Introduction: Navigating the Global Market for titanium drinking bottle

In today’s competitive landscape, sourcing high-quality titanium drinking bottles can be a significant challenge for international B2B buyers. As businesses increasingly prioritize sustainability and health-conscious products, the demand for titanium bottles—known for their durability, lightweight nature, and non-reactive properties—has surged. This guide aims to demystify the global market for titanium drinking bottles, offering insights into various types, applications, and critical factors to consider when sourcing these products.

Throughout this comprehensive resource, we will explore essential topics such as supplier vetting processes, cost considerations, and the environmental benefits associated with titanium. By equipping B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—with actionable insights, this guide empowers you to make informed purchasing decisions. Whether you’re looking to stock your retail shelves or provide durable hydration solutions for outdoor enthusiasts, understanding the nuances of the titanium drinking bottle market is crucial.

This guide is designed not only to facilitate a smoother sourcing process but also to enhance your competitive edge by aligning your product offerings with current consumer trends. With the right knowledge and resources at your disposal, you can confidently navigate this growing market and meet the evolving demands of your customers.

Article Navigation

- Top 7 Titanium Drinking Bottle Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for titanium drinking bottle

- Understanding titanium drinking bottle Types and Variations

- Key Industrial Applications of titanium drinking bottle

- 3 Common User Pain Points for ‘titanium drinking bottle’ & Their Solutions

- Strategic Material Selection Guide for titanium drinking bottle

- In-depth Look: Manufacturing Processes and Quality Assurance for titanium drinking bottle

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium drinking bottle’

- Comprehensive Cost and Pricing Analysis for titanium drinking bottle Sourcing

- Alternatives Analysis: Comparing titanium drinking bottle With Other Solutions

- Essential Technical Properties and Trade Terminology for titanium drinking bottle

- Navigating Market Dynamics and Sourcing Trends in the titanium drinking bottle Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of titanium drinking bottle

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for titanium drinking bottle

Understanding titanium drinking bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Titanium Water Bottle | Lightweight, non-reactive, corrosion-resistant | Outdoor gear retailers, corporate gifts | Pros: Durable, eco-friendly; Cons: Higher cost compared to plastic. |

| Insulated Titanium Bottle | Double-wall design for temperature retention | Adventure tourism, hiking equipment suppliers | Pros: Keeps liquids hot/cold; Cons: Heavier than standard bottles. |

| Wide Mouth Titanium Bottle | Larger opening for easy filling and cleaning | Camping gear distributors, outdoor events | Pros: Easy access; Cons: Bulky size may not fit all packs. |

| Ultralight Titanium Bottle | Minimalist design, extremely lightweight | Backpacking gear retailers, minimalist lifestyle brands | Pros: Ideal for weight-conscious consumers; Cons: Less robust for heavy use. |

| Specialized Titanium Canteen | Military-grade durability, often includes additional features | Military supply stores, survival gear retailers | Pros: Extremely durable; Cons: Higher price point. |

What Are the Characteristics of Standard Titanium Water Bottles?

Standard titanium water bottles are recognized for their lightweight and non-reactive properties, making them ideal for outdoor enthusiasts. These bottles do not corrode and are BPA-free, ensuring that they do not leach harmful chemicals into the stored liquids. For B2B buyers, these bottles are suitable for retailers focusing on outdoor gear, as they cater to a health-conscious market. Buyers should consider the durability and long lifespan of these bottles, which justify their higher price compared to plastic alternatives.

How Do Insulated Titanium Bottles Differ from Standard Options?

Insulated titanium bottles feature a double-wall construction that provides excellent thermal retention for both hot and cold beverages. This makes them particularly appealing to adventure tourism companies and hiking equipment suppliers. The insulation ensures that drinks maintain their desired temperature for extended periods, enhancing user experience. However, B2B buyers must account for the increased weight compared to standard options, which may affect portability for certain customer segments.

Why Choose Wide Mouth Titanium Bottles?

Wide mouth titanium bottles are designed with a larger opening, facilitating easier filling, pouring, and cleaning. This feature is particularly advantageous for camping gear distributors and outdoor event organizers, as it caters to users who prefer convenience. While these bottles offer practicality, they can be bulkier, potentially limiting their appeal for consumers with space constraints in their backpacks or gear.

What Makes Ultralight Titanium Bottles Ideal for Backpackers?

Ultralight titanium bottles are crafted with minimalism in mind, appealing to weight-conscious consumers such as backpackers and hikers. Their extremely lightweight design allows for easy transportation, making them a popular choice among retailers focused on minimalist lifestyles. However, B2B buyers should note that while these bottles are lightweight, they may not withstand heavy use as effectively as more robust models.

What Are the Benefits of Specialized Titanium Canteens?

Specialized titanium canteens are built to military-grade standards, often incorporating additional features like integrated cups or multi-use capabilities. These products are well-suited for military supply stores and survival gear retailers, catering to customers seeking durable and versatile hydration solutions. While they provide exceptional durability, the higher price point may deter some budget-conscious buyers.

Key Industrial Applications of titanium drinking bottle

| Industry/Sector | Specific Application of titanium drinking bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Recreation | Used by hikers and campers for hydration | Lightweight and durable, enhances outdoor experience | Ensure compatibility with various outdoor gear and sizes |

| Military and Defense | Utilized in military mess kits | Non-reactive, safe for various liquids, reliable | Compliance with military standards and regulations |

| Health and Wellness | Employed in fitness and wellness programs | BPA-free, promotes healthy hydration practices | Certification for health safety and eco-friendliness |

| Hospitality and Catering | Offered in premium resorts and restaurants | Enhances brand image, eco-friendly alternative | Custom branding options and bulk purchase agreements |

| Travel and Adventure Tourism | Essential for adventure tour operators | Lightweight, reduces luggage weight for travelers | Sourcing from reliable manufacturers with global reach |

How Are Titanium Drinking Bottles Used in Outdoor Recreation?

In the outdoor recreation industry, titanium drinking bottles are favored for their lightweight and robust properties, making them ideal for hikers and campers. These bottles can withstand extreme temperatures and rough handling, ensuring that users stay hydrated without the risk of breakage. B2B buyers in this sector should look for bottles that are compatible with various outdoor gear and come in different sizes to cater to diverse customer needs.

What Role Do Titanium Drinking Bottles Play in Military and Defense?

In military applications, titanium drinking bottles are integrated into mess kits due to their non-reactive nature and durability. These bottles can safely store various liquids without leaching harmful substances, making them essential for soldiers in the field. Buyers in this sector must consider compliance with military standards and regulations, ensuring that the products meet rigorous safety and operational requirements.

How Do Titanium Drinking Bottles Support Health and Wellness Initiatives?

The health and wellness sector utilizes titanium drinking bottles as part of fitness programs and wellness initiatives. These bottles are BPA-free and promote healthy hydration practices among users. International B2B buyers should prioritize sourcing options that provide certification for health safety and eco-friendliness, as these factors are crucial for attracting health-conscious consumers.

Why Are Titanium Drinking Bottles Beneficial for Hospitality and Catering?

In the hospitality industry, titanium drinking bottles are offered in premium resorts and restaurants as an eco-friendly alternative to plastic. These bottles enhance the establishment’s brand image while providing guests with a durable and stylish hydration option. Buyers should seek custom branding options and establish bulk purchase agreements to maximize cost efficiency and brand visibility.

How Do Titanium Drinking Bottles Cater to Travel and Adventure Tourism?

Adventure tour operators rely on titanium drinking bottles to provide travelers with a lightweight hydration solution that reduces overall luggage weight. The durability and resistance to extreme conditions make these bottles an essential item for outdoor enthusiasts. B2B buyers in this sector should focus on sourcing from reliable manufacturers with a global reach to ensure product availability and consistency across different markets.

3 Common User Pain Points for ‘titanium drinking bottle’ & Their Solutions

Scenario 1: Sourcing High-Quality Titanium Drinking Bottles for Export Markets

The Problem: B2B buyers often struggle with sourcing high-quality titanium drinking bottles that meet the specific standards and regulations of their respective markets, particularly in regions like Africa and the Middle East. The challenge lies not only in identifying reliable suppliers but also in ensuring that the bottles are manufactured from genuine titanium, comply with local safety regulations, and offer durability against harsh environmental conditions. Inadequate product quality can lead to customer dissatisfaction and harm a buyer’s reputation in their market.

The Solution: To effectively source titanium drinking bottles, B2B buyers should begin by conducting thorough market research to identify reputable manufacturers with a strong track record in titanium production. It is advisable to request samples and certifications that verify the titanium’s authenticity and quality, such as ASTM standards. Engaging in direct communication with suppliers can also provide insights into their production processes, ensuring they adhere to international safety regulations. Additionally, buyers should consider visiting manufacturing facilities or trade shows to establish relationships and assess the product quality firsthand, which can lead to better negotiation terms and assurance of the product’s longevity.

Scenario 2: Overcoming Customer Concerns About Titanium Safety

The Problem: Many end consumers express concerns regarding the safety of using titanium drinking bottles, particularly regarding whether they are BPA-free and non-toxic. This skepticism can hinder sales for B2B buyers who need to assure their clients about the safety and health benefits of titanium products. Misunderstandings about the material properties can lead to potential market rejection, impacting revenue.

The Solution: To mitigate these concerns, B2B buyers should proactively provide comprehensive information about the safety and advantages of titanium drinking bottles. This includes detailed product descriptions that highlight that titanium is non-reactive and does not leach chemicals, making it a safe choice for hydration. Buyers can create informative marketing materials, including brochures and digital content, that explain the benefits of titanium compared to other materials like plastic. Hosting webinars or workshops with industry experts to discuss the safety aspects of titanium can further educate customers and build trust. Additionally, obtaining third-party safety certifications and displaying them prominently can reassure consumers about the products’ safety.

Scenario 3: Addressing the Durability Challenge in Extreme Conditions

The Problem: B2B buyers often face challenges when marketing titanium drinking bottles for outdoor and extreme conditions, such as those experienced in South America or the Middle East. Buyers must ensure that the products can withstand high temperatures, rough handling, and potential exposure to corrosive substances. If the bottles fail to perform under these conditions, it can lead to high return rates and damage to the buyer’s brand reputation.

The Solution: To address durability concerns, B2B buyers should focus on sourcing titanium drinking bottles that are specifically designed for extreme conditions. This means looking for features such as double-walled construction for insulation, reinforced lids, and finishes that enhance corrosion resistance. Buyers should collaborate with suppliers to ensure they provide products that have been tested in real-world conditions and can withstand the stresses of outdoor use. Providing warranties and guarantees on product durability can also instill confidence in customers. Furthermore, collecting and sharing customer testimonials or case studies that demonstrate the bottles’ performance in challenging environments can serve as powerful marketing tools to attract new clients.

Strategic Material Selection Guide for titanium drinking bottle

What Are the Key Properties of Titanium for Drinking Bottles?

Titanium is a premium choice for manufacturing drinking bottles due to its unique properties. It boasts a high melting point (over 1,600°C) and excellent corrosion resistance, making it suitable for a variety of environments, including those with high humidity or exposure to harsh chemicals. Additionally, titanium is non-reactive, meaning it does not leach harmful substances into liquids, ensuring safe consumption. Its lightweight nature, combined with high strength, allows for durable yet portable designs, appealing to outdoor enthusiasts and health-conscious consumers alike.

How Does Titanium Compare to Other Common Materials?

Stainless Steel

Key Properties: Stainless steel offers good corrosion resistance and can withstand high temperatures. It is durable and has a relatively high tensile strength.

Pros & Cons: Stainless steel is more affordable than titanium and widely available. However, it is heavier, which can be a disadvantage for portable products. Manufacturing processes for stainless steel can be complex, especially for insulated designs.

Impact on Application: Stainless steel is compatible with a wide range of liquids, but it can retain flavors and odors if not properly cleaned. For international buyers, compliance with food safety standards (like FDA regulations) is crucial.

Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity. It is often anodized for enhanced corrosion resistance.

Pros & Cons: Aluminum is less expensive and lighter than stainless steel and titanium. However, it is less durable and can dent easily. Additionally, aluminum may react with acidic or alkaline substances unless coated.

Impact on Application: Aluminum bottles are suitable for general use but may not be ideal for hot liquids due to potential leaching of aluminum ions. Buyers should ensure compliance with relevant health standards in their regions.

Plastic (BPA-Free)

Key Properties: BPA-free plastics are lightweight and inexpensive. They can be molded into various shapes and sizes.

Pros & Cons: While plastic is cost-effective and versatile, it is less durable than metal options and can degrade over time. It is also less environmentally friendly compared to titanium and stainless steel.

Impact on Application: Plastic bottles are suitable for cold beverages but may warp or leach chemicals when exposed to heat. International buyers should be aware of regulations regarding plastic usage, especially in regions with strict environmental laws.

What Should International B2B Buyers Consider When Selecting Materials?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, several factors are crucial when selecting materials for titanium drinking bottles. Compliance with local and international standards, such as ASTM, DIN, or JIS, is essential to ensure product safety and marketability. Buyers should also consider regional preferences for sustainability and environmental impact, as well as the potential for tariffs and trade regulations that may affect costs. Understanding the end-user market’s preferences can guide material selection, ensuring the product meets consumer expectations for quality and functionality.

Summary Table of Material Comparisons

| Material | Typical Use Case for titanium drinking bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Outdoor activities, health-conscious users | Lightweight, non-reactive, durable | Higher cost compared to alternatives | High |

| Stainless Steel | General use, insulated bottles | Affordable, good corrosion resistance | Heavier, complex manufacturing | Medium |

| Aluminum | Lightweight camping gear | Very lightweight, cost-effective | Less durable, can dent easily | Low |

| Plastic (BPA-Free) | Everyday hydration solutions | Inexpensive, versatile | Less durable, potential leaching | Low |

This analysis provides a comprehensive overview of the materials commonly used in the production of titanium drinking bottles, equipping B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium drinking bottle

What Are the Key Stages in the Manufacturing Process of Titanium Drinking Bottles?

The manufacturing of titanium drinking bottles involves several critical stages, each designed to ensure the final product meets the highest standards of quality and functionality. Here are the main stages:

Material Preparation: How Is Titanium Processed for Bottles?

The process begins with sourcing high-grade titanium, often in the form of titanium ingots or sheets. The material is typically selected for its purity and performance characteristics, as impurities can lead to weaknesses in the final product. Advanced techniques like vacuum arc remelting (VAR) or electron beam melting (EBM) may be employed to further enhance material quality.

Once the titanium is procured, it undergoes cutting and machining to create the initial bottle shapes. This step often involves precision tools and CNC (Computer Numerical Control) machines to ensure accuracy. The goal is to achieve the desired dimensions while maintaining the integrity of the titanium.

How Are Titanium Bottles Formed? Exploring Techniques and Methods

The forming stage utilizes various methods, such as deep drawing, hydroforming, or spinning, depending on the design complexity and intended use of the bottle. For instance, hydroforming involves using high-pressure fluids to shape the titanium, allowing for intricate designs while minimizing waste.

These techniques are crucial for achieving the lightweight and durable characteristics that titanium is known for. The forming process is closely monitored to prevent any defects that could compromise the bottle’s performance.

What Does the Assembly Process Involve for Titanium Bottles?

After forming, the individual components of the titanium bottle are assembled. This can include attaching lids, handles, or any additional features that enhance functionality. The assembly process may involve welding, bonding, or mechanical fastening, depending on the design.

Precision is paramount during assembly, as even minor misalignments can affect the bottle’s ability to seal and maintain temperature. Automated systems are often used to ensure consistency and quality across batches.

How Is the Finishing Process Conducted for Titanium Drinking Bottles?

The finishing stage includes several steps aimed at improving the aesthetic and functional properties of the bottle. This may involve surface treatments like anodizing, which enhances corrosion resistance and provides a range of color options.

Additionally, polishing may be employed to create a visually appealing finish while ensuring the bottle is easy to clean. Quality checks are often integrated into this stage to catch any imperfections before the final product is packaged.

What Quality Assurance Measures Are Essential for Titanium Drinking Bottles?

Quality assurance is a critical aspect of the manufacturing process, especially for international B2B buyers. Here’s how it typically unfolds:

Which International Standards Apply to Titanium Drinking Bottles?

Manufacturers of titanium drinking bottles must adhere to various international quality standards. ISO 9001 is one of the most recognized standards, focusing on quality management systems and ensuring consistent product quality.

In addition to ISO standards, other certifications may be relevant, including CE marking for products sold in Europe and API standards for those targeting the oil and gas industry. These certifications indicate compliance with specific safety and performance criteria, which is essential for B2B buyers looking for reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of production to ensure compliance with standards. These typically include:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials for quality and specifications upon arrival at the manufacturing facility.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from standards are identified and rectified promptly.

-

Final Quality Control (FQC): The final inspection occurs before packaging, focusing on overall product quality, functionality, and safety compliance.

Which Testing Methods Are Commonly Used for Titanium Drinking Bottles?

Common testing methods include:

-

Hydrostatic Testing: This checks for leaks and ensures that the bottle can withstand internal pressure.

-

Visual Inspection: A thorough examination for surface defects, ensuring aesthetic and functional integrity.

-

Mechanical Testing: This includes tensile strength tests to verify that the bottle meets durability requirements.

-

Chemical Composition Analysis: Ensures that the titanium used meets specified alloy standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are some methods:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting detailed reports from suppliers about their quality control processes is crucial. These reports should outline their adherence to ISO standards, any certifications obtained, and the results of their internal audits.

Buyers should also consider scheduling periodic audits of the manufacturing facility, which can provide firsthand insights into their operational practices and quality management systems.

How Important Are Third-Party Inspections for Ensuring Quality?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations assess compliance with international standards and offer unbiased evaluations of the manufacturing process. This is particularly vital for B2B buyers in emerging markets where local standards may vary.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control that can affect their procurement decisions. Understanding regional regulations and certifications can be complex, especially when dealing with different countries.

For instance, products sold in Europe may require CE marking, while those in the Middle East might need to comply with specific local standards. Buyers should work closely with suppliers to ensure that all necessary certifications are obtained, which can facilitate smoother trade and reduce the risk of compliance issues.

In conclusion, the manufacturing and quality assurance processes for titanium drinking bottles are intricate and require a comprehensive understanding of both manufacturing techniques and quality control measures. For B2B buyers, particularly those operating on an international scale, thorough due diligence is essential to ensure that they partner with reliable manufacturers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium drinking bottle’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure titanium drinking bottles. As the demand for durable, lightweight, and environmentally friendly hydration solutions grows, understanding the nuances of sourcing titanium products is essential. This checklist will help you navigate the procurement process efficiently and effectively.

1. Identify Your Target Market Needs

Understanding your target market’s preferences is crucial. Consider factors such as size, design, and functionality that appeal to your customer base. Research local trends and consumer behaviors in regions like Africa, South America, the Middle East, and Europe to tailor your offerings.

2. Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring product quality. Determine the desired capacity (e.g., 500ml, 1L), weight, and design features, such as insulation or spouts. Specifications should also include compliance with safety standards relevant to your market.

3. ✅ Verify Supplier Certifications

Before selecting a supplier, confirm their certifications and compliance with international quality standards. Look for certifications such as ISO 9001, which indicates quality management systems. These certifications ensure that the supplier adheres to industry regulations and maintains product integrity.

4. Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your requirements. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their production capabilities, lead times, and customer service reputation to gauge reliability.

5. Conduct Quality Assurance Checks

Prior to finalizing your order, implement quality assurance measures. Request samples to evaluate the product’s durability, weight, and finish. This step allows you to verify that the titanium drinking bottles meet your specifications and quality expectations.

6. Understand Pricing Structures and Terms

Analyze the pricing structure and payment terms offered by suppliers. Look for transparency in pricing, including any additional costs for shipping, customs, or bulk orders. Understanding these terms can help you manage your budget effectively and avoid unexpected expenses.

7. Establish a Logistics Plan

Develop a comprehensive logistics plan for the procurement process. Consider factors such as shipping methods, delivery timelines, and potential customs regulations that may impact your order. A well-structured logistics plan will help ensure timely delivery and minimize disruptions in your supply chain.

By following this step-by-step checklist, B2B buyers can streamline the procurement process for titanium drinking bottles, ensuring they meet market demands while maintaining product quality and compliance.

Comprehensive Cost and Pricing Analysis for titanium drinking bottle Sourcing

What Are the Key Cost Components in Sourcing Titanium Drinking Bottles?

When evaluating the cost structure of titanium drinking bottles, several key components come into play. Materials represent the most significant expense, with titanium being a premium metal known for its strength and durability. The price of titanium can fluctuate based on market demand and sourcing locations, making it essential to monitor these trends.

Labor costs are another critical factor, as skilled labor is required to manufacture titanium products. This includes not only the labor involved in the production process but also in design and engineering. Manufacturing overhead covers expenses such as utilities, maintenance, and equipment depreciation, which can vary based on the manufacturing facility’s location and efficiency.

Tooling costs are also significant, particularly for custom designs or specialized features. These costs can be amortized over larger production runs, making it more cost-effective to order higher quantities. Additionally, quality control (QC) measures must be factored in to ensure that the bottles meet safety and performance standards, which can include testing for leachability and durability.

Logistics encompasses shipping, handling, and any tariffs or duties associated with importing titanium bottles. These costs can vary widely depending on the shipping method and the distance from the supplier. Finally, the margin added by the manufacturer or distributor should be considered, which can be influenced by market conditions and competition.

How Do Price Influencers Affect Titanium Drinking Bottle Costs?

Several factors influence the pricing of titanium drinking bottles, particularly for B2B buyers. Volume and minimum order quantity (MOQ) are critical; larger orders typically result in lower per-unit costs due to economies of scale. However, buyers must balance the benefits of bulk purchasing with the risk of overstocking.

Specifications and customization play a significant role in pricing. Customized designs or additional features, such as insulation or specialized lids, can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

Material quality and certifications can also affect pricing. Bottles with higher-grade titanium or those that comply with international safety standards may command a premium. Understanding the certifications required in specific regions, such as FDA approval or EU regulations, is essential for compliance and market acceptance.

Supplier factors, including their reputation, reliability, and production capacity, can influence pricing. Working with established suppliers may offer more consistent quality but could come at a higher price. Lastly, the choice of Incoterms can significantly impact overall costs. Terms that include delivery to the buyer’s location may seem convenient but can add hidden expenses.

What Tips Can Help Buyers Negotiate Better Prices for Titanium Drinking Bottles?

When sourcing titanium drinking bottles, B2B buyers can adopt several strategies to enhance cost-efficiency. Negotiation is vital; understanding the supplier’s cost structure can provide leverage during discussions. Buyers should not hesitate to ask for discounts based on volume commitments or long-term contracts.

Considering the Total Cost of Ownership (TCO) is crucial. While the initial purchase price of titanium bottles may be higher than alternatives, their durability and non-reactive properties can lead to savings over time. This includes reduced replacement costs and the potential for improved health outcomes due to the absence of harmful chemicals.

Buyers should also be aware of pricing nuances in international markets. Factors such as currency fluctuations, local taxes, and import duties can affect the final cost. Conducting thorough market research on comparable products in target regions, like Saudi Arabia or Brazil, can inform better purchasing decisions.

Lastly, maintaining a good relationship with suppliers can open doors for better pricing and terms. Regular communication and feedback can lead to more favorable agreements and ensure that the supplier prioritizes the buyer’s needs.

Disclaimer on Indicative Prices

Prices for titanium drinking bottles can vary widely based on the factors outlined above. Buyers should conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing titanium drinking bottle With Other Solutions

Introduction: What Are the Alternatives to Titanium Drinking Bottles?

When considering hydration solutions for outdoor activities, travel, or daily use, B2B buyers often evaluate various materials and designs. Titanium drinking bottles are renowned for their strength, durability, and safety, but alternatives exist that may cater to different needs or budgets. This analysis compares titanium bottles with stainless steel and BPA-free plastic bottles, providing insights into their respective advantages and drawbacks.

Comparison Table

| Comparison Aspect | Titanium Drinking Bottle | Stainless Steel Bottle | BPA-Free Plastic Bottle |

|---|---|---|---|

| Performance | Lightweight, corrosion-resistant, non-reactive | Durable, retains temperature well | Lightweight, less durable, may absorb odors |

| Cost | Higher ($69.95 – $159.95) | Moderate ($19.95 – $49.95) | Lower ($5.00 – $20.00) |

| Ease of Implementation | Requires careful handling to avoid dents | Easy to clean, versatile | Very easy to use and clean |

| Maintenance | Low maintenance, high durability | Moderate maintenance, prone to scratches | High maintenance, may need frequent replacement |

| Best Use Case | Outdoor adventures, long-term investment | Everyday use, travel, gym | Casual use, budget-conscious consumers |

Detailed Breakdown of Alternatives

Stainless Steel Bottle

Stainless steel bottles are a popular alternative to titanium due to their durability and ability to retain temperature. They are generally more affordable than titanium, making them an attractive option for businesses looking to equip employees or customers with hydration solutions. However, stainless steel can be heavier and may not be as corrosion-resistant as titanium. While they perform well for everyday use and can keep beverages hot or cold, they can also scratch easily and may not be as long-lasting as titanium options.

BPA-Free Plastic Bottle

BPA-free plastic bottles represent the most budget-friendly alternative for hydration solutions. These bottles are lightweight and often available in various designs and colors, appealing to a younger demographic or those seeking casual use. However, they may not provide the same level of durability or safety as titanium and stainless steel. Plastic bottles can absorb odors and flavors, which may deter consumers who frequently switch between different beverages. Additionally, they typically require more frequent replacement, which could impact overall sustainability efforts.

Conclusion: How to Choose the Right Hydration Solution

For B2B buyers evaluating hydration solutions, the choice between a titanium drinking bottle, stainless steel bottle, and BPA-free plastic bottle hinges on specific needs and budget constraints. Titanium bottles excel in durability and safety, making them ideal for long-term investments and outdoor activities. Conversely, stainless steel offers a balance of affordability and performance suitable for everyday use. On the other hand, BPA-free plastic may appeal to budget-conscious consumers but lacks longevity and robustness. Understanding these differences will enable buyers to select the most appropriate solution that aligns with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for titanium drinking bottle

What Are the Key Technical Properties of Titanium Drinking Bottles?

When considering titanium drinking bottles for B2B procurement, several critical specifications should be evaluated to ensure product quality, performance, and suitability for various applications.

1. Material Grade

Titanium bottles are primarily made from commercially pure titanium (Grade 1 or Grade 2) or titanium alloys. Grade 1 is highly ductile and corrosion-resistant, making it ideal for lightweight applications. Grade 2 offers a balance of strength and corrosion resistance, suitable for outdoor and industrial use. Understanding material grade helps buyers assess durability and performance in specific environments, especially in regions with extreme temperatures or humidity.

2. Weight and Capacity

Titanium is renowned for its lightweight properties, which significantly reduces the overall weight of the bottle compared to stainless steel or plastic alternatives. Common capacities range from 500 ml to 1500 ml. B2B buyers should consider the weight-to-volume ratio to ensure the product meets their customers’ needs for portability and usability, particularly for outdoor and travel applications.

3. Corrosion Resistance

Titanium exhibits exceptional resistance to corrosion from seawater and various chemicals. This property is crucial for companies targeting markets with high humidity or salty environments, such as coastal regions in Africa or the Middle East. Ensuring the product’s longevity and reliability in challenging conditions can enhance brand reputation and customer satisfaction.

4. Non-Reactivity

Unlike plastic and some metals, titanium does not leach harmful substances into liquids, maintaining the purity of the contents. This property is particularly important for health-conscious consumers and businesses aiming to promote eco-friendly products. B2B buyers should emphasize this feature when marketing to industries such as sports, outdoor recreation, and health products.

5. Thermal Conductivity

Titanium has low thermal conductivity, which means it does not easily transfer heat. This property allows titanium bottles to keep beverages at stable temperatures longer than many other materials. For buyers, this translates to a competitive advantage in markets focused on high-performance outdoor gear or travel accessories.

6. Manufacturing Tolerances

Precise tolerances in manufacturing ensure that the bottles fit standard accessories like lids and filters. Tighter tolerances can lead to better performance and durability. Buyers should inquire about the tolerances during the procurement process, as it affects the product’s usability and compatibility with other equipment.

Which Trade Terminology Is Essential for B2B Transactions of Titanium Drinking Bottles?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms relevant to titanium drinking bottle procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of titanium bottles, businesses may partner with OEMs to design and manufacture unique products tailored to their specifications, enhancing brand differentiation.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and overall procurement costs. Understanding MOQ helps companies plan their purchases according to demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing information for specific products or services. B2B buyers use RFQs to compare offers from different manufacturers, ensuring they secure the best pricing and terms for titanium drinking bottles.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B transactions, as they clarify shipping costs, risk transfer, and delivery responsibilities. This knowledge helps buyers negotiate favorable terms in their contracts.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the products. This term is critical for supply chain management, especially for businesses in regions with fluctuating demand. Knowing the lead time allows companies to plan their inventory and avoid stockouts.

6. Certification

Certification indicates that a product meets specific industry standards or regulations. For titanium drinking bottles, certifications related to safety, environmental impact, and material quality can enhance marketability and consumer trust. Buyers should verify the certifications of their suppliers to ensure compliance with local and international standards.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing titanium drinking bottles, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the titanium drinking bottle Sector

What Are the Current Market Dynamics and Key Trends in the Titanium Drinking Bottle Sector?

The titanium drinking bottle sector is experiencing significant growth, driven by a rising global awareness of health and sustainability. As consumers increasingly prioritize eco-friendly products, the demand for durable, non-reactive materials like titanium is on the rise. This trend is particularly evident among international B2B buyers from Africa, South America, the Middle East, and Europe, where outdoor activities and health-conscious lifestyles are becoming more prevalent.

Emerging technology trends such as advanced manufacturing techniques and e-commerce platforms are reshaping the sourcing landscape. Companies are leveraging 3D printing and precision machining to produce lightweight yet robust titanium bottles that cater to specific consumer needs. Furthermore, the rise of direct-to-consumer models allows B2B buyers to access a wider range of products and customizable options, enhancing their purchasing power.

Market dynamics are also influenced by regional factors. For instance, in Saudi Arabia and Brazil, the demand for titanium bottles aligns with the growing outdoor adventure tourism sector. Buyers in these regions seek products that offer longevity and performance in extreme conditions. The competitive landscape is characterized by a mix of established brands and new entrants, all vying for market share through innovative designs and strategic partnerships.

How Is Sustainability and Ethical Sourcing Impacting the Titanium Drinking Bottle Industry?

Sustainability and ethical sourcing are becoming crucial considerations for B2B buyers in the titanium drinking bottle market. The environmental impact of production processes and material sourcing cannot be overlooked, as consumers increasingly demand transparency from brands. Titanium, known for its durability and resistance to corrosion, offers a sustainable alternative to plastic bottles, which contribute significantly to global waste.

Buyers should prioritize suppliers who adhere to ethical supply chain practices, ensuring that titanium is sourced responsibly. Certifications such as ISO 14001 (Environmental Management) and compliance with the Responsible Titanium Initiative are essential indicators of a supplier’s commitment to sustainability. Brands that invest in recycling programs or use recycled titanium can further enhance their appeal to environmentally conscious buyers.

In addition, the push for ‘green’ certifications is reshaping the market landscape. Companies that emphasize sustainability in their branding and product offerings not only attract eco-conscious consumers but also align with the growing regulatory frameworks promoting environmental responsibility. This trend is especially relevant for buyers from regions like Europe, where stringent environmental policies are in place.

How Has the Titanium Drinking Bottle Sector Evolved Over Time?

The evolution of the titanium drinking bottle sector reflects broader trends in consumer preferences and technological advancements. Initially, titanium was primarily used in aerospace and military applications due to its strength and lightweight properties. However, as outdoor activities gained popularity, manufacturers began to explore titanium’s potential in consumer products, including drinking bottles.

Over the past two decades, the market has shifted towards a greater focus on health and environmental sustainability. The introduction of titanium bottles has provided consumers with a safe, non-toxic alternative to plastic, appealing to a growing demographic that values both performance and eco-friendliness. As innovations continue to emerge, the sector is poised for further growth, driven by a blend of advanced materials, design, and sustainability initiatives.

This ongoing transformation presents ample opportunities for B2B buyers seeking to align their product offerings with contemporary consumer values and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium drinking bottle

-

How do I determine the quality of titanium drinking bottles from suppliers?

To assess the quality of titanium drinking bottles, request samples from potential suppliers. Inspect the material for purity and durability; titanium should ideally be of grade 1 or grade 2, ensuring it is lightweight and corrosion-resistant. Additionally, verify certifications such as ISO 9001 for quality management and check for compliance with health standards, especially if the bottles will be used for food and beverages. Engaging in factory audits can also provide insight into the manufacturing processes and quality control measures in place. -

What is the best titanium bottle size for outdoor activities?

The optimal size of a titanium bottle for outdoor activities typically ranges from 500ml to 1,500ml, depending on the duration of the activity. For day hikes or short trips, a bottle between 800ml and 1,000ml is ideal, providing ample hydration without excessive weight. For extended excursions or camping trips, consider larger sizes (1,200ml to 1,500ml) to ensure sufficient water supply. Ultimately, the choice should align with the specific needs of your target market and the types of activities they engage in. -

What customization options are available for titanium drinking bottles?

Many suppliers offer customization options such as laser engraving, color anodizing, or the addition of specific features like flip-top lids or built-in straws. When sourcing, inquire about minimum order quantities (MOQs) for customized products, as these can vary significantly. Customization not only enhances brand visibility but also allows you to cater to specific market preferences, making your offerings more appealing to potential clients. Ensure that you receive clear guidelines on the customization process, timelines, and any associated costs. -

What are the minimum order quantities (MOQs) for titanium drinking bottles?

MOQs for titanium drinking bottles can vary widely based on the supplier and the complexity of the order. Typically, MOQs can range from 100 to 1,000 units for standard models, while customized designs may require higher quantities. It is essential to clarify MOQs during initial discussions with suppliers to gauge the feasibility of your order. Negotiating lower MOQs might be possible, especially for first-time orders or long-term partnership arrangements. -

What payment terms should I expect when sourcing titanium drinking bottles internationally?

International payment terms can vary, but common practices include a 30% deposit upfront with the remaining balance due before shipment. Some suppliers may offer more flexible terms, such as net 30 or net 60 days, depending on the buyer’s creditworthiness and relationship with the supplier. It’s advisable to use secure payment methods like letters of credit or PayPal for added protection. Discuss these terms early in the negotiation process to avoid any misunderstandings later on. -

How can I ensure compliance with international trade regulations for titanium drinking bottles?

To ensure compliance with international trade regulations, familiarize yourself with the specific import/export laws of your target markets. This includes understanding customs duties, tariffs, and labeling requirements for consumer products. Working with a knowledgeable freight forwarder can help navigate these complexities. Additionally, ensure that your suppliers provide necessary documentation, such as certificates of origin and quality, to facilitate smooth customs clearance and compliance with local regulations. -

What quality assurance measures should I expect from suppliers of titanium drinking bottles?

Reputable suppliers should implement rigorous quality assurance measures, including material inspections, in-process quality checks, and final product testing. Request details on their quality control processes, including any certifications such as ISO 9001, which demonstrate adherence to international quality standards. It’s also beneficial to ask for reports from third-party testing labs that confirm the safety and performance of the products. Establishing clear quality expectations from the outset can significantly reduce the risk of receiving subpar products. -

What logistics considerations should I be aware of when importing titanium drinking bottles?

When importing titanium drinking bottles, consider logistics factors such as shipping methods, transit times, and potential customs delays. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Evaluate the supplier’s ability to handle logistics, including packaging and labeling for international shipping. It’s also crucial to ensure that you have a reliable customs broker to facilitate the clearance process and avoid unexpected fees or delays upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Titanium Drinking Bottle Manufacturers & Suppliers List

1. Silver Ant Outdoors – Titanium Water Bottles

Domain: silverantoutdoors.com

Registered: 2019 (6 years)

Introduction: Titanium Water Bottles: 1. Large Titanium Water Bottle Wide Mouth – 1200ml/42.2 fl oz & 1500ml/52.8 fl oz 2. Ultralight Titanium Water Bottle – 800ml/28.16 fl oz 3. Slim Round Titanium Water Bottle – 500ml/17.6 fl oz & 800ml/28.1 fl oz

2. Snow Peak – Ti-Aurora Bottle

Domain: snowpeak.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Ti-Aurora Bottle”, “material”: “Titanium”, “capacity”: “500ml”, “weight”: “100g”, “dimensions”: “7.5 x 7.5 x 20 cm”, “features”: [“Lightweight”, “Durable”, “Corrosion-resistant”, “Easy to clean”], “usage”: “Ideal for outdoor activities and travel”, “color”: “Natural Titanium”}

3. Valtcan – 1000ml Titanium Water Bottle

Domain: valtcan.com

Registered: 2016 (9 years)

Introduction: Valtcan 1000ml Titanium Water Bottle, Wide Mouth, Single Wall, 34oz capacity, Free Canteen Cover Upgrade, Limited time Sale Promotion.

4. Vargo – Titanium Water Bottle

Domain: backpackinglight.com

Registered: 2000 (25 years)

Introduction: Vargo Titanium Water Bottle (MSRP: $85, 3.9 oz / 111 g)\n- Capacity: 650 ml (22 oz)\n- Material: Grade 2 titanium\n- Features: Screw-on titanium lid, silicone O-ring, matte finish, 44 mm (1.7 in) mouth, tall and narrow design for easy packing\n- Cap: Minimally threaded with a foldaway carry loop\n- Shipping: Quick shipping within 24 hours and excellent customer service experience.

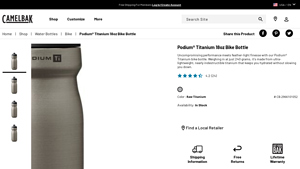

5. CamelBak – Podium® Titanium 18oz Bike Bottle

Domain: camelbak.com

Registered: 1996 (29 years)

Introduction: Podium® Titanium 18oz Bike Bottle, Weight: 240 grams, Material: ultra-lightweight titanium, Performance: uncompromising performance, Color: Raw Titanium, Price: $100.00, Availability: In Stock, Not available for purchase in California or New York.

6. 24Bottles – Titanium Bottle

Domain: 24bottles.com

Registered: 2011 (14 years)

Introduction: Titanium Bottle is an exclusive line of titanium insulated bottles designed for maximum performance with minimal weight. It keeps beverages hot for 12 hours and cold for 24 hours. Made entirely of premium-grade titanium, it is lightweight, safe, and ideal for those seeking a sophisticated alternative. The design features clean, elegant lines and refined finishes. Available in a 500 ml size, it inc…

7. Crua – Titanium Water Bottle

Domain: cruaoutdoors.com

Registered: 2016 (9 years)

Introduction: Product Name: Titanium Water Bottle with Ti Lid

Sale Price: $84.95 USD

Material: 100% pure titanium

Features: Complete biocompatibility, incredibly light, strong, and biocompatible, lightweight and slim profile for easy carrying.

Strategic Sourcing Conclusion and Outlook for titanium drinking bottle

As the market for titanium drinking bottles continues to expand, strategic sourcing has become increasingly vital for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The unique properties of titanium—its durability, non-reactivity, and eco-friendliness—position it as a superior choice over traditional materials like plastic and stainless steel. By prioritizing quality sourcing, businesses can ensure they meet the growing consumer demand for sustainable and long-lasting products.

In addition to enhancing product offerings, strategic sourcing allows companies to negotiate better terms with suppliers, streamline their procurement processes, and reduce costs. International buyers should focus on building partnerships with reputable manufacturers that prioritize sustainable practices and quality assurance. This not only safeguards their supply chain but also aligns their brand with the growing trend towards environmental responsibility.

Looking ahead, the titanium drinking bottle market is poised for growth, driven by increased consumer awareness and demand for sustainable alternatives. B2B buyers are encouraged to seize this opportunity by engaging with suppliers who can deliver innovative, high-quality products that meet the evolving needs of their customers. Embrace the future of hydration solutions and position your business for success in this dynamic market.