Introduction: Navigating the Global Market for jug water bottle

In the competitive landscape of international trade, sourcing high-quality jug water bottles presents a unique challenge for B2B buyers. These versatile containers are essential for various applications, from outdoor events to corporate gatherings, but navigating the complexities of global suppliers can be daunting. This guide aims to demystify the process of procuring jug water bottles, addressing critical factors such as material quality, design variations, and supplier reliability.

Throughout this comprehensive resource, we will explore the diverse types of jug water bottles available on the market, including insulated options for temperature retention and eco-friendly materials that align with sustainability goals. Additionally, we will provide insights into supplier vetting processes, cost considerations, and best practices for ensuring a successful purchase. By equipping international buyers—particularly those from Africa, South America, the Middle East, and Europe (including key markets like Germany and Brazil)—with actionable information, this guide empowers organizations to make informed purchasing decisions.

Ultimately, understanding the nuances of the jug water bottle market not only enhances procurement strategies but also strengthens brand offerings in a growing consumer market that values quality and functionality. With the right knowledge at hand, businesses can confidently navigate their sourcing journeys, ensuring they choose products that meet both their operational needs and customer expectations.

Navigazione tra gli articoli

- Top 4 Jug Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for jug water bottle

- Understanding jug water bottle Types and Variations

- Key Industrial Applications of jug water bottle

- 3 Common User Pain Points for ‘jug water bottle’ & Their Solutions

- Strategic Material Selection Guide for jug water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for jug water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘jug water bottle’

- Comprehensive Cost and Pricing Analysis for jug water bottle Sourcing

- Alternatives Analysis: Comparing jug water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for jug water bottle

- Navigating Market Dynamics and Sourcing Trends in the jug water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of jug water bottle

- Disclaimer importante e condizioni d'uso

- Strategic Sourcing Conclusion and Outlook for jug water bottle

Understanding jug water bottle Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Insulated Gallon Jug | Double-wall vacuum insulation, keeps liquids cold/hot | Eventi all'aperto, squadre sportive | Pro: Excellent temperature retention; durable. Contro: Heavier; higher price point. |

| Classic Plastic Jug | Lightweight, often BPA-free, various colors available | Family gatherings, casual events | Pro: Affordable; easy to transport. Contro: Less durable; may not keep liquids cold. |

| Bottiglia d'acqua per lo sport | Ergonomic design, often with a spout or straw | Gyms, fitness centers | Pro: Convenient for active use; lightweight. Contro: Smaller capacity; may leak if not sealed properly. |

| Motivational Water Bottle | Time markers for hydration goals, often BPA-free | Corporate wellness programs | Pro: Encourages hydration; visually appealing. Contro: Limited capacity; may require frequent refills. |

| Growler Jug | Designed for carbonated beverages, often glass or stainless steel | Breweries, restaurants | Pro: Keeps beverages fresh; reusable. Contro: Heavier; more expensive than plastic alternatives. |

What Are the Characteristics of Insulated Gallon Jugs?

Insulated gallon jugs are designed with double-wall vacuum insulation technology, making them ideal for maintaining the temperature of beverages for extended periods. These jugs are often constructed from stainless steel, providing durability and resistance to rust. They are particularly suitable for outdoor events and sports teams that require a reliable way to keep drinks cold or hot. When purchasing, B2B buyers should consider factors such as insulation performance, weight, and the availability of various lid types to meet specific needs.

How Do Classic Plastic Jugs Compare in Terms of Suitability?

Classic plastic jugs are a cost-effective option for various applications, from family gatherings to casual events. They are lightweight and often available in a range of colors, making them visually appealing. While they may not offer the same level of temperature retention as insulated options, their affordability makes them attractive for bulk purchases. B2B buyers should assess the durability and material quality, particularly whether the jugs are BPA-free, to ensure they meet health and safety standards.

What Makes Sports Water Bottles Ideal for Active Environments?

Sports water bottles are designed with ergonomics in mind, often featuring spouts or straws for easy drinking during physical activities. They are typically lightweight and portable, making them perfect for gyms and fitness centers. These bottles usually have a smaller capacity compared to jugs but are highly convenient for on-the-go hydration. B2B buyers should evaluate the sealing mechanisms to avoid leaks and consider the material, as some may prefer BPA-free options for health reasons.

Why Are Motivational Water Bottles Gaining Popularity in Corporate Settings?

Motivational water bottles come equipped with time markers to encourage users to stay hydrated throughout the day. They are often used in corporate wellness programs to promote health and productivity among employees. These bottles are generally BPA-free and come in visually appealing designs, making them suitable for promotional giveaways. Buyers should consider capacity and design features that align with their branding and employee preferences.

What Are the Unique Features of Growler Jugs?

Growler jugs are specifically designed for storing and transporting carbonated beverages, such as beer. They are typically made from glass or stainless steel, providing an airtight seal that helps maintain freshness. These jugs are popular among breweries and restaurants for serving craft beverages. B2B buyers should take into account the weight and material, as well as the jug’s compatibility with different types of beverages, to ensure they meet their operational needs.

Key Industrial Applications of jug water bottle

| Industria/Settore | Specific Application of jug water bottle | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Cibo e bevande | Beverage distribution in restaurants and cafes | Ensures consistent supply of chilled beverages for customers | Durability, insulation properties, and ease of cleaning |

| Outdoor and Recreational | Hydration solutions for sports events and outdoor activities | Promotes hydration and convenience for participants | Lightweight design, capacity, and portability |

| Construction and Heavy Industry | On-site hydration for workers | Enhances worker productivity and safety through hydration | Robust construction, temperature retention, and capacity |

| Istruzione | School and university events hydration needs | Encourages healthy hydration habits among students | Easy handling, safety features, and eco-friendliness |

| Assistenza sanitaria | Patient hydration in hospitals and clinics | Supports patient recovery and well-being | Sterilization capability, BPA-free materials, and capacity |

How Are Jug Water Bottles Used in the Food and Beverage Industry?

In the food and beverage sector, jug water bottles are essential for beverage distribution in restaurants and cafes. They allow establishments to serve chilled drinks efficiently, ensuring customer satisfaction during peak hours. The durability and insulation properties of these jugs are critical, as they must withstand frequent use while maintaining beverage temperature. International buyers should consider sourcing bottles that comply with local health regulations and are easy to clean, as hygiene is paramount in food service environments.

What Role Do Jug Water Bottles Play in Outdoor and Recreational Activities?

Jug water bottles are widely used in outdoor and recreational activities, such as sports events and camping trips. They provide a convenient hydration solution for participants, encouraging regular water intake during physical exertion. For businesses catering to these markets, lightweight designs and large capacities are essential features. Buyers should prioritize sourcing options that are portable and insulated to keep beverages cool throughout the day, especially in hot climates prevalent in regions like Africa and South America.

Why Are Jug Water Bottles Important in Construction and Heavy Industries?

In construction and heavy industries, jug water bottles serve as vital hydration tools for workers on-site. They help maintain hydration, which is crucial for safety and productivity in demanding environments. The robust construction of these jugs is necessary to withstand harsh conditions, while their capacity ensures that workers have sufficient water throughout the day. Buyers in this sector should focus on sourcing jugs that are easy to transport and refill, as well as those that provide excellent thermal insulation to keep water cool in high temperatures.

How Do Educational Institutions Benefit from Using Jug Water Bottles?

Educational institutions utilize jug water bottles during events and daily activities to promote hydration among students. By providing easy access to water, schools and universities can encourage healthier habits. The design of these jugs should be user-friendly, with safety features to prevent spills. Eco-friendliness is also a significant consideration, as institutions increasingly seek sustainable solutions. International buyers should look for jugs that are compliant with safety standards and made from non-toxic materials, aligning with educational policies.

In What Ways Are Jug Water Bottles Utilized in Healthcare Settings?

In healthcare settings, jug water bottles are crucial for ensuring patients receive adequate hydration during their recovery. They are often used in hospitals and clinics, where maintaining patient well-being is a priority. Sourcing jugs that are easy to sterilize and made from BPA-free materials is essential to meet health regulations. Additionally, capacity is a consideration, as larger jugs can reduce the need for frequent refills, making them more convenient for healthcare staff managing multiple patients.

3 Common User Pain Points for ‘jug water bottle’ & Their Solutions

Scenario 1: Insufficient Insulation for Hot Climates

Il problema: In regions with high temperatures, such as parts of Africa and the Middle East, B2B buyers often face the challenge of ensuring that beverages remain cool for extended periods. Poor insulation in jug water bottles can lead to warm water, which not only diminishes the drinking experience but also affects the hydration needs of workers, especially in outdoor settings. This scenario can be particularly detrimental for businesses that rely on outdoor activities, events, or fieldwork where access to cool water is limited.

La soluzione: When sourcing jug water bottles for hot climates, prioritize options that feature double-wall vacuum insulation technology. This design significantly enhances temperature retention, keeping beverages cool for up to 48 hours. Buyers should also consider selecting stainless steel models, which tend to have better insulation properties than plastic counterparts. Additionally, conducting thorough product testing before bulk purchases can help ensure that the chosen products meet performance expectations. Look for suppliers that provide detailed specifications and customer reviews, which can offer insights into the bottle’s performance in extreme temperatures. Offering a variety of colors and sizes can also cater to different preferences, enhancing customer satisfaction.

Scenario 2: Durability Concerns in Industrial Settings

Il problema: In industrial environments, such as construction sites or factories, jug water bottles are subjected to harsh conditions, including drops, impacts, and exposure to dust and dirt. B2B buyers often find that many available options do not withstand these demanding environments, leading to frequent replacements and increased costs. This not only affects budget considerations but can also disrupt operations when workers are unable to access proper hydration.

La soluzione: To address durability concerns, buyers should focus on sourcing jug water bottles made from high-quality, impact-resistant materials such as heavy-duty BPA-free plastic or stainless steel. Look for bottles that are specifically marketed as rugged or designed for outdoor use, as these will typically feature reinforced construction. Furthermore, consider sourcing from manufacturers that offer warranties or guarantees on their products, ensuring that you are protected against premature wear and tear. Incorporating features like a textured grip or a wide base can enhance usability in industrial settings, reducing the risk of spills and breakage.

Scenario 3: Difficulty in Cleaning and Maintenance

Il problema: Maintaining hygiene standards is crucial for B2B buyers, especially in sectors like food service or healthcare. Many jug water bottles can be challenging to clean, with narrow openings that make thorough washing difficult. This can lead to the buildup of bacteria, odors, and stains, ultimately compromising the quality of the water and the health of consumers.

La soluzione: When selecting jug water bottles, prioritize those with wide mouths or detachable parts that facilitate easy cleaning. Bottles with removable straws or lids allow for comprehensive cleaning and drying, reducing the risk of contamination. Additionally, consider sourcing bottles that are dishwasher-safe, as this can streamline the cleaning process for busy teams. It’s also beneficial to educate staff on proper maintenance practices, such as regular cleaning schedules and using natural cleaning solutions to avoid chemical residues. By investing in high-quality, easy-to-maintain products, businesses can ensure their hydration solutions remain safe and effective over time.

Strategic Material Selection Guide for jug water bottle

What Are the Key Properties of Common Materials for Jug Water Bottles?

When selecting materials for jug water bottles, several options stand out, each with unique properties that affect performance, durability, and suitability for various applications. Here, we analyze four common materials: stainless steel, high-density polyethylene (HDPE), glass, and Tritan™ copolyester.

How Does Stainless Steel Perform in Jug Water Bottles?

Stainless steel is renowned for its strength and resistance to corrosion, making it an excellent choice for jug water bottles. It typically has a high temperature and pressure rating, which allows it to maintain beverage temperatures for extended periods. The material is also BPA-free, ensuring safety for food and drink applications.

Pro: Stainless steel is highly durable and resistant to rust and staining. It can withstand rough handling, making it suitable for outdoor use. However, it is generally more expensive than other materials and can be heavier, which might affect portability.

Contro: The manufacturing process for stainless steel can be complex, requiring specialized equipment. Additionally, while it is suitable for a wide range of beverages, it may not be compatible with acidic drinks over long periods.

Considerazioni internazionali: Buyers from regions like Europe and South America should ensure compliance with food safety regulations, such as EU regulations or Brazilian ANVISA standards. ASTM standards may also apply, particularly regarding corrosion resistance.

Quali vantaggi offre il polietilene ad alta densità (HDPE)?

HDPE is a lightweight, cost-effective plastic commonly used for jug water bottles. It has a moderate temperature resistance and is resistant to impact and chemicals, making it suitable for various beverages.

Pro: HDPE is generally less expensive to produce, which can lower the overall cost of the final product. It is also recyclable, appealing to environmentally conscious buyers. Its lightweight nature enhances portability.

Contro: While HDPE is durable, it may not provide the same insulation properties as stainless steel. It can also become brittle over time, especially when exposed to UV light, which may limit its lifespan.

Considerazioni internazionali: Compliance with international recycling standards is essential for B2B buyers. In regions like Africa and the Middle East, understanding local recycling capabilities can influence material selection.

Why Choose Glass for Jug Water Bottles?

Glass is a traditional material that offers excellent taste preservation and is non-reactive, making it ideal for storing beverages without altering their flavor.

Pro: Glass is highly resistant to chemical leaching, ensuring that beverages remain pure. It is also aesthetically pleasing, often seen as a premium option.

Contro: The primary drawback of glass is its fragility; it can easily break upon impact. Additionally, it is heavier than plastic options, which may be a concern for portability.

Considerazioni internazionali: Buyers should be aware of regulations regarding glass packaging in their regions, including safety standards for transportation and handling. Compliance with DIN or JIS standards may be relevant in European and Asian markets.

What Is the Role of Tritan™ Copolyester in Jug Water Bottles?

Tritan™ copolyester is a newer material that combines the benefits of plastic with enhanced durability and clarity. It is BPA-free and offers good temperature resistance.

Pro: Tritan™ is lightweight and impact-resistant, making it a practical choice for active lifestyles. It also maintains clarity and does not retain odors or tastes.

Contro: While Tritan™ is durable, it may not offer the same level of insulation as stainless steel. Additionally, it can be more expensive than traditional plastics like HDPE.

Considerazioni internazionali: B2B buyers should consider the material’s compliance with food safety regulations in their respective markets. Tritan™ is often marketed as a safer alternative to traditional plastics, which may appeal to health-conscious consumers.

Summary Table of Material Properties for Jug Water Bottles

| Materiale | Typical Use Case for Jug Water Bottle | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Acciaio inox | Outdoor activities, premium markets | Eccellente durata e isolamento | Higher cost, heavier weight | Alto |

| High-Density Polyethylene | Budget-friendly, casual use | Leggero e conveniente | Less durable over time, limited insulation | Basso |

| Vetro | Premium and aesthetic markets | Superior taste preservation | Fragile, heavier than plastic | Medio |

| Copoliestere Tritan™ | Active lifestyles, health-conscious | Lightweight, BPA-free | Less insulation compared to stainless steel | Medio |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for jug water bottles, ensuring that they can make informed decisions based on performance, cost, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for jug water bottle

What Are the Key Stages in the Manufacturing Process of Jug Water Bottles?

The manufacturing process of jug water bottles involves several critical stages, each ensuring the end product meets quality and durability standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Jug Water Bottle Production?

The first step in manufacturing jug water bottles is material preparation. Common materials include high-density polyethylene (HDPE), stainless steel, and Tritan™ copolyester. Each material is selected based on its properties—HDPE is lightweight and durable, stainless steel offers superior insulation and longevity, and Tritan™ is known for being BPA-free and resistant to impact.

During this stage, raw materials are sourced from certified suppliers who adhere to international quality standards. It’s crucial for B2B buyers to verify the material sources to ensure compliance with safety regulations, especially in markets with stringent health guidelines.

How Are Jug Water Bottles Formed?

The forming stage utilizes various techniques depending on the material. For plastic jug bottles, blow molding is the prevalent technique. This process involves heating plastic pellets until they are malleable, followed by blowing air into the heated material to form the desired shape. For stainless steel jugs, deep drawing is commonly used, where sheets of metal are shaped into the bottle form using a die.

This stage may also incorporate advanced technology like injection molding for specific components, ensuring a consistent shape and size, which is vital for maintaining quality across large production runs.

What Does the Assembly Process Involve for Jug Water Bottles?

After forming, the assembly stage involves combining various components, such as lids, seals, and handles. Automated systems often handle this process to enhance efficiency and reduce human error. Quality checks are implemented at this stage to ensure that all parts fit correctly and meet design specifications.

For B2B buyers, understanding the assembly process is essential. Suppliers should provide information on assembly line capabilities and whether they utilize automation or manual processes, as these factors can impact lead times and costs.

What Are the Finishing Techniques Used in Jug Water Bottle Production?

The finishing stage focuses on final touches that enhance aesthetics and functionality. This may include painting, printing logos, or applying coatings for additional insulation. Techniques like powder coating or anodizing for metal bottles improve corrosion resistance and durability.

B2B buyers should inquire about finishing processes, especially if branding is a priority. Customization options can significantly affect order size and pricing.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a cornerstone of the manufacturing process for jug water bottles. It ensures that products not only meet customer expectations but also comply with international standards. Various QA checkpoints are established, including:

- Controllo qualità in entrata (CQI): Assessing raw materials upon arrival to ensure they meet specified requirements.

- Controllo di qualità in corso d'opera (IPQC): Continuous monitoring during production to identify defects early.

- Controllo finale della qualità (CQC): A thorough inspection of finished products before they are packaged and shipped.

Quali sono gli standard internazionali che gli acquirenti B2B dovrebbero conoscere?

International standards play a critical role in ensuring product quality and safety. For jug water bottles, ISO 9001 is a widely recognized standard that outlines requirements for a quality management system. Additionally, industry-specific certifications such as CE marking (for products sold in Europe) and compliance with American National Standards Institute (ANSI) guidelines may also be relevant.

For buyers in Africa, South America, the Middle East, and Europe, understanding local regulations and how they relate to international standards is crucial. This awareness can prevent costly compliance issues and ensure that products meet market demands.

What Common Testing Methods Are Employed for Jug Water Bottles?

Testing methods are integral to the QA process. Common tests for jug water bottles include:

- Test di tenuta: Ensures that bottles do not leak under pressure or during normal use.

- Test di ritenzione termica: Assess how well insulated bottles maintain temperature over time.

- Drop Tests: Evaluate durability and resistance to impacts.

B2B buyers should seek suppliers that provide detailed testing reports to confirm the performance of their products. Such documentation can serve as a valuable asset during procurement decisions.

Come possono gli acquirenti B2B verificare le pratiche di controllo qualità dei fornitori?

Verifying a supplier’s quality control practices is essential for B2B buyers to ensure reliability and consistency. Here are effective strategies:

- Conduzione di audit: Regular on-site audits can help assess the manufacturing processes and quality control measures in place.

- Richiesta di rapporti sulla qualità: Suppliers should be willing to share quality assurance documentation, including test results and compliance certifications.

- Ispezioni di terzi: Engaging third-party inspection services can provide an unbiased assessment of product quality and adherence to standards.

By implementing these strategies, buyers can mitigate risks and ensure they partner with reputable suppliers.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must navigate various nuances in quality control that may differ by region. For example, the expectations for compliance and certification may vary significantly between Europe and Africa. Understanding these differences is crucial for avoiding compliance failures.

Moreover, cultural considerations may affect communication and expectations regarding quality. Establishing clear lines of communication with suppliers and ensuring mutual understanding of quality standards can lead to more successful partnerships.

Conclusion: Why Quality Assurance Is Vital for Jug Water Bottle Manufacturing

In conclusion, the manufacturing processes and quality assurance practices for jug water bottles are complex and multi-faceted. By understanding these processes, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet international standards. Emphasizing quality assurance not only helps in compliance but also builds trust with end consumers, ultimately leading to a stronger market presence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jug water bottle’

In the global marketplace, sourcing jug water bottles involves careful consideration of various factors to ensure that your procurement meets quality standards and market needs. This checklist is designed to guide B2B buyers through the essential steps in the sourcing process, ensuring a successful acquisition of jug water bottles that align with your business objectives.

Fase 1: Definire le specifiche tecniche

Before engaging suppliers, establish clear technical specifications for the jug water bottles you need. Consider factors such as size (e.g., 64oz, 128oz), material (stainless steel, BPA-free plastic), and insulation properties. These specifications will help you narrow down potential suppliers and ensure that the products meet your quality and performance standards.

Fase 2: Research Market Trends and Demands

Understanding current market trends is crucial for making informed sourcing decisions. Analyze consumer preferences in your target regions (e.g., Africa, South America, Europe) regarding design, colors, and functionality. This research can inform your buying strategy, ensuring that you select products that are likely to resonate with your customer base.

Fase 3: Valutare i potenziali fornitori

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product samples, and references from other buyers in similar industries. Look for suppliers with proven track records and positive reviews to mitigate risks associated with low-quality products or delivery issues.

Passo 4: Verifica delle certificazioni dei fornitori

Confirm that suppliers possess the necessary certifications and compliance with international standards. Certifications such as ISO 9001 for quality management and FDA approval for materials ensure that the products are safe and of high quality. This verification is vital for maintaining your company’s reputation and adhering to legal requirements.

Passo 5: Assess Pricing Structures and Terms

Engage in discussions about pricing structures, payment terms, and shipping costs. It’s essential to compare quotes from multiple suppliers to ensure you’re getting competitive pricing without compromising quality. Be clear about your budget constraints and look for suppliers who offer flexibility in payment terms.

Passo 6: Negotiate Contracts and Terms

Once you have identified a suitable supplier, proceed to negotiate contracts. Focus on key aspects such as delivery schedules, return policies, and warranties. A well-drafted contract protects your interests and establishes clear expectations for both parties, reducing the likelihood of disputes down the line.

Passo 7: Plan for Quality Control and Testing

Implement a quality control plan to monitor the products upon delivery. Arrange for testing of the jug water bottles to verify that they meet the agreed-upon specifications and quality standards. Establishing a quality assurance process is crucial for maintaining product integrity and customer satisfaction.

By following this checklist, B2B buyers can streamline the sourcing process for jug water bottles, ensuring that they make informed decisions that align with their business goals and customer expectations.

Comprehensive Cost and Pricing Analysis for jug water bottle Sourcing

What Are the Key Cost Components in Sourcing Jug Water Bottles?

When sourcing jug water bottles, understanding the cost structure is vital for B2B buyers. The main components include:

-

I materiali: The choice of materials significantly impacts the cost. Common options include stainless steel, BPA-free plastic, and glass. Stainless steel tends to be more expensive but offers better durability and insulation properties.

-

Lavoro: Labor costs vary by region. Countries with lower wage standards may offer reduced labor costs, but this can affect quality and compliance with international standards.

-

Spese generali di produzione: This includes utilities, factory maintenance, and administrative costs. Overhead can vary based on the scale of production and operational efficiency of the supplier.

-

Utensili: Initial costs for molds and machinery can be substantial, especially for custom designs. Buyers should consider these costs when evaluating suppliers.

-

Controllo qualità (CQ): Implementing rigorous QC procedures is essential to ensure product safety and compliance with regulations. This can add to overall costs but is crucial for maintaining brand reputation.

-

Logistica: Shipping and handling costs depend on the origin and destination of the products. Factors such as distance, transport mode, and freight rates will influence total logistics expenses.

-

Margine: Suppliers will typically add a margin to cover profit and risk. Understanding the margin expectations can help buyers negotiate better pricing.

How Do Price Influencers Affect Jug Water Bottle Sourcing?

Several factors can influence the pricing of jug water bottles, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Higher volume orders can lead to bulk discounts, making it essential to align purchasing plans with supplier capabilities.

-

Specifiche e personalizzazione: Custom features, such as unique colors or branding, can raise costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materiali e certificazioni di qualità: Premium materials and certifications (like FDA or ISO standards) can increase costs but also enhance product value and marketability.

-

Fattori di fornitura: The supplier’s reputation, production capacity, and geographic location can influence pricing. Established suppliers may offer better reliability but at a premium.

-

Incoterms: Understanding Incoterms is crucial for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total landed costs.

What Tips Can Help Buyers Negotiate Better Pricing?

To optimize sourcing strategies for jug water bottles, consider the following tips:

-

Negotiate on Volume: Leverage your purchasing power by negotiating for discounts based on larger orders. Suppliers are often willing to accommodate buyers who can commit to higher volumes.

-

Attenzione al costo totale di proprietà (TCO): Evaluate not just the unit price but also the overall costs associated with the product, including shipping, storage, and disposal. A lower initial price might lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances in Different Regions: Be aware of regional pricing strategies. For example, suppliers in Europe might have higher labor costs than those in South America, affecting the overall pricing structure.

-

Evaluate Supplier Relationships: Long-term relationships can yield better pricing and terms. Building trust with suppliers may lead to more favorable negotiations and consistent quality.

-

Keep an Eye on Market Trends: Fluctuations in material costs and global supply chain issues can impact pricing. Staying informed about market conditions can help in timing purchases effectively.

Esclusione di responsabilità per i prezzi

The prices referenced in this analysis are indicative and may fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing jug water bottle With Other Solutions

When considering hydration solutions for businesses, it’s essential to explore alternatives to the traditional jug water bottle. This analysis will compare the jug water bottle with two viable alternatives: water filtration systems and water coolers. Each option has distinct advantages and disadvantages that may better suit specific business needs.

| Aspetto di confronto | Jug Water Bottle | Water Filtration System | Water Cooler |

|---|---|---|---|

| Prestazioni | Keeps beverages cold for hours | Provides continuous access to filtered water | Delivers cold water instantly |

| Costo | Moderate initial purchase | Higher installation and maintenance costs | Moderate purchase and maintenance costs |

| Facilità di implementazione | Simple to use and transport | Requires professional installation | Easy to set up, requires water supply |

| Manutenzione | Minimal (cleaning, refilling) | Regular filter replacements needed | Regular cleaning and bottle changes needed |

| Il miglior caso d'uso | Family gatherings, outdoor events | Offices, restaurants, schools | High-traffic areas needing quick access to cold water |

What Are the Advantages and Disadvantages of Water Filtration Systems?

Water filtration systems provide a sustainable solution for businesses looking for an eco-friendly alternative. These systems can offer unlimited access to clean, filtered water, making them ideal for offices, schools, and restaurants. However, they typically involve higher initial installation costs and ongoing maintenance expenses due to the need for regular filter replacements. They also require a reliable water source, which may not be available in all locations.

How Do Water Coolers Compare to Jug Water Bottles?

Water coolers are another popular alternative that provides instant access to cold water. They are easy to set up and usually require minimal maintenance, primarily involving the replacement of water bottles. However, the cost can accumulate over time, especially in high-traffic environments where bottles need to be changed frequently. While they deliver immediate hydration, the reliance on bottled water can lead to environmental concerns and additional logistical challenges.

Conclusion: Which Hydration Solution Is Right for Your Business?

When choosing the right hydration solution, B2B buyers should assess their specific needs, including the volume of water consumption, budget constraints, and environmental considerations. Jug water bottles are excellent for events and gatherings due to their portability and ease of use. In contrast, water filtration systems and coolers may be more suitable for environments requiring constant access to hydration. Ultimately, the best choice will depend on the particular circumstances and priorities of the business, such as sustainability goals, budget, and operational logistics.

Essential Technical Properties and Trade Terminology for jug water bottle

What Are the Key Technical Properties of a Jug Water Bottle?

1. Composizione del materiale

Jug water bottles are typically made from materials like stainless steel, BPA-free plastic, or glass. Stainless steel offers durability and excellent insulation properties, making it ideal for keeping beverages cold or hot for extended periods. BPA-free plastic is lightweight and shatter-resistant, while glass provides a premium feel but is heavier and more fragile. Understanding material composition is crucial for B2B buyers as it affects product longevity, safety, and consumer appeal.

2. Prestazioni dell'isolamento

Insulation is a critical property that determines how well a jug maintains the temperature of its contents. High-quality insulated jugs can keep beverages cold for up to 48 hours or hot for around 24 hours. This performance is vital for businesses targeting outdoor events, sports, or long-duration activities. B2B buyers should assess insulation ratings to meet customer expectations for temperature retention.

3. Capacity and Dimensions

Jug water bottles come in various sizes, commonly ranging from 20 ounces to over 128 ounces (1 gallon). The capacity is a significant factor for consumers, influencing their purchasing decisions based on usage scenarios, such as family gatherings or outdoor adventures. Understanding dimensions helps buyers optimize storage, shipping, and display strategies in retail environments.

4. Weight and Portability

The weight of the jug when filled and empty impacts its portability. Lightweight options are more appealing for on-the-go consumers, while heavier jugs may indicate sturdiness and durability. For B2B buyers, considering weight is essential when targeting specific markets, such as hiking enthusiasts or families.

5. Lid and Spout Design

The design of the lid and spout affects usability and convenience. Features such as wide mouths for easy filling and cleaning, flip-top lids for quick access, and built-in straws for drinking enhance user experience. B2B buyers should prioritize these design elements to cater to consumer preferences and improve product functionality.

What Are Common Trade Terms Used in the Jug Water Bottle Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the jug water bottle market, understanding OEM relationships can help businesses source high-quality products without incurring high development costs.

2. MOQ (Quantità minima d'ordine)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and initial investment. Knowing the MOQ helps businesses plan their orders and manage cash flow effectively.

3. RFQ (Richiesta di offerta)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This term is essential for B2B transactions as it facilitates competitive pricing and helps buyers evaluate different suppliers based on cost and terms.

4. Incoterms (Termini commerciali internazionali)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for B2B buyers involved in cross-border transactions to clarify costs, risk, and delivery responsibilities.

5. Tempo di esecuzione

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the jug water bottle industry, lead time can vary based on production schedules and shipping methods. B2B buyers should consider lead times when planning inventory and managing customer expectations.

6. Certification Standards

Certification standards are regulatory requirements that products must meet to ensure safety and quality. For jug water bottles, certifications like BPA-free or FDA approval are crucial for market acceptance. B2B buyers should verify compliance with these standards to avoid liability and enhance product credibility.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions that align with market demands and enhance their product offerings in the competitive jug water bottle landscape.

Navigating Market Dynamics and Sourcing Trends in the jug water bottle Sector

What Are the Key Market Dynamics and Trends Influencing the Jug Water Bottle Sector?

The jug water bottle market is witnessing significant growth driven by several global factors. Increased health awareness has prompted consumers to prioritize hydration, leading to a surge in demand for larger capacity bottles. Additionally, outdoor activities and travel have gained popularity, particularly in regions like Africa and South America, where consumers seek reliable hydration solutions. B2B buyers are also increasingly looking for innovative designs that combine functionality with aesthetic appeal, reflecting a broader consumer trend towards personalized products.

Emerging technologies in manufacturing, such as the use of advanced materials for insulation and durability, are revolutionizing the jug water bottle market. For instance, insulated bottles that maintain temperature for extended periods are becoming a preferred choice. Furthermore, the integration of smart technology, such as hydration reminders and tracking apps, is appealing to a tech-savvy demographic. International buyers from Europe and the Middle East are particularly interested in these innovations, as they align with the growing trend of health-conscious and eco-friendly living.

Moreover, the supply chain dynamics are evolving, with a shift towards local sourcing to reduce lead times and carbon footprints. This trend is especially relevant in Africa and South America, where buyers are keen on supporting regional manufacturers and minimizing reliance on distant suppliers. As global trade conditions fluctuate, understanding these market dynamics will be crucial for B2B buyers looking to navigate sourcing effectively.

How Is Sustainability Shaping the Jug Water Bottle Industry?

Sustainability is becoming a cornerstone of the jug water bottle sector, with buyers increasingly prioritizing eco-friendly products. The environmental impact of plastic waste has led to a push for reusable water bottles made from sustainable materials. Many manufacturers are now offering products made from BPA-free plastics, stainless steel, and recycled materials, appealing to the eco-conscious consumer.

Ethical sourcing is also gaining traction, with businesses recognizing the importance of transparency in their supply chains. B2B buyers are looking for partners who adhere to ethical practices, including fair labor standards and environmentally responsible manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can significantly enhance a brand’s credibility in the market.

Additionally, the incorporation of ‘green’ certifications is becoming a competitive differentiator. Buyers from Europe, particularly in Germany, are more inclined to select products with recognized environmental labels, as these align with their sustainability goals. By investing in sustainable products, companies not only fulfill regulatory requirements but also cater to the growing consumer demand for responsible business practices.

What Is the Historical Context of the Jug Water Bottle Market?

The jug water bottle has evolved significantly since its inception, adapting to changing consumer needs and environmental considerations. Initially designed for practicality, the focus shifted towards aesthetics and functionality in the late 20th century. The rise of outdoor activities and fitness culture in the 1990s prompted manufacturers to innovate, leading to the introduction of insulated and collapsible designs.

In recent years, the emphasis on sustainability has transformed the market landscape. As awareness of plastic pollution and environmental degradation has grown, manufacturers have increasingly sought to produce reusable, eco-friendly products. This evolution reflects broader societal changes, where consumers are now more informed and conscious of their purchasing decisions. For B2B buyers, understanding this historical context can provide insights into current consumer preferences and future trends, allowing for more informed sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of jug water bottle

-

How do I select the right jug water bottle supplier for my business needs?

Choosing the right supplier for jug water bottles involves several steps. Start by identifying suppliers with a solid reputation and positive reviews in your target market. Verify their certifications, such as ISO or FDA compliance, which indicate adherence to quality standards. Request product samples to evaluate quality, and inquire about their manufacturing processes and materials. Additionally, consider their communication responsiveness and willingness to accommodate customization requests. Building a rapport with your supplier can facilitate smoother transactions and better support down the line. -

What factors should I consider when determining the best jug water bottle for my target market?

When selecting jug water bottles for your target market, consider factors such as capacity, insulation properties, and design. Evaluate the climate and cultural preferences of your target audience; for instance, insulated bottles may be preferred in hotter regions. Assess the durability of materials like BPA-free plastic or stainless steel, which can influence long-term use. Pricing is also essential—ensure the product aligns with your market’s purchasing power while maintaining quality. Finally, design elements such as color and branding can significantly impact consumer appeal. -

What are the common minimum order quantities (MOQs) for jug water bottles?

Minimum order quantities (MOQs) for jug water bottles can vary widely depending on the supplier and product specifications. Typically, MOQs can range from 100 to 1,000 units for standard models, while customized bottles might have higher MOQs. It’s crucial to discuss MOQs upfront with potential suppliers to avoid misunderstandings. Additionally, some suppliers may offer tiered pricing based on order volume, which can be beneficial if you plan to scale your purchases over time. -

What payment terms are standard when sourcing jug water bottles internationally?

Standard payment terms in international B2B transactions often include options such as a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may also accept letters of credit or escrow services for added security. Discussing payment methods early in negotiations is essential to ensure both parties are comfortable and to avoid delays in production. Additionally, consider the implications of currency fluctuations and transaction fees, which can affect overall costs. -

How can I ensure quality assurance (QA) when sourcing jug water bottles?

To ensure quality assurance when sourcing jug water bottles, request samples before placing large orders. Establish clear product specifications, including material quality, safety standards, and design requirements. Consider conducting third-party inspections at the manufacturing facility during production and before shipment. Building a strong relationship with your supplier can also facilitate better communication regarding any potential quality issues. Finally, understand the return and warranty policies to address any discrepancies in product quality upon receipt. -

What shipping and logistics considerations should I keep in mind when importing jug water bottles?

When importing jug water bottles, consider the shipping methods available (air, sea, or land) based on your budget and timeline. Evaluate customs regulations and duties for your target countries, as these can impact overall costs. Work with a reliable freight forwarder who understands the complexities of international shipping. Additionally, ensure that the supplier provides proper documentation, including commercial invoices and packing lists, to facilitate smooth customs clearance. Tracking shipments is also crucial to manage delivery timelines effectively. -

What customization options are available for jug water bottles, and how can they benefit my business?

Customization options for jug water bottles can include printing your logo, selecting colors, and modifying sizes or shapes to align with your brand identity. Offering customized products can enhance brand recognition and differentiate your offerings in a competitive market. Additionally, you can tailor features such as lids, handles, or insulation types based on consumer preferences. Discuss available customization options with your supplier early in the negotiation process to ensure they can meet your specific requirements. -

How do I handle potential disputes with my jug water bottle supplier?

Handling disputes with suppliers effectively requires clear communication and a well-defined contract. Ensure that your agreement outlines key terms, including product specifications, delivery timelines, and payment terms. If issues arise, address them promptly and professionally, providing evidence and documentation to support your claims. If direct negotiation fails, consider involving a third party for mediation. Establishing a good relationship with your supplier can often prevent disputes from escalating, leading to mutually beneficial resolutions.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo fatto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Top 4 Jug Water Bottle Manufacturers & Suppliers List

1. Igloo Coolers – Free Delivery on Orders Over $99

Dominio: igloocoolers.com

Registrato: 1997 (28 anni)

Introduzione: This company, Igloo Coolers – Free Delivery on Orders Over $99, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Under Armour – UA Sideline 1-Gallon Jug Water Bottle

Dominio: underarmour.com

Registrato: 1997 (28 anni)

Introduzione: {‘name’: ‘UA Sideline 1-Gallon Jug Water Bottle’, ‘price’: ‘$22’, ‘rating’: ‘4.3’, ‘reviews_count’: 98, ‘colors’: [‘Black / Red – 001’, ‘Silica Green / Titan Gray – 348’, ‘Stream – 494’, ‘Blaze Orange – 825’], ‘features’: [‘Leakproof 2-way cap with smooth spout design’, ‘Wide mouth top for easy cleaning and adding ice or supplements’, ‘Air gaps on the bottom to reduce heat generation’, ‘Durable, s…

3. Hydro Flask – 24 oz Wide Mouth with Flex Chug Cap

Dominio: nytimes.com

Registrato: 1994 (31 anni)

Introduzione: Questa azienda, Hydro Flask - 24 oz Wide Mouth with Flex Chug Cap, è un'entità di rilievo nel mercato. Per informazioni specifiche sui prodotti, si consiglia di visitare direttamente il loro sito web.

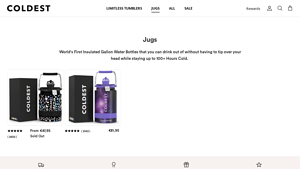

4. Coldest – Insulated Gallon Jugs

Dominio: coldest.com

Registrato: 1998 (27 anni)

Introduzione: Coldest Half Gallon Jug: Rating 4.6/5.0 (2432 reviews), Price: From $51 (originally $64), Status: Sold Out. Coldest Gallon Jug: Rating 4.6/5.0 (2163 reviews), Price: $88 (originally $110). Features: World’s First Insulated Gallon Water Bottles, keeps drinks cold for 100+ hours, free shipping on orders over $125.

Strategic Sourcing Conclusion and Outlook for jug water bottle

In the evolving landscape of beverage containers, the jug water bottle stands out as a versatile and essential product for various markets. Key takeaways from this guide emphasize the importance of durability, insulation, and capacity in meeting the diverse needs of consumers. As international B2B buyers, understanding regional preferences and sourcing high-quality, competitively priced products will enhance market positioning and profitability.

Strategic sourcing is vital in securing reliable suppliers who can provide innovative and sustainable jug water bottles. By prioritizing quality and functionality, businesses can cater to the rising demand for hydration solutions across Africa, South America, the Middle East, and Europe.

Looking ahead, the market for jug water bottles is poised for growth, driven by increasing health awareness and outdoor recreational activities. As consumer preferences shift towards environmentally friendly and reusable products, now is the time for B2B buyers to capitalize on these trends. Engage with suppliers who align with your values and objectives, and explore new opportunities in this dynamic sector. Your strategic sourcing decisions today will pave the way for future success in an ever-competitive marketplace.