Introduction: Navigating the Global Market for one bottle of water oz

The global market for bottled water is evolving rapidly, presenting unique challenges for B2B buyers seeking to source the right product. With the myriad of options available, understanding the nuances of “one bottle of water oz” becomes crucial in making informed purchasing decisions. This guide provides an in-depth exploration of various bottle sizes, including the common 8 oz, 12 oz, and 16.9 oz formats, while also addressing their applications in different markets—from family events to corporate gatherings.

As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigating this landscape requires careful supplier vetting and a keen awareness of cost implications. This comprehensive resource not only outlines the key factors to consider, such as shipping logistics and packaging efficiency, but also offers insights into consumer preferences that can influence purchasing choices.

By empowering you with essential knowledge about bottle sizes, labeling options, and market trends, this guide aims to streamline your procurement process. Whether you’re looking to cater to hydration needs at an event or seeking sustainable solutions to reduce plastic waste, understanding the dynamics of bottled water sourcing will enhance your strategic decision-making and ultimately drive business success.

Navigazione tra gli articoli

- Top 7 One Bottle Of Water Oz Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for one bottle of water oz

- Understanding one bottle of water oz Types and Variations

- Key Industrial Applications of one bottle of water oz

- 3 Common User Pain Points for ‘one bottle of water oz’ & Their Solutions

- Strategic Material Selection Guide for one bottle of water oz

- In-depth Look: Manufacturing Processes and Quality Assurance for one bottle of water oz

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘one bottle of water oz’

- Comprehensive Cost and Pricing Analysis for one bottle of water oz Sourcing

- Alternatives Analysis: Comparing one bottle of water oz With Other Solutions

- Essential Technical Properties and Trade Terminology for one bottle of water oz

- Navigating Market Dynamics and Sourcing Trends in the one bottle of water oz Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of one bottle of water oz

- Disclaimer importante e condizioni d'uso

- Strategic Sourcing Conclusion and Outlook for one bottle of water oz

Understanding one bottle of water oz Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| 8 oz Bottle | Small size, ideal for kids or quick sips | Schools, events, hospitality | Pro: Cost-effective, easy to carry. Contro: Limited hydration capacity. |

| 16.9 oz Bottle | Standard size, popular for retail and events | Retail, corporate gifting, travel | Pro: Widely accepted size, good balance of portability and hydration. Contro: Higher plastic waste per serving. |

| 1 Liter Bottle | Larger capacity, often used for group settings | Offices, gyms, outdoor events | Pro: Reduces the need for multiple bottles, suitable for sharing. Contro: Bulkier, may not fit in all holders. |

| 1.5 Liter Bottle | Extra-large, ideal for extended use | Sports teams, outdoor activities | Pro: Excellent for hydration during events, less frequent refills. Contro: Heavy when full, less portable. |

| Custom Sizes | Tailored dimensions and designs based on needs | Branding, niche markets | Pro: Unique branding opportunities, meets specific customer needs. Contro: Higher production costs, longer lead times. |

What are the Characteristics of an 8 oz Bottle?

The 8 oz water bottle is particularly suited for children or situations where only a small amount of hydration is needed. Its compact size makes it ideal for schools, children’s events, and hospitality settings where portion control is necessary. B2B buyers should consider factors like cost-effectiveness and ease of transport, especially for bulk purchases. However, the limited capacity may not meet the hydration needs of adults or active individuals.

Why Choose a 16.9 oz Bottle for B2B Needs?

The 16.9 oz bottle is the industry standard for bottled water, making it a popular choice for retailers and corporate events. This size strikes a balance between portability and hydration, making it suitable for various applications, from corporate gifting to outdoor events. Buyers should keep in mind that while this size is widely accepted, it can contribute to plastic waste if not recycled properly.

How Does a 1 Liter Bottle Fit into B2B Applications?

The 1-liter water bottle offers a larger capacity, making it ideal for group settings such as offices and gyms. Its design facilitates sharing, which is beneficial for events where multiple people need access to hydration. When purchasing, B2B buyers should evaluate the trade-off between size and portability, as these bottles can be bulkier and may require larger storage solutions.

What are the Benefits of a 1.5 Liter Bottle?

Designed for extended use, the 1.5-liter bottle is perfect for sports teams and outdoor activities where hydration is crucial. It minimizes the frequency of refills, making it a practical choice for events that last several hours. However, buyers should consider the weight of the full bottle, as it can be cumbersome for individual users, particularly in mobile settings.

How Do Custom Sizes Serve Niche Markets?

Custom-sized bottles allow businesses to cater to specific market needs, offering unique branding opportunities and tailored hydration solutions. This flexibility can be advantageous for companies looking to differentiate their products in competitive markets. However, B2B buyers should be aware that custom orders often come with higher production costs and longer lead times, necessitating careful planning and budgeting.

Key Industrial Applications of one bottle of water oz

| Industria/Settore | Specific Application of one bottle of water oz | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Cibo e bevande | Catering services for events and conferences | Enhances guest experience and promotes brand visibility | Custom labeling options and bulk pricing for cost efficiency |

| Sport e ricreazione | Hydration stations at sports events and gyms | Encourages hydration, boosts performance and recovery | Need for durable, portable bottles that can handle high usage |

| Education and Childcare | Providing water in schools and daycare facilities | Promotes health and wellness among children | Compliance with safety standards and eco-friendly materials |

| Ospitalità e turismo | In-room amenities in hotels and resorts | Improves guest satisfaction and loyalty | Consistency in branding and availability of various sizes |

| Programmi di benessere aziendale | Employee hydration initiatives in offices | Aumenta la produttività e il benessere dei dipendenti | Flexible delivery options and custom branding for corporate identity |

How is ‘one bottle of water oz’ utilized in the Food and Beverage Industry?

In the food and beverage sector, particularly catering services, offering single-serve bottles of water is a common practice during events and conferences. These bottles not only enhance the guest experience by providing convenient hydration options but also serve as a branding opportunity through custom labels. For B2B buyers, sourcing considerations include negotiating bulk pricing and ensuring the availability of different sizes to cater to varying guest preferences. Additionally, suppliers must comply with local regulations regarding food and beverage safety.

What role does ‘one bottle of water oz’ play in Sports and Recreation?

In sports and recreation, hydration is critical for performance and recovery. Facilities often set up hydration stations featuring single-serve bottles to ensure athletes and participants stay hydrated during events. The demand for durable, portable bottles that can withstand high usage is essential. B2B buyers in this sector should focus on suppliers that offer reliable logistics and the ability to customize bottle sizes and designs, enhancing both functionality and team branding.

Why is ‘one bottle of water oz’ important in Education and Childcare?

Providing water bottles in schools and daycare centers is vital for promoting health and wellness among children. Small-sized bottles, such as 8 oz or 12 oz, are particularly effective for younger children, making hydration accessible and manageable. Buyers in this sector must ensure that the products comply with safety standards and are made from eco-friendly materials, addressing both health concerns and environmental impacts. Suppliers should also offer bulk purchasing options to meet the needs of multiple facilities.

How does ‘one bottle of water oz’ enhance Hospitality and Tourism?

In the hospitality industry, offering bottled water as part of in-room amenities is a standard practice that can significantly enhance guest satisfaction. Hotels and resorts can customize bottles with their branding, promoting a cohesive guest experience. B2B buyers must consider the consistency in branding across all water bottle sizes and the reliability of supply to maintain high guest standards. Additionally, eco-conscious options can appeal to environmentally aware travelers.

What benefits does ‘one bottle of water oz’ provide in Corporate Wellness Programs?

Corporate wellness initiatives increasingly incorporate hydration as a key component of employee health. Providing single-serve water bottles in office settings encourages employees to stay hydrated, which can lead to improved productivity and overall well-being. B2B buyers should focus on suppliers that offer flexible delivery schedules and the option for custom branding, reinforcing the corporate identity while promoting a healthy workplace culture. Additionally, sourcing sustainably produced bottles can align with corporate social responsibility goals.

3 Common User Pain Points for ‘one bottle of water oz’ & Their Solutions

Scenario 1: Misalignment of Bottle Sizes with Market Needs

Il problema: B2B buyers often face the challenge of selecting water bottle sizes that do not align with the preferences of their target market. For instance, a distributor in Brazil might choose to stock primarily 16.9 oz bottles, believing them to be the standard. However, local consumers may prefer larger or smaller sizes due to cultural habits, such as larger gatherings or personal hydration needs. This mismatch can lead to excess inventory, wasted resources, and lost sales opportunities.

La soluzione: To effectively address this issue, buyers should conduct thorough market research before finalizing their order. Surveys and focus groups can provide insights into consumer preferences regarding bottle sizes. Additionally, leveraging sales data from similar markets can help predict demand for various sizes. Once the optimal sizes are identified, consider sourcing a diverse range of bottle sizes—like 8 oz, 12 oz, and 1-liter options—to cater to different consumer needs. This strategy not only minimizes the risk of overstocking but also positions the buyer as a responsive supplier in a competitive market.

Scenario 2: Inconsistent Labeling and Branding Across Bottle Sizes

Il problema: Another common pain point is the inconsistency in labeling and branding across different bottle sizes. For a company looking to establish a cohesive brand image, this inconsistency can dilute brand recognition and confuse consumers. For example, a company might have a vibrant label for its 16.9 oz bottles but fails to replicate that design for the 8 oz bottles, leading to a fragmented brand experience.

La soluzione: Buyers should implement standardized branding guidelines that detail the design elements applicable to all bottle sizes. Collaborating with manufacturers that offer customizable labeling solutions can ensure a uniform look across the product range. Consider creating a comprehensive design template that includes color schemes, fonts, and logo placement for each bottle size. This approach not only strengthens brand identity but also enhances customer loyalty as consumers can easily recognize the brand regardless of the bottle size they choose.

Scenario 3: Inefficient Supply Chain Logistics for Water Bottles

Il problema: B2B buyers often encounter logistical challenges when sourcing water bottles, particularly in regions with limited infrastructure. Buyers in the Middle East, for instance, may struggle with long lead times and high shipping costs due to reliance on international suppliers. This inefficiency can result in stockouts, missed sales opportunities, and dissatisfied customers.

La soluzione: To overcome these logistical hurdles, buyers should consider establishing relationships with local manufacturers or distributors that can provide shorter lead times and lower shipping costs. Engaging in a dual-sourcing strategy—where both local and international suppliers are utilized—can also enhance flexibility in supply chain management. Furthermore, investing in technology that tracks inventory levels and predicts demand can help streamline operations. This allows for timely reordering and prevents stockouts, ensuring that the business can meet customer needs efficiently while minimizing costs associated with excess inventory.

Strategic Material Selection Guide for one bottle of water oz

What Are the Best Materials for Bottling Water in Different Ounce Sizes?

When selecting materials for water bottles, particularly for international B2B markets, it is crucial to consider various factors such as performance properties, manufacturing complexities, and compliance with regional standards. Here, we analyze four common materials used in the production of water bottles—plastic (PET), glass, aluminum, and stainless steel—highlighting their key properties, advantages, disadvantages, and considerations for international buyers.

How Does Plastic (PET) Perform in Water Bottles?

Polyethylene Terephthalate (PET) is the most commonly used plastic for water bottles. It exhibits excellent clarity and is lightweight, making it ideal for consumer convenience. PET bottles can withstand moderate temperatures, typically up to 120°F (49°C), but they are not suitable for hot liquids. They are resistant to impact and do not corrode, making them a durable option for packaging.

Pro: PET is cost-effective and widely available, making it an economical choice for mass production. It is also recyclable, aligning with sustainability goals.

Contro: While PET is durable, it can leach chemicals if exposed to high temperatures or stored for extended periods. Additionally, it is less environmentally friendly compared to reusable materials.

Considerazioni internazionali: B2B buyers should ensure compliance with local regulations regarding food safety and recycling, such as the European Union’s Plastics Directive or Brazil’s National Solid Waste Policy.

Quali vantaggi offre il vetro per le bottiglie d'acqua?

Glass is another popular material for water bottles, especially in premium markets. It is non-reactive, meaning it does not leach chemicals into the water. Glass bottles can handle high temperatures, making them suitable for hot beverages, and are often preferred for their aesthetic appeal.

Pro: Glass is highly durable and can be reused multiple times without degrading in quality. It also offers superior taste preservation, making it ideal for flavored or mineral waters.

Contro: The main drawback of glass is its weight, which can increase shipping costs. It is also more prone to breakage compared to plastic or metal options.

Considerazioni internazionali: Buyers should be aware of packaging regulations and standards in their target markets, such as ASTM standards in the U.S. or DIN standards in Europe, which may dictate packaging safety and performance.

How Does Aluminum Compare for Water Bottles?

Aluminum is increasingly being used for water bottles, particularly in sports and outdoor applications. It is lightweight and can be easily shaped into various designs. Aluminum bottles can handle a range of temperatures and are resistant to corrosion, especially when coated with a protective liner.

Pro: Aluminum is recyclable and can be produced with a lower carbon footprint than plastic. It also offers a modern look that appeals to consumers.

Contro: The primary limitation is that aluminum bottles often require a lining to prevent chemical reactions with acidic beverages, which can complicate manufacturing.

Considerazioni internazionali: B2B buyers should check for compliance with food-grade certifications, such as those from the FDA or EFSA, to ensure safety in their markets.

What Are the Benefits of Using Stainless Steel for Water Bottles?

Stainless steel is gaining popularity for its durability and resistance to corrosion. It is suitable for both hot and cold beverages, making it versatile for various applications. Stainless steel bottles can maintain temperature for extended periods, making them ideal for outdoor and sports use.

Pro: Stainless steel is highly durable and can be reused indefinitely without degrading. It is also resistant to staining and does not impart flavors to the water.

Contro: The main drawback is the higher cost compared to plastic and aluminum. Additionally, stainless steel bottles can be heavier, which may affect shipping logistics.

Considerazioni internazionali: Buyers should look for compliance with international standards such as ISO and ASTM for material safety and performance, particularly in regions with strict regulations.

Summary of Material Selection for Water Bottles

| Materiale | Typical Use Case for one bottle of water oz | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastic (PET) | Standard single-use water bottles | Leggero e conveniente | Can leach chemicals at high temps | Basso |

| Vetro | Premium bottled water | Non-reactive and taste-preserving | Pesante e fragile | Med |

| Alluminio | Sports and outdoor bottles | Lightweight and modern aesthetic | Requires lining for acidic beverages | Med |

| Acciaio inox | Reusable water bottles | Highly durable and temperature-retaining | Higher cost and heavier | Alto |

Selecting the right material for water bottles is essential for meeting consumer needs while complying with international standards. Understanding the properties and implications of each material helps B2B buyers make informed decisions that align with their market strategies.

In-depth Look: Manufacturing Processes and Quality Assurance for one bottle of water oz

What Are the Main Stages in the Manufacturing Process of a Water Bottle?

The manufacturing process of a water bottle, particularly for a standard size like 16.9 ounces, involves several critical stages that ensure quality, efficiency, and compliance with international standards. Here’s a breakdown of the main stages:

-

Preparazione del materiale: The primary material used in water bottle production is polyethylene terephthalate (PET) due to its lightweight, strength, and recyclability. The process begins with the procurement of PET resin, which is then dried to remove moisture, ensuring optimal processing conditions.

-

Formazione: The dried PET is melted and extruded into preforms, which are small tube-like structures. These preforms are then heated and blown into the desired bottle shape using a blow molding technique. This method is efficient for mass production and allows for precise control over bottle dimensions and thickness.

-

Montaggio: After forming, the bottles undergo a cooling phase to solidify their shape. Once cooled, they are transported to an assembly line where caps and labels are applied. The caps are typically made from polypropylene (PP) and are designed to create a secure seal to prevent leakage. Labeling can be customized based on the buyer’s specifications, ensuring branding consistency.

-

Finitura: The final stage involves quality checks and packaging. Bottles are inspected for defects, and those that pass inspection are packaged into cases, typically 24 bottles per case for standard sizes. Packaging is done in a way that maximizes space and minimizes shipping costs, such as shrink-wrapping.

What Are the Key Techniques Used in Water Bottle Manufacturing?

Key techniques in water bottle manufacturing focus on efficiency and sustainability:

-

Injection and Blow Molding: This technique allows for rapid production of bottles with consistent quality. The preform is injected into a mold, heated, and then blown into the final bottle shape, reducing material waste and energy consumption.

-

Recycling and Sustainability Practices: Many manufacturers are adopting practices that emphasize the recycling of PET materials. This not only reduces environmental impact but also appeals to B2B buyers who prioritize sustainability.

-

Automation: The use of automated machinery in the assembly line increases production speed and reduces human error. Automation also enables real-time monitoring of the production process, allowing for immediate corrections if issues arise.

How Is Quality Assurance Implemented in Water Bottle Production?

Quality assurance (QA) is critical in ensuring that water bottles meet both safety and quality standards. Here’s how it’s typically implemented:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which sets criteria for quality management systems. This certification demonstrates that the manufacturer has established processes to ensure consistent quality and customer satisfaction.

-

Certificazioni specifiche del settore: Depending on the market, additional certifications may be required. For example, bottles sold in the European Union may need CE marking, while in the United States, compliance with FDA regulations is essential for food-grade products.

-

Punti di controllo della qualità:

- Controllo qualità in entrata (CQI): Raw materials like PET resin and PP caps are inspected upon arrival to ensure they meet specified standards.

- Controllo qualità in corso d'opera (IPQC): During production, various parameters such as temperature, pressure, and mold integrity are monitored to ensure consistency.

- Controllo qualità finale (CQC): The finished bottles are subjected to a series of tests, including dimensional checks, leak tests, and visual inspections for surface defects.

What Testing Methods Are Commonly Used for Water Bottles?

Several testing methods are implemented to ensure the safety and quality of water bottles:

-

Test fisici: This includes testing the bottle’s resistance to impact, drop tests, and tensile strength assessments to ensure the bottles can withstand handling and transportation.

-

Test chimici: Bottles are tested for leachables and extractables to ensure that no harmful substances migrate from the bottle to the water. This is especially important for compliance with safety regulations.

-

Microbial Testing: In some cases, bottles may undergo microbial testing to ensure they are free from contaminants that could compromise water quality.

Come possono gli acquirenti B2B verificare il controllo qualità dei fornitori?

For B2B buyers, verifying the quality control processes of suppliers is crucial to ensuring product reliability and safety:

-

Audit dei fornitori: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, quality control systems, and compliance with international standards. This also allows buyers to assess the supplier’s commitment to quality.

-

Rapporti di garanzia della qualità: Requesting detailed QA reports can help buyers understand the testing methods employed, results of quality checks, and any corrective actions taken for past issues.

-

Ispezioni di terze parti: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing processes and quality control measures in place. This is especially important for international buyers, as it can mitigate risks associated with cross-border transactions.

Quali sono le sfumature del controllo qualità per gli acquirenti internazionali B2B?

When dealing with international suppliers, B2B buyers should be aware of specific nuances:

-

Conformità normativa: Different countries have varying regulations regarding bottled water production. Buyers from regions like Africa and South America should ensure suppliers comply with local health and safety standards.

-

Considerazioni culturali: Understanding cultural differences in business practices can facilitate smoother negotiations and collaborations. Buyers should be aware of how quality assurance is perceived and implemented in different regions.

-

Logistical Considerations: International shipping can introduce additional risks, such as damage during transit. Buyers should inquire about the supplier’s packaging and handling procedures to minimize such risks.

In summary, understanding the manufacturing processes and quality assurance practices for water bottles is essential for B2B buyers looking to ensure product quality and compliance. By focusing on these aspects, buyers can make informed decisions that align with their business needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘one bottle of water oz’

Introduzione

This practical sourcing guide provides a step-by-step checklist for international B2B buyers looking to procure water bottles of various ounce sizes. Understanding the specific requirements for different bottle sizes is crucial for optimizing logistics, meeting consumer needs, and maintaining quality standards. This guide will help you navigate the selection process effectively.

Fase 1: Determine Your Target Market’s Preferences

Understanding the preferences of your target market is essential. Different regions may favor specific bottle sizes based on cultural habits, lifestyle, and environmental considerations. For example, in urban areas, smaller bottles (8oz to 12oz) may be more popular for convenience, while larger bottles (1 liter or more) might be favored in rural settings for family use.

Fase 2: Definire le specifiche tecniche

Clearly outline the technical specifications for the water bottles you intend to source. This includes size, material (e.g., PET plastic, glass), and label dimensions. Having precise specifications will streamline the sourcing process and ensure that suppliers can meet your needs without unnecessary back-and-forth.

- Size Options: Consider common sizes such as 8oz, 12oz, 16.9oz, and 1 liter, each catering to different market segments.

- Materiale: Assess whether you need recyclable materials to appeal to eco-conscious consumers.

Fase 3: Valutare i potenziali fornitori

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request company profiles, product samples, and references from buyers in similar industries. This diligence helps ensure that the supplier can meet your quality and service expectations.

- Request Certifications: Verify that suppliers hold relevant certifications for quality and safety, such as ISO or FDA compliance.

- Check Reviews: Look for customer reviews or case studies that demonstrate the supplier’s reliability.

Passo 4: Assess Logistics and Packaging Solutions

Logistics play a significant role in the overall cost and efficiency of your procurement. Investigate how suppliers package and ship their products, including whether they offer bulk shipping options.

- Palletization: Understand how many cases can fit on a standard pallet to optimize shipping costs.

- Packaging Materials: Consider the environmental impact of packaging materials and whether they align with your brand values.

Passo 5: Negoziare prezzi e condizioni

Once you’ve identified potential suppliers, engage in negotiations to secure favorable pricing and payment terms. Understanding the pricing structure for different bottle sizes and materials is essential for maintaining your budget.

- Volume Discounts: Inquire about discounts for bulk orders, which can significantly reduce overall costs.

- Payment Flexibility: Discuss payment terms that accommodate your cash flow requirements.

Passo 6: Test Product Quality

Before finalizing your order, conduct quality tests on sample products. This step is vital to ensure that the bottles meet your specifications and quality standards.

- Durability Tests: Check for resistance to breakage and leakage.

- Label Quality: Ensure that labels adhere well and maintain print quality under various conditions.

Passo 7: Establish a Relationship with Your Supplier

Building a strong relationship with your supplier can lead to better service and collaboration in the long run. Maintain open communication and provide feedback on products and services.

- Regular Check-ins: Schedule periodic reviews to discuss performance and any emerging needs.

- Feedback Loop: Encourage suppliers to share insights on market trends that could benefit your business.

By following this checklist, you can streamline the sourcing process for water bottles, ensuring that you meet market demands while optimizing costs and quality.

Comprehensive Cost and Pricing Analysis for one bottle of water oz Sourcing

What Are the Key Cost Components in Sourcing One Bottle of Water?

When sourcing bottled water, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

I materiali: The most significant cost is often the raw materials, including the type of plastic used for bottles, labels, and caps. High-quality materials may incur higher costs but can enhance product appeal and durability.

-

Lavoro: Labor costs vary based on the location of the manufacturing facility. Regions with lower labor costs can provide significant savings but may compromise quality if not managed properly.

-

Spese generali di produzione: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient operations can minimize these costs.

-

Utensili: Initial tooling costs can be substantial, especially for custom bottle designs or unique labeling. Buyers should factor in these costs, particularly for smaller orders where tooling costs can significantly impact unit pricing.

-

Controllo qualità (CQ): Ensuring compliance with international standards often requires rigorous QC processes, which can add to the overall cost. Certifications such as ISO can enhance credibility but may also increase expenses.

-

Logistica: Transportation costs vary widely based on distance, shipping method, and volume. Bulk purchasing can reduce per-unit logistics costs, making it an attractive option for international buyers.

-

Margine: Suppliers typically add a markup to cover their operational costs and profit. Understanding the margin expectations can help buyers negotiate more effectively.

What Price Influencers Should B2B Buyers Consider for Bottled Water?

Several factors influence the pricing of bottled water, particularly for international buyers.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders typically result in lower per-unit costs. Buyers should consider their storage capabilities and demand forecasts when negotiating MOQs.

-

Specifiche e personalizzazione: Custom bottle sizes, designs, and labeling can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materiali e qualità: The choice of materials (e.g., recycled plastic vs. virgin plastic) and the quality of water (spring, purified, or mineral) affect pricing. Higher quality often commands a premium.

-

Fattori di fornitura: Different suppliers may offer varying prices based on their production capabilities, market position, and geographic location. Building relationships with multiple suppliers can provide leverage in negotiations.

-

Incoterms: Understanding international commercial terms (Incoterms) is crucial for determining who bears shipping costs and risks. This knowledge can help buyers manage total costs effectively.

What Negotiation Tips Can Help Buyers Optimize Costs?

B2B buyers can implement several strategies to enhance cost efficiency when sourcing bottled water:

-

Leverage Volume Discounts: Buyers should explore bulk purchasing agreements to reduce per-unit costs. Suppliers often provide better pricing for larger orders, making it essential to assess long-term needs accurately.

-

Explore Alternative Suppliers: Conducting market research to identify multiple suppliers can foster competition, resulting in better pricing and terms.

-

Valutare il costo totale di proprietà (TCO): Beyond the purchase price, TCO includes logistics, storage, and potential wastage costs. Analyzing these factors can reveal more cost-efficient options.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns. Buyers should negotiate favorable terms that align with their financial strategy.

-

Comprendere le sfumature dei prezzi per i mercati internazionali: Each region may have unique factors influencing water bottle pricing, such as tariffs, taxes, and local competition. Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of these nuances to make informed decisions.

What Should Buyers Keep in Mind Regarding Pricing and Costs?

It is important to note that pricing can fluctuate based on market conditions, seasonal demand, and raw material costs. Buyers should remain vigilant and flexible to adapt to these changes. Engaging in continuous communication with suppliers can help in anticipating price adjustments and securing better deals.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies can empower B2B buyers to make informed decisions in sourcing bottled water.

Alternatives Analysis: Comparing one bottle of water oz With Other Solutions

In the global marketplace, B2B buyers are continually faced with choices that can impact their operational efficiency and sustainability. One common product is bottled water, which comes in various sizes and serves different hydration needs. However, as businesses assess their options, it’s essential to consider alternative solutions that might offer similar benefits, often with added advantages. This analysis compares a standard water bottle holding a specific number of ounces against two alternative hydration solutions.

| Aspetto di confronto | One Bottle Of Water Oz | Reusable Water Bottle | Water Dispenser with 5-Gallon Jugs |

|---|---|---|---|

| Prestazioni | Provides a single-use, convenient hydration solution. | Offers a customizable hydration solution with varying capacities. | Delivers high volume water supply, ideal for larger groups. |

| Costo | Generally low cost per bottle; cumulative costs can add up. | Higher initial cost, but lower long-term expense. | Moderate cost; requires ongoing purchase of 5-gallon jugs. |

| Facilità di implementazione | Easy to purchase and distribute, but creates waste. | Requires an initial investment and habit change. | Installation needed; requires regular maintenance. |

| Manutenzione | Minimal maintenance; single-use. | Regular cleaning needed; can be durable with proper care. | Requires regular jug replacement and occasional cleaning. |

| Il miglior caso d'uso | Ideal for events, travel, or individual use. | Suitable for office environments, gyms, or personal use. | Best for workplaces, schools, and events with many users. |

Analisi approfondita delle alternative

Reusable Water Bottle

Reusable water bottles present a sustainable alternative to single-use bottled water. They come in various sizes and materials, allowing users to choose based on their needs. The initial investment may be higher than purchasing single-use bottles, but the long-term cost savings are significant. Additionally, businesses can customize these bottles with their branding, promoting their brand while encouraging hydration. However, they require regular cleaning and maintenance to ensure hygiene.

Water Dispenser with 5-Gallon Jugs

Water dispensers utilizing 5-gallon jugs are another viable alternative, particularly suited for environments with high water consumption, such as offices or schools. This solution provides a steady supply of water and reduces plastic waste compared to single-use bottles. While the upfront cost of the dispenser and initial jugs can be moderate, the ongoing expense involves purchasing new jugs regularly. Maintenance includes ensuring the dispenser is clean and functional, making it a commitment for businesses. This option is particularly beneficial for catering to larger groups or during events.

Conclusione: Scegliere la soluzione giusta per le proprie esigenze aziendali

When selecting the best hydration solution, B2B buyers should consider their specific operational requirements, budget constraints, and sustainability goals. A single bottle of water may suffice for events or travel, but for ongoing hydration needs, alternatives like reusable bottles or water dispensers can provide more sustainable and cost-effective solutions. Assessing factors such as performance, ease of implementation, and maintenance will help businesses make informed decisions that align with their values and operational strategies.

Essential Technical Properties and Trade Terminology for one bottle of water oz

What Are the Key Technical Properties of a Water Bottle Measured in Ounces?

Understanding the technical specifications of water bottles is essential for B2B buyers, especially when considering factors like shipment, storage, and consumer preferences. Here are some critical specifications to consider:

-

Grado del materiale

Water bottles are typically made from various materials, including PET (polyethylene terephthalate), HDPE (high-density polyethylene), and glass. PET is the most common for single-use bottles due to its lightweight nature and recyclability. HDPE offers greater durability and is often used for larger containers. Understanding the material grade helps buyers assess the bottle’s environmental impact and suitability for their target market. -

Volume Capacità

The volume capacity, measured in ounces, is a crucial factor that dictates consumer usage patterns. Common sizes include 8 oz, 12 oz, 16.9 oz, and larger formats like 1 liter (33.8 oz). The choice of bottle size affects hydration strategies for various demographics, such as athletes needing larger bottles or families preferring smaller sizes for children. Buyers should consider regional preferences and market demands when selecting bottle sizes. -

Label Size and Customization Options

The label size varies by bottle size and is critical for branding. For instance, a 16.9 oz bottle may have a label size of approximately 7.75″ by 2.25″. Customization options, including material and print quality, influence marketing effectiveness. Understanding these specifications allows businesses to align their branding with consumer expectations. -

Packaging and Shipping Dimensions

Packaging plays a vital role in logistics. For example, a case of 24 bottles might measure 16″ long by 11″ wide by 9″ high and weigh 30 lbs. Knowing the packaging dimensions is essential for calculating shipping costs, optimizing warehouse storage, and ensuring compliance with international shipping regulations. Efficient packing can significantly reduce transportation expenses. -

Stackability and Palletization

The ability to stack bottles effectively on pallets is crucial for shipping efficiency. For instance, a standard pallet can hold up to 120 cases of 8 oz bottles. Understanding stackability helps buyers maximize shipping loads, reduce costs, and optimize storage space.

What Are Common Trade Terminology and Jargon in the Water Bottle Industry?

Familiarity with industry terminology is vital for B2B buyers to navigate contracts, negotiations, and logistics effectively. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the water bottle industry, buyers often work with OEMs to create custom bottle designs or packaging that meet specific market demands. -

MOQ (quantità minima d'ordine)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs to ensure they are not over-committing to stock that may not move quickly. -

RFQ (Richiesta di offerta)

An RFQ is a document that buyers send to suppliers to request pricing information for specific products or services. This process helps buyers compare costs and understand pricing structures, which is essential for making informed purchasing decisions. -

Incoterms (Termini commerciali internazionali)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) specify who is responsible for shipping costs, insurance, and risk during transportation. Understanding these terms is critical for managing logistics and cost expectations. -

Tempi di consegna

Lead time refers to the duration it takes from placing an order to receiving the product. This timeframe can vary significantly depending on the supplier’s location and production capabilities. Buyers should factor in lead times when planning inventory levels and customer deliveries.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions, ensuring that they select the right products for their markets while optimizing logistics and cost efficiency.

Navigating Market Dynamics and Sourcing Trends in the one bottle of water oz Sector

What Are the Key Market Dynamics and Trends Affecting the One Bottle of Water Oz Sector?

The global bottled water market has seen a steady rise, driven by increasing health consciousness among consumers and the growing demand for convenient hydration solutions. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed purchasing decisions. The market is witnessing a shift towards smaller bottle sizes, such as the 8oz and 10oz options, which cater to on-the-go consumers and families. Moreover, the standard 16.9oz bottle remains a staple due to its balance of portability and volume, making it ideal for various applications, from retail to corporate events.

Emerging technologies are reshaping sourcing strategies. Innovations in packaging, such as lightweight materials and eco-friendly designs, are becoming increasingly popular. Suppliers are now leveraging data analytics to optimize inventory management and streamline logistics, reducing lead times for international orders. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers across different regions, making it simpler for buyers to compare prices and product specifications.

B2B buyers should also be aware of regional market preferences. For instance, in Saudi Arabia and Brazil, cultural factors influence bottle size preferences and branding strategies. Understanding these nuances can help businesses tailor their offerings to meet local demands effectively.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the One Bottle of Water Oz Market?

Sustainability is no longer just a buzzword; it has become a critical consideration for B2B buyers in the bottled water sector. The environmental impact of plastic waste is prompting companies to seek suppliers who prioritize ethical sourcing and sustainable practices. This includes using biodegradable materials and implementing recycling programs. For instance, companies that offer bottles made from recycled plastics or plant-based materials are gaining traction among environmentally conscious buyers.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices, ensuring that they comply with environmental regulations and labor standards. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. Partnering with brands that prioritize these certifications not only enhances a company’s reputation but also aligns with the growing consumer demand for responsible business practices.

As global regulations around single-use plastics tighten, it is crucial for B2B buyers to stay informed about the latest developments in sustainability standards. By choosing suppliers that invest in sustainable technologies and materials, companies can mitigate risks associated with compliance and enhance their market positioning.

What Is the Historical Context of the One Bottle of Water Oz Sector That Matters for B2B Buyers?

The bottled water industry has evolved significantly since its inception. Initially, bottled water was perceived as a luxury item, primarily consumed by the affluent. However, the late 20th century saw a paradigm shift as health trends began to favor bottled water over sugary beverages. The introduction of convenient packaging sizes, including the standard 16.9oz bottle, made hydration accessible to a broader audience.

In the early 2000s, environmental concerns began to surface, leading to increased scrutiny of plastic waste and its impact on the planet. This prompted a wave of innovation focused on sustainability, influencing not only consumer preferences but also sourcing strategies for B2B buyers. Today, understanding the historical trajectory of the one bottle of water oz sector is essential for navigating current market trends and anticipating future shifts, particularly in a landscape that increasingly values sustainability and ethical sourcing.

By leveraging insights from this historical context, B2B buyers can make strategic decisions that align with both market demands and their own corporate responsibility goals.

Frequently Asked Questions (FAQs) for B2B Buyers of one bottle of water oz

-

How do I determine the right water bottle size for my business needs?

Choosing the right water bottle size depends on your target market and usage context. For events or corporate gifting, smaller bottles (8-12 oz) can be effective for portability, while larger bottles (16.9 oz or more) are ideal for hydration stations or sports events. Evaluate the preferences of your customers and the occasions where the bottles will be used. Additionally, consider environmental factors; larger bottles can reduce plastic waste and appeal to sustainability-focused consumers. -

What is the most popular water bottle size for international markets?

The standard 16.9 oz (500 mL) bottle is widely recognized and preferred in international markets due to its balance of convenience and hydration capacity. This size is commonly used in retail and vending machines, making it easily accessible to consumers. However, specific regions may have preferences for different sizes; for example, 1-liter bottles are popular in Europe, while smaller sizes may appeal to markets in Africa and South America. Understanding local market trends is crucial when sourcing products. -

What customization options are available for water bottles?

Most suppliers offer extensive customization options, including label design, bottle color, and even the material used. Custom labels can enhance brand visibility, especially when the bottles are used at events or in public settings. Additionally, some manufacturers provide options for eco-friendly materials, which can resonate well with environmentally-conscious buyers. Discuss your branding needs with suppliers to explore the best options for your business. -

What are the minimum order quantities (MOQ) for water bottles?

Minimum order quantities can vary significantly based on the supplier and the type of bottle. Typically, smaller bottles may have a MOQ of 24 or 48 units per case, while larger bottles might require orders of 100 units or more. It’s advisable to negotiate MOQs with suppliers, especially if you are testing a new market or product line. Some suppliers may offer flexibility in MOQs for repeat customers or larger contracts. -

How should I vet suppliers for international water bottle sourcing?

When sourcing internationally, it’s vital to conduct thorough due diligence on potential suppliers. Check their certifications, production capabilities, and customer reviews. Request samples to assess quality and ensure they meet your standards. Additionally, verify their compliance with international trade regulations and quality assurance processes. Networking with other businesses in your region can also provide insights into reliable suppliers. -

What payment terms are common for B2B water bottle purchases?

Payment terms can vary widely among suppliers, but common options include upfront payments, partial deposits, and payment upon delivery. Letters of credit are often used for larger transactions, providing security for both parties. It’s essential to establish clear payment terms upfront to avoid misunderstandings. Consider your cash flow and negotiate terms that align with your business needs while ensuring the supplier’s requirements are also met. -

What quality assurance measures should I expect from water bottle suppliers?

Reputable suppliers should implement strict quality assurance protocols, including testing for material safety, durability, and compliance with local health regulations. Ask about their quality control processes, such as inspections during production and before shipping. Request documentation for certifications like ISO or FDA approvals, which can provide peace of mind regarding the product’s safety and quality standards. -

What logistics considerations should I keep in mind when importing water bottles?

Logistics plays a crucial role in international sourcing. Consider shipping costs, delivery timelines, and customs clearance processes. Partner with a freight forwarder experienced in handling food and beverage products to navigate these complexities. Ensure that your supplier is familiar with the export regulations of their country and that you have all necessary documentation ready to avoid delays. Planning for potential disruptions in the supply chain will also help maintain a steady inventory.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo fatto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Top 7 One Bottle Of Water Oz Manufacturers & Suppliers List

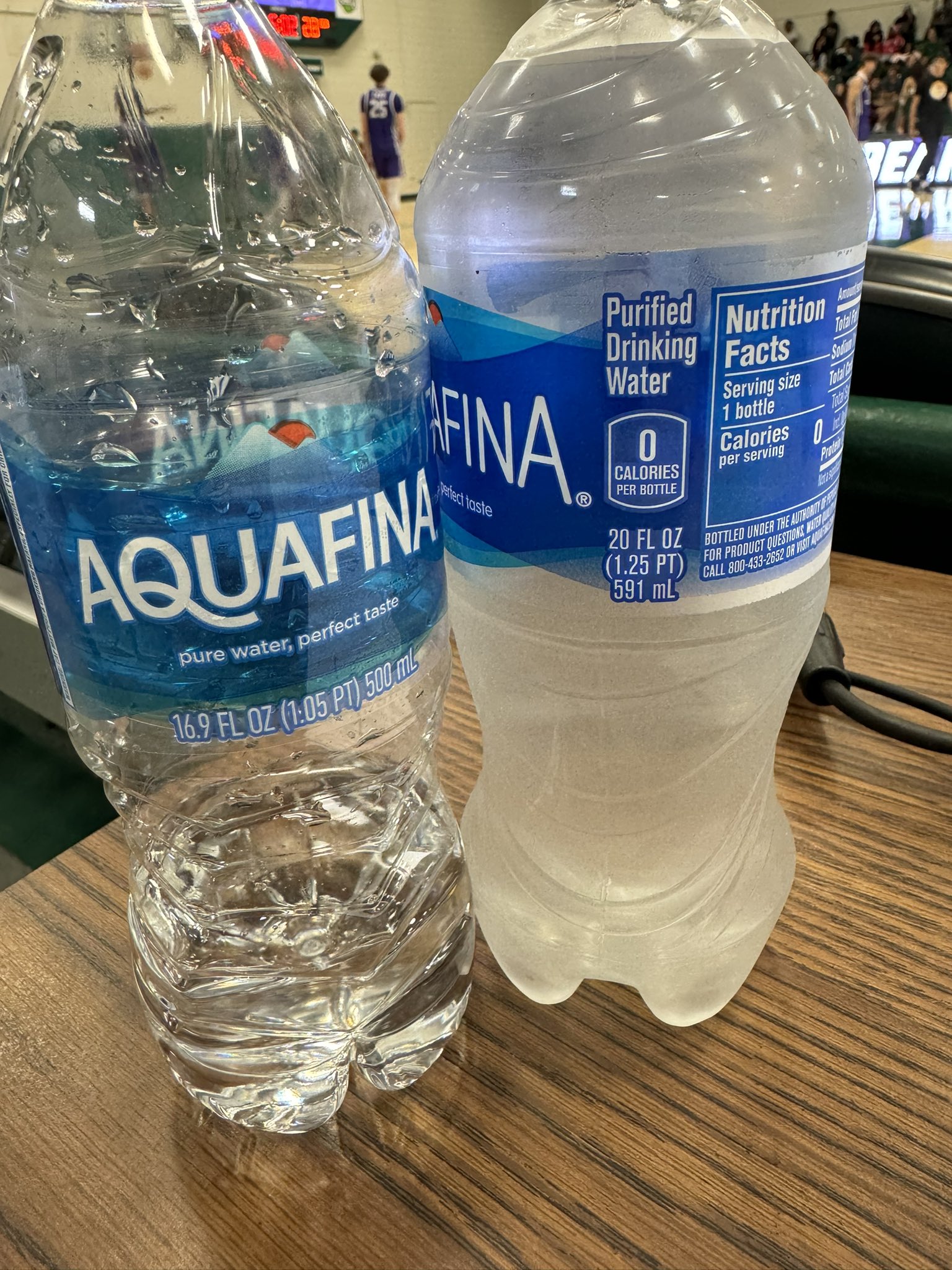

1. Bottle Your Brand – 8oz Water Bottle

Dominio: bottleyourbrand.com

Registrato: 2004 (21 anni)

Introduzione: {“8oz_Water_Bottle”:{“capacity”:”8 fluid ounces”,”dimensions”:{“height”:”5 inches”,”diameter”:”2.25 inches”},”label_size”:{“length”:”6.375 inches”,”height”:”2.25 inches”},”label_material”:”high gloss vinyl”,”sold_in”:”multiples of 48 bottles”,”case_size”:{“length”:”16.75 inches”,”width”:”10.25 inches”,”height”:”10.75 inches”},”weight”:”30 lbs per box”,”pallet_capacity”:”120 cases”},”10oz_Water_Bot…

2. Dual Drinks – Portable Plastic Water Bottles

Dominio: dualdrinks.com

Registrazione: 2023 (2 anni)

Introduzione: The standard size for single-use plastic water bottles is 16.9 fluid ounces (500 milliliters), which is portable and easy to store. Other sizes range from 8 ounces to 1.5 liters (50.7 ounces), catering to various needs. Smaller bottles (8-12 ounces) are ideal for short outings and children, while larger bottles (1-liter and 1.5-liter) are suited for long durations and sharing. A gallon contains 12…

3. Owala – 40 oz FreeSip Water Bottle

Dominio: owalalife.com

Registrazione: 2019 (6 anni)

Introduzione: Owala’s 40 oz FreeSip water bottle is priced at $37.99. It is designed for convenience, allowing users to drink more water without frequent refills. The bottle is eco-friendly and budget-savvy, as it helps reduce the cost associated with single-use bottles. The average price of a 16.9 oz water bottle in the US is around $0.87, leading to a daily cost of approximately $6.525, a weekly cost of $45.6…

4. ScrapingDog – Instagram Scraping Services

Dominio: instagram.com

Registrato: 2004 (21 anni)

Introduzione: Contact us at info@scrapingdog.com for scraping Instagram. Let us know how many pages you want to scrape per month.

5. SIP Vessel – Water Bottle Sizes

Dominio: sipvessel.com

Registered: 2025 (0 years)

Introduzione: Standard water bottles typically contain 16.9 ounces (500 milliliters). Smaller bottles can hold 8 ounces, while larger ones can go up to 33.8 ounces (1 liter). Common sizes include: 8 oz (small bottle), 12 oz (mini bottles or flavored water), 16.9 oz (standard bottle), 20 oz (sports bottles), and 33.8 oz (heavy hydration). Popular brands like Dasani, Fiji, and Nestlé Pure Life usually sell their …

6. CueMath – Gallon Conversion Guide

Dominio: cuemath.com

Registrato: 2011 (14 anni)

Introduzione: 8 bottles of 16 oz are required to make one gallon. 1 oz equals 0.0078125 Gallons, therefore 16 oz equals 0.125 Gallons.

7. HydroJug – Large Water Bottles for Optimal Hydration

Dominio: thehydrojug.com

Registrato: 2016 (9 anni)

Introduzione: HydroJug offers larger water bottles designed to help users stay hydrated throughout the day. The product range includes: Traveler (20oz, 32oz, 40oz), Sport (14oz, 20oz, 32oz, 40oz), and a Sport Jug (64oz). These bottles are effective for meeting daily water intake requirements, which range from half a gallon to a gallon, depending on individual needs.

Strategic Sourcing Conclusion and Outlook for one bottle of water oz

In the competitive landscape of bottled water sourcing, understanding the various sizes and their implications for logistics, branding, and consumer preferences is crucial. The most common sizes, such as 8 oz, 12 oz, and 16.9 oz, each serve distinct markets, from children to athletes, and influence purchasing decisions based on convenience and hydration needs. Strategic sourcing allows B2B buyers to optimize their supply chains, ensuring they meet local demands efficiently while minimizing costs associated with shipping and packaging.

Furthermore, as global trends shift towards sustainability, selecting the right bottle size can significantly impact environmental footprints. Smaller bottles may cater to immediate needs but can lead to increased plastic waste, while larger containers promote fewer purchases and reduce packaging waste.

As you consider your next sourcing decision, leverage this knowledge to enhance your product offerings and align with market expectations. Engage with suppliers who prioritize quality, sustainability, and cost-effectiveness to ensure your bottled water brand stands out in the international market. Embrace the future of hydration by making informed choices that resonate with consumers across Africa, South America, the Middle East, and Europe.