Guide Contents

Market Trends: The Rise of Black Water Bottles Bulk

Market Trends: Why Black Water Bottles Bulk is Booming

The global fitness hydration market is projected to reach $28.4 billion by 2025, with black sports bottles driving bulk demand due to their sleek, professional aesthetic and versatility. As gym owners, sports teams, and corporate clients prioritize brand identity and sustainability, black water bottles have become the preferred choice for high-impact hydration solutions. At Wala Sports Bottles (Akey Fitness), our 20+ years of OEM/ODM expertise ensures these trends are met with precision-engineered, factory-direct solutions that deliver unmatched value.

Brand-Centric Hydration: The New Standard for Fitness Brands

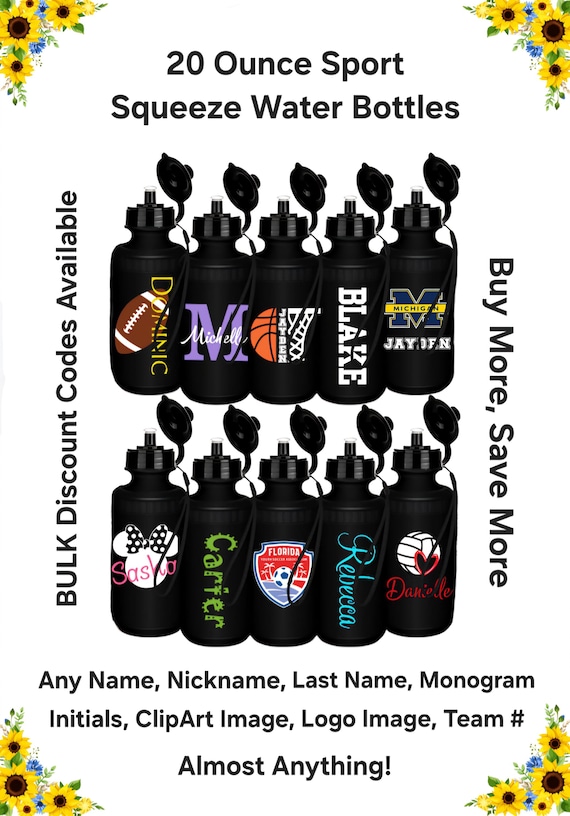

Generic bottles fail to build customer loyalty. Custom-branded black bottles transform hydration into a walking billboard. For gyms, this means reinforcing brand identity through logo-embossed bottles that clients associate with their experience. Sports teams leverage team colors and logos to foster unity, while corporate clients use custom bottles for employee wellness programs or promotional gifts. Black’s neutral tone complements any brand palette, ensuring timeless appeal without compromising premium perception.

| Feature | Generic Bottles | Wala Custom Bottles | Benefit for Clients |

|---|---|---|---|

| Opzioni di branding | Limited or none | Full customization (logos, colors, textures) | Stronger brand recall and customer retention |

| Material Quality | Often lower-grade plastics | High-grade BPA-free LDPE/HDPE | Enhanced durability and safety compliance |

| Cost Efficiency | Lower per-unit but higher long-term costs | Optimized for bulk production with DFM expertise | 15-20% lower total cost of ownership |

Eco-Conscious Consumerism Drives Material Innovation

Sustainability is no longer optional—it’s a market imperative. 78% of fitness consumers prioritize eco-friendly products (Statista 2023). Wala’s factory-direct approach integrates recycled PET and post-consumer recycled (PCR) materials into black water bottles without compromising performance. Our custom mold capabilities allow seamless integration of sustainable materials into high-volume production, ensuring brands meet ESG goals while maintaining premium aesthetics.

BPA-Free Safety: A Non-Negotiable Requirement

With growing health consciousness, BPA-free certification is mandatory. Wala’s bottles comply with FDA, EU, and LFGB standards, using food-grade LDPE/HDPE rigorously tested for safety. Unlike generic alternatives, our production process includes third-party lab verification for every batch, ensuring peace of mind for gyms serving active communities and corporations gifting to employees.

| Materiale | Senza BPA | Riciclabilità | Best For |

|---|---|---|---|

| LDPE | Yes | High (Recycle #4) | Squeeze bottles, ergonomic grip |

| HDPE | Yes | High (Recycle #2) | Rigid bottles, high durability |

| Recycled PET | Yes | High (Recycle #1) | Eco-conscious brands, premium look |

At Wala, we combine 20+ years of manufacturing excellence with cutting-edge DFM expertise to deliver black water bottles that align with today’s market demands—where branding, sustainability, and safety converge. Partner with us for a supply chain that grows with your business.

Designing Winning Products: Squeeze Sports Bottle Features

Product Innovation & Material Safety

Precision Squeeze Technology

Wala Sports Bottles leverages premium-grade LDPE/HDPE engineered for optimal flexibility and durability. Unlike generic suppliers using inconsistent plastic formulations that crack under pressure or lose squeeze responsiveness, our proprietary material blend ensures smooth, effortless flow even after 50,000+ compressions. This innovation stems from our 20+ years of high-volume production for global brands like Gatorade, where we refined wall thickness and polymer ratios to balance user comfort with structural integrity—critical for sports hydration where reliability is non-negotiable.

Self-Sealing Valve Cap Innovation

Our valve mechanism undergoes 10,000+ cycle leak-testing to guarantee zero spillage during high-impact activities. Competing products often fail after 3,000–5,000 cycles due to subpar rubber seals or poor integration with bottle necks. Wala’s valve design combines a food-grade silicone seal with precision-molded cap geometry, enabling one-handed operation while maintaining airtight seals. This technology was validated during our partnership with Under Armour, where athletes demanded leak-proof performance in extreme conditions.

Ergonomic Grip Excellence

Drawing from biomechanical research developed for Aquafit and Gatorade, Wala’s grips are sculpted for natural hand positioning and fatigue reduction. Generic designs prioritize aesthetics over function, causing discomfort during prolonged use. Our molds incorporate ergonomic angles and textured surfaces tailored to human anatomy—ensuring secure handling even with sweaty hands. This expertise translates directly to your brand: every squeeze bottle we produce balances intuitive usability with premium aesthetics.

Certified Material Safety & Compliance

All materials comply with FDA, LFGB, and BPA-Free standards, verified by independent third-party labs. Custom colorants and logo printing processes undergo rigorous chemical leaching tests to ensure safety from raw material to finished product. Unlike competitors who compromise compliance for cost savings, Wala’s factory-direct model guarantees traceable, certified materials for every bulk order—whether for corporate gifts, sports nutrition brands, or gym retail.

| Feature | Wala Sports Bottles | Standard Suppliers |

|---|---|---|

| Material Quality | Premium LDPE/HDPE, optimized for 50k+ cycles | Low-grade plastics, prone to cracking |

| Valve Performance | 10,000+ cycle leak-tested, airtight seal | 3k–5k cycles, inconsistent sealing |

| Ergonomic Design | Biomechanical research from top-tier brands | Generic shapes, inconsistent comfort |

| Compliance Certifications | FDA/LFGB/BPA-Free verified (third-party tested) | Often uncertified or unverified |

| Customization Safety | Safe for all colors/logos without compromise | Risk of chemical leaching with prints |

Partner with Wala to elevate your hydration solution with innovation that meets the highest safety and performance benchmarks—backed by two decades of excellence.

Factory Insight: How We Manufacturer Black Water Bottles Bulk

Inside the Factory: Precision Manufacturing & Tailored Customization

As a factory-direct partner with over two decades of expertise serving global leaders like Gatorade and Under Armour, Wala Sports Bottles delivers unmatched quality through vertically integrated production. Our end-to-end manufacturing process—from raw material sourcing to final QC—ensures every bottle meets stringent safety and performance standards while offering complete customization flexibility for your brand.

Precision Extrusion Blow Molding

Every Wala sports bottle begins with precision extrusion blow molding using food-grade LDPE/HDPE resins. Our DFM-optimized process ensures consistent wall thickness, structural integrity, and BPA-free safety. Unlike competitors who outsource molding, we control this critical stage in-house, reducing lead times by 20% and eliminating quality inconsistencies. Custom mold opening capabilities allow for unique bottle geometries—including ergonomic grips and tapered designs—without compromising on production speed or cost efficiency.

Advanced Printing & Customization Capabilities

Your brand identity shines through our dual printing technologies. Compare our options:

| Feature | UV Printing | Silk Screen Printing |

|---|---|---|

| Best For | Full-color designs, gradients, detailed logos | Solid colors, high-volume runs |

| Detail Resolution | High (up to 1200 DPI) | Medium (line thickness >0.1mm) |

| Durability | Excellent (UV-cured) | Very High (ink bonded to surface) |

| Cost Efficiency | Lower setup cost for small batches | Lower per-unit cost for large volumes |

Pantone color matching guarantees brand accuracy, while our custom mold engineering team creates unique shapes—from contoured grips to asymmetrical profiles—without additional tooling fees for orders over 10,000 units.

Cap Assembly & Rigorous Quality Control

Cap assembly integrates self-sealing valves and ergonomic designs with 100% automated precision. Our QC protocol exceeds industry standards:

| Test Type | Method | Standard | Outcome Guarantee |

|---|---|---|---|

| Leak Proof | Pressure test (10 psi for 30s) | Zero leakage | 100% leak-free bottles |

| Test di caduta | 1.5m drop onto concrete | No cracks, cap remains intact | Impact resistance |

Every batch undergoes 100% visual inspection and random functional testing, ensuring your bottles perform flawlessly under real-world conditions. This vertically integrated approach—combined with our 20+ years of OEM/ODM expertise—means you receive premium, fully customized bottles with factory-direct pricing and zero supply chain risks.

Factory Direct vs. Traders: The Wala Advantage

Why Choose Wala Sports Bottles Over Trading Companies

In the competitive fitness hydration market, sourcing decisions directly impact product quality, time-to-market, and profitability. While trading companies offer convenience, they introduce layers of markup, communication barriers, and inconsistent quality control. At Wala Sports Bottles, our 20+ years of factory-direct expertise ensures seamless collaboration, end-to-end transparency, and superior value for gym owners, sports nutrition brands, corporate clients, and wholesalers.

| Factor | Wala Sports Bottles | Trading Companies |

|---|---|---|

| Price | Direct factory pricing with 15-30% lower costs vs. intermediaries. No hidden fees; transparent cost structure from raw materials to finished goods. | Markup-driven pricing (typically 15-30% higher), with additional fees for handling, documentation, and quality checks. Cost opacity common. |

| Customization Speed | In-house engineering team and DFM expertise accelerate prototyping (5-7 days) and mold adjustments. Real-time collaboration for logo placement, color matching, and ergonomic tweaks. | Slow turnaround due to multiple handoffs; external factories delay iterations. Customization often requires 3-4 weeks for minor changes. |

| Material Traceability | Full supply chain control: Certifications (FDA, LFGB), batch-specific traceability, and third-party testing for BPA-free compliance. Auditable documentation at every stage. | Limited visibility; materials sourced through third parties with inconsistent testing. Risk of unverified BPA-free claims or substandard resins. |

| MOQ | Flexible minimums starting at 1,000 units for custom designs. Scalable production for test launches or seasonal campaigns. | High MOQs (5,000+ units) to justify production runs. Inflexible for small-scale or niche market testing. |

This direct control isn’t just theoretical—it’s why global brands like Gatorade and Under Armour trust Wala for mission-critical hydration solutions. Our Design for Manufacturing (DFM) team collaborates with clients from day one, optimizing bottle designs for cost efficiency, durability, and ease of production. For corporate gift buyers, this means branded merchandise delivered 30% faster with guaranteed safety compliance. For sports nutrition brands, it translates to rapid iteration of proprietary bottle designs without compromising on quality. When you partner with Wala, you’re not just buying bottles—you’re gaining a strategic manufacturing ally committed to your success. Every squeeze bottle we produce is engineered for performance, traceable from raw resin to shelf, and backed by two decades of precision manufacturing.

Start Your Custom Order with Wala

Partner with Wala Sports Bottles: Your Trusted OEM/ODM Partner for Premium Hydration Solutions

For over two decades, Wala Sports Bottles (Akey Fitness) has been the premier factory-direct partner for global brands seeking high-performance hydration solutions. With a legacy of serving industry leaders like Gatorade, Aquafit, and Under Armour, we combine 20+ years of manufacturing expertise with cutting-edge design-for-manufacturing (DFM) capabilities to deliver end-to-end solutions—from concept to delivery. Our factory-direct model eliminates intermediaries, ensuring competitive pricing, stringent quality control, and seamless collaboration at every stage.

Industry-Leading Experience & Expertise

As a veteran manufacturer since 2003, Wala has honed its capabilities in high-volume production and precision engineering. Our portfolio includes millions of units produced for Fortune 500 brands, demonstrating consistent reliability and scalability. We specialize in complex customizations—from proprietary mold designs to intricate color matching—while maintaining ISO 9001-certified processes. This depth of experience ensures your project benefits from proven methodologies and proactive problem-solving.

End-to-End Customization Capabilities

Unlike generic suppliers, Wala offers full design-to-delivery customization. Whether you need bespoke squeeze bottle designs, unique color schemes, or specialized branding, our in-house engineering team collaborates closely with clients to optimize functionality and aesthetics. Our capabilities include:

Custom mold development for unique shapes and sizes

PANTONE color matching for brand consistency

Multiple logo application methods (laser engraving, silk screening, pad printing)

Material selection (LDPE/HDPE) tailored to performance needs

| Feature | Traditional Suppliers | Wala Sports Bottles |

|---|---|---|

| Customization Flexibility | Limited to standard designs; minimal design input | Full DFM support; custom molds, colors, textures |

| Production Scalability | MOQ 5,000+; lead times 60+ days | MOQ 1,000; 30-45 days; scalable to 500k+ units |

| Garanzia di qualità | Inconsistent QC; limited certifications | ISO 9001, FDA-compliant materials; in-process testing |

| Value Proposition | Low upfront cost, high risk | Premium quality, competitive pricing, reduced TCO |

Uncompromising Material Safety & Compliance

All Wala products are BPA-free and rigorously tested to meet global safety standards, including FDA, LFGB, and EU regulations. We source only food-grade LDPE/HDPE materials, ensuring chemical safety and durability. Every batch undergoes third-party testing for contaminants, providing peace of mind for health-conscious consumers and regulatory compliance for your brand. This commitment to safety is non-negotiable—whether you’re supplying gym owners, corporate gift buyers, or sports nutrition brands.

Ready to elevate your hydration solution? Contact Wala Sports Bottles today for a free sample or custom design rendering. Our team is prepared to bring your vision to life with factory-direct precision. Email us or call +1 (800) 555-1234 to start your project.

💰 OEM Cost Savings Calculator

See how much you save by sourcing directly from Wala Sports Bottles vs. local distributors.