Introduction: Navigating the Global Market for plastic bottle properties

In today’s competitive landscape, international B2B buyers face the challenge of sourcing reliable plastic bottle properties that align with their diverse needs. Whether you’re seeking sustainable packaging solutions for beverages or durable containers for industrial applications, understanding the intricacies of plastic bottle materials is crucial. This comprehensive guide delves into the essential characteristics of various plastics, including Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), and Polypropylene (PP), among others, while also exploring their applications and environmental impacts.

Beyond material properties, the guide will cover critical aspects such as supplier vetting processes, cost considerations, and the latest trends in sustainable practices. With insights tailored for buyers from regions including Africa, South America, the Middle East, and Europe—like Vietnam and Brazil—this resource empowers you to make informed decisions that enhance your procurement strategies and bolster your product offerings. By equipping yourself with knowledge about plastic bottle properties, you can navigate the global market more effectively, ensuring that your choices support both your business objectives and sustainability goals.

記事ナビゲーション

- Top 9 Plastic Bottle Properties Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for plastic bottle properties

- Understanding plastic bottle properties Types and Variations

- Key Industrial Applications of plastic bottle properties

- 3 Common User Pain Points for ‘plastic bottle properties’ & Their Solutions

- Strategic Material Selection Guide for plastic bottle properties

- In-depth Look: Manufacturing Processes and Quality Assurance for plastic bottle properties

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic bottle properties’

- Comprehensive Cost and Pricing Analysis for plastic bottle properties Sourcing

- Alternatives Analysis: Comparing plastic bottle properties With Other Solutions

- Essential Technical Properties and Trade Terminology for plastic bottle properties

- Navigating Market Dynamics and Sourcing Trends in the plastic bottle properties Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of plastic bottle properties

- 重要な免責事項および利用規約

- Strategic Sourcing Conclusion and Outlook for plastic bottle properties

Understanding plastic bottle properties Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| Polyethylene Terephthalate (PET) | High strength-to-weight ratio, transparent, shatterproof | Beverage bottles, food containers, packaging | 長所だ: Lightweight, highly recyclable. 短所だ: Limited temperature resistance. |

| High-Density Polyethylene (HDPE) | Opaque, excellent moisture barrier, impact-resistant | Milk jugs, detergent containers, household products | 長所だ: Strong, versatile, recyclable. 短所だ: Less transparent, limited aesthetic options. |

| Polypropylene (PP) | Heat-resistant, flexible, good moisture barrier | Hot-fill bottles, caps, condiment containers | 長所だ: Durable, chemical resistant. 短所だ: Lower recycling rate compared to PET. |

| Low-Density Polyethylene (LDPE) | Flexible, moisture-resistant, less rigid | Squeeze bottles, flexible packaging | 長所だ: Excellent for flexible designs. 短所だ: Not as strong or rigid as other options. |

| Polylactic Acid (PLA) | Biodegradable, derived from renewable resources | Eco-friendly packaging, food containers | 長所だ: Sustainable, compostable. 短所だ: Limited application due to specific composting needs. |

What Are the Key Properties of Polyethylene Terephthalate (PET) Bottles?

PET is renowned for its high strength-to-weight ratio, making it an ideal choice for beverage and food packaging. Its transparency enhances product visibility, appealing to consumers. B2B buyers should consider PET for products requiring durability and recyclability, as it can be easily reprocessed into new items. However, its limited resistance to high temperatures may restrict its use in hot-fill applications.

How Does High-Density Polyethylene (HDPE) Stand Out in Bottle Manufacturing?

HDPE is characterized by its opaque appearance and excellent moisture barrier properties. It’s widely used for packaging liquids, such as milk and detergents, due to its impact resistance and rigidity. For B2B buyers, HDPE offers a strong, versatile option for a variety of products, although its lack of transparency may not align with branding needs that require visibility.

Why Choose Polypropylene (PP) for Specialized Applications?

PP is particularly valued for its heat resistance and flexibility, making it suitable for hot-fill applications like sauces and condiments. It is commonly used for bottle caps and closures due to its excellent chemical resistance. Buyers should consider PP when packaging products that require durability under moderate pressure; however, its lower recycling rate compared to PET may pose environmental concerns.

What Are the Advantages of Low-Density Polyethylene (LDPE) Bottles?

LDPE is known for its flexibility and is often utilized in squeeze bottles, providing excellent resistance to moisture and chemicals. This material is ideal for applications requiring a softer, more pliable design. B2B buyers should weigh LDPE’s flexibility against its lower rigidity, which may limit its use in more robust packaging solutions.

How Does Polylactic Acid (PLA) Contribute to Sustainable Packaging Solutions?

PLA is a bioplastic made from renewable resources, making it an environmentally friendly choice for packaging. Its compostable nature appeals to eco-conscious consumers and businesses. However, PLA’s application is limited due to specific composting requirements, which may not align with all operational capabilities. B2B buyers should evaluate the sustainability benefits against the practical limitations of PLA in their supply chains.

Key Industrial Applications of plastic bottle properties

| 業界/セクター | Specific Application of plastic bottle properties | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達上の考慮事項 |

|---|---|---|---|

| Beverage Industry | Production of PET bottles for soft drinks | Lightweight, shatterproof packaging enhances safety and consumer appeal | Ensure compliance with food safety standards and recyclability of materials |

| Household Cleaning Products | HDPE bottles for detergents and cleaners | Chemical resistance and durability reduce leakage risks | Consider supply chain logistics for heavy-duty materials and local recycling options |

| Pharmaceutical Sector | PP bottles for medicine and supplements | Heat resistance and moisture barrier ensure product integrity | Verify regulatory compliance and potential for child-resistant closures |

| Food Packaging | LDPE squeeze bottles for sauces | Flexibility and moisture resistance enhance usability | Source from suppliers with experience in food-grade materials and certifications |

| Eco-Friendly Products | PLA bottles for biodegradable packaging | Attract environmentally-conscious consumers with sustainable options | Assess composting capabilities and regional regulations on bioplastics |

How Are Plastic Bottle Properties Applied in the Beverage Industry?

In the beverage industry, PET bottles are the standard for soft drinks and water packaging due to their lightweight and shatterproof properties. This ensures safety during transportation and enhances consumer appeal through transparency, allowing customers to see the product. For international B2B buyers, particularly in regions like Africa and South America, it’s crucial to source PET bottles that comply with local food safety regulations and possess a high recyclability rate, aligning with growing sustainability trends.

What Are the Benefits of Plastic Bottle Properties for Household Cleaning Products?

HDPE is widely used for household cleaning products due to its excellent chemical resistance and durability. This plastic type prevents leakage and maintains product integrity, which is critical for consumer safety. Buyers in the Middle East and Europe should consider sourcing HDPE bottles that meet rigorous quality standards and explore local recycling solutions to enhance their sustainability practices. Additionally, understanding the supply chain logistics for heavier materials can optimize costs.

How Are Plastic Bottle Properties Utilized in the Pharmaceutical Sector?

The pharmaceutical sector often utilizes polypropylene (PP) bottles for packaging medicines and dietary supplements. PP’s heat resistance and moisture barrier properties are essential for preserving product quality. B2B buyers must ensure that their suppliers provide bottles that comply with stringent regulatory requirements, including child-resistant features. This is particularly important for markets in Europe and the Middle East, where compliance can significantly impact market access.

Why Are Plastic Bottle Properties Important in Food Packaging?

In food packaging, low-density polyethylene (LDPE) is frequently used for squeeze bottles, especially for sauces. Its flexibility and moisture resistance make it ideal for products that require ease of use. Buyers from regions like Brazil and Vietnam should prioritize sourcing LDPE bottles that are food-grade certified and assess suppliers’ capabilities in producing safe, reliable packaging. Understanding local regulations on food safety can also guide better sourcing decisions.

How Do Eco-Friendly Plastic Bottle Properties Benefit Sustainable Product Lines?

Polylactic acid (PLA) bottles represent an eco-friendly alternative in packaging, appealing to environmentally-conscious consumers. Their biodegradable nature aligns with global sustainability goals, particularly in markets focused on reducing plastic waste. For international buyers in Africa and South America, sourcing PLA requires assessing the availability of composting facilities and understanding regional regulations regarding bioplastics. This ensures that the products not only meet consumer demand but also adhere to local environmental standards.

3 Common User Pain Points for ‘plastic bottle properties’ & Their Solutions

Scenario 1: Navigating Environmental Compliance Challenges

問題だ: B2B buyers often face the challenge of ensuring that their plastic bottles meet stringent environmental regulations, especially in regions like Europe where sustainability standards are increasingly rigorous. Many buyers are uncertain about which materials are deemed acceptable or how to prove that their products are recyclable or biodegradable. This uncertainty can lead to costly delays in product launches or even the rejection of shipments at customs.

解決策 To navigate these compliance issues, it is crucial for buyers to conduct thorough research on the specific regulations governing plastic bottle materials in their target markets. This includes understanding the recyclability of materials such as PET and HDPE, which are widely accepted due to their established recycling streams. Buyers should collaborate with suppliers who can provide certifications and detailed documentation on the environmental impact of their products. Additionally, considering the use of bioplastics like PLA may enhance sustainability profiles, but it is essential to verify local composting capabilities. By integrating these practices into sourcing strategies, businesses can not only ensure compliance but also enhance their brand image among environmentally conscious consumers.

Scenario 2: Addressing Durability and Performance Issues

問題だ: Many B2B buyers encounter problems with the durability of plastic bottles, particularly in industries where bottles must withstand extreme conditions. For example, a beverage company may find that bottles made from lower-quality plastics become brittle in cold temperatures, leading to product leaks and customer complaints. This can result in significant financial losses and damage to brand reputation.

解決策 To mitigate durability concerns, buyers should prioritize sourcing bottles made from high-performance plastics such as HDPE or PET, which are known for their strength and resistance to impact. It is advisable to conduct stress tests or request samples from suppliers to evaluate how different materials perform under specific conditions. Additionally, incorporating additives such as UV stabilizers can enhance the longevity of bottles exposed to sunlight. Establishing a strong relationship with manufacturers that specialize in high-quality plastic formulations can further ensure that the products meet rigorous performance standards, ultimately reducing the risk of product failure.

Scenario 3: Overcoming Limitations in Customization and Branding

問題だ: In a competitive marketplace, B2B buyers often struggle with the limitations of standard plastic bottle designs, which can hinder their branding efforts. For instance, a cosmetics company may require uniquely shaped bottles to differentiate its products but find that many suppliers offer only generic options. This lack of customization can result in missed marketing opportunities and reduced market share.

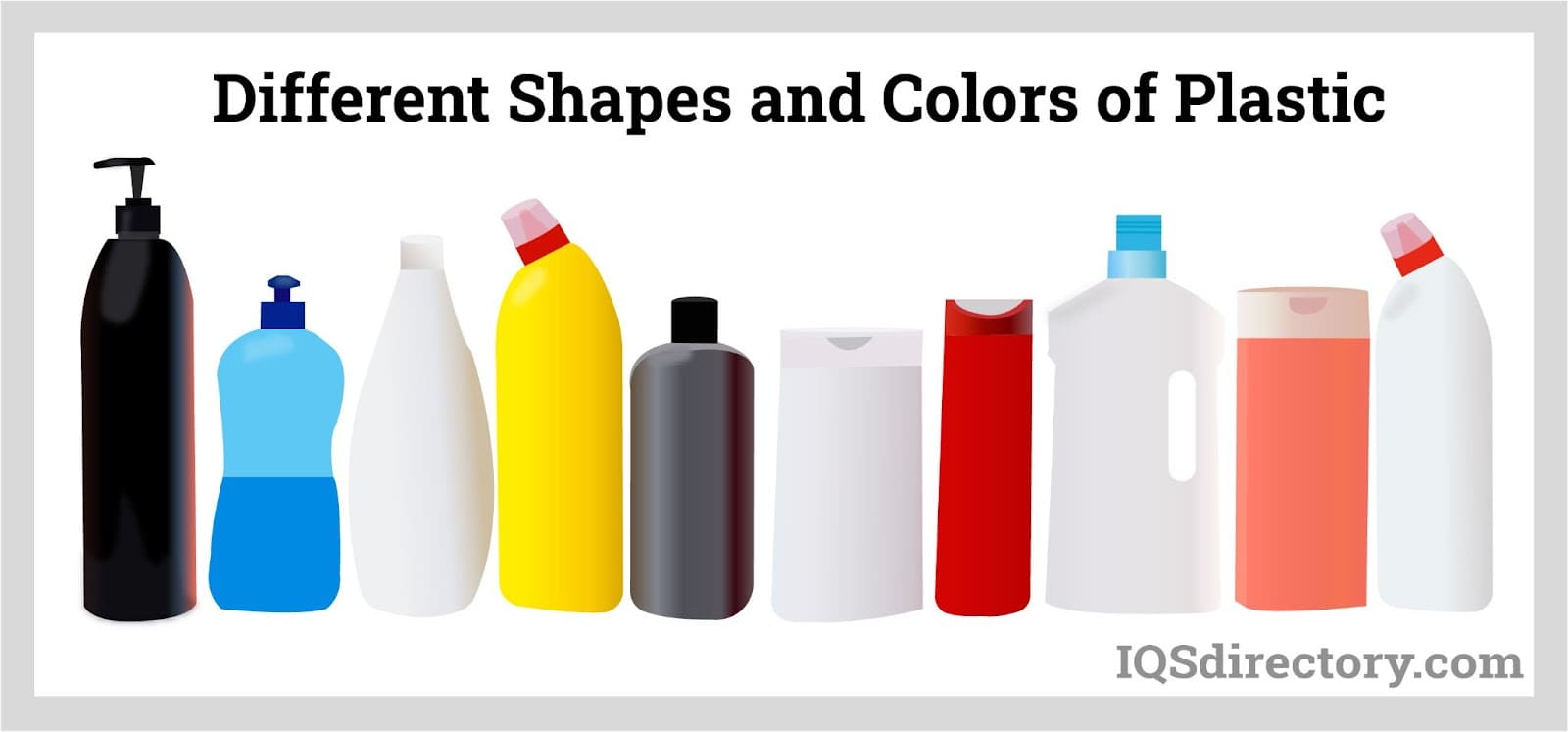

解決策 To overcome these limitations, buyers should seek suppliers that offer a range of customization options, including bottle shapes, sizes, and finishes. Engaging in collaborative design processes with manufacturers can lead to the development of unique packaging solutions that align with brand identity. Additionally, exploring the use of color masterbatches can allow for vibrant, on-brand colors that enhance visual appeal. Attending industry trade shows or networking with packaging experts can provide insights into innovative materials and design techniques that cater to specific branding needs. By prioritizing customization, companies can create memorable products that resonate with consumers and stand out in the marketplace.

Strategic Material Selection Guide for plastic bottle properties

What are the Key Properties of Common Plastic Materials Used in Bottle Production?

When selecting materials for plastic bottles, understanding the properties of each type is critical for ensuring product performance and compliance with international standards. Here, we analyze four common plastic materials: Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), Polypropylene (PP), and Polylactic Acid (PLA). Each material has unique characteristics that can significantly impact their suitability for various applications.

How Does Polyethylene Terephthalate (PET) Perform in Bottling Applications?

PET is renowned for its excellent strength-to-weight ratio, making it a popular choice for beverage bottles. It can withstand moderate temperature fluctuations, with a glass transition temperature around 70°C. PET is also highly resistant to impact, which is crucial for maintaining integrity during transportation and storage.

長所と短所: The main advantages of PET include its transparency, which enhances product visibility, and its high recyclability, aligning with sustainability goals. However, PET can be sensitive to UV light, which may degrade its properties over time. Additionally, while it is cost-effective, the initial setup for manufacturing can be complex due to the need for specific machinery.

アプリケーションへの影響: PET is ideal for carbonated beverages and water, as it maintains the integrity of the contents. Its compatibility with food-grade applications is a significant advantage, particularly in regions with strict food safety regulations.

海外バイヤーへの配慮: Compliance with standards such as ASTM and EU regulations is essential. Buyers from Africa and South America may also need to consider local recycling infrastructures, as PET’s recyclability can vary by region.

What are the Advantages and Limitations of High-Density Polyethylene (HDPE)?

HDPE is characterized by its robust chemical resistance and moisture barrier properties, making it suitable for a wide range of applications, including household and industrial products. It can withstand temperatures up to 120°C, which is beneficial for products that require sterilization.

長所と短所: The key advantage of HDPE is its durability and resistance to impact, making it suitable for heavy-duty applications. However, its opaque nature may limit its use for products where visibility is essential. Although HDPE is relatively inexpensive, the recycling process can be complicated due to contamination issues.

アプリケーションへの影響: HDPE is commonly used for containers that hold household cleaners, detergents, and food products. Its chemical resistance ensures that it can safely store various substances without degradation.

海外バイヤーへの配慮: Buyers should be aware of the specific regulations regarding chemical storage in their regions. Compliance with local standards, such as DIN in Europe, is crucial for ensuring product safety.

How Does Polypropylene (PP) Compare in Terms of Performance?

Polypropylene is a versatile material often used for bottle caps and closures due to its excellent heat resistance and flexibility. It can handle temperatures up to 130°C, making it suitable for hot-fill applications.

長所と短所: The flexibility of PP allows for easy handling and manufacturing, but it may not be as rigid as PET or HDPE. While it is generally cost-effective, the lower recycling rates compared to PET and HDPE can be a disadvantage for companies focused on sustainability.

アプリケーションへの影響: PP is ideal for products that require a moisture barrier and heat resistance, such as sauces and condiments. Its chemical resistance also makes it suitable for storing oils and other perishable liquids.

海外バイヤーへの配慮: Buyers should consider the availability of recycling facilities for PP in their regions. Compliance with local food safety standards is also essential, particularly in the Middle East and Europe.

What Makes Polylactic Acid (PLA) a Sustainable Option?

PLA is a bioplastic derived from renewable resources, making it an attractive option for eco-conscious companies. It is biodegradable under industrial composting conditions, which can significantly reduce environmental impact.

長所と短所: The primary advantage of PLA is its sustainability and biodegradability. However, its performance can be limited in high-temperature applications, as it has a lower melting point compared to traditional plastics. Additionally, the cost of PLA is generally higher due to the manufacturing process.

アプリケーションへの影響: PLA is suitable for short-term applications, such as single-use bottles for beverages or food items. However, its limitations in durability and temperature resistance may restrict its use in certain markets.

海外バイヤーへの配慮: Buyers should ensure that local composting facilities can process PLA. Compliance with international sustainability certifications can enhance brand reputation, particularly in Europe.

Summary Table of Plastic Bottle Materials

| 素材 | Typical Use Case for plastic bottle properties | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| Polyethylene Terephthalate (PET) | Beverage bottles, food containers | High recyclability and transparency | UV sensitivity and manufacturing complexity | ミディアム |

| High-Density Polyethylene (HDPE) | Household cleaners, industrial containers | Excellent chemical resistance | Opaque nature and recycling challenges | 低い |

| Polypropylene (PP) | Bottle caps, hot-fill applications | Heat resistance and flexibility | Lower rigidity and recycling rates | ミディアム |

| Polylactic Acid (PLA) | Eco-friendly packaging, single-use bottles | Biodegradable and sustainable | Lower temperature resistance and higher cost | 高い |

This strategic material selection guide provides essential insights for B2B buyers in diverse markets, enabling informed decisions that align with product requirements and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic bottle properties

What Are the Key Stages in Plastic Bottle Manufacturing Processes?

Manufacturing plastic bottles involves several critical stages, each of which plays a significant role in determining the final product’s quality and properties. Understanding these stages will help B2B buyers make informed decisions when sourcing plastic bottles.

How Is Material Prepared for Plastic Bottle Production?

The first step in the manufacturing process is the preparation of raw materials. Common materials used include Polyethylene Terephthalate (PET), High-Density Polyethylene (HDPE), and Polypropylene (PP). These materials are often sourced in pellet form.

- Material Selection: Buyers must consider the intended application of the bottle—be it beverages, chemicals, or cosmetics—as different materials offer varying properties, such as strength, flexibility, and chemical resistance.

- Drying: For materials like PET, drying is crucial to eliminate moisture, which can cause defects during the molding process.

- Additives: During this stage, additives such as color masterbatches, UV stabilizers, and impact modifiers may be mixed with the raw material to enhance properties like appearance, durability, and resistance to environmental factors.

What Forming Techniques Are Used in Plastic Bottle Manufacturing?

After material preparation, the next stage involves forming the bottles. This is typically done using one of the following techniques:

- Injection Molding: This method is often used for producing preforms, which are then reheated and blown into bottles. The preforms are molded into a specific shape that can be efficiently blown into the final bottle form.

- Blow Molding: In this technique, preforms are heated and placed in a mold where air is blown into them, expanding them to fit the mold. This is particularly common for PET bottles, which are used for beverages.

- Extrusion Blow Molding: This method combines extrusion and blow molding, allowing for the continuous production of bottles. It is suitable for producing larger containers and specialized shapes.

- Thermoforming: Although less common for bottles, thermoforming can be used for creating thin-walled containers from sheets of plastic.

How Are Plastic Bottles Assembled and Finished?

Once the bottles are formed, the assembly and finishing processes come into play:

- Trimming and Cutting: Excess material from the molding process is trimmed away to ensure a clean finish.

- Labeling and Printing: Bottles may undergo labeling or printing processes to enhance branding and provide product information.

- Quality Checks: Before packaging, bottles are inspected for defects such as cracks, warping, or discoloration.

What Quality Assurance Measures Are Essential for Plastic Bottle Production?

Quality assurance (QA) is crucial in ensuring that the final product meets both customer expectations and international standards. Here are the key components of QA in plastic bottle manufacturing.

Which International Standards Should B2B Buyers Be Aware Of?

Understanding applicable international standards is vital for B2B buyers looking to ensure product quality:

- ISO 9001: This standard outlines criteria for a quality management system and is essential for manufacturers aiming for consistency in product quality and customer satisfaction.

- CE Marking: Particularly relevant in Europe, CE marking indicates that products meet EU safety, health, and environmental protection standards.

- API Standards: For bottles used in pharmaceuticals, adhering to API standards ensures that products meet specific safety and efficacy requirements.

品質管理の重要なチェックポイントとは?

Quality control (QC) should be integrated throughout the manufacturing process. Key checkpoints include:

- 受入品質管理(IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- インプロセス品質管理(IPQC): Ongoing checks during the manufacturing process help identify defects early, reducing waste and rework.

- 最終品質管理(FQC): A thorough inspection of finished bottles ensures they meet all quality and safety standards before shipping.

What Common Testing Methods Are Used in Quality Assurance?

B2B buyers should be familiar with various testing methods employed during the QC process:

- フィジカル・テスト: This includes tests for strength, impact resistance, and flexibility.

- 化学試験: Ensures that the materials used are safe and do not leach harmful substances.

- Environmental Testing: Assessing how bottles perform under various environmental conditions, such as temperature fluctuations and exposure to UV light.

B2Bバイヤーがサプライヤーの品質管理プロセスを検証するには?

Establishing trust in suppliers is crucial for B2B buyers. Here are ways to verify their QC processes:

- Audits: Regular audits of the supplier’s facilities can provide insights into their manufacturing practices and adherence to quality standards.

- Quality Reports: Requesting documentation of QC practices, including inspection reports and testing results, can help assess a supplier’s reliability.

- 第三者検査: Engaging third-party inspectors can offer an unbiased evaluation of the supplier’s quality assurance practices.

国際的なB2Bバイヤーのための品質管理とは?

When sourcing plastic bottles from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, several nuances should be considered:

- 規制遵守: Different regions have varying regulations concerning packaging materials, especially for food and beverages. Understanding these regulations is crucial for compliance.

- 文化的考察: Communication styles and business practices can differ significantly across regions. Building relationships and understanding local practices can enhance collaboration.

- Supply Chain Logistics: International shipping can introduce risks, such as damage during transit. Ensuring that suppliers have robust packaging and shipping practices is essential for maintaining quality.

By comprehensively understanding the manufacturing processes and quality assurance measures associated with plastic bottles, B2B buyers can make informed decisions that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic bottle properties’

はじめに

This practical sourcing guide is designed to assist B2B buyers in identifying and procuring the right plastic bottle properties to meet their specific needs. Understanding the various types of plastics, their properties, and their applications is crucial for making informed decisions that align with both product requirements and sustainability goals.

ステップ1: 技術仕様の定義

Establishing clear technical specifications is the foundation of your sourcing process. Consider the intended use of the plastic bottles, such as whether they will hold beverages, chemicals, or personal care products.

– Key considerations:

– Material type (e.g., PET, HDPE, PP)

– Size and shape requirements

– Barrier properties needed (e.g., moisture resistance, UV protection)

ステップ2: Research Material Properties

Familiarize yourself with the properties of different plastics used in bottle manufacturing. Each material offers unique advantages and disadvantages that can impact product performance.

– Focus on:

– Durability and impact resistance (e.g., PET’s shatterproof nature)

– Recyclability and environmental impact (e.g., HDPE’s reusability)

– Chemical compatibility with contents (e.g., PP’s heat resistance for hot-fill applications)

ステップ3: サプライヤー候補の評価

Conduct thorough evaluations of potential suppliers to ensure they meet your quality standards and specifications. This step minimizes risks associated with procurement and product quality.

– Actions to take:

– Request company profiles and certifications (e.g., ISO, FDA)

– Ask for case studies or references from similar industries

– Visit production facilities if possible to assess capabilities firsthand

ステップ4: Verify Compliance with Regulatory Standards

Ensure that the plastic bottles comply with local and international regulations, particularly for food and beverage applications. This is crucial for maintaining safety and product integrity.

– Look for:

– Compliance with FDA or EFSA regulations for food contact materials

– Certifications related to sustainability, such as recycling programs

– Documentation proving the absence of harmful substances (e.g., BPA in polycarbonate)

ステップ5: Assess Customization Options

Determine whether suppliers can customize the bottles to meet your branding and functional requirements. Customization can enhance product appeal and usability.

– Considerations include:

– Availability of color masterbatch for branding

– Options for unique shapes or sizes

– Capability to add features like tamper-evident caps or special closures

ステップ6: Analyze Cost Structures

Understanding the cost structures associated with different materials and suppliers is essential for budgeting and overall procurement strategy. Look beyond just the unit price to include long-term costs.

– Factors to evaluate:

– Minimum order quantities and bulk pricing

– Transportation and logistics costs

– Potential savings from using recyclable materials

ステップ7: Plan for Sustainability

Incorporate sustainability into your sourcing strategy by selecting suppliers committed to environmentally friendly practices. This is increasingly important for brand reputation and compliance with global trends.

– Action steps:

– Inquire about the use of recycled materials (e.g., rPET)

– Assess suppliers’ waste management and recycling initiatives

– Look for certifications indicating sustainable practices (e.g., ISO 14001)

By following these steps, B2B buyers can effectively navigate the complexities of sourcing plastic bottles, ensuring that they select the right materials and suppliers to meet their operational and environmental objectives.

Comprehensive Cost and Pricing Analysis for plastic bottle properties Sourcing

What Are the Key Cost Components for Sourcing Plastic Bottle Properties?

When sourcing plastic bottle properties, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

材料: The choice of raw materials, such as PET, HDPE, and PP, significantly influences the overall cost. Each material has varying price points based on its properties and applications. For instance, PET is often favored for beverage containers due to its recyclability and clarity, while HDPE is preferred for household products due to its chemical resistance.

-

労働: Labor costs can vary widely depending on the region and the complexity of the manufacturing process. Skilled labor may be required for specialized production techniques, impacting the overall labor cost.

-

製造間接費: This encompasses all indirect costs associated with production, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs.

-

工具: Initial tooling costs for molds and machinery can be significant, particularly for custom bottle designs. These costs are typically amortized over the production volume, making them a crucial consideration for bulk orders.

-

品質管理(QC): Ensuring product quality through testing and inspections is essential, especially for international markets where compliance with local regulations is critical. QC costs can vary based on the standards required for certification.

-

物流: Transportation and shipping costs are particularly important for international buyers. Factors such as distance, shipping method, and Incoterms can greatly affect logistics expenses.

-

マージン: Suppliers typically include a profit margin in their pricing. Understanding the average margin in the industry can help buyers gauge whether a quote is competitive.

How Do Volume and Customization Affect Pricing?

The pricing of plastic bottles is heavily influenced by order volume and customization requirements. Higher volume orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, which can significantly reduce overall expenditure.

Customization, such as specific shapes, sizes, or printing, can increase costs. Tailored solutions may require specialized tooling or additional labor, impacting the final price. Buyers should assess whether the added expense of customization aligns with their branding and product differentiation strategies.

What External Factors Influence Pricing in Different Regions?

International B2B buyers should consider various external factors that influence pricing:

-

Quality and Certifications: Regions may have different regulatory requirements for product safety and environmental impact. Certifications can add to costs but are often necessary for market entry, particularly in Europe and North America.

-

サプライヤー要因: The reputation, reliability, and negotiation flexibility of suppliers can influence pricing. Established suppliers may charge more due to their track record, while newer entrants might offer lower prices to gain market share.

-

インコタームズ: The chosen Incoterms dictate the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms can help buyers avoid unexpected costs.

What Are the Best Practices for Negotiating and Ensuring Cost-Efficiency?

To achieve cost-efficiency, buyers should adopt the following strategies:

-

Conduct a Total Cost of Ownership Analysis: Look beyond the initial purchase price. Consider factors such as shipping, customs duties, and lifecycle costs of the plastic bottles to understand the true financial impact.

-

Negotiate Terms: Engage suppliers in discussions about volume discounts, payment terms, and delivery schedules. Having a clear understanding of market prices and competitors can strengthen your negotiation position.

-

Build Long-term Relationships: Establishing a reliable relationship with suppliers can lead to better pricing and terms over time. Consider entering into contracts for ongoing supply to lock in favorable rates.

Are There Pricing Nuances for International Buyers?

International buyers must be aware of pricing nuances that may affect their sourcing decisions. Currency fluctuations can impact costs, especially for long-term contracts. Additionally, varying import tariffs and taxes in different regions can affect the final price. It is advisable to account for these factors in budgeting and cost forecasting.

Disclaimer: Prices for plastic bottle properties can vary widely based on market conditions, supplier negotiations, and specific project requirements. Always consult multiple suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing plastic bottle properties With Other Solutions

Exploring Alternatives to Plastic Bottle Properties for B2B Buyers

In today’s environmentally conscious market, businesses are increasingly evaluating alternative packaging solutions to traditional plastic bottles. Understanding the properties of plastic bottles in comparison to other viable options can guide B2B buyers in making informed decisions that align with their sustainability goals, cost considerations, and performance requirements.

| 比較の側面 | Plastic Bottle Properties | Glass Bottles | Biodegradable Bottles |

|---|---|---|---|

| パフォーマンス | Lightweight, durable, recyclable, excellent moisture barrier | Heavy, breakable, reusable, non-reactive | Compostable under specific conditions, may not be as durable |

| コスト | Generally low production cost | Higher production and transport costs | Moderate cost, varies by material and production scale |

| 実施しやすさ | Simple manufacturing process; widely available | Requires specialized manufacturing and logistics | May require new production methods; availability can be limited |

| メンテナンス | Low; recyclable through established systems | High; requires careful handling and cleaning | Variable; dependent on composting infrastructure |

| ベスト・ユースケース | Beverages, cleaning products, personal care items | High-end beverages, reusable products | Eco-friendly brands, organic products |

What Are the Advantages and Disadvantages of Glass Bottles?

Glass bottles present a premium alternative to plastic, especially for beverages. They are non-reactive, preserving the taste and quality of the contents without leaching chemicals. Their recyclability is also a significant advantage, as they can be reused multiple times. However, glass bottles are heavier and more fragile, increasing shipping costs and the risk of breakage. This makes them less suitable for high-volume, low-cost products.

How Do Biodegradable Bottles Compare to Plastic?

Biodegradable bottles, often made from materials like PLA (polylactic acid), offer a compelling option for brands focusing on sustainability. These bottles break down in composting environments, reducing plastic waste. They are ideal for organic and eco-conscious brands. However, their performance can be a drawback; they may not withstand the same conditions as traditional plastic bottles, and their availability can be inconsistent, potentially complicating supply chains. Additionally, they require specific composting facilities to degrade properly, which may not be accessible in all regions.

Conclusion: How Should B2B Buyers Choose the Right Packaging Solution?

When selecting the appropriate packaging solution, B2B buyers should consider their specific needs in terms of product type, target market, and sustainability goals. Plastic bottles offer a cost-effective, lightweight option with established recycling systems. In contrast, glass bottles provide premium quality but at a higher cost and risk of breakage. Biodegradable options cater to environmentally focused brands but may pose challenges in terms of durability and availability. By carefully weighing these factors, buyers can make strategic decisions that align with their business objectives and consumer expectations.

Essential Technical Properties and Trade Terminology for plastic bottle properties

Understanding the technical properties and trade terminology related to plastic bottles is crucial for B2B buyers seeking to make informed purchasing decisions. This knowledge can help in evaluating suppliers, negotiating contracts, and ensuring product compliance with industry standards.

What Are the Key Technical Properties of Plastic Bottles?

1. Material Grade

Material grade refers to the specific type of plastic used in manufacturing bottles, such as PET, HDPE, or PP. Each material has distinct properties that influence durability, weight, and suitability for different contents. Understanding material grades enables buyers to select bottles that meet their product requirements, ensuring both performance and safety.

2. Tolerance

Tolerance is the allowable deviation in dimensions and weight of the plastic bottle. Precise tolerances are essential for ensuring that bottles fit specific machinery or meet regulatory requirements. Inconsistent tolerances can lead to production inefficiencies or product contamination, making it vital for buyers to specify and verify tolerance levels with suppliers.

3. Barrier Properties

Barrier properties refer to a bottle’s ability to resist the permeation of gases, moisture, and light. This characteristic is critical for preserving the quality and shelf-life of beverages or other sensitive products. Buyers must assess barrier properties to ensure that the selected bottles protect their contents effectively, especially in markets with varying climatic conditions.

4. Recyclability

Recyclability is a key consideration in today’s environmentally conscious market. Different plastics have different recycling potentials, impacting the sustainability profile of a brand. Buyers should prioritize materials that are easily recyclable, as this can enhance brand reputation and align with global sustainability trends, particularly in regions where environmental regulations are stringent.

5. Temperature Resistance

Temperature resistance indicates a bottle’s ability to withstand temperature fluctuations without deforming or releasing harmful substances. This property is particularly important for products that require hot-filling or are stored in varying climates. Buyers should ensure that their chosen bottles can handle the required temperature ranges for their specific applications.

What Are Common Trade Terms in the Plastic Bottle Industry?

1.OEM(相手先ブランド製造)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of plastic bottles, an OEM may manufacture bottles that are branded and sold by another company. Understanding OEM partnerships can help buyers identify reliable suppliers who can meet their production needs.

2.MOQ(最小注文数量)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to understand their investment requirements and manage inventory effectively. Suppliers often set MOQs based on production costs, so buyers should negotiate to find quantities that align with their demand.

3.RFQ (見積依頼書)

An RFQ is a formal document sent to suppliers requesting a detailed price quote for specific products. This process allows buyers to compare costs, terms, and conditions from multiple vendors. A well-prepared RFQ can streamline procurement processes and ensure that buyers receive competitive pricing.

4.インコタームズ(国際商業条件)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms can help buyers understand shipping costs, risk responsibilities, and delivery timelines. This knowledge is essential for effective negotiation and contract management in cross-border transactions.

5.リードタイム

Lead time refers to the amount of time between placing an order and receiving the product. Understanding lead times is crucial for buyers to plan their inventory and production schedules effectively. Longer lead times can impact supply chain efficiency, so buyers should communicate clearly with suppliers about expected timelines.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right products for their needs while navigating the complexities of the global plastic bottle market.

Navigating Market Dynamics and Sourcing Trends in the plastic bottle properties Sector

What Are the Key Trends Influencing the Plastic Bottle Properties Market?

The global plastic bottle properties market is experiencing significant shifts driven by increasing consumer demand for convenience and sustainability. Key trends include the rising preference for lightweight and durable materials, such as Polyethylene Terephthalate (PET) and High-Density Polyethylene (HDPE), which are favored for their strength-to-weight ratios and recyclability. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide innovative solutions that meet both functional and environmental criteria.

Emerging technologies are also transforming sourcing strategies. Automation in manufacturing processes enhances efficiency and product consistency, while advances in recycling technologies are paving the way for closed-loop systems that minimize waste. Digital platforms are becoming essential for international buyers to streamline procurement, allowing them to compare suppliers and materials quickly. Blockchain technology is gaining traction for its potential to enhance supply chain transparency, which is crucial for buyers looking to ensure ethical sourcing practices.

As global markets become more interconnected, understanding regional dynamics is vital. For instance, in South America and Africa, where economic growth is rapid, the demand for plastic bottles in consumer goods is skyrocketing, prompting suppliers to adapt their offerings to local market needs and regulatory standards. Conversely, European buyers are focusing more on compliance with stringent environmental regulations, driving innovation in sustainable bottle designs.

How Is Sustainability Shaping the Sourcing of Plastic Bottle Properties?

Sustainability is no longer just a buzzword; it is a fundamental principle shaping the plastic bottle properties sector. The environmental impact of plastic waste has prompted B2B buyers to prioritize suppliers who adopt sustainable practices. This shift is evident in the growing demand for recycled materials and biodegradable options. For example, companies are increasingly exploring bioplastics, such as Polylactic Acid (PLA), derived from renewable resources, which offer a more eco-friendly alternative to traditional plastics.

Ethical supply chains are becoming paramount, with buyers seeking certifications that guarantee the sustainable sourcing of materials. Certifications such as Global Recycle Standard (GRS) and Cradle to Cradle (C2C) are valuable indicators for buyers looking to partner with manufacturers committed to reducing their environmental footprint. Additionally, incorporating sustainability into procurement strategies not only addresses regulatory requirements but also enhances brand reputation, appealing to environmentally conscious consumers.

Investing in sustainable packaging solutions can yield long-term cost savings as well. By reducing reliance on virgin materials and embracing recycling initiatives, businesses can lower production costs and potentially benefit from government incentives for eco-friendly practices. As sustainability becomes ingrained in corporate strategy, B2B buyers must align with suppliers who share their commitment to environmental stewardship.

How Have Plastic Bottle Properties Evolved Over Time?

The evolution of plastic bottle properties has been marked by significant advancements in material science and manufacturing techniques. Initially, glass and metal were the primary materials used for packaging; however, the introduction of plastics in the mid-20th century revolutionized the industry. The lightweight, shatterproof nature of plastics made them an attractive alternative, leading to widespread adoption.

Over the decades, innovations such as the development of PET and HDPE have further enhanced the properties of plastic bottles, making them more durable and versatile. These materials have become staples in beverage and consumer goods packaging due to their excellent barrier properties and recyclability. The focus has now shifted towards not only improving the physical characteristics of plastic bottles but also addressing environmental concerns through recycling and sustainable sourcing practices.

As market dynamics continue to change, the future of plastic bottle properties will likely be shaped by ongoing research into new materials and technologies that prioritize both functionality and sustainability. This evolution presents a unique opportunity for B2B buyers to engage with forward-thinking suppliers who are committed to driving positive change in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic bottle properties

-

How do I choose the right plastic bottle material for my product?

Selecting the appropriate plastic bottle material depends on various factors, including the type of product, storage conditions, and regulatory requirements. For beverages, Polyethylene Terephthalate (PET) is commonly used due to its clarity and recyclability. If your product requires durability and resistance to chemicals, High-Density Polyethylene (HDPE) is suitable. Assess your product’s temperature sensitivity and interaction with the bottle material to ensure safety and maintain quality. -

What is the best plastic for environmentally friendly packaging?

For sustainable packaging, consider using materials like Polyethylene Terephthalate (PET) and Polylactic Acid (PLA). PET is highly recyclable and can be reprocessed into new bottles or fibers, promoting a circular economy. PLA, a bioplastic made from renewable resources, is biodegradable under specific conditions, making it an excellent choice for eco-conscious brands. Evaluate your supply chain to ensure that the chosen material aligns with your sustainability goals. -

What customization options are available for plastic bottles?

Customization options for plastic bottles include shape, size, color, and labeling. Many manufacturers offer tailored solutions to meet specific branding and functional needs, such as ergonomic designs or child-proof caps. Additionally, you can incorporate unique features like tamper-evident seals or UV protection additives. Discuss your requirements with suppliers to explore the best options for your brand. -

How can I vet suppliers for plastic bottle manufacturing?

To vet suppliers, start by researching their industry reputation, certifications, and experience in producing the specific type of plastic bottles you need. Request samples to evaluate quality and durability. Additionally, check for compliance with international standards and regulations applicable in your market. Engaging in direct communication and visiting manufacturing facilities, if possible, can provide further insights into their operational capabilities. -

What are the typical minimum order quantities (MOQ) for plastic bottles?

Minimum order quantities (MOQ) for plastic bottles can vary significantly based on the supplier and the complexity of the customization required. Generally, MOQs can range from a few thousand units for standard products to tens of thousands for custom designs. It’s crucial to discuss your needs with potential suppliers to find a balance between your budget and production capabilities. -

What payment terms should I expect when sourcing plastic bottles?

Payment terms for sourcing plastic bottles typically include options such as upfront deposits (usually 30-50%), with the balance paid before shipment. Some suppliers may offer credit terms depending on the volume of business and relationship history. Ensure that you understand the payment structure, including any potential fees for late payments or currency exchange rates, particularly when dealing with international suppliers. -

How do I ensure quality assurance (QA) in plastic bottle production?

To ensure quality assurance in plastic bottle production, establish clear specifications and standards before production begins. Work closely with your supplier to implement regular quality checks at various stages of manufacturing. Consider conducting third-party inspections and testing for compliance with relevant safety and quality standards. Developing a robust communication channel with your supplier can help address any issues promptly. -

What logistics considerations should I keep in mind when importing plastic bottles?

When importing plastic bottles, consider logistics factors such as shipping methods, customs clearance, and lead times. Choose a reliable freight forwarder familiar with your product type and target markets. Ensure that all necessary documentation, including invoices and certificates of origin, is in order to avoid delays. Additionally, factor in storage solutions upon arrival to manage inventory effectively.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを行う必要がある。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。

Top 9 Plastic Bottle Properties Manufacturers & Suppliers List

1. US Plastic – HDPE Solutions

ドメイン usplastic.com

登録:1996年(29年)

はじめに HDPE – High Density Polyethylene: Excellent moisture barrier, impact resistant, translucent, ideal for high-speed filling, well suited for demanding pharmaceutical specifications, water-based chemicals, toiletries & cosmetics, and certain food products. Inadequate for products sensitive to oxidation or those containing solvents. Economical, flexible, provides good moisture barrier, compatible with…

2. Bottlestore – Plastic Properties Explained

ドメイン bottlestore.com

登録:1998年(27年)

はじめに The article discusses the chemical properties of plastic, highlighting that ‘plastic’ is a general term for various chemicals and synthetic materials. It mentions the lightweight composition and strength of plastic, which makes it prevalent in many industries. The text distinguishes between two main categories of plastics: thermoplastics, which can be heated and remolded, and thermosets, which can…

3. Chemistry is Life – Ethylene in LDPE and HDPE

ドメイン chemistryislife.com

Registered: 2013 (12 years)

はじめに This company, Chemistry is Life – Ethylene in LDPE and HDPE, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Living1991 – Types of Plastic Bottles

ドメイン living1991.com

Registered: 2019 (6 years)

はじめに Types of Plastic Bottles: 1. PET (Polyethylene Terephthalate) – Characteristics: High transparency, lightweight, good oil resistance, excellent barrier properties. Common Uses: Detergent bottles, cosmetic spray bottles, food-grade beverage bottles. Suitable For: Liquid detergents, toner, alcohol. Note: Not heat-resistant. 2. PE (Polyethylene) – Divided into HDPE (High-Density) and LDPE (Low-Densit…

5. Cosmo Packs – Key Differences Between HDPE and PET

ドメイン cosmopacks.com

Registered: 2015 (10 years)

はじめに Key Differences between HDPE and PET:

1. **Chemical Composition and Structure**:

– HDPE (High-Density Polyethylene): Made from ethylene, a petroleum compound; semi-crystalline, puncture-resistant, high strength-to-density ratio.

– PET (Polyethylene Terephthalate): Made from ethylene glycol and terephthalic acid; clear plastic, commonly used in beverage bottles.

2. **Physical Properties**:

…

6. Wrap – PET Resin

ドメイン wrap.ngo

Registered: 2023 (2 years)

はじめに PET (polyethylene terephthalate) is a type of resin and a form of polyester commonly labeled with a code on or near the bottom of bottles and containers. Key characteristics include strength, thermo-stability, gas barrier properties, transparency, lightweight, shatter-resistant, and recyclable. In 2011, PET bottles made up over half of the 306,000 tonnes of plastic bottles captured for recycling t…

7. Compax Packaging – High-Density Polyethylene (HDPE) & Polyethylene Terephthalate (PET)

ドメイン knowledge.compaxpackaging.com

Registered: 2011 (14 years)

はじめに High-Density Polyethylene (HDPE): Robust, chemical-resistant, used for cleaning solutions, milk jugs, beverages, personal care products, less squeezable, slightly cloudy appearance, second most recycled plastic in the US. Polyethylene Terephthalate (PET): Most widely used polymer, high clarity, thin-walled, rigid, lightweight, hygroscopic, most recycled plastic resin in the US. Polypropylene (PP):…

8. The Plastic Bottles Company – HDPE Solutions

ドメイン blog.theplasticbottlescompany.com

Registered: 2013 (12 years)

はじめに This company, The Plastic Bottles Company – HDPE Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. ScienceDirect – Polyethylene Terephthalate (PET)

ドメイン sciencedirect.com

登録:1997年(28年)

はじめに Polyethylene terephthalate (PET) is a semicrystalline thermoplastic polyester commonly used for single-use bottles and packaging. It has a higher density than seawater and is frequently found in marine environments, raising concerns about plastic pollution. PET is produced from the polycondensation of ethylene glycol and terephthalic acid. It is characterized by high strength, toughness, good abra…

Strategic Sourcing Conclusion and Outlook for plastic bottle properties

In the rapidly evolving landscape of plastic bottle production, strategic sourcing has become paramount for international B2B buyers. Understanding the diverse properties of materials such as PET, HDPE, and PP not only enhances product performance but also aligns with sustainability goals. By prioritizing recyclable materials and innovative designs, businesses can significantly reduce their environmental footprint while meeting consumer demands for transparency and durability.

The key takeaway for buyers across Africa, South America, the Middle East, and Europe is to leverage the unique properties of various plastics to optimize their supply chains. Considerations such as regional recycling capabilities, cost-effectiveness, and compliance with local regulations should guide sourcing decisions. Additionally, engaging with suppliers who prioritize sustainability can foster long-term partnerships and improve brand reputation.

As we look toward the future, the emphasis on eco-friendly materials and practices will only intensify. Buyers are encouraged to stay informed about emerging technologies and market trends in plastic production. By doing so, they can position themselves as leaders in responsible sourcing, ensuring their products not only meet the needs of today but are also aligned with the sustainability priorities of tomorrow.