Introduction: Navigating the Global Market for water bottle gallon size

In today’s competitive landscape, sourcing water bottles in gallon sizes presents unique challenges for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. The demand for sustainable hydration solutions has surged, prompting businesses to seek reliable suppliers who can provide high-quality, cost-effective products. This guide serves as a comprehensive resource, detailing various types of gallon water bottles, their applications, and essential supplier vetting processes.

Navigating the global market involves understanding the intricacies of product specifications, including materials, design, and functionality, which can significantly impact purchasing decisions. Additionally, this guide addresses crucial aspects such as pricing structures and market trends, equipping buyers with the insights needed to make informed choices.

By focusing on the unique needs of regions like Brazil and Vietnam, the guide empowers businesses to identify suitable suppliers and negotiate favorable terms. With actionable strategies and expert recommendations, buyers can confidently enhance their product offerings while ensuring compliance with local regulations and sustainability goals. Ultimately, this guide aims to simplify the sourcing process, enabling companies to thrive in the dynamic global market for gallon-sized water bottles.

記事ナビゲーション

- Top 5 Water Bottle Gallon Size Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for water bottle gallon size

- Understanding water bottle gallon size Types and Variations

- Key Industrial Applications of water bottle gallon size

- 3 Common User Pain Points for ‘water bottle gallon size’ & Their Solutions

- Strategic Material Selection Guide for water bottle gallon size

- In-depth Look: Manufacturing Processes and Quality Assurance for water bottle gallon size

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle gallon size’

- Comprehensive Cost and Pricing Analysis for water bottle gallon size Sourcing

- Alternatives Analysis: Comparing water bottle gallon size With Other Solutions

- Essential Technical Properties and Trade Terminology for water bottle gallon size

- Navigating Market Dynamics and Sourcing Trends in the water bottle gallon size Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of water bottle gallon size

- 重要な免責事項および利用規約

- Strategic Sourcing Conclusion and Outlook for water bottle gallon size

Understanding water bottle gallon size Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| Standard Plastic Gallon Jug | Lightweight, made from BPA-free plastic, often with a handle | Water delivery services, retail sales | 長所だ: Cost-effective, easy to transport. 短所だ: Less durable, not insulated. |

| Insulated Stainless Steel | Double-walled construction, keeps beverages cold/hot longer | Outdoor events, sports teams, gyms | 長所だ: Excellent temperature retention, durable. 短所だ: Higher price point, heavier. |

| Motivational Water Bottles | Time markers for hydration tracking, often with straws | Fitness centers, corporate wellness programs | 長所だ: Encourages hydration, visually appealing. 短所だ: Limited capacity options, can be bulky. |

| Reusable Glass Gallon Bottles | Eco-friendly, stylish, often with protective sleeves | Restaurants, cafes, eco-conscious brands | 長所だ: Sustainable, aesthetic appeal. 短所だ: Fragile, heavier than plastic. |

| Bulk Dispensing Systems | Connects to water sources, large capacity for refillable jugs | Offices, schools, public events | 長所だ: Reduces waste, efficient for large groups. 短所だ: Requires installation, maintenance needed. |

What Are the Characteristics of Standard Plastic Gallon Jugs?

Standard plastic gallon jugs are lightweight and typically made from BPA-free materials, making them a popular choice for water delivery services and retail sales. They often come with a handle for easy transport and are cost-effective, which is advantageous for businesses looking to minimize expenses. However, their lack of insulation and durability can be a drawback for buyers who need long-lasting or temperature-controlled solutions.

How Do Insulated Stainless Steel Gallon Bottles Benefit B2B Buyers?

Insulated stainless steel gallon bottles are designed with double-walled construction that keeps beverages cold or hot for extended periods. These bottles are particularly suitable for outdoor events, sports teams, and gyms, where maintaining beverage temperature is crucial. While they offer excellent durability and insulation, they come at a higher price point and are heavier than plastic alternatives, which businesses must consider when budgeting for hydration solutions.

Why Choose Motivational Water Bottles for Corporate Wellness?

Motivational water bottles often feature time markers to encourage hydration, making them ideal for fitness centers and corporate wellness programs. These bottles can be visually appealing and serve as a motivational tool for employees or gym members. Despite their advantages, they may have limited capacity options and can be bulkier than standard bottles, which could affect portability for some users.

What Makes Reusable Glass Gallon Bottles Attractive to Eco-Conscious Brands?

Reusable glass gallon bottles are an eco-friendly option that appeals to restaurants, cafes, and brands focused on sustainability. They often come with protective sleeves to prevent breakage and add an aesthetic touch to any setting. However, their fragility and weight compared to plastic options can be a concern for businesses that require more durable solutions for high-traffic environments.

How Do Bulk Dispensing Systems Enhance Hydration at Large Events?

Bulk dispensing systems connect directly to water sources and can accommodate large refillable jugs, making them ideal for offices, schools, and public events. These systems are efficient for serving large groups and help reduce plastic waste. However, they require proper installation and ongoing maintenance, which businesses must factor into their operational considerations when investing in hydration infrastructure.

Key Industrial Applications of water bottle gallon size

| 業界/セクター | Specific Application of water bottle gallon size | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達上の考慮事項 |

|---|---|---|---|

| Food & Beverage | Bulk water supply for restaurants and catering services | Ensures consistent hydration for staff and customers | Quality of materials, compliance with food safety standards |

| Construction | Hydration stations on job sites | Promotes worker health and productivity | Durability, ease of transport, and refill options |

| Event Management | Water distribution at festivals and large gatherings | Enhances attendee experience and satisfaction | Portability, branding options, and refill capabilities |

| Health & Fitness | Water supply in gyms and fitness centers | Supports fitness goals and hydration awareness | BPA-free materials, motivational designs, and easy handling |

| Agriculture | Water supply for livestock and irrigation | Supports animal health and crop irrigation | UV resistance, robust construction, and environmental safety |

How is Water Bottle Gallon Size Used in the Food & Beverage Industry?

In the food and beverage sector, gallon-sized water bottles serve as a reliable bulk water supply for restaurants, cafes, and catering services. These bottles ensure that staff and customers have consistent access to hydration, which is crucial during busy service hours. Buyers in this industry should prioritize sourcing bottles that comply with food safety standards and are made from quality materials to prevent contamination.

What Role Does Water Bottle Gallon Size Play in Construction?

Construction sites often face challenges in providing adequate hydration for workers. Utilizing gallon-sized water bottles allows for the establishment of hydration stations, promoting health and productivity among staff. B2B buyers should consider the durability and ease of transport of these bottles, ensuring they can withstand the rigors of a construction environment while offering convenient refill options.

How Are Water Bottles Used in Event Management?

In event management, especially during festivals or large gatherings, gallon-sized water bottles are essential for effective water distribution. They enhance the attendee experience by ensuring easy access to hydration throughout the event. When sourcing these bottles, businesses should look for options that offer portability, branding opportunities, and the ability to be refilled conveniently to maintain an efficient supply chain.

Why Are Water Bottles Important in Health & Fitness?

Gyms and fitness centers use gallon-sized water bottles to promote hydration awareness among members. These bottles can be designed with motivational markers to encourage users to meet their daily water intake goals. Buyers in this sector should focus on BPA-free materials and ergonomic designs that facilitate easy handling, as well as options that can withstand frequent use.

How Do Agricultural Businesses Benefit from Water Bottle Gallon Size?

In agriculture, gallon-sized water bottles are utilized for providing hydration to livestock and aiding in irrigation practices. They support the health of animals and the efficiency of crop irrigation systems. When sourcing these bottles, agricultural buyers should prioritize features like UV resistance and robust construction to ensure longevity and environmental safety, aligning with sustainable practices in the industry.

3 Common User Pain Points for ‘water bottle gallon size’ & Their Solutions

Scenario 1: Sourcing Sustainable and Cost-Effective Water Bottles

問題だ: Many B2B buyers, particularly in regions like Africa and South America, face challenges in sourcing sustainable water bottles that meet both environmental standards and budget constraints. As companies increasingly prioritize eco-friendly products, the demand for BPA-free, reusable, and recyclable gallon-sized water bottles is rising. However, buyers often struggle to find suppliers who can provide high-quality products at competitive prices without compromising on sustainability.

解決策 To address this issue, B2B buyers should focus on establishing relationships with manufacturers and suppliers who prioritize sustainability in their production processes. Conduct thorough research to identify suppliers who offer certifications such as ISO 14001 (Environmental Management) and BPA-free materials. Additionally, consider bulk purchasing agreements, which can lead to significant cost savings. Buyers can also negotiate terms that encourage suppliers to minimize their environmental impact, such as using recycled materials in their gallon-sized bottles. Engaging in regular supplier evaluations based on sustainability metrics can help ensure that the partnership continues to align with the company’s eco-friendly goals.

Scenario 2: Ensuring Quality and Durability for Bulk Orders

問題だ: When purchasing water bottles in large quantities, B2B buyers often encounter issues with product quality and durability. This is particularly relevant for companies in regions with extreme climates, where bottles must withstand high temperatures and potential impacts during transport. Buyers may receive products that are not as robust as advertised, leading to increased replacement costs and customer dissatisfaction.

解決策 To mitigate this risk, buyers should prioritize sourcing from reputable brands known for their quality control processes. Request detailed product specifications, including material composition, weight, and user reviews, before placing large orders. It’s also advisable to order samples for testing prior to committing to bulk purchases. Establishing a clear return policy with the supplier can provide a safety net if the products do not meet the expected standards. Furthermore, consider conducting field tests to evaluate the bottles’ performance under different conditions, ensuring they meet the specific needs of your target market.

Scenario 3: Navigating Regulatory Compliance and Health Standards

問題だ: International buyers often face challenges related to regulatory compliance when sourcing gallon-sized water bottles. Different regions have varying health and safety regulations regarding food-grade materials, labeling, and product safety standards. This complexity can lead to potential legal issues or product recalls if the bottles do not meet local regulations, causing significant financial and reputational damage.

解決策 To navigate these challenges effectively, B2B buyers should familiarize themselves with the relevant regulations in their target markets, such as the FDA standards in the United States or the European Food Safety Authority (EFSA) regulations in Europe. Collaborating with local legal experts or compliance consultants can provide valuable insights into specific requirements. Additionally, buyers should request documentation from suppliers that confirms compliance with local regulations, such as safety data sheets and certifications. Implementing a robust quality assurance process that includes regular audits of suppliers can help ensure ongoing compliance, reducing the risk of penalties and enhancing product reliability in the market.

Strategic Material Selection Guide for water bottle gallon size

What Are the Key Materials for Water Bottle Gallon Size?

When selecting materials for gallon-sized water bottles, it is essential to consider properties that affect performance, durability, and cost. Below, we analyze four common materials used in the production of these bottles: plastic, stainless steel, glass, and aluminum.

How Does Plastic Perform in Water Bottle Applications?

Plastic, particularly high-density polyethylene (HDPE) and polyethylene terephthalate (PET), is widely used for water bottles due to its lightweight nature and cost-effectiveness. HDPE is known for its high strength-to-density ratio and resistance to impact and moisture, making it suitable for outdoor applications. PET, on the other hand, is favored for its clarity and recyclability.

長所だ: Plastic bottles are generally low-cost, lightweight, and resistant to breakage. They can be produced in various colors and designs, appealing to a wide range of consumers.

短所だ: However, plastic can be less durable over time, especially under UV exposure, leading to degradation. Additionally, concerns about leaching chemicals, particularly BPA, have led to a demand for BPA-free options.

アプリケーションへの影響 Plastic is compatible with cold and room temperature liquids but may not withstand high temperatures. For international buyers, compliance with food safety standards such as FDA in the U.S. or EFSA in Europe is crucial.

What Are the Benefits of Using Stainless Steel for Water Bottles?

Stainless steel is a popular choice for premium water bottles due to its durability and corrosion resistance. It can withstand high temperatures and is often insulated to maintain beverage temperatures for extended periods.

長所だ: Stainless steel bottles are robust, resistant to rust, and can keep liquids hot or cold for long durations. They are also easy to clean and do not retain flavors.

短所だ: The primary drawback is the higher cost compared to plastic. Stainless steel bottles are heavier, which may not be ideal for all consumers.

アプリケーションへの影響 Stainless steel is suitable for both cold and hot liquids, making it versatile. Buyers in regions with stringent health regulations will appreciate that stainless steel is often compliant with various international standards.

Why Choose Glass for Water Bottle Gallon Size?

Glass bottles are known for their purity and ability to maintain the taste of liquids without imparting flavors. They are completely recyclable and can be produced in various designs.

長所だ: Glass is chemically inert, ensuring that no harmful substances leach into the water. It is also aesthetically pleasing and can be produced in various styles.

短所だ: The main limitation of glass is its fragility; it can break easily, making it less suitable for outdoor or rugged use. Additionally, glass bottles are heavier than their plastic or stainless steel counterparts.

アプリケーションへの影響 Glass is ideal for cold liquids and is often used in upscale markets. International buyers should ensure compliance with packaging regulations, especially in regions where glass is less commonly used.

What Advantages Does Aluminum Offer in Water Bottle Manufacturing?

Aluminum is lightweight and can be produced in various designs, often featuring an inner coating to prevent reaction with liquids. It is commonly used for both single-use and reusable bottles.

長所だ: Aluminum bottles are lightweight, durable, and recyclable. They can be insulated to maintain temperature and are often available in eye-catching designs.

短所だ: However, aluminum can be prone to denting and may require a protective lining to prevent corrosion from acidic beverages.

アプリケーションへの影響 Aluminum is suitable for cold liquids and is often favored in sports and outdoor markets. Buyers should consider local recycling capabilities and compliance with international standards for food-grade materials.

Summary of Material Selection for Water Bottle Gallon Size

| 素材 | Typical Use Case for water bottle gallon size | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| Plastic | Everyday use, budget-friendly options | 軽量でコストパフォーマンスが高い | Less durable, potential chemical leaching | 低い |

| ステンレス鋼 | Premium, insulated options | Durable and excellent temperature retention | Heavier and higher cost | 高い |

| Glass | Upscale markets, purity-focused applications | Chemically inert, maintains taste | Fragile and heavier | Medium |

| Aluminum | Sports and outdoor markets | Lightweight, recyclable | Prone to denting, may require lining | Medium |

This strategic guide provides B2B buyers with essential insights into material selection for gallon-sized water bottles, helping them make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for water bottle gallon size

What Are the Main Stages in the Manufacturing Process for Gallon Water Bottles?

The manufacturing process for gallon-sized water bottles typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages is vital for B2B buyers looking to partner with reliable suppliers.

Material Preparation: What Materials Are Used?

The primary materials used in the production of gallon water bottles are high-density polyethylene (HDPE) and stainless steel. HDPE is favored for its lightweight, durability, and resistance to impact and chemicals, making it suitable for large-volume containers. Stainless steel, on the other hand, offers excellent insulation properties and is often used for premium products.

Before production, these materials undergo rigorous quality checks to ensure they meet the required standards. For HDPE, checks typically include assessing the melt flow index, density, and presence of contaminants. For stainless steel, suppliers often verify the grade and gauge of the metal.

How Are Gallon Water Bottles Formed?

The forming stage involves shaping the materials into the desired bottle design. For HDPE bottles, this is usually accomplished through blow molding, where molten plastic is inflated within a mold to create the bottle’s shape. This method ensures uniform wall thickness and reduces waste material.

For stainless steel bottles, the process generally involves deep drawing and spinning techniques, where sheets of metal are transformed into the desired shape through mechanical force. This stage is crucial, as any defects in the forming process can lead to product failure.

What Assembly Techniques Are Employed in Water Bottle Production?

Once the individual components are formed, they undergo assembly. For plastic bottles, this often involves attaching lids, handles, and any additional features, such as straws or motivational time markers. The assembly process may utilize automated machinery for efficiency, but many companies still rely on skilled labor to ensure precision and quality.

For stainless steel bottles, assembly may include welding or using food-grade adhesives to attach parts. Each assembly line should be equipped with quality control checkpoints to catch any defects before moving on to the finishing stage.

What Finishing Processes Are Applied to Ensure Product Quality?

The finishing stage typically involves cleaning, labeling, and packaging the bottles. For plastic bottles, the surface may be treated to enhance clarity and resistance to UV light. Stainless steel bottles often undergo polishing to improve aesthetic appeal and prevent corrosion.

Labeling is also an essential part of the finishing process, as it provides critical information to consumers and regulatory authorities. This stage must comply with various international regulations, including food safety standards, which can vary significantly by region.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a critical aspect of the manufacturing process. B2B buyers should be familiar with international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with this standard ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for certain industrial applications are also essential. These certifications provide assurance that the products have undergone rigorous testing and meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in the Production Process?

Quality control (QC) is integrated into multiple stages of the manufacturing process. Common checkpoints include:

- インカミング・クオリティ・コントロール(IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- インプロセス品質管理(IPQC): Continuous monitoring during the production process to catch defects early.

- 最終品質管理(FQC): A thorough inspection of the finished product to ensure it meets all quality standards before shipping.

Implementing these checkpoints helps minimize defects and ensures that only high-quality products reach the market.

B2Bバイヤーはサプライヤーの品質管理慣行をどのように検証できるか?

B2B buyers can take several steps to verify the quality control practices of potential suppliers. Conducting regular audits of the manufacturing facilities is one effective method. These audits should assess compliance with international standards, production processes, and overall quality management systems.

Requesting detailed quality reports that outline QC procedures, testing results, and certifications is another critical step. Buyers should also consider third-party inspections, which can provide an unbiased assessment of the supplier’s quality control practices.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying regulations and standards that must be adhered to. For instance, the FDA regulates food and beverage packaging in the United States, while the EU has stringent regulations regarding materials in contact with food.

Additionally, cultural and logistical factors may influence quality assurance practices. Buyers should engage with suppliers who are familiar with both local and international standards to ensure compliance and mitigate risks.

Conclusion: Why Understanding Manufacturing and QC Processes is Crucial for B2B Buyers

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for gallon water bottles is essential for B2B buyers. By familiarizing themselves with the stages of production, quality control standards, and verification methods, buyers can make informed decisions that enhance their supply chain resilience and product quality. This knowledge not only facilitates better supplier relationships but also contributes to the overall success of their business in a competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water bottle gallon size’

はじめに

This guide aims to assist B2B buyers in the international market, specifically targeting those interested in procuring gallon-sized water bottles. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their business needs, quality standards, and regional regulations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for identifying the right gallon water bottles for your needs. Consider factors such as material (plastic, stainless steel, etc.), size (1 gallon = 128 oz), and design (with or without straws, insulated or non-insulated).

– Material Considerations: Assess whether you need BPA-free options or insulated designs for temperature retention.

– Design Features: Think about whether features like motivational time markers or easy-carry handles are important for your target market.

Step 2: Identify Your Target Market

Understanding the preferences and needs of your target market is crucial for successful sourcing. Different regions may have varying preferences based on climate, usage, and cultural factors.

– Regional Preferences: For example, markets in hot climates may favor insulated bottles, while others might prioritize affordability.

– Customer Insights: Conduct surveys or gather feedback from potential customers to refine your product selection.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request company profiles, product catalogs, and references from other buyers in similar markets.

– Supplier Credentials: Check for certifications that demonstrate compliance with international safety and quality standards.

– Product Samples: Always request samples to assess quality firsthand and ensure they meet your specifications.

Step 4: Compare Pricing and Payment Terms

Pricing can vary significantly between suppliers, so it’s crucial to compare costs while also considering payment terms. Look for suppliers that offer competitive pricing without compromising on quality.

– Bulk Pricing: Inquire about discounts for bulk orders, which can significantly impact your overall costs.

– Payment Flexibility: Evaluate payment terms, including deposits, payment schedules, and credit options, to ensure they align with your financial strategy.

Step 5: Verify Compliance with Regulations

Ensure that the products you are sourcing comply with local regulations and standards relevant to your market. This is especially important for food and beverage containers, which may be subject to stringent safety regulations.

– Labeling and Packaging: Confirm that the labeling complies with local laws, including language requirements and safety warnings.

– Health and Safety Standards: Verify that the materials used are approved for food contact and meet any necessary health regulations.

Step 6: Assess Shipping and Delivery Options

Shipping logistics can significantly impact your operations, so it’s essential to understand the delivery options provided by your suppliers.

– Lead Times: Inquire about production and shipping lead times to ensure timely delivery of your orders.

– Shipping Costs: Compare shipping options and costs, as these can affect your overall budget and pricing strategy.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your supplier can lead to better pricing, improved service, and more favorable terms over time.

– Communication Channels: Set up regular check-ins to discuss performance and any potential issues.

– Feedback Loop: Provide feedback on product performance and customer satisfaction to help your supplier align with your evolving needs.

By following this checklist, B2B buyers can navigate the complexities of sourcing gallon-sized water bottles more effectively, ensuring a successful procurement process that meets their business objectives.

Comprehensive Cost and Pricing Analysis for water bottle gallon size Sourcing

What Are the Key Cost Components in Sourcing Gallon Water Bottles?

When sourcing gallon water bottles, several cost components come into play that significantly influence the overall pricing structure. Key factors include:

-

材料: The choice of materials—such as BPA-free plastics, stainless steel, or glass—will impact costs considerably. Stainless steel bottles, for instance, tend to be more expensive due to their durability and insulation properties compared to plastic options.

-

Labor: Manufacturing labor costs vary by region. Countries with lower wage structures may offer competitive pricing, but buyers should consider the potential trade-offs in quality and compliance with international standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Factories with advanced machinery may charge higher overhead but could provide better quality assurance.

-

Tooling: Custom designs or unique molds for bottle shapes or features (like integrated straws) can add to initial tooling costs. However, these costs may be amortized over larger production runs.

-

品質管理(QC): Implementing stringent QC measures ensures product safety and compliance with health regulations. This aspect can add to the cost, but it is essential for maintaining quality standards, especially when exporting to regions with strict regulations.

-

Logistics: Shipping costs, including freight charges, customs duties, and insurance, can significantly influence total costs, particularly for international buyers. Understanding Incoterms is crucial to navigating these expenses effectively.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary widely based on market demand, competition, and the perceived value of the product.

What Price Influencers Should International Buyers Consider?

When negotiating prices for gallon water bottles, several price influencers come into play:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often results in lower per-unit costs. Suppliers are more inclined to offer discounts for larger orders, making it beneficial for buyers to consider their inventory needs carefully.

-

Specifications and Customization: Custom designs or specific functionality (like double-walled insulation) can increase costs. Buyers should weigh the importance of these features against their budget constraints.

-

Material Quality and Certifications: Bottles that meet international safety and quality certifications may carry a premium price. Buyers should prioritize suppliers that can provide these certifications to ensure product safety.

-

Supplier Factors: Reputation, reliability, and experience in the industry can influence pricing. Established suppliers may charge more but often offer better service and quality assurance.

-

インコタームズ: Understanding the terms of shipping and delivery can help buyers manage costs effectively. For instance, choosing DDP (Delivered Duty Paid) can simplify logistics but may come at a higher price.

What Are the Best Practices for Negotiating Pricing and Ensuring Cost-Efficiency?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, strategic negotiation and understanding of pricing nuances are essential:

-

Negotiate Terms: Always aim to negotiate not just on price, but also on payment terms, delivery schedules, and warranty conditions. Flexibility on both sides can lead to a more favorable deal.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with the product, including maintenance, shipping, and potential replacements. This broader view can reveal better value propositions.

-

Research Market Trends: Stay informed about market prices and emerging trends. Understanding regional demand can empower buyers to negotiate better deals and identify optimal sourcing strategies.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Consider long-term partnerships that could yield benefits beyond initial cost savings.

Disclaimer

Prices for gallon water bottles can vary widely based on several factors, including market conditions, material costs, and supplier negotiations. The information provided here is indicative and should be verified with potential suppliers for accurate and current pricing.

Alternatives Analysis: Comparing water bottle gallon size With Other Solutions

Exploring Alternatives to Water Bottle Gallon Size

In the realm of hydration solutions, the water bottle gallon size has become a popular choice for businesses seeking to provide a convenient and efficient way to maintain water intake. However, several alternatives can also meet the needs of organizations looking for effective hydration solutions. This section will compare the standard one-gallon water bottle against two viable alternatives: water filtration systems and large-capacity beverage dispensers.

| 比較の側面 | Water Bottle Gallon Size | Water Filtration System | Large-Capacity Beverage Dispenser |

|---|---|---|---|

| パフォーマンス | High; easy to transport and refill | High; provides clean drinking water on demand | Moderate; typically requires manual refilling |

| コスト | Moderate; initial purchase cost, but reusable | High; initial investment but low ongoing costs | Moderate; varying based on size and usage |

| 実施しやすさ | Simple; widely available and easy to use | Moderate; requires installation and maintenance | Easy; needs initial setup but user-friendly |

| メンテナンス | Low; minimal upkeep required | High; requires regular filter changes and system maintenance | Low; occasional cleaning needed |

| ベスト・ユースケース | Individual and small group use | Office environments and large facilities | Events, cafeterias, and high-traffic areas |

Understanding Each Alternative

Water Filtration Systems

Water filtration systems are designed to purify tap water, providing a sustainable and convenient hydration solution. These systems range from under-sink units to countertop models.

長所だ: They offer unlimited access to clean water without the need for recurring purchases of bottled water. Additionally, they can significantly reduce plastic waste, aligning with sustainability goals.

短所だ: The initial investment can be substantial, and regular maintenance is essential, including filter replacements, which can incur ongoing costs. Furthermore, installation may require professional assistance, complicating the implementation for some businesses.

Large-Capacity Beverage Dispensers

Large-capacity beverage dispensers are excellent for serving water and other beverages at events or in communal settings. These dispensers can hold several gallons and are designed for easy access.

長所だ: They are highly effective for serving multiple people at once, making them ideal for gatherings or office settings. They also eliminate the need for multiple individual bottles, reducing waste.

短所だ: They may require manual refilling, especially during busy events. Additionally, they can take up more space compared to individual water bottles and may not be as portable, limiting their use in some scenarios.

Conclusion: Choosing the Right Hydration Solution for Your Business

When selecting a hydration solution, B2B buyers must assess their specific needs, including the size of their workforce, the frequency of use, and budget constraints. The water bottle gallon size offers convenience and ease of use for small groups, while water filtration systems provide a sustainable option for larger facilities looking to reduce waste. Large-capacity beverage dispensers serve well in high-traffic environments but may require additional handling. By carefully evaluating these alternatives, businesses can implement an effective hydration strategy that aligns with their operational goals and enhances employee wellness.

Essential Technical Properties and Trade Terminology for water bottle gallon size

What Are the Key Technical Properties of Water Bottles in Gallon Size?

Understanding the essential technical properties of gallon-sized water bottles is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The most common materials used for gallon water bottles include high-density polyethylene (HDPE), low-density polyethylene (LDPE), and stainless steel. HDPE is known for its durability and resistance to impact, making it suitable for outdoor use. LDPE is softer and more flexible, often used for lightweight designs. Stainless steel provides excellent insulation properties and is rust-resistant, ideal for premium offerings. Choosing the right material impacts durability, weight, and insulation capabilities, which are vital for various markets, including retail and outdoor activities.

2. Capacity and Dimensions

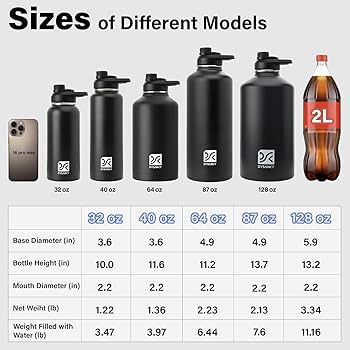

Gallon-sized bottles typically hold 128 ounces (3.785 liters). Understanding the dimensions—such as height and diameter—is essential for storage and transportation considerations. Bottles that are too bulky may not fit into standard shipping containers, leading to increased logistics costs. Accurate capacity specifications ensure that buyers can adequately meet consumer demand without overstocking.

3. BPA-Free Certification

With growing health concerns, especially in markets like Europe, BPA (Bisphenol A) free certification has become a non-negotiable property. BPA can leach into liquids, posing health risks. B2B buyers should prioritize suppliers that offer BPA-free products to ensure compliance with health regulations and to appeal to health-conscious consumers.

4. Insulation Properties

Insulation can be a key differentiator in the market. Insulated bottles keep liquids cold or hot for extended periods, making them more appealing to consumers. Specifications on insulation performance—such as how long the bottle can maintain a specific temperature—should be provided. This is particularly important in regions with extreme climates, as it directly affects consumer satisfaction and product usability.

5. Weight and Portability

The weight of an empty bottle, as well as its filled weight, is crucial for end-users who may be transporting the bottles. A lightweight design enhances portability, which is especially important for outdoor and fitness markets. Buyers should consider the balance between sturdiness and portability to meet customer preferences.

What Are Common Trade Terms Used in the Water Bottle Industry?

Understanding industry jargon is vital for effective communication and negotiation in the B2B space. Here are some common terms related to the water bottle industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand. In the context of water bottles, an OEM might manufacture bottles for a retailer who sells them under their own label. This relationship can help businesses expand their product offerings without investing in manufacturing capabilities.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers as it affects initial investment and inventory management. Understanding MOQ can help businesses plan their purchasing strategy and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing for specific products or services. B2B buyers should utilize RFQs to gather competitive pricing and terms, ensuring they are making informed purchasing decisions based on market conditions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping and insurance obligations. Familiarity with these terms helps businesses mitigate risks and understand their liabilities during transportation.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving it. This is a critical factor in supply chain management. Understanding lead times can help businesses manage their inventory levels and meet customer demand effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the water bottle market with greater confidence, ensuring that they select products that meet their needs while also facilitating efficient transactions.

Navigating Market Dynamics and Sourcing Trends in the water bottle gallon size Sector

What Are the Key Market Trends Influencing the Water Bottle Gallon Size Sector?

The global market for water bottle gallon sizes is witnessing substantial growth, driven by an increasing emphasis on hydration, health consciousness, and sustainability. As urban populations expand in regions like Africa, South America, the Middle East, and Europe, the demand for convenient and portable hydration solutions is surging. Emerging markets are experiencing a shift toward reusable and eco-friendly water bottles, aligning with global sustainability trends.

Technological advancements are also reshaping the sector, with innovations in materials and manufacturing processes leading to lighter, more durable, and insulated products. Brands are increasingly leveraging e-commerce platforms for direct-to-consumer sales, enhancing accessibility for international buyers. Additionally, the rise of social media is influencing purchasing decisions, as customers seek products that align with their lifestyle and values, such as motivational designs and customizable options.

International B2B buyers should pay attention to these dynamics to optimize sourcing strategies. Establishing relationships with manufacturers that prioritize innovation and sustainability can provide a competitive edge in capturing the growing market segment.

How Is Sustainability Shaping the Sourcing of Water Bottle Gallon Sizes?

Sustainability is no longer just a trend; it is a necessity in the water bottle gallon size sector. The environmental impact of single-use plastics is prompting both consumers and businesses to seek eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of recycled materials and ethical sourcing.

Certifications such as BPA-free, FDA approval, and eco-labels can significantly enhance a product’s marketability. Buyers should also consider the entire supply chain, ensuring that manufacturers adhere to ethical labor practices and environmentally responsible production methods. This not only enhances brand reputation but also meets the growing consumer demand for transparency and accountability.

Investing in products made from sustainable materials—like stainless steel and BPA-free plastics—will not only reduce environmental impact but also align with the values of a conscientious customer base. By prioritizing sustainability, B2B buyers can foster loyalty and trust among their clientele.

What Is the Historical Context of the Water Bottle Gallon Size Sector?

The evolution of the water bottle gallon size sector reflects broader societal shifts towards health and wellness. Initially dominated by single-use plastic bottles, the market began to change in response to growing environmental concerns in the late 20th century. The introduction of reusable water bottles in the early 2000s marked a significant turning point, as consumers sought durable alternatives that contributed to hydration without harming the planet.

Over the past two decades, the design and functionality of water bottles have advanced significantly, with innovations in insulation technology and ergonomic designs. Brands have emerged that focus on health-oriented features, such as motivational markings and built-in straws, catering to a demographic increasingly aware of hydration’s role in overall wellness.

This historical context is crucial for B2B buyers, as it highlights the importance of aligning product offerings with consumer values and preferences. Understanding the trajectory of the market can inform better sourcing decisions, ensuring that businesses remain competitive and relevant in an ever-evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of water bottle gallon size

-

How do I choose the right supplier for water bottle gallon size?

Selecting the right supplier involves evaluating their credibility, quality of products, and customer service. Start by checking for certifications such as ISO or FDA compliance, which indicate adherence to safety and quality standards. Additionally, request samples to assess the quality of their water bottles. It’s also beneficial to read reviews and testimonials from other B2B buyers. Establish clear communication to gauge their responsiveness and willingness to customize products according to your needs. -

What is the best material for water bottle gallon size?

The best material for water bottles largely depends on your target market and usage. Stainless steel is highly durable and effective in maintaining temperature, making it ideal for outdoor and active consumers. BPA-free plastic is lightweight and cost-effective, suitable for everyday use. Glass, while premium, is heavier and can break easily. Evaluate your customers’ preferences, environmental concerns, and pricing strategies to determine the most suitable material. -

What are common customization options for gallon water bottles?

Customization options for gallon water bottles can include branding, color choices, and functional features like handles or straws. Many suppliers offer printing services for logos or marketing messages, enhancing brand visibility. Additionally, consider options like motivational time markers for health-conscious consumers. Always discuss your specific requirements with suppliers to ensure they can accommodate your customization needs while maintaining quality. -

What is the minimum order quantity (MOQ) for water bottle gallon size?

MOQs vary by supplier and are often influenced by material, complexity of customization, and production capabilities. Typically, MOQs for water bottle gallon sizes range from 100 to 1,000 units. It’s crucial to communicate your expected order volume to suppliers to negotiate favorable terms. Some suppliers may offer lower MOQs for established relationships or bulk orders, so explore options that align with your business strategy. -

How can I ensure quality assurance (QA) for my gallon water bottles?

To ensure quality assurance, implement a robust QA process that includes supplier audits, product sampling, and testing. Request documentation of quality standards and production processes from your supplier. Conduct regular inspections throughout the manufacturing process, especially if ordering large quantities. Establish clear criteria for quality acceptance and consider third-party inspections to verify product standards before shipment. -

What payment terms should I expect when sourcing gallon water bottles?

Payment terms can vary significantly between suppliers. Common practices include partial upfront payments (usually 30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer payment after shipment, but this is less common. Always negotiate terms that protect your cash flow while ensuring the supplier feels secure in their transaction. Consider using secure payment methods to mitigate risks in international transactions. -

What logistics considerations are important when importing water bottle gallon sizes?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Determine whether you prefer air freight for speed or sea freight for cost-effectiveness. Familiarize yourself with import regulations in your country, especially regarding food-grade materials. Collaborate with a reliable freight forwarder to navigate customs procedures and ensure timely delivery. Proper documentation is essential to avoid delays and additional costs. -

How can I effectively market water bottle gallon sizes to international customers?

Effective marketing strategies include emphasizing the health benefits of hydration, showcasing unique features (like insulation or eco-friendliness), and leveraging social media platforms. Tailor your marketing messages to resonate with cultural preferences in different regions. Participate in international trade shows to connect with potential buyers and distributors. Consider partnerships with local influencers or retailers to enhance brand visibility and credibility within target markets.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを行う必要がある。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。

Top 5 Water Bottle Gallon Size Manufacturers & Suppliers List

1. Zulu Athletic – Goals Gallon Water Bottle 128oz

ドメイン zuluathletic.com

Registered: 2012 (13 years)

はじめに {‘name’: ‘Goals Gallon 128oz Water Bottle With Straw’, ‘price’: ‘$21.99’, ‘shipping_info’: ‘Shipping calculated at checkout’, ‘colors’: [‘Aquaviva’, ‘Gray’, ‘Royal Blue’, ‘Tropical Violet’, ‘Dusty Blue – Sold Out’], ‘dimensions’: ‘5.18 x 5.12 x 10.63 Inches’, ‘weight’: ‘1.85 lbs’, ‘features’: [‘128oz capacity’, ‘Motivational time markings’, ‘One-touch lid’, ‘BPA free’, ‘Portable handle’], ‘care_in…

2. Hydro Gallon – Key Products

ドメイン hydrogallon.com

Registered: 2020 (5 years)

はじめに Hydro Gallon® offers a range of gallon water bottles designed for all-day hydration. Key products include: 1 Gallon Hydro Gallon, Hydro Gallon 1 Pro, Hydro Gallon Tactical, and the new Half Gallon Nomad. Features include a backpack mode for the Nomad, 24-hour cold retention for the Tactical model, and durability for the original Hydro Gallon 1. Additional offerings include sleeves, replacement par…

3. YETI – Rambler 128 oz Water Bottle

Registered: 2024 (1 years)

はじめに [{‘name’: ‘YETI Rambler’, ‘price’: ‘$130’, ‘capacity_fl_oz’: 128, ‘dimensions’: ‘6.4 x 12.3 inches’, ‘material’: ‘Stainless Steel’, ‘insulated’: ‘Yes’, ‘weight’: ‘4.5 lb’, ‘pros’: [‘5-year warranty’, ‘Bombproof’, ‘Incredible insulation’, ‘Very easy to clean’, ‘Doesn’t hold the taste of your beverages for long’], ‘cons’: [‘Heavier than other options’, ‘Can be difficult to open’]}, {‘name’: ‘Hydro F…

4. Poland Spring® – 1 Gallon Jug Spring Water

ドメイン polandspring.com

Registered: 1996 (29 years)

はじめに {“Product Name”: “1 Gallon Jug Spring Water”, “Brand”: “Poland Spring®”, “Product Size”: “1 gal”, “Available Sizes”: [“12 fl oz”, “8 fl oz”, “16.9 fl oz”, “20 fl oz”, “23.7 fl oz”, “1 L”, “1.5 L”, “3 L”, “1 G”, “2.5 G”, “3 G”, “5 G”, “25 fl oz”], “Pack Size”: “single”, “Nutritional Information”: {“Calories”: “0mg”, “Total Fat”: “0%”, “Sodium”: “0%”, “Protein”: “0%”}, “Ingredients”: “Spring Water, …

5. The Water Bottle Store – 1 Gallon BPA Free Water Bottles

Registered: 2005 (20 years)

はじめに 1 Gallon BPA Free Water Bottles, available in various styles and colors including black, purple, and pink. Key products include: 1 Gallon Combo BPA Free Water Bottle (includes 8 pieces, $34.48), GEO Sports 1 Gallon BPA Free Water Bottle with Stainless Steel Cap and Handle (purple, $18.88; pink, $16.88), 1 Gallon Reusable Plastic Drinking Water Bottle Jug Container (black, $18.88), and 1 Gallon Dai…

Strategic Sourcing Conclusion and Outlook for water bottle gallon size

In the competitive landscape of water bottle sourcing, particularly for gallon-sized options, understanding market trends and consumer preferences is crucial for international B2B buyers. The rising demand for sustainable, reusable water bottles underscores the importance of aligning sourcing strategies with eco-friendly practices. Key insights reveal that buyers should focus on product variety, including insulated options, which enhance user experience by maintaining temperature and offering convenience through features like straws and motivational markings.

Strategic sourcing not only optimizes procurement processes but also fosters strong supplier relationships, ensuring access to quality products that meet diverse regional needs. As markets in Africa, South America, the Middle East, and Europe continue to evolve, leveraging insights into local preferences can drive competitive advantage.

Looking ahead, international buyers are encouraged to actively seek partnerships with manufacturers that prioritize innovation and sustainability. By doing so, they can meet the growing consumer demand for high-quality, environmentally responsible products. Engage with suppliers who are equipped to navigate these trends, and position your business for success in the dynamic water bottle market.