Introduction: Navigating the Global Market for cool blender bottle

In today’s fast-paced global market, sourcing the ideal cool blender bottle presents a significant challenge for international B2B buyers. With an overwhelming variety of options available, businesses must navigate through quality, functionality, and aesthetics to find products that resonate with their target audience. This comprehensive guide is designed to equip buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Germany—with the essential insights needed to make informed purchasing decisions.

We will delve into the diverse types of blender bottles available, including insulated, stainless steel, and customizable options. Each section will highlight their unique applications, whether for fitness enthusiasts, health-conscious consumers, or everyday hydration needs. Additionally, we will cover critical aspects of supplier vetting, ensuring that your sourcing process is both efficient and effective.

Cost considerations will also be addressed, providing you with a clear understanding of pricing structures across different regions and materials. By the end of this guide, you will be empowered to select the perfect blender bottles that not only meet your business requirements but also enhance your product offerings in a competitive marketplace. With the right knowledge and resources, navigating the global market for cool blender bottles can transform into a streamlined and rewarding experience.

Navigazione tra gli articoli

- Top 6 Cool Blender Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cool blender bottle

- Understanding cool blender bottle Types and Variations

- Key Industrial Applications of cool blender bottle

- 3 Common User Pain Points for ‘cool blender bottle’ & Their Solutions

- Strategic Material Selection Guide for cool blender bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for cool blender bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cool blender bottle’

- Comprehensive Cost and Pricing Analysis for cool blender bottle Sourcing

- Alternatives Analysis: Comparing cool blender bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for cool blender bottle

- Navigating Market Dynamics and Sourcing Trends in the cool blender bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cool blender bottle

- Disclaimer importante e condizioni d'uso

- Strategic Sourcing Conclusion and Outlook for cool blender bottle

Understanding cool blender bottle Types and Variations

| Nome del tipo | Caratteristiche distintive principali | Applicazioni primarie B2B | Brevi pro e contro per gli acquirenti |

|---|---|---|---|

| Insulated Stainless Steel | Keeps beverages cold for hours, durable, leak-proof design | Gyms, fitness centers, health cafes | Pro: Excellent thermal retention, stylish design. Contro: Prezzo più alto. |

| Tritan Sport Bottle | Made from BPA-free plastic, lightweight, and odor-resistant | Corporate wellness programs, events | Pro: Cost-effective, customizable. Contro: Less durable than stainless steel. |

| Bicchiere shaker 2 in 1 | Combines shaker and tumbler features, versatile design | Retail and promotional giveaways | Pro: Multi-functional, appealing to diverse users. Contro: May compromise on mixing efficiency. |

| Electric Mixing Bottle | Battery-operated, offers automatic mixing capabilities | High-end fitness clubs, personal trainers | Pro: Effortless mixing, ideal for protein shakes. Contro: Requires charging, higher maintenance. |

| Bottiglie personalizzabili | Personalized designs through engraving or printing | Branding, corporate gifts | Pro: Enhances brand visibility, unique offerings. Contro: Tempi di produzione più lunghi. |

What Are the Key Characteristics of Insulated Stainless Steel Blender Bottles?

Insulated stainless steel blender bottles are designed to maintain the temperature of beverages for extended periods, making them ideal for fitness enthusiasts. Their robust construction ensures durability, while features like a leak-proof lid enhance usability. For B2B buyers in the gym or health cafe sectors, these bottles offer a premium product that aligns with customer expectations for quality and performance.

Why Choose Tritan Sport Bottles for Your Business Needs?

Tritan sport bottles are made from BPA-free plastic, making them a safer choice for consumers. They are lightweight and often available in various colors, which can appeal to a broad audience. These bottles are particularly suitable for corporate wellness programs or events where cost-effectiveness and customization are priorities. B2B buyers can benefit from their lower price point while still providing a quality product.

How Do 2-in-1 Shaker Tumblers Serve Diverse B2B Markets?

2-in-1 shaker tumblers combine the functionality of a shaker and a drinking tumbler, catering to consumers who appreciate versatility. Their unique design makes them attractive for retail and promotional giveaways, allowing businesses to offer products that serve multiple purposes. However, potential buyers should consider that while they offer convenience, they may not be as effective in mixing as dedicated shaker bottles.

What Advantages Do Electric Mixing Bottles Offer for Fitness Professionals?

Electric mixing bottles provide an effortless solution for mixing beverages, particularly protein shakes. Their automatic mixing capabilities are appealing for high-end fitness clubs and personal trainers who want to enhance the user experience. While they require charging and may involve higher maintenance costs, their convenience can justify the investment for B2B buyers looking to attract a tech-savvy clientele.

How Can Customizable Blender Bottles Enhance Brand Visibility?

Customizable blender bottles allow businesses to engrave or print their logos, creating unique promotional items. These bottles are particularly effective for branding and corporate gifts, as they leave a lasting impression on customers. While the production time may be longer, the benefits of increased brand visibility and customer loyalty can make them a worthwhile investment for B2B buyers.

Key Industrial Applications of cool blender bottle

| Industria/Settore | Specific Application of cool blender bottle | Valore/Beneficio per l'azienda | Considerazioni chiave sull'approvvigionamento per questa applicazione |

|---|---|---|---|

| Fitness e benessere | Protein and supplement mixing for gyms and health clubs | Enhances client experience and satisfaction, leading to retention | Durability, ease of cleaning, customization options |

| Cibo e bevande | On-the-go beverages for cafes and food trucks | Increases sales of healthy options and promotes brand visibility | Insulation properties, leak-proof design, aesthetic appeal |

| Sport e ricreazione | Hydration solutions for athletes and sports teams | Improves athlete performance through better hydration management | Lightweight materials, ergonomic design, branding opportunities |

| Benessere aziendale | Employee hydration stations in offices | Promotes healthier lifestyles among employees, reducing sick days | Custom branding, bulk purchasing options, eco-friendly materials |

| Education and Training | Student hydration and nutrition for schools and universities | Encourages healthy habits among students, fostering a wellness culture | Safety standards, BPA-free materials, color and design variety |

How Are Cool Blender Bottles Used in the Fitness and Wellness Industry?

In the fitness and wellness sector, cool blender bottles are essential for mixing protein shakes and supplements. Gyms and health clubs leverage these bottles to enhance the client experience, allowing members to easily prepare their pre- and post-workout nutrition. The durability and ease of cleaning are critical for B2B buyers in this space, as they require products that can withstand frequent use and are simple to maintain.

What Role Do Cool Blender Bottles Play in Food and Beverage Businesses?

For cafes and food trucks, cool blender bottles serve as convenient on-the-go beverage containers, particularly for smoothies and health drinks. By offering these bottles, businesses can increase sales of nutritious options while promoting their brand through custom designs. Buyers in this sector should prioritize features like insulation to keep drinks cold and a leak-proof design to ensure customer satisfaction.

How Do Sports Teams Benefit from Cool Blender Bottles?

In the sports and recreation industry, hydration is crucial for athlete performance. Cool blender bottles provide a practical solution for teams, enabling athletes to mix hydration solutions and supplements easily. Key considerations for sourcing include lightweight materials for portability and ergonomic designs that facilitate easy handling, especially during training sessions or competitions.

Why Are Cool Blender Bottles Important for Corporate Wellness Programs?

Companies are increasingly adopting cool blender bottles as part of their corporate wellness initiatives. By providing these bottles at hydration stations, businesses encourage employees to stay hydrated, promoting overall health and potentially reducing absenteeism. Custom branding options are vital for corporate buyers looking to reinforce their brand identity while sourcing eco-friendly materials to appeal to environmentally conscious employees.

How Are Cool Blender Bottles Used in Educational Institutions?

In schools and universities, cool blender bottles are effective tools for promoting hydration and nutrition among students. They are particularly useful for mixing sports drinks or healthy smoothies, fostering a culture of wellness. Buyers in the education sector should ensure that the bottles meet safety standards, are made from BPA-free materials, and come in a variety of colors and designs to appeal to a youthful demographic.

3 Common User Pain Points for ‘cool blender bottle’ & Their Solutions

Scenario 1: Ensuring Product Quality and Safety Compliance

Il problema: B2B buyers, especially those importing ‘cool blender bottles’ for retail or distribution, often face challenges related to ensuring product quality and compliance with safety standards. This is particularly critical in regions like Europe and the Middle East, where regulations regarding materials used in food and beverage containers are stringent. Buyers may encounter issues with products that fail to meet these standards, leading to potential recalls, financial loss, and damage to reputation.

La soluzione: To mitigate these risks, B2B buyers should prioritize sourcing from reputable manufacturers who provide comprehensive documentation of product specifications and compliance certifications. It’s essential to request samples before making bulk purchases and conduct independent testing for materials like BPA-free plastics or stainless steel. Establishing a solid relationship with suppliers who understand the regulatory landscape in your target market can streamline this process. Additionally, investing in third-party inspections can further ensure that the products meet all necessary safety standards, providing peace of mind for both buyers and end consumers.

Scenario 2: Managing Inventory and Supply Chain Efficiency

Il problema: Another common pain point for B2B buyers is managing inventory levels effectively, especially for seasonal products like ‘cool blender bottles.’ Fluctuating demand can lead to overstocking or stockouts, impacting cash flow and customer satisfaction. This issue is compounded in international markets where shipping times and logistics can be unpredictable, particularly in regions with less developed infrastructure.

La soluzione: To address these challenges, B2B buyers should implement a robust inventory management system that leverages data analytics to forecast demand accurately. Utilizing inventory management software that integrates with sales channels can help track trends and adjust orders proactively. Additionally, establishing partnerships with multiple suppliers can provide flexibility and reduce lead times. Consider negotiating consignment agreements where applicable, allowing for lower upfront costs and better inventory turnover. Regular communication with suppliers about market trends can also help them anticipate your needs and ensure timely deliveries.

Scenario 3: Differentiating Product Offerings in a Competitive Market

Il problema: In the crowded market of blender bottles, B2B buyers often struggle to differentiate their product offerings to attract customers. This is especially true in regions like South America and Africa, where competition from local and international brands can be fierce. Buyers need to find unique selling propositions that resonate with their target audiences to stand out.

La soluzione: To effectively differentiate products, B2B buyers should focus on customization and branding opportunities. Offering personalized options, such as custom colors, sizes, or engravings, can appeal to various customer demographics, including fitness enthusiasts and corporate clients. Collaborating with influencers or fitness experts to endorse the products can also enhance brand visibility. Additionally, highlighting unique features—such as leak-proof designs, thermal insulation, or eco-friendly materials—can create a compelling narrative around the product. Conducting market research to understand consumer preferences in different regions will provide insights into what features or designs are likely to resonate, guiding product development and marketing strategies.

Strategic Material Selection Guide for cool blender bottle

What Are the Key Properties of Common Materials Used in Cool Blender Bottles?

When selecting materials for cool blender bottles, it is crucial to consider their properties, advantages, and limitations. The most common materials include plastic (specifically Tritan), stainless steel, aluminum, and glass. Each material comes with distinct characteristics that influence performance, durability, and user preference.

How Does Tritan Plastic Compare for Use in Blender Bottles?

Tritan plastic is a popular choice for many blender bottles due to its lightweight nature and excellent clarity. It is known for its high impact resistance and is BPA-free, making it a safe option for food and beverage applications. Tritan can withstand temperatures up to 100°C (212°F), making it suitable for both hot and cold beverages.

Pro: Tritan is durable, lightweight, and cost-effective. Its resistance to odors and stains ensures that the bottles maintain their aesthetic appeal over time.

Contro: While Tritan is robust, it may not be as long-lasting as metal options. It can also be less effective in maintaining temperature compared to insulated materials.

Impatto sull'applicazione: Tritan is compatible with a variety of liquids, including protein shakes and smoothies, but it may not perform well under extreme temperature variations.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with food safety standards, such as FDA regulations and EU directives. Tritan is widely accepted in many regions, but buyers in Africa and the Middle East should verify local regulations regarding plastic use.

What Advantages Does Stainless Steel Offer for Blender Bottles?

Stainless steel is renowned for its durability and corrosion resistance, making it an excellent choice for high-performance blender bottles. It can withstand extreme temperatures and is often insulated to keep beverages cold or hot for extended periods.

Pro: Stainless steel is incredibly durable and offers excellent thermal insulation. It is also non-reactive, meaning it won’t impart flavors or odors to the contents.

Contro: The primary drawback is the higher cost compared to plastic options. Additionally, stainless steel bottles can be heavier, which may be a consideration for users seeking portability.

Impatto sull'applicazione: Stainless steel is suitable for a wide range of beverages, including acidic drinks, without the risk of corrosion or flavor alteration.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with ASTM standards for food-grade stainless steel. In regions like Europe, adherence to EN standards is also essential.

What Role Does Aluminum Play in Blender Bottle Construction?

Aluminum is lightweight and offers good strength, making it a favorable option for portable blender bottles. It is often coated with a protective layer to prevent corrosion and improve aesthetic appeal.

Pro: Aluminum is lightweight and can be produced at a lower cost than stainless steel, making it an attractive option for budget-conscious buyers.

Contro: The main limitation is that aluminum can react with acidic substances, which may affect the taste of drinks. Additionally, it is less durable than stainless steel.

Impatto sull'applicazione: Aluminum bottles are suitable for water and non-acidic beverages but may not be ideal for protein shakes or smoothies that contain acidic ingredients.

Considerazioni per gli acquirenti internazionali: Compliance with local regulations regarding aluminum coatings and food safety is crucial. Buyers in South America and Africa should pay particular attention to these standards.

How Does Glass Compare as a Material for Blender Bottles?

Glass is a traditional choice for beverage containers and is valued for its purity and inertness. It does not leach chemicals and is easy to clean, making it a safe option for various drinks.

Pro: Glass is non-reactive and does not retain flavors or odors. It is also aesthetically pleasing and can be designed in various styles.

Contro: The primary disadvantage is its fragility; glass bottles are prone to breakage. They are also heavier than plastic and metal alternatives.

Impatto sull'applicazione: Glass is suitable for all types of beverages, including acidic drinks, without any risk of chemical leaching.

Considerazioni per gli acquirenti internazionali: Buyers should ensure compliance with safety standards for glass products, particularly in regions with stringent regulations like Germany.

Summary Table of Material Selection for Cool Blender Bottles

| Materiale | Typical Use Case for cool blender bottle | Vantaggio chiave | Svantaggi/limitazioni principali | Costo relativo (Basso/Medio/Alto) |

|---|---|---|---|---|

| Plastica Tritan | Protein shakes, smoothies | Lightweight, BPA-free | Less durable than metal | Basso |

| Acciaio inox | Hot/cold beverages | Excellent thermal insulation | Costo più elevato, peso maggiore | Alto |

| Alluminio | Water, non-acidic beverages | Lightweight, cost-effective | Reacts with acidic substances | Medio |

| Vetro | All types of beverages | Non-reactive, easy to clean | Fragile, heavier | Medio |

This material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on performance, cost, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cool blender bottle

What Are the Key Stages in the Manufacturing Process of a Cool Blender Bottle?

The manufacturing process for cool blender bottles involves several crucial stages that ensure the final product meets quality and performance standards. Understanding these stages can help B2B buyers evaluate suppliers more effectively.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing a blender bottle is material preparation. Common materials include high-density polyethylene (HDPE), polypropylene, and stainless steel. Each of these materials is chosen for specific properties; for instance, stainless steel is favored for its durability and insulation capabilities, while HDPE and polypropylene are lightweight and resistant to impact.

Before forming, raw materials undergo quality checks to ensure they meet specifications. This may involve testing for density, strength, and flexibility, which are critical for the bottle’s performance. Suppliers often maintain detailed records of material certifications to assure buyers of compliance with international standards.

How Are Blender Bottles Formed and Shaped?

Forming techniques for blender bottles typically include injection molding and blow molding. Injection molding is commonly used for plastic bottles, where heated plastic is injected into a mold to create the desired shape. This method allows for precise control over thickness and dimensions, resulting in uniformity across batches.

For stainless steel bottles, the manufacturing process often involves deep drawing, where sheets of metal are pressed into molds. After forming, the bottles may undergo welding to attach components like lids and handles. It’s essential for B2B buyers to inquire about the forming techniques used, as these can affect the product’s durability and usability.

What Is the Assembly Process for Blender Bottles?

Once the individual components are formed, they are assembled. This process usually involves:

- Joining: Components such as lids, seals, and mixing balls are attached using techniques like ultrasonic welding or mechanical fastening.

- Sealing: Ensuring that the bottle is leak-proof is critical. High-quality seals are tested for their ability to withstand pressure and temperature variations.

- Quality Checks: During assembly, checkpoints are established to ensure that all components fit correctly and function as intended.

B2B buyers should confirm that suppliers have a robust assembly process in place, as this directly influences the performance and reliability of the final product.

What Finishing Techniques Are Used to Enhance the Product?

Finishing touches are essential for both aesthetic appeal and functionality. Common finishing techniques include:

- Surface Treatment: Processes such as anodizing for metal bottles or UV coating for plastic bottles enhance durability and resistance to scratches and fading.

- Printing and Labeling: Custom branding is often applied at this stage, using methods like screen printing or laser engraving. This is particularly important for B2B buyers looking to market their products effectively.

- Garanzia di qualità: Final inspections are conducted to check for surface defects, proper labeling, and overall appearance before packaging.

How Is Quality Assurance Implemented in Blender Bottle Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures each blender bottle meets established standards. For B2B buyers, understanding these QA processes can aid in supplier selection.

What International Standards Are Relevant for Quality Assurance?

International standards, such as ISO 9001, set the framework for quality management systems. Compliance with ISO standards indicates that the manufacturer has implemented processes to ensure consistent quality. Additionally, industry-specific certifications like CE marking in Europe or API standards for food-grade materials are also crucial.

B2B buyers should request documentation of compliance with these standards to ensure the supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early:

- Controllo qualità in entrata (CQI): Inspects raw materials upon arrival, ensuring they meet specifications.

- Controllo di qualità in corso d'opera (IPQC): Conducts checks during various manufacturing stages, including material preparation, forming, and assembly.

- Controllo finale della qualità (CQC): A comprehensive inspection of the finished product before shipping, assessing functionality, appearance, and safety features.

These checkpoints help maintain high standards and reduce the risk of defects reaching the market.

Which Testing Methods Are Commonly Used for Quality Assurance?

Manufacturers employ various testing methods to ensure product reliability:

- Test di tenuta: Essential for assessing seal integrity, ensuring that bottles do not leak under pressure.

- Test di caduta: Simulates real-world usage by dropping bottles from specified heights to evaluate durability.

- Test termici: Assesses insulation performance by measuring how well bottles maintain temperature over time.

B2B buyers should inquire about the specific tests performed and request access to test reports to verify product quality.

Come possono gli acquirenti B2B verificare le pratiche di controllo qualità dei fornitori?

To ensure that suppliers maintain rigorous QC practices, B2B buyers can adopt several strategies:

- Audit dei fornitori: Conducting regular audits of the manufacturing facility allows buyers to assess quality practices firsthand. This includes reviewing documentation, observing processes, and verifying compliance with international standards.

- Requesting QC Reports: Suppliers should provide detailed reports that outline testing results and quality checks. This transparency builds trust and confidence in the supplier’s capabilities.

- Ispezioni di terzi: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. This is particularly valuable for international buyers who may be unable to visit facilities in person.

Quali sono le sfumature del controllo qualità e della certificazione per gli acquirenti internazionali?

For international B2B buyers, understanding the nuances of quality control and certification can be complex. Different regions may have specific regulations and standards that must be adhered to. For instance, buyers from Europe may prioritize CE certification, while those in the Middle East might focus on local health and safety regulations.

Furthermore, language barriers and cultural differences can complicate communication regarding quality expectations. Therefore, it is vital for buyers to establish clear lines of communication with suppliers and ensure that all quality requirements are explicitly documented.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for cool blender bottles enables B2B buyers to make informed decisions when selecting suppliers. By focusing on material preparation, forming, assembly, finishing, and stringent QC measures, buyers can ensure they procure high-quality products that meet their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cool blender bottle’

To help B2B buyers navigate the procurement process for “cool blender bottles,” this practical sourcing guide provides a structured checklist. It aims to ensure that buyers make informed decisions while considering quality, functionality, and supplier reliability.

Fase 1: Definire le specifiche tecniche

Start by outlining the specific features and functionalities that your ideal blender bottle should possess. Consider factors such as size, material (plastic vs. stainless steel), insulation properties, and any unique design elements that appeal to your target market. Clearly defined specifications will streamline the sourcing process and help you communicate effectively with potential suppliers.

Fase 2: Research Market Trends

Stay updated on current trends in the blender bottle market, particularly in your target regions like Africa, South America, the Middle East, and Europe. Analyze consumer preferences for colors, designs, and functionalities. Understanding these trends will help you choose products that resonate with your target audience and increase their marketability.

Fase 3: Identify Potential Suppliers

Create a list of potential suppliers who specialize in manufacturing blender bottles. Utilize online platforms, trade shows, and industry networks to find reputable manufacturers. Pay attention to their production capabilities, product range, and geographical reach, as this will influence shipping times and costs.

Passo 4: Evaluate Supplier Certifications and Compliance

Verify that your shortlisted suppliers possess the necessary certifications and comply with international quality standards. Look for certifications such as ISO 9001 or specific food safety standards relevant to your market. This step is crucial for ensuring that the products meet safety and quality benchmarks, reducing the risk of potential liabilities.

Passo 5: Richiesta di campioni per la valutazione della qualità

Before finalizing any orders, request samples from your potential suppliers to assess the quality of their products. Evaluate aspects like durability, ease of cleaning, and user experience. Testing samples will provide insight into the product’s performance and help you make an informed decision.

Passo 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and conditions. Discuss pricing, payment options, minimum order quantities, and delivery timelines. Clear communication at this stage is vital to avoid misunderstandings and ensure a smooth procurement process.

Passo 7: Stabilire una relazione a lungo termine

After successfully sourcing your blender bottles, focus on building a long-term relationship with your supplier. Regular communication, feedback, and collaboration can lead to better pricing, priority service, and potential product development opportunities in the future. A solid partnership can significantly enhance your supply chain efficiency and product offerings.

By following these steps, B2B buyers can effectively navigate the sourcing process for cool blender bottles, ensuring quality products that meet market demands and enhance customer satisfaction.

Comprehensive Cost and Pricing Analysis for cool blender bottle Sourcing

What Are the Key Cost Components for Sourcing Cool Blender Bottles?

When sourcing cool blender bottles, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

I materiali: The choice of materials significantly impacts pricing. Common materials for blender bottles include Tritan plastic, stainless steel, and BPA-free plastics. Premium materials, like insulated stainless steel, offer durability and thermal retention but come at a higher cost.

Lavoro: Labor costs vary by region and manufacturing practices. Countries with lower labor costs, such as those in South America or parts of Africa, may provide competitive pricing. However, it’s essential to balance cost with quality, as cheaper labor can sometimes lead to lower-quality products.

Spese generali di produzione: This encompasses indirect costs associated with production, including utilities, equipment maintenance, and factory management. Efficient manufacturing processes can help reduce these overheads, impacting the final price.

Utensili: Custom designs or unique bottle features require specific tooling, which can be a significant upfront investment. Buyers should consider whether the supplier has the capability to provide customized products and the associated costs.

Controllo qualità: Ensuring product quality is crucial, especially when dealing with international markets. QC processes can add to costs but are essential for maintaining standards and reducing returns or complaints.

Logistica: Shipping costs can vary greatly depending on the mode of transport, distance, and Incoterms. Import duties and taxes can also significantly affect the total cost, particularly for buyers in Europe and the Middle East.

Margine: Suppliers typically add a profit margin to their costs, which can vary based on market demand and competition. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect the Cost of Cool Blender Bottles?

Several factors can influence the pricing of blender bottles. Understanding these can help buyers make informed purchasing decisions.

Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing. Higher volumes can lead to discounts, making it crucial for buyers to assess their needs and negotiate terms that benefit both parties.

Specifiche e personalizzazione: Custom features, such as logos or unique colors, can increase costs. Buyers should weigh the importance of customization against the potential price increase.

Materiali e certificazioni di qualità: Higher-quality materials and certifications (e.g., FDA approval) can lead to increased costs but may be necessary for specific markets. Buyers should evaluate whether the added expense aligns with their target market’s expectations.

Fattori di fornitura: The reputation and reliability of suppliers can also impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive pricing to gain market share.

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly influence overall costs, as they determine responsibility for shipping and insurance.

What Buyer Tips Can Help Optimize Cost-Efficiency in Sourcing Blender Bottles?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency when sourcing blender bottles.

Negoziazione: Effective negotiation can lead to better pricing and terms. Buyers should be prepared to discuss quantities, delivery schedules, and payment terms to find a mutually beneficial agreement.

Costo totale di proprietà (TCO): It’s essential to consider the TCO, which includes purchase price, shipping, customs duties, and potential returns. Understanding the complete cost landscape helps buyers make informed decisions.

Le sfumature dei prezzi per gli acquirenti internazionali: International buyers should be aware of currency fluctuations and their impact on pricing. Establishing contracts in stable currencies can mitigate risks associated with exchange rate volatility.

Research and Benchmarking: Conducting thorough market research and benchmarking against competitors can provide insights into fair pricing and potential cost-saving opportunities.

Esclusione di responsabilità

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and other factors. Buyers are encouraged to conduct due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing cool blender bottle With Other Solutions

Exploring Alternatives to Cool Blender Bottles for Mixing Solutions

In the competitive landscape of beverage and supplement mixing solutions, it’s essential for B2B buyers to evaluate various options available in the market. While the ‘cool blender bottle’ is a popular choice for its convenience and functionality, several alternatives offer unique features that may better suit specific business needs. This analysis will compare the cool blender bottle against two viable alternatives: electric mixer bottles and traditional shaker cups.

| Aspetto di confronto | Cool Blender Bottle | Electric Mixer Bottle | Traditional Shaker Cup |

|---|---|---|---|

| Prestazioni | Excellent for protein shakes and smoothies; features a whisk ball for effective mixing. | Superior mixing performance, especially for thick or viscous liquids; often includes a rechargeable battery. | Basic mixing capability; may require manual shaking for thorough mixing. |

| Costo | Ranges from $9.99 to $29.99 depending on features. | Higher price point, typically between $30 and $60. | Generally the most affordable option, often priced under $10. |

| Facilità di implementazione | Simple to use; just add ingredients and shake. | Requires charging and sometimes additional setup for use. | Very easy to use; simply add ingredients and shake. |

| Manutenzione | Dishwasher safe and easy to clean; some models are odor-resistant. | Requires more maintenance due to electrical components; not all parts are dishwasher safe. | Low maintenance; can be cleaned easily by hand or in the dishwasher. |

| Il miglior caso d'uso | Ideal for on-the-go users mixing protein shakes or smoothies. | Best for users needing quick, consistent mixing of dense liquids, such as meal replacement shakes. | Suitable for casual use and budget-conscious consumers. |

What Are the Pros and Cons of Electric Mixer Bottles?

Electric mixer bottles represent a technological advancement in the mixing space. They utilize battery-powered agitation to blend ingredients seamlessly. Pro include superior mixing efficiency, particularly for thicker substances that traditional shakers struggle with. However, the contro include a higher upfront cost and potential complications with maintenance due to electrical components. Businesses may find these bottles particularly useful in settings where consistent mixing is critical, such as gyms or health food cafes.

How Do Traditional Shaker Cups Compare?

Traditional shaker cups are the most basic form of mixing bottles. They are affordable and straightforward, allowing users to mix drinks simply by shaking. The pros of traditional shakers include their low cost and ease of cleaning. However, they may not provide the same level of mixing efficiency as the cool blender bottle or electric mixer bottles, especially for thicker liquids. These cups are best suited for casual users or businesses looking to minimize expenses while still providing a functional mixing solution.

In che modo gli acquirenti B2B devono scegliere la soluzione giusta?

When selecting the ideal mixing solution, B2B buyers should carefully consider their specific needs, including the types of products they will be mixing, their budget constraints, and how frequently the bottles will be used. For businesses focused on high-performance mixing and willing to invest more, electric mixer bottles may offer the best results. Conversely, companies looking for cost-effective solutions may find traditional shaker cups or cool blender bottles to be more suitable. Ultimately, understanding the unique benefits and limitations of each option will help businesses make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for cool blender bottle

What Are the Key Technical Properties of a Cool Blender Bottle?

When evaluating cool blender bottles for B2B procurement, understanding the technical specifications is crucial. Here are some essential properties to consider:

-

Composizione del materiale

The primary materials used in blender bottles include BPA-free Tritan plastic, stainless steel, and glass. Tritan is known for its durability and resistance to odors and stains, making it ideal for repeated use. Stainless steel provides excellent insulation, keeping beverages cold for extended periods. Understanding the material helps buyers assess product longevity and safety, particularly in markets with strict health regulations. -

Capacità

Blender bottles typically range from 20 to 36 ounces. The capacity affects the product’s usability in various contexts, from fitness to everyday hydration. For B2B buyers, selecting the right capacity is essential to meet customer preferences and market demands, ensuring that the product is versatile enough for multiple applications. -

Leak-proof Design

A leak-proof design is vital for consumer satisfaction and product reliability. Features such as screw-on lids and silicone seals prevent spills, which is crucial for maintaining brand reputation. Buyers should look for certifications or customer reviews that confirm the effectiveness of the leak-proof design, as this can significantly influence purchasing decisions. -

Proprietà dell'isolamento

Insulated bottles can maintain the temperature of beverages for hours, enhancing user experience. Double-walled vacuum insulation is a common feature in high-quality bottles. This property is particularly appealing in warmer climates, making it a valuable selling point for B2B buyers targeting specific regional markets. -

Opzioni di personalizzazione

Many manufacturers offer customization features, such as laser engraving or color options. Customization can be an attractive selling point for corporate branding or promotional events. B2B buyers should consider the potential for personalization to differentiate their offerings in competitive markets. -

Facilità di pulizia

Bottles that are dishwasher safe or have wide mouths for easy cleaning are more appealing to consumers. Buyers should evaluate cleaning convenience as it directly impacts user satisfaction and repeat purchases.

What Are Common Trade Terms Used in the Blender Bottle Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces products that are sold under another company’s brand name. For buyers, working with an OEM can provide access to high-quality products that can be branded as their own, expanding their market presence. -

MOQ (quantità minima d'ordine)

This term refers to the smallest order size that a supplier will accept. Understanding MOQ is essential for buyers to manage inventory effectively and ensure that they are meeting their budgetary constraints while maximizing profitability. -

RFQ (Richiesta di offerta)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This helps buyers compare prices and terms from multiple suppliers, enabling informed decision-making. -

Incoterms (Termini commerciali internazionali)

Incoterms are a set of predefined commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk management, and cost implications. -

Tempi di consegna

This term refers to the time taken from placing an order to delivery. Understanding lead times is crucial for inventory management and ensuring that products are available when needed, especially in fast-paced markets. -

Product Certification

Certifications, such as FDA or ISO, indicate that a product meets specific safety and quality standards. Buyers should prioritize certified products to ensure compliance with regulations and enhance consumer trust.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing cool blender bottles, ensuring they meet market demands and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the cool blender bottle Sector

What Are the Current Market Dynamics and Key Trends Impacting the Cool Blender Bottle Sector?

The cool blender bottle market is experiencing robust growth driven by a rising global health consciousness and an increasing demand for fitness-related products. Internationally, particularly in regions like Africa, South America, the Middle East, and Europe, buyers are increasingly seeking high-quality, durable, and stylish shaker bottles that align with their active lifestyles. This trend is further accelerated by the growing popularity of protein supplements, meal replacement shakes, and on-the-go hydration solutions.

Emerging technologies are reshaping sourcing practices in this sector. For instance, the rise of e-commerce platforms has simplified the purchasing process for B2B buyers, allowing them to access a broader range of products and suppliers. Furthermore, innovations such as customizable designs and eco-friendly materials are gaining traction. Brands that offer personalization options, such as engraving or unique color patterns, can differentiate themselves in a competitive marketplace.

Additionally, suppliers are increasingly adopting smart technology in their products, such as temperature retention and self-mixing capabilities, to enhance user experience. International buyers should consider these features as they can significantly impact customer satisfaction and loyalty. Understanding regional preferences—like color trends and popular designs—can also influence sourcing strategies and product selection.

How Does Sustainability Influence Sourcing and Production in the Cool Blender Bottle Market?

Sustainability is becoming a critical factor in the sourcing and production of cool blender bottles. The environmental impact of plastic waste has prompted consumers and businesses alike to demand more eco-friendly alternatives. Manufacturers are responding by adopting sustainable practices, such as using recycled materials and biodegradable options in their production processes.

For B2B buyers, this shift presents both opportunities and challenges. Sourcing from suppliers who emphasize ethical supply chains and sustainability can enhance brand reputation and meet consumer demand for greener products. Certifications such as ISO 14001 (Environmental Management) and materials labeled as BPA-free or made from recycled content are increasingly important in the decision-making process.

Moreover, investing in sustainable products can lead to long-term cost savings through reduced waste and increased efficiency. As awareness of environmental issues continues to grow globally, B2B buyers who prioritize sustainability will likely gain a competitive edge in their markets.

What Is the Evolution of the Cool Blender Bottle Market?

The cool blender bottle market has evolved significantly over the past two decades. Initially, shaker bottles were primarily utilitarian, designed simply for mixing protein powders and supplements. However, as health and fitness culture gained momentum, so did the demand for aesthetically pleasing and functional designs.

Innovations in materials, such as BPA-free plastics and stainless steel, have transformed product offerings, enhancing durability and performance. The introduction of features like leak-proof lids and integrated mixing mechanisms has further improved user experience. Today, brands are not only competing on functionality but also on design, customization, and sustainability, reflecting a broader shift in consumer expectations.

As this market continues to grow, international B2B buyers must stay attuned to emerging trends and innovations to effectively meet the evolving needs of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of cool blender bottle

-

How do I choose the right blender bottle for my business?

Choosing the right blender bottle for your business involves assessing your target market’s needs and preferences. Consider factors such as material (plastic vs. stainless steel), size (e.g., 20oz, 32oz), and features (insulation, leak-proof designs, or customizable options). Additionally, review customer feedback and trends within your industry to identify popular designs and functionalities. This ensures you source products that align with your brand values and meet customer expectations. -

What are the customization options available for blender bottles?

Customization options for blender bottles can vary by supplier but typically include features like color selection, logo printing, and personalized engravings. Suppliers may offer a range of finishes, from matte to glossy, and the ability to add unique designs or branding elements. It’s advisable to discuss your specific needs with potential suppliers to understand their capabilities and any minimum order requirements for customized products. -

What is the minimum order quantity (MOQ) for blender bottles?

The minimum order quantity (MOQ) for blender bottles can vary significantly depending on the supplier and the complexity of the product. Generally, MOQs can range from as low as 100 units to several thousand. When negotiating with suppliers, inquire about their flexibility regarding MOQs, especially if you are testing the market or entering a new region. This can help you manage inventory and minimize financial risk. -

What payment terms should I expect when sourcing blender bottles internationally?

Payment terms for international orders of blender bottles typically vary by supplier but commonly include options like advance payment, letter of credit, or 30-60 days credit after shipment. It’s crucial to clarify payment terms upfront to ensure alignment with your cash flow and budgeting strategies. Additionally, consider using secure payment methods that provide buyer protection, especially when dealing with new suppliers. -

How do I vet suppliers for quality assurance in blender bottle production?

Vetting suppliers for quality assurance involves several steps: researching their company background, checking certifications (like ISO), and requesting samples before placing large orders. You can also ask for references from other businesses they supply to and conduct site visits if feasible. Quality control processes should be clearly defined, including inspections during production and before shipment to ensure the final products meet your standards. -

What logistics considerations should I keep in mind when importing blender bottles?

When importing blender bottles, consider logistics factors such as shipping methods (air vs. sea), customs duties, and lead times. Ensure you have a reliable freight forwarder who understands the complexities of international shipping. Additionally, familiarize yourself with the import regulations in your country, including labeling and safety standards, to avoid delays or penalties upon arrival. -

What are the best practices for managing inventory of blender bottles?

Effective inventory management for blender bottles involves forecasting demand based on market trends and historical sales data. Implement a robust inventory tracking system to monitor stock levels and automate reordering processes. Regularly assess your inventory turnover rate and adjust your purchasing strategy accordingly to prevent overstocking or stockouts, which can impact your cash flow and customer satisfaction. -

How can I market blender bottles to my target audience effectively?

To market blender bottles effectively, identify your target audience’s demographics and preferences. Utilize social media platforms and influencer partnerships to reach potential customers, showcasing the unique features and benefits of your products. Consider creating engaging content that highlights customer testimonials and usage scenarios, such as fitness enthusiasts or busy professionals, to resonate with your audience and drive sales.

Disclaimer importante e condizioni d'uso

⚠️ Disclaimer importante

Le informazioni fornite in questa guida, compresi i contenuti relativi ai produttori, alle specifiche tecniche e all'analisi di mercato, hanno uno scopo puramente informativo ed educativo. Non costituiscono una consulenza professionale in materia di acquisti, né una consulenza finanziaria o legale.

Pur avendo fatto ogni sforzo per garantire l'accuratezza e la tempestività delle informazioni, non siamo responsabili di eventuali errori, omissioni o informazioni non aggiornate. Le condizioni di mercato, i dettagli aziendali e gli standard tecnici sono soggetti a modifiche.

Gli acquirenti B2B devono condurre una due diligence indipendente e approfondita. prima di prendere qualsiasi decisione di acquisto. Per questo è necessario contattare direttamente i fornitori, verificare le certificazioni, richiedere campioni e chiedere una consulenza professionale. Il rischio di affidarsi alle informazioni contenute in questa guida è esclusivamente a carico del lettore.

Top 6 Cool Blender Bottle Manufacturers & Suppliers List

1. BlenderBottle – Insulated Stainless Sport

Dominio: blenderbottle.com

Registrato: 1999 (26 anni)

Introduzione: Best Shaker Cups & Protein Shaker Bottles from BlenderBottle® include a variety of options such as Insulated Stainless Shakers, Plastic Shakers, and 2-in-1 Tumblers. Key products include: 1. Insulated Stainless Sport – Sale price $27.99, 4.5 stars (739 reviews), available in colors like Cobalt, Cranberry, Nightshade, and Grapefruit. 2. Stainless Sleek Sport – Sale price $29.99, 4.4 stars (113 revi…

2. Contigo – Shake and Go Fit Shaker Bottle

Dominio: verywellfit.com

Registrato: 2017 (8 anni)

Introduzione: Best Overall: Contigo Shake and Go Fit Shaker Bottle – $15, Capacity: 28 ounces, Material: BPA-free plastic, Blending Mechanism: Weighted shaker ball, Insulated: No, Dishwasher Safe: Yes, top rack only. Easiest to Clean: Helimix Vortex Blender Shaker Bottle – $25, Capacity: 28 ounces, Material: BPA-free plastic, Blending Mechanism: Helix walls of cup, Insulated: No, Dishwasher Safe: Yes, top rack …

3. Helimix - Innovative bottiglie shaker per proteine

Dominio: helimix.com

Registrato: 2016 (9 anni)

Introduzione: Helimix offers innovative protein shaker bottles, including the Helimix Original, Helimix Monochrome, and Signature Series. The Monochrome Series features a variety of colors such as Black, Graphite, Cement Gray, White, Quicksand, Espresso, Evergreen, OD Green, Neon Green, Mint, Island Paradise, Slate Blue, Midnight Blue, Purple, Lilac, Bubblegum Pink, Yarrow Red, 140 Burgundy, Citrus Orange, and …

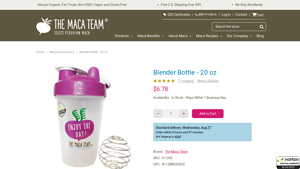

4. The Maca Team – Blender Bottle 20 oz

Dominio: themacateam.com

Registered: 2013 (12 years)

Introduzione: Product Name: Blender Bottle – 20 oz

Brand: The Maca Team

Volume: 20 oz (590 ml)

Color: Pink & White

Material: BPA Free

Shipping: Free U.S. Shipping Over $99, Ships Worldwide

Availability: In Stock – Ships Within 1 Business Day

Price: $6.78

Manufacturer: Blender Bottle, Inc.

Caratteristiche:

– Designed for mixing Maca powder with beverages

– Includes stainless steel spring for better mixing

– Dishwasher…

5. BlenderBottle – Classic V2 Shaker Bottle

Dominio: garagegymreviews.com

Registrato: 2014 (11 anni)

Introduzione: Migliore bottiglia shaker in assoluto: BlenderBottle Classic V2 Shaker Bottle

- Punteggio GGR: 4,65

- Caratteristiche: Marcature delle misure, base arrotondata, passante regolabile per il trasporto, frusta a filo BlendBall classica, protezione del beccuccio

– Pros: Affordable, top rack dishwasher safe, multiple sizes (20-45 oz), durable

– Cons: Difficult to close spout guard, not odor resistant, limited colors for 45 oz, mixed reviews on leakiness

– Botto…

6. Be Amazing – Metal Blender Bottle

Dominio: shopbeamazing.com

Registered: 2024 (1 years)

Introduzione: Be Amazing Metal Blender Bottle

– Material: Stainless Steel

– Insulation: 24-hour insulation

– Size: 24 oz

– Regular Price: $27.99

– Available Colors: Lavender, Snow White, Hyper Red, Banana, Purple Heart, Jade, Ocean Blue, Matte Black, Satin Gray

– Note: All color variants are currently sold out.

Strategic Sourcing Conclusion and Outlook for cool blender bottle

In the evolving market of cool blender bottles, international B2B buyers must recognize the importance of strategic sourcing to maximize value and meet consumer demands. As trends indicate a growing preference for durable, customizable, and insulated options, sourcing partners that offer innovative designs and high-quality materials will be crucial. Buyers should focus on suppliers that provide a diverse range of products to cater to varied consumer preferences across regions, ensuring they remain competitive in their local markets.

Leveraging strategic sourcing not only enhances product offerings but also fosters relationships with manufacturers who can adapt to changing market conditions and consumer preferences. This adaptability is particularly vital in regions like Africa, South America, the Middle East, and Europe, where consumer tastes and purchasing power can vary significantly.

Looking ahead, B2B buyers are encouraged to invest in partnerships that prioritize sustainability and innovation. By aligning with suppliers committed to eco-friendly practices and cutting-edge designs, businesses can not only enhance their brand value but also attract a broader customer base. Embrace the opportunity to redefine your product line with cool blender bottles that resonate with today’s health-conscious consumers.