should seek materials that are certified for food contact, such as those compliant with FDA or EU standards.

3. ABS (Acrylonitrile Butadiene Styrene)

Propriétés principales :

ABS is a widely used thermoplastic with a melting temperature of around 220-250°C. It is known for its toughness and impact resistance.

Avantages et inconvénients :

ABS is highly durable and can withstand higher temperatures compared to PLA. However, it can be challenging to print due to warping and requires a heated bed. It also emits fumes during printing, necessitating good ventilation.

Impact sur l'application :

Suitable for both hot and cold beverages, ABS is often used in applications requiring high strength and durability.

Considérations pour les acheteurs internationaux :

Buyers should be aware of local regulations regarding emissions and safety standards. ABS is not biodegradable, which may not align with sustainability goals in certain markets.

4. Stainless Steel (for Metal 3D Printing)

Propriétés principales :

Stainless steel is a corrosion-resistant alloy that can withstand high temperatures and pressures. It is typically used in metal 3D printing processes like SLS (Selective Laser Sintering).

Avantages et inconvénients :

Stainless steel offers exceptional durability and is suitable for both hot and cold beverages. However, the cost of metal 3D printing is significantly higher, and the manufacturing process is more complex.

Impact sur l'application :

Ideal for high-end products, stainless steel water bottles can provide a premium feel and durability, appealing to a market segment willing to pay more for quality.

Considérations pour les acheteurs internationaux :

Compliance with international standards for food safety and material quality is essential. Buyers should verify certifications such as ISO or ASTM to ensure product safety and quality.

Summary Table of Material Selection for 3D Printed Water Bottles

| Matériau | Typical Use Case for 3D Printer Water Bottle | Avantage clé | Principaux inconvénients/limites | Coût relatif (faible/moyen/élevé) |

|---|---|---|---|---|

| PLA | Prototypes, cold beverages | Biodegradable, easy to print | Low heat resistance, less durable | Faible |

| PETG | Cold and warm beverages | Durable, good chemical resistance | Higher cost, requires precise printing | Moyen |

| ABS | Boissons chaudes et froides | High strength, impact-resistant | Warping issues, emissions during printing | Moyen |

| Acier inoxydable | Premium, high-end products | Exceptional durability and quality | High manufacturing cost, complex process | Haut |

This strategic material selection guide provides valuable insights for B2B buyers looking to produce 3D printed water bottles tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printer water bottle

What Are the Main Stages in the Manufacturing Process of 3D Printed Water Bottles?

The manufacturing of 3D printed water bottles involves several critical stages, each designed to ensure the final product meets both functional and aesthetic requirements. The primary stages include material preparation, forming, assembly, and finishing.

-

Préparation du matériel: The choice of material is vital in the production of 3D printed water bottles. Common materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol-Modified). These materials are sourced based on their properties, such as durability, flexibility, and ease of printing. The preparation process involves obtaining these materials in filament or resin form, ensuring they are free from contaminants that could affect the quality of the final product.

-

Techniques de formage: The forming process varies depending on the 3D printing technology employed. Common techniques include:

– Fused Deposition Modeling (FDM): This method involves melting plastic filament and extruding it layer by layer to create the water bottle shape.

– Stereolithography (SLA): SLA uses a laser to cure liquid resin into solid layers, allowing for highly detailed designs.

– Selective Laser Sintering (SLS): In SLS, a laser sinters powdered material, creating a solid object. This technique is often used for more complex designs requiring higher durability. -

Assemblée: Depending on the design, additional components may need to be assembled. This could include caps, spouts, or insulation layers for thermos-style bottles. For custom logo water bottles, branding elements may also be integrated during this stage.

-

Finition: After forming and assembly, the bottles undergo finishing processes to enhance their aesthetics and functionality. This may include sanding, polishing, or applying coatings to improve durability and appearance. Customization options, such as engraving or printing, can also be performed during this phase.

How Does Quality Assurance Work in the 3D Printed Water Bottle Manufacturing Process?

Quality assurance (QA) is crucial in the manufacturing of 3D printed water bottles, ensuring that products meet international standards and customer expectations. The QA process typically aligns with international standards such as ISO 9001, which focuses on consistent quality management systems.

-

Normes internationales: Compliance with ISO standards is essential for B2B buyers. ISO 9001 ensures that manufacturers have a robust quality management system in place, focusing on continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the specific use cases of the water bottles, especially in industries where safety and reliability are paramount.

-

Points de contrôle de la qualité: The QA process includes several checkpoints:

– Contrôle de la qualité à l'arrivée (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Materials that fail to meet these standards are rejected.

– Contrôle de la qualité en cours de fabrication (IPQC): During the manufacturing process, random samples are tested to verify that the production is adhering to quality standards. This might include checking the consistency of layer adhesion in FDM or ensuring proper curing in SLA.

– Contrôle de qualité final (CQF): Once the bottles are produced, a final inspection is conducted. This includes visual inspections, dimensional checks, and functional testing to ensure that each bottle is free from defects and meets specifications.

What Testing Methods Are Commonly Used in Quality Assurance for 3D Printed Water Bottles?

Various testing methods are employed to ensure the quality and safety of 3D printed water bottles. These methods can include:

- Essais mécaniques: Assessing the strength and durability of the material under stress. This can involve tensile tests, impact resistance tests, and fatigue tests to ensure the bottles can withstand typical use conditions.

- Essais chimiques: Evaluating the material’s resistance to chemicals, particularly if the bottles are intended for specific industries, such as food and beverage or pharmaceuticals.

- Essais thermiques: Ensuring the bottles can withstand varying temperatures, particularly for insulated models. This can include testing for thermal conductivity and insulation properties.

Comment les acheteurs B2B peuvent-ils vérifier les pratiques de contrôle de la qualité des fournisseurs ?

B2B buyers must ensure their suppliers adhere to stringent quality control processes. Here are some effective methods for verification:

-

Audits des fournisseurs: Conducting regular audits of the supplier’s manufacturing facility allows buyers to assess the quality management systems in place. This includes reviewing documentation, observing processes, and evaluating compliance with international standards.

-

Quality Assurance Reports: Requesting detailed QA reports can provide insights into the supplier’s quality control practices. These reports should outline testing results, compliance with standards, and any corrective actions taken in response to identified issues.

-

Inspections par des tiers: Engaging independent third-party inspection services can provide an unbiased evaluation of the supplier’s processes and products. This can help verify compliance with international standards and industry-specific regulations.

What Are the Quality Control Nuances for International B2B Buyers in Different Regions?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

- Regional Standards Compliance: Different regions may have specific regulations that apply to imported goods. For example, products sold in the European market must meet CE standards, while those in the Middle East might require compliance with local safety regulations.

- Considérations culturelles: Understanding the cultural context of quality perception can aid in establishing effective communication with suppliers. Different regions may have varying expectations regarding product quality and certification.

- Transparence de la chaîne d'approvisionnement: Buyers should prioritize suppliers that offer transparency in their supply chains. This includes traceability of materials, production methods, and adherence to ethical manufacturing practices, which can be particularly important in markets focused on sustainability.

Conclusion

The manufacturing processes and quality assurance practices for 3D printed water bottles play a pivotal role in ensuring product quality, safety, and customer satisfaction. By understanding the stages of production, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions that align with their business needs and regulatory requirements. As the demand for innovative and customized products continues to grow, maintaining a focus on quality will be essential for success in this competitive market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printer water bottle’

In this guide, we present a practical checklist tailored for B2B buyers interested in procuring 3D printer water bottles. The growing demand for custom and functional designs makes understanding the sourcing process essential for making informed purchasing decisions. Here’s a step-by-step approach to streamline your procurement process.

Étape 1 : Définir les spécifications techniques

Establishing clear technical specifications is crucial for aligning your needs with potential suppliers. Consider factors such as size, material (e.g., PLA, ABS, or metal), and design intricacies. A well-defined specification will help you filter suppliers that can meet your requirements and avoid miscommunications later.

Étape 2 : Research Material Options and Sustainability

Investigate the types of materials available for 3D printing water bottles. Look for options that not only meet durability and safety standards but also consider environmental impact. Sustainable materials can enhance your brand’s image and appeal to eco-conscious consumers, particularly in regions like Europe where sustainability is prioritized.

Étape 3 : Évaluer les fournisseurs potentiels

Before making a commitment, it’s vital to conduct thorough evaluations of potential suppliers. Request detailed company profiles, case studies, and references from businesses in similar industries or regions. Pay attention to their production capabilities, lead times, and customer service reputation to ensure they align with your expectations.

Étape 4 : Request Samples and Prototypes

Requesting samples or prototypes is a critical step in the sourcing process. This allows you to assess the quality of the 3D printed water bottles firsthand. Evaluate aspects like design accuracy, material quality, and functionality to ensure they meet your standards before placing a larger order.

Étape 5 : Verify Compliance and Certifications

Ensure that your chosen suppliers adhere to relevant industry standards and regulations. Look for certifications related to food safety, material safety data sheets (MSDS), and ISO standards. This verification process is crucial for mitigating risks associated with product safety and quality, especially when entering diverse international markets.

Étape 6 : Négocier les conditions et les prix

Engage in negotiations to secure favorable terms and pricing that align with your budget and procurement strategy. Discuss aspects like minimum order quantities, payment terms, and shipping costs. A clear agreement will help avoid misunderstandings and ensure a smooth transaction process.

Étape 7 : Plan for Logistics and Delivery

Finally, develop a logistics plan for the delivery of your 3D printer water bottles. Consider factors such as shipping methods, lead times, and customs regulations, particularly for international shipments. Having a clear logistics strategy will help you manage timelines and ensure that products reach your market efficiently.

By following this checklist, B2B buyers can streamline their sourcing process for 3D printer water bottles, ensuring they select the right suppliers and materials while minimizing risks associated with international procurement.

Comprehensive Cost and Pricing Analysis for 3d printer water bottle Sourcing

In the evolving landscape of 3D printing, the cost structure and pricing for sourcing 3D printed water bottles is multifaceted. Understanding the components and factors influencing pricing is crucial for international B2B buyers aiming to optimize their procurement strategies.

What Are the Key Cost Components Involved in Sourcing 3D Printed Water Bottles?

The cost structure for 3D printed water bottles encompasses several components:

-

Matériaux: The choice of materials significantly impacts costs. Common options include PLA, ABS, and PETG, each varying in price based on quality and sourcing. High-grade materials may enhance product durability but will increase the overall expenditure.

-

Travail: Labor costs can vary based on the complexity of the design and the level of skill required for production. Skilled labor for custom designs may demand higher wages, which can affect the final pricing of the product.

-

Frais généraux de fabrication: This includes expenses related to utilities, equipment depreciation, and facility maintenance. Advanced 3D printing technologies, such as SLS or SLA, may incur higher overhead due to the specialized equipment needed.

-

Outillage: While 3D printing minimizes traditional tooling costs, initial setup for custom designs or large production runs may still require investment in specialized software or hardware.

-

Contrôle de la qualité (CQ): Ensuring product quality is paramount, especially for international markets. QC processes can add to costs, particularly if certifications are needed for compliance with regional regulations.

-

Logistique: Shipping costs can vary based on destination, volume, and chosen Incoterms. International shipping may involve tariffs and customs duties that need to be factored into the total cost.

-

Marge: Suppliers often add a profit margin based on market conditions and competition. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of 3D Printed Water Bottles?

Several factors can influence the pricing of 3D printed water bottles:

-

Volume/MOQ: Minimum order quantities (MOQ) and bulk orders often attract discounts. Suppliers may provide better pricing for larger orders, reducing the per-unit cost.

-

Spécifications et personnalisation: Custom designs or specific features can increase costs. Buyers should evaluate the necessity of these features against their budget.

-

Matériaux: The choice of material not only influences durability but also affects the cost. Buyers should balance quality with their budgetary constraints.

-

Qualité et certifications: Products that meet international quality standards may carry a premium. Buyers should assess the value of certifications relevant to their market.

-

Facteurs liés au fournisseur: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven quality and service.

-

Incoterms: Understanding Incoterms is essential for budgeting logistics costs. Different terms can shift responsibility for shipping costs, affecting overall expenses.

What Are the Best Negotiation Tips for B2B Buyers Sourcing 3D Printed Water Bottles?

When negotiating prices, B2B buyers should consider the following strategies:

-

Leverage Volume: Use projected order volumes to negotiate better pricing. Suppliers are often willing to reduce costs for bulk orders.

-

Explore Alternatives: If a supplier’s pricing is uncompetitive, consider alternative suppliers or materials that may offer better value.

-

Évaluer le coût total de possession (TCO): Beyond initial costs, consider long-term factors such as durability and maintenance, which can affect overall value.

-

Be Informed About Market Trends: Keeping abreast of industry trends can provide leverage during negotiations. Understanding typical price ranges and cost drivers helps in making informed decisions.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing, improved service, and priority during high-demand periods.

Conclusion: What Should International Buyers Keep in Mind When Sourcing?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing 3D printed water bottles is essential. Factors like local regulations, shipping logistics, and cultural differences in business practices can significantly impact procurement decisions.

Buyers are advised to conduct thorough market research, engage in transparent negotiations, and consider the total cost of ownership to make informed decisions.

Clause de non-responsabilité: Pricing may vary based on market conditions and specific supplier agreements. This analysis provides indicative insights for planning purposes.

Alternatives Analysis: Comparing 3d printer water bottle With Other Solutions

Exploring Alternatives to 3D Printer Water Bottles

In the realm of water bottle manufacturing, 3D printing technology offers unique advantages, particularly in customization and rapid prototyping. However, it is essential for B2B buyers to consider alternative solutions that may better suit their specific needs, depending on factors like cost, production efficiency, and intended use. Below, we compare 3D printer water bottles with two viable alternatives: injection-molded water bottles and stainless steel manufacturing processes.

| Aspect comparatif | 3D Printer Water Bottle | Injection-Molded Water Bottle | Stainless Steel Manufacturing |

|---|---|---|---|

| Performance | High customization, suitable for prototypes | High volume, consistent quality | Durable, insulated, premium feel |

| Coût | Moderate initial costs, variable per unit | Lower per unit cost at scale | Higher initial costs, variable based on design |

| Facilité de mise en œuvre | Requires CAD design and printer setup | Simple once molds are made | Complex due to material processing |

| Maintenance | Moderate; printers require upkeep | Low; molds are durable | Low; easy to clean and maintain |

| Meilleur cas d'utilisation | Custom designs, short runs, promotional items | Mass production, standard designs | Premium products, eco-friendly branding |

What Are the Pros and Cons of Injection-Molded Water Bottles?

Injection molding is a widely adopted method in the production of water bottles, particularly for mass production. The primary advantage is cost-effectiveness at scale; once the mold is created, the cost per unit significantly decreases with increased production volume. Additionally, injection molding provides consistent quality and durability across large batches, making it ideal for standard designs.

However, the initial investment in mold creation can be substantial, making it less attractive for smaller businesses or custom designs. The process also lacks the flexibility that 3D printing offers; once a mold is made, any changes to the design require a new mold, leading to increased costs and time delays.

How Does Stainless Steel Manufacturing Compare?

Stainless steel manufacturing is known for producing high-quality, durable water bottles that appeal to environmentally conscious consumers. The benefits of stainless steel include excellent insulation properties, resistance to corrosion, and a premium aesthetic that can enhance brand image. This method is particularly suited for businesses looking to position themselves as eco-friendly or premium brands.

On the downside, the manufacturing process for stainless steel bottles can be more complex and costly compared to 3D printing or injection molding. The initial setup costs are higher, and while the bottles are durable, they may not offer the same level of customization as 3D printed options. Moreover, the production timeline can be longer due to the additional processing steps involved.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate water bottle manufacturing solution, B2B buyers must weigh their specific requirements against the characteristics of each method. For businesses focused on customization, small batch runs, or promotional items, 3D printing presents a compelling option despite its moderate costs. Conversely, if the goal is mass production with cost efficiency, injection molding is the ideal choice. Lastly, for brands emphasizing sustainability and premium quality, investing in stainless steel manufacturing can elevate their product offerings. Ultimately, understanding these alternatives allows buyers to align their manufacturing choices with their business objectives and market demands.

Essential Technical Properties and Trade Terminology for 3d printer water bottle

What Are the Key Technical Properties of a 3D Printed Water Bottle?

When considering a 3D printed water bottle for your business needs, understanding the technical specifications is crucial for making informed decisions. Here are several essential properties to consider:

Material Grade: What Should You Look For?

The material used in 3D printing is one of the most critical factors affecting durability, safety, and usability. Common materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), and PETG (Polyethylene Terephthalate Glycol-modified). Each material has unique properties: PLA is biodegradable and easy to print, ABS offers higher durability and heat resistance, while PETG combines the best of both worlds with excellent chemical resistance and flexibility. Understanding these materials helps businesses choose the right type for their target market, whether for outdoor activities or everyday use.

Tolerance: How Precise Should Your Design Be?

Tolerance refers to the allowable deviation in dimensions during the manufacturing process. In the context of 3D printed water bottles, a typical tolerance range is ±0.1 mm. Ensuring tight tolerances is vital for parts that need to fit together, such as lids and spouts, preventing leaks and ensuring a proper seal. For B2B buyers, understanding tolerance specifications ensures that the final product meets quality standards and customer expectations.

Print Resolution: Why Does It Matter?

Print resolution, measured in microns, indicates the layer height used during printing. A lower micron count (e.g., 50 microns) results in smoother finishes and higher detail, which may be desirable for custom designs or logos on water bottles. Conversely, higher layer heights (e.g., 200 microns) may be sufficient for more functional designs. Businesses must balance aesthetics and functionality to cater to their specific audience.

Volume Capacity: What Should You Consider?

Volume capacity is a critical factor that determines the usability of the water bottle. Common sizes range from 500 ml to 2 liters. Depending on the target market—whether outdoor enthusiasts, sports teams, or corporate branding—volume capacity can significantly influence purchasing decisions. Offering a range of sizes can help businesses capture diverse market segments.

What Trade Terminology Is Essential for B2B Transactions in 3D Printed Water Bottles?

Understanding the jargon used in the 3D printing industry can enhance communication and negotiation with suppliers. Here are key terms to familiarize yourself with:

OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM refers to a company that produces components or products that are then sold under another company’s brand name. For water bottle manufacturers, collaborating with an OEM can enable access to specialized designs or materials that enhance product offerings without incurring significant development costs.

MOQ (Minimum Order Quantity): Why Is It Important?

MOQ is the minimum quantity a supplier is willing to produce or sell. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Understanding the MOQ can help businesses determine if a supplier aligns with their production scale and budget.

RFQ (Request for Quotation): How Should You Use It?

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. When looking for 3D printed water bottles, submitting an RFQ can help businesses compare costs, materials, and production times from different suppliers, ensuring they make the best purchasing decision.

Incoterms: What Are They and Why Do They Matter?

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms (like FOB – Free on Board or CIF – Cost, Insurance, and Freight) is crucial for B2B transactions, as they dictate who bears the shipping costs and risks, helping to avoid misunderstandings and disputes.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing 3D printed water bottles more effectively, ensuring they meet their business needs while optimizing costs and quality.

Navigating Market Dynamics and Sourcing Trends in the 3d printer water bottle Sector

What Are the Key Market Dynamics and Trends Influencing the 3D Printer Water Bottle Sector?

The global market for 3D printed water bottles is experiencing significant growth, driven by several key factors. First, the increasing demand for personalized and customizable products is reshaping consumer expectations. Businesses are leveraging 3D printing technology to create bespoke designs that cater to individual preferences, a trend particularly appealing to international B2B buyers in regions like Africa, South America, the Middle East, and Europe. The ability to produce unique items quickly and cost-effectively is a game changer in competitive markets.

Additionally, advancements in 3D printing technologies—such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA)—are enhancing production capabilities. These technologies allow for greater material diversity and design intricacy, enabling manufacturers to meet diverse consumer demands efficiently. Emerging trends include the integration of smart features into water bottles, such as tracking hydration levels through connected apps, which could appeal to tech-savvy markets.

Another important dynamic is the shift towards digital supply chains. International buyers are increasingly sourcing products online, utilizing platforms like Cults3D and Printables.com, which offer vast libraries of 3D models. This transition is complemented by a growing network of designers and manufacturers, facilitating collaboration and innovation in product development.

How Is Sustainability and Ethical Sourcing Shaping the 3D Printer Water Bottle Market?

Sustainability has become a critical consideration for B2B buyers in the 3D printed water bottle sector. The environmental impact of traditional plastic production is prompting companies to seek alternatives that are not only eco-friendly but also ethically sourced. This shift is driving the demand for biodegradable materials and recycled plastics in 3D printing, aligning with global sustainability goals.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to responsible sourcing practices, such as using renewable resources and maintaining transparency in their operations. Certifications like ISO 14001 for environmental management and the Global Recycle Standard are becoming essential criteria for selecting suppliers.

Moreover, the adoption of “green” certifications and materials is enhancing brand reputation and appealing to environmentally conscious consumers. Companies that effectively communicate their sustainability efforts are likely to gain a competitive edge in the marketplace, especially in regions where environmental awareness is on the rise.

How Has the 3D Printer Water Bottle Sector Evolved Over Time?

The evolution of the 3D printer water bottle market reflects broader trends in manufacturing and consumer behavior. Initially, 3D printing was primarily used for prototyping and low-volume production. However, advancements in technology have made it feasible for mass production, particularly for customized products.

The early 2010s saw the introduction of more accessible 3D printing technologies, which democratized the design and production process. As a result, a diverse range of designs emerged, catering to niche markets and individual preferences. Over time, this has led to a greater emphasis on personalization and functionality in water bottle designs.

Today, the market is characterized by a blend of traditional manufacturing techniques and cutting-edge 3D printing capabilities, allowing businesses to respond quickly to market demands while reducing waste and production costs. As the technology continues to advance, the possibilities for innovation in the 3D printed water bottle sector are virtually limitless, making it an exciting field for B2B buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printer water bottle

-

How can I ensure the quality of 3D printed water bottles from suppliers?

To ensure quality, start by vetting suppliers through their certifications and production processes. Request samples to evaluate the material, finish, and durability. It’s beneficial to inquire about their quality assurance protocols, including testing methods and compliance with international standards. Additionally, consider visiting the manufacturing facility if possible, or utilizing third-party inspection services to verify product quality before bulk orders. -

What customization options are available for 3D printed water bottles?

Customization options for 3D printed water bottles are extensive. You can choose different materials, colors, and sizes, as well as incorporate unique designs or logos. Many suppliers offer CAD modeling services, allowing you to create bespoke designs tailored to your brand’s identity. Be sure to discuss your specific requirements with potential suppliers to understand their capabilities and any associated costs. -

What are the typical minimum order quantities (MOQs) for 3D printed water bottles?

Minimum order quantities can vary significantly based on the supplier and production capabilities. Generally, MOQs for 3D printed items can range from 50 to several hundred units. Smaller businesses or startups may find suppliers willing to accommodate lower MOQs, especially for customized orders. Always confirm MOQs before placing an order to ensure they align with your business needs. -

What payment terms should I expect when sourcing 3D printed water bottles internationally?

Payment terms can differ by supplier and region, but common practices include a deposit upfront (typically 30-50%) and the balance upon delivery or prior to shipping. Some suppliers may offer payment plans or letters of credit for larger orders. It’s advisable to negotiate terms that provide you with adequate protection while ensuring the supplier has enough commitment to fulfill your order. -

How do I navigate international shipping logistics for 3D printed water bottles?

Navigating international shipping requires careful planning. Start by understanding the shipping methods available—air freight is faster but more expensive, while sea freight is cost-effective for larger orders. Collaborate with logistics providers who have experience in handling custom goods to ensure compliance with import/export regulations. Consider factors like customs duties, taxes, and insurance to avoid unexpected costs. -

What are the advantages of using 3D printing for water bottle production?

3D printing offers several advantages, including rapid prototyping, design flexibility, and reduced material waste. This technology allows for the creation of complex designs that may be difficult or impossible to achieve with traditional manufacturing methods. Additionally, 3D printing can lower production costs for small batches, making it an ideal choice for businesses looking to offer customized products without significant investment. -

What should I include in my supplier vetting process for 3D printed water bottles?

Your supplier vetting process should include evaluating their production capabilities, quality control measures, and experience in the industry. Request references from previous clients and review their portfolio of work. Additionally, assess their communication responsiveness and willingness to collaborate on design and customization. Conducting a factory audit can also provide insights into their operational standards and reliability. -

How can I leverage 3D printing to enhance my brand’s sustainability efforts?

3D printing can significantly enhance sustainability by reducing material waste and allowing for the use of eco-friendly materials. By sourcing water bottles made from recycled plastics or biodegradable materials, you can align your product offerings with environmentally conscious consumers. Additionally, the ability to produce on-demand reduces overproduction and inventory waste, contributing positively to your brand’s sustainability initiatives.

Avis de non-responsabilité et conditions d'utilisation

⚠️ Avis de non-responsabilité important

Les informations fournies dans ce guide, y compris le contenu concernant les fabricants, les spécifications techniques et l'analyse du marché, sont uniquement destinées à des fins d'information et d'éducation. Elles ne constituent pas un conseil professionnel en matière d'achat, un conseil financier ou un conseil juridique.

Bien que nous ayons fait tout notre possible pour garantir l'exactitude et l'actualité des informations, nous ne sommes pas responsables des erreurs, des omissions ou des informations obsolètes. Les conditions du marché, les détails de l'entreprise et les normes techniques sont susceptibles d'être modifiés.

Les acheteurs B2B doivent faire preuve d'une diligence raisonnable indépendante et approfondie. avant de prendre toute décision d'achat. Il convient notamment de contacter directement les fournisseurs, de vérifier les certifications, de demander des échantillons et de solliciter une consultation professionnelle. Le risque lié à l'utilisation des informations contenues dans ce guide est supporté uniquement par le lecteur.

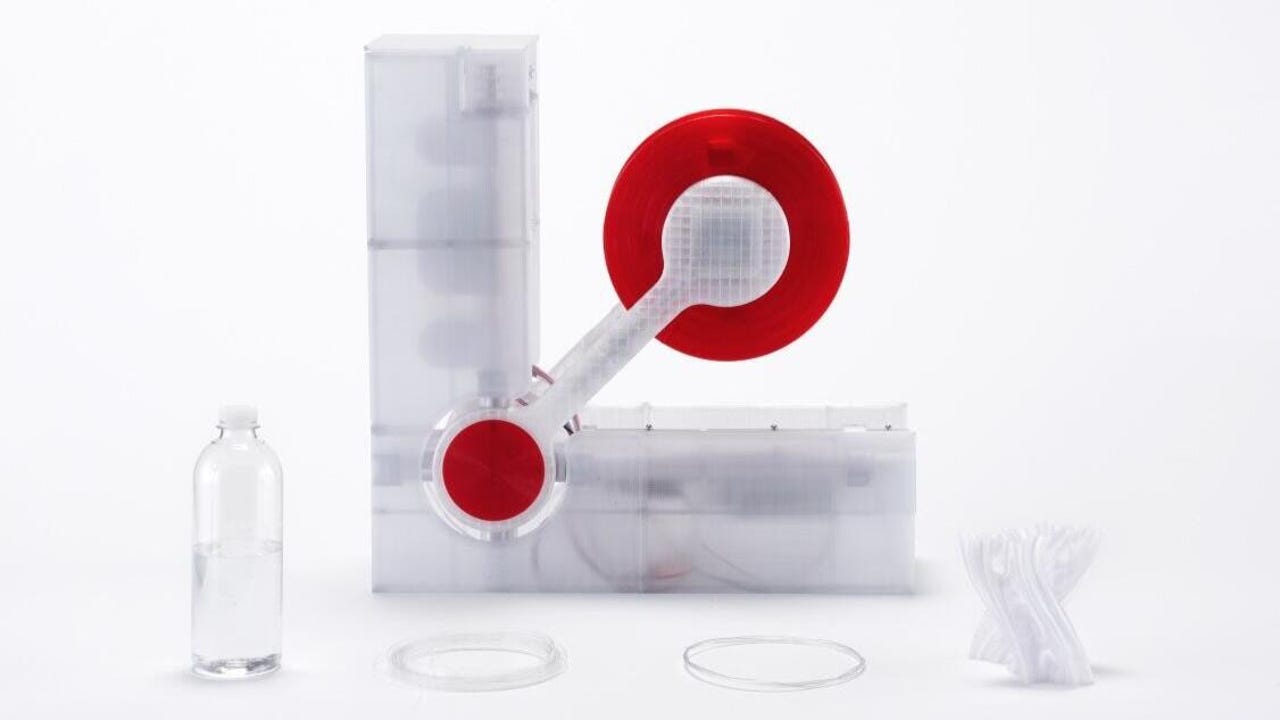

Top 8 3D Printer Water Bottle Manufacturers & Suppliers List

1. 3D Printing – Safe Filament Materials for Water Bottles

Domaine : reddit.com

Enregistré : 2005 (20 ans)

Introduction : User is interested in 3D printing a water bottle and is seeking information on the safety of filament materials for human use. They express uncertainty about whether it is possible to print such items and if there are safe materials available. Comments from others suggest that while some filaments may be safe, the printed bottles may harbor bacteria and mold due to their design, making them unsuit…

2. Printables – Water Bottle

Domaine : printables.com

Enregistré : 1996 (29 ans)

Introduction : {“name”:”Water Bottle”,”author”:”Seth”,”description”:”A generic plastic water bottle that can be printed in various materials, including TPU. Very low infill needed, and can potentially be printed in vase mode.”,”tags”:[“water”,”box”,”waterbottle”],”model_origin”:”Not provided”,”license”:”Not specified”,”last_updated”:”March 15, 2022″}

3. Cults3D – Water Bottle STL Files

Domaine : cults3d.com

Enregistré : 2013 (12 ans)

Introduction : Water bottle STL files for 3D printing available for download. Cults3D offers a vast collection of high-quality free and premium models, compatible with FDM, SLA, or SLS 3D printers. Supported file formats include STL, OBJ, STEP, 3MF, SCAD for 3D printing, and DXF, SVG, PDF, AI for CNC machining and laser cutting. The platform connects designers and makers, with a community of 204k designers and 1…

4. CreativeTools – 3D Printable Bottle and Screw Cap

Domaine : thingiverse.com

Registered: 2008 (17 years)

Introduction : 3D printable bottle and screw cap by CreativeTools

5. Instructables – PET Bottle to Filament Recycler

Domaine : instructables.com

Enregistré : 2005 (20 ans)

Introduction : The project involves turning old PET bottles into filament for 3D printers using a custom-built recycler. The recycler consists of four main components: a cutter that cuts the bottles into strips, a hot-end that partially melts the strips into filament, a reel that stores the filament, and a controller that manages the hot-end temperature and reeler motor. Key supplies include various screws, nuts…

6. Facebook – 3D Printer Filament from Recycled Plastic

Domaine : facebook.com

Enregistré : 1997 (28 ans)

Introduction : I turned plastic water bottles into 3D printer filament.

7. Bambu Lab – PET Filament Production

Domaine : forum.bambulab.com

Enregistré : 2019 (6 ans)

Introduction : Filament from plastic bottles can be made if the plastic is turned into a 1.75mm diameter filament. The filament is typically made from PET plastic. However, the yield from a single plastic bottle is low, approximately 7 to 8 grams of filament per bottle, making it impractical for small-scale use. The process requires a filament extruder, which can be costly and requires monitoring. Homemade filam…

8. WaterBottle.tech – Custom 3D Printed Water Bottles

Domaine : waterbottle.tech

Enregistré : 2018 (7 ans)

Introduction : Custom logo water bottles manufactured using 3D printing technology. Key features include: 1. Customization capabilities with logos, molding, manufacturing, decorating, and packaging. 2. Utilizes various 3D printing technologies such as FDM, SLA, and SLS for production. 3. Allows for intricate designs and patterns that enhance personalization. 4. Faster production cycles compared to traditional me…

Strategic Sourcing Conclusion and Outlook for 3d printer water bottle

In today’s competitive market, strategic sourcing of 3D printed water bottles presents a significant opportunity for international B2B buyers. The versatility and customization capabilities offered by 3D printing technology not only enhance product differentiation but also streamline production processes. By leveraging platforms that provide diverse STL files and manufacturing options, businesses can quickly respond to consumer demands while maintaining cost efficiency.

Furthermore, the growing trend towards personalized and sustainable products aligns with global consumer preferences, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers can capitalize on this trend by partnering with manufacturers who utilize advanced 3D printing techniques to create bespoke solutions tailored to their market needs.

Looking ahead, it is essential for businesses to invest in strategic sourcing partnerships that prioritize innovation and quality. As the 3D printing landscape continues to evolve, staying informed and adaptable will be crucial. We encourage international B2B buyers to explore the vast potential of 3D printed water bottles and engage with suppliers who can offer not just products, but also insights and support in navigating this transformative market.