Introduction: Navigating the Global Market for 18 oz hotshot bottle

In today’s competitive marketplace, sourcing high-quality 18 oz hotshot bottles can be a daunting task for international B2B buyers. With diverse needs spanning various regions—such as Africa, South America, the Middle East, and Europe—businesses face challenges related to product quality, supplier reliability, and cost-effectiveness. This guide serves as a comprehensive resource to navigate these complexities, offering insights into the types of 18 oz hotshot bottles available, their applications in different industries, and effective strategies for vetting suppliers.

We delve into critical aspects such as material quality, insulation technology, and design features, enabling buyers to make informed choices tailored to their specific market demands. Additionally, this guide explores cost considerations, ensuring that businesses can budget effectively while securing the best products for their needs. By empowering B2B buyers with knowledge and actionable strategies, this resource aims to streamline the procurement process and enhance operational efficiency. Whether you’re operating in bustling urban centers or remote locations, understanding the nuances of the global market for 18 oz hotshot bottles will position your business for success in an increasingly interconnected world.

Navigazione tra gli articoli

- Top 7 18 Oz Hotshot Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for 18 oz hotshot bottle

- Understanding 18 oz hotshot bottle Types and Variations

- Key Industrial Applications of 18 oz hotshot bottle

- 3 Common User Pain Points for ’18 oz hotshot bottle’ & Their Solutions

- Strategic Material Selection Guide for 18 oz hotshot bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for 18 oz hotshot bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ’18 oz hotshot bottle’

- Comprehensive Cost and Pricing Analysis for 18 oz hotshot bottle Sourcing

- Alternatives Analysis: Comparing 18 oz hotshot bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for 18 oz hotshot bottle

- Navigating Market Dynamics and Sourcing Trends in the 18 oz hotshot bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 18 oz hotshot bottle

- Disclaimer importante e condizioni d'uso

- Strategic Sourcing Conclusion and Outlook for 18 oz hotshot bottle

Understanding 18 oz hotshot bottle Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Rambler HotShot Bottle | 360-degree sipping, leakproof, double-wall vacuum insulation | Corporate gifting, outdoor events | Pro: Durable, versatile sipping; Contro: Opzioni di colore limitate. |

| Rambler Chug Bottle | Shatter-resistant, easy to clean, wide mouth for filling | Sports teams, active lifestyle brands | Pro: Fast hydration, easy access; Contro: Not suitable for carbonated drinks. |

| Insulated Stainless Steel Bottle | Kitchen-grade stainless steel, puncture-resistant | Retail and hospitality sectors | Pro: Long-lasting, maintains temperature; Contro: Heavier than plastic options. |

| Customizable Hotshot Bottle | Available in various colors and branding options | Promotional products, branding opportunities | Pro: Migliora la visibilità del marchio; Contro: Higher cost for customization. |

| Travel-Friendly Hotshot Bottle | Compact design, fits most cup holders | Travel agencies, commuter-focused brands | Pro: Convenient for on-the-go hydration; Contro: Smaller capacity compared to larger bottles. |

What are the Key Characteristics of the Rambler HotShot Bottle?

The Rambler HotShot Bottle is designed for convenience and durability, featuring a unique 360-degree sipping capability that allows users to drink from any angle. Its double-wall vacuum insulation ensures that beverages maintain their temperature for extended periods, making it ideal for both hot and cold drinks. This bottle is particularly well-suited for corporate gifting and outdoor events, where functionality and style are paramount. B2B buyers should consider its robust construction and leakproof design, which enhances its appeal for daily use.

How Does the Rambler Chug Bottle Stand Out?

The Rambler Chug Bottle is characterized by its shatter-resistant design and easy-to-clean features, with a wide mouth that simplifies filling and cleaning. This makes it an excellent choice for sports teams and active lifestyle brands, where quick hydration is essential. B2B buyers should note that while this bottle is great for water and other non-carbonated beverages, its limitations with carbonated drinks may restrict its use in some markets.

What are the Advantages of Insulated Stainless Steel Bottles?

Insulated stainless steel bottles are crafted from kitchen-grade materials, making them puncture-resistant and ideal for various environments. Their ability to maintain beverage temperature makes them popular in the retail and hospitality sectors, where quality is crucial. B2B purchasers should weigh the longevity and robustness of these bottles against their heavier weight compared to plastic alternatives, which may be a consideration for portability.

Why Should You Consider Customizable Hotshot Bottles?

Customizable Hotshot Bottles offer businesses the opportunity to enhance brand visibility through personalized designs. Available in a range of colors and branding options, these bottles can serve as effective promotional products. However, B2B buyers must consider the higher costs associated with customization, which may impact budget allocations for marketing materials.

What Makes Travel-Friendly Hotshot Bottles Ideal for Commuters?

Travel-friendly Hotshot Bottles are designed with a compact structure that fits most cup holders, making them perfect for commuters and travelers. Their lightweight and portable nature appeals to travel agencies and commuter-focused brands. Buyers should assess the convenience of on-the-go hydration against the smaller capacity, which may not meet the needs of all users.

Key Industrial Applications of 18 oz hotshot bottle

| Industria/Settore | Specific Application of 18 oz Hotshot Bottle | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Cibo e bevande | Employee hydration during shifts in cafes and restaurants | Enhances employee productivity and satisfaction with accessible hydration | Consider durability, ease of cleaning, and leak-proof features |

| Ricreazione all'aperto | Essential gear for hiking and camping expeditions | Keeps beverages at optimal temperatures, improving outdoor experience | Look for lightweight materials and compatibility with outdoor gear |

| Transportation | Ideal for long-haul drivers and commuters | Provides reliable hydration on the go, improving driver focus | Ensure leak-proof design and compatibility with vehicle cup holders |

| Regali aziendali | Promotional items for client gifts or employee rewards | Strengthens brand visibility and employee morale | Evaluate custom branding options and bulk purchasing discounts |

| Salute e benessere | Used in fitness centers and wellness retreats | Supports hydration goals, promoting a healthier lifestyle | Assess material safety, ease of cleaning, and insulation performance |

How is the 18 oz Hotshot Bottle Used in the Food and Beverage Industry?

In the food and beverage sector, the 18 oz hotshot bottle is a vital tool for enhancing employee hydration during shifts in cafes and restaurants. With long hours on the floor, staff require easy access to beverages to maintain energy levels and focus. The bottle’s leak-proof design and stainless steel construction ensure durability, making it an excellent investment for businesses. International buyers should prioritize sourcing options that emphasize easy cleaning and long-lasting performance, especially in high-traffic environments.

What Role Does the 18 oz Hotshot Bottle Play in Outdoor Recreation?

For outdoor recreation, the 18 oz hotshot bottle is essential gear for hiking and camping expeditions. Its ability to maintain beverage temperatures allows adventurers to enjoy hot coffee or cold water throughout their journey, enhancing the overall experience. Buyers in this sector should focus on lightweight and durable options that can withstand rugged conditions. Additionally, compatibility with various outdoor gear, such as backpack pockets, is a crucial consideration for international buyers looking to equip their teams or customers effectively.

How Does the 18 oz Hotshot Bottle Benefit Transportation Workers?

In the transportation industry, long-haul drivers and daily commuters benefit significantly from the 18 oz hotshot bottle. It provides reliable hydration solutions that help maintain focus and energy during long hours on the road. The bottle’s design fits most vehicle cup holders, ensuring easy access while driving. When sourcing for this application, businesses should prioritize leak-proof features to prevent spills and promote safety on the road, which is particularly important for international buyers operating in diverse climates.

Why is the 18 oz Hotshot Bottle Valuable for Corporate Gifting?

The 18 oz hotshot bottle serves as an excellent promotional item for corporate gifting, whether for client gifts or employee rewards. By providing high-quality, branded drinkware, businesses can enhance brand visibility while promoting employee morale. Buyers should explore customization options to align the product with their branding strategy. Bulk purchasing discounts can also provide cost savings, making this an attractive option for companies looking to make a lasting impression on clients and employees alike.

How Does the 18 oz Hotshot Bottle Support Health and Wellness Initiatives?

In health and wellness settings, such as fitness centers and wellness retreats, the 18 oz hotshot bottle plays a crucial role in supporting hydration goals. By encouraging users to maintain fluid intake, businesses can promote healthier lifestyles among clients. When sourcing bottles for this application, international buyers should evaluate material safety, ease of cleaning, and insulation performance. Ensuring that the product meets health regulations and preferences in different markets is essential for successful procurement.

3 Common User Pain Points for ’18 oz hotshot bottle’ & Their Solutions

Scenario 1: Difficulty in Maintaining Beverage Temperature During Long Commutes

Il problema: For many B2B buyers in regions with extreme climates, such as the Middle East or South America, ensuring that beverages maintain their desired temperature throughout lengthy commutes can be a significant challenge. Long travel times can lead to lukewarm coffee or tea, negatively impacting the user experience and overall satisfaction with the product. Additionally, businesses that provide these bottles to employees or clients must consider that a lack of temperature retention can reflect poorly on their brand.

La soluzione: To address this issue, buyers should prioritize sourcing 18 oz hotshot bottles that feature double-wall vacuum insulation technology. This design ensures that both hot and cold beverages maintain their temperature for extended periods. When selecting a supplier, verify product specifications, such as insulation performance metrics, to ensure they align with user needs. Furthermore, educate users on optimal usage practices, such as pre-heating the bottle with hot water before filling it with coffee or tea, to maximize heat retention. By choosing a high-quality product and providing proper usage guidelines, businesses can enhance customer satisfaction and brand loyalty.

Scenario 2: Concerns About Durability and Wear Over Time

Il problema: B2B buyers often face concerns regarding the durability of drinkware, particularly in rugged environments or industries where wear and tear are common, such as construction or outdoor activities. An 18 oz hotshot bottle that dents, rusts, or breaks easily can lead to frequent replacements, which not only incurs additional costs but also disrupts workflow. For companies looking to provide reliable hydration solutions to their workforce, the quality of the product is paramount.

La soluzione: When sourcing hotshot bottles, buyers should look for those made from high-grade materials, such as 18/8 kitchen-grade stainless steel, which offers superior resistance to rust and punctures. It’s advisable to request samples or conduct product testing to evaluate durability before making bulk purchases. Additionally, consider seeking out suppliers that offer warranties or guarantees on their products, as this can provide peace of mind regarding long-term usage. By investing in durable bottles upfront, companies can minimize replacement costs and enhance the overall experience for users.

Scenario 3: Challenges with Cleaning and Maintenance

Il problema: In sectors where hygiene is critical, such as healthcare or food service, maintaining cleanliness in drinkware is a significant concern. B2B buyers may struggle with sourcing bottles that are easy to clean, leading to potential hygiene issues if residues are left behind. This can be particularly problematic for organizations that distribute beverages for shared use among employees or customers.

La soluzione: To mitigate cleaning challenges, buyers should opt for 18 oz hotshot bottles that are dishwasher safe and designed with easy-to-clean features, such as wide mouths and removable components. When evaluating products, inquire about the cleaning recommendations from manufacturers to ensure compatibility with commercial dishwashers. Furthermore, consider creating a regular cleaning schedule for employees, emphasizing the importance of hygiene in maintaining their drinkware. By choosing user-friendly products and implementing a cleaning protocol, businesses can ensure that their drinkware remains hygienic and safe for daily use.

Strategic Material Selection Guide for 18 oz hotshot bottle

What Are the Key Materials Used in 18 oz Hotshot Bottles?

When selecting materials for the 18 oz hotshot bottle, several options are commonly considered, each offering distinct properties and benefits. This analysis focuses on four prevalent materials: stainless steel, Tritan plastic, glass, and aluminum. Understanding these materials will help international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

How Does Stainless Steel Perform in Hotshot Bottles?

Stainless steel, particularly 18/8 kitchen-grade stainless steel, is a popular choice for hotshot bottles. Its key properties include excellent corrosion resistance and high durability, making it ideal for both hot and cold beverages. The double-wall vacuum insulation capabilities of stainless steel ensure that drinks maintain their temperature for extended periods, which is crucial for users on the go.

Pro: Stainless steel is highly durable, resistant to rust and punctures, and dishwasher safe, which simplifies maintenance. It also offers a premium feel, appealing to consumers looking for quality products.

Contro: The manufacturing process can be more complex and costly compared to other materials, impacting the final product’s price. Additionally, while stainless steel is generally safe, it can react with certain acidic beverages if not properly treated.

For international buyers, particularly in regions like the Middle East and Africa, compliance with food safety standards (like ASTM or DIN) is vital. Buyers should ensure that the stainless steel used meets these standards to avoid issues related to food safety.

What Role Does Tritan Plastic Play in Hotshot Bottles?

Tritan plastic is a BPA-free copolyester known for its clarity and toughness. It is lightweight and offers good impact resistance, making it suitable for active lifestyles. Tritan bottles can withstand high temperatures, although they may not retain heat as effectively as stainless steel.

Pro: Tritan is less expensive than stainless steel, making it an attractive option for budget-conscious buyers. It is also dishwasher safe and can be molded into various shapes, allowing for innovative designs.

Contro: While Tritan is durable, it is not as resistant to scratches and dents as stainless steel. Additionally, it may not provide the same level of thermal insulation, which could be a drawback for users who prioritize temperature retention.

For B2B buyers in South America and Europe, it is essential to verify that Tritan products comply with local regulations regarding food safety and recycling, as preferences for sustainable materials are growing.

How Does Glass Compare for Hotshot Bottles?

Glass is another material option, offering a premium aesthetic and excellent thermal properties. It is non-reactive, meaning it won’t leach chemicals into beverages, making it a safe choice for health-conscious consumers.

Pro: Glass provides superior taste preservation and is often considered more environmentally friendly than plastic. It is also easy to clean and can be recycled.

Contro: The primary disadvantage of glass is its fragility; it can shatter upon impact, making it less suitable for outdoor or rugged use. Additionally, glass bottles tend to be heavier, which may deter some users.

International buyers, especially in Europe, may find glass bottles appealing due to their sustainability. However, they must consider shipping costs and the potential for breakage during transport.

What Advantages Does Aluminum Offer for Hotshot Bottles?

Aluminum is lightweight and can be easily molded into various shapes. It is often coated with a protective layer to prevent corrosion and enhance durability.

Pro: Aluminum bottles are typically less expensive than stainless steel and provide good thermal insulation when insulated properly. They are also lightweight, making them easy to carry.

Contro: Aluminum can dent more easily than stainless steel and may react with acidic beverages unless lined with a protective coating. This can limit the types of drinks suitable for use in aluminum bottles.

For buyers in regions like Africa and the Middle East, understanding the local preferences for materials and compliance with safety standards is crucial, as aluminum products may face scrutiny regarding their safety and environmental impact.

Summary of Material Properties for 18 oz Hotshot Bottles

| Materiale | Typical Use Case for 18 oz hotshot bottle | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Acciaio inox | Bevande calde e fredde | High durability and insulation | Costi di produzione più elevati | Alto |

| Plastica Tritan | Lightweight, everyday use | Cost-effective and versatile | Less thermal insulation | Medio |

| Vetro | Premium, health-conscious beverages | Eccellente conservazione del gusto | Fragile e pesante | Medio |

| Alluminio | Lightweight, portable use | Lightweight and inexpensive | Prone to dents and reactions | Basso |

This comprehensive analysis of materials provides B2B buyers with actionable insights for selecting the best 18 oz hotshot bottle that meets their needs and complies with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 18 oz hotshot bottle

What Are the Main Stages in the Manufacturing Process of an 18 oz Hotshot Bottle?

The manufacturing of the 18 oz Hotshot bottle involves several critical stages, each requiring precision and adherence to quality standards to ensure a durable and functional product.

Preparazione del materiale

The first stage begins with the selection and preparation of materials. High-quality 18/8 kitchen-grade stainless steel is typically used for its durability, rust-resistance, and ability to maintain temperature. This steel is sourced from reputable suppliers who meet international standards to ensure consistency and reliability. The material is cut into sheets or rolls and then subjected to processes like surface cleaning and coating, often utilizing DuraCoat™ technology to ensure longevity and resistance to chipping and fading.

Tecniche di formatura

Once the material is prepared, the next step is forming. This process can involve several techniques, including:

- Stamping: For shaping the body of the bottle, large stamping machines apply pressure to create the desired contours.

- Hydroforming: This technique uses high-pressure fluid to shape the steel into complex geometries, ensuring a precise fit for various components like the cap and base.

- Welding: In some cases, pieces of stainless steel are welded together to form the bottle’s body, ensuring a strong and leak-proof structure.

Processo di assemblaggio

After the individual components are formed, assembly takes place. This stage typically includes the integration of the HotShot™ cap, which features a 360-degree drinking design. The cap is designed for easy operation, allowing users to sip from any side. Each bottle is fitted with a silicone gasket to guarantee leak-proof performance. Automated assembly lines often handle this process, ensuring consistency and speed, although some quality-sensitive components may be manually assembled to uphold high standards.

Finishing Touches

The final stage in manufacturing involves finishing processes that enhance both aesthetics and functionality. This can include polishing the stainless steel surface, applying additional coatings, and adding branding elements. After finishing, each bottle undergoes thorough cleaning to remove any residues from manufacturing, ensuring it is ready for use.

How Is Quality Assurance Implemented in the Production of Hotshot Bottles?

Quality assurance is paramount in the production of the 18 oz Hotshot bottle, especially considering its international market presence. Manufacturers typically adhere to several international and industry-specific standards to ensure product reliability and safety.

What International Standards Are Relevant for Quality Control?

Manufacturers often comply with international quality standards such as ISO 9001, which outlines criteria for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Furthermore, industry-specific certifications such as CE marking for products sold in Europe and API standards for materials used in industrial applications may also be relevant, depending on the intended use of the bottle.

What Are the Key QC Checkpoints During Manufacturing?

To ensure that each bottle meets quality standards, several checkpoints are established throughout the manufacturing process:

-

Controllo qualità in entrata (CQI): This stage involves inspecting raw materials upon arrival to confirm they meet specified standards. Any materials failing to meet these standards are rejected.

-

Controllo qualità in corso d'opera (IPQC): During the manufacturing process, regular checks are performed to monitor the forming and assembly stages. This includes verifying dimensions, checking for defects, and ensuring assembly integrity.

-

Controllo qualità finale (CQC): Before packaging, each bottle undergoes a final inspection where functionality tests, such as leak tests and thermal performance evaluations, are conducted. This ensures that the product performs as expected before reaching the customer.

Which Testing Methods Are Commonly Used in Quality Assurance?

Testing methods are critical in validating the quality of the 18 oz Hotshot bottle. Common methods include:

-

Test di tenuta: This involves filling the bottle and observing for any signs of leakage under pressure to ensure the integrity of the seals and joints.

-

Thermal Performance Testing: This assesses the bottle’s ability to maintain hot or cold temperatures over specified durations, verifying the effectiveness of its double-wall vacuum insulation.

-

Durability Testing: Bottles may be subjected to drop tests and stress tests to evaluate their resilience under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential.

What Steps Should Buyers Take for Supplier Audits?

-

Request Certifications: Buyers should request copies of relevant certifications (ISO, CE, etc.) to confirm compliance with international quality standards.

-

Conduzione di audit sui fornitori: Regular audits can be conducted, either by the buyers themselves or through third-party organizations, to evaluate the supplier’s manufacturing processes and quality control measures.

-

Review Quality Reports: Suppliers should provide detailed quality reports that outline testing results, inspection outcomes, and any corrective actions taken.

-

Engage Third-party Inspection Services: Utilizing third-party inspectors can provide an unbiased assessment of the manufacturing processes, ensuring adherence to quality standards.

What Are the Quality Control Nuances for International Buyers?

International buyers must be cognizant of several nuances in quality control:

-

Cultural and Regulatory Differences: Understanding local regulations and cultural practices is crucial, as these can affect manufacturing standards and product safety.

-

Sfide logistiche: Shipping products across borders introduces additional risks, making it vital to confirm that quality assurance processes extend to packaging and transportation.

-

Communication Barriers: Effective communication with suppliers is essential. Establishing clear quality expectations and processes can mitigate misunderstandings and ensure compliance.

In summary, the manufacturing processes and quality assurance protocols for the 18 oz Hotshot bottle are designed to ensure a durable, high-quality product that meets the needs of international B2B buyers. By understanding these processes and implementing thorough verification measures, buyers can confidently source products that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ’18 oz hotshot bottle’

In today’s competitive market, sourcing the right product is essential for maintaining quality and meeting customer expectations. This guide serves as a comprehensive checklist for B2B buyers looking to procure the 18 oz hotshot bottle, ensuring that you make informed decisions throughout the sourcing process.

Fase 1: Definire le specifiche tecniche

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as material composition, insulation properties, and cap design. For example, look for bottles made from 18/8 stainless steel for durability, and ensure they offer double-wall vacuum insulation for temperature retention.

Fase 2: Condurre ricerche di mercato

Understanding the market landscape is critical for identifying potential suppliers. Research the latest trends, pricing structures, and customer preferences within the regions you are targeting, such as Africa, South America, or the Middle East. This information will help you gauge the competitiveness of your sourcing strategy and align your product offerings accordingly.

Fase 3: Valutare i potenziali fornitori

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request company profiles, product samples, and references from previous clients in similar industries. Pay special attention to their production capabilities and lead times, which can significantly impact your supply chain.

- Ask for Certifications: Verify if the suppliers have necessary certifications such as ISO or product safety standards relevant to your market.

- Check Reviews and Testimonials: Look for feedback from other businesses that have sourced similar products to gauge reliability and quality.

Passo 4: Assess Pricing and Payment Terms

Pricing can vary significantly among suppliers, so it’s essential to assess not only the base cost but also payment terms and conditions. Look for transparency in pricing structures, including any additional costs such as shipping or customs duties. Understanding payment terms can also help in managing cash flow effectively.

- Negotiate Bulk Discounts: If you plan to order large quantities, discuss bulk pricing options to maximize your budget.

- Consider Payment Flexibility: Evaluate suppliers who offer favorable payment terms, such as extended payment periods or financing options.

Passo 5: Review Quality Assurance Processes

Quality assurance is a non-negotiable aspect of sourcing products. Inquire about the supplier’s quality control measures, including inspection procedures and testing protocols for the 18 oz hotshot bottles. A robust quality assurance process ensures that the products meet your specifications and standards before they reach your customers.

- Request Quality Certificates: Ask for documentation that verifies the quality and safety of the products.

- Understand Return Policies: Familiarize yourself with the supplier’s return and warranty policies in case of defective items.

Passo 6: Piano per la logistica e la distribuzione

Consider logistics and distribution capabilities as you finalize your sourcing decisions. Evaluate the supplier’s ability to deliver products on time and whether they can accommodate your distribution channels. Effective logistics planning is essential to maintain inventory levels and meet customer demand.

- Discuss Shipping Options: Inquire about different shipping methods and their associated costs to determine the best option for your needs.

- Consider Local Regulations: Be aware of import regulations in your target markets to avoid delays and compliance issues.

Passo 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Establish a clear communication plan with your supplier to ensure that both parties are aligned on expectations, timelines, and any potential challenges. Regular updates and open lines of communication can help mitigate misunderstandings and foster a strong partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing the 18 oz hotshot bottle with confidence, ensuring that they select the right suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for 18 oz hotshot bottle Sourcing

What Are the Key Cost Components in Sourcing 18 oz Hotshot Bottles?

When sourcing 18 oz hotshot bottles, understanding the comprehensive cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

I materiali: The main material for these bottles is typically 18/8 kitchen-grade stainless steel, known for its durability and resistance to rust. Additional materials may include specialized caps and coatings that enhance functionality and aesthetics.

-

Lavoro: Labor costs encompass the wages of workers involved in the manufacturing process, including assembly, quality assurance, and packaging. Labor rates can vary significantly based on the region, impacting overall costs.

-

Spese generali di produzione: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs.

-

Utensili: Initial investment in molds and machinery required for production can be significant. However, this cost is amortized over large production runs, which can lower the per-unit cost.

-

Controllo qualità (CQ): Ensuring that the bottles meet safety and quality standards involves costs for testing and inspection. This is crucial for maintaining product integrity and customer satisfaction.

-

Logistica: This includes shipping and handling costs, which can fluctuate based on distance, shipping methods, and Incoterms agreed upon. Import duties and taxes also need to be factored in, especially for international transactions.

-

Margine: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

How Do Price Influencers Impact the Cost of 18 oz Hotshot Bottles?

Several factors influence the pricing of 18 oz hotshot bottles, making it crucial for buyers to consider these elements during negotiations.

-

Volume/MOQ: Ordering in larger quantities can lead to discounts due to economies of scale. Manufacturers often have minimum order quantities (MOQ) that can affect pricing.

-

Specifiche e personalizzazione: Custom designs, colors, or features will typically increase costs. Buyers should assess whether these customizations align with their market needs.

-

Materiali e certificazioni di qualità: Higher quality materials and certifications (such as BPA-free or FDA compliance) can drive up costs but may also enhance product appeal and marketability.

-

Fattori di fornitura: The reputation, reliability, and production capabilities of suppliers can influence prices. Established suppliers may charge more but often offer better quality assurance and service.

-

Incoterms: Understanding Incoterms is vital for determining who bears shipping costs and risks. These terms can significantly affect the total landed cost of the bottles.

What Are the Best Tips for B2B Buyers When Sourcing 18 oz Hotshot Bottles?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

-

Negoziazione: Always negotiate pricing and terms. Suppliers may have flexibility, especially for bulk orders or long-term contracts. Building a relationship can lead to better deals over time.

-

Efficienza dei costi: Evaluate the total cost of ownership, including purchase price, shipping, and potential returns due to quality issues. Opt for suppliers that provide a good balance of price and quality.

-

Understanding Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing.

-

Sample Orders: Requesting samples before committing to large orders can help assess quality and ensure the product meets specifications without incurring significant costs.

-

Long-Term Partnerships: Building a long-term relationship with suppliers can lead to more favorable pricing structures and priority service, ultimately benefiting your business.

Disclaimer per i prezzi indicativi

Prices for 18 oz hotshot bottles can vary widely based on the factors mentioned above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing 18 oz hotshot bottle With Other Solutions

Understanding Alternatives in Drinkware Solutions

In the competitive landscape of insulated drinkware, the 18 oz Hotshot Bottle stands out for its durability and innovative design. However, businesses often need to evaluate various options to ensure they select the best solution for their specific needs. This analysis will compare the 18 oz Hotshot Bottle against two viable alternatives: the YETI Rambler 18 oz Insulated Water Bottle with Chug Cap and the Hydro Flask 20 oz Standard Mouth Bottle. Each of these alternatives offers unique features and benefits, making it essential for B2B buyers to understand their distinctions.

Tabella di confronto

| Aspetto di confronto | 18 Oz Hotshot Bottle | YETI Rambler 18 oz Insulated Water Bottle with Chug Cap | Hydro Flask 20 oz Standard Mouth Bottle |

|---|---|---|---|

| Prestazioni | Excellent thermal insulation; keeps drinks hot or cold for hours | Superior thermal insulation; retains temperature effectively | Good insulation; keeps drinks cold for long periods |

| Costo | Approximately $30 | Approximately $32 | Approximately $30 |

| Facilità di implementazione | Simple to use; ideal for daily commuters | User-friendly with versatile cap options | Straightforward design; easy to fill and clean |

| Manutenzione | Dishwasher safe; easy to clean | Dishwasher safe; requires cap management | Dishwasher safe; straightforward maintenance |

| Il miglior caso d'uso | Ideal for hot beverages during travel | Great for both hot and cold beverages on the go | Best for cold beverages during outdoor activities |

Pros and Cons of Each Alternative

YETI Rambler 18 oz Insulated Water Bottle with Chug Cap

The YETI Rambler is designed for versatility, equipped with a chug cap that allows for easy drinking on the move. Its double-wall vacuum insulation ensures beverages maintain their desired temperatures, making it suitable for both hot coffee and cold water. While it is slightly more expensive than the Hotshot Bottle, the extra cost is justified by its robust construction and leakproof design. However, the chug cap is not as versatile for hot drinks compared to the Hotshot’s 360-degree sipping capability.

Hydro Flask 20 oz Standard Mouth Bottle

The Hydro Flask is known for its high-quality materials and excellent insulation. It features a wide mouth that facilitates easy filling, pouring, and cleaning. This bottle is particularly effective for cold drinks, making it an excellent choice for outdoor activities like hiking and camping. While it is competitively priced, users may find that it does not retain heat as effectively as the Hotshot Bottle, which may limit its use for hot beverages.

La scelta giusta per le vostre esigenze aziendali

When selecting the ideal insulated drinkware, B2B buyers should consider their specific use cases, budget constraints, and the types of beverages they intend to store. The 18 oz Hotshot Bottle excels in keeping hot drinks at the perfect temperature, making it a strong contender for businesses focused on coffee or tea service. In contrast, the YETI Rambler offers versatility for both hot and cold drinks, while the Hydro Flask is perfect for those prioritizing cold beverage retention. Ultimately, the choice should align with the intended application, ensuring that the selected solution meets operational demands while providing value to customers.

Essential Technical Properties and Trade Terminology for 18 oz hotshot bottle

What Are the Key Technical Properties of an 18 oz Hotshot Bottle?

When sourcing an 18 oz hotshot bottle, understanding its technical properties is crucial for ensuring product quality, durability, and suitability for intended markets. Here are some critical specifications:

1. Material Grade: 18/8 Stainless Steel

The primary construction material for the 18 oz hotshot bottle is 18/8 stainless steel, which refers to the composition of 18% chromium and 8% nickel. This material is known for its resistance to rust and corrosion, making it ideal for outdoor and active use. For B2B buyers, selecting products made from high-grade stainless steel ensures longevity and reduced replacement costs, vital for maintaining inventory and customer satisfaction.

2. Insulation Technology: Double-Wall Vacuum Insulation

This technology keeps beverages hot or cold for extended periods. The double-wall design minimizes heat transfer, ensuring that the external surface remains cool to the touch even when the contents are hot. For businesses, this feature is essential, particularly in markets where temperature retention is a selling point, such as in the outdoor and travel sectors.

3. Leakproof Design

A 100% leakproof design is critical for preventing spills during transport. This feature is especially important for consumers who carry their bottles in bags or vehicles. For B2B buyers, promoting leakproof bottles can enhance brand reputation and reduce returns due to product defects, which is a significant concern in the competitive drinkware market.

4. Lavabile in lavastoviglie

The dishwasher-safe property simplifies the cleaning process, making the bottle user-friendly. This feature is particularly appealing to consumers in busy markets who prioritize convenience. For companies, emphasizing ease of maintenance can differentiate products in a saturated market and attract more customers.

5. Dimensions: 9.5” H x 3” W

The specific dimensions of the bottle affect its portability and compatibility with standard cup holders. Understanding these measurements is vital for B2B buyers who want to ensure their products fit within consumer lifestyle needs. A well-sized bottle can enhance customer satisfaction and increase repeat purchases.

6. Capacity: 18 oz

The capacity of the bottle is a crucial specification that influences consumer choice. An 18 oz size strikes a balance between portability and sufficient hydration, appealing to a broad audience. For B2B buyers, knowing your target market’s preferences regarding size can help in inventory management and marketing strategies.

What Are Common Trade Terms Related to the 18 oz Hotshot Bottle?

In the B2B landscape, familiarity with trade terminology is vital for effective communication and negotiation. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of the hotshot bottle, an OEM might create the bottle design or components that another brand sells under its label. Understanding OEM relationships can help buyers identify potential partners for customized products.

2. MOQ (quantità minima d'ordine)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it can significantly impact budgeting and inventory planning. Knowing the MOQ can help businesses manage cash flow and avoid overcommitting to stock that may not sell.

3. RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers to request pricing information for specific products. For buyers, issuing RFQs for the 18 oz hotshot bottle allows them to compare costs and negotiate better terms, ensuring they receive competitive pricing.

4. Incoterms (Termini commerciali internazionali)

These are international rules that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is essential for B2B buyers, especially when importing products like the hotshot bottle from different regions, as they dictate who pays for shipping, insurance, and tariffs.

5. Customization

This term refers to the ability to modify a product to meet specific customer needs or branding requirements. For B2B buyers, customization options for the 18 oz hotshot bottle can enhance marketability and cater to niche markets, providing a competitive edge.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their business goals and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the 18 oz hotshot bottle Sector

What Are the Current Market Dynamics and Key Trends in the 18 oz Hotshot Bottle Sector?

The global market for drinkware, particularly insulated bottles like the 18 oz hotshot bottle, is experiencing robust growth driven by increasing consumer awareness around hydration, health, and wellness. As more individuals prioritize on-the-go lifestyles, there is a rising demand for portable, durable, and efficient hydration solutions. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing products that offer both functionality and aesthetic appeal, which aligns with regional preferences for style and quality.

Emerging technologies are reshaping sourcing strategies, with digital platforms enhancing supplier visibility and facilitating more efficient procurement processes. For instance, the adoption of e-commerce solutions allows buyers to explore a wider range of suppliers while leveraging data analytics for informed decision-making. Additionally, the integration of smart features, such as temperature monitoring and app connectivity, is becoming prevalent, appealing to tech-savvy consumers and businesses.

Market dynamics are also influenced by shifts in consumer behavior. The demand for customization options is growing, as buyers seek products that reflect their brand identity or cater to specific customer preferences. Furthermore, the rise of eco-conscious consumers is compelling manufacturers to innovate with sustainable materials and ethical production practices, thereby creating a competitive edge in the market.

How Is Sustainability Influencing B2B Sourcing of the 18 oz Hotshot Bottle?

Sustainability has become a key consideration in the sourcing strategies of B2B buyers, particularly in the context of the 18 oz hotshot bottle. The environmental impact of single-use plastics and traditional manufacturing processes has prompted businesses to prioritize sustainable alternatives. This includes sourcing bottles made from 18/8 kitchen-grade stainless steel, which is not only durable but also recyclable, thus minimizing the ecological footprint.

Incorporating sustainability into the supply chain is essential for fostering brand loyalty among consumers who are increasingly making purchase decisions based on environmental ethics. Certifications such as ISO 14001 (Environmental Management) and the use of BPA-free materials are becoming benchmarks for quality assurance in sourcing. B2B buyers should look for suppliers who adhere to these standards and can demonstrate their commitment to sustainable practices.

Moreover, the implementation of circular economy principles—where products are designed for reuse and recycling—presents significant opportunities for businesses in this sector. By investing in sustainable sourcing, companies can enhance their brand reputation, comply with regulatory requirements, and meet the growing consumer demand for eco-friendly products.

What Is the Brief Evolution and History of the Hotshot Bottle Market?

The evolution of the hotshot bottle market reflects broader trends in consumer lifestyle and environmental awareness. Initially, insulated bottles were primarily used for outdoor activities; however, their popularity surged as urban consumers recognized the convenience and benefits of portable hydration. The introduction of advanced materials, such as double-wall vacuum insulation, revolutionized the market by significantly improving the thermal retention of beverages.

In recent years, the growth of the wellness movement has further propelled the demand for high-quality drinkware. As consumers become more health-conscious, the focus has shifted toward products that not only offer functionality but also promote a lifestyle of sustainability and responsible consumption. Today, the 18 oz hotshot bottle is not merely a hydration tool but a statement of personal values and lifestyle choices, appealing to a diverse range of consumers from fitness enthusiasts to environmentally conscious individuals.

Frequently Asked Questions (FAQs) for B2B Buyers of 18 oz hotshot bottle

-

How do I ensure the quality of 18 oz hotshot bottles before placing a bulk order?

To ensure the quality of 18 oz hotshot bottles, request samples from potential suppliers. Evaluate the material, insulation performance, and overall durability. Additionally, inquire about the manufacturing process and quality assurance practices they implement. Certifications such as ISO standards or compliance with international safety regulations can also provide peace of mind regarding product quality. Establishing a clear communication line with the supplier for quality checks and inspections during production can further mitigate risks. -

What is the best type of 18 oz hotshot bottle for hot beverages?

The best type of 18 oz hotshot bottle for hot beverages should feature double-wall vacuum insulation, which maintains temperature effectively. Look for bottles made from 18/8 kitchen-grade stainless steel, as they are known for their durability and resistance to rust and punctures. A leakproof and shatter-resistant lid, like the HotShot™ Cap, allows for easy sipping from any side and ensures no spills during transport. Always verify that the bottle is dishwasher safe for easy cleaning. -

What should I consider when negotiating payment terms with suppliers?

When negotiating payment terms, consider factors such as payment methods (e.g., bank transfer, letter of credit), payment schedules (e.g., upfront deposit, net 30/60 days), and currency fluctuations. It’s important to assess the supplier’s reliability and reputation before committing to significant upfront payments. Additionally, clarify any penalties for late payments or discounts for early settlements. Establishing trust through transparent communication can lead to more favorable terms for both parties. -

What are the minimum order quantities (MOQs) for 18 oz hotshot bottles?

Minimum order quantities (MOQs) for 18 oz hotshot bottles can vary significantly between suppliers, often ranging from 100 to 1,000 units. Factors influencing MOQs include the supplier’s production capacity, material costs, and customization options. It is advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your budget and inventory requirements. Some suppliers may offer flexible MOQs for repeat customers or larger orders. -

How can I verify the credibility of a supplier for 18 oz hotshot bottles?

To verify a supplier’s credibility, conduct thorough research, including checking their business licenses and certifications. Look for reviews or testimonials from previous customers and assess their track record through platforms like Alibaba or global sourcing directories. Engage in direct communication to gauge their responsiveness and willingness to provide references. Additionally, consider requesting a factory visit or third-party inspection to evaluate their operations and product quality firsthand. -

What customization options are available for 18 oz hotshot bottles?

Customization options for 18 oz hotshot bottles typically include branding, colors, and additional features like different cap types or sizes. Many suppliers offer printing or engraving services to add logos or designs, making them suitable for promotional purposes. Discuss your branding requirements with potential suppliers to understand their capabilities and any associated costs. Ensure that the customization process does not compromise the bottle’s functionality or quality. -

What logistics considerations should I keep in mind when importing 18 oz hotshot bottles?

When importing 18 oz hotshot bottles, consider factors such as shipping methods (air vs. sea), customs regulations, and potential tariffs. Assess the total landed cost, which includes product price, shipping fees, and import duties. Collaborate with a freight forwarder to streamline logistics and ensure compliance with all import/export regulations. It’s also prudent to plan for potential delays in shipping and customs clearance, especially when sourcing from international suppliers. -

How do I handle potential issues with defective products upon delivery?

To handle potential issues with defective products, establish a clear return and warranty policy with your supplier before placing an order. Upon delivery, conduct a thorough inspection of the shipment to identify any defects or discrepancies. Document any issues with photos and detailed descriptions, and communicate promptly with the supplier for resolution. A reputable supplier will typically offer replacements or refunds for defective items, ensuring a smooth resolution process.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo fatto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Top 7 18 Oz Hotshot Bottle Manufacturers & Suppliers List

1. YETI – Rambler Bottle

Dominio: acehardware.com

Registrato: 1995 (30 anni)

Introduzione: This company, YETI – Rambler Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Rambler – 18oz Hotshot Bottle

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: 18oz Rambler Hotshot bottle – Discontinued; available replacement only in hot pink; issues with interior peeling; potential redesign of hotshot lid; supply chain concerns affecting production; interchangeable lids with other 18oz Rambler bottles.

3. Yeti – Rambler with Hotshot Cap

Dominio: llbean.com

Registrato: 1995 (30 anni)

Introduzione: {“product_name”: “Yeti Rambler with Hotshot Cap”, “capacity”: “18 oz”, “weight”: “17.6 oz”, “dimensions”: “8.9’H x 3′ diam.”, “construction”: “Stainless steel, double-wall vacuum insulation”, “features”: [“Keeps drinks hot or cold for hours”, “100% leakproof HotShot Cap”, “Puncture- and rust-resistant”, “No Sweat Design prevents condensation”, “FatLid insulation in the cap”, “360-degree drinking c…

4. YETI – Rambler 18 oz Bottle with HotShot Cap

Dominio: steelcitycon.com

Registrato: 2006 (19 anni)

Introduzione: YETI Rambler 18 oz Bottle with HotShot Cap, designed for on-the-go hot drink needs, holds piping-hot coffee or tea, features 360-degree HotShot Cap that is 100% leak-proof and fully rotational for easy sipping from any side.

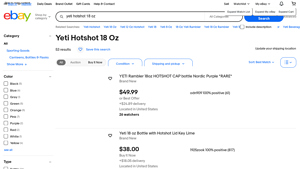

5. YETI – Hotshot 18 Oz

Dominio: ebay.com

Registrato: 1995 (30 anni)

Introduzione: Yeti Hotshot 18 Oz; Brand: YETI; Condition: New; Available Colors: Nordic Purple, Key Lime, Wetlands Brown, Alpine Yellow, Camp Green, Tan Camo, Canopy Green, Seafoam, High Desert Clay, Navy Blue, Silver, Sandstone Pink; Price Range: HKD 152.25 to HKD 781.09; Delivery: Varies by seller; Features: Hotshot Cap, Insulated Stainless Steel, Limited Edition options available.

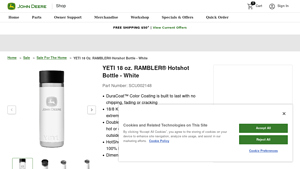

6. YETI – 18 oz. RAMBLER® Hotshot Bottle

Dominio: shop.deere.com

Registered: 1990 (35 years)

Introduzione: {“product_name”: “YETI 18 oz. RAMBLER® Hotshot Bottle – White”, “part_number”: “SCU002148”, “features”: {“DuraCoat_Color_Coating”: “Built to last with no chipping, fading or cracking”, “material”: “18/8 Kitchen-grade stainless steel construction for extreme durability”, “insulation”: “Double-wall vacuum insulation keeps your beverage hot or cold longer”, “design”: “No Sweat™ Design keeps the outsi…

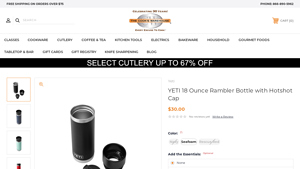

7. YETI – 18 Ounce Rambler Bottle

Dominio: cookswarehouse.com

Registrato: 1997 (28 anni)

Introduzione: YETI 18 ounce Rambler Bottle with Hotshot Cap, MSRP: $30.00, available colors: Navy, Seafoam, Rescue Red. Optional accessories: YETI Bottle 5 oz Cup Cap – $30.00, YETI Bottle Straw Cap – $13.00, YETI Rambler Bottle Chug Cap – $13.00. Free shipping on orders over $75.

Strategic Sourcing Conclusion and Outlook for 18 oz hotshot bottle

The strategic sourcing of the 18 oz hotshot bottle presents significant opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The robust construction, including 18/8 kitchen-grade stainless steel and double-wall vacuum insulation, ensures durability and exceptional temperature retention. Buyers can leverage these features to cater to a growing market demand for high-quality, versatile hydration solutions, which are increasingly sought after by consumers prioritizing both function and style.

Emphasizing the importance of strategic sourcing, businesses should focus on establishing reliable supplier relationships that guarantee consistent quality and timely delivery. Engaging with manufacturers that offer customizable options can further enhance brand differentiation in competitive markets.

As we look to the future, the demand for innovative drinkware solutions like the 18 oz hotshot bottle is poised to grow. International buyers are encouraged to explore partnerships with reputable brands, ensuring they capitalize on this trend. By doing so, companies can not only enhance their product offerings but also position themselves as leaders in the hydration market, ready to meet the evolving needs of consumers across diverse regions.