Introduction: Navigating the Global Market for average cost of a water bottle

In today’s global marketplace, understanding the average cost of a water bottle presents a unique challenge for international B2B buyers. With the rising demand for bottled water across diverse regions—including Africa, South America, the Middle East, and Europe—purchasing decisions can significantly impact operational budgets and sustainability goals. This comprehensive guide delves into the various types of water bottles available, their applications, and the factors influencing their costs. From disposable plastic bottles to premium insulated stainless steel options, we will explore how material choices, production processes, and branding affect pricing structures.

Moreover, navigating the complexities of supplier vetting is crucial for ensuring quality and compliance with regional regulations. By providing insights into market trends, average pricing, and sourcing strategies, this guide empowers businesses to make informed purchasing decisions that align with their needs and ethical standards. Whether you are a distributor looking to expand your product line or a retailer aiming to meet consumer demand, understanding the landscape of bottled water costs will enhance your strategic planning and foster sustainable practices. Equip yourself with the knowledge necessary to optimize your supply chain and capitalize on market opportunities in the bottled water sector.

記事ナビゲーション

- Top 7 Average Cost Of A Water Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for average cost of a water bottle

- Understanding average cost of a water bottle Types and Variations

- Key Industrial Applications of average cost of a water bottle

- 3 Common User Pain Points for ‘average cost of a water bottle’ & Their Solutions

- Strategic Material Selection Guide for average cost of a water bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for average cost of a water bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘average cost of a water bottle’

- Comprehensive Cost and Pricing Analysis for average cost of a water bottle Sourcing

- Alternatives Analysis: Comparing average cost of a water bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for average cost of a water bottle

- Navigating Market Dynamics and Sourcing Trends in the average cost of a water bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of average cost of a water bottle

- 重要な免責事項および利用規約

- Strategic Sourcing Conclusion and Outlook for average cost of a water bottle

Understanding average cost of a water bottle Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| Plastic Bottles | Lightweight, affordable, often available in bulk | Events, promotions, and giveaways | 長所だ: Low cost, versatile; 短所だ: Less durable, environmental concerns. |

| Stainless Steel Bottles | Durable, insulated, often reusable | Corporate gifts, outdoor events | 長所だ: Long-lasting, eco-friendly; 短所だ: Higher upfront cost. |

| Glass Bottles | Premium feel, non-reactive, often with stylish designs | High-end retail, health-focused markets | 長所だ: Aesthetic appeal, recyclable; 短所だ: Fragile, heavier. |

| Aluminum Bottles | Lightweight, often customizable, good for branding | Sports events, promotional campaigns | 長所だ: Durable, good insulation; 短所だ: Can dent, less eco-friendly than stainless steel. |

| Reusable Water Bottles | Variety of materials and features (e.g., filtration, insulation) | Wellness programs, eco-friendly initiatives | 長所だ: Sustainable, customizable; 短所だ: Price varies widely based on features. |

What are the Characteristics and Suitability of Plastic Bottles for B2B Buyers?

Plastic bottles are a popular choice for B2B buyers due to their affordability and lightweight nature. Typically available in bulk, they are ideal for promotional events, giveaways, and corporate branding. While they offer a versatile solution, buyers should consider the environmental implications of plastic use, particularly in regions where sustainability is a growing concern. The low cost makes them suitable for high-volume distribution, but the potential for rapid degradation and negative public perception can be drawbacks.

Why Choose Stainless Steel Bottles for Corporate Gifting?

Stainless steel bottles are favored for their durability and insulation properties, making them suitable for corporate gifts and outdoor events. They can maintain beverage temperatures for extended periods, appealing to eco-conscious consumers. While the initial investment is higher than plastic options, the longevity and perceived value can justify the cost. B2B buyers should assess their target market’s preferences, as these bottles often align well with sustainability goals, enhancing brand reputation.

What Makes Glass Bottles Attractive for High-End Retail?

Glass bottles provide a premium feel and aesthetic, making them suitable for high-end retail environments and health-focused markets. Their non-reactive nature ensures that beverages retain their original taste, appealing to discerning consumers. However, B2B buyers must weigh the fragility and weight of glass against the benefits. While they can elevate brand image, the risk of breakage during transport and handling should be considered, especially in regions with challenging logistics.

How Do Aluminum Bottles Fit into Sports and Promotional Campaigns?

Aluminum bottles are lightweight and often customizable, making them an excellent choice for sports events and promotional campaigns. Their durability and potential for insulation add to their appeal for active consumers. B2B buyers can leverage the branding opportunities presented by aluminum, as these bottles can be easily printed or engraved. However, they may dent upon impact and are not as eco-friendly as stainless steel, which could influence purchasing decisions based on corporate sustainability policies.

Why are Reusable Water Bottles Important for Wellness Programs?

Reusable water bottles encompass a wide variety of materials and features, including filtration and insulation, appealing to businesses focused on wellness initiatives. They promote sustainability and can be customized for branding purposes, making them suitable for corporate events and eco-friendly campaigns. B2B buyers should consider the diverse price range, which reflects the features and materials used. Investing in high-quality reusable bottles can enhance brand loyalty and contribute positively to corporate social responsibility objectives.

Key Industrial Applications of average cost of a water bottle

| 業界/セクター | Specific Application of Average Cost of a Water Bottle | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達上の考慮事項 |

|---|---|---|---|

| 飲食 | Bulk purchasing for restaurants and cafes | Reduces operational costs through volume discounts | Quality assurance, supplier reliability, and delivery timelines |

| コーポレート・ギフト | Custom branded water bottles for employee gifts | Enhances brand visibility and employee satisfaction | Customization options, minimum order quantities, and lead times |

| イベント管理 | Providing water bottles at conferences and events | Improves attendee experience and supports sustainability | Eco-friendly options, logistics, and pricing flexibility |

| Sports and Recreation | Supplying water bottles for sports teams | Promotes hydration and team branding | Durability, size options, and branding capabilities |

| 小売 | Selling bottled water in supermarkets | Meets consumer demand and generates additional revenue | Pricing strategies, shelf life, and packaging design |

How is the Average Cost of a Water Bottle Relevant to the Food and Beverage Industry?

In the food and beverage sector, restaurants and cafes often buy bottled water in bulk. Understanding the average cost helps these businesses negotiate better deals with suppliers, thus reducing operational expenses. Key considerations include ensuring the quality of the water, the reliability of the supplier, and the logistics of delivery, especially for international buyers in regions like Africa and South America where supply chains can be complex.

Why are Custom Branded Water Bottles Important for Corporate Gifting?

Corporate gifting is a strategic way to enhance brand visibility. Custom branded water bottles serve as practical gifts that employees appreciate, fostering a sense of belonging and loyalty. Companies need to consider customization options, minimum order quantities, and lead times to ensure timely delivery, especially for events or campaigns targeted at international markets in the Middle East and Europe.

What Role do Water Bottles Play in Event Management?

Water bottles are essential for event management, particularly at conferences and large gatherings. They improve the attendee experience by providing hydration while also promoting sustainability if eco-friendly options are chosen. Event planners should focus on logistics, sourcing from reliable suppliers, and pricing flexibility to accommodate varying budgets, especially in regions where sourcing costs can fluctuate.

How Do Water Bottles Benefit Sports Teams and Recreation Facilities?

For sports teams, hydration is critical for performance, making water bottles a staple item. Supplying durable and branded water bottles not only meets hydration needs but also enhances team identity. Buyers should consider durability, size options, and branding capabilities when sourcing these products, particularly in regions like Europe and Asia where sports culture is prevalent.

Why is Understanding the Average Cost of Bottled Water Crucial for Retail?

In the retail sector, selling bottled water can meet consumer demand for convenient hydration options. Understanding the average cost aids retailers in setting competitive pricing strategies that drive sales while maintaining profit margins. Factors such as shelf life, packaging design, and supplier agreements become crucial in ensuring that the product remains attractive and profitable, especially in diverse markets across Africa and the Middle East.

3 Common User Pain Points for ‘average cost of a water bottle’ & Their Solutions

Scenario 1: Managing Cost Variability in Bulk Purchases

問題だ: B2B buyers often face significant variability in the cost of water bottles, especially when sourcing in bulk. Prices can fluctuate dramatically based on material, design, and order quantity. This inconsistency can lead to budgeting challenges, especially for businesses that require a consistent supply of bottled water for events, employee wellness programs, or customer giveaways. Additionally, the lack of transparent pricing across different suppliers complicates the decision-making process, making it difficult to compare options effectively.

解決策 To navigate cost variability, B2B buyers should establish a clear procurement strategy that includes setting a defined budget and researching multiple suppliers. Conducting a thorough market analysis to identify the average cost for the type of water bottle needed—whether disposable or reusable—can help. Consider approaching suppliers for bulk pricing options or establishing long-term contracts to lock in prices. Utilizing platforms that aggregate supplier data can also provide insights into competitive pricing and help negotiate better rates. Additionally, incorporating features such as custom branding can justify higher costs by enhancing brand visibility, making the investment more worthwhile.

Scenario 2: Understanding the Cost-Effectiveness of Different Materials

問題だ: B2B buyers frequently struggle to understand the cost-effectiveness of various materials used in water bottles. With options ranging from plastic to stainless steel, each material has its own price point and lifecycle cost. This confusion can lead to poor purchasing decisions that either inflate operational costs or result in lower-quality products that fail to meet customer expectations. For instance, while cheaper plastic bottles may seem attractive initially, their short lifespan and environmental impact can lead to higher long-term costs.

解決策 To make informed decisions regarding material costs, buyers should evaluate the total cost of ownership (TCO) for each type of water bottle. This involves not only the purchase price but also factors such as durability, recyclability, and potential for reuse. Buyers can create a comparative analysis chart that includes initial costs, expected lifespan, and environmental considerations for each material. Additionally, consulting with suppliers who specialize in sustainable products can provide insights into eco-friendly options that might offer long-term savings through recyclability or energy-efficient production. Ultimately, prioritizing quality over initial cost will yield a better return on investment.

Scenario 3: Addressing Quality Concerns in Low-Cost Options

問題だ: When seeking to minimize expenses, B2B buyers may be tempted to opt for the lowest-cost water bottles available. However, this can lead to significant quality issues, including leaks, poor insulation, or even health risks associated with inferior materials. These concerns are particularly pronounced when sourcing from suppliers with limited quality assurance processes. Such problems not only impact customer satisfaction but can also damage a brand’s reputation if subpar products are distributed widely.

解決策 To ensure quality while managing costs, B2B buyers should implement a rigorous supplier vetting process that includes evaluating product certifications and customer reviews. Establishing partnerships with reputable manufacturers known for their quality control can mitigate risks associated with low-cost options. Additionally, requesting product samples before committing to large orders allows buyers to assess quality firsthand. Consider implementing a trial period for new products and gathering feedback from end-users to ensure they meet quality expectations. Investing in quality upfront will ultimately lead to greater customer satisfaction and reduce costs associated with returns or replacements.

Strategic Material Selection Guide for average cost of a water bottle

What Are the Key Properties of Common Materials Used in Water Bottles?

When selecting materials for water bottles, B2B buyers must consider various factors that impact performance, cost, and suitability for specific applications. Here, we analyze four common materials: stainless steel, aluminum, glass, and plastic.

Stainless Steel: A Durable and Versatile Option

Stainless steel water bottles are known for their exceptional durability and resistance to corrosion. They can withstand high temperatures and pressures, making them suitable for both hot and cold beverages. The primary advantage of stainless steel is its longevity; it does not retain flavors or odors and is easy to clean. However, the manufacturing process can be complex and costly, leading to a higher retail price compared to other materials. For international buyers, compliance with food safety standards (e.g., ASTM, DIN) is crucial, as is ensuring that the stainless steel used is of food-grade quality.

Aluminum: Lightweight and Cost-Effective

Aluminum water bottles are lightweight and often more affordable than stainless steel. They are suitable for a variety of beverages and can be easily molded into different shapes. However, aluminum is less durable than stainless steel and can dent or scratch easily. Additionally, unless coated, aluminum may react with acidic beverages, impacting flavor. Buyers should consider the environmental regulations in their region, as some countries have stringent guidelines regarding aluminum recycling and sustainability practices.

Glass: A Premium, Eco-Friendly Choice

Glass water bottles offer a premium feel and are completely recyclable, making them an eco-friendly option. They do not leach chemicals into beverages, ensuring purity of taste. However, glass is heavier and more fragile than other materials, which can limit its practicality for certain applications, particularly in rugged environments. For B2B buyers, it’s essential to assess market demand for eco-friendly products, as well as compliance with safety standards to prevent breakage during transport and use.

Plastic: Affordable and Versatile

Plastic water bottles are the most common and cost-effective option available. They are lightweight, durable, and can be produced in various shapes and sizes. However, concerns about chemical leaching and environmental impact have led to a decline in popularity. While they are generally less expensive, buyers should be aware of regulations regarding BPA and other harmful substances in plastics. In regions like Africa and South America, where single-use plastics are heavily scrutinized, companies may face challenges in promoting plastic bottles.

Summary Table of Material Selection for Water Bottles

| 素材 | Typical Use Case for average cost of a water bottle | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| ステンレス鋼 | Sports, outdoor activities | Highly durable and insulated | Higher manufacturing cost | 高い |

| アルミニウム | Travel, promotional giveaways | 軽量でコストパフォーマンスが高い | Less durable, potential flavor impact | ミディアム |

| ガラス | Premium markets, eco-friendly products | No chemical leaching, recyclable | Heavy and fragile | 高い |

| Plastic | 普段使いの、予算に合ったオプション | Affordable and versatile | Environmental concerns, potential leaching | 低い |

In conclusion, understanding the properties, advantages, and limitations of each material is essential for B2B buyers when selecting water bottles. By considering factors such as cost, compliance, and market preferences, businesses can make informed decisions that align with their sustainability goals and customer expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for average cost of a water bottle

What Are the Key Stages in the Manufacturing Process of a Water Bottle?

Manufacturing a water bottle involves several critical stages, each designed to ensure that the final product meets quality and safety standards while also being cost-effective. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Water Bottle Production?

The first step in the manufacturing process is material preparation. Depending on the type of water bottle being produced—be it plastic, glass, aluminum, or stainless steel—the raw materials must be sourced and treated accordingly. For instance, plastic bottles typically use polyethylene terephthalate (PET), which is processed into pellets and then melted down for shaping. In contrast, stainless steel bottles require the procurement of high-grade alloys that are cut and shaped before use.

What Techniques Are Used in Forming Water Bottles?

Forming is the next critical stage. For plastic bottles, blow molding is a common technique where heated plastic is inflated into a mold to create the desired shape. Aluminum bottles are often manufactured using an extrusion process, where metal is forced through a die to form a tube, which is then cut to size. For glass bottles, the glass is melted and shaped using molds. Each of these techniques has its advantages, particularly in terms of production speed and scalability.

How Are Water Bottles Assembled and Finished?

Once the individual components are formed, the assembly process begins. This may involve adding caps, spouts, or other features like insulation layers. For instance, insulated stainless steel bottles often require an additional layer of vacuum insulation, which involves careful assembly to ensure effectiveness. The finishing stage includes polishing, labeling, and packaging, ensuring that the bottles not only meet aesthetic standards but also comply with safety regulations.

What Quality Control Measures Are Essential for Water Bottle Manufacturing?

Quality control (QC) is vital in the production of water bottles, ensuring that they meet international and industry-specific standards. Adhering to standards such as ISO 9001 is essential for manufacturers aiming to maintain high-quality production processes. This standard focuses on maintaining consistent quality in products and services, which is crucial for B2B buyers concerned with reliability and safety.

What Are the Common QC Checkpoints in Water Bottle Production?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

インカミング・クオリティ・コントロール(IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Suppliers must provide documentation and certifications to verify that materials meet established standards.

-

インプロセス品質管理(IPQC): During production, samples are taken at various stages to ensure that each component meets specified tolerances. This may include checking the dimensions of molded parts or the integrity of seals.

-

最終品質管理(FQC): Once production is complete, the final products undergo rigorous testing. This may include pressure testing for leaks in insulated bottles, ensuring caps fit securely, and checking for any surface defects.

What International Standards and Certifications Should B2B Buyers Consider?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the regulatory landscape is crucial. Besides ISO 9001, other relevant certifications include CE marking for products sold in Europe and API standards for water quality in specific regions. These certifications signify compliance with safety and environmental regulations, providing assurance to buyers.

B2Bバイヤーはサプライヤーの品質管理慣行をどのように検証できるか?

B2B buyers must conduct due diligence to ensure that their suppliers adhere to high-quality standards. Here are several strategies for verification:

-

サプライヤーの監査 Regular audits of suppliers can provide insight into their manufacturing processes and quality control systems. This helps identify potential weaknesses and ensures compliance with international standards.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers assess the effectiveness of their quality assurance practices. Reports should include data on testing methods, failure rates, and corrective actions taken.

-

第三者による検査: Engaging third-party inspection services can offer an unbiased evaluation of supplier quality. These inspectors can verify that products meet specified standards and regulations before shipment.

What Are the Unique QC Considerations for International B2B Buyers?

International B2B buyers face additional challenges regarding quality control, particularly in ensuring compliance with local regulations. For example, water bottles sold in the EU must comply with stringent regulations regarding food safety and materials used. Buyers should also be aware of the specific certification requirements in their target markets to avoid compliance issues.

Conclusion: Ensuring Quality and Cost-Effectiveness in Water Bottle Manufacturing

Navigating the manufacturing processes and quality assurance for water bottles requires a keen understanding of the production stages and the applicable standards. By focusing on rigorous quality control measures, international B2B buyers can ensure that they receive products that not only meet their needs but also adhere to the highest safety and quality standards. This due diligence is essential for establishing long-term partnerships with reliable suppliers across various global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘average cost of a water bottle’

In the competitive landscape of bottled water procurement, understanding the average cost of a water bottle is essential for B2B buyers. This guide offers a practical checklist to help you navigate the sourcing process effectively, ensuring you obtain quality products at a fair price.

ステップ1: Define Your Product Requirements

Before reaching out to suppliers, clearly outline your specific needs. Consider factors such as the type of bottled water (still or sparkling), the packaging format (single-use or reusable), and the volume required. Defining these parameters will help you narrow down your options and make more informed purchasing decisions.

ステップ2: Research Market Prices

Understanding the average market prices for different types of water bottles is critical. Gather data from various sources, including wholesale distributors and retailers. Take note of the price range for different materials (e.g., plastic, glass, stainless steel) and features (like insulation or filtration), which can significantly impact costs.

ステップ3: サプライヤー候補の評価

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and references from other businesses in similar regions or industries. Look for suppliers with a proven track record in quality and reliability, as this can save you from potential issues down the line.

- Check Certifications: Ensure that suppliers have the necessary certifications for quality and safety, particularly if you plan to distribute bottled water in regions with strict regulatory standards.

ステップ4: Compare Material Costs and Features

Different materials come with varying costs and benefits. For instance, stainless steel bottles may be pricier but offer durability and insulation. Make a list of the materials you are considering and compare their costs, benefits, and environmental impacts.

- Consider Eco-Friendly Options: As sustainability becomes a priority, look for suppliers offering eco-friendly materials or those with recycling programs.

ステップ5: サンプル請求

Once you have shortlisted potential suppliers, request samples of their products. This step is crucial in assessing the quality and functionality of the water bottles. Pay attention to the materials used, the design, and any special features that may add value to your offering.

ステップ6: Negotiate Terms and Pricing

Engage in discussions with your chosen suppliers to negotiate pricing, payment terms, and delivery schedules. Be transparent about your budget and expected order volumes, as this can often lead to better pricing or terms.

- Consider Bulk Discounts: Many suppliers offer significant discounts for bulk purchases, which can help you reduce overall costs.

ステップ7: Finalize Your Order and Terms

After negotiations, finalize the order details, including quantities, pricing, and expected delivery dates. Ensure that all terms are documented in a contract to protect your interests.

- Review Shipping and Handling Costs: Don’t overlook the logistics; shipping costs can significantly affect your total expenditure.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for bottled water, ensuring they make informed decisions that align with their business goals and budgetary constraints.

Comprehensive Cost and Pricing Analysis for average cost of a water bottle Sourcing

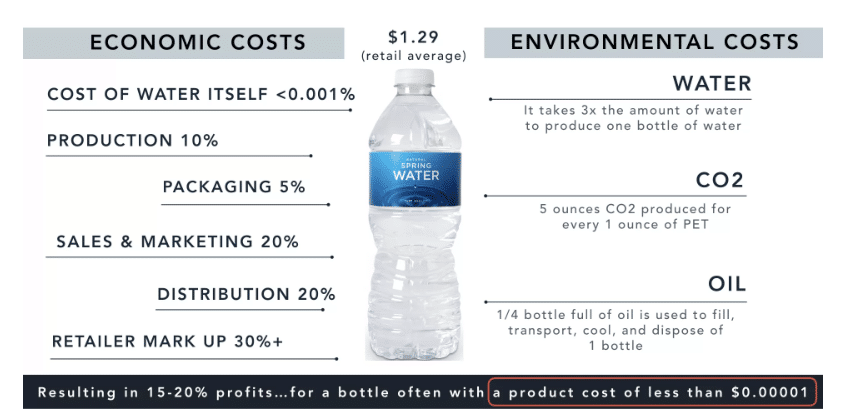

What Are the Main Cost Components in Sourcing Water Bottles?

When sourcing water bottles, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

材料: The choice of material significantly impacts the cost. Options range from low-cost plastic to higher-end materials like stainless steel and glass. For instance, stainless steel bottles may cost between $20 to $50 depending on quality, while plastic bottles can be sourced for as low as $1 to $5.

-

労働: Labor costs vary by region and manufacturing process. Countries with lower labor costs may offer more competitive pricing, but it’s crucial to consider the quality of workmanship and compliance with international labor standards.

-

製造間接費: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can help reduce overhead, but they may require higher initial investments.

-

工具: Custom molds and tooling for unique bottle shapes or sizes add to the initial costs. For bulk orders, these costs can be amortized over a larger number of units, making them more manageable.

-

品質管理(QC): Ensuring that products meet specified standards is critical, especially for international markets. Investing in robust QC processes can prevent costly recalls and damage to brand reputation.

-

物流: Transportation costs can vary significantly based on the shipping method, distance, and Incoterms. For international buyers, understanding the implications of shipping terms is vital for total cost calculations.

-

マージン: Finally, suppliers typically add a profit margin, which can range from 10% to 30% depending on the product and market conditions.

How Do Price Influencers Affect the Cost of Water Bottles?

Several factors can influence the pricing of water bottles in a B2B context:

-

数量/MOQ (最小注文数量): Larger orders often yield lower per-unit prices due to economies of scale. Buyers should negotiate MOQs that align with their inventory strategies.

-

仕様とカスタマイズ: Custom designs, colors, or features (like insulation or filtration) can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

材料と品質認証: Bottles made from eco-friendly or premium materials may command higher prices. Certifications, such as BPA-free or FDA-approved, also add value but can increase costs.

-

サプライヤー要因: The reputation and reliability of suppliers affect pricing. Established suppliers may charge more but offer better quality assurance and service.

-

インコタームズ: Understanding shipping terms (e.g., FOB, CIF) is crucial for calculating total landed costs. This includes duties, taxes, and insurance, which can vary significantly by destination.

What Are the Best Buyer Tips for Negotiating Water Bottle Prices?

B2B buyers looking to source water bottles should consider the following tips for effective negotiation and cost efficiency:

-

Negotiate Effectively: Establish clear communication with suppliers and leverage volume commitments to negotiate better pricing. Always inquire about bulk discounts and payment terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential quality issues, and the environmental impact of materials. A seemingly low-cost option may lead to higher costs in the long run.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, and the Middle East should be aware of fluctuating currency rates, tariffs, and import regulations that can impact total costs.

-

Research Local and Global Suppliers: Diversifying supplier options can lead to better pricing and availability. Utilize platforms that aggregate supplier information for comparative analysis.

-

市場動向を常に把握: Being aware of trends in consumer preferences, such as a shift toward sustainable materials, can provide leverage in negotiations and help buyers align their offerings with market demands.

Disclaimer

The prices mentioned in this analysis are indicative and can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and engage in detailed discussions with potential suppliers to arrive at the most accurate pricing for your needs.

Alternatives Analysis: Comparing average cost of a water bottle With Other Solutions

Introduction to Alternative Solutions for Water Consumption

As global awareness of environmental sustainability and health continues to grow, businesses are increasingly seeking alternatives to traditional bottled water. This section explores the average cost of a water bottle in comparison to other viable solutions, such as water filtration systems and reusable water bottles. Understanding these alternatives can help international B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, make informed purchasing decisions that align with their operational needs and sustainability goals.

比較表

| 比較の側面 | Average Cost Of A Water Bottle | Water Filtration System | Reusable Water Bottle |

|---|---|---|---|

| パフォーマンス | Provides immediate hydration, varies in quality | High-quality water with reduced contaminants | Durable, customizable, and encourages hydration |

| コスト | $1.44 per gallon (bulk) | $200 – $1,500 (initial setup) | $15 – $50 (one-time purchase) |

| 実施しやすさ | Readily available at stores | Requires installation and maintenance | Simple to use, no installation required |

| メンテナンス | Minimal (recycling) | Regular filter replacement (every 6-12 months) | Occasional cleaning required |

| ベスト・ユースケース | Events, travel, convenience | Long-term office or home use | Daily hydration on-the-go, eco-conscious businesses |

代替案の詳細な内訳

1. Water Filtration System

Water filtration systems provide a sustainable alternative to bottled water by delivering high-quality drinking water directly from taps. Although the initial investment can range from $200 to $1,500, depending on the type and complexity of the system, the long-term savings can be substantial. Businesses can significantly reduce their reliance on bottled water, aligning with eco-friendly practices. However, these systems require regular maintenance, including filter replacements, which can add to overall costs over time. They are best suited for companies looking for a permanent solution that supports high-volume water consumption.

2. Reusable Water Bottle

Reusable water bottles are an increasingly popular choice among environmentally conscious consumers and businesses. Priced between $15 and $50, these bottles offer a one-time purchase solution that can save money in the long run by reducing the need for single-use plastics. They come in various materials—such as stainless steel, aluminum, and glass—each with unique benefits. The main advantages include durability, portability, and customization options for branding. However, users must consistently clean and refill them, which may pose a challenge for some businesses. Reusable bottles are ideal for companies promoting sustainability and encouraging hydration among employees.

Conclusion: Choosing the Right Solution for Your Business

When selecting the right solution for water consumption, B2B buyers should consider their specific needs, including cost, convenience, and sustainability goals. While the average cost of bottled water may seem low, the hidden expenses and environmental impact can make alternatives more appealing. Water filtration systems offer a long-term, sustainable option for businesses that require consistent water access, while reusable water bottles provide flexibility and customization for on-the-go hydration. Ultimately, the decision should align with the company’s operational requirements, budget, and commitment to sustainability.

Essential Technical Properties and Trade Terminology for average cost of a water bottle

What Are the Essential Technical Properties of Water Bottles That Affect Their Cost?

Understanding the technical properties of water bottles is crucial for B2B buyers seeking to optimize their purchasing decisions. Here are several critical specifications that significantly influence the average cost of a water bottle:

-

素材グレード

– The material used in water bottles can vary widely, impacting both cost and functionality. Common materials include stainless steel, aluminum, glass, and various plastics. For instance, stainless steel bottles tend to be more expensive due to their durability and insulation properties, whereas plastic bottles are generally cheaper but may have lower longevity. Selecting the right material grade is essential for meeting customer expectations regarding quality and sustainability. -

Capacity and Size

– Water bottles come in various sizes, typically measured in ounces or liters. The capacity affects pricing, as larger bottles generally cost more due to increased material usage and production complexity. Additionally, the size may influence the bottle’s marketability, catering to different consumer preferences, such as portability for outdoor activities versus capacity for hydration on-the-go. -

Insulation Properties

– Insulated water bottles, often made from double-walled stainless steel, can maintain the temperature of liquids for extended periods. This feature adds to the production cost but also increases the value proposition for buyers seeking premium products. Understanding insulation technology can help B2B buyers position their offerings in a competitive market, especially in regions with extreme temperatures. -

カスタマイズ・オプション

– Many manufacturers offer customization, such as branding or personalization. This can significantly impact the cost, as customized bottles often require additional processes, such as screen printing or engraving. For B2B buyers, customization can enhance brand visibility and appeal to corporate clients looking for promotional items. -

Sustainability Certifications

– Eco-friendly certifications and sustainable production practices can influence the pricing of water bottles. Products with recognized certifications (e.g., BPA-free, recycled materials) may command higher prices due to their perceived value. B2B buyers should consider the growing demand for sustainable products and how these certifications can differentiate their offerings in the marketplace. -

Production Tolerance

– Tolerance levels refer to the acceptable variations in the dimensions and characteristics of the bottles during manufacturing. Higher precision in production generally leads to better quality control but can also raise costs. For B2B buyers, understanding tolerance specifications is crucial for ensuring product consistency and meeting customer expectations.

What Are Key Trade Terms Relevant to the Water Bottle Industry?

Familiarity with industry jargon can enhance communication and negotiation processes for B2B buyers. Here are some important terms to know:

-

OEM(相手先ブランド製造)

– This term refers to companies that produce parts or products that are sold under another company’s brand name. For water bottles, an OEM might manufacture bottles that are then branded by a retailer. Understanding OEM relationships can help buyers navigate supply chain dynamics and pricing strategies. -

MOQ(最小注文数量)

– MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For B2B transactions, knowing the MOQ is vital for budgeting and inventory planning. Suppliers often set MOQs to ensure profitability, so buyers should assess their needs against these requirements. -

RFQ(見積依頼)

– An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This is a critical step in the procurement process, allowing buyers to compare pricing and terms across different suppliers. A well-structured RFQ can lead to better negotiation outcomes. -

インコタームズ(国際商業取引用語)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing logistics and cost allocation in cross-border water bottle purchases. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). -

リードタイム

– Lead time refers to the amount of time it takes from placing an order to receiving the products. For B2B buyers, understanding lead times is critical for inventory management and ensuring timely delivery to customers. -

SKU (Stock Keeping Unit)

– An SKU is a unique identifier for each distinct product and service that can be purchased. In the water bottle market, SKUs help in inventory management and sales tracking. Buyers should pay attention to SKUs when ordering to avoid confusion and ensure they receive the correct products.

These technical properties and industry terms are crucial for B2B buyers looking to make informed purchasing decisions regarding water bottles. By understanding these elements, businesses can enhance their market strategies and meet customer demands more effectively.

Navigating Market Dynamics and Sourcing Trends in the average cost of a water bottle Sector

What are the Current Market Dynamics and Key Trends Influencing the Average Cost of a Water Bottle?

The bottled water sector is experiencing significant transformations driven by various global factors. The rising demand for convenient hydration solutions is primarily fueled by urbanization, increased health consciousness, and the shift towards sustainable living. In emerging markets across Africa, South America, the Middle East, and Europe, the average cost of bottled water can vary widely due to factors such as local production costs, import tariffs, and distribution logistics. For instance, while bulk purchasing from mass retailers can lower costs significantly, convenience stores often mark up prices, affecting overall market dynamics.

B2B buyers are increasingly leveraging technology to streamline sourcing processes. E-commerce platforms and digital supply chain management tools are gaining traction, allowing buyers to compare prices and suppliers effectively. Additionally, the integration of data analytics helps companies forecast demand and optimize inventory management, which is crucial in a market characterized by fluctuating prices influenced by seasonal demand and water scarcity issues.

In the context of international trade, geopolitical factors and trade agreements play a vital role. For example, trade tariffs between regions can affect the cost of imported bottled water, while local regulations regarding packaging and environmental standards may influence sourcing decisions. Understanding these dynamics is essential for B2B buyers looking to navigate the complex landscape of the bottled water market.

How Does Sustainability and Ethical Sourcing Impact the Average Cost of a Water Bottle?

Sustainability is increasingly becoming a focal point for B2B buyers in the bottled water sector. The environmental impact of single-use plastic bottles has prompted a surge in demand for reusable and eco-friendly alternatives. As consumers and businesses alike prioritize sustainability, suppliers are responding by offering bottles made from recycled materials or biodegradable options. While these sustainable options may have a higher upfront cost, they often lead to long-term savings and align with corporate social responsibility goals.

Moreover, ethical sourcing practices are gaining importance among international buyers. Companies are increasingly scrutinizing their supply chains to ensure they adhere to fair labor practices and environmentally responsible production methods. Certifications such as Fair Trade, ISO 14001 (Environmental Management), and other green certifications can serve as benchmarks for ethical sourcing. These certifications not only enhance brand reputation but also appeal to a growing segment of environmentally conscious consumers.

Understanding the relationship between sustainability, ethical sourcing, and the average cost of a water bottle is crucial for B2B buyers. While sustainable products may initially appear more expensive, the long-term benefits, including reduced environmental impact and alignment with consumer values, can outweigh the costs.

What is the Brief Evolution and History of the Water Bottle Industry?

The water bottle industry has evolved significantly over the past few decades, driven by changes in consumer behavior and environmental awareness. Initially dominated by single-use plastic bottles, the market has shifted towards more sustainable options as public concern over plastic waste has grown. The introduction of reusable water bottles in various materials—such as stainless steel, glass, and BPA-free plastics—has revolutionized the industry.

In recent years, the trend towards personalization and customization has gained traction, allowing brands to cater to specific consumer preferences. This evolution reflects broader societal shifts towards sustainability and health, with consumers now more likely to invest in products that align with their values. As a result, the average cost of water bottles has diversified, with options ranging from budget-friendly plastic models to premium insulated stainless steel varieties.

This historical context is vital for B2B buyers to understand the forces shaping the current market landscape, enabling them to make informed sourcing decisions that resonate with both their business goals and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of average cost of a water bottle

-

How do I determine the average cost of a water bottle for bulk purchases?

To determine the average cost of a water bottle for bulk purchases, consider multiple factors such as material, customization, and features. Typically, prices range from $1 to $50 per unit, depending on whether you choose plastic, stainless steel, or glass. Request quotes from several suppliers and compare their pricing structures, including discounts for larger quantities. Additionally, assess shipping costs and import duties that may apply based on your location, as these can significantly affect the total expenditure. -

What are the key factors influencing the cost of water bottles?

The cost of water bottles is influenced by material quality, manufacturing processes, and additional features like insulation or filtration systems. High-quality materials such as stainless steel or glass generally command higher prices due to durability and eco-friendliness. Customization options, such as branding or personalization, also add to the cost. Lastly, regional market trends and currency fluctuations can impact pricing, so it’s essential to stay informed about local conditions. -

What is the typical minimum order quantity (MOQ) for water bottles?

Minimum order quantities (MOQs) for water bottles can vary significantly based on the supplier and the type of bottle. For standard models, MOQs may range from 100 to 1,000 units, while custom-designed bottles could require higher quantities, sometimes upwards of 5,000 units. It’s advisable to discuss MOQs directly with potential suppliers to negotiate terms that align with your business needs. Additionally, consider your storage capacity and inventory management when determining the optimal order size. -

How can I vet suppliers for water bottles in international trade?

To vet suppliers for water bottles, start by researching their reputation through customer reviews and industry ratings. Verify their certifications and compliance with international quality standards, such as ISO or FDA regulations. Request samples to assess product quality firsthand. Additionally, check their production capabilities and lead times, ensuring they can meet your demand. Establishing clear communication channels and asking for references from previous clients can further solidify your confidence in their reliability. -

水筒を国際的に調達する場合、支払条件はどうなりますか?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer payment upon delivery or extended payment terms based on your relationship with them. It’s crucial to discuss and negotiate these terms upfront to avoid misunderstandings. Consider using secure payment methods, such as letters of credit, to protect your investment during international transactions. -

How do I ensure quality assurance for bulk water bottle orders?

To ensure quality assurance for bulk orders, implement a thorough inspection process both pre-production and post-production. Establish clear quality standards and communicate these to your supplier before manufacturing begins. Consider hiring third-party inspection services to evaluate the products at various stages of production. Additionally, conduct random sampling of the final products upon delivery to verify compliance with your quality expectations, which can help minimize risks of defects. -

What logistics considerations should I be aware of when importing water bottles?

When importing water bottles, consider factors such as shipping methods, customs clearance, and import duties. Choose a reliable freight forwarder who understands the specific logistics of your supply chain. Understand the documentation required for customs clearance, including invoices, packing lists, and certificates of origin. Additionally, factor in lead times for shipping and potential delays at customs to ensure timely delivery to your business. -

What customization options are available for water bottles, and how do they impact pricing?

Customization options for water bottles can include branding, color selection, and additional features like built-in filters or insulation. These enhancements can significantly impact pricing, often increasing costs by 10-30% depending on the complexity and quantity of the customizations. Discuss your specific needs with suppliers to explore available options and their associated costs. Customization can enhance your brand visibility and product appeal, making it a worthwhile investment for your business.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを行う必要がある。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。

Top 7 Average Cost Of A Water Bottle Manufacturers & Suppliers List

1. Hydro Flask – Campus Collection Water Bottle

ドメイン ハイドロフラスコドットコム

登録:2009年(16年)

はじめに This company, Hydro Flask – Campus Collection Water Bottle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – Bottled Water Pricing Insights

ドメイン レッドディット・コム

登録:2005年(20年)

はじめに A 0.5 L bottle of water typically costs around $1 when sold individually in convenience stores, while purchasing in bulk (like a 35-pack) can reduce the price to about $0.14 per bottle. Single bottles are often sold cold for immediate consumption, and room temperature options are less common.

3. 4imprint – Custom Water Bottles

ドメイン 4imprint.com

登録:1998年(27年)

はじめに Custom water bottles available in aluminum, stainless steel, glass, and plastic. Suitable for company events, trade shows, and wellness programs. Options include insulated varieties and various capacities ranging from 8 oz. to 37 oz. and above. Products can be ordered in bulk with personalization options for logos. Filters available for color, price range, production time, material, and imprint lo…

4. Home Water Solutions – Eco-Friendly Water Solutions

ドメイン homewatersolutionsllc.com

登録:2014年(11年)

はじめに Bottled water costs between $0.89 to $8.65 per gallon; often sourced from municipal tap water with no additional filtering. Environmental concerns include plastic waste, with 50 million bottles ending up in landfills. Production of plastic bottles emits toxins and uses more water than the bottled amount. BPA in plastic bottles poses health risks. Reusable water bottles are a better alternative, av…

5. Bottled Water – Global Price Overview

ドメイン statista.com

登録:2005年(20年)

はじめに A 1.5-liter bottle of water costs an average of $0.70 globally. The most expensive markets for bottled water are Australia and the Philippines, at US$2.02 per bottle. Other high-priced countries include Singapore, Uruguay, Puerto Rico, and Norway, with prices ranging from US$1.59 to US$1.74. Conversely, Egypt and Tunisia have the lowest prices, at $0.

6. Stanley – Insulated Water Bottles

ドメイン stanley1913.com

Registered: 2019 (6 years)

はじめに Stainless Steel, Insulated Water Bottles; Features: double-wall vacuum insulation, eliminates condensation, available in various sizes (14 OZ, 16 OZ, 20 OZ, 24 OZ, 30 OZ, 40 OZ); QuadVac technology for extra insulation; designed for hot and cold beverages; not recommended for freezing.

7. Culligan Quench – Bottleless Water Coolers

ドメイン quench.culligan.com

登録:1997年(28年)

はじめに Culligan Quench offers bottleless water coolers that connect to existing water lines and filter water on-site. Key features include:

– Built-in advanced filtration technology (reverse osmosis and touchless dispensing)

– Cost savings by eliminating the need for bottled water and delivery services

– Installation fees starting at $199

– Monthly service fees

– Environmental benefits: 53% reductio…

Strategic Sourcing Conclusion and Outlook for average cost of a water bottle

The water bottle market presents a diverse landscape for international B2B buyers, characterized by varying costs influenced by materials, features, and production processes. Understanding these factors is crucial for strategic sourcing. High-end reusable bottles can command prices exceeding $50, while basic options start around $15, indicating a significant range depending on quality and functionality.

For companies focused on sustainability, investing in eco-friendly materials and processes not only enhances brand reputation but can also drive long-term savings through reduced waste. Bulk purchasing from mass retailers remains a cost-effective strategy, particularly in markets across Africa, South America, the Middle East, and Europe, where logistical considerations may impact pricing.

As you navigate this competitive landscape, prioritize suppliers who align with your values and offer transparency in their sourcing practices. The future of the bottled water industry is leaning towards sustainability and innovation. By making informed purchasing decisions today, your business can lead the charge towards a greener tomorrow while capitalizing on market trends. Engage with suppliers who can provide tailored solutions to meet your specific needs, ensuring that your investment in water bottles is both strategic and impactful.