Introduction: Navigating the Global Market for bottle top dimensions

In the dynamic landscape of global commerce, understanding the intricacies of bottle top dimensions is paramount for B2B buyers seeking to ensure product integrity and compatibility. Sourcing the right bottle closures involves navigating a maze of specifications, from neck finishes to thread sizes, which can significantly impact the efficiency of packaging operations. This guide serves as a comprehensive resource, addressing the diverse types of bottle tops, their applications across various industries, and essential metrics for supplier vetting, including cost considerations and quality standards.

International buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe—including markets such as Vietnam and Germany—face unique challenges in sourcing appropriate packaging solutions. This guide empowers these stakeholders by providing actionable insights into bottle top dimensions, enabling informed purchasing decisions that enhance operational efficiency and reduce the risk of product loss due to poor sealing or incompatibility.

From understanding the critical measurements that determine closure compatibility to exploring the implications of different thread styles, this resource equips buyers with the knowledge needed to make strategic choices. By mastering the nuances of bottle top dimensions, B2B buyers can not only ensure product safety and compliance but also foster stronger relationships with suppliers and optimize their supply chain operations.

記事ナビゲーション

- Top 8 Bottle Top Dimensions Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bottle top dimensions

- Understanding bottle top dimensions Types and Variations

- Key Industrial Applications of bottle top dimensions

- 3 Common User Pain Points for ‘bottle top dimensions’ & Their Solutions

- Strategic Material Selection Guide for bottle top dimensions

- In-depth Look: Manufacturing Processes and Quality Assurance for bottle top dimensions

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle top dimensions’

- Comprehensive Cost and Pricing Analysis for bottle top dimensions Sourcing

- Alternatives Analysis: Comparing bottle top dimensions With Other Solutions

- Essential Technical Properties and Trade Terminology for bottle top dimensions

- Navigating Market Dynamics and Sourcing Trends in the bottle top dimensions Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bottle top dimensions

- 重要な免責事項および利用規約

- Strategic Sourcing Conclusion and Outlook for bottle top dimensions

Understanding bottle top dimensions Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| Continuous Thread | Features uninterrupted threads around the neck, ensuring a tight seal. | Beverage, personal care, and food packaging. | 長所だ: Reliable sealing, ease of use. 短所だ: Limited to specific cap compatibility. |

| DBJ (Tamper-Evident) | Includes a tamper-evident ring that breaks upon first use. | Food, beverage, and pharmaceutical industries. | 長所だ: Enhances product safety, consumer trust. 短所だ: May not be suitable for all product types. |

| 38-400 Neck Finish | Common neck size with a diameter of 38mm and one thread turn. | Essential oils, pharmaceuticals, and sauces. | 長所だ: Widely used, easy to source compatible caps. 短所だ: May not fit specialty caps. |

| 22-400 Neck Finish | Smaller neck size (22mm) with various cap options available. | Personal care, household products, and smaller beverages. | 長所だ: Versatile, numerous color and style options. 短所だ: Smaller opening may limit product dispensing options. |

| Buttress Thread | Features a unique thread design allowing for better pouring control. | Specialty beverages and precision dispensing products. | 長所だ: Improved pouring accuracy. 短所だ: Requires specific cap types, limiting compatibility. |

What Are Continuous Thread Closures and Their Applications?

Continuous thread closures are characterized by their uninterrupted threading, which wraps around the neck of the bottle. This design ensures a secure seal, making them ideal for a variety of applications, including beverages, personal care items, and food packaging. When purchasing, buyers should consider the compatibility of caps with the bottle’s thread size, as mismatched closures can lead to leakage or contamination.

How Do DBJ (Tamper-Evident) Closures Enhance Product Safety?

DBJ closures are designed with a tamper-evident ring that breaks upon first use, providing visual confirmation that the product has not been altered. This feature is crucial for industries such as food and pharmaceuticals, where consumer safety is paramount. Buyers should evaluate their specific requirements for tamper evidence, as some products may not necessitate this feature, potentially leading to increased costs.

What Makes the 38-400 Neck Finish Popular Among Buyers?

The 38-400 neck finish is one of the most common dimensions in the packaging industry, with a diameter of 38mm and a single thread turn. This standardization allows for easy sourcing of compatible caps, making it suitable for essential oils, sauces, and pharmaceuticals. Buyers should ensure they understand the full specifications of their packaging needs, including the type of closure required, to avoid compatibility issues.

Why Choose the 22-400 Neck Finish for Diverse Applications?

The 22-400 neck finish features a 22mm diameter, offering a variety of cap options that cater to personal care, household products, and smaller beverage containers. This versatility allows businesses to customize their packaging according to branding needs. However, buyers should consider that the smaller opening may limit dispensing methods, which could affect product usage.

How Does Buttress Threading Improve Pouring Accuracy?

Buttress threading is distinct for its design that enhances pouring control, making it particularly useful for specialty beverages and precision dispensing products. This type of closure can be more challenging to source due to its specific cap requirements, so buyers must weigh the benefits of improved accuracy against potential limitations in cap availability.

Key Industrial Applications of bottle top dimensions

| 業界/セクター | Specific Application of bottle top dimensions | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達上の考慮事項 |

|---|---|---|---|

| Food & Beverage | Standardization of bottle caps for beverages | Ensures product safety and compatibility across markets | Compliance with regional standards and regulations |

| Pharmaceuticals | Precision in bottling pharmaceutical liquids | Guarantees proper sealing and integrity of products | Quality certifications and material specifications |

| Cosmetics & Personal Care | Customization of bottle tops for cosmetic products | Enhances brand identity and user experience | Availability of diverse designs and closure types |

| Industrial Chemicals | Compatibility of closures for chemical containers | Prevents contamination and ensures safe handling | Chemical compatibility and durability of materials |

| Household Products | Adaptation of bottle tops for cleaning agents | Improves dispensing efficiency and reduces waste | Consideration of user-friendly designs and sizes |

How Are Bottle Top Dimensions Utilized in the Food & Beverage Industry?

In the food and beverage sector, precise bottle top dimensions are critical for ensuring that closures fit securely, preventing contamination and spoilage. Standardization of dimensions, such as the 28-400 neck size, facilitates compatibility across different brands and products, streamlining production and distribution. International buyers must consider regional regulations and standards to ensure compliance, especially in markets with stringent food safety laws.

What Role Do Bottle Top Dimensions Play in Pharmaceuticals?

In pharmaceuticals, the integrity of product packaging is paramount. Accurate bottle top dimensions ensure that closures create a proper seal, protecting sensitive liquids from exposure to air and contaminants. This is particularly important for products that require strict adherence to safety protocols. Buyers should prioritize sourcing materials with relevant quality certifications, as well as dimensions that align with industry standards to maintain product efficacy.

How Are Bottle Top Dimensions Important for Cosmetics & Personal Care Products?

Cosmetic and personal care brands often leverage unique bottle top dimensions to differentiate their products in a competitive market. Custom closures not only enhance brand identity but also improve user experience through features like easy dispensing or tamper-evident seals. B2B buyers should seek suppliers that offer a variety of designs and sizes, ensuring they can find solutions that align with their branding and functional requirements.

Why Are Bottle Top Dimensions Critical for Industrial Chemicals?

In the industrial chemicals sector, accurate bottle top dimensions are essential for preventing leaks and ensuring safe handling of hazardous materials. Properly designed closures minimize the risk of contamination and ensure that chemical properties remain stable. Buyers must consider the chemical compatibility of materials used for closures and ensure that the dimensions meet safety standards for their specific applications.

What Benefits Do Bottle Top Dimensions Offer for Household Products?

For household cleaning products, the right bottle top dimensions enhance dispensing efficiency, allowing consumers to use products effectively while minimizing waste. Features like flip-top or spray closures can be designed to accommodate specific flow rates based on the product’s viscosity. Buyers should focus on sourcing user-friendly designs that cater to consumer preferences while ensuring that dimensions meet packaging standards for safety and convenience.

3 Common User Pain Points for ‘bottle top dimensions’ & Their Solutions

Scenario 1: Misalignment of Bottle and Cap Dimensions Leading to Product Loss

問題だ: B2B buyers often face significant challenges when the dimensions of the bottle neck and cap do not align properly. This misalignment can lead to product spills or leaks, resulting in both financial loss and damage to reputation. For instance, a company in the beverage industry may order caps based on assumed specifications, only to find that the actual neck finish of the bottles does not match. This can cause delays in production and distribution, affecting supply chain timelines.

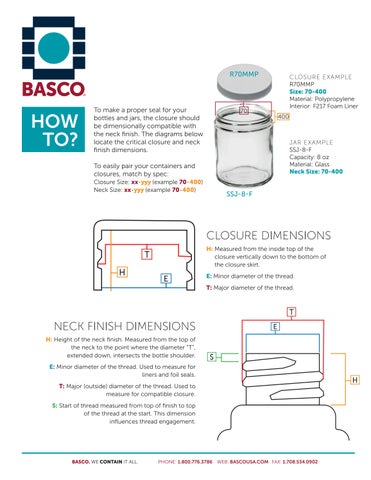

解決策 To mitigate this issue, it is crucial for buyers to perform thorough measurements and comparisons of bottle neck dimensions before placing orders for caps. Utilizing industry-standard measurements such as the “T” dimension (outer diameter of the thread) and the “E” dimension (outer diameter of the neck) ensures a precise fit. Buyers should also refer to detailed specifications provided by manufacturers and engage in pre-production sampling to verify compatibility. Creating a standardized checklist for bottle and cap specifications can streamline this process, reducing the risk of errors and ensuring that all products fit seamlessly.

Scenario 2: Inadequate Understanding of Thread Finishes Complicating Closure Selection

問題だ: Another common pain point arises from a lack of understanding regarding the different types of thread finishes available for bottle tops. Buyers may select closures based on visual appeal or cost without realizing that specific thread finishes are required for a secure seal. For example, a manufacturer sourcing caps for high-temperature applications may inadvertently choose a closure type not designed for such conditions, leading to product spoilage or safety hazards.

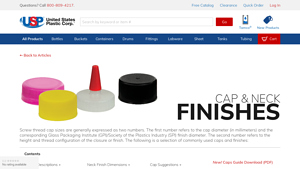

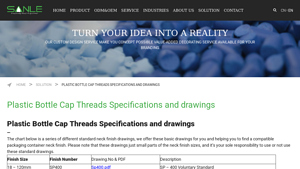

解決策 To avoid such pitfalls, B2B buyers should invest time in learning about the various thread finishes and their applications. This can be achieved by consulting comprehensive guides or seeking advice from suppliers who specialize in bottle and closure compatibility. When evaluating products, buyers should look for standard designations like “38-400” or “24-410,” which indicate both the neck width and the thread style. Additionally, collaborating with packaging engineers or material specialists can provide deeper insights into the best closure types for specific product applications, ensuring safety and product integrity.

Scenario 3: Difficulty in Sourcing Custom Bottle Caps for Unique Dimensions

問題だ: Many international B2B buyers face challenges when their products require custom bottle caps that do not conform to standard dimensions. For instance, a startup in South America developing a unique line of herbal supplements may find that conventional cap sizes do not fit their specially designed bottles. This can lead to limited options, higher costs, and delays in bringing products to market.

解決策 To address the challenge of sourcing custom bottle caps, businesses should engage in early discussions with suppliers regarding their specific needs. This includes providing detailed drawings or prototypes of their bottles to manufacturers who can create tailored solutions. Furthermore, utilizing advanced design software can help visualize how custom caps will fit and function. Establishing a relationship with a reliable supplier who offers custom design services can also streamline the development process, ensuring that the final product not only fits perfectly but also meets branding and functional requirements. By proactively addressing these needs, businesses can enhance their product offerings and reduce time-to-market.

Strategic Material Selection Guide for bottle top dimensions

What are the Key Properties of Common Materials for Bottle Tops?

When selecting materials for bottle tops, it is essential to consider their properties, as they directly affect product performance, compatibility, and overall effectiveness in various applications. Below, we analyze four common materials used in bottle top manufacturing.

How Do Plastic Bottle Caps Perform in Various Applications?

Plastic (Polypropylene and Polyethylene)

Plastic bottle caps, particularly those made from polypropylene (PP) and polyethylene (PE), are widely used due to their lightweight nature and versatility. They offer good chemical resistance and can withstand moderate temperatures, making them suitable for beverages, personal care products, and household chemicals. However, they may not perform well under extreme temperatures or pressures.

長所だ:

– Cost-effective and lightweight.

– Good resistance to moisture and chemicals.

– Available in various colors and designs for branding.

短所だ:

– Limited temperature and pressure tolerance.

– Environmental concerns regarding recyclability.

– Potential for deformation under high heat.

アプリケーションへの影響

Plastic caps are ideal for products that do not require high-pressure sealing, such as soft drinks and non-carbonated beverages. However, they may not be suitable for products that require tamper-evident features or high-temperature sterilization.

海外バイヤーへの配慮

Buyers should ensure compliance with local regulations regarding food safety and environmental impact. Common standards such as ASTM and ISO should be referenced, especially in regions like Europe and the Middle East where regulations can be stringent.

What are the Advantages of Metal Caps for Bottles?

Metal (Aluminum and Steel)

Metal caps, particularly aluminum, are favored for their strength and ability to create airtight seals. They are often used for carbonated beverages and products requiring longer shelf life due to their superior barrier properties against oxygen and moisture.

長所だ:

– Excellent sealing capabilities and durability.

– High resistance to corrosion and temperature extremes.

– Provides a premium feel for high-end products.

短所だ:

– Higher manufacturing costs compared to plastic.

– Heavier, which may increase shipping costs.

– Requires more complex production processes.

アプリケーションへの影響

Metal caps are particularly effective for carbonated beverages and products that need to remain sealed for extended periods. They are also preferred for pharmaceutical products due to their tamper-evident features.

海外バイヤーへの配慮

Buyers must consider compliance with industry standards like DIN and JIS for metal packaging. Additionally, the recyclability of metal caps can be a selling point in environmentally conscious markets.

How Do Glass Caps Compare in Terms of Performance?

ガラス

Glass caps are less common but are used for specialty applications where purity and non-reactivity are critical, such as in pharmaceuticals and high-end beverages. They provide an excellent barrier against external contaminants and do not leach chemicals.

長所だ:

– Non-reactive and maintains product integrity.

– Excellent barrier properties against gases and moisture.

– Recyclable and environmentally friendly.

短所だ:

– Fragile and prone to breakage.

– Higher cost and heavier than plastic alternatives.

– Limited design flexibility.

アプリケーションへの影響

Glass caps are ideal for products requiring high purity, such as essential oils and pharmaceuticals. However, their fragility limits their use in high-volume production environments.

海外バイヤーへの配慮

Buyers should ensure compliance with safety standards specific to glass packaging, especially in regions with stringent regulations like Europe. They should also consider the logistics of transporting fragile materials.

What Role Do Composite Materials Play in Bottle Top Manufacturing?

Composite Materials

Composite materials, often a blend of plastic and other materials, offer unique advantages such as enhanced strength and flexibility. They are increasingly being used for specialized applications, including those requiring high durability and resistance to environmental factors.

長所だ:

– Enhanced mechanical properties and durability.

– Can be designed for specific applications, such as high-pressure environments.

– Lightweight compared to metal.

短所だ:

– More expensive than traditional materials.

– May require specialized manufacturing processes.

– Environmental impact can vary based on composition.

アプリケーションへの影響

Composite caps are suitable for products that require both strength and lightweight properties, such as in the automotive or industrial sectors.

海外バイヤーへの配慮

Buyers should evaluate the environmental impact of composite materials and ensure compliance with local regulations regarding materials used in packaging.

Summary Table of Material Selection for Bottle Tops

| 素材 | Typical Use Case for bottle top dimensions | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| Plastic | Beverages, personal care products | コストパフォーマンスが高く、軽量 | Limited temperature tolerance | 低い |

| Metal | Carbonated beverages, pharmaceuticals | Excellent sealing and durability | Higher manufacturing costs | 高い |

| ガラス | Pharmaceuticals, high-end beverages | Non-reactive and excellent barrier | Fragile and higher cost | 高い |

| Composite | High-pressure applications | Enhanced strength and flexibility | More expensive and complex to produce | ミディアム |

In-depth Look: Manufacturing Processes and Quality Assurance for bottle top dimensions

What Are the Main Stages in Manufacturing Bottle Tops and Their Dimensions?

The manufacturing process for bottle tops involves several critical stages, each of which plays a significant role in ensuring that the final product meets the required specifications for dimensions, durability, and functionality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used for Bottle Tops?

The initial stage of manufacturing involves selecting appropriate materials, typically plastics such as polypropylene (PP) or polyethylene (PE) for most bottle caps, or metals like aluminum for certain applications. The choice of material impacts the cap’s strength, flexibility, and compatibility with various liquids. For instance, food-grade materials are essential for caps used in food and beverage packaging to comply with health regulations.

Once the materials are selected, they undergo quality checks to ensure they meet industry standards. This includes testing for chemical resistance, thermal stability, and compliance with safety regulations.

2. Forming: How Are Bottle Tops Shaped?

In the forming stage, the prepared material is shaped into bottle tops using techniques such as injection molding or compression molding.

-

Injection Molding: This is the most common method for producing plastic bottle caps. The raw material is heated until it melts, then injected into a mold where it cools and solidifies into the desired shape. This process allows for high precision in dimensions, which is crucial for ensuring a proper fit with the bottle neck finish.

-

Compression Molding: This technique is often used for larger or more complex caps. The material is placed into a heated mold and then compressed to form the cap. While this method can be slower, it may be more suitable for specific applications requiring intricate designs.

3. Assembly: What Is Involved in the Assembly Process?

After forming, the caps may require additional assembly, especially if they include features such as tamper-evident bands or inner liners for sealing. Automated assembly lines often handle this process, where caps are fitted with liners and any additional components, ensuring a uniform quality across all products.

4. Finishing: How Is the Final Product Prepared?

The finishing stage involves surface treatments to enhance the appearance and performance of the caps. This can include printing, labeling, or applying coatings to improve durability or provide branding opportunities. Quality control checks are also performed to ensure that the caps meet aesthetic and functional standards.

What Are the Key Quality Assurance Measures for Bottle Tops?

Quality assurance (QA) is crucial in ensuring that bottle tops meet the required specifications for safety, functionality, and performance. B2B buyers should be aware of the various QA processes and standards that suppliers adhere to.

International Standards: What Standards Should B2B Buyers Look For?

ISO 9001 is a widely recognized international standard for quality management systems. It requires manufacturers to implement processes that ensure consistent quality in their products. Compliance with ISO 9001 indicates that a supplier has a robust quality management system in place.

Additionally, industry-specific standards may apply, such as:

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for bottle tops used in pharmaceutical applications, ensuring they meet stringent quality and safety requirements.

Quality Control Checkpoints: What Are the Common QC Checkpoints?

Quality control is typically divided into three main checkpoints:

-

受入品質管理(IQC): At this stage, raw materials and components are inspected upon arrival at the manufacturing facility. This ensures that only materials that meet specified standards are used in production.

-

インプロセス品質管理(IPQC): During the manufacturing process, various parameters such as temperature, pressure, and dimensions are monitored. This step ensures that any deviations from the specified standards are identified and corrected promptly.

-

最終品質管理(FQC): After the production is complete, the finished bottle tops undergo rigorous testing. This includes dimensional checks, strength tests, and compatibility assessments with the intended bottle materials.

B2Bバイヤーはサプライヤーの品質管理をどのように検証できるか?

Verifying a supplier’s quality control processes is essential for B2B buyers, especially in international markets where standards may vary.

1. Audits: What Role Do Audits Play?

Conducting regular audits of suppliers can help ensure that they maintain compliance with quality standards. B2B buyers can request third-party audits or perform their own inspections to assess the supplier’s manufacturing processes and quality assurance practices.

2. Reports and Documentation: What Documentation Should Be Requested?

Buyers should request quality assurance documentation, including:

- Certificates of compliance with relevant standards (e.g., ISO, CE).

- Test reports showing results from FQC checks.

- Records of any non-conformance issues and corrective actions taken.

This documentation provides insight into the supplier’s commitment to quality and can help mitigate risks associated with substandard products.

3. Third-Party Inspections: How Can They Enhance Confidence?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s operations and product quality. These inspections can be scheduled at various points in the manufacturing process, providing an additional layer of assurance for B2B buyers.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances related to quality control and certification.

-

Regional Standards: Different regions may have unique standards and regulations. Buyers should familiarize themselves with local requirements to ensure compliance and avoid potential legal issues.

-

Language Barriers: Documentation and communication may be affected by language differences. Buyers should ensure that all quality assurance reports and certifications are available in a language they understand.

-

Cultural Practices: Understanding the manufacturing culture and practices in different regions can provide insights into potential challenges and help buyers establish effective communication with suppliers.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for bottle tops is vital for B2B buyers. By focusing on material selection, manufacturing techniques, and rigorous quality control practices, buyers can ensure they partner with reliable suppliers who meet their product specifications and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bottle top dimensions’

はじめに

This guide serves as a practical checklist for B2B buyers seeking to procure bottle tops with specific dimensions. Understanding the nuances of bottle top dimensions is essential for ensuring compatibility with your bottles, optimizing product functionality, and maintaining quality standards. This step-by-step approach will help you navigate the complexities of sourcing the right bottle tops for your needs.

ステップ1: 技術仕様の定義

Clearly outline the technical specifications required for your bottle tops. This includes dimensions such as the neck width (T dimension), thread finish, and any other relevant measurements. Documenting these specifications upfront ensures that you have a clear reference point when evaluating suppliers and their products.

- Key Measurements: Focus on the “T” dimension (outer diameter of threads) and the “H” dimension (height of the neck finish).

- Application Considerations: Consider how the bottle tops will be used, as different applications may require specific closure types (e.g., tamper-evident, dispensing).

ステップ2: Research Common Bottle Top Dimensions

Familiarize yourself with standard bottle top dimensions commonly used in your industry. This knowledge enables you to identify the sizes that best fit your products and ensures compatibility with existing packaging solutions.

- Common Sizes: Examples include 28-400, 38-400, and 22-400 neck finishes.

- Industry Standards: Consult resources like the Glass Packaging Institute for standard specifications in your product category.

ステップ3: サプライヤー候補の評価

Before committing to a supplier, perform a thorough evaluation. This step is crucial to ensure that the suppliers can meet your technical specifications and quality standards.

- Request Documentation: Ask for product specifications, including detailed measurements and material information.

- Assess Experience: Look for suppliers with experience in your specific market or industry to ensure they understand your needs.

ステップ4: Verify Quality Assurance Processes

Quality assurance is paramount when sourcing bottle tops. Confirm that suppliers adhere to strict quality control measures to prevent defects and ensure product reliability.

- ISO認証: Check for relevant certifications (e.g., ISO 9001) that indicate a commitment to quality management.

- Sampling: Request samples to evaluate the fit, finish, and overall quality before placing larger orders.

ステップ5: Understand Compliance and Regulations

Ensure that the bottle tops comply with regional and international regulations. This step is particularly important for industries such as food and beverage, where safety standards are stringent.

- Material Safety: Confirm that the materials used are safe for the intended application, particularly if they come into contact with consumables.

- Labeling Requirements: Be aware of any labeling or documentation requirements for shipping across borders, especially in diverse markets like Africa and South America.

ステップ6: Negotiate Terms and Pricing

Once you have identified potential suppliers, engage in negotiations regarding pricing, minimum order quantities, and delivery timelines. This step is essential to secure favorable terms that align with your budget and operational needs.

- 一括割引: Inquire about pricing structures for bulk orders to optimize costs.

- Lead Times: Clarify lead times to ensure timely delivery in line with your production schedules.

ステップ7: Establish a Reliable Communication Channel

Finally, establish a reliable communication channel with your chosen supplier. Clear communication helps to address any concerns promptly and fosters a better working relationship.

- Regular Updates: Schedule regular check-ins to discuss order status and any potential issues.

- Feedback Loop: Create a feedback mechanism to ensure continuous improvement in product quality and service.

By following these steps, you will be well-equipped to source bottle tops that meet your specifications and support your business objectives.

Comprehensive Cost and Pricing Analysis for bottle top dimensions Sourcing

What Are the Key Cost Components for Sourcing Bottle Top Dimensions?

When sourcing bottle tops, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

-

材料: The choice of materials, such as plastic, metal, or composite, directly influences cost. For instance, high-quality plastics or specialized metals may incur higher costs but provide better durability and functionality.

-

労働: Labor costs can vary significantly based on geographic location. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing, while European suppliers may have higher labor costs but can provide advanced technology and expertise.

-

製造間接費: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can reduce overhead, impacting overall pricing.

-

工具: Custom tooling for specific bottle top designs can be a significant upfront investment. However, once established, tooling costs are amortized over larger production runs, thus decreasing per-unit costs.

-

品質管理(QC): Implementing stringent QC measures can add to costs but is essential for ensuring product reliability and compliance with international standards. Certifications such as ISO can also influence pricing.

-

物流: Transportation costs, including shipping and customs duties, can vary widely based on the destination. Buyers should consider the total logistics costs when evaluating supplier pricing.

-

マージン: Suppliers typically mark up their costs to ensure profitability. Understanding the typical margins in the bottle cap industry can help buyers negotiate better deals.

How Do Price Influencers Impact Bottle Top Sourcing?

Several factors influence the pricing of bottle tops, and understanding these can aid buyers in making informed purchasing decisions:

-

数量/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Ordering larger volumes often leads to lower per-unit costs, making it essential to assess your needs carefully.

-

仕様とカスタマイズ: Custom designs or specific thread finishes can increase costs. Buyers should balance the need for customization with budget constraints.

-

材料の品質と認証: Higher-quality materials often come at a premium. Certifications for food safety or environmental compliance can also add to costs, but they are crucial for certain markets.

-

サプライヤー要因: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their quality assurance processes, while newer entrants might offer lower prices to gain market share.

-

インコタームズ: The choice of Incoterms (International Commercial Terms) affects logistics costs and responsibilities. Understanding these terms can help buyers negotiate better shipping arrangements and avoid unexpected costs.

What Buyer Tips Can Help Optimize Costs in Bottle Top Sourcing?

To ensure cost-effective sourcing of bottle tops, international buyers should consider the following strategies:

-

Negotiation: Effective negotiation can lead to better pricing. Buyers should be prepared to discuss volume discounts, payment terms, and delivery schedules to enhance their negotiating position.

-

Focus on Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes purchase price, shipping, handling, and potential waste costs. A lower initial price may not always translate to overall savings.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences. Factors such as import tariffs and local market conditions can significantly influence costs.

-

Consider Long-term Partnerships: Building relationships with suppliers can lead to better pricing and service over time. Long-term contracts can also stabilize costs against market fluctuations.

Disclaimer on Indicative Prices

Prices for bottle tops can vary widely based on the factors outlined above. Buyers should conduct thorough research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing bottle top dimensions With Other Solutions

Introduction: Understanding Alternatives in Bottle Closure Solutions

In the packaging industry, selecting the right bottle closure is pivotal for ensuring product integrity and consumer satisfaction. While traditional bottle top dimensions are widely used, alternative solutions exist that may offer unique advantages. This analysis will compare bottle top dimensions with two viable alternatives: snap-on closures and pump dispensers. By evaluating these options, B2B buyers can make informed decisions based on their specific needs and market demands.

| 比較の側面 | Bottle Top Dimensions | Snap-On Closures | Pump Dispensers |

|---|---|---|---|

| パフォーマンス | Reliable sealing, multiple thread options | Quick application, less secure | Controlled dispensing, precision |

| コスト | Moderate, varies by material | Generally lower cost | Higher initial investment |

| 実施しやすさ | Requires matching dimensions | Easy to apply | Requires more setup |

| メンテナンス | Low, but check for wear | Low, but prone to loss | Medium, needs regular cleaning |

| ベスト・ユースケース | Liquids requiring sealing | Fast-serve products | Products needing precise dosage |

What Are the Benefits and Drawbacks of Snap-On Closures?

Snap-on closures are an attractive alternative for many manufacturers due to their ease of use and lower cost. They are particularly effective for products that require quick access, such as beverages or condiments. The application process is straightforward, allowing for rapid assembly on the production line. However, snap-on closures may not provide the same level of security as traditional threaded caps, making them less suitable for products that are sensitive to tampering or require airtight seals. Additionally, they can be lost easily if not properly managed, leading to potential product leakage.

How Do Pump Dispensers Compare to Traditional Bottle Tops?

Pump dispensers represent a more sophisticated solution for products that require precise dosing, such as lotions, oils, or cleaning agents. They allow users to dispense the exact amount needed, reducing waste and enhancing user experience. While they can be more expensive upfront, the value they provide in terms of product control often justifies the cost. However, pump dispensers may require more maintenance and thorough cleaning to prevent clogging and ensure longevity. They also necessitate more complex manufacturing processes, which could increase overall production time.

Conclusion: How Should B2B Buyers Choose the Right Closure Solution?

When determining the best closure solution, B2B buyers must weigh their specific product requirements against the advantages and disadvantages of each option. For products that prioritize sealing and security, traditional bottle top dimensions may be the best choice. Conversely, if speed and convenience are paramount, snap-on closures could be advantageous. For items requiring precision in dispensing, pump dispensers may be worth the investment. Ultimately, understanding the unique demands of your product and market will guide you to the most effective closure solution.

Essential Technical Properties and Trade Terminology for bottle top dimensions

What Are the Essential Technical Properties of Bottle Top Dimensions?

Understanding the technical properties of bottle top dimensions is critical for B2B buyers involved in packaging decisions. Here are several key specifications that impact compatibility, functionality, and overall product integrity.

1. Neck Width (T Dimension)

The neck width, measured in millimeters, represents the outer diameter of the threads on the bottle. This measurement is crucial because it determines the appropriate size of the closure that will fit securely. For instance, a bottle with a neck width of 38 mm will require a cap designed for a 38 mm neck finish. Ensuring the correct neck width is vital for preventing leaks and ensuring product longevity.

2. Thread Finish

The thread finish indicates how many turns the threads make around the neck of the bottle. Common thread finishes include 400, 410, and 415, where the number signifies the number of thread turns and their characteristics. This specification is essential for ensuring that the cap can be securely fastened without stripping the threads, which could lead to product spillage or contamination.

3. Height of Neck Finish (H Dimension)

The height of the neck finish is measured from the top of the neck to where the threads begin. This dimension is important for assessing how much of the cap will engage with the bottle, impacting sealing effectiveness. A well-designed height can also facilitate easier handling and dispensing of the product.

4. Inner Diameter (I Dimension)

The inner diameter is critical for ensuring that filling tubes can fit properly within the neck of the bottle. This measurement is particularly important for products that require precise filling processes, as it helps to avoid obstructions that could lead to inefficiencies or product loss during production.

5. 素材グレード

The material used for both the bottle and the cap can greatly influence product safety and functionality. Common materials include polyethylene, polypropylene, and glass. Each material has its own properties regarding durability, chemical resistance, and recyclability, making it important for buyers to choose the right material for their specific product requirements.

6. 許容レベル

Tolerance refers to the allowable deviation from specified dimensions. Tight tolerances are often necessary for products that require precise fitting of closures to avoid leaks and ensure product integrity. Understanding tolerance levels is essential for quality control and can affect the overall cost of production.

What Are Common Trade Terms Related to Bottle Top Dimensions?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B packaging market. Here are several essential terms:

1. OEM(相手先ブランド製造)

An OEM refers to a company that produces components that are used in another company’s product. In the context of bottle tops, it could mean a supplier that manufactures caps or closures designed to fit specific bottle neck dimensions for another brand.

2. MOQ(最小注文数量)

MOQ is the smallest number of units a supplier is willing to produce or sell. Understanding MOQ is crucial for budgeting and inventory management, as it can significantly impact purchasing decisions and supply chain efficiency.

3. RFQ(見積依頼)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is a common practice in the B2B sector to ensure competitive pricing and clear expectations regarding delivery and payment terms.

4. インコタームズ

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is critical for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risks during transit.

5. リードタイム

Lead time refers to the amount of time from placing an order to its delivery. This term is essential for planning production schedules and inventory management, especially in industries where timely product availability is crucial.

By grasping these technical properties and trade terminology, B2B buyers can make informed decisions that enhance their packaging solutions and drive business success.

Navigating Market Dynamics and Sourcing Trends in the bottle top dimensions Sector

What Are the Current Market Dynamics and Key Trends Affecting Bottle Top Dimensions?

The global market for bottle top dimensions is shaped by various factors, including increasing consumer demand for convenience and sustainability, advancements in packaging technology, and regulatory pressures for safety and standardization. In emerging markets like Africa and South America, there is a growing trend toward locally sourced materials, driven by both economic considerations and a desire for reduced environmental impact. In contrast, markets in Europe, such as Germany, are witnessing a shift towards innovative designs that enhance usability while maintaining compliance with stringent regulations.

Additionally, the rise of e-commerce and direct-to-consumer sales channels has compelled manufacturers to offer versatile packaging solutions that cater to diverse products. This trend fosters a demand for a wider range of bottle top dimensions, accommodating everything from traditional beverages to niche products like essential oils and specialty sauces. Moreover, the advent of smart packaging technologies, including QR codes and tamper-evident features, is becoming increasingly relevant, enhancing consumer trust and product security.

International B2B buyers must stay attuned to these dynamics, as they influence not only product selection but also pricing and supply chain logistics. Establishing partnerships with suppliers that are innovative and responsive to market demands can provide a competitive edge.

How Is Sustainability Influencing Sourcing Trends in Bottle Top Dimensions?

Sustainability has become a cornerstone of sourcing strategies for B2B buyers in the bottle top dimensions sector. Environmental concerns regarding plastic waste and carbon footprints are prompting companies to seek materials that are recyclable, biodegradable, or made from post-consumer recycled content. This shift is particularly pronounced in regions like Europe, where regulations are increasingly favoring eco-friendly practices.

Ethical sourcing is also gaining traction, with buyers prioritizing suppliers that adhere to fair labor practices and sustainable resource management. Certifications such as FSC (Forest Stewardship Council) for paper products and ISO 14001 for environmental management systems are becoming essential credentials for manufacturers looking to establish credibility in the marketplace.

Moreover, the use of ‘green’ materials, such as plant-based plastics or glass, not only meets consumer demand for sustainable products but also enhances brand reputation. B2B buyers who integrate sustainability into their sourcing strategies not only mitigate risks associated with regulatory compliance but also position themselves favorably in an increasingly eco-conscious market.

What Is the Historical Context of Bottle Top Dimensions That Shapes Today’s Market?

The evolution of bottle top dimensions can be traced back to the early days of packaging, where functionality dictated design. Initially, closures were simple corks or metal caps, but as consumer needs evolved, so did the complexity of bottle neck finishes and dimensions. The introduction of continuous thread finishes revolutionized the industry by providing a more secure seal and enabling mass production of bottles for various beverages and products.

Over the decades, technological advancements and the rise of global trade expanded the variety of bottle designs available. This evolution has allowed manufacturers to cater to diverse markets and consumer preferences, leading to the development of standardized neck finishes and thread sizes that facilitate compatibility across products. Understanding this historical context is crucial for B2B buyers, as it provides insights into current trends and helps inform future sourcing decisions in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of bottle top dimensions

-

How do I solve compatibility issues with bottle tops and containers?

To resolve compatibility issues, ensure that the neck finish of your bottle matches the closure specifications. Check the neck width (e.g., 38-400), which indicates the outer diameter of the threads and the thread finish. Conduct thorough measurements, including “T,” “E,” and “I” dimensions, to ensure the closure fits securely. If necessary, consult with suppliers to confirm compatibility and request samples for testing before finalizing your order. -

What is the best bottle top design for eco-friendly packaging?

The best bottle top design for eco-friendly packaging includes closures made from recyclable or biodegradable materials. Look for suppliers who offer caps that minimize waste, such as lightweight designs or those that can be refilled. Additionally, consider closures with tamper-evident features to ensure product safety without compromising sustainability. Collaborating with manufacturers focused on sustainable practices can further enhance your eco-friendly packaging efforts. -

How can I verify the quality of bottle tops from suppliers?

To verify the quality of bottle tops, request samples from potential suppliers and conduct rigorous testing for fit, durability, and sealing effectiveness. Review certifications related to quality assurance and industry standards, such as ISO certifications. Establish clear quality control measures, including inspection protocols and material specifications, before placing bulk orders. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What are the minimum order quantities (MOQs) for bottle tops?

Minimum order quantities (MOQs) for bottle tops can vary significantly between suppliers and depend on factors like material, customization, and manufacturing processes. Typically, MOQs may range from a few thousand to tens of thousands. When sourcing, inquire about MOQs upfront and discuss your specific needs, especially if you require smaller quantities for testing or initial launches. Some suppliers may offer flexibility or tiered pricing based on order volume. -

How do payment terms work when purchasing bottle tops internationally?

Payment terms for international purchases of bottle tops often include options like advance payment, letters of credit, or payment upon delivery. Discuss payment methods with your supplier to understand their policies. It’s advisable to establish clear terms in your purchase agreement, including payment schedules, currency, and any applicable taxes or duties. Using a secure payment method can mitigate risks associated with international transactions. -

What logistics considerations should I keep in mind when sourcing bottle tops?

When sourcing bottle tops, consider logistics factors such as shipping methods, lead times, and customs regulations. Assess whether your supplier can accommodate your shipping preferences, including air or sea freight, and evaluate the associated costs. Ensure that all necessary documentation for customs clearance is in order to avoid delays. Additionally, factor in storage requirements and inventory management practices to streamline your supply chain. -

How can I customize bottle tops for my brand?

Customizing bottle tops for your brand can involve selecting specific colors, finishes, or adding logos and labeling. Engage with suppliers who offer design services and have the capability to produce custom molds. Provide your design specifications and collaborate closely with the supplier to ensure the final product aligns with your branding. Be prepared for potential additional costs and longer lead times associated with custom orders. -

What are common neck finish sizes used in the industry?

Common neck finish sizes in the industry include dimensions like 18-400, 28-410, and 38-400, each indicating the outer diameter and thread type. Understanding these specifications is critical for selecting compatible closures. Research your target market’s preferences and regulatory requirements regarding bottle designs and closures. This knowledge can inform your sourcing decisions and ensure that your products meet consumer expectations.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを行う必要がある。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。

Top 8 Bottle Top Dimensions Manufacturers & Suppliers List

1. Paramount Global – Key Product Details

ドメイン paramountglobal.com

Registered: 1999 (26 years)

はじめに Key product details include: 1. Bottle neck refers to the narrowest part of the bottle, allowing for better control and a variety of closures. 2. Neck finish is where the outer threads connect to the cap, commonly represented by a two-digit number (neck width) and a three-digit number (thread finish), e.g., 38-400. 3. Dimensions to measure include: “T” (outer diameter of the thread), “E” (outer di…

2. Midwest Bottles – Plastic Caps by Size

ドメイン midwestbottles.com

登録:2006年(19年)

はじめに Plastic Caps by Size: 15-415 Bottle Caps, 18-410 Bottle Caps, 18-415 Bottle Caps, 20-400 Bottle Caps, 20-410 Bottle Caps, 20-415 Bottle Caps, 22-400 Bottle Caps, 22-410 Bottle Caps, 22-415 Bottle Caps, 24-400 Bottle Caps, 24-410 Bottle Caps, 24-415 Bottle Caps, 25 mm Bottle Caps, 28 mm Bottle Caps, 28-400 Bottle Caps, 28-410 Bottle Caps, 28-415 Bottle Caps, 33-400 Bottle-Jar Caps, 38-400 Bottle-Ja…

3. US Plastic – Cap and Neck Finishes

ドメイン usplastic.com

登録:1996年(29年)

はじめに Cap and Neck Finishes: Screw thread cap sizes are expressed as two numbers. The first number refers to the cap diameter (in millimeters) and the corresponding Glass Packaging Institute (GPI)/Society of the Plastics Industry (SPI) finish diameter. The second number refers to the height and thread configuration of the closure or finish. Common dimensions include: “T” Dimension (outside diameter of t…

4. Sanle Plastics – Versatile Packaging Solutions

ドメイン sanleplastics.com

登録:2017年(8年目)

はじめに Type: Jar, Box, Other shapes, Bottle; Volume: <1oz(30ml), 1-4oz(120ml), 4-8oz(240ml), 8-16oz(480ml), 16-34oz(1000ml), >34oz(1000ml); Material: HDPE Bottles, LDPE Bottles, PS Jar, Other PET Bottles, PET Jar, PP Bottle, PP Box, PP Jar, PS Bottle; Application: Laboratory, Beauty & Personal care, Food & beverage, Household & commercial, CBD Packaging, Home & kitchen, Bio Packaging, Bamboo, Biodegradab…

5. SKS Bottle – Caps and Closures

ドメイン sks-bottle.com

登録:1997年(28年)

はじめに Caps and closures available in various sizes including: 12 mm & 13 mm, 15 mm, 18 mm, 20 mm & 22 mm, 24 mm, 28 mm, 33 mm, 38 mm, 43 mm & 45 mm, 48 mm, 53 mm, 58 mm, 70 mm, 82 mm – 89 mm, 100 mm and 120 mm. Types include plastic caps, metal caps, dispensing caps, child resistant caps, tamper evident caps, and specialty closures. Additional options for lip balm tube caps and various dispensing styles…

6. Berlin Packaging – Crown Beer Bottle Caps

ドメイン berlinpackaging.com

登録:1997年(28年)

はじめに {“item_number”:”X26-0611″,”size”:”26 mm”,”color”:”Gold”,”type”:”Crown Beer Bottle Caps”,”liner”:”Oxy Scavenger Liner”,”FDA_compliant”:”Yes”,”bulk_pricing”:”Not available”,”price”:”$0.08″,”free_shipping”:”Available for orders of $150+”,”inventory_status”:”Currently unavailable”,”material”:”Tin free steel, PVC free”,”BPA_non_intent”:”Yes”,”case_packaging”:”Convenient re-shipper carton with cardboard…

7. Qorpak – Cap Diameter Measurement Tool

ドメイン shop.qorpak.com

登録:1996年(29年)

はじめに This company, Qorpak – Cap Diameter Measurement Tool, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

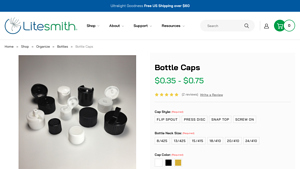

8. Litesmith – Bottle Caps

ドメイン litesmith.com

登録:2014年(11年)

はじめに Bottle Caps available in four styles: Flip Spout, Press Disc, Snap Top, and Screw On. Price range: $0.35 – $0.75. Neck sizes: 8/425, 13/425, 15/415, 18/410, 20/410, 24/410. Cap colors: White, Black, Gold. Materials: Polyethylene (PE), Polypropylene (PP), Phenolic (PF). Features include various orifice diameters for different liquid types, effective sealing with F-217 liner for certain styles, and …

Strategic Sourcing Conclusion and Outlook for bottle top dimensions

In navigating the complexities of bottle top dimensions, B2B buyers must prioritize strategic sourcing to ensure compatibility and performance. Understanding the intricacies of neck finishes, thread sizes, and the associated measurements is critical for achieving a secure seal and enhancing product integrity. By aligning closure specifications with bottle dimensions, businesses can minimize production delays, reduce costs, and improve supply chain efficiency.

Furthermore, as global markets continue to evolve, the demand for sustainable and innovative packaging solutions is on the rise. Buyers should be proactive in seeking suppliers who offer not only a variety of dimensions but also eco-friendly options that meet international standards. This forward-thinking approach will position companies favorably in competitive markets across Africa, South America, the Middle East, and Europe.

As you explore your sourcing strategies, consider establishing long-term partnerships with reliable manufacturers who can provide tailored solutions to meet your unique needs. Embrace the opportunity to innovate and differentiate your products in the marketplace. Now is the time to act—invest in strategic sourcing to leverage the benefits of optimized bottle top dimensions for your business growth.