Introduction: Navigating the Global Market for price of bottle

In today’s global market, sourcing the right price of bottles can be a daunting challenge for international B2B buyers. With a myriad of options available—from stainless steel and aluminum to BPA-free plastic—understanding the nuances of pricing and quality becomes crucial for businesses looking to make informed purchasing decisions. This guide aims to demystify the complexities surrounding bottle pricing, providing insights into various types, applications, and the factors influencing cost.

Our comprehensive resource covers essential topics including supplier vetting processes, market trends, and the impact of material choices on pricing. By addressing these critical areas, we empower buyers from diverse regions—especially those in Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Nigeria—to navigate the marketplace effectively.

With actionable insights and expert analysis, this guide serves as a valuable tool for businesses aiming to optimize their procurement strategies and enhance product offerings. By equipping decision-makers with the knowledge they need to assess suppliers and negotiate prices, we facilitate a smoother purchasing experience that aligns with their specific market demands. Whether you are a startup or an established company, understanding the price of bottles is key to ensuring quality and sustainability in your product line.

Article Navigation

- Top 7 Price Of Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for price of bottle

- Understanding price of bottle Types and Variations

- Key Industrial Applications of price of bottle

- 3 Common User Pain Points for ‘price of bottle’ & Their Solutions

- Strategic Material Selection Guide for price of bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for price of bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘price of bottle’

- Comprehensive Cost and Pricing Analysis for price of bottle Sourcing

- Alternatives Analysis: Comparing price of bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for price of bottle

- Navigating Market Dynamics and Sourcing Trends in the price of bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of price of bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for price of bottle

Understanding price of bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Bottles | Durable, insulated, often reusable; maintains temperature | Corporate gifting, promotional products | Pros: Long-lasting, premium feel. Cons: Higher initial cost. |

| Plastic Bottles | Lightweight, versatile, often less expensive | Mass distribution, events, outdoor activities | Pros: Cost-effective, customizable. Cons: Less eco-friendly. |

| Glass Bottles | Aesthetic appeal, non-reactive, preserves taste | High-end brands, specialty beverages | Pros: Premium look, recyclable. Cons: Fragile, heavier. |

| Aluminum Bottles | Lightweight, recyclable, often with a sleek design | Sports events, eco-conscious brands | Pros: Durable, good for branding. Cons: Can dent easily. |

| Filtered Water Bottles | Built-in filtration systems for clean drinking water | Health-focused brands, fitness markets | Pros: Promotes health, reusable. Cons: Higher maintenance. |

What are the Characteristics of Stainless Steel Bottles for B2B Buyers?

Stainless steel bottles are renowned for their durability and insulation properties, making them ideal for various applications, including corporate gifting and promotional items. These bottles often maintain the temperature of liquids for extended periods, appealing to businesses targeting outdoor enthusiasts or health-conscious consumers. When considering stainless steel bottles, B2B buyers should evaluate the initial investment against long-term value, as they tend to be more expensive but offer a premium feel and longevity.

Why Choose Plastic Bottles for Mass Distribution?

Plastic bottles are a versatile and cost-effective option for mass distribution, making them popular in events and outdoor activities. Their lightweight nature allows for easy transport, and they can be customized with branding. However, B2B buyers must weigh the benefits of lower costs against the environmental impact and potential perceptions of quality. Opting for BPA-free options can enhance brand image and appeal to eco-conscious consumers.

How Do Glass Bottles Stand Out in the Market?

Glass bottles are favored for their aesthetic appeal and ability to preserve the taste of beverages without leaching chemicals. They are commonly used by high-end brands and specialty beverage companies looking to convey quality and sophistication. While glass bottles can enhance product perception, B2B buyers should consider their fragility and weight, which may affect shipping costs and consumer experience. Sustainability is also a factor, as glass is fully recyclable.

What Advantages Do Aluminum Bottles Offer for Branding?

Aluminum bottles are lightweight and recyclable, making them an excellent choice for brands focused on sustainability. Their sleek design often attracts consumers at sports events and outdoor activities. B2B buyers appreciate the branding potential of aluminum bottles, as they can be easily printed with logos and designs. However, buyers should consider that aluminum bottles can dent and may not maintain temperature as effectively as stainless steel options.

Why Are Filtered Water Bottles Gaining Popularity Among Health-Conscious Brands?

Filtered water bottles, equipped with built-in filtration systems, are becoming increasingly popular among health-focused brands and fitness markets. They promote clean drinking water and are reusable, aligning with sustainability trends. For B2B buyers, these bottles represent an opportunity to cater to a growing consumer base that prioritizes health and wellness. However, the higher maintenance required for filters and potential additional costs should be carefully evaluated.

Key Industrial Applications of price of bottle

| Industry/Sector | Specific Application of price of bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Industry | Bottled Water Production | Consistent supply of quality products | Quality standards, sourcing local materials, and regulatory compliance |

| Sports and Fitness | Reusable Water Bottles for Gyms and Sports Facilities | Enhanced customer experience and brand loyalty | Durability, design, and eco-friendliness of materials |

| Hospitality and Events | Customized Bottled Water for Events and Catering | Unique branding opportunity and customer satisfaction | Customization options, volume pricing, and delivery timelines |

| Retail and E-commerce | Online Sales of Eco-friendly Bottles | Increased market reach and customer engagement | Product variety, shipping costs, and sustainability certifications |

| Health and Wellness | Nutritional Supplements in Bottles | Convenience for consumers and product differentiation | Compliance with health regulations, packaging integrity, and labeling |

How is ‘price of bottle’ utilized in the Beverage Industry?

In the beverage industry, the price of bottled water is a critical factor. Companies must balance cost with quality to remain competitive. Buyers seek suppliers who can provide high-quality water at a reasonable price while ensuring compliance with local regulations. For international buyers, particularly in regions like Africa and the Middle East, sourcing from local producers can reduce shipping costs and enhance sustainability. These buyers also look for flexibility in order volumes to adjust to market demands.

What role does the price of bottles play in Sports and Fitness?

In the sports and fitness sector, reusable water bottles are essential for gyms and athletic facilities. The price of these bottles can influence purchasing decisions, especially for bulk orders. Businesses benefit from providing high-quality, durable bottles that enhance customer experience and promote brand loyalty. Buyers often require products that are easy to clean, leak-proof, and made from eco-friendly materials. This is particularly important in regions like South America, where environmental consciousness is growing.

How does the price of bottles impact the Hospitality and Events sector?

Customized bottled water is a unique offering in the hospitality and events industry. The price of these bottles can vary significantly based on customization options, impacting event budgets. Businesses can leverage branded bottles to enhance guest experiences and create memorable events. International buyers need to consider factors such as minimum order quantities, design capabilities, and delivery schedules to ensure timely availability for events, especially in competitive markets like Europe.

Why is the price of bottles significant in Retail and E-commerce?

Retailers and e-commerce platforms are increasingly focusing on eco-friendly bottled products. The price of these bottles can affect profit margins and consumer purchasing decisions. Businesses benefit from offering a variety of options to cater to different customer preferences, enhancing engagement and sales. Key considerations for buyers include product variety, shipping costs, and sustainability certifications, which are particularly relevant for buyers in regions like Africa, where eco-conscious purchasing is on the rise.

How does the price of bottles relate to Health and Wellness?

In the health and wellness sector, nutritional supplements often come in bottled formats. The price of these bottles can influence product accessibility and consumer choices. Businesses must ensure compliance with health regulations and provide packaging that maintains product integrity. Buyers in this sector, especially from the Middle East and Europe, are increasingly looking for transparent labeling and safety certifications to build consumer trust in their products.

3 Common User Pain Points for ‘price of bottle’ & Their Solutions

Scenario 1: Navigating Fluctuating Costs of Bottles in Global Markets

The Problem: B2B buyers often face significant challenges when sourcing bottles due to fluctuating prices influenced by various factors such as raw material costs, transportation fees, and geopolitical tensions. This volatility can lead to unexpected budget overruns and difficulty in maintaining consistent pricing for end consumers. For example, a beverage company in Nigeria may find that the price of aluminum bottles rises sharply due to supply chain disruptions, leaving them scrambling to adjust their pricing strategy or seek alternative suppliers.

The Solution: To mitigate the impact of price fluctuations, B2B buyers should establish relationships with multiple suppliers across different regions. This not only provides leverage during negotiations but also ensures a reliable source of bottles, regardless of market conditions. Additionally, buyers can implement a long-term purchasing strategy, locking in prices for bulk orders or negotiating fixed-price contracts for a defined period. Utilizing market intelligence tools can also help buyers track price trends and forecast future costs, enabling proactive budgeting and planning.

Scenario 2: Understanding the Total Cost of Ownership for Bottles

The Problem: Many B2B buyers focus solely on the initial purchase price of bottles, neglecting other critical factors that contribute to the total cost of ownership (TCO). This oversight can result in higher long-term expenses due to factors such as shipping costs, storage requirements, and disposal fees. For instance, a distributor in South America might choose the cheapest plastic bottles, only to discover later that they incur additional costs due to their bulkiness and the need for special handling.

The Solution: To address this issue, buyers should conduct a comprehensive TCO analysis when evaluating bottle options. This involves considering not just the purchase price, but also logistics, storage, recycling, and potential environmental penalties associated with certain materials. Creating a detailed cost breakdown and comparing different options based on their overall impact can lead to more informed purchasing decisions. Additionally, engaging with suppliers who provide transparent pricing models and lifecycle assessments can enhance understanding and optimize cost efficiency.

Scenario 3: Balancing Quality and Price in Bottle Selection

The Problem: B2B buyers often grapple with the dilemma of balancing price and quality in their bottle selection. Opting for cheaper options can result in poor product performance, which may lead to customer dissatisfaction or even product recalls. For example, a beverage company in Europe may choose low-cost glass bottles that shatter easily during transport, resulting in significant losses and damaged reputation.

The Solution: To strike the right balance, buyers should prioritize quality assessments alongside pricing. This can be achieved by requesting samples and conducting rigorous testing to evaluate durability, safety, and functionality. Establishing clear quality standards and including them in supplier contracts can also ensure that manufacturers meet expectations. Moreover, collaborating with suppliers who specialize in sustainable materials can provide long-term benefits, as they often combine quality with competitive pricing. By integrating quality metrics into the procurement process, buyers can avoid the pitfalls of compromising on quality for cost.

Strategic Material Selection Guide for price of bottle

What Are the Key Properties of Common Materials Used in Bottles?

When selecting materials for bottles, particularly in the B2B context, it is essential to consider the properties that directly affect product performance. The most common materials include stainless steel, aluminum, glass, and plastic. Each material has unique characteristics that influence their suitability for various applications.

How Does Stainless Steel Perform in Bottle Manufacturing?

Stainless steel is renowned for its durability and resistance to corrosion, making it an ideal choice for insulated water bottles. It can withstand high temperatures and pressures, which is crucial for applications requiring thermal insulation. Additionally, stainless steel is non-reactive, ensuring that the contents remain uncontaminated.

Pros: Stainless steel bottles are highly durable, easy to clean, and can be recycled. They also offer excellent temperature retention, keeping liquids hot or cold for extended periods.

Cons: The manufacturing process can be more complex and costly compared to other materials. Additionally, stainless steel bottles can be heavier than their plastic counterparts, which may be a consideration for consumers prioritizing portability.

Impact on Application: Stainless steel is suitable for a wide range of media, including hot beverages and carbonated drinks. However, it may not be ideal for acidic liquids, as prolonged contact can lead to a metallic taste.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and the Middle East should ensure that suppliers adhere to local regulations regarding food safety and material quality.

What Advantages Does Aluminum Offer for Bottles?

Aluminum is lightweight and offers excellent resistance to corrosion, making it a popular choice for beverage containers. It can be easily molded into various shapes and sizes, allowing for creative designs that appeal to consumers.

Pros: Aluminum bottles are lightweight, which reduces shipping costs. They are also recyclable and can be produced at a lower cost than stainless steel.

Cons: While aluminum is durable, it is less robust than stainless steel and can dent easily. Additionally, it may require a protective lining to prevent reactions with acidic contents, which can add to manufacturing complexity.

Impact on Application: Aluminum is suitable for a variety of beverages, including soft drinks and flavored waters. However, its use with hot liquids is not recommended due to heat conductivity.

Considerations for International Buyers: Buyers should verify that aluminum bottles meet specific safety standards, particularly in regions where regulations are stringent, such as Europe. The presence of BPA in linings should also be a concern for health-conscious markets.

Why Choose Glass for Bottle Production?

Glass is a traditional material that offers excellent chemical resistance and does not leach substances into its contents. It is inert, ensuring that flavors remain pure, making it ideal for premium beverages.

Pros: Glass bottles are recyclable and provide an upscale appearance, which can enhance brand perception. They are also suitable for a wide range of beverages, including juices and alcoholic drinks.

Cons: The fragility of glass makes it less suitable for environments where breakage is a concern. Additionally, glass is heavier, which can increase shipping costs.

Impact on Application: Glass is compatible with most liquids, but its weight and breakability can limit its use in certain markets, particularly where transport conditions are challenging.

Considerations for International Buyers: Compliance with safety regulations is critical, especially in regions with strict import standards. Buyers should also consider the environmental impact of glass production and recycling in their local markets.

What Role Does Plastic Play in Bottle Manufacturing?

Plastic bottles, particularly those made from PET (polyethylene terephthalate), are widely used due to their lightweight and cost-effective nature. They are versatile and can be produced in various shapes and sizes.

Pros: Plastic bottles are inexpensive, lightweight, and can be produced quickly, making them ideal for mass production. They are also shatter-resistant, which is advantageous for transport.

Cons: Plastic is less durable than metal or glass and can degrade over time, especially when exposed to heat. Concerns about the leaching of chemicals, particularly BPA, can also deter environmentally conscious consumers.

Impact on Application: Plastic is suitable for a wide array of beverages, including water and soft drinks. However, it is less suitable for hot liquids or long-term storage due to potential degradation.

Considerations for International Buyers: Buyers should ensure that plastic bottles comply with food safety standards and regulations in their respective countries. The increasing demand for sustainable options may also influence material choices.

Summary Table of Material Selection for Bottles

| Material | Typical Use Case for price of bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Insulated water bottles | Excellent durability and insulation | Higher manufacturing complexity | High |

| Aluminum | Soft drink containers | Lightweight and cost-effective | Prone to dents, may require lining | Medium |

| Glass | Premium beverage packaging | Chemical resistance and purity | Fragile and heavier | High |

| Plastic | Mass-produced water bottles | Inexpensive and lightweight | Less durable, potential chemical leaching | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for price of bottle

What Are the Main Stages of the Bottle Manufacturing Process?

Manufacturing bottles, particularly for water and beverage applications, involves several critical stages. Each stage is designed to ensure the product meets both functional and aesthetic standards required by B2B buyers.

-

Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used in bottle production include stainless steel, aluminum, and various plastics. For stainless steel bottles, high-quality food-grade stainless steel is often selected to ensure durability and resistance to corrosion. For plastic bottles, BPA-free plastics are increasingly preferred due to health concerns. The materials undergo cleaning and conditioning to remove any contaminants. -

Forming

The next stage involves shaping the material into the desired bottle form. For metal bottles, techniques such as deep drawing and spinning are used. These processes create a seamless finish, enhancing strength and insulation properties. In contrast, plastic bottles are usually produced using blow molding or injection molding techniques, which allow for rapid production of complex shapes. This stage is crucial as it lays the foundation for the bottle’s performance and aesthetics. -

Assembly

Once formed, bottles may require additional components such as lids or spouts. Assembly involves integrating these parts, often using automated systems to ensure efficiency and precision. For instance, leak-proof lids may require specific sealing techniques to ensure they function correctly. This stage often involves quality checks to confirm that all components fit and function as intended. -

Finishing

The final stage in the manufacturing process is finishing, which includes polishing, coating, and labeling. For stainless steel bottles, a surface treatment may be applied to enhance appearance and resistance to scratches. Plastic bottles may receive UV coatings to prevent degradation from sunlight. Labels are often applied in this stage, which can be customized for branding purposes. This step ensures the product is market-ready and meets consumer expectations.

How Is Quality Assurance Implemented in Bottle Manufacturing?

Quality assurance (QA) is a critical component of the bottle manufacturing process. It ensures that products meet international standards and customer specifications.

-

Relevant International Standards

Adhering to international standards is essential for quality assurance. ISO 9001, which focuses on quality management systems, is commonly applied in manufacturing processes. This standard helps organizations ensure consistent quality in their products and services. Additionally, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API standards (for petroleum and natural gas industry products) may also be relevant, depending on the bottle’s intended use. -

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor quality at various stages. These include:

– Incoming Quality Control (IQC): This checkpoint assesses raw materials before production begins. Inspecting materials ensures they meet required specifications.

– In-Process Quality Control (IPQC): During manufacturing, samples are tested at different stages to catch defects early. This includes checking dimensions, weight, and structural integrity.

– Final Quality Control (FQC): Before packaging, finished bottles undergo rigorous testing to ensure they meet all specifications. This can include leak tests, pressure tests, and visual inspections. -

Common Testing Methods

Various testing methods are employed to ensure product quality. These may include:

– Physical Testing: Checking for durability, weight tolerance, and resistance to impact.

– Chemical Testing: Ensuring that materials are free from harmful substances and that the bottles meet safety standards.

– Functional Testing: Assessing the performance of lids and seals to prevent leaks.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

-

Supplier Audits

Conducting supplier audits is an effective way to assess the manufacturing processes and quality control measures in place. Buyers can schedule on-site visits to evaluate the factory conditions, equipment, and staff training. This firsthand observation can provide insights into the supplier’s commitment to quality. -

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports, including results from various tests conducted throughout the manufacturing process. These reports should outline compliance with international standards and any corrective actions taken in response to quality issues. -

Third-Party Inspections

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can conduct independent evaluations of the manufacturing processes and final products. They can verify compliance with international standards and provide unbiased reports, which can be particularly valuable for buyers in regions with strict import regulations.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international buyers to navigate the complexities of global supply chains effectively.

-

Cultural Differences in Quality Standards

Quality expectations may vary significantly across different regions. For instance, European buyers may have stricter regulations compared to those in Africa or South America. It’s crucial for buyers to communicate their quality requirements clearly and ensure that suppliers understand these expectations. -

Regulatory Compliance

Buyers should be aware of the regulatory landscape in their respective countries. This includes understanding import regulations, safety standards, and labeling requirements. Suppliers should demonstrate compliance with these regulations to avoid potential legal issues. -

Sustainability and Environmental Standards

Increasingly, B2B buyers are prioritizing sustainability in their sourcing decisions. Suppliers should have certifications that demonstrate their commitment to environmentally friendly practices, such as using recycled materials and sustainable manufacturing processes.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing bottles, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘price of bottle’

Introduction

Navigating the procurement process for bottles requires a strategic approach, particularly for B2B buyers seeking to ensure quality, compliance, and cost-effectiveness. This checklist provides a structured methodology to guide your sourcing journey, helping you make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the bottles you need, including materials, capacity, and intended use. This initial step ensures you communicate your requirements effectively to potential suppliers. Consider the following:

– Material Type: Stainless steel, aluminum, or plastic can significantly impact durability and cost.

– Capacity: Specify the volume (e.g., 24 oz., 28 oz.) to meet your customer needs.

Step 2: Conduct Market Research

Investigate the current market trends and pricing for the type of bottles you intend to procure. Understanding the landscape can help you identify competitive pricing and potential suppliers.

– Pricing Benchmarks: Gather data on average prices across different suppliers and regions to set a realistic budget.

– Consumer Preferences: Analyze market demands for specific features, such as eco-friendliness or innovative designs.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers thoroughly to ensure they can meet your specifications and quality standards. Request company profiles, case studies, and references from buyers in similar industries.

– Certifications: Look for suppliers with relevant certifications (e.g., ISO, FDA) that indicate compliance with safety and quality standards.

– Customer Reviews: Assess feedback from previous clients to gauge reliability and service quality.

Step 4: Request Samples

Always request samples of the bottles before making a bulk purchase. This step allows you to evaluate the quality and functionality firsthand.

– Quality Assurance: Inspect the sample for durability, design, and usability.

– Brand Alignment: Ensure the product aligns with your brand values and customer expectations.

Step 5: Negotiate Pricing and Terms

Engage in discussions with suppliers to negotiate pricing, payment terms, and delivery schedules. Effective negotiation can lead to cost savings and favorable conditions.

– Volume Discounts: Inquire about pricing breaks for larger orders to maximize savings.

– Payment Flexibility: Discuss payment terms that align with your cash flow needs.

Step 6: Confirm Compliance and Sustainability

Ensure that the bottles meet regional regulations and sustainability standards. This is particularly crucial for international buyers who must navigate varying compliance requirements.

– Regulatory Compliance: Verify that the products adhere to local and international regulations, including safety and environmental guidelines.

– Sustainability Practices: Consider suppliers that prioritize eco-friendly practices, such as using recycled materials or sustainable production methods.

Step 7: Finalize the Purchase Agreement

Once all terms are agreed upon, draft a comprehensive purchase agreement that outlines all details, including product specifications, pricing, and delivery timelines.

– Legal Protection: Ensure the agreement includes clauses that protect your interests, such as quality assurance and return policies.

– Clear Communication: Maintain open lines of communication with the supplier to address any issues that may arise post-purchase.

Following this step-by-step checklist will empower you to make informed, strategic decisions while sourcing bottles for your B2B needs, ultimately enhancing your operational efficiency and product offering.

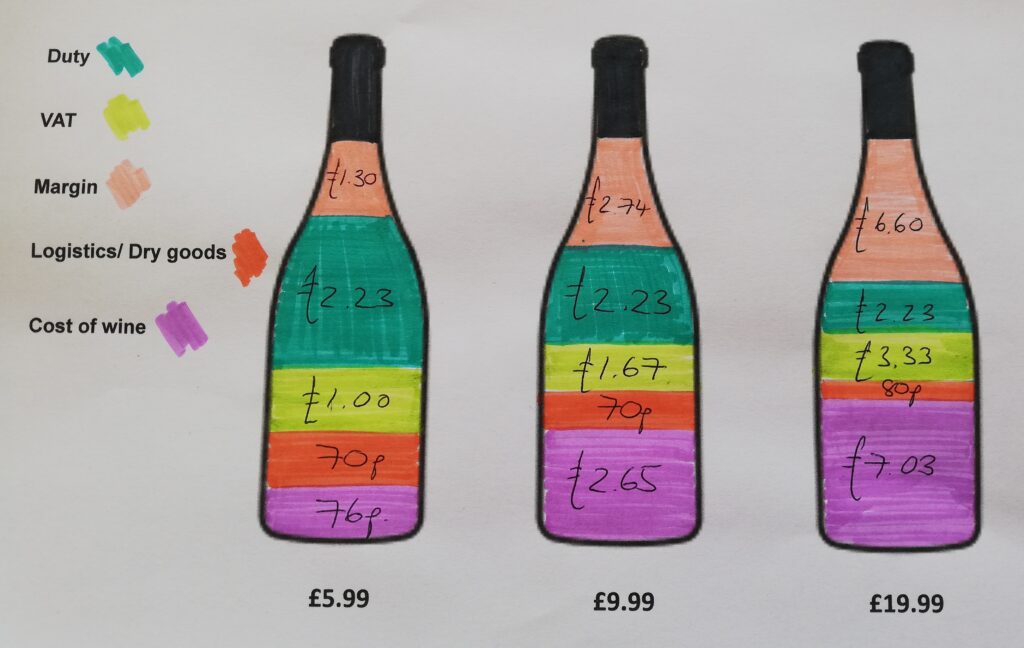

Comprehensive Cost and Pricing Analysis for price of bottle Sourcing

What Are the Key Cost Components in Bottle Sourcing?

When analyzing the cost structure for sourcing bottles, several critical components come into play. The primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences the overall cost. Bottles made from stainless steel, glass, or BPA-free plastics tend to have varying costs, with stainless steel often being the most expensive due to its durability and insulation properties. For instance, brands like Hydro Flask and Contigo use premium materials that enhance product longevity and user experience.

-

Labor and Manufacturing Overhead: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs can provide competitive pricing, but this may affect quality. Manufacturing overhead, which includes utilities and facility maintenance, should also be considered, particularly in regions where energy costs are high.

-

Tooling and Quality Control: Tooling costs are incurred during the initial setup for production, which can be substantial for custom bottle designs. Effective QC processes are essential to ensure that the bottles meet the required specifications, adding another layer of cost.

-

Logistics and Margin: Transportation costs can fluctuate due to fuel prices and shipping methods. For international buyers, understanding Incoterms is crucial, as they dictate who bears the shipping and insurance costs. Margins can vary based on market competition and the brand’s positioning.

How Do Price Influencers Affect Bottle Costs?

Several factors influence the pricing of bottles, particularly for international B2B buyers.

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may offer tiered pricing, encouraging larger purchases.

-

Specifications and Customization: Custom designs, colors, or features (like insulated walls) can increase costs. Buyers should weigh the necessity of these customizations against the potential increase in price.

-

Materials and Quality Certifications: Bottles made from premium materials or those that comply with specific certifications (like FDA approval) typically command higher prices. Buyers should assess whether the added costs align with their market demands.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers might charge more but offer better quality assurance and faster delivery times.

What Buyer Tips Can Help Optimize Costs?

B2B buyers can employ various strategies to optimize their sourcing costs effectively.

-

Negotiation Strategies: Engage in discussions about pricing, especially if you can commit to larger orders. Suppliers may be willing to offer discounts or better terms to secure a long-term partnership.

-

Understanding Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like shipping, storage, and potential waste or quality issues. A cheaper bottle may end up costing more in the long run if it requires frequent replacements.

-

Navigating Pricing Nuances for International Purchases: International buyers should be aware of currency fluctuations, import duties, and taxes that can affect overall costs. Ensuring clarity on Incoterms can help manage expectations regarding delivery responsibilities and costs.

What Should Buyers Keep in Mind About Indicative Pricing?

It is essential to recognize that the prices for bottles can vary significantly based on the aforementioned factors. Indicative pricing serves as a benchmark, but actual costs may differ due to changes in material prices, labor rates, and shipping costs. Always request detailed quotes from suppliers and consider multiple options to find the best value.

By understanding these cost structures and pricing influences, B2B buyers can make informed decisions that align with their business needs and budget constraints, ensuring a successful sourcing strategy.

Alternatives Analysis: Comparing price of bottle With Other Solutions

Exploring Alternatives to Traditional Bottled Water Solutions

In the evolving landscape of hydration solutions, B2B buyers must consider not only the price of bottled water but also viable alternatives that can offer similar benefits. Understanding these alternatives can help businesses make informed purchasing decisions that align with their operational needs and sustainability goals. Below, we compare traditional bottled water with two alternative solutions: water filtration systems and reusable stainless steel bottles.

| Comparison Aspect | Price Of Bottle | Water Filtration System | Reusable Stainless Steel Bottle |

|---|---|---|---|

| Performance | Consistent hydration, but dependent on supply chain reliability | High-quality water filtration, effective against contaminants | Durable, can maintain temperature, and is environmentally friendly |

| Cost | $0.50 – $3.00 per bottle depending on size and brand | $100 – $500 initial investment, with ongoing filter replacement costs | $20 – $50 one-time purchase |

| Ease of Implementation | Simple; requires minimal setup | Requires installation; may need professional help | Very easy to use; no setup required |

| Maintenance | None, but relies on continuous supply | Regular filter replacements needed (every 6 months to 1 year) | Minimal; cleaning is straightforward |

| Best Use Case | Events, offices, and travel | Long-term use in homes, offices, and commercial settings | Personal use, gyms, and on-the-go hydration |

What Are the Pros and Cons of Water Filtration Systems?

Water filtration systems offer high-quality hydration by removing contaminants and improving the taste of tap water. The initial investment can be significant, ranging from $100 to $500, depending on the system’s complexity. While the ongoing costs of filter replacements can add up, the overall savings compared to purchasing bottled water can be substantial over time. These systems are ideal for businesses looking to provide consistent hydration while minimizing environmental impact. However, they may require professional installation and regular maintenance to ensure optimal performance.

Why Choose Reusable Stainless Steel Bottles?

Reusable stainless steel bottles are an eco-friendly alternative that promotes sustainability by reducing single-use plastic waste. Priced between $20 and $50, they offer a cost-effective solution for long-term hydration needs. These bottles are durable, often insulated to keep drinks at the desired temperature, and easy to clean. They are perfect for gyms, outdoor activities, and everyday use. However, they require users to fill them regularly, which might not be ideal for all settings, especially in environments where water sources are limited.

Making the Right Choice for Your Business

When deciding between bottled water and its alternatives, B2B buyers should assess their specific hydration needs, budget constraints, and sustainability goals. Bottled water offers convenience, especially for events or immediate consumption, but the long-term costs and environmental implications can be significant. Conversely, water filtration systems and reusable bottles provide sustainable solutions that can save money over time while promoting a healthier planet. By evaluating these factors, businesses can choose the best hydration solution that aligns with their operational priorities and values.

Essential Technical Properties and Trade Terminology for price of bottle

What Are the Key Technical Properties to Consider When Pricing Bottles?

Understanding the technical properties of bottles is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications that impact the pricing and functionality of bottles:

-

Material Grade

Bottles can be made from various materials such as stainless steel, aluminum, glass, and BPA-free plastic. The material grade affects durability, weight, insulation properties, and environmental impact. For instance, stainless steel bottles are often more expensive due to their longevity and thermal insulation capabilities, making them ideal for premium markets. -

Capacity

The capacity of a bottle, usually measured in ounces or liters, plays a significant role in pricing. Larger bottles tend to cost more but may offer better value for businesses that require higher volume usage. Understanding the capacity needs of your target market can help in choosing the right product without overspending. -

Weight Tolerance

Weight tolerance refers to the ability of a bottle to withstand certain loads without deformation. This property is particularly important for reusable bottles intended for outdoor or industrial use. Buyers should consider the weight tolerance in relation to the intended application to ensure product reliability and safety. -

Thermal Properties

For insulated bottles, thermal properties are critical. These include the ability to maintain temperature for hot or cold liquids. Different insulation technologies, such as double-wall vacuum insulation, can significantly impact pricing. Buyers should evaluate the thermal needs of their consumers to justify the investment in higher-priced insulated products. -

Finish and Coating

The finish and coating of a bottle can influence both aesthetics and functionality. Coatings can provide additional features such as slip resistance or UV protection, which can be appealing in specific markets. The complexity of these finishes can also add to manufacturing costs, impacting the final price.

What Are the Common Trade Terms in the Bottle Pricing Industry?

Navigating the B2B landscape requires familiarity with industry jargon. Here are some essential trade terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the bottle industry, it may involve manufacturers that create customized bottles for brands. Understanding OEM relationships can help buyers negotiate better pricing and ensure quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. It’s crucial for buyers to know the MOQ when negotiating orders, as it can significantly impact cash flow and inventory management. Smaller companies may struggle with high MOQs, while larger organizations might benefit from bulk pricing. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products. It’s an essential step in the procurement process, allowing buyers to compare costs and terms from multiple suppliers. Crafting a clear RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is vital for B2B transactions, as they dictate who is responsible for shipping costs, insurance, and customs duties, thereby influencing overall pricing. -

TDS (Total Dissolved Solids)

TDS is a measure of the combined content of all inorganic and organic substances in a liquid. In bottled water, a lower TDS often indicates higher purity, which can affect pricing. Buyers should evaluate TDS levels to ensure the product meets quality standards and consumer expectations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands, ultimately leading to better purchasing outcomes.

Navigating Market Dynamics and Sourcing Trends in the price of bottle Sector

What Are the Key Drivers Influencing the Price of Bottles in the Global Market?

The global bottled water market has witnessed significant growth, driven by increasing health consciousness and a rising demand for convenient hydration solutions. In regions such as Africa, South America, the Middle East, and Europe, the need for reliable water sources has spurred investment in bottled water production. Furthermore, innovations in packaging, such as insulated and stainless steel options, are gaining popularity among consumers seeking durability and sustainability.

International B2B buyers should note the emerging trend of smart packaging, integrating technology that enhances user experience and product tracking. This trend is particularly relevant in markets like Saudi Arabia and Nigeria, where supply chain transparency is crucial. Enhanced production techniques, such as blow molding and extrusion, have also improved efficiency and reduced costs, impacting the overall pricing strategy. Additionally, fluctuations in raw material costs—especially plastics and metals—can directly influence bottle pricing, making it essential for buyers to stay informed about commodity market trends.

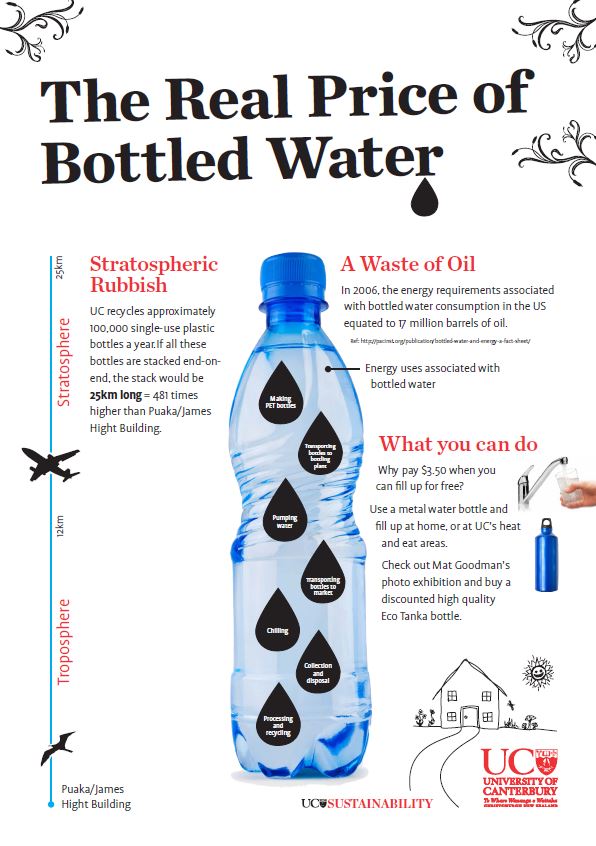

How Are Sustainability and Ethical Sourcing Shaping the Bottle Market?

Sustainability has become a non-negotiable aspect of sourcing strategies within the bottle sector. As environmental awareness grows, buyers are increasingly prioritizing products made from recycled materials or those that minimize ecological footprints. Certifications like ISO 14001 and the use of biodegradable materials are becoming critical for establishing credibility in the marketplace.

Ethical sourcing is not just about environmental impact; it also involves ensuring fair labor practices and community engagement in production processes. Brands that commit to ethical sourcing often enjoy enhanced brand loyalty and market differentiation, particularly in regions sensitive to social responsibility, such as Europe. Buyers in Africa and South America should seek partnerships with suppliers who demonstrate a commitment to sustainability, as this can lead to long-term benefits both in terms of cost savings and brand reputation.

What Is the Historical Context of Bottle Pricing Trends?

The evolution of bottle pricing has been shaped by various factors, including technological advancements and changing consumer preferences. Initially, the market was dominated by single-use plastic bottles, which were cost-effective but came under scrutiny due to environmental concerns. As awareness of plastic pollution grew, a shift towards reusable and sustainable options emerged, leading to innovations in materials and designs.

This transition has not only transformed consumer habits but has also influenced pricing strategies. Suppliers that adapted early to sustainable practices often gained a competitive edge, allowing them to command premium prices for eco-friendly products. Understanding this historical context can provide international B2B buyers with insights into current market dynamics and help them make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of price of bottle

-

How do I determine the best price for bulk water bottles?

To determine the best price for bulk water bottles, start by researching various suppliers and comparing their pricing structures. Factors such as material (plastic, stainless steel, or glass), size, and features (like insulated or customizable options) can significantly affect prices. Request quotes from multiple manufacturers and consider additional costs such as shipping, customs duties, and taxes that may apply based on your location in Africa, South America, the Middle East, or Europe. Always assess the total landed cost to make an informed decision. -

What are common payment terms for international bottle suppliers?

Payment terms can vary widely among international suppliers. Common arrangements include full payment upfront, a deposit with the balance due before shipping, or payment upon delivery. It’s advisable to negotiate terms that suit your cash flow needs while ensuring the supplier’s security. Consider using secure payment methods like letters of credit or escrow services, especially for larger transactions, to mitigate risks associated with international trade. -

What should I consider when vetting a bottle supplier?

When vetting a bottle supplier, assess their credibility through industry certifications (like ISO), client testimonials, and years of operation. Request samples to evaluate product quality and confirm their ability to meet your specifications. Check their manufacturing capacity to ensure they can fulfill your order volume, and inquire about their quality assurance processes. Additionally, consider their logistics capabilities, especially if you are importing bottles from overseas. -

What are the minimum order quantities (MOQ) for water bottles?

Minimum order quantities (MOQ) for water bottles typically depend on the supplier and the type of bottle being ordered. Standard MOQs can range from a few hundred to several thousand units. For customized bottles, MOQs may be higher due to setup costs. Always clarify MOQs before placing an order, as this can impact your budget and inventory management, especially for businesses in regions like Africa or South America where market dynamics differ. -

Can I customize the design of my bottles, and what is the cost?

Yes, many suppliers offer customization options for water bottles, including branding, colors, and sizes. The cost of customization varies based on the complexity of the design, the number of colors, and the quantity ordered. Typically, a one-time setup fee is charged for custom designs, in addition to a per-unit increase in price. Always request a detailed quote that outlines customization costs to ensure it aligns with your budget. -

What are the quality assurance practices for bottle manufacturers?

Quality assurance practices for bottle manufacturers should include regular testing of materials and finished products for safety and durability. Look for suppliers that follow international quality standards and conduct inspections at various stages of production. Inquire about their testing protocols, including certifications for BPA-free materials and compliance with health regulations. Establishing a clear QA process will help ensure that the bottles meet your quality expectations. -

What logistics considerations should I keep in mind when importing bottles?

When importing bottles, consider logistics factors such as shipping methods, lead times, and customs clearance. Choose a reliable freight forwarder experienced in handling bottled products to streamline the process. Be aware of import regulations specific to your country, including any duties or tariffs that may apply. Additionally, plan for potential delays due to customs inspections, especially in regions with strict import policies. -

What trends should I be aware of in the bottled water industry?

Stay informed about current trends in the bottled water industry, such as the increasing demand for sustainable packaging and eco-friendly materials. Consumers are becoming more environmentally conscious, prompting businesses to seek bottles made from recycled materials or those that are biodegradable. Additionally, flavored and functional waters are gaining popularity, providing opportunities for differentiation in the market. Understanding these trends can help you align your product offerings with customer preferences and enhance your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Price Of Bottle Manufacturers & Suppliers List

1. Hydro Flask – Insulated Water Bottles

Domain: hydroflask.com

Registered: 2009 (16 years)

Introduction: Insulated & Stainless Steel Water Bottles | Hydro Flask. Labor Day Sale: 25% off summer’s hottest styles. Free shipping on orders $39+. New Limited Edition Campus Collection. Product options include: 16 oz Coffee with Flex Sip™ Lid ($32.95, sale $24.71), 21 oz Standard Mouth with Flex Straw Cap ($34.95), Remix 32 oz Wide Mouth with Flex Straw Cap – Polar Plunge ($31.47, sale $44.95), Remix 24 oz W…

2. Walmart – Water Bottles

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Water Bottles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Grocery Store – Bottled Water

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 0.5 L bottle of water; cheapest brand in a grocery store costs approximately $0.14 per bottle when bought in bulk (35-pack for $4.99); single bottles typically sold for around $1; single bottles are usually kept cold for immediate consumption; room temperature options are less common and considered unusual.

4. Manna Hydration – Titan Bottle

Domain: mannahydration.com

Registered: 2015 (10 years)

Introduction: {“products”:[{“name”:”135 oz Titan Bottle”,”sale_price”:”$50.00″,”regular_price”:”$75.00″,”colors”:[“Black”,”Onyx”,”Hammered”,”Sapphire”],”rating”:”4.8″},{“name”:”40 oz Saratoga Bottle”,”sale_price”:”$35.00″,”colors”:[“Red Ombre”,”Stainless Steel”,”Sky Ombre”,”Smoke”,”Powder Berry Ombre”],”rating”:”5.0″},{“name”:”26 oz Saratoga Bottle”,”sale_price”:”$25.00″,”colors”:[“Blackberry Ombre”,”Indigo”,”P…

5. Stanley – Insulated Water Bottles

Domain: stanley1913.com

Registered: 2019 (6 years)

Introduction: Stainless Steel, Insulated Water Bottles; Features: double-wall vacuum insulation, eliminates condensation, available in various sizes (14 OZ, 16 OZ, 20 OZ, 24 OZ, 30 OZ, 40 OZ); options include IceFlow Flip Straw Tumbler, IceFlow Bottle with Fast Flow Lid, Quick Flip GO Bottle, All Day Slim Bottle; Master Unbreakable Water Bottle with QuadVac technology for enhanced insulation; not recommended fo…

6. Contigo UK – Thermal Mugs and Bottles

Domain: gocontigo.com

Registered: 2005 (20 years)

Introduction: Contigo UK offers a variety of products including Thermal Mugs, Water Bottles, Kids Bottles, Tumblers, and Premium Outdoor Bottles. Their products are designed for easy hydration, keeping beverages hot or cold for hours, and are ideal for both home and on-the-go use. The Kids’ Bottles feature colorful designs and are easy to use. Contigo emphasizes innovation and consumer-centric design, ensuring …

7. Numbeo – Water Price Rankings

Domain: numbeo.com

Registered: 2009 (16 years)

Introduction: This company, Numbeo – Water Price Rankings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for price of bottle

How Can Strategic Sourcing Optimize Your Bottle Procurement Costs?

In the competitive landscape of bottled products, strategic sourcing emerges as a pivotal approach for international B2B buyers. By leveraging global supplier networks, businesses can access a diverse range of bottle types—be it stainless steel, BPA-free plastic, or glass—tailored to various market demands. Understanding regional price fluctuations and material availability is essential, particularly for buyers in Africa, South America, the Middle East, and Europe, where sourcing strategies must align with local market conditions and consumer preferences.

The insights gained from analyzing trends in bottle pricing and material innovation can empower buyers to negotiate better terms and select sustainable options that resonate with environmentally conscious consumers. Additionally, establishing strong relationships with suppliers can lead to improved pricing structures and reliability in supply chains.

As we look to the future, the demand for quality and sustainability in packaging will continue to rise. International B2B buyers are encouraged to proactively adapt their sourcing strategies, ensuring they remain agile and responsive to market changes. Embrace the opportunity to refine your procurement processes and enhance your competitive edge in the evolving bottled products market.