Introduction: Navigating the Global Market for large blender bottle

In today’s fast-paced global market, sourcing high-quality large blender bottles presents a unique challenge for B2B buyers, particularly those catering to the health and fitness sector. As the demand for versatile and durable shaker bottles grows, businesses must navigate a myriad of options that promise performance, safety, and style. This comprehensive guide explores the various types of large blender bottles available, their applications across diverse markets, and essential supplier vetting processes. Additionally, it delves into cost considerations, ensuring that buyers make informed decisions that align with their budget and quality expectations.

With a focus on international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—this guide equips decision-makers with the insights needed to select the best products for their unique markets. By understanding the key features and benefits of large blender bottles, businesses can enhance their offerings and meet the growing consumer demand for reliable, high-performance products.

Empowering buyers with actionable knowledge, this guide serves as a vital resource for those seeking to establish or expand their presence in the competitive landscape of health and fitness accessories. Through careful analysis and expert recommendations, readers will gain the confidence to make strategic purchasing decisions that drive growth and customer satisfaction in their respective markets.

Navigazione tra gli articoli

- Top 7 Large Blender Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for large blender bottle

- Understanding large blender bottle Types and Variations

- Key Industrial Applications of large blender bottle

- 3 Common User Pain Points for ‘large blender bottle’ & Their Solutions

- Strategic Material Selection Guide for large blender bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for large blender bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘large blender bottle’

- Comprehensive Cost and Pricing Analysis for large blender bottle Sourcing

- Alternatives Analysis: Comparing large blender bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for large blender bottle

- Navigating Market Dynamics and Sourcing Trends in the large blender bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of large blender bottle

- Disclaimer importante e condizioni d'uso

- Strategic Sourcing Conclusion and Outlook for large blender bottle

Understanding large blender bottle Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Classic™ Shaker Bottle | Rounded base, BlenderBall® whisk, measurement markings, BPA-free | Fitness centers, health clubs, retail stores | Pro: Affordable, durable, versatile. Contro: Limited insulation options. |

| Pro Series Shaker Bottle | Lockable lid, odor-resistant, enhanced mixing capabilities | Gyms, personal trainers, nutritionists | Pro: High-quality materials, leak-proof. Contro: Prezzo più alto. |

| Insulated Stainless Sport | Double-wall insulation, keeps drinks cold, stainless steel design | Outdoor events, sports teams, fitness events | Pro: Excellent temperature retention, durable. Contro: Heavier than plastic options. |

| Tritan Sport Bottle | Odor-resistant, lightweight, various color options | Corporate wellness programs, promotional items | Pro: Leggero, personalizzabile. Contro: Less durable than stainless steel. |

| Bicchiere shaker 2 in 1 | Combines shaker and tumbler functionalities, stylish design | Cafés, smoothie bars, meal prep businesses | Pro: Versatile use, appealing design. Contro: May not mix as effectively as traditional shakers. |

What are the Characteristics of the Classic™ Shaker Bottle?

The Classic™ Shaker Bottle is designed for everyday use, featuring a rounded base that prevents powder from settling at the bottom, ensuring smooth mixing. It is available in various sizes and colors, making it an attractive option for fitness enthusiasts. For B2B buyers, its affordability and durability make it an ideal choice for bulk purchases for gyms and health clubs. However, its lack of insulation may be a consideration for those needing temperature control.

How Does the Pro Series Shaker Bottle Stand Out?

The Pro Series Shaker Bottle is distinguished by its lockable lid and odor-resistant materials, ensuring a high-quality mixing experience. With enhanced mixing capabilities, it’s particularly suited for personal trainers and nutritionists who require reliable equipment for their clients. While it comes at a higher price point, the quality and features justify the investment for businesses focused on premium offerings.

Why Choose the Insulated Stainless Sport Bottle?

The Insulated Stainless Sport Bottle is perfect for outdoor and sports events, featuring double-wall insulation that keeps beverages cold for extended periods. Its stainless steel design offers durability, making it a preferred choice for sports teams and fitness events. While it may be heavier than plastic alternatives, its ability to maintain temperature makes it a valuable asset for buyers looking to provide a premium hydration solution.

What Benefits Does the Tritan Sport Bottle Offer?

The Tritan Sport Bottle is lightweight and customizable, appealing to corporate wellness programs and promotional item distributors. Its odor-resistant properties and variety of colors make it an attractive choice for branding and marketing purposes. However, while it offers versatility, it may not withstand heavy-duty use compared to stainless steel options, which should be considered by B2B buyers.

How Does the 2-in-1 Shaker Tumbler Function?

The 2-in-1 Shaker Tumbler combines the functionality of a shaker with that of a tumbler, catering to cafés and smoothie bars. Its stylish design enhances customer appeal, making it suitable for meal prep businesses that want to offer both convenience and aesthetics. However, it may not mix as effectively as traditional shakers, which is an important consideration for businesses prioritizing performance.

Key Industrial Applications of large blender bottle

| Industria/Settore | Specific Application of Large Blender Bottle | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Fitness e benessere | Protein and Nutritional Supplement Mixing | Enhances customer experience by providing effective mixing for protein shakes, smoothies, and meal replacements. | Material quality (BPA-free), size options (20oz to 45oz), and design features like leak-proof lids. |

| Cibo e bevande | Beverage Preparation for Events and Catering | Ensures consistent mixing of beverages, aiding in the creation of uniform products for large gatherings. | Durability for repeated use, ease of cleaning, and capacity to handle large volumes. |

| Ospitalità e turismo | Servizi per gli ospiti in hotel e resort | Provides guests with convenient options for protein shakes or smoothies, enhancing their stay experience. | Aesthetic appeal, branding opportunities, and bulk purchasing options. |

| Squadre sportive | Pre- and Post-Workout Nutrition | Facilitates quick and effective preparation of nutritional drinks for athletes, promoting performance and recovery. | Robust construction, ease of transport, and personalized branding for team merchandise. |

| Education and Training | Nutritional Education Programs in Schools | Supports health initiatives by allowing students to prepare healthy drinks easily, promoting better nutrition. | Compliance with health standards, educational branding, and affordability for bulk orders. |

In the fitness and wellness industry, large blender bottles are essential for mixing protein powders and nutritional supplements. They provide a convenient solution for fitness enthusiasts who require quick and efficient preparation of their shakes. Buyers in this sector should prioritize BPA-free materials, various size options, and features like leak-proof lids to ensure a reliable product.

In the food and beverage sector, large blender bottles play a significant role in beverage preparation for events and catering services. They enable consistent mixing of drinks, ensuring uniformity in flavor and quality for large gatherings. Businesses should consider the durability of the bottles for repeated use, ease of cleaning, and capacity to handle larger volumes to meet their operational needs.

For the hospitality and tourism industry, large blender bottles serve as valuable guest amenities in hotels and resorts. They allow guests to conveniently prepare protein shakes or smoothies during their stay, enhancing their overall experience. Key sourcing considerations include the aesthetic appeal of the bottles, branding opportunities for hotels, and the potential for bulk purchasing to accommodate various guest needs.

In the context of sports teams, large blender bottles are instrumental for pre- and post-workout nutrition. They facilitate quick preparation of nutritional drinks, which is vital for athletes looking to optimize performance and recovery. Buyers in this sector should focus on robust construction to withstand rigorous use, ease of transport, and opportunities for personalized branding to promote team identity.

Finally, in education and training, large blender bottles can support nutritional education programs in schools. They allow students to easily prepare healthy drinks, fostering better nutrition habits. Compliance with health standards is crucial for sourcing, along with considerations for educational branding and affordability for bulk orders to ensure accessibility for all students.

3 Common User Pain Points for ‘large blender bottle’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Mix Quality

Il problema: B2B buyers in the fitness and health sectors often encounter issues with the mixing quality of large blender bottles. When purchasing in bulk, the variability in the mixing performance can lead to dissatisfaction among end-users, such as gym-goers and health-conscious consumers. Bottles with poor mixing capabilities can leave clumps of protein powder or other ingredients stuck at the bottom or sides, leading to inconsistent product experiences. This not only affects user satisfaction but can also harm the reputation of the retailer or distributor.

La soluzione: To ensure consistent mixing performance, buyers should prioritize sourcing large blender bottles that feature a rounded base and a robust mixing system, such as the BlenderBall® whisk. When placing bulk orders, specify these features in your procurement process and request samples to evaluate their effectiveness. Additionally, consider investing in insulated options that maintain the temperature of liquids, as this can enhance the mixing process when combined with cold ingredients. Educating end-users on the importance of adding liquids before powders can also improve mixing results and enhance customer satisfaction.

Scenario 2: Concerns Over Hygiene and Cleanliness

Il problema: Hygiene is a significant concern for B2B buyers, especially those supplying products to health clubs, gyms, and wellness centers. Many large blender bottles can become breeding grounds for bacteria if not properly designed for cleanliness. Customers may express concerns over the safety of drinking from bottles that can be difficult to clean, leading to potential health risks and decreased consumer trust.

La soluzione: Buyers should look for large blender bottles that incorporate hygiene-focused features, such as SpoutGuard™ lids that prevent contact with dirty hands and easy-to-clean designs. When negotiating with suppliers, request information on the materials used, ensuring they are BPA-free and dishwasher safe. Additionally, consider including education on proper cleaning methods as part of your customer support strategy. Offering promotional materials that highlight the importance of hygiene can also reassure end-users about their purchase, reinforcing brand loyalty and trust.

Scenario 3: Sizing and Portability Issues for Diverse Markets

Il problema: International buyers often face challenges related to the sizing and portability of large blender bottles. Different markets may have varying preferences for bottle sizes and designs, influenced by cultural and lifestyle factors. A one-size-fits-all approach can lead to inventory issues and decreased sales if the products do not resonate with local customers.

La soluzione: To address this pain point, buyers should conduct market research to understand the preferences and needs of their target demographics. Consider sourcing a range of sizes, from 20oz to 45oz, allowing flexibility based on consumer demand. Additionally, prioritize bottles with ergonomic designs, such as adjustable carry loops, that enhance portability for users on the go. Engage with local distributors to gain insights into preferred bottle specifications and incorporate their feedback into your product selection process. By offering a variety of sizes and designs tailored to local preferences, you can improve customer satisfaction and increase market penetration.

Strategic Material Selection Guide for large blender bottle

What are the Key Properties of Common Materials Used in Large Blender Bottles?

When selecting materials for large blender bottles, several options are prevalent in the market. Each material offers unique properties that can significantly impact product performance, durability, and user satisfaction. Here, we analyze four common materials: plastic (Tritan), stainless steel, glass, and aluminum.

How Does Tritan Plastic Perform for Large Blender Bottles?

Tritan plastic is a copolyester known for its clarity, toughness, and resistance to impact and heat. It is BPA-free, making it a popular choice for health-conscious consumers. Tritan can withstand temperatures up to 100°C (212°F) and has good chemical resistance, which is essential for compatibility with various protein powders and supplements.

Pro: Tritan is lightweight, shatter-resistant, and cost-effective, making it suitable for mass production. Its transparency allows for easy monitoring of contents, enhancing user convenience.

Contro: While Tritan is durable, it may scratch over time and can retain odors from strong-flavored liquids. Additionally, its long-term exposure to high heat can lead to degradation.

Impatto sull'applicazione: Tritan is ideal for protein shakes and smoothies, but it may not be suitable for hot liquids or prolonged exposure to extreme temperatures.

Considerazioni per gli acquirenti internazionali: Buyers from regions like Africa or South America should ensure compliance with local food safety regulations. Tritan is widely accepted in many markets, but it’s essential to verify certifications like FDA or EU food contact compliance.

What Advantages Does Stainless Steel Offer for Large Blender Bottles?

Stainless steel is renowned for its durability, corrosion resistance, and ability to maintain temperature. It can withstand high pressures and temperatures, making it suitable for both hot and cold beverages. Stainless steel bottles often come with double-wall insulation, which can keep drinks cold for hours.

Pro: Stainless steel is highly durable, resistant to rust and corrosion, and does not retain flavors or odors. It is also recyclable, appealing to environmentally conscious consumers.

Contro: The primary drawback is the higher cost compared to plastic options. Additionally, stainless steel bottles can be heavier, which may not appeal to all consumers.

Impatto sull'applicazione: Perfect for both protein shakes and hot beverages, stainless steel bottles are versatile and can cater to a broader audience.

Considerazioni per gli acquirenti internazionali: Buyers in Europe and the Middle East should ensure compliance with ASTM and DIN standards for food safety. Stainless steel is generally well-regarded globally, but specific certifications may vary by region.

What Role Does Glass Play in Large Blender Bottle Production?

Glass is another material used for blender bottles, appreciated for its non-reactive nature and aesthetic appeal. It does not leach chemicals, making it a safe option for health-conscious consumers. Glass can withstand high temperatures, making it suitable for hot beverages.

Pro: Glass is durable, easy to clean, and does not retain flavors or odors. It is also fully recyclable, which enhances its appeal to environmentally conscious buyers.

Contro: The primary limitation is its weight and fragility, making it less suitable for on-the-go use. It can break easily if dropped, which poses a risk for consumers.

Impatto sull'applicazione: Glass is suitable for smoothies and protein shakes but may not be ideal for high-impact environments like gyms.

Considerazioni per gli acquirenti internazionali: Buyers should check for compliance with local safety standards, as glass may be subject to stricter regulations in some regions.

How Does Aluminum Compare for Large Blender Bottles?

Aluminum is lightweight and can be treated for insulation, making it a popular choice for portable bottles. It is often coated to prevent reactions with acidic beverages, ensuring safety and flavor integrity.

Pro: Aluminum is lightweight, durable, and can be produced in various colors and designs, appealing to a broad consumer base. It also offers good thermal insulation when treated properly.

Contro: Aluminum bottles can dent easily and may require additional coatings to prevent corrosion. They are also not suitable for hot liquids unless specifically designed for that purpose.

Impatto sull'applicazione: Aluminum is ideal for cold beverages and protein shakes but may not be suitable for hot drinks unless insulated.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with international standards like JIS for food safety. Aluminum is widely accepted but may need specific certifications depending on the region.

Summary Table of Material Selection for Large Blender Bottles

| Materiale | Typical Use Case for Large Blender Bottle | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica Tritan | Protein shakes, smoothies | Lightweight and shatter-resistant | Scratches easily, retains odors | Basso |

| Acciaio inox | Bevande calde e fredde | Durable and corrosion-resistant | Costo più elevato, peso maggiore | Alto |

| Vetro | Smoothies, protein shakes | Non-reactive, easy to clean | Fragile, pesante | Medio |

| Alluminio | Cold beverages, protein shakes | Lightweight and customizable | Dents easily, may require coatings | Medio |

In-depth Look: Manufacturing Processes and Quality Assurance for large blender bottle

What Are the Key Stages in the Manufacturing Process of Large Blender Bottles?

The manufacturing process for large blender bottles involves several critical stages, each designed to ensure that the final product meets the quality and functionality expected by consumers.

Preparazione del materiale

The first step in manufacturing large blender bottles is material preparation. High-quality, food-grade materials such as BPA-free plastic (commonly Tritan or polyethylene) or stainless steel are selected. Suppliers of these materials must adhere to specific health and safety regulations, ensuring they are suitable for food contact. Material testing is often conducted to verify that it meets international safety standards, such as FDA regulations in the United States or EU food safety regulations in Europe.

Tecniche di formatura

Once the materials are prepared, the next stage involves forming the bottle components. This can be achieved through various techniques, including injection molding for plastic bottles or stamping for stainless steel. Injection molding allows for precise control over the bottle’s shape and thickness, which is crucial for maintaining structural integrity and ensuring a leak-proof design. For stainless steel bottles, techniques such as deep drawing or hydroforming are used to create seamless designs, which further enhance durability and insulation properties.

Assembly of Components

After forming, the different components of the blender bottle—such as the body, lid, and mixing mechanism—are assembled. This step may involve manual labor as well as automated processes, depending on the scale of production. Key features, such as the BlenderBall® wire whisk, are integrated during this stage. Quality assurance measures are implemented to check the fit and function of each component, ensuring that they work together seamlessly.

Finishing Processes

The final stage of manufacturing involves various finishing processes, which may include surface treatments, printing, and packaging. For plastic bottles, additional steps like UV coating or texturing can enhance grip and aesthetics. For stainless steel models, polishing and powder coating may be applied to improve appearance and resistance to corrosion. Quality checks at this stage ensure that the bottles meet aesthetic and functional standards.

How Is Quality Assurance Implemented in Large Blender Bottle Production?

Quality assurance (QA) is a critical aspect of the manufacturing process for large blender bottles. It ensures that the final products not only meet consumer expectations but also comply with international standards.

What International Standards Are Relevant for Quality Assurance?

To maintain high standards, manufacturers often comply with international quality management standards such as ISO 9001. This standard outlines criteria for an effective quality management system, emphasizing continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) certification for certain materials may also apply.

Quali sono i principali punti di controllo della qualità?

Quality control (QC) checkpoints are established throughout the manufacturing process to monitor quality at various stages:

-

Controllo qualità in entrata (CQI): This initial checkpoint assesses the quality of raw materials upon delivery. Suppliers are often required to provide certificates of compliance to verify that materials meet specified standards.

-

Controllo di qualità in corso d'opera (IPQC): During the manufacturing process, regular inspections are conducted to ensure that production adheres to established specifications. This may include monitoring temperature and pressure during molding or checking tolerances during assembly.

-

Controllo finale della qualità (CQC): Once the products are assembled, final inspections are conducted to verify that each bottle meets functional and aesthetic requirements. This may include leak tests, durability tests, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should conduct thorough due diligence to verify the quality control measures of their suppliers. Here are some actionable steps:

Conducting Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices. Audits can be conducted either by the buyer or by third-party inspection agencies. During these audits, buyers should assess the supplier’s adherence to international standards, examine their quality management systems, and review records of past quality issues.

Requesting Quality Assurance Reports

Buyers can request detailed quality assurance reports that outline the supplier’s QC processes, including records of IQC, IPQC, and FQC. These reports should also detail any corrective actions taken in response to past quality issues, demonstrating the supplier’s commitment to continuous improvement.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can further validate the supplier’s claims about their quality control processes. These services can provide unbiased assessments and reports on the quality of the products being produced, ensuring that they meet the buyer’s specifications before shipment.

Quali sono le sfumature del controllo qualità per gli acquirenti internazionali B2B?

International B2B buyers must be aware of specific quality control nuances that may vary by region. For example:

-

Conformità normativa: Different countries have varying regulatory requirements for food contact materials. Buyers must ensure that their suppliers comply with local regulations, which may include specific certifications for materials used in the manufacturing of large blender bottles.

-

Cultural Expectations: Quality expectations can differ significantly across regions. For instance, buyers from Europe may prioritize eco-friendly materials and designs, while those from Africa may focus more on durability and cost-effectiveness.

-

Shipping and Handling Standards: The quality of products can be affected during shipping. Buyers should discuss packaging standards with suppliers to ensure that products are protected during transport, which can be crucial for maintaining quality upon arrival.

By understanding the manufacturing processes and quality assurance protocols involved in the production of large blender bottles, B2B buyers can make informed decisions when sourcing products from international suppliers. This knowledge not only helps in selecting reliable partners but also ensures that the products meet the high standards required in diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘large blender bottle’

Introduzione

When sourcing large blender bottles for your business, it’s essential to have a clear, structured approach. This guide provides a step-by-step checklist to ensure you select the right products that meet your quality standards and market demands. By following these actionable steps, you can streamline your procurement process and make informed decisions.

Fase 1: Definizione delle specifiche tecniche

Establishing clear technical specifications is crucial for ensuring that the large blender bottles meet your operational needs. Consider factors such as size, material (e.g., BPA-free plastic, stainless steel), and design features like a rounded base for better mixing or a secure lid to prevent leaks.

– Size Options: Determine if you need bottles in various sizes (e.g., 20oz, 28oz, 45oz) to cater to different consumer preferences.

– Material Quality: Choose materials that are durable and safe for food contact, as this impacts both product quality and customer satisfaction.

Step 2: Research Market Trends

Understanding current market trends can help you select products that resonate with your target audience. Analyze consumer preferences in your region, focusing on popular features and designs.

– Regional Preferences: For instance, buyers in Europe may prioritize eco-friendly materials, while those in Africa might look for cost-effective solutions.

– Competitor Analysis: Evaluate what similar businesses are offering to identify gaps in the market that you can fill.

Fase 3: valutare i potenziali fornitori

Before committing to a supplier, it’s critical to assess their reliability and capabilities. Request detailed company profiles, including their production capacity, quality control processes, and previous client testimonials.

– Certificazioni: Ensure that suppliers have relevant certifications (e.g., ISO, FDA) to guarantee product safety and quality.

– Case Studies: Ask for examples of past projects or partnerships that demonstrate their ability to meet business needs.

Fase 4: Richiesta di campioni da testare

Obtaining samples allows you to evaluate the quality and functionality of the large blender bottles before placing a bulk order. Assess factors such as durability, ease of use, and the effectiveness of features like the mixing system.

– Testing for Performance: Conduct tests to ensure the bottles mix smoothly without leaving powder residue, which is a common concern for users.

– Consumer Feedback: Consider organizing focus groups to gather opinions on the samples from potential customers.

Step 5: Negotiate Terms and Pricing

Once you have shortlisted potential suppliers, initiate negotiations to secure favorable terms. Discuss pricing, minimum order quantities, delivery timelines, and payment conditions.

– Bulk Discounts: Inquire about discounts for larger orders to optimize your procurement costs.

– Payment Terms: Establish clear payment terms that align with your cash flow requirements to avoid financial strain.

Step 6: Confirm Compliance with Regulations

Ensure that the large blender bottles comply with local regulations regarding food safety and packaging. This is particularly important when importing products from different countries.

– Import Regulations: Familiarize yourself with the specific import regulations in your region to avoid potential legal issues.

– Safety Standards: Verify that the bottles meet international safety standards to protect your brand reputation.

Step 7: Establish a Quality Assurance Process

After selecting a supplier, implement a quality assurance process to monitor the product quality consistently. This can involve regular inspections and feedback loops with your supplier.

– Ongoing Assessments: Schedule periodic reviews of product quality and supplier performance to ensure compliance with your standards.

– Customer Feedback: Encourage customer feedback on product performance to identify areas for improvement and enhance customer satisfaction.

By following this checklist, you will be well-equipped to source high-quality large blender bottles that meet your business objectives and customer expectations.

Comprehensive Cost and Pricing Analysis for large blender bottle Sourcing

What Are the Key Cost Components in Sourcing Large Blender Bottles?

When sourcing large blender bottles, it’s crucial to understand the various cost components involved. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

I materiali typically account for a significant portion of the total cost. Common materials for blender bottles include BPA-free plastics, stainless steel, and silicone for lids and grips. The choice of material can influence both price and durability.

Labor costs can vary based on the location of production. Regions with lower labor costs, such as Southeast Asia, may offer more competitive pricing but could compromise on quality if not properly managed.

Spese generali di produzione encompasses utilities, rent, and other operational costs. This can also be affected by the scale of production; larger quantities often lead to lower per-unit costs.

Utensili refers to the initial setup costs for molds and machinery, which can be substantial but are amortized over larger production runs.

Controllo qualità is essential, especially for products intended for international markets. Ensuring compliance with safety and quality standards can add to costs but is necessary to avoid costly recalls or legal issues.

Logistica expenses include shipping, handling, and storage. These costs can fluctuate based on fuel prices, shipping routes, and geopolitical factors.

Lastly, the margin represents the supplier’s profit and can vary significantly based on market conditions and competition.

How Do Price Influencers Impact the Sourcing of Large Blender Bottles?

Several factors influence the pricing of large blender bottles in the B2B market. Volume e quantità minima d'ordine (MOQ) are crucial; higher orders typically reduce unit costs. Suppliers may set MOQs to optimize production efficiency, which can affect smaller buyers.

Specifiche e personalizzazione also play a significant role. Custom designs, colors, or features can increase costs due to the need for specialized tooling or materials.

La scelta di materiali directly impacts the price. Premium materials, such as insulated stainless steel, generally cost more than standard plastics but can command higher retail prices.

Qualità e certificazioni are essential, particularly in regulated markets. Products that meet specific standards (e.g., FDA-approved materials) may have higher upfront costs but offer long-term value by ensuring safety and compliance.

Fattori di fornitura such as reputation, reliability, and service level can influence pricing. Established suppliers may charge a premium for their proven quality and support.

Infine, Incoterms—international commercial terms—define the responsibilities of buyers and sellers in shipping and logistics. Understanding these can help buyers avoid unexpected costs related to shipping and customs.

What Are Effective Buyer Tips for Sourcing Large Blender Bottles?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation is key. Establishing a strong relationship with suppliers can lead to better pricing and more favorable terms.

Considerate il Costo totale di proprietà (TCO) rather than just the initial purchase price. This includes factors such as durability, maintenance, and potential resale value. Investing in higher-quality bottles may result in lower long-term costs.

Understanding sfumature di prezzo is essential for international transactions. Currency fluctuations, trade tariffs, and local market conditions can affect final costs. Buyers should stay informed and consider these factors when negotiating prices.

Finally, always seek multiple quotes from different suppliers to ensure competitive pricing. This not only helps in understanding the market rate but also provides leverage in negotiations.

Esclusione di responsabilità: Prices mentioned in reference materials are indicative and can vary based on market conditions, supplier relationships, and other external factors. Always verify current pricing and terms directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing large blender bottle With Other Solutions

Introduction to Alternatives for Large Blender Bottles

When considering large blender bottles for mixing protein shakes or other beverages, it’s essential to evaluate various alternatives that may meet your specific needs. B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, must weigh factors like performance, cost, and usability. This analysis will compare the large blender bottle against two viable alternatives: electric blenders and manual shaker jars.

Tabella di confronto

| Aspetto di confronto | Large Blender Bottle | Electric Blender | Manual Shaker Jar |

|---|---|---|---|

| Prestazioni | Excellent for mixing powders and liquids evenly | High performance for blending and chopping | Good for mixing liquids, less effective for powders |

| Costo | $10.99 – $27.99 | $30 – $200+ | $5 – $15 |

| Facilità di implementazione | Very easy to use and portable | Requires electricity and setup | Simple to use, but less portable |

| Manutenzione | Low maintenance; dishwasher safe | Moderate maintenance; requires cleaning blades | Low maintenance; easy to clean |

| Il miglior caso d'uso | Ideal for fitness enthusiasts on-the-go | Best for smoothies, soups, and larger batches | Suitable for casual use and smaller servings |

Ripartizione dettagliata delle alternative

Electric Blenders

Electric blenders offer superior performance for those needing to mix a variety of ingredients, including ice, fruits, and vegetables. They provide a smooth consistency that can be essential for creating high-quality smoothies or protein shakes. However, the main drawbacks are their higher cost and the need for an electrical outlet, making them less portable. Additionally, they require more cleanup due to their complex components, which can deter users seeking convenience.

Manual Shaker Jars

Manual shaker jars are a budget-friendly option that allows users to mix liquids manually. They are lightweight and easy to carry, making them suitable for casual users who may not need the robust features of a large blender bottle. While they are simple to use and maintain, their mixing efficiency, especially with powders, can be limited compared to larger bottles. Users may find that powders can settle at the bottom, leading to uneven mixing unless shaken vigorously.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers evaluating large blender bottles, the choice between a large blender bottle, an electric blender, and a manual shaker jar depends largely on specific use cases and operational contexts. If portability and ease of use are paramount, the large blender bottle stands out as the best option. However, for businesses focused on high-volume blending with diverse ingredients, investing in electric blenders may be justified despite the higher cost and maintenance. Manual shaker jars can serve well for those with budget constraints or less frequent use, but they may not provide the same quality of mixing. Ultimately, assessing these factors will help buyers select the most appropriate solution for their unique business needs.

Essential Technical Properties and Trade Terminology for large blender bottle

What Are the Essential Technical Properties of a Large Blender Bottle?

When sourcing large blender bottles, understanding their technical properties is crucial for ensuring product quality and suitability for market demands. Here are key specifications to consider:

-

Grado del materiale

The most common materials for blender bottles include BPA-free plastic (Tritan) and stainless steel. Tritan is lightweight, durable, and resistant to odors and stains, making it ideal for fitness enthusiasts. Stainless steel offers superior insulation and durability, appealing to premium markets. Selecting the right material impacts product longevity and consumer safety, which can significantly affect brand reputation. -

Capacità e dimensioni

Large blender bottles typically range from 28oz to 45oz. Understanding the dimensions, such as height and width, is essential for packaging and shipping considerations. Different markets may have preferences for specific sizes, influencing purchasing decisions. For instance, a larger capacity may be more appealing in regions with a growing fitness culture, such as parts of Africa and South America. -

Leak-proof Design

A reliable leak-proof lid is a critical feature that enhances the user experience. This design not only prevents spills during transport but also ensures that the contents remain secure. For B2B buyers, the assurance of a leak-proof design can reduce customer complaints and returns, making it a vital selling point. -

Dishwasher and Microwave Safe

Products that are dishwasher and microwave safe provide convenience for end-users. This property is particularly appealing in markets where consumers value ease of use and cleaning. Highlighting these features can improve marketability and reduce the perceived effort required to maintain the product. -

Measurement Markings

Clear measurement markings allow users to accurately gauge liquid and powder quantities. This feature is especially important for fitness enthusiasts monitoring their intake. Providing precise measurement capabilities can differentiate a product in a crowded market, catering to consumers who prioritize health and fitness. -

Peso e portabilità

The overall weight of the blender bottle can influence its portability. Lightweight options are preferred for active users who carry their bottles to gyms or outdoor activities. For B2B buyers, understanding the weight can inform shipping costs and consumer preferences in various regions.

What Common Trade Terms Should B2B Buyers Know When Purchasing Large Blender Bottles?

Navigating the B2B landscape requires familiarity with specific industry jargon. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for B2B buyers who may seek to customize products under their brand name, ensuring quality and consistency. -

MOQ (quantità minima d'ordine)

MOQ is the smallest quantity a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and initial investment. Knowing the MOQ helps in budgeting and determining the feasibility of entering a new market. -

RFQ (Richiesta di offerta)

An RFQ is a document used by buyers to solicit price quotes from suppliers. This process is essential for comparing costs and understanding market pricing. For B2B transactions, a well-structured RFQ can streamline the procurement process and ensure competitive pricing. -

Incoterms (Termini commerciali internazionali)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in global transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk transfer, and cost implications, which is crucial for international trade. -

Tempi di consegna

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is essential for inventory planning and meeting customer demands. Shorter lead times can enhance competitiveness, especially in fast-paced markets. -

Quality Assurance (QA)

QA encompasses the processes and procedures that ensure product quality. For B2B buyers, knowing a supplier’s QA standards can mitigate risks associated with product defects, ensuring that the blender bottles meet market expectations and regulatory standards.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed purchasing decisions, ensuring that their investments align with market demands and consumer preferences.

Navigating Market Dynamics and Sourcing Trends in the large blender bottle Sector

What Are the Current Market Dynamics and Key Trends Impacting Large Blender Bottles?

The large blender bottle market is witnessing robust growth, driven by a surge in health consciousness among consumers globally. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where fitness and wellness have become integral parts of daily life. International B2B buyers should note the growing demand for multifunctional products, such as blender bottles that not only serve as shakers but also double as storage containers for supplements and snacks.

Emerging technologies in manufacturing, including advanced materials that are BPA-free and odor-resistant, are reshaping the product landscape. Buyers should also be aware of the increasing customization options available, allowing businesses to offer personalized products that resonate with regional aesthetics and preferences. Moreover, the rise of e-commerce platforms is transforming sourcing strategies, enabling buyers to access a wider range of suppliers and products without geographical constraints.

As competition intensifies, companies are leveraging digital marketing strategies to enhance brand visibility and reach targeted audiences effectively. The integration of data analytics into supply chain management is becoming essential for optimizing inventory and forecasting demand, thus ensuring that businesses can respond swiftly to market changes.

How Is Sustainability and Ethical Sourcing Influencing Large Blender Bottle Purchases?

Sustainability is no longer a mere trend; it has become a fundamental expectation among consumers and businesses alike. In the large blender bottle sector, buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste in production processes. Products that are certified by recognized ‘green’ organizations not only appeal to environmentally conscious consumers but also help businesses comply with increasing regulatory pressures regarding sustainability.

Ethical sourcing is equally important, as stakeholders demand transparency in supply chains. Companies that can showcase their ethical practices—such as fair labor conditions and responsible sourcing of raw materials—are likely to foster stronger relationships with B2B partners. This focus on ethics can also enhance brand loyalty and open new market opportunities, particularly in regions where consumers are becoming more discerning about the products they support.

By integrating sustainable practices into their sourcing strategies, businesses can not only reduce their environmental footprint but also position themselves favorably in an increasingly competitive marketplace.

How Has the Large Blender Bottle Industry Evolved Over Time?

The evolution of the large blender bottle sector can be traced back to the early days of fitness culture when basic shaker bottles were primarily designed for mixing protein powders. Over the years, the industry has experienced significant transformations, marked by advancements in materials and design. Modern large blender bottles now incorporate features such as leak-proof lids, ergonomic designs, and enhanced mixing systems that cater to a diverse range of consumer needs.

As fitness trends have evolved, so too have consumer expectations, leading to the introduction of insulated models that keep beverages cold for extended periods and stylish designs that appeal to a broader demographic. This shift has encouraged manufacturers to innovate continuously, ensuring that they remain competitive in a dynamic market landscape. Today, large blender bottles are not just functional items; they represent a lifestyle choice that resonates with health-conscious consumers globally.

Frequently Asked Questions (FAQs) for B2B Buyers of large blender bottle

-

How do I ensure the quality of large blender bottles from international suppliers?

To ensure the quality of large blender bottles, start by verifying the supplier’s credentials and certifications, such as ISO or FDA compliance. Request samples to evaluate the materials, durability, and functionality. Conduct factory audits, if possible, or use third-party inspection services to assess production standards. Additionally, review customer feedback and testimonials to gauge the supplier’s reliability. Establish a clear quality assurance (QA) process that includes regular inspections during production and before shipment. -

What is the best material for large blender bottles used in B2B applications?

The best materials for large blender bottles in B2B applications are BPA-free plastic, stainless steel, and Tritan™. BPA-free plastic is lightweight, durable, and cost-effective, making it suitable for bulk orders. Stainless steel offers superior insulation and is ideal for high-end markets, providing a premium feel and durability. Tritan™ is a copolyester that is both tough and transparent, making it a popular choice for products that require visibility of contents. Each material has unique benefits, so consider your target market and intended use when making a choice. -

What are the typical minimum order quantities (MOQs) for large blender bottles?

Minimum order quantities (MOQs) for large blender bottles can vary significantly based on the supplier and customization options. Generally, MOQs range from 500 to 5,000 units for standard designs. For customized products, such as those with unique branding or colors, MOQs may be higher, often starting at 1,000 units. It’s essential to discuss your needs with potential suppliers to understand their specific MOQs and explore options for smaller orders if necessary. -

What customization options are available for large blender bottles?

Customization options for large blender bottles typically include printing logos, selecting colors, and modifying sizes. Many suppliers offer various printing techniques, such as screen printing or pad printing, to accommodate different branding needs. You may also request specific features, such as ergonomic grips or unique lid designs. Discuss your vision with the supplier to explore the range of customization possibilities and any associated costs or MOQs. -

How can I manage logistics for importing large blender bottles?

To manage logistics for importing large blender bottles, start by choosing a reliable freight forwarder familiar with international shipping regulations. Clearly communicate your shipping requirements, including timelines and budget constraints. Ensure proper documentation, such as bills of lading and customs declarations, is prepared to avoid delays. Consider shipping by sea for larger orders to reduce costs, but account for longer transit times. Lastly, stay informed about customs duties and tariffs that may apply to your imported goods. -

What payment terms should I expect when sourcing large blender bottles?

Payment terms for sourcing large blender bottles can vary widely among suppliers. Common terms include a 30% deposit before production and the remaining balance before shipment. Some suppliers may offer letters of credit or payment through escrow services for added security. It’s important to negotiate terms that protect your interests while also considering the supplier’s policies. Establishing a good relationship with your supplier can lead to more favorable terms over time. -

How do I vet suppliers for large blender bottles in international markets?

Vetting suppliers for large blender bottles involves several steps. Start by researching potential suppliers through trade directories, industry forums, and exhibitions. Request references from other businesses that have worked with them. Check their company registration and any certifications relevant to product quality and safety standards. Conduct video calls or site visits to assess their manufacturing capabilities and working conditions. Using third-party verification services can also enhance your confidence in the supplier’s legitimacy. -

What are the common challenges faced when sourcing large blender bottles internationally?

Common challenges when sourcing large blender bottles internationally include language barriers, cultural differences, and varying quality standards. Additionally, navigating customs regulations and tariffs can complicate the shipping process. To mitigate these challenges, establish clear communication channels and use professional translation services if necessary. Building strong relationships with suppliers can also help address issues promptly. Lastly, staying informed about international trade laws and market trends will empower you to make better sourcing decisions.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo fatto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Top 7 Large Blender Bottle Manufacturers & Suppliers List

1. Contigo – Shake and Go Fit Shaker Bottle

Dominio: verywellfit.com

Registrato: 2017 (8 anni)

Introduzione: Best Overall: Contigo Shake and Go Fit Shaker Bottle – $15, Capacity: 28 ounces, Material: BPA-free plastic, Blending Mechanism: Weighted shaker ball, Insulated: No, Dishwasher Safe: Yes, top rack only. Easiest to Clean: Helimix Vortex Blender Shaker Bottle – $25, Capacity: 28 ounces, Material: BPA-free plastic, Blending Mechanism: Helix walls of cup, Insulated: No, Dishwasher Safe: Yes, top rack …

2. Stainless Steel Shaker Bottle – Fully Plastic-Free Options

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: The discussion revolves around the search for a fully stainless steel shaker bottle that does not contain any plastic components, such as lids or agitators. The user expresses frustration in finding such a product on Amazon and questions why lids must be plastic. Suggestions include using a stainless steel bar shaker, which is commonly used for cocktails, and the idea that a metal ball can be used…

3. Garage Gym Reviews – Insulated Shaker Bottle

Dominio: garagegymreviews.com

Registrato: 2014 (11 anni)

Introduzione: This company, Garage Gym Reviews – Insulated Shaker Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Gnarly Nutrition – Blender Bottle

Dominio: gognarly.com

Registrato: 2012 (13 anni)

Introduzione: Blender Bottle | Gnarly Nutrition

- Prezzo: $9.99

– Size: 28oz

- Caratteristiche:

– BPA-free bottle

– BlenderBall® whisk inside for mixing

– Embossed ounce and milliliter markings

– Wide mouth for easy filling

– Secure screw-on lid

– Stay Open flip cap™

– GripperBars™ for easy handling

– Large drink/pour spout

- Lavabile in lavastoviglie

– Fits in most car drink holders

– Rating: 5.0 out of 5 b…

5. GNC – BlenderBottle® Strada™ Tritan Protein Shaker Bottle

Dominio: gnc.com

Registrato: 1996 (29 anni)

Introduzione: This company, GNC – BlenderBottle® Strada™ Tritan Protein Shaker Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. BlenderBottle – Pro 45oz

Dominio: blenderbottlesea.com

Registered: 2022 (3 years)

Introduzione: {“product_name”: “Pro 45oz”, “capacity”: “45 ounces”, “features”: [“Durable construction”, “Wide mouth for easy filling and cleaning”, “Secure screw-on lid”, “Integrated carrying loop”, “BPA-free materials”], “colors_available”: [“Black”, “Blue”, “Red”, “Green”], “usage”: [“Shakes”, “Smoothies”, “Protein drinks”], “dimensions”: “10.5 x 4.5 inches”, “weight”: “0.75 pounds”}

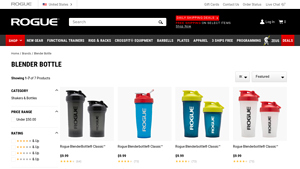

7. Rogue Fitness – BlenderBottle Classic™

Dominio: roguefitness.com

Registrato: 2006 (19 anni)

Introduzione: BlenderBottle products available include: 1. Rogue BlenderBottle Classic™ – Price: $9.99, Rating: ★★★★★ (64 reviews), Available in 5 colors. 2. Rogue BlenderBottle Classic™ – Price: $9.99, Rating: ★★★★★ (73 reviews), Available in 4 colors. 3. Rogue BlenderBottle Classic™ – Price: $9.99, Rating: ★★★★★ (73 reviews), Available in 4 colors. 4. Rogue BlenderBottle Classic™ – Price: $9.99, Rating: ★★★★★…

Strategic Sourcing Conclusion and Outlook for large blender bottle

In navigating the global market for large blender bottles, strategic sourcing emerges as a critical component for B2B buyers aiming to optimize their supply chain and enhance product offerings. By selecting high-quality, durable products like the BlenderBottle® Classic™, companies can cater to the growing demand among fitness enthusiasts and health-conscious consumers. The extensive range of sizes, colors, and features allows businesses to tailor their inventory to meet diverse customer preferences, which is essential in competitive markets across Africa, South America, the Middle East, and Europe.

Furthermore, the emphasis on features such as leak-proof designs, ergonomic carry loops, and easy-to-read measurement markings not only enhances customer satisfaction but also builds brand loyalty. As international buyers focus on sustainability and quality, sourcing from reputable manufacturers who prioritize BPA-free materials and innovative designs will be advantageous.

Looking ahead, the demand for large blender bottles is poised to grow as health and wellness trends continue to gain momentum. Now is the time to leverage strategic sourcing to secure partnerships with trusted suppliers, ensuring your business remains at the forefront of this dynamic market. Embrace this opportunity to elevate your product offerings and capture new markets.