Introduction: Navigating the Global Market for types of water bottles

Navigating the diverse landscape of types of water bottles presents a significant challenge for international B2B buyers, especially when aiming to meet the unique demands of various markets such as Africa, South America, the Middle East, and Europe. As businesses seek to source quality, sustainable, and functional hydration solutions, understanding the nuances of different water bottle designs becomes paramount. This comprehensive guide delves into an array of water bottle types, including insulated tumblers, cold cups, canteens, and commuter cups, each tailored for specific applications and consumer preferences.

By exploring key features, material considerations, and functionality, this guide empowers B2B buyers to make informed purchasing decisions that align with market trends and consumer expectations. Additionally, it highlights essential supplier vetting criteria, cost analysis, and branding opportunities that can enhance product offerings. With the global market for reusable water bottles projected to expand rapidly, staying abreast of these insights will enable businesses to capitalize on emerging opportunities and foster sustainable practices. Whether you are a distributor in Vietnam or a retailer in Brazil, this resource equips you with the knowledge needed to navigate the complexities of sourcing water bottles effectively, ensuring you meet your clients’ hydration needs while contributing positively to the environment.

Article Navigation

- Top 7 Types Of Water Bottles Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for types of water bottles

- Understanding types of water bottles Types and Variations

- Key Industrial Applications of types of water bottles

- 3 Common User Pain Points for ‘types of water bottles’ & Their Solutions

- Strategic Material Selection Guide for types of water bottles

- In-depth Look: Manufacturing Processes and Quality Assurance for types of water bottles

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of water bottles’

- Comprehensive Cost and Pricing Analysis for types of water bottles Sourcing

- Alternatives Analysis: Comparing types of water bottles With Other Solutions

- Essential Technical Properties and Trade Terminology for types of water bottles

- Navigating Market Dynamics and Sourcing Trends in the types of water bottles Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of types of water bottles

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for types of water bottles

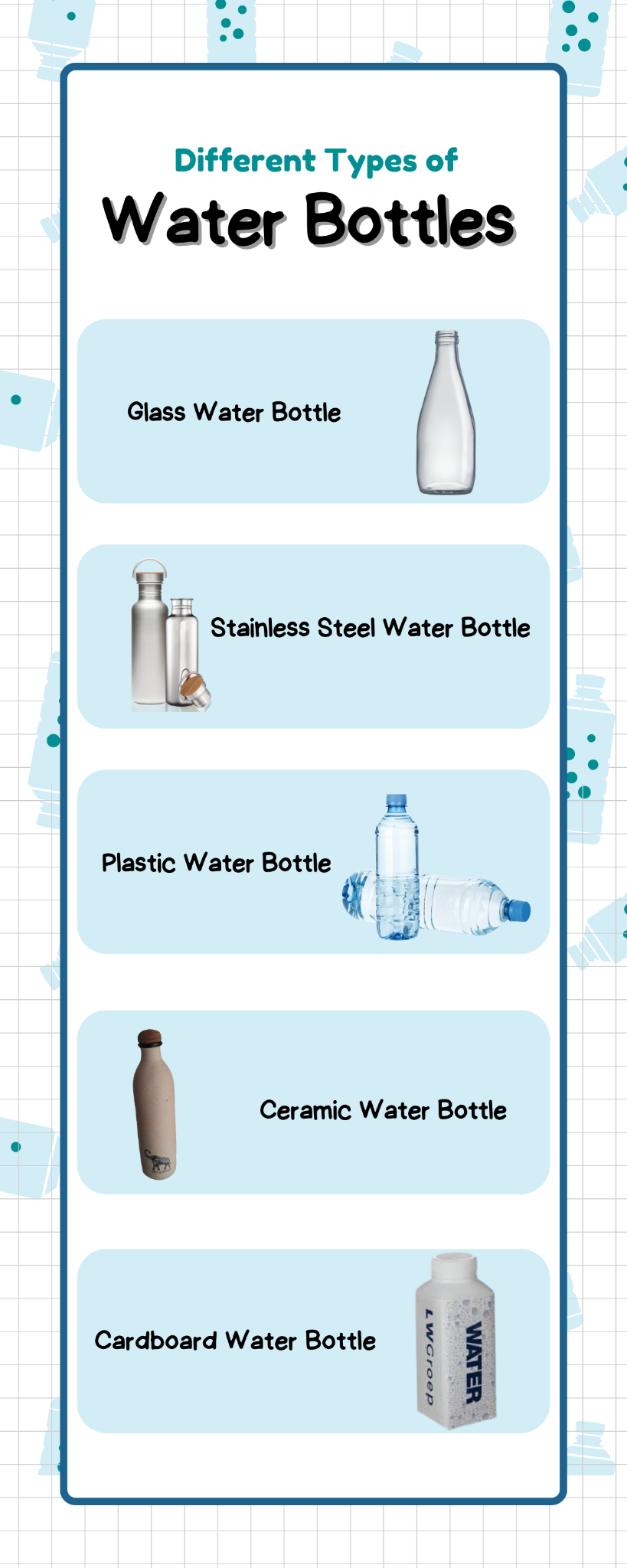

Understanding types of water bottles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Cups | Triple-walled insulation, straw for easy sipping | Retail, promotional gifts, corporate events | Pros: Keeps drinks cold for hours; customizable designs. Cons: Limited to cold beverages only. |

| Tumblers | Durable stainless steel, triple-walled for temperature control | Hospitality, outdoor activities, corporate gifts | Pros: Versatile for hot and cold drinks; easy to clean. Cons: Heavier than plastic options. |

| Canteens | Triple insulated, tough DURAPRENE finish, ergonomic handle | Outdoor sports, travel, corporate wellness | Pros: Excellent for long durations; durable for rugged use. Cons: Bulkier compared to other types. |

| Commuter Cups | Slim design, 360-degree sip lid, spill-proof | Daily commuting, corporate gifting, event giveaways | Pros: Convenient for on-the-go hydration; fits in most cup holders. Cons: Limited capacity for heavy drinkers. |

| Collapsible Bottles | Lightweight, foldable design, often made from silicone | Travel, outdoor events, promotional giveaways | Pros: Highly portable; saves space. Cons: May lack durability compared to rigid bottles. |

What Are the Key Characteristics of Cold Cups and Their B2B Suitability?

Cold cups are designed with triple-walled insulation, ensuring beverages remain chilled for hours. They often include a straw for ease of use, making them particularly appealing in retail settings or as promotional items at corporate events. B2B buyers should consider the customization options available, as these can enhance brand visibility. However, it’s important to note that cold cups are primarily suited for cold beverages, which may limit their versatility in certain applications.

How Do Tumblers Serve Various Business Needs?

Tumblers are constructed from durable stainless steel and feature triple-walled insulation, allowing them to maintain the temperature of both hot and cold drinks. This versatility makes them ideal for hospitality businesses, outdoor activities, and corporate gifting. When purchasing tumblers, B2B buyers should evaluate the ease of cleaning and the variety of sizes available. While they offer significant benefits, their weight compared to plastic options may be a consideration for some buyers.

What Advantages Do Canteens Offer for Active B2B Environments?

Canteens are engineered for durability and performance, often featuring a tough DURAPRENE finish and triple insulation that keeps drinks cold for extended periods. They are particularly suitable for outdoor sports, travel, and corporate wellness initiatives. B2B buyers should look for ergonomic designs that facilitate easy transport. While canteens are excellent for rugged use, their bulkiness can be a drawback for businesses seeking lightweight hydration solutions.

Why Are Commuter Cups Essential for On-the-Go Hydration?

Commuter cups are designed for individuals who need quick access to hydration while traveling. With a slim profile and a spill-proof, 360-degree sip lid, they fit seamlessly into most cup holders, making them ideal for daily commuting and corporate giveaways. Buyers should consider the capacity of these cups, as they may not meet the needs of heavy drinkers. Their convenience makes them a valuable product for businesses catering to busy professionals.

What Benefits Do Collapsible Bottles Provide for B2B Buyers?

Collapsible bottles are made from lightweight, flexible materials such as silicone, allowing them to be easily folded and stored when not in use. They are particularly useful for travel and outdoor events, making them a popular choice for promotional giveaways. B2B buyers should assess the durability of these bottles, as they may not withstand heavy use compared to rigid options. Their space-saving design is a significant advantage for businesses focused on portability.

Key Industrial Applications of types of water bottles

| Industry/Sector | Specific Application of types of water bottles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Guest hydration stations in hotels and resorts | Enhances guest experience and satisfaction | Custom branding options and durability for high-traffic use |

| Outdoor Recreation | Hydration solutions for adventure tourism companies | Promotes customer safety and well-being during activities | Lightweight, insulated options suitable for various climates |

| Corporate Wellness | Employee wellness programs with reusable bottles | Encourages hydration, reducing health-related absences | Eco-friendly materials and bulk purchasing discounts |

| Education | School hydration initiatives for students | Supports health and hydration among students | Size and design suitable for children, easy-to-clean materials |

| Event Management | Promotional giveaways during conferences and trade shows | Increases brand visibility and engagement | Customizable options for branding and bulk order capabilities |

How Are Water Bottles Used in the Hospitality Sector?

In the hospitality industry, water bottles are pivotal for enhancing guest experiences, particularly through hydration stations in hotels and resorts. These stations often feature branded reusable bottles that guests can fill throughout their stay, promoting sustainability and reducing plastic waste. Buyers in this sector must consider customization options for branding, ensuring bottles are durable enough to withstand frequent use while aligning with the hotel’s aesthetic and environmental initiatives.

What Role Do Water Bottles Play in Outdoor Recreation?

Adventure tourism companies utilize specialized water bottles to ensure the safety and hydration of participants during outdoor activities. These bottles are designed to be lightweight and insulated, keeping beverages cold in hot climates or warm in cooler environments. For B2B buyers in this sector, sourcing durable bottles that can withstand rugged conditions is essential, alongside options that reflect the adventurous spirit of the brand, appealing to eco-conscious consumers.

Why Are Water Bottles Important for Corporate Wellness Programs?

In corporate wellness initiatives, reusable water bottles serve as practical tools to promote hydration among employees. By providing employees with quality water bottles, companies can reduce health-related absences and foster a culture of wellness. Buyers in this domain should focus on eco-friendly materials and consider bulk purchasing options to maximize cost-effectiveness while ensuring the products align with corporate sustainability goals.

How Can Schools Benefit from Hydration Initiatives?

Schools are increasingly adopting hydration initiatives by providing students with reusable water bottles to encourage healthy drinking habits. These bottles must be designed for children, featuring fun colors and designs, while also being easy to clean to maintain hygiene. B2B buyers in the education sector should look for bottles that are durable and affordable, ensuring they can withstand daily use and meet the needs of a younger demographic.

What Is the Impact of Water Bottles at Events?

Event management companies leverage water bottles as promotional giveaways during conferences and trade shows, enhancing brand visibility and attendee engagement. Customizable options allow companies to print logos and messages on the bottles, ensuring they serve as lasting reminders of the event. Buyers in this sector should prioritize bulk order capabilities and unique designs that resonate with the event’s theme, maximizing their marketing impact while promoting sustainability.

3 Common User Pain Points for ‘types of water bottles’ & Their Solutions

Scenario 1: Managing Temperature Control for Different Environments

The Problem: B2B buyers in regions with extreme weather conditions, such as the Middle East or parts of Africa, often face challenges in maintaining beverage temperature within their products. For instance, companies providing promotional items or corporate gifts might find that water bottles do not effectively keep drinks cold or hot when exposed to intense heat or cold. This can lead to customer dissatisfaction and a negative impact on brand perception, as consumers expect consistent quality regardless of the environment.

The Solution: To ensure optimal temperature control, buyers should focus on sourcing insulated water bottles with advanced thermal technology, such as double or triple-wall vacuum insulation. When selecting products, inquire about the insulation performance metrics, specifically how long the bottles can maintain temperature under specific conditions. It’s essential to work with suppliers who provide testing data or certifications regarding their products’ insulation capabilities. Additionally, consider customizing bottles with branding that highlights their insulation features, which not only serves promotional purposes but also reassures customers of the product’s quality. Ensuring that the chosen bottles have been tested in various climates can further mitigate this pain point.

Scenario 2: Ensuring Leak-Proof and Spill-Proof Designs

The Problem: For businesses distributing water bottles in active settings, such as gyms or outdoor events, a common concern is the risk of leaks and spills. Buyers often receive complaints from end-users about bottles that do not seal properly, leading to frustrations and potential damage to personal belongings. This issue can be particularly detrimental in B2B relationships, as it reflects poorly on the distributor’s quality control and product selection.

The Solution: Buyers should prioritize sourcing water bottles that feature reliable sealing mechanisms, such as silicone seals or locking lids that are specifically designed to prevent leaks. It’s advisable to request samples and conduct rigorous testing before committing to a bulk order, ensuring that the bottles withstand various levels of pressure and movement without leaking. Furthermore, providing clear usage instructions and care tips to customers can enhance their experience and reduce complaints. Consider also offering a return or exchange policy for faulty products, which can build trust and demonstrate a commitment to quality.

Scenario 3: Customization and Personalization Challenges

The Problem: In a competitive market, B2B buyers often struggle to find water bottles that can be easily customized to reflect their brand identity or cater to specific customer preferences. This is particularly relevant for companies looking to create unique promotional items or gifts that resonate with their audience. Limited options for customization can hinder marketing efforts and fail to engage potential customers.

The Solution: To address this pain point, buyers should seek suppliers that offer a wide range of customizable options, including color choices, sizes, and printing techniques. Engaging with manufacturers that specialize in promotional products can provide access to innovative designs that allow for full-color branding or even personalized engraving. Additionally, buyers can explore partnerships with local artisans who can create bespoke designs, which not only supports local economies but also provides unique offerings that stand out in the market. When placing orders, ensure to communicate specific customization requirements upfront and verify production timelines to align with marketing campaigns or events. This proactive approach will enable businesses to effectively leverage customized water bottles as a powerful branding tool.

Strategic Material Selection Guide for types of water bottles

What Are the Key Materials for Water Bottles in B2B Markets?

When selecting water bottle materials, international B2B buyers must consider various factors, including performance characteristics, cost-effectiveness, and compliance with regional standards. Here, we analyze four common materials used in water bottle manufacturing: stainless steel, plastic, glass, and aluminum. Each material has unique properties that influence its suitability for different applications.

How Does Stainless Steel Perform in Water Bottle Applications?

Stainless steel is renowned for its durability and resistance to corrosion, making it a popular choice for high-performance water bottles. It typically has a temperature rating that allows it to withstand both hot and cold liquids without compromising the integrity of the bottle. The material is also resistant to staining and retains its aesthetic appeal over time.

Pros and Cons: Stainless steel bottles are incredibly durable and can last for years, reducing the need for frequent replacements. However, they tend to be more expensive than plastic alternatives, which can be a significant factor for bulk purchases. Additionally, the manufacturing process can be complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a wide range of beverages, including acidic drinks, which can corrode other materials. This makes it ideal for diverse markets, especially where consumers prefer reusable options for health-conscious beverages.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with food safety standards, such as those set by ASTM or local health regulations. The weight of stainless steel may also impact shipping costs, which is a critical consideration for bulk orders.

What Are the Advantages and Disadvantages of Plastic Water Bottles?

Plastic, particularly high-density polyethylene (HDPE) and Tritan™, is widely used due to its lightweight nature and cost-effectiveness. These materials are generally resistant to impact and provide good temperature retention, although they may not match stainless steel in this regard.

Pros and Cons: The primary advantage of plastic bottles is their affordability and versatility. They can be produced in various colors and designs, appealing to different consumer preferences. However, plastic bottles may not have the same longevity as metal options and can be susceptible to wear and tear over time.

Impact on Application: Plastic bottles are suitable for a wide range of beverages but may not be ideal for hot liquids due to potential deformation. They are often used in promotional products, making them popular in corporate gifting.

Considerations for International Buyers: Compliance with regulations concerning BPA and other harmful chemicals is essential. Buyers should verify that products meet local standards, such as those set by the European Union or other regional bodies.

How Does Glass Compare as a Water Bottle Material?

Glass bottles are favored for their premium feel and the fact that they do not leach chemicals into beverages. They are excellent for maintaining the purity of drinks, making them suitable for health-conscious consumers.

Pros and Cons: Glass bottles are highly durable in terms of chemical resistance and do not retain odors or flavors. However, they are heavier and more fragile than other materials, which can lead to higher shipping costs and breakage concerns.

Impact on Application: Glass is ideal for beverages that require a clean taste, such as flavored waters or juices. However, its weight and fragility can limit its use in rugged environments.

Considerations for International Buyers: Buyers need to consider shipping logistics, as glass bottles require careful handling and packaging. Compliance with safety standards is also crucial, particularly in regions with stringent regulations on packaging materials.

What Role Does Aluminum Play in Water Bottle Manufacturing?

Aluminum bottles are lightweight and often come with a protective coating to prevent corrosion. They are suitable for both hot and cold beverages, making them versatile for various applications.

Pros and Cons: Aluminum is generally more affordable than stainless steel and can be produced in various designs. However, its durability is lower than that of stainless steel, and the coating can wear off over time, potentially affecting the taste of beverages.

Impact on Application: Aluminum bottles are popular for outdoor activities and sports due to their lightweight nature. However, they may not be suitable for acidic drinks unless adequately coated.

Considerations for International Buyers: Buyers should ensure that aluminum bottles comply with local food safety standards. Additionally, the recycling potential of aluminum can be a selling point in eco-conscious markets.

Summary Table of Material Selection for Water Bottles

| Material | Typical Use Case for types of water bottles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Reusable bottles for hot and cold drinks | Highly durable and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Plastic | Promotional products and everyday use | Lightweight and cost-effective | Less durable and may leach chemicals | Low |

| Glass | Premium drinks and health-focused beverages | Maintains beverage purity | Heavy and fragile | Medium |

| Aluminum | Sports and outdoor activities | Lightweight and versatile | Lower durability and potential taste impact | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for types of water bottles

What Are the Main Stages in the Manufacturing Process of Water Bottles?

The manufacturing process for water bottles encompasses several critical stages, ensuring that the final product meets both functionality and aesthetic standards. Understanding these stages can help B2B buyers make informed decisions when sourcing water bottles from manufacturers.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is material preparation. Common materials used for water bottles include stainless steel, glass, and various plastics like BPA-free polyethylene and Tritan™. Each material has distinct properties that cater to different market demands.

-

Selection of Raw Materials: Manufacturers must select high-quality raw materials that comply with safety standards. For instance, food-grade stainless steel is preferred for its durability and resistance to corrosion. B2B buyers should inquire about the material sourcing and certifications to ensure compliance with international regulations.

-

Material Processing: Once selected, raw materials undergo various processes such as cutting, molding, or extrusion, depending on the bottle type. For example, plastic bottles are typically produced through blow molding, while stainless steel bottles may be manufactured using deep drawing techniques.

What Are the Key Techniques Used in Forming Water Bottles?

The forming stage is crucial as it shapes the prepared materials into the desired bottle form.

-

Blow Molding: This is a prevalent technique for producing plastic water bottles. It involves inflating a heated plastic tube until it conforms to the shape of the mold. This process is efficient and allows for mass production of lightweight bottles.

-

Injection Molding: Used mainly for caps and lids, this technique involves injecting molten plastic into molds. It is known for producing precise shapes with a high-quality finish.

-

Deep Drawing: For stainless steel bottles, deep drawing is often employed. This process involves stretching a metal sheet into a cup shape, which is then further shaped into a bottle. This method offers excellent durability and a sleek finish.

How Do Assembly and Finishing Processes Contribute to Quality?

Following the forming stage, assembly and finishing are essential to ensure the functionality and aesthetics of water bottles.

-

Assembly: This stage may involve attaching lids, straws, or additional features like insulation layers. Automated systems are commonly used to enhance efficiency and maintain consistency.

-

Finishing: This includes surface treatment processes such as polishing, coating, or screen printing. For insulated bottles, a vacuum sealing process is often employed to enhance thermal retention. B2B buyers should assess the finishing processes to ensure that the final products meet their branding and quality expectations.

What Quality Assurance Measures Are Essential for Water Bottles?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each product meets specific standards and customer requirements.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with various international and industry-specific standards that apply to water bottles.

-

ISO 9001: This standard outlines criteria for a quality management system (QMS). It emphasizes customer satisfaction and continuous improvement, making it essential for manufacturers aiming for global competitiveness.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: If the bottles are intended for specific industries, such as pharmaceuticals or food service, adherence to American Petroleum Institute (API) standards may be necessary.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

To maintain quality, manufacturers implement several quality control checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival. It ensures that the materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted at various stages. This includes checking dimensions, weights, and tolerances to ensure that the production process remains within acceptable limits.

-

Final Quality Control (FQC): After production, a thorough inspection is performed on the finished products. This may involve drop tests, thermal performance tests, and visual inspections to identify any defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

-

Audits: Conducting regular audits of potential suppliers can help assess their manufacturing processes and adherence to quality standards. This includes reviewing their QMS and production capabilities.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s quality metrics, including defect rates and compliance with standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer unbiased evaluations of the manufacturing processes and finished products. This is particularly important for buyers in regions like Africa and South America, where local regulations may differ.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various nuances in quality control and certification processes.

-

Regulatory Compliance: Different regions have specific regulations regarding food safety and material safety. Understanding these regulations is essential for import compliance.

-

Cultural Considerations: In regions like the Middle East and Africa, cultural preferences may influence design and functionality. B2B buyers should communicate these preferences clearly to their suppliers.

-

Sustainability Practices: Increasingly, buyers are looking for suppliers who prioritize sustainability. This includes using eco-friendly materials and processes that minimize environmental impact.

By understanding the manufacturing processes and quality assurance protocols for water bottles, B2B buyers can make informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of water bottles’

The following checklist serves as a practical guide for B2B buyers looking to procure various types of water bottles. Each step is designed to help you navigate the complexities of sourcing while ensuring you make informed decisions that align with your business needs.

Step 1: Identify Your Target Market

Understanding who your end-users are is crucial. Different markets have distinct preferences based on factors such as climate, cultural habits, and lifestyle. Conduct market research to determine what types of water bottles are popular in your target regions, such as insulated options in colder climates or lightweight designs in tropical areas.

Step 2: Define Your Technical Specifications

Clearly outline the specifications your water bottles must meet. Consider materials (e.g., stainless steel, plastic, glass), insulation properties, and design features such as lids and handles. This step is essential to ensure that the products meet both your quality standards and customer expectations.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This step ensures you are dealing with reputable suppliers who can deliver quality products consistently.

- Check Certifications: Ensure suppliers comply with international quality standards and safety regulations.

- Assess Production Capacity: Confirm that suppliers can meet your order volume and delivery timelines.

Step 4: Request Samples for Testing

Always request product samples before finalizing your order. This allows you to evaluate the quality, durability, and functionality of the water bottles firsthand. Pay attention to the materials used and any specific features that are important for your market.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and tested their products, enter into negotiations. Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms that enhance your profit margins.

Step 6: Review Logistics and Shipping Options

Consider the logistics involved in importing water bottles from your chosen supplier. Look into shipping methods, customs regulations, and potential tariffs. Proper planning in this area can save costs and avoid delays in bringing products to market.

Step 7: Establish a Quality Control Process

Set up a quality control protocol to monitor the product quality upon arrival. This can include inspecting shipments for defects and ensuring that the products meet the agreed specifications. A robust quality control process protects your brand reputation and customer satisfaction.

By following this checklist, B2B buyers can streamline the sourcing process for water bottles, ensuring they find the right products that meet their business needs while maintaining quality and efficiency.

Comprehensive Cost and Pricing Analysis for types of water bottles Sourcing

What Are the Key Cost Components in Sourcing Water Bottles?

When sourcing different types of water bottles, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the overall cost. Stainless steel, glass, and high-grade plastics vary in price, with stainless steel typically being more expensive due to its durability and insulation properties. Eco-friendly materials may also attract a premium.

-

Labor: Labor costs depend on the manufacturing location. Countries with higher wage standards, such as those in Europe, will have higher labor costs compared to those in regions like Southeast Asia or South America.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment. Efficient production processes can help minimize these costs, impacting the final price of the water bottles.

-

Tooling: Custom molds and tools for specific designs can be a significant upfront investment. The complexity and uniqueness of the bottle designs will affect tooling costs.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability but adds to overall costs. Certifications (e.g., BPA-free, ISO standards) can also contribute to higher pricing.

-

Logistics: Shipping and handling costs vary based on the origin of the products and the destination market. Factors like distance, shipping methods, and tariffs need to be considered.

-

Margin: Suppliers typically mark up their costs to maintain profitability. Understanding the average margins in the industry can help buyers gauge if they are receiving a fair price.

How Do Price Influencers Affect Water Bottle Costs?

Several factors can influence the pricing of water bottles:

-

Volume/MOQ: Larger orders usually result in lower per-unit costs. Suppliers often provide discounts for higher Minimum Order Quantities (MOQ), which can lead to significant savings.

-

Specifications and Customization: Custom designs, colors, and features can increase costs. Standard models will typically be cheaper than bespoke options.

-

Materials and Quality Certifications: Higher-quality materials and certifications can raise the price but may be necessary for certain markets or customer preferences.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The chosen Incoterms (International Commercial Terms) will affect logistics costs and responsibilities. Understanding these terms is crucial for accurate cost assessments.

What Are the Best Negotiation Tips for B2B Buyers in the Water Bottle Market?

For B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, effective negotiation can lead to cost efficiencies:

-

Research and Benchmarking: Understand market prices and supplier offerings to negotiate better deals. Having comparative data can strengthen your position.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs such as maintenance, potential waste, and environmental impact. Suppliers may be more willing to negotiate if they see you are focused on long-term partnerships.

-

Building Relationships: Establishing strong relationships with suppliers can lead to more favorable pricing and terms over time. Trust can also encourage suppliers to offer exclusive deals.

-

Flexibility on Specifications: If your needs allow for it, being flexible on certain specifications can open up cost-saving opportunities.

-

Cultural Considerations: Be mindful of cultural differences in negotiation styles, especially when dealing with suppliers from different regions. Tailoring your approach can lead to more successful outcomes.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should be aware of specific pricing nuances:

-

Currency Fluctuations: Changes in currency value can impact costs significantly. It’s wise to lock in prices when favorable exchange rates are available.

-

Import Duties and Taxes: Understand local import regulations, tariffs, and taxes that may apply when sourcing from abroad. These can substantially increase the total cost.

-

Shipping Challenges: Be prepared for potential delays and additional costs in logistics, especially in regions with less reliable infrastructure.

-

Cultural and Legal Factors: Different countries may have varying regulations regarding product safety and environmental standards. Compliance with local laws is crucial to avoid costly penalties.

Disclaimer on Indicative Prices

Prices for water bottles can vary widely based on the factors discussed above. This analysis provides a general framework; actual costs may differ based on specific supplier agreements, market conditions, and the unique requirements of each order. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing types of water bottles With Other Solutions

Exploring Alternatives to Traditional Water Bottles for B2B Buyers

In the landscape of hydration solutions, various alternatives to traditional water bottles have emerged, each offering unique advantages and disadvantages. For businesses looking to make informed decisions about the best hydration options for their employees or clients, understanding these alternatives is crucial.

Comparison Table

| Comparison Aspect | Types Of Water Bottles | Water Filtration Systems | Hydration Packs |

|---|---|---|---|

| Performance | High insulation; keeps beverages hot/cold | Provides clean water but requires source | Convenient for outdoor activities; hands-free hydration |

| Cost | Moderate to high upfront cost, long-term savings | Varies widely; initial investment can be high | Generally affordable, but can vary based on design |

| Ease of Implementation | Simple; ready-to-use | Installation may require plumbing; maintenance needed | Easy to use; simply fill and wear |

| Maintenance | Low; occasional cleaning required | Moderate; filters need regular replacement | Low; clean after each use |

| Best Use Case | Office, travel, outdoor activities | Permanent installations in offices or homes | Hiking, biking, and outdoor sports |

Understanding the Pros and Cons of Alternatives

Water Filtration Systems

Water filtration systems are designed to purify tap water, providing a continuous supply of clean drinking water. These systems can range from simple countertop models to complex whole-house filtration setups.

Pros: They offer a sustainable solution by reducing reliance on bottled water, ensuring a constant supply of fresh water. They can also be cost-effective in the long run, as they eliminate the need for purchasing bottled water.

Cons: Initial setup can be costly and may require professional installation. Regular maintenance, including filter changes, is necessary to ensure optimal performance, which may pose an inconvenience for some businesses.

Hydration Packs

Hydration packs are portable water reservoirs worn on the back, equipped with a drinking tube for hands-free access. They are particularly popular among outdoor enthusiasts and athletes.

Pros: Hydration packs are incredibly convenient for active users, allowing for easy access to water while on the move. They are lightweight and designed to be ergonomic, making them ideal for activities like hiking or biking.

Cons: While generally affordable, the need to refill the pack and ensure cleanliness after each use can be seen as a drawback. Additionally, they may not be suitable for all environments, especially formal settings.

Making the Right Choice for Your Business Needs

When deciding between types of water bottles and alternative hydration solutions, B2B buyers should consider several factors. Evaluate the specific needs of your organization—are you looking for convenience, cost-effectiveness, or sustainability? Water bottles provide a versatile and portable solution suitable for various environments, while water filtration systems offer a long-term, eco-friendly approach for stationary setups. Hydration packs cater specifically to active lifestyles but may not fit all business contexts.

Ultimately, selecting the right hydration solution should align with your company’s culture, the preferences of your employees, and your budgetary constraints. By weighing these alternatives, businesses can make informed decisions that enhance hydration practices while supporting their sustainability goals.

Essential Technical Properties and Trade Terminology for types of water bottles

What Are the Key Technical Properties of Water Bottles in B2B Procurement?

When sourcing water bottles, understanding their technical properties is essential for making informed purchasing decisions. Here are critical specifications to consider:

1. Material Grade

Water bottles are typically made from materials such as stainless steel, plastic (like Tritan or BPA-free), and glass. The grade of material affects durability, safety, and insulation capabilities. For example, 304-grade stainless steel is corrosion-resistant and ideal for insulated bottles, while Tritan is a lightweight, shatter-resistant plastic that is popular in consumer markets. Choosing the right material can significantly impact the product’s lifespan and consumer satisfaction.

2. Insulation Technology

Insulation is a crucial feature, particularly for bottles designed to maintain temperature. The most common types are double-walled or triple-walled vacuum insulation. This technology can keep beverages cold for up to 24 hours or hot for 12 hours. For B2B buyers, selecting insulated bottles can provide added value to customers looking for functionality in their hydration solutions, enhancing brand loyalty and repeat purchases.

3. Capacity and Size Options

Water bottles come in various sizes, typically ranging from 300 ml to 2 liters. The choice of capacity should align with target market preferences and use cases, such as sports, travel, or everyday use. Providing diverse size options allows B2B buyers to cater to different customer needs, maximizing market reach and sales potential.

4. Lid Mechanism

The type of lid significantly influences the usability of a water bottle. Common lid types include screw-on, flip-top, and straw lids. Each offers different functionalities, such as ease of use, spill-proofing, and cleaning convenience. Understanding these mechanisms can help buyers choose products that enhance user experience and reduce return rates due to dissatisfaction.

5. Durability and Impact Resistance

Durability is a vital consideration for water bottles, especially for outdoor or sports applications. Features such as impact-resistant materials and protective coatings can prolong the life of the product. B2B buyers should prioritize bottles that can withstand rough handling, as this can lead to higher customer satisfaction and lower warranty claims.

6. Eco-Friendliness

With increasing consumer awareness about sustainability, the eco-friendliness of materials used in water bottles is becoming a selling point. Options like biodegradable plastics or recycled materials can appeal to environmentally conscious consumers. B2B buyers can leverage these attributes in marketing strategies to attract a broader audience and meet regulatory requirements in various regions.

What Are Common Trade Terms in Water Bottle Procurement?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are essential trade terms relevant to water bottles:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of water bottles, OEM partnerships can allow businesses to offer customized products without investing in manufacturing capabilities, making it easier to expand product lines.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is critical for B2B buyers to manage inventory effectively and ensure that production runs are economically viable.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. For buyers, issuing an RFQ can streamline the procurement process by allowing for a comparison of pricing and terms from multiple suppliers, ensuring the best value.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping. Familiarity with these terms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is essential for B2B transactions to clarify shipping costs and liability during transport.

5. Lead Time

Lead time is the amount of time from placing an order to receiving it. For B2B buyers, understanding lead times is essential for inventory planning and meeting customer demand without delays.

6. Certification Standards

Certification standards, such as FDA approval for food-safe materials or ISO certifications for quality management, are vital in the water bottle industry. Ensuring that products meet these standards can enhance marketability and compliance with regulations, particularly in international markets.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions, ensuring they select the best water bottle products to meet market demands and enhance customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the types of water bottles Sector

What Are the Current Market Dynamics Driving the Types of Water Bottles Sector?

The global market for water bottles is experiencing significant growth, driven by increasing consumer awareness regarding health and environmental issues. Factors such as the shift towards sustainable living and the growing demand for convenient hydration solutions are reshaping the landscape. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for innovative and functional products that cater to diverse consumer needs. For instance, the popularity of insulated and reusable water bottles is surging, as they align with the trend of reducing single-use plastic consumption.

Emerging technologies are also influencing sourcing trends in this sector. Smart water bottles equipped with hydration reminders, temperature indicators, and integration with mobile applications are gaining traction. Additionally, manufacturers are leveraging advanced materials like stainless steel and BPA-free plastics to enhance durability and safety, which appeals to environmentally conscious buyers. As competition intensifies, brands are differentiating themselves through unique designs and customizable options, allowing businesses to cater to niche markets effectively.

How Does Sustainability Influence Sourcing Practices for Water Bottles?

Sustainability is a crucial consideration in the sourcing of water bottles, impacting both product design and supply chain management. The environmental impact of single-use plastics has prompted businesses to prioritize eco-friendly alternatives. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability through ethical sourcing practices and transparency in their supply chains.

Materials such as recycled plastics, glass, and biodegradable options are becoming essential in the product offerings. Certifications like FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management) are key indicators of sustainable practices and can enhance a company’s reputation. By opting for suppliers with green certifications, businesses not only fulfill consumer demands for sustainability but also mitigate risks associated with environmental regulations. This shift towards ethical sourcing is not only beneficial for the planet but also represents a significant market opportunity, as consumers increasingly favor brands that prioritize environmental responsibility.

How Has the Water Bottle Market Evolved Over Time?

The water bottle industry has undergone a remarkable transformation over the past few decades. Initially dominated by single-use plastic bottles, the market has shifted dramatically towards reusable options, driven by a growing awareness of plastic pollution and its environmental consequences. The introduction of innovative materials and designs has expanded the functionality of water bottles, making them more appealing to consumers.

In the early 2000s, simple stainless steel bottles began to emerge, offering durability and insulation. As technology advanced, features like double-walled insulation and built-in filters became commonplace, enhancing the user experience. Today, the market is characterized by a diverse range of products, from insulated tumblers to smart water bottles, catering to various lifestyles and preferences. This evolution reflects a broader trend towards sustainability and health-conscious living, positioning the water bottle sector as a dynamic and lucrative space for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of types of water bottles

1. How can I determine the right type of water bottle for my business needs?

When selecting a water bottle for your business, consider factors such as your target audience, intended use, and branding opportunities. For instance, insulated bottles are ideal for outdoor events or corporate gifts, while stylish commuter cups suit urban professionals. Assess the material—stainless steel offers durability and insulation, whereas BPA-free plastic is lightweight and cost-effective. Additionally, think about the customization options available, such as printing your logo or choosing specific colors that align with your brand identity.

2. What are the advantages of sourcing reusable water bottles from international suppliers?

Sourcing reusable water bottles from international suppliers can provide cost advantages due to lower manufacturing costs in certain regions. Additionally, many international suppliers offer a diverse range of products and customization options, which can enhance your brand’s appeal. However, it’s crucial to evaluate suppliers based on quality assurance standards, certifications, and their ability to meet your specific requirements. Engaging with suppliers from regions like Asia or South America can also allow you to tap into emerging markets with growing demand for eco-friendly products.

3. What is the minimum order quantity (MOQ) typically required for water bottles?

The minimum order quantity for water bottles can vary significantly depending on the supplier and type of bottle. Generally, MOQs can range from 100 to 10,000 units. Suppliers may set higher MOQs for customized products or specialized designs due to the cost of production setups. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your budget and sales forecasts, especially if you’re entering a new market.

4. How do I ensure the quality of water bottles when sourcing internationally?

To ensure the quality of water bottles sourced internationally, conduct thorough supplier vetting. Request samples to assess material quality, construction, and functionality before placing bulk orders. Verify the supplier’s certifications, such as ISO or FDA compliance, which indicate adherence to industry standards. Regular quality assurance checks during production and before shipment can help identify any defects. Building a strong relationship with your supplier can also facilitate open communication regarding quality expectations.

5. What payment terms should I expect when sourcing water bottles internationally?

Payment terms can vary widely among international suppliers, but common practices include advance payments, letters of credit, and payment upon delivery. Many suppliers require a partial deposit (e.g., 30% upfront) with the balance due upon shipment or delivery. It’s essential to negotiate favorable terms that provide security for both parties. Always ensure that payment methods are secure and consider using escrow services for large transactions to mitigate risks.

6. What customization options are available for water bottles?

Customization options for water bottles can include branding through screen printing, engraving, or embossing your logo. You can also select colors, shapes, and sizes that resonate with your brand identity. Some suppliers offer additional features, such as personalized lids or accessories, to enhance the user experience. Discuss your vision with potential suppliers to explore the full range of customization possibilities that can help differentiate your products in the market.

7. How can I manage logistics effectively when importing water bottles?

Effective logistics management when importing water bottles involves choosing the right shipping method—air freight for speed or sea freight for cost savings. Work with a reliable freight forwarder to navigate customs regulations and ensure compliance with local laws. Plan for potential delays and consider warehousing options to manage inventory levels effectively. Additionally, establish clear communication with your supplier regarding shipment schedules and tracking to stay informed throughout the shipping process.

8. What are the environmental considerations when sourcing water bottles?

When sourcing water bottles, consider the environmental impact of materials and manufacturing processes. Opt for suppliers that use sustainable materials like recycled plastics or biodegradable options. Assess the lifecycle of the products, including transportation emissions and end-of-life disposal. Many consumers, especially in emerging markets, are increasingly prioritizing eco-friendly products, so aligning your sourcing strategy with sustainability goals can enhance your brand’s reputation and appeal to environmentally conscious buyers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Types Of Water Bottles Manufacturers & Suppliers List

1. Contigo – Key Product

Domain: gocontigo.com

Registered: 2005 (20 years)

Introduction: Key Product Details:

– Types: Reusable Water Bottles, Shaker Bottles

– Features: Spill-Proof, Leak-Proof, Dishwasher Safe, Easy Mixing & Shaking, Built-In Carabiner Clip Handle, Microban® Antimicrobial Product Protection

– Lid Technologies: AUTOPOP®, AUTOSPOUT®, AUTOSEAL®, AutoClose

– Materials: Plastic, Stainless Steel, Tritan Plastic, Plastic with Microban® Antimicrobial Material

– Sizes Availab…

2. NY Times – Versatile Bottles

Domain: nytimes.com

Registered: 1994 (31 years)

Introduction: This company, NY Times – Versatile Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. WaterBottle.tech – Water Bottles

Domain: waterbottle.tech

Registered: 2018 (7 years)

Introduction: Different types of water bottles available on the market include: 1. Stainless Steel Water Bottles – Durable, excellent temperature retention, stylish designs, suitable for office workers and outdoor enthusiasts. 2. Aluminum Water Bottles – Lightweight, strong, portable, ideal for outdoor adventurers, improved insulation, recyclable. 3. Plastic Water Bottles – Affordable, lightweight, popular amon…

4. Nalgene – Durable Leak-Proof Bottles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Nalgene: Made from durable plastic, leak-proof, various shapes and sizes, S-tier for plastic bottles, made in the USA. 2. CamelBak Chute: Wide opening for easy cleaning, narrow lid for controlled drinking, various sizes, magnetic lid feature. 3. Yonder Bottle (Hydro Flask): Similar benefits to CamelBak, good for chugging. 4. Zulu Water Bottle: 2L capacity, user-friendly. 5. Vapur Water Bottle: …

5. Whitewater Now – Types of Bottled Water

Domain: whitewaternow.com

Registered: 2002 (23 years)

Introduction: Types of Bottled Water: 1. Spring Water – Sourced from natural springs, known for purity and crisp taste, contains beneficial minerals. 2. Purified Water – Undergoes extensive treatment to remove impurities, offers consistent purity and clean taste, ideal for appliances. 3. Mineral Water – Rich in essential minerals like calcium and magnesium, provides unique flavor and potential digestive benefit…

6. Hydro Flask – Insulated Bottle

Domain: waterbottleadvisor.com

Registered: 2024 (1 years)

Introduction: 8 Main Types of Reusable Water Bottles: 1. Insulated Bottles – Recommended: Hydro Flask 32 oz. Pros: Temperature retention, versatility, great for active lifestyles. Cons: Price, not always dishwasher safe, need for proper maintenance. 2. Collapsible Bottles – Recommended: Hydaway. Pros: Space-saving, lightweight, portable. Cons: No insulation, less stable when full, narrow opening can be harder t…

7. BottlePro – Water Bottle Safety Guide

Domain: bottlepro.net

Registered: 2014 (11 years)

Introduction: The article discusses the safety of various water bottle materials, ranking seven types: plastic, stainless steel, glass, aluminum, copper, silicone, and titanium. It emphasizes the importance of regular cleaning to prevent bacteria buildup and mentions leaching concerns, particularly with plastics containing BPA. It highlights that most modern plastic bottles are BPA-free, with Tritan being a rec…

Strategic Sourcing Conclusion and Outlook for types of water bottles

What Are the Key Takeaways for B2B Buyers in the Water Bottle Market?

In conclusion, the diverse landscape of water bottles offers significant opportunities for strategic sourcing, particularly for international B2B buyers targeting markets in Africa, South America, the Middle East, and Europe. Understanding the unique features and benefits of various types—such as cold cups, tumblers, canteens, and commuter cups—enables businesses to cater to specific consumer needs, from durability and insulation to convenience and eco-friendliness.

Strategic sourcing is vital in selecting high-quality products that align with both market demand and sustainability goals. As the global market for reusable water bottles continues to expand, driven by increasing awareness of environmental issues and consumer preferences for convenience, there is a pressing need for businesses to adapt their sourcing strategies accordingly.

How Can You Position Your Business for Future Success?

As you explore the water bottle market, consider forging partnerships with reliable suppliers who prioritize quality and innovation. Investing in versatile and appealing designs can enhance your product offerings and resonate with eco-conscious consumers. Embrace this opportunity to not only meet growing market demand but also to position your brand as a leader in sustainable drinkware solutions. Engage with the evolving market trends and make informed sourcing decisions that will ensure your business thrives in the competitive landscape ahead.