Introduction: Navigating the Global Market for stainless steel drinking bottles made in usa

In an increasingly eco-conscious world, sourcing high-quality stainless steel drinking bottles made in the USA presents a unique challenge for international B2B buyers. Whether you are in Nigeria, Germany, or Brazil, the need for sustainable, durable, and aesthetically pleasing drinkware is paramount for your clientele. This comprehensive guide delves into the diverse types of stainless steel drinking bottles available, their various applications across industries, and effective strategies for vetting suppliers.

As the demand for sustainable products rises, buyers must navigate considerations such as material quality, manufacturing practices, and customization options to ensure they make informed purchasing decisions. This guide empowers B2B buyers by providing insights into cost structures, potential suppliers, and key differentiators in the marketplace.

By understanding the nuances of the stainless steel drinking bottle market, you can streamline your procurement processes and align your product offerings with the preferences of a global audience. From promotional items to corporate gifts, the right bottle can enhance brand visibility while meeting consumer expectations for sustainability and functionality. Equip yourself with the knowledge needed to thrive in this competitive landscape and make choices that resonate with your business values and customer needs.

Navigazione tra gli articoli

- Top 7 Stainless Steel Drinking Bottles Made In Usa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for stainless steel drinking bottles made in usa

- Understanding stainless steel drinking bottles made in usa Types and Variations

- Key Industrial Applications of stainless steel drinking bottles made in usa

- 3 Common User Pain Points for ‘stainless steel drinking bottles made in usa’ & Their Solutions

- Strategic Material Selection Guide for stainless steel drinking bottles made in usa

- In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel drinking bottles made in usa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel drinking bottles made in usa’

- Comprehensive Cost and Pricing Analysis for stainless steel drinking bottles made in usa Sourcing

- Alternatives Analysis: Comparing stainless steel drinking bottles made in usa With Other Solutions

- Essential Technical Properties and Trade Terminology for stainless steel drinking bottles made in usa

- Navigating Market Dynamics and Sourcing Trends in the stainless steel drinking bottles made in usa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel drinking bottles made in usa

- Disclaimer importante e condizioni d'uso

- Strategic Sourcing Conclusion and Outlook for stainless steel drinking bottles made in usa

Understanding stainless steel drinking bottles made in usa Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Bottiglie d'acqua isolate | Double-wall vacuum insulation, keeps drinks hot or cold | Outdoor gear retailers, corporate gifting | Pro: Excellent temperature retention, durable construction. Contro: Typically heavier than non-insulated options. |

| Non-Insulated Water Bottles | Lightweight, single-wall construction | Sports teams, schools, promotional products | Pro: Lighter and more portable, cost-effective. Contro: Limited temperature retention. |

| Custom Branded Bottles | Options for logo printing or engraving | Branding agencies, corporate gifts | Pro: Enhances brand visibility, personalized touch. Contro: Higher minimum order quantities may apply. |

| Bottiglie d'acqua per bambini | Smaller sizes, colorful designs, and easy-to-use caps | Schools, daycare centers, children’s events | Pro: Encourages hydration among children, appealing designs. Contro: May not withstand rough use. |

| Adventure-Ready Bottles | Designed for outdoor activities, often with rugged features | Outdoor retailers, adventure tourism companies | Pro: Tailored for durability and functionality in nature. Contro: Can be more expensive due to specialized design. |

What Are Insulated Water Bottles and Their B2B Applications?

Insulated water bottles are designed with double-wall vacuum insulation that keeps beverages hot or cold for extended periods. They are ideal for outdoor gear retailers looking to provide high-quality hydration solutions for adventurers and corporate gifting opportunities, where product reliability is paramount. When purchasing, businesses should consider factors such as insulation efficiency, durability, and branding options, as these features significantly enhance the product’s marketability.

How Do Non-Insulated Water Bottles Differ in Use Cases?

Non-insulated water bottles are lightweight and constructed from single-wall stainless steel, making them perfect for sports teams, schools, and promotional products. Their cost-effectiveness and portability make them attractive to businesses that prioritize budget and convenience. However, buyers should be aware of their limited temperature retention capabilities, which may not suit all applications, particularly in extreme climates.

What Advantages Do Custom Branded Bottles Offer for Businesses?

Custom branded bottles allow businesses to enhance their visibility through logo printing or engraving. This option is particularly appealing to branding agencies and companies looking to give personalized gifts. The primary considerations for B2B buyers include minimum order quantities and the potential for increased marketing reach. While they can be pricier, the promotional benefits often justify the investment.

Why Are Kids’ Water Bottles Important for Educational Institutions?

Kids’ water bottles are specifically designed for smaller hands, featuring colorful designs and easy-to-use caps. They are particularly suited for schools, daycare centers, and children’s events, promoting hydration among children. When sourcing these products, buyers should consider durability and design appeal, as products that can withstand daily use while engaging children are essential for long-term satisfaction.

What Features Make Adventure-Ready Bottles Essential for Outdoor Activities?

Adventure-ready bottles are tailored for rugged outdoor use, often incorporating features like carabiner clips or reinforced materials. They are essential for outdoor retailers and adventure tourism companies seeking to equip customers with reliable hydration solutions. Key purchasing considerations include the bottle’s durability, weight, and functional design, which can significantly impact user experience in challenging environments.

Key Industrial Applications of stainless steel drinking bottles made in usa

| Industria/Settore | Specific Application of stainless steel drinking bottles made in usa | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Outdoor and Adventure | Used by outdoor sports brands for hiking, camping, and travel gear. | Enhances brand reputation by promoting sustainability. | Look for durable, lightweight materials and customizable branding. |

| Benessere aziendale | Provided as part of employee wellness programs or corporate gifts. | Boosts employee health and morale, promoting hydration. | Ensure BPA-free and food-grade materials with branding options. |

| Ospitalità | Utilized in hotels and restaurants for guest services and eco-friendly initiatives. | Enhances customer experience and supports sustainability goals. | Sourcing should focus on design, insulation properties, and bulk purchasing options. |

| Istruzione | Used in schools and universities for student hydration initiatives. | Promotes a healthy lifestyle among students. | Consider size variations and customization for school branding. |

| Vendita al dettaglio | Sold in retail outlets as eco-friendly alternatives to plastic bottles. | Attracts environmentally conscious consumers. | Look for competitive pricing and attractive packaging options. |

How Are Stainless Steel Drinking Bottles Applied in the Outdoor and Adventure Sector?

Stainless steel drinking bottles are integral to outdoor and adventure brands, catering to hiking, camping, and travel enthusiasts. These bottles are designed to withstand harsh conditions, providing insulation for hot and cold beverages. For international buyers, particularly from regions like Africa and South America, sourcing durable, lightweight bottles is essential. These products often feature customizable branding, allowing companies to enhance their visibility while promoting sustainability.

What Role Do Stainless Steel Bottles Play in Corporate Wellness Programs?

In corporate environments, stainless steel drinking bottles are increasingly included in wellness programs and as corporate gifts. These bottles encourage employees to stay hydrated, which can lead to improved health and productivity. For buyers in Europe, such as Germany, the focus should be on BPA-free and food-grade materials. Custom branding options can also help reinforce company values and enhance employee engagement.

How Are Stainless Steel Bottles Used in the Hospitality Industry?

In the hospitality sector, stainless steel drinking bottles are used in hotels and restaurants to offer eco-friendly alternatives to single-use plastics. These bottles can be provided to guests as part of a sustainability initiative, improving the overall customer experience. Buyers should prioritize sourcing bottles with appealing designs and effective insulation properties. Bulk purchasing options are also critical for cost-effectiveness in this competitive industry.

Why Are Stainless Steel Bottles Important for Educational Institutions?

Educational institutions utilize stainless steel drinking bottles to promote hydration among students. By providing these bottles, schools can encourage healthy habits while reducing plastic waste. Buyers, particularly in regions like the Middle East, should consider various size options and customization features that align with school branding. Emphasizing safety and durability is also crucial to meet the needs of active students.

How Do Retailers Benefit from Offering Stainless Steel Bottles?

Retailers increasingly stock stainless steel drinking bottles as eco-friendly alternatives to plastic. These products appeal to environmentally conscious consumers, enhancing the store’s reputation and driving sales. When sourcing, retailers should focus on competitive pricing and attractive packaging to differentiate their offerings. Additionally, understanding market trends can help retailers select designs and features that resonate with their target audience.

3 Common User Pain Points for ‘stainless steel drinking bottles made in usa’ & Their Solutions

Scenario 1: Sourcing Quality and Compliance Issues

Il problema: B2B buyers often face significant challenges when sourcing stainless steel drinking bottles made in the USA, particularly concerning quality assurance and compliance with safety regulations. Many international buyers may not be familiar with the stringent standards required for products sold in the U.S. market, leading to potential discrepancies in quality, safety, and durability. This could result in product returns, damage to reputation, and financial losses if the products do not meet the required specifications or customer expectations.

La soluzione: To mitigate these risks, buyers should prioritize sourcing from manufacturers that are transparent about their production processes and quality control measures. Conducting thorough due diligence is crucial; this includes verifying certifications such as FDA approval and compliance with ASTM standards for food safety. Engaging in direct communication with suppliers about their sourcing practices, materials used, and production methods can also provide peace of mind. Utilizing third-party inspection services during the manufacturing process can further ensure that the products meet the necessary quality benchmarks before shipment.

Scenario 2: Customization and Branding Limitations

Il problema: Many B2B buyers seek to differentiate their products in a competitive market through customization and branding. However, when sourcing stainless steel drinking bottles, they often encounter limitations in design options, sizes, and branding capabilities from suppliers. This can hinder their ability to offer unique products that resonate with their target audience, particularly in regions like Africa and South America, where local branding can significantly impact sales.

La soluzione: To overcome these challenges, buyers should seek manufacturers that specialize in customizable solutions. Look for suppliers that provide a range of options for sizes, colors, and printing techniques, including laser engraving and full-color printing. Establishing a collaborative relationship with the supplier can also facilitate the development of exclusive designs tailored to specific market needs. Additionally, consider leveraging technology such as 3D modeling or virtual samples to visualize potential customizations before committing to large orders, ensuring that the final product aligns with your branding strategy.

Scenario 3: Misunderstanding Product Features and Usability

Il problema: B2B buyers often struggle with understanding the specific features and usability of stainless steel drinking bottles, which can lead to poor purchasing decisions. Features like insulation, lid types, and cleaning requirements can vary significantly between products. This can result in customer dissatisfaction if the bottles fail to meet the intended use—be it for outdoor activities, corporate gifts, or everyday hydration.

La soluzione: To effectively navigate these complexities, buyers should invest time in educating themselves about the various types of stainless steel drinking bottles available. This includes understanding the differences between insulated and non-insulated options, the benefits of different cap designs, and the importance of materials used (e.g., 18/8 food-grade stainless steel). Suppliers that offer detailed product specifications, user manuals, and even sample products can be invaluable. Additionally, consider reaching out to existing customers or industry peers for testimonials and recommendations, which can provide insights into real-world usability and satisfaction. Engaging with suppliers during the selection process can also clarify any doubts, ensuring that the selected products align with specific usage scenarios and customer expectations.

Strategic Material Selection Guide for stainless steel drinking bottles made in usa

What Are the Key Materials Used in Stainless Steel Drinking Bottles Made in the USA?

When selecting materials for stainless steel drinking bottles, several options are commonly utilized, each with distinct properties and implications for performance, cost, and suitability for international markets. Below, we analyze four prevalent materials used in the manufacturing of these bottles.

1. 18/8 Stainless Steel

Proprietà chiave:

18/8 stainless steel, also known as type 304 stainless steel, contains 18% chromium and 8% nickel. This composition provides excellent corrosion resistance, making it suitable for a variety of beverages, including acidic liquids. It can withstand high temperatures, making it ideal for insulated bottles.

Pro e contro:

The durability of 18/8 stainless steel is a significant advantage, as it resists rust, staining, and corrosion. However, the cost is relatively high compared to other materials, which may impact pricing strategies for B2B buyers. Manufacturing complexity is moderate, requiring specialized techniques for shaping and welding.

Impatto sull'applicazione:

This material is compatible with a wide range of liquids, including water, juices, and even hot beverages. Its resistance to leaching ensures that the taste and quality of the contents remain unaffected.

Considerazioni per gli acquirenti internazionali:

For buyers in regions like Africa and South America, compliance with food safety standards is crucial. The material meets ASTM standards, which are recognized globally, including in Germany and the Middle East. Buyers should verify local regulations regarding food-grade materials.

2. 18/10 Stainless Steel

Proprietà chiave:

18/10 stainless steel is similar to 18/8 but contains a higher nickel content (10%). This enhances its corrosion resistance and durability, making it ideal for high-performance applications.

Pro e contro:

The primary advantage of 18/10 stainless steel is its superior resistance to corrosion and staining, making it ideal for long-term use. However, this material is more expensive than 18/8 stainless steel, which may not align with all budget constraints. The manufacturing process is similar but requires additional quality control.

Impatto sull'applicazione:

This material is particularly suitable for insulated bottles and can handle a variety of beverages, including carbonated drinks, without risk of degradation.

Considerazioni per gli acquirenti internazionali:

Buyers in Europe and the Middle East often prefer 18/10 stainless steel due to its high quality and compliance with stringent standards. Ensuring adherence to local regulations regarding food safety is essential.

3. Aluminum with Stainless Steel Coating

Proprietà chiave:

Aluminum is lightweight and has good thermal conductivity. When coated with stainless steel, it gains additional durability and corrosion resistance.

Pro e contro:

The lightweight nature of aluminum makes it easy to transport, which is a significant advantage for outdoor activities. However, the coating process can complicate manufacturing and increase costs. Additionally, aluminum may not be as durable as stainless steel in harsh conditions.

Impatto sull'applicazione:

This material is suitable for lightweight bottles designed for casual use, but it may not be ideal for high-temperature liquids due to the potential for the coating to degrade.

Considerazioni per gli acquirenti internazionali:

While aluminum is recyclable, buyers should consider the environmental impact of the coating process. Compliance with local recycling regulations is vital, particularly in Europe, where sustainability is a priority.

4. Tritan™ Copolyester

Proprietà chiave:

Tritan is a BPA-free copolyester known for its clarity and impact resistance. It is not a metal but is often used in conjunction with stainless steel for bottle components.

Pro e contro:

The primary advantage of Tritan is its lightweight nature and shatter resistance, making it ideal for active lifestyles. However, it is less durable than stainless steel and may not withstand high temperatures.

Impatto sull'applicazione:

Tritan is suitable for non-insulated bottles and is often used for sports and children’s bottles. It is compatible with a range of beverages but may not be suitable for hot liquids.

Considerazioni per gli acquirenti internazionali:

International buyers should verify compliance with food safety standards, especially in regions with strict regulations like Germany. The material’s recyclability may also influence purchasing decisions in environmentally conscious markets.

Summary Table

| Materiale | Typical Use Case for stainless steel drinking bottles made in usa | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| 18/8 Stainless Steel | Insulated and non-insulated bottles for various beverages | Eccellente resistenza alla corrosione | Costo più elevato | Alto |

| 18/10 Stainless Steel | High-performance insulated bottles for premium markets | Superior durability and corrosion resistance | Most expensive | Alto |

| Aluminum with Coating | Lightweight casual use bottles for outdoor activities | Lightweight and easy to transport | Meno durevole dell'acciaio inossidabile | Medio |

| Copoliestere Tritan™ | Non-insulated bottles for sports and kids | Shatter-resistant and lightweight | Not suitable for hot liquids | Basso |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel drinking bottles made in usa

What Are the Main Stages in the Manufacturing Process of Stainless Steel Drinking Bottles?

The manufacturing process of stainless steel drinking bottles involves several critical stages, each designed to ensure the product meets high standards of quality and performance. The main stages include:

-

Preparazione del materiale: The process begins with the selection of high-grade stainless steel, typically 18/8 (304) food-grade stainless steel, known for its corrosion resistance and durability. The steel is cut into sheets or coils, which are then cleaned to remove any contaminants that could affect the final product.

-

Formazione: In this stage, the prepared steel is shaped into the desired bottle form using techniques such as deep drawing or hydroforming. Deep drawing involves pushing the steel through a die to create the bottle’s body, while hydroforming uses high-pressure water to mold the metal. These methods ensure a consistent wall thickness and structural integrity.

-

Montaggio: Once the bottle bodies are formed, they undergo assembly, which may involve attaching components such as lids, caps, and handles. This stage may also include the integration of any insulation layers for double-walled designs, enhancing thermal performance for hot or cold beverages.

-

Finitura: The finishing process encompasses polishing, coating, and branding. Polishing enhances the aesthetic appeal and surface smoothness, while powder coating provides additional durability and customization options. Branding can be achieved through laser engraving or screen printing, allowing for unique designs that appeal to B2B buyers seeking custom solutions.

What Quality Assurance Practices Are Commonly Used in Stainless Steel Bottle Manufacturing?

Quality assurance (QA) is paramount in the production of stainless steel drinking bottles, ensuring that products meet both industry standards and customer expectations. Key QA practices include:

-

International Standards Compliance: Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures consistent quality across manufacturing processes.

-

Certificazioni specifiche del settore: Additional certifications, such as CE (Conformité Européenne) for products sold in Europe, and FDA (Food and Drug Administration) compliance for food-contact materials, are crucial. These certifications validate that products meet safety and regulatory requirements.

-

Punti di controllo della qualità: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Controllo qualità in entrata (CQI): This step assesses the quality of raw materials before production begins.

– Controllo qualità in corso d'opera (IPQC): Regular inspections during production help identify and rectify issues early in the process.

– Controllo qualità finale (CQC): Finished products undergo thorough testing to ensure they meet specifications before shipping. -

Common Testing Methods: Testing methods may include pressure tests, leak tests, and thermal insulation tests. These ensure that the bottles can withstand physical stress and maintain their intended performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control practices of suppliers, particularly when sourcing from international markets. Here are some strategies:

-

Audits: Conducting on-site audits of the manufacturing facilities allows buyers to assess the operational processes, staff competency, and adherence to quality standards. This firsthand observation can provide valuable insights into the supplier’s commitment to quality.

-

Rapporti di garanzia della qualità: Requesting detailed QA reports can help buyers understand the supplier’s quality control measures. Reports should include information on testing outcomes, compliance with industry standards, and any corrective actions taken in response to quality issues.

-

Ispezioni di terze parti: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. These inspections typically occur at various stages of production and can be crucial for ensuring that products meet specified standards before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate several nuances in quality control and certification when sourcing stainless steel drinking bottles:

-

Understanding Regional Standards: Different regions have varying regulations and standards. For example, European buyers must be aware of CE marking requirements, while buyers from Africa may need to consider local certifications. Familiarity with these regulations is essential for compliance and market entry.

-

Language and Cultural Barriers: Communication can pose challenges. Buyers should ensure that suppliers provide documentation and support in languages they understand, including clear explanations of quality assurance processes and certifications.

-

Logistics and Shipping: Quality control does not end with production. International shipping can introduce risks, including damage and contamination. Buyers should ensure that suppliers use appropriate packaging and handling procedures to maintain product integrity during transit.

-

Building Long-Term Relationships: Establishing a strong relationship with suppliers can facilitate better communication regarding quality control issues. Long-term partnerships often yield better support and responsiveness to quality concerns, enhancing the overall supply chain reliability.

Conclusione

In summary, the manufacturing processes and quality assurance practices for stainless steel drinking bottles made in the USA are integral to ensuring product quality and safety. By understanding the main stages of production, the importance of quality assurance, and strategies for verifying supplier practices, international B2B buyers can make informed decisions. This knowledge not only aids in selecting reliable suppliers but also enhances the overall quality of products offered in the marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel drinking bottles made in usa’

In this guide, we present a structured approach to sourcing stainless steel drinking bottles made in the USA, aimed at international B2B buyers. This checklist will help you navigate the procurement process effectively, ensuring that you select a supplier that meets your requirements for quality, compliance, and sustainability.

Fase 1: Definire le specifiche tecniche

Begin by clearly outlining the specifications for the stainless steel drinking bottles you intend to procure. Consider factors such as size, insulation properties, design features, and material grade. Understanding these details will help you communicate your needs effectively to potential suppliers.

- Material Quality: Look for bottles made from food-grade stainless steel, preferably 18/8 (304) grade, which is durable and resistant to rust and corrosion.

- Design Requirements: Specify any unique features, such as leak-proof lids or custom branding options.

Fase 2: Ricerca di potenziali fornitori

Conduct thorough research to identify suppliers that specialize in stainless steel drinkware manufactured in the USA. Utilize online directories, industry trade shows, and recommendations from peers.

- Supplier Background: Evaluate the supplier’s history, market reputation, and experience in producing stainless steel products.

- Geographic Considerations: Consider suppliers located in regions known for manufacturing expertise in drinkware, such as the Midwest.

Fase 3: Valutare le certificazioni dei fornitori

Verify that potential suppliers possess relevant certifications that ensure product quality and compliance with health and safety standards. This step is crucial for maintaining product integrity and gaining consumer trust.

- Garanzia di qualità: Look for ISO 9001 certification, which indicates a commitment to quality management.

- Material Compliance: Ensure that the materials used are BPA-free and comply with FDA regulations.

Passo 4: Richiesta di campioni per la valutazione

Once you have shortlisted potential suppliers, request samples of their stainless steel drinking bottles. This is vital for assessing the quality and functionality of the products.

- Functional Testing: Check for aspects like insulation performance, ease of use, and leak-proof functionality.

- Aesthetic Appeal: Evaluate the design and finish to ensure it aligns with your brand image.

Passo 5: Inquire About Customization Options

Discuss customization possibilities with your selected suppliers. This can include co-branding, color choices, and unique designs that cater to your target market.

- Branding Solutions: Confirm if they offer printing or engraving services to personalize the bottles.

- Minimum Order Quantities: Understand the minimum order requirements for customized products.

Passo 6: Negoziare termini e prezzi

After selecting your preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. This step is crucial to ensure you achieve favorable terms while maintaining quality.

- Volume Discounts: Discuss potential discounts for larger orders to maximize your investment.

- Payment Terms: Clarify payment schedules to align with your cash flow needs.

Passo 7: Establish a Clear Communication Channel

Finally, establish a reliable communication channel with your supplier for ongoing interactions. Clear communication is essential for addressing any issues that may arise during the order process.

- Point of Contact: Designate a specific contact person for all inquiries and updates.

- Feedback Mechanisms: Implement a system for providing feedback on product quality and service, ensuring continuous improvement.

By following this step-by-step checklist, you can streamline your sourcing process for stainless steel drinking bottles made in the USA, ensuring that you partner with a supplier that meets your business needs and expectations.

Comprehensive Cost and Pricing Analysis for stainless steel drinking bottles made in usa Sourcing

What Are the Key Cost Components in Sourcing Stainless Steel Drinking Bottles Made in the USA?

When sourcing stainless steel drinking bottles manufactured in the USA, understanding the cost structure is vital for B2B buyers. The main cost components include:

-

I materiali: Stainless steel quality significantly impacts the price. Common grades include 18/8 (304 stainless steel), which is food-grade and corrosion-resistant. Prices can vary based on market fluctuations, with higher-grade materials generally resulting in a higher cost.

-

Lavoro: Labor costs in the USA can be higher than in other countries. Factors such as skill level, local labor laws, and wage standards contribute to the overall labor costs in production.

-

Spese generali di produzione: This includes costs related to utilities, factory maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thus lowering the overall cost.

-

Utensili: Initial setup for production molds and machinery can be a significant upfront cost. This is particularly relevant for custom designs or unique bottle specifications, as tooling costs can vary widely based on complexity.

-

Controllo qualità (CQ): Ensuring product quality through rigorous QC processes is essential. The cost of quality assurance can add to the overall expense but is necessary for maintaining high standards, especially for international exports.

-

Logistica: Transportation costs, both domestic and international, play a crucial role in the pricing structure. Factors such as distance, shipping method, and tariffs can influence these costs significantly.

-

Margine: Suppliers typically include a profit margin in their pricing. Understanding the average margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Sourcing of Stainless Steel Drinking Bottles?

Several factors can influence the pricing of stainless steel drinking bottles:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Ordering larger volumes often leads to bulk discounts, making it more cost-effective per unit.

-

Specifiche e personalizzazione: Custom designs or specifications (like colors, logos, or additional features) can increase production costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Qualità dei materiali e certificazioni: High-quality materials and certifications (e.g., FDA approval, BPA-free) can raise costs but are essential for ensuring product safety and compliance in various markets.

-

Fattori di fornitura: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their reputation for quality and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) impact overall costs, particularly in terms of shipping responsibilities, risk transfer, and cost allocations. Understanding these terms can help buyers manage their total expenses effectively.

What Tips Can B2B Buyers Utilize for Cost-Efficient Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negoziazione: Engage in open discussions with suppliers about pricing, especially for bulk orders or long-term contracts. Highlight your potential for repeat business to negotiate better terms.

-

Costo totale di proprietà (TCO): Evaluate the TCO, which includes purchase price, shipping, handling, and maintenance costs. This holistic view helps in making informed decisions that go beyond initial pricing.

-

Pricing Nuances: Be aware of currency fluctuations, import duties, and taxes that may affect final costs when sourcing from the USA. Establishing a clear understanding of these factors can prevent unexpected expenses.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices across different suppliers. This practice can provide leverage during negotiations and ensure you receive competitive pricing.

-

Rapporti con i fornitori: Building strong relationships with suppliers can lead to more favorable pricing and terms. Regular communication and feedback can enhance collaboration and trust.

Disclaimer sui prezzi indicativi

It is important to note that prices for stainless steel drinking bottles can vary widely based on the aforementioned factors. The values mentioned here are indicative and subject to change based on market conditions, supplier pricing strategies, and specific buyer requirements. Always consult with suppliers for accurate and current pricing tailored to your needs.

Alternatives Analysis: Comparing stainless steel drinking bottles made in usa With Other Solutions

Introduction to Alternative Solutions for Drinking Bottles

In the competitive market for reusable drinking solutions, businesses are increasingly looking to compare the benefits of stainless steel drinking bottles made in the USA against other viable options. Understanding these alternatives is crucial for B2B buyers who aim to make informed decisions based on factors like performance, cost, and environmental impact. This section explores two primary alternatives: aluminum drinking bottles and plastic reusable bottles, providing a comprehensive analysis to guide procurement strategies.

Tabella di confronto

| Aspetto di confronto | Stainless Steel Drinking Bottles Made in USA | Aluminum Drinking Bottles | Plastic Reusable Bottles |

|---|---|---|---|

| Prestazioni | Excellent insulation; durable; resistant to rust | Good insulation; lightweight | Lower durability; can warp or crack |

| Costo | Higher initial investment; long-term savings | Moderate cost; affordable | Low cost; inexpensive |

| Facilità di implementazione | Custom branding available; easily integrated into promotional strategies | Custom designs possible; lightweight for shipping | Easily sourced; customizable but less durable |

| Manutenzione | Low maintenance; easy to clean; dishwasher safe | Low maintenance; prone to dents | Requires regular cleaning; may retain odors |

| Il miglior caso d'uso | Ideal for outdoor activities and corporate gifting | Great for sports and casual use | Suitable for everyday use, schools, and events |

Ripartizione dettagliata delle alternative

Aluminum Drinking Bottles

Aluminum drinking bottles present a compelling alternative to stainless steel options. They are lightweight, making them suitable for sports and activities where weight is a concern. While they offer good insulation capabilities, their durability is often less than that of stainless steel, as they can dent and scratch easily. Aluminum bottles are typically more affordable than their stainless steel counterparts, making them an attractive option for businesses looking to minimize costs. However, they can have a shorter lifespan due to wear and tear, which may not align with sustainability goals.

Plastic Reusable Bottles

Plastic reusable bottles are the most cost-effective option available, appealing to budget-conscious buyers. They are widely accessible and available in various sizes and colors, making them easy to customize for branding purposes. However, their performance lags behind stainless steel and aluminum options, as they are less durable and can warp or crack over time. Additionally, plastic bottles may retain odors and require more frequent cleaning to maintain hygiene. While suitable for casual use in schools or events, they may not project the same level of quality as stainless steel options.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right drinking bottle solution for your business, it’s essential to consider the specific needs of your target market. Stainless steel drinking bottles made in the USA offer a premium, durable, and sustainable option that is ideal for high-end branding and outdoor use. In contrast, aluminum and plastic alternatives may serve well in less demanding environments or for businesses prioritizing budget constraints. By carefully evaluating the performance, cost, maintenance, and best use cases of each option, B2B buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for stainless steel drinking bottles made in usa

What Are the Key Technical Properties of Stainless Steel Drinking Bottles Made in the USA?

When evaluating stainless steel drinking bottles, several critical specifications must be considered. These properties not only influence product quality but also impact buyer decisions in the B2B marketplace.

1. Grado del materiale

The most common stainless steel grades used for drinking bottles are 18/8 (304) and 18/10 (316). The numbers indicate the percentage of chromium and nickel in the alloy, which enhances corrosion resistance and durability. For B2B buyers, understanding material grades is essential as it affects product longevity and safety, especially in diverse climates.

2. Insulation Type

Many stainless steel bottles feature double-wall vacuum insulation, which maintains the temperature of beverages—keeping drinks cold for up to 24 hours and hot for up to 12 hours. B2B buyers should consider insulation types based on their target market’s needs, such as outdoor enthusiasts or office workers seeking to keep beverages at a desired temperature.

3. Capacity Options

Stainless steel drinking bottles come in various capacities, commonly ranging from 12 oz to 64 oz. The right capacity is crucial for meeting customer demands, whether it’s for everyday hydration, sports activities, or travel. Buyers should assess the market trends in their region to determine the most popular sizes.

4. BPA-Free Certification

While stainless steel is inherently free from BPA (Bisphenol A), certifications that verify a product’s safety for food and drink use are vital. BPA-free certifications assure customers that products are safe for long-term use, which can be a significant selling point in markets sensitive to health and environmental issues.

5. Custom Branding Options

Many manufacturers offer customization options, such as laser engraving or full-color printing. This feature allows businesses to co-brand bottles for promotional purposes. B2B buyers should evaluate customization capabilities to enhance brand visibility and customer loyalty.

What Are Common Trade Terminologies in the Stainless Steel Bottle Industry?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are some key terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are sold under another company’s brand. In the context of stainless steel bottles, buyers may collaborate with OEMs to produce custom designs or specifications. Knowing the OEM landscape can help buyers find reliable manufacturing partners.

2. MOQ (Quantità minima d'ordine)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to ensure they can meet their purchasing needs without overcommitting financially. This term is particularly relevant for small and medium-sized enterprises looking to manage inventory effectively.

3. RFQ (Richiesta di offerta)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. B2B buyers should use RFQs to compare offers and negotiate better pricing and terms, ensuring they make informed purchasing decisions.

4. Incoterms (Termini commerciali internazionali)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and risks in international transactions, particularly when sourcing from the USA.

5. Tempo di esecuzione

Lead time refers to the amount of time it takes from placing an order to receiving it. For B2B buyers, understanding lead times is crucial for planning inventory and ensuring timely delivery to customers.

By grasping these technical properties and industry terminologies, B2B buyers can make informed decisions when sourcing stainless steel drinking bottles made in the USA, ultimately enhancing their procurement processes and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the stainless steel drinking bottles made in usa Sector

What Are the Current Market Dynamics for Stainless Steel Drinking Bottles Made in the USA?

The stainless steel drinking bottles market is experiencing robust growth driven by rising global health consciousness and environmental sustainability. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing products that align with these values. The growing demand for reusable water bottles stems from a collective shift away from single-use plastics, driven by both consumer preferences and regulatory pressures. This trend is further reinforced by an increase in outdoor activities and fitness culture, which has solidified the demand for durable, insulated, and portable hydration solutions.

Emerging B2B technology trends include the rise of direct-to-consumer (DTC) sales models, where manufacturers leverage e-commerce platforms to reach international buyers directly. This approach not only streamlines the supply chain but also provides valuable consumer data to inform product development and marketing strategies. Additionally, customization options for branding and personal expression are gaining traction. Brands are now offering co-branding opportunities, allowing businesses to leverage unique designs or logos to enhance their market presence.

How Are Sustainability and Ethical Sourcing Reshaping the B2B Landscape?

Sustainability has become a cornerstone of B2B purchasing decisions in the stainless steel drinking bottle sector. The environmental impact of production processes is now under scrutiny, with buyers increasingly seeking suppliers who adhere to ethical sourcing practices. This shift is evident in the growing emphasis on using 100% recyclable materials and ensuring that all components are sourced responsibly. For instance, brands that utilize food-grade stainless steel and environmentally friendly coatings appeal to eco-conscious buyers.

Certifications such as the Global Recycle Standard (GRS) and the Forest Stewardship Council (FSC) are becoming critical benchmarks for assessing sustainability credentials. By aligning with suppliers that hold these certifications, international buyers can ensure they are not only investing in high-quality products but also contributing positively to environmental conservation efforts. Furthermore, transparent supply chains that highlight ethical practices resonate with consumers and businesses alike, reinforcing brand loyalty and enhancing market competitiveness.

What Is the Historical Context of Stainless Steel Drinking Bottles?

The stainless steel drinking bottle industry has evolved significantly over the past few decades. Initially, these bottles were primarily used in industrial applications, but the late 1990s and early 2000s saw a surge in consumer interest as awareness of environmental issues grew. This shift was catalyzed by the advent of BPA-free materials, which addressed health concerns related to plastic containers.

As outdoor and fitness activities gained popularity, the market expanded to include insulated designs capable of keeping beverages cold or hot for extended periods. Today, brands focus on innovation, sustainability, and customization, reflecting the dynamic needs of international B2B buyers. This evolution illustrates a broader trend where product functionality is increasingly intertwined with ethical considerations, shaping how businesses approach sourcing and procurement in the stainless steel drinking bottle market.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel drinking bottles made in usa

-

How do I ensure the stainless steel drinking bottles meet international quality standards?

To ensure that stainless steel drinking bottles meet international quality standards, request certifications from your supplier, such as ISO 9001 for quality management and FDA approval for food safety. Conduct factory audits to assess manufacturing practices and quality control processes. Additionally, consider third-party testing for materials and durability, which can provide further assurance of compliance with international regulations. -

What is the best type of stainless steel for drinking bottles?

The best type of stainless steel for drinking bottles is 18/8 stainless steel, also known as type 304. This grade is highly resistant to corrosion and rust, making it ideal for beverage containers. It is also BPA-free, ensuring safety for consumers. When sourcing, ensure that the bottles are made from food-grade stainless steel to maintain the integrity of the liquids stored. -

What customization options are available for stainless steel drinking bottles?

Customization options for stainless steel drinking bottles often include color finishes, size variations, and branding through laser engraving or screen printing. Many manufacturers can accommodate unique designs or logos, which can enhance brand visibility. Inquire about the minimum order quantities (MOQs) for custom designs, as they may vary by supplier. -

What are the minimum order quantities (MOQs) for bulk purchases of stainless steel bottles?

Minimum order quantities (MOQs) for stainless steel bottles can vary significantly by manufacturer and product type, typically ranging from 100 to 1,000 units. It’s essential to clarify MOQs with potential suppliers before placing an order, as lower MOQs may be available for certain standard products. Discussing your specific needs may also lead to flexible arrangements, especially for long-term partnerships. -

How can I vet suppliers for stainless steel drinking bottles?

To vet suppliers, begin by researching their company history, reputation, and customer reviews. Request references and case studies from previous clients, especially those in your industry. Conduct video calls or on-site visits to assess their manufacturing capabilities and quality control measures. Additionally, consider using third-party platforms or trade organizations that provide supplier ratings and certifications. -

What payment terms should I expect when sourcing stainless steel bottles?

Payment terms for sourcing stainless steel bottles can vary, but common practices include a deposit upfront (usually 30%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or other financing options for larger orders. Always negotiate terms that align with your cash flow needs and ensure clarity on payment methods to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing stainless steel bottles?

When importing stainless steel bottles, consider shipping costs, lead times, and customs regulations specific to your country. Work with logistics partners familiar with international trade to navigate tariffs and duties effectively. Additionally, ensure that your supplier provides proper documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. -

What quality assurance practices should I implement when receiving shipments of stainless steel bottles?

Upon receiving shipments, conduct a thorough inspection of the bottles for defects such as dents, scratches, or inconsistencies in finish. Verify that the quantity matches your order and that all customization specifications are met. Implement a quality assurance process that includes random sampling for testing durability and safety. Document any discrepancies with photos and communicate with the supplier promptly for resolution.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo fatto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Top 7 Stainless Steel Drinking Bottles Made In Usa Manufacturers & Suppliers List

1. Black+Blum - Bottiglie d'acqua riutilizzabili

Dominio: blackblum.com

Registrato: 2001 (24 anni)

Introduzione: Reusable water bottles from Black+Blum are 100% leak proof, BPA-free, and designed for everyday use. They are made from glass, stainless steel, and Tritan. A Binchotan charcoal water filter can be added to all bottles. The collection includes various products such as the Explorer Bottle Large ($42.95), Explorer Bottle ($37.95), Insulated Water Bottle Large ($37.95), Insulated Water Bottle ($34.95)…

2. Liberty Hydration Products – Liberty Originals™

Dominio: libertybottles.com

Registrato: 2008 (17 anni)

Introduzione: Liberty Hydration Products LLC offers a range of water bottles, including the Liberty Originals™ and Liberty Insulated™. Key features include:

– Liberty Originals™: 24 oz. flagship bottle, American made, 100% recyclable US sourced aluminum, improved threaded cap, wider mouth, BPA free, food-grade materials.

– Liberty Insulated™: Vacuum sealed, insulated bottles made from ethically sourced imported…

3. TAKEYA® – Sport Water Bottles

Dominio: takeyausa.com

Registrato: 2008 (17 anni)

Introduzione: TAKEYA® offers a variety of water bottles and drinkware designed for sport and fitness. Key products include: 1. Takeya Sport Water Bottle with Spout Lid available in sizes 22oz, 32oz, 40oz, and 64oz priced at $34.99. 2. Kids Sport Water Bottle with Straw Lid available in 18oz priced at $29.99. 3. Actives Water Bottle with Spout Lid available in sizes 18oz, 22oz, 24oz, 32oz, 40oz, and 64oz priced …

4. Liberty Bottle Works – USA-Made Stainless Steel Water Bottles

Dominio: reddit.com

Registrato: 2005 (20 anni)

Introduzione: Made in USA stainless steel water bottles are difficult to find, as most brands are manufactured in China or India. Some users mentioned brands like Klean Kanteen, which is designed in California but made in China, and Liberty Bottle Works, which produces some items in the USA. There are also mentions of Laken bottles, which were previously made in Spain but may now be made in China. Users express…

5. CamelBak – Key Adventure-Ready Water Bottles

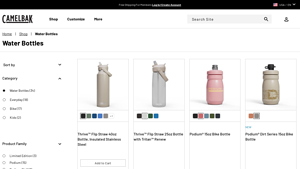

Dominio: camelbak.com

Registrato: 1996 (29 anni)

Introduzione: CamelBak offers a variety of adventure-ready water bottles, including the following key products: 1. Thrive™ Flip Straw 40oz Bottle, Insulated Stainless Steel – $37.99 2. Thrive™ Flip Straw 25oz Bottle with Tritan™ Renew – $17.99 3. Podium® 15oz Bike Bottle – $12.00 4. New Podium® Dirt Series 15oz Bike Bottle – $15.00 5. Thrive™ Chug 25oz Bottle, Insulated Stainless Steel – $30.99 6. Thrive™ Chug …

6. Snipers Hide – Insulated Water Bottles

Dominio: snipershide.com

Registrato: 2000 (25 anni)

Introduzione: US made water bottles mentioned include Nalgene and TruFlask. Liberty Works offers aluminum bottles made in the USA, but they are not double-wall insulated. Tervis bottles are also mentioned, but they are insulated and made in China. There is a challenge in finding stainless steel insulated water bottles that are not made in China.

7. Stanley – Insulated Water Bottles

Dominio: stanley1913.com

Registrazione: 2019 (6 anni)

Introduzione: Stainless Steel, Insulated Water Bottles; Features: double-wall vacuum insulation, eliminates condensation, available in various sizes (14 OZ, 16 OZ, 20 OZ, 24 OZ, 30 OZ, 40 OZ); QuadVac™ technology for extra insulation; designed to keep beverages hot or cold longer; leakproof lids; not recommended for freezing.

Strategic Sourcing Conclusion and Outlook for stainless steel drinking bottles made in usa

In conclusion, the landscape of stainless steel drinking bottles made in the USA presents lucrative opportunities for international B2B buyers. The increasing consumer demand for sustainable, durable, and customizable drinkware underscores the value of strategic sourcing. By partnering with American manufacturers, businesses can ensure high-quality products that comply with stringent safety standards, while also benefiting from the growing trend towards eco-friendly alternatives.

Moreover, American-made products often come with the advantage of shorter lead times and enhanced supply chain reliability, crucial for businesses looking to optimize operational efficiency. As markets in Africa, South America, the Middle East, and Europe continue to embrace sustainability, aligning sourcing strategies with these values will not only enhance brand reputation but also meet the evolving preferences of consumers.

Looking ahead, now is the ideal time for international buyers to engage with U.S. manufacturers and explore the diverse offerings in stainless steel drinkware. Leveraging these partnerships can lead to innovative product designs and co-branding opportunities that resonate with environmentally conscious consumers. Take the next step in your sourcing strategy—connect with American manufacturers today and lead the charge in promoting sustainable hydration solutions worldwide.